The Effect of the Cooling Rates on the Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Single Crystal Superalloy

Abstract

:1. Introduction

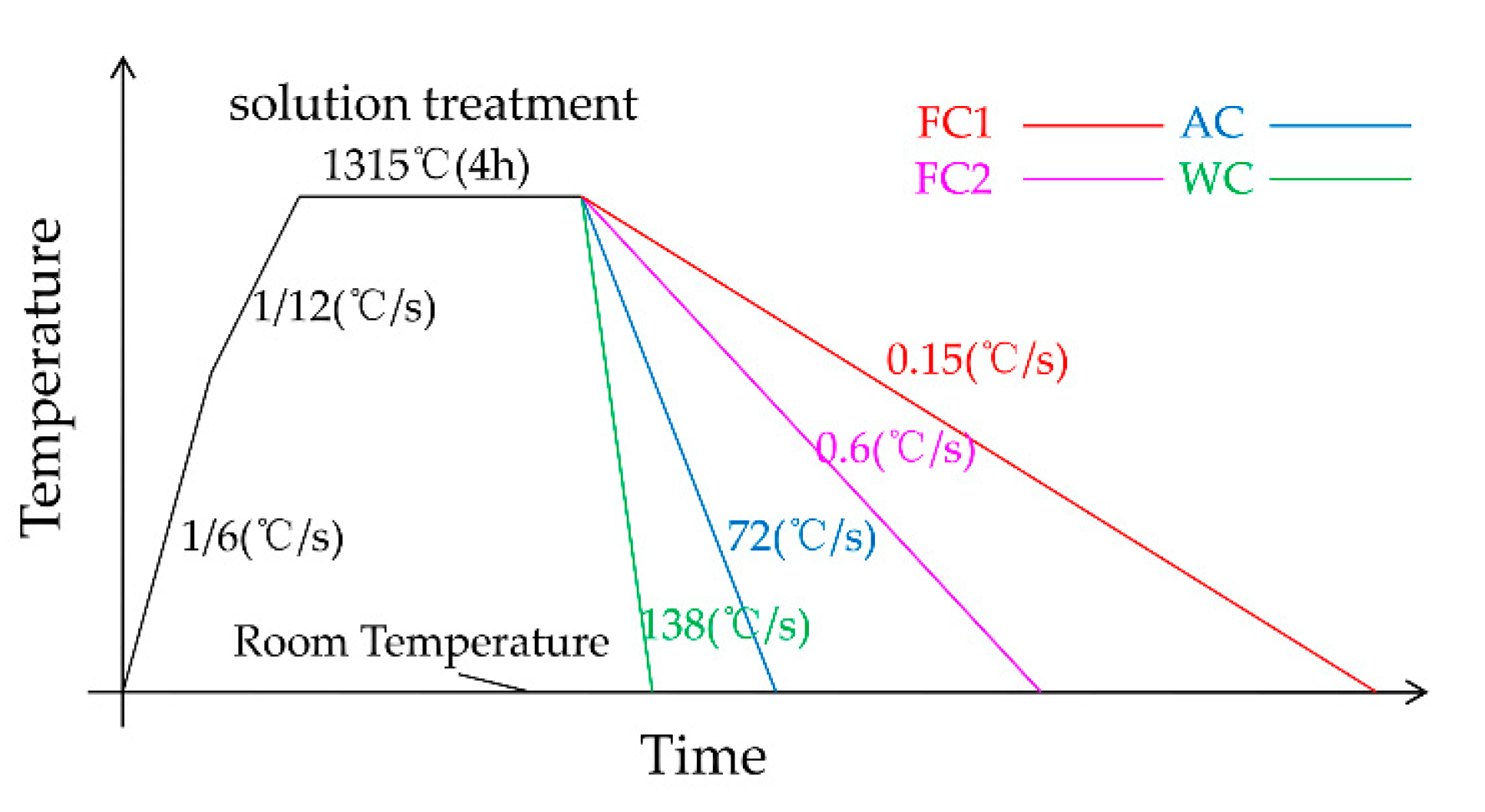

2. Test Materials and Process

3. Test Results and Discussion

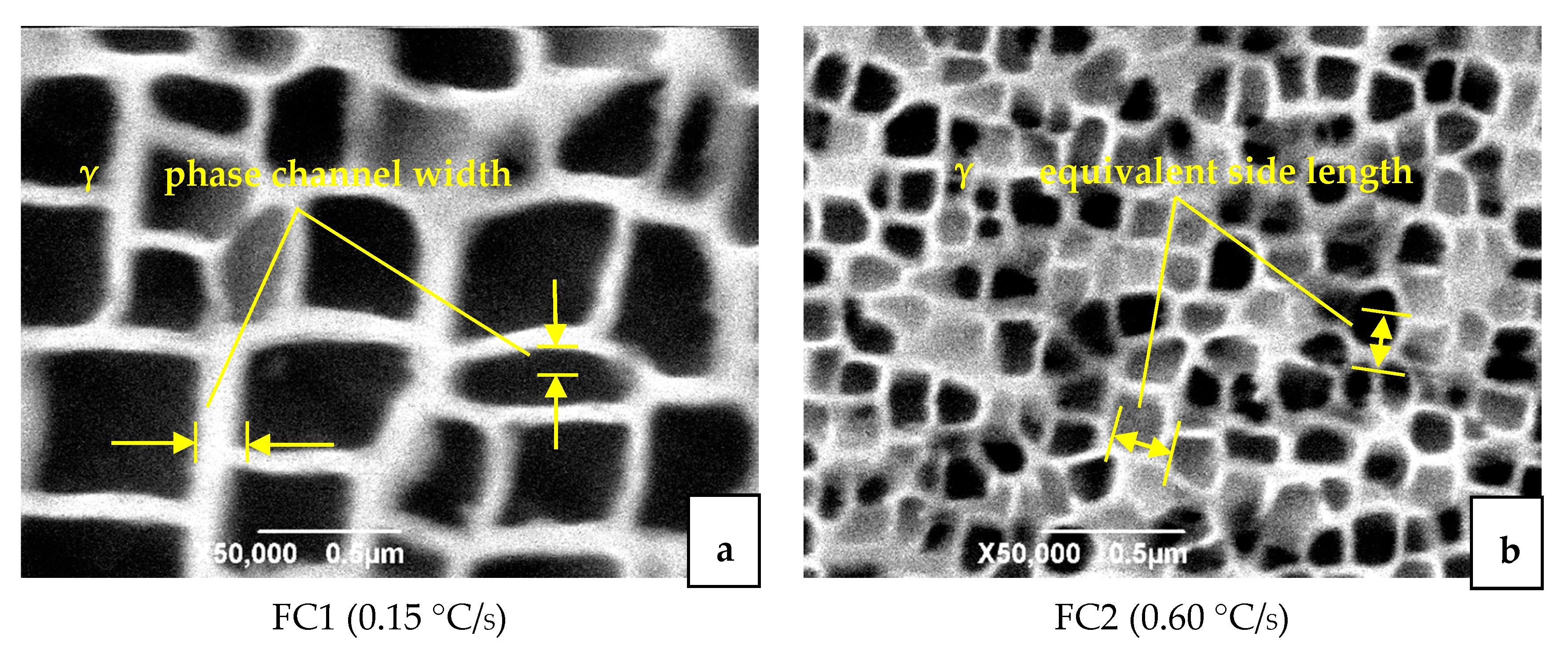

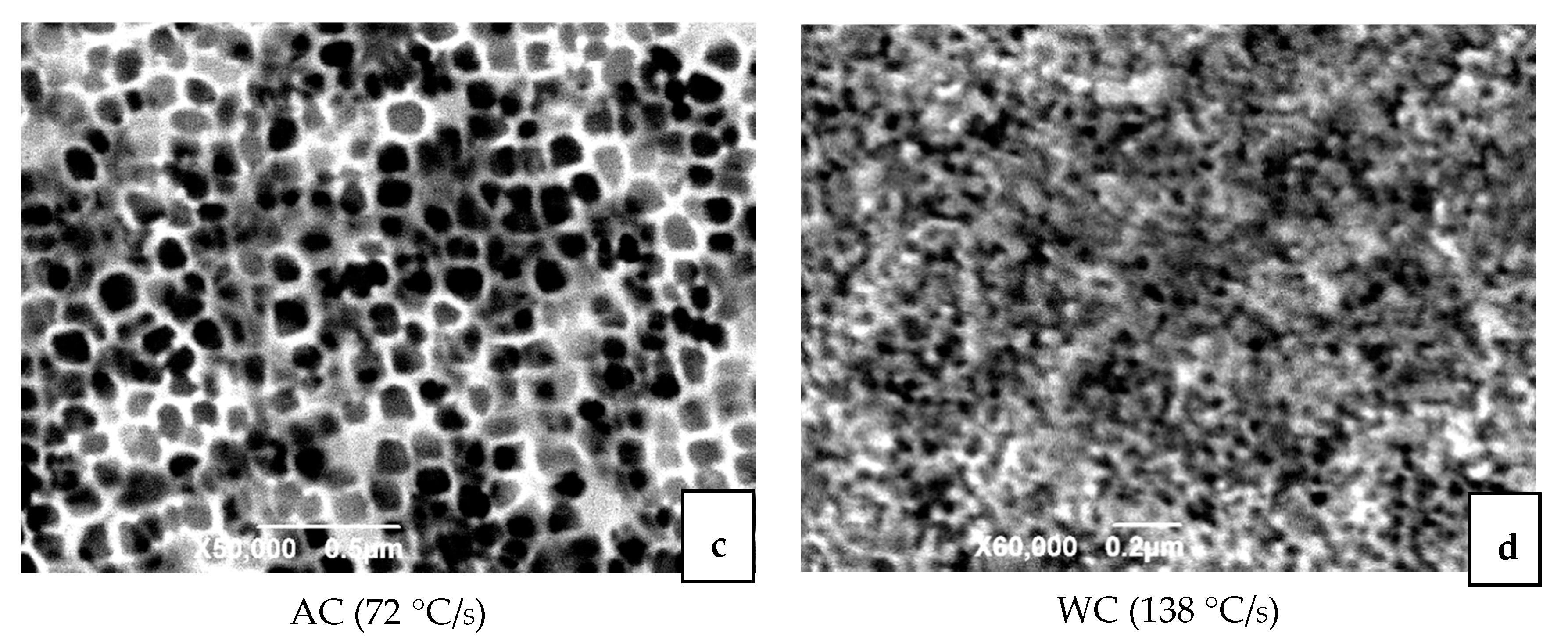

3.1. Microstructure After Heat Treatment

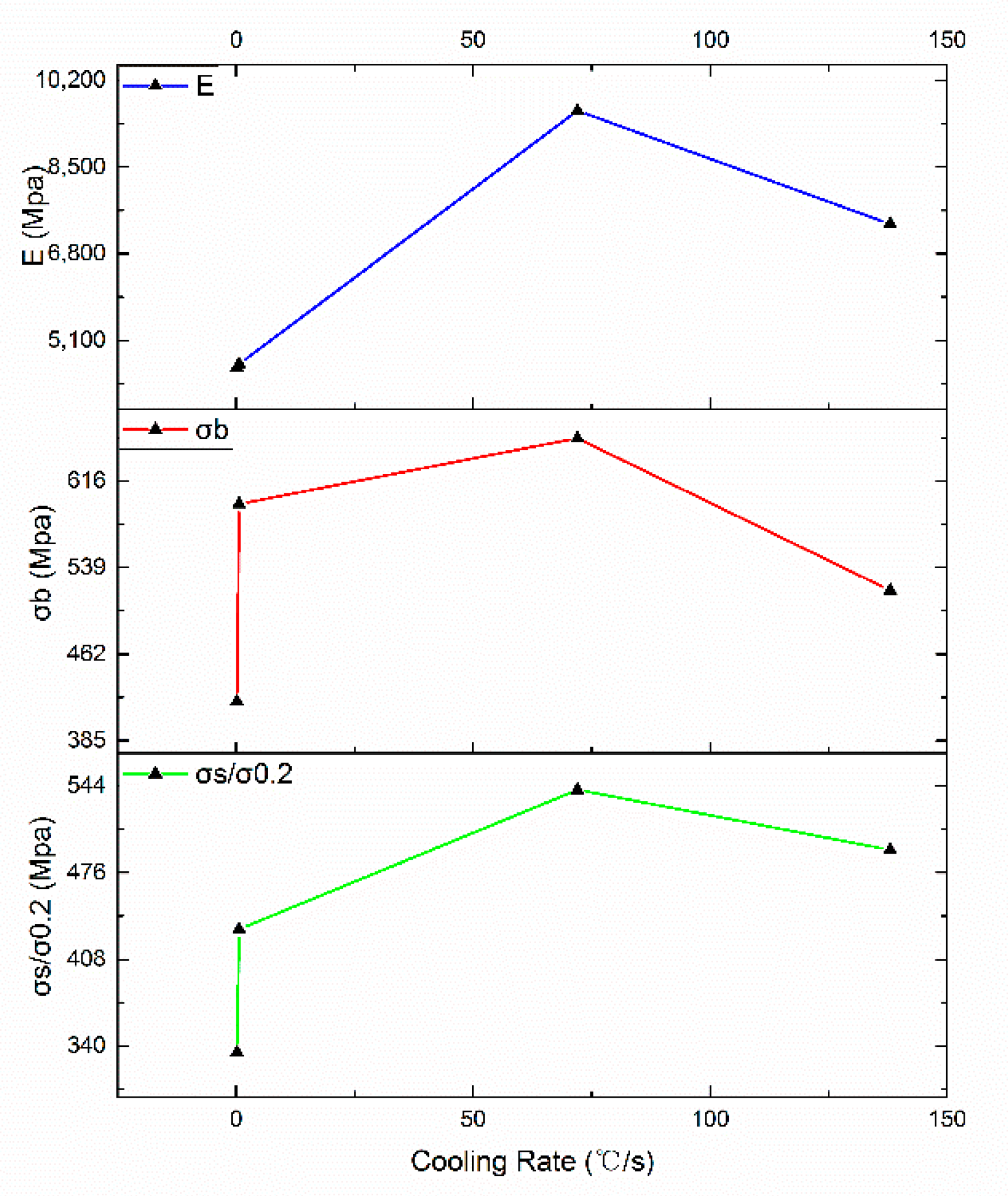

3.2. High-temperature (980 °C) Tensile Test Results

3.3. Microstructure Analysis After Tensile Fracture

4. Conclusions

- (1)

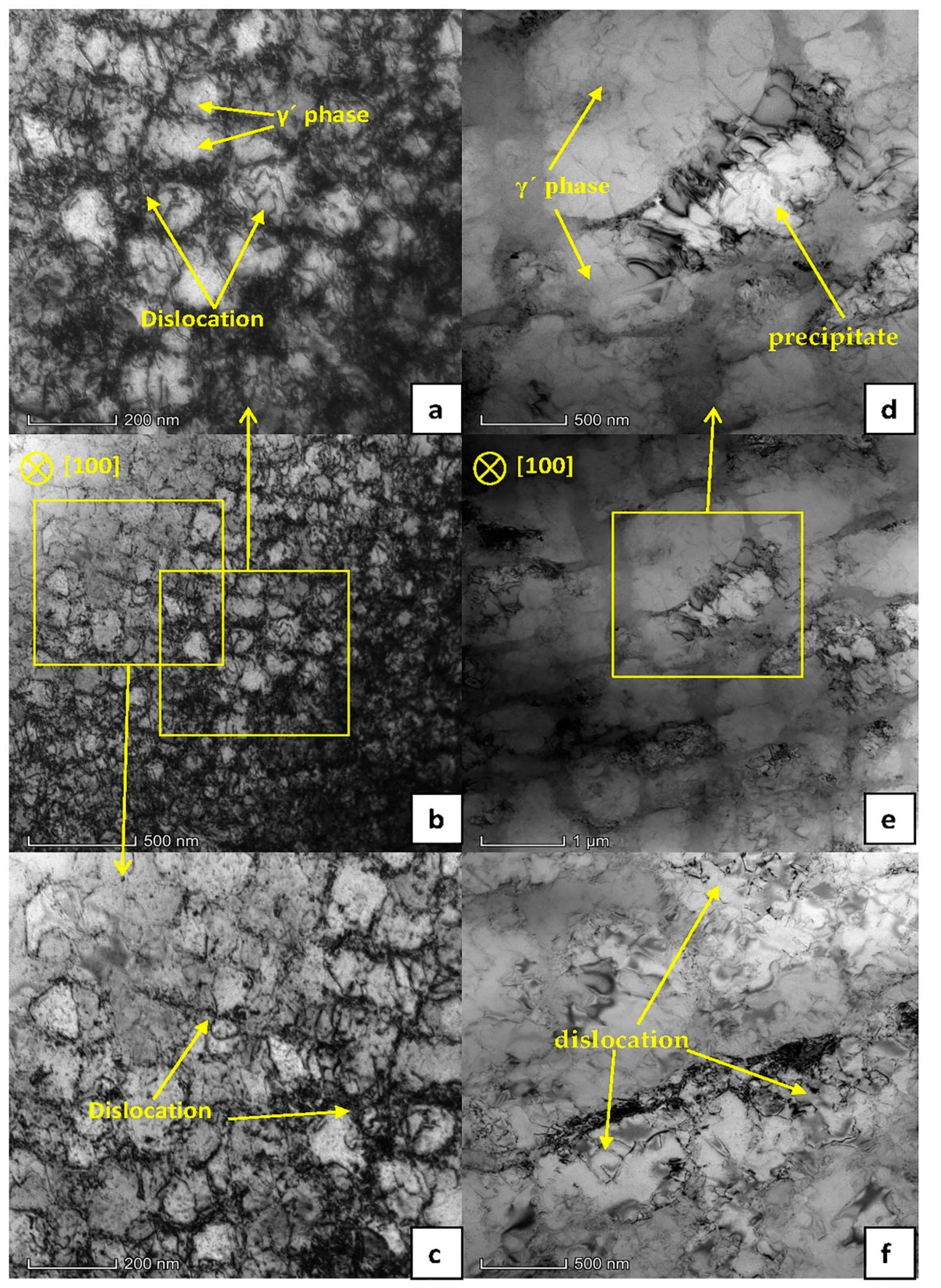

- The difference in cooling rates during the solution treatment had a significant effect on the precipitation microstructure of the γ′ phase. As the cooling rate increases, the larger the nucleation rate of the γ’ phase, the smaller the size of the formed γ’ phase, the greater the number;

- (2)

- Due to the interaction between strain energy and interface energy, the cubic degree of the γ′ phase gradually deteriorated, transitioning from square to spherical. When air cooling was used, the uniformity of the γ′ phase was better and the coherent relationship between the γ′ phase and the γ phase was also better;

- (3)

- Compared with FC1, FC2, WC, when AC was used, the yield strength (σs/σ0.2), ultimate tensile strength (σb) and elastic modulus (E) of the test alloy at high-temperature (980 °C) were the largest. In other words, the high-temperature tensile performance was the best under this condition. Combined with its microstructure, the size of the γ′ phase and the coherence relationship between the γ′ phase and the γ phase were the most reasonable;

- (4)

- When AC was used, the higher cooling rate increased the lattice mismatch of the material, resulting in coherent strain between the γ′ phase and the γ phase, which caused a higher elastic stress field around the γ′ phase and hinder dislocation movement. In addition, the smaller γ′ phase increased the proportion of the matrix-phase channel and had a stronger hindering effect on the movement of dislocations.

Author Contributions

Funding

Conflicts of Interest

References

- Caron, P.; Khan, T. Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp. Sci. Technol. 1999, 3, 513–523. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Guo, J. High-Temperature Alloy Materials; Science Press: Beijing, China, 2008; Volume 1. [Google Scholar]

- Devaux, A.; Naze, L.; Molins, R.; Pineau, A.; Organista, A.; Guedou, J.Y.; Uginet, J.F.; Heritier, P. Gamma double prime precipitation kinetic in Alloy 718. Mater. Sci. Eng. A 2008, 486, 117–122. [Google Scholar] [CrossRef]

- Tang, X.; Wang, B.; Huo, Y.; Ma, W.; Zhou, J.; Ji, H.; Fu, X. Unified modeling of flow behavior and microstructure evolution in hot forming of a Ni-based superalloy. Mater. Sci. Eng. A 2016, 662, 54–64. [Google Scholar] [CrossRef]

- Li, H.Y.; Kong, Y.H.; Chen, G.S.; Xie, L.X.; Zhu, S.G.; Sheng, X.A. Effect of different processing technologies and heat treatments on the microstructure and creep behavior of GH4169 superalloy. Mater. Sci. Eng. A 2013, 582, 368–373. [Google Scholar] [CrossRef]

- Grosdidier, T.; Hazotte, A.; Simon, A. Precipitation and dissolution processes in γ/γ′ single crystal nickel-based superalloys. Mater. Sci. Eng. A 1998, 256, 183–196. [Google Scholar] [CrossRef]

- You, X.; Tan, Y.; Shi, S.; Yang, J.-M.; Wang, Y.; Li, J.; You, Q. Effect of solution heat treatment on the precipitation behavior and strengthening mechanisms of electron beam smelted Inconel 718 superalloy. Mater. Sci. Eng. A 2017, 689, 257–268. [Google Scholar] [CrossRef]

- Radis, R.; Schaffer, M.; Albu, M.; Kothleitner, G.; Pölt, P.; Kozeschnik, E. Multimodal size distributions of γ’ precipitates during continuous cooling of UDIMET 720 Li. Acta Mater. 2009, 57, 5739–5747. [Google Scholar] [CrossRef]

- Mostafaei, A.; Behnamian, Y.; Krimer, Y.L.; Stevens, E.L.; Luo, J.-L.; Chmielus, M. Effect of solutionizing and aging on the microstructure and mechanical properties of powder bed binder jet printed nickel-based superalloy 625. Mater. Des. 2016, 111, 482–491. [Google Scholar] [CrossRef]

- Wang, T.; Wang, X.; Zhao, Z.; Zhang, Z. Dissolution behaviour of the γ’ precipitates in two kinds of Ni-based superalloys. Mater. High. Temp. 2016, 33, 51–57. [Google Scholar] [CrossRef]

- Mitchell, R.J.; Preuss, M.; Tin, S.; Hardy, M.C. The influence of cooling rate from temperatures above theγ’ solvus on morphology, mismatch and hardness in advanced polycrystalline nickel-base superalloys. Mater. Sci. Eng. A 2008, 473, 158–165. [Google Scholar] [CrossRef]

- Gao, S.; Hou, J.S.; Dong, K.X.; Zhou, L.Z. Influences of Cooling Rate After Solution Treatment on Microstructural Evolution and Mechanical Properties of Superalloy Rene 80. Acta Metall. Sin. Engl. Lett. 2017, 30, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.; Liu, G.Q.; Feng, M.; Zhang, M.; Hu, B.; Wang, H. The effect of cooling rates from temperatures above the γ’ solvus on the microstructure of a new nickel-based powder metallurgy superalloy. J. Alloys Compd. 2018, 747, 1062–1072. [Google Scholar] [CrossRef]

- Behrouzghaemi, S.; Mitchell, R.J. Morphological Changes Of γ’ Precipitates in Superalloy IN738IC At Various Cooling Rates. Mater. Sci. Eng. 2008, 498, 266–271. [Google Scholar] [CrossRef]

- Singh, A.R.P.; Nag, S.; Hwang, J.Y.; Viswanathan, G.B.; Tiley, J.; Srinivasan, R.; Fraser, H.L.; Banerjee, R. Characterization, Influence of cooling rate on the development of multiple generations of γ’ precipitates in a commercial nickel base superalloy. Mater. Charact. 2011, 62, 878–886. [Google Scholar] [CrossRef]

- Milenkovic, S.; Sabirov, I.; Llorca, J. Effect of the cooling rate on microstructure and hardness of MAR-M247 Ni-based superalloy. Mater. Lett. 2012, 73, 216–219. [Google Scholar] [CrossRef] [Green Version]

- Safari, J.; Nategh, S. On the heat treatment of Rene-80 nickel-base superalloy. J. Mater. Process. Technol. 2006, 176, 240–250. [Google Scholar] [CrossRef]

- Letnikov, M.N.; Lomberg, B.S.; Ospennikova, O.G.; Bakradze, M.M. Influence of quench rate on microstructure and mechanical properties of nickel-based wrought superalloy vzh175-ID. Aviatsionnye Mater. I Tekhnologii 2019, 2, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Zhuang, X.; Nie, Y.; Li, Y.; Jiang, L. Effect of heat treatment on mechanical property and microstructure of a powder metallurgy nickel-based superalloy. Mater. Sci. Eng. A 2019, 754, 29–37. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.; He, D.-G.; Chen, M.-S.; Liu, G.-Q. Effects of pre-treatments on mechanical properties and fracture mechanism of a nickel-based superalloy. Mater. Sci. Eng. A 2017, 679, 401–409. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Liu, Y.; Xia, X.; Wu, Y.; Ma, Z.; Wang, H. Influences of solution cooling rate on microstructural evolution of a multiphase Ni3Al-based intermetallic alloy. Intermetallics 2019, 109, 48–59. [Google Scholar] [CrossRef]

- Wang, X.Y.; Wen, Z.X.; Cheng, H.; Gu, S.N.; Lu, G.X. Influences of the Heating and Cooling Rates on the Dissolution and Precipitation Behavior of a Nickel-Based Single-Crystal Superalloy. Metals 2019, 9, 360. [Google Scholar] [CrossRef] [Green Version]

- Guan, Y.; Liu, Y.; Ma, Z.; Li, H.; Yu, H. Precipitation and coarsening behavior of γ′phase in CoNi-base superalloy under different aging treatments. Vacuum 2020, 175, 109247. [Google Scholar] [CrossRef]

- Carr, J. Stability of self-similar solutions in a simplified LSW model. Phys. D Nonlinear Phenom. 2006, 222, 73–79. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Huang, T.; Chen, J.; Cao, K.; Liu, X.; Zhang, J.; Fu, H. Coarsening kinetics of γ′ precipitates in a Re-containing Ni-based single crystal superalloy during long-term aging. Mater. Sci. Technol. 2021, 62, 1–10. [Google Scholar] [CrossRef]

- Tiley, J.; Viswanathan, G.B.; Srinivasan, R.; Banerjee, R.; Dimiduk, D.M.; Fraser, H.L. Coarsening kinetics of γ′precipitates in the commercial nickel base Superalloy René 88 DT. Acta Mater. 2009, 57, 2538–2549. [Google Scholar] [CrossRef]

- Zhang, H.; Guan, Z.W.; Wang, Q.Y.; Liu, Y.J.; Li, J.K. Effects of Stress Ratio and Microstructure on Fatigue Failure Behavior of Polycrystalline Nickel Superalloy. J. Mater. Eng. Perform. 2018, 27, 2534–2544. [Google Scholar] [CrossRef]

| C | Cr | Ni | Co | W | Mo | Al | Ti | Ta | Re | Nb | B | Si | Hf |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.015 | 4.0 | Bal. | 9.0 | 8.0 | 2.0 | 5.7 | 0.10 | 7.0 | 2.2 | 1.0 | 0.02 | 0.02 | 1.0 |

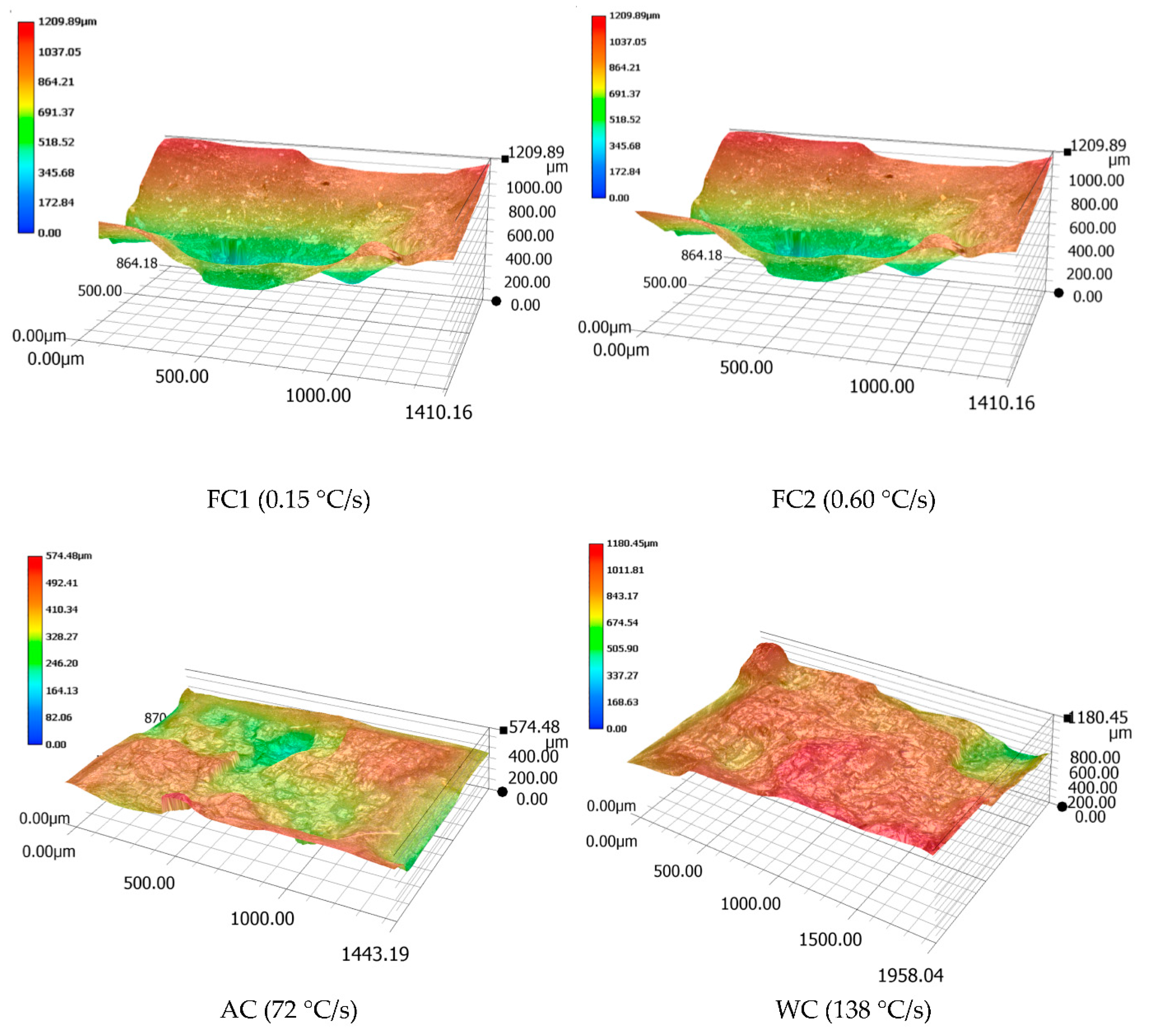

| Number | Cooling Rate | γ′ Microstructure | γ′ Equivalent Side Length | γ′ Phase Channel Width |

|---|---|---|---|---|

| 1 | FC1 (0.15 °C/s) | Approximate cube | 375 nm | 30 nm |

| 2 | FC2 (0.60 °C/S) | Shape of irregular surface | 183 nm | 14 nm |

| 3 | AC (72 °C/S) | Approximate sphere | 86 nm | 8 nm |

| 4 | WC (138 °C/S) | Irregular dots | 20 nm | 1 nm |

| Number | Cooling Rate | Yield Strength (σs/σ0.2) | Ultimate Tensile strength (σb) | Elastic Modulus (E) | Elongation (δ) | Rate of Reduction in Area (Ψ) |

|---|---|---|---|---|---|---|

| 1 | FC1 (0.15 ℃/s) | 334.88 MPa | 419.73 MPa | 4.568 GPa | 41.66% | 32.64% |

| 2 | FC2 (0.60 ℃/s) | 431.42 MPa | 595.41 MPa | 4.634 GPa | 22.23% | 46.49% |

| 3 | AC (72 ℃/s) | 540.95 MPa | 653.91 MPa | 9.603 GPa | 40.15% | 43.02% |

| 4 | WC (138 ℃/s) | 493.74 MPa | 518.61 MPa | 7.381 GPa | 13.32% | 20.71% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.-Y.; Li, M.; Wen, Z.-X. The Effect of the Cooling Rates on the Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Single Crystal Superalloy. Materials 2020, 13, 4256. https://doi.org/10.3390/ma13194256

Wang X-Y, Li M, Wen Z-X. The Effect of the Cooling Rates on the Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Single Crystal Superalloy. Materials. 2020; 13(19):4256. https://doi.org/10.3390/ma13194256

Chicago/Turabian StyleWang, Xiao-Yan, Meng Li, and Zhi-Xun Wen. 2020. "The Effect of the Cooling Rates on the Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Single Crystal Superalloy" Materials 13, no. 19: 4256. https://doi.org/10.3390/ma13194256