Mechanical Properties and Serration Behavior of a NiCrFeCoMn High-Entropy Alloy at High Strain Rates

Abstract

1. Introduction

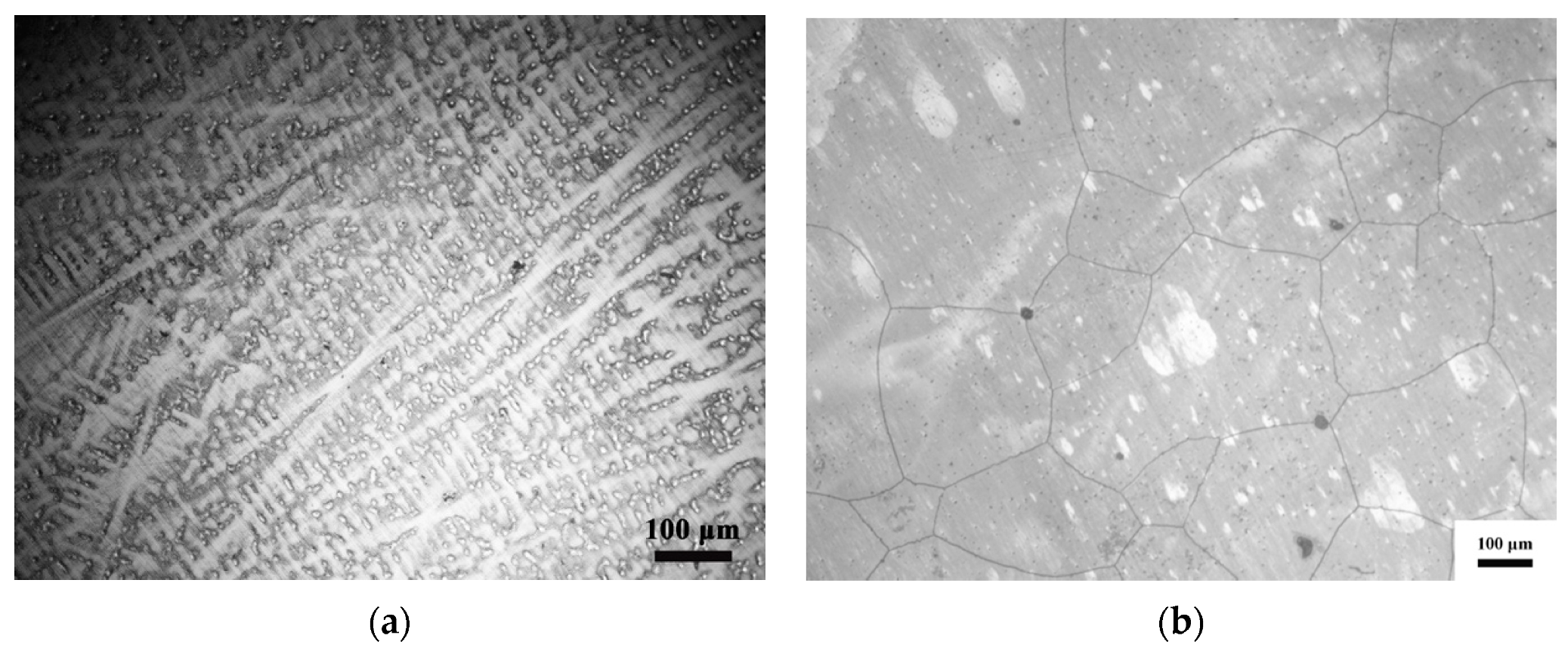

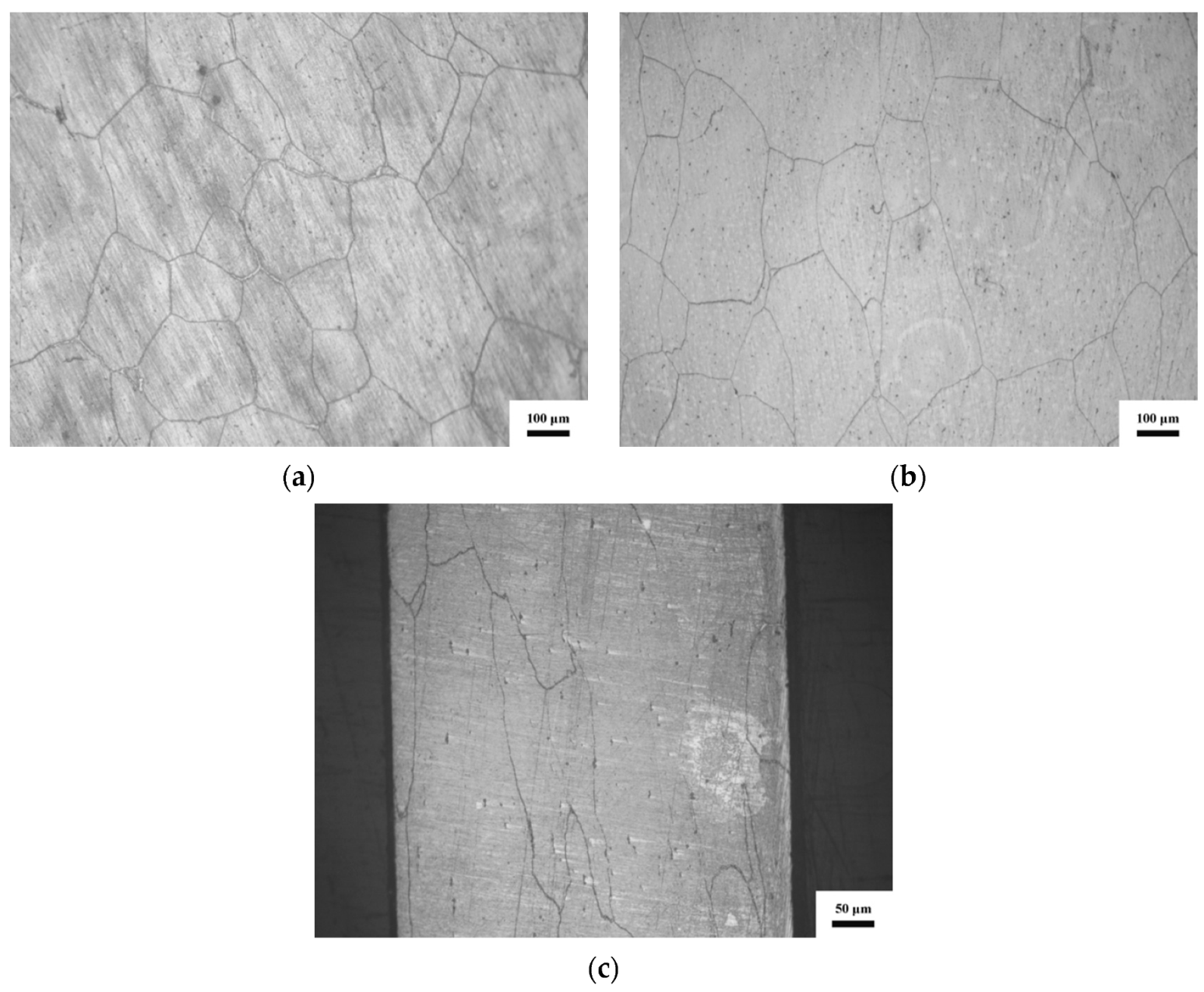

2. Materials and Methods

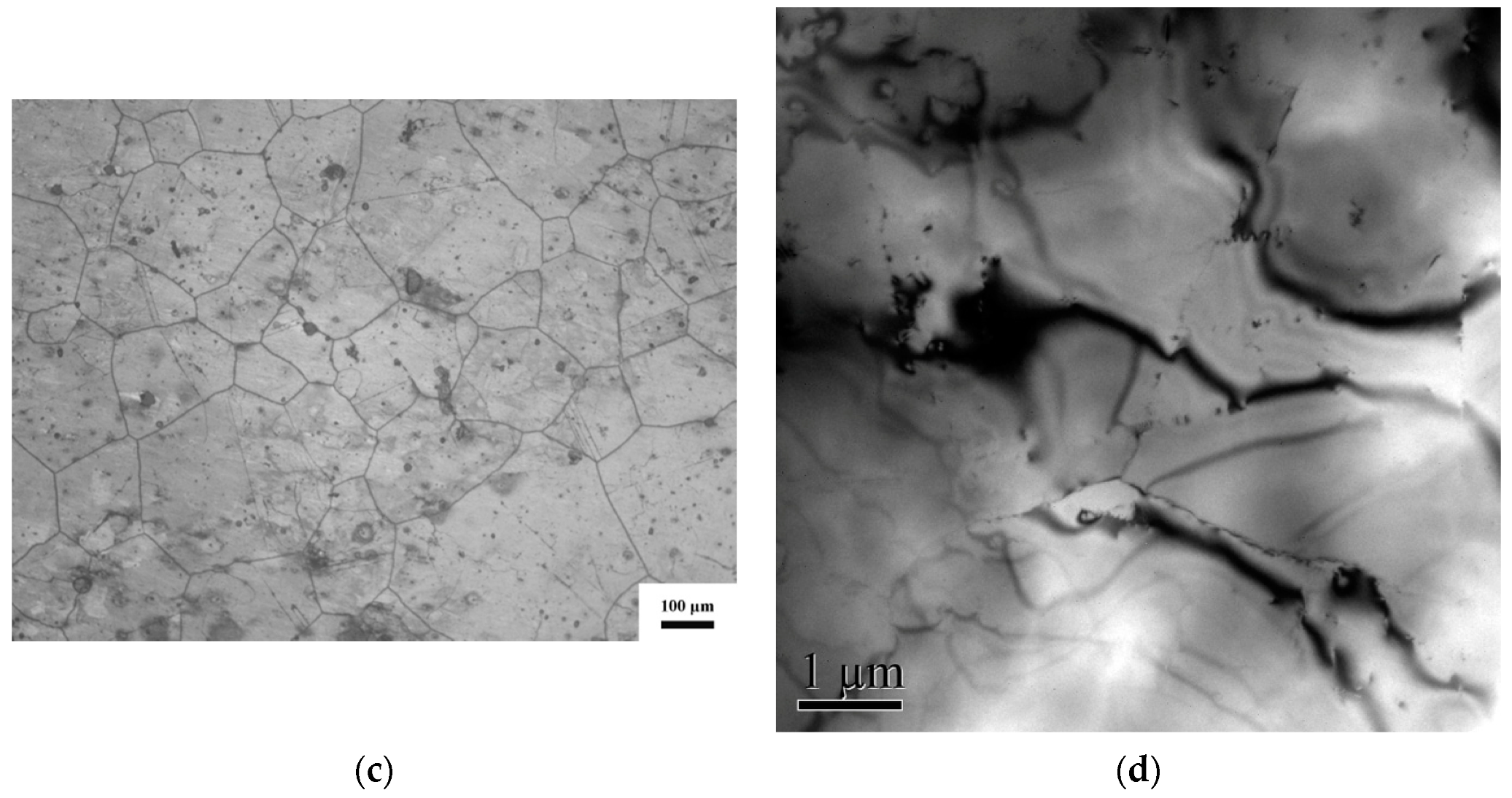

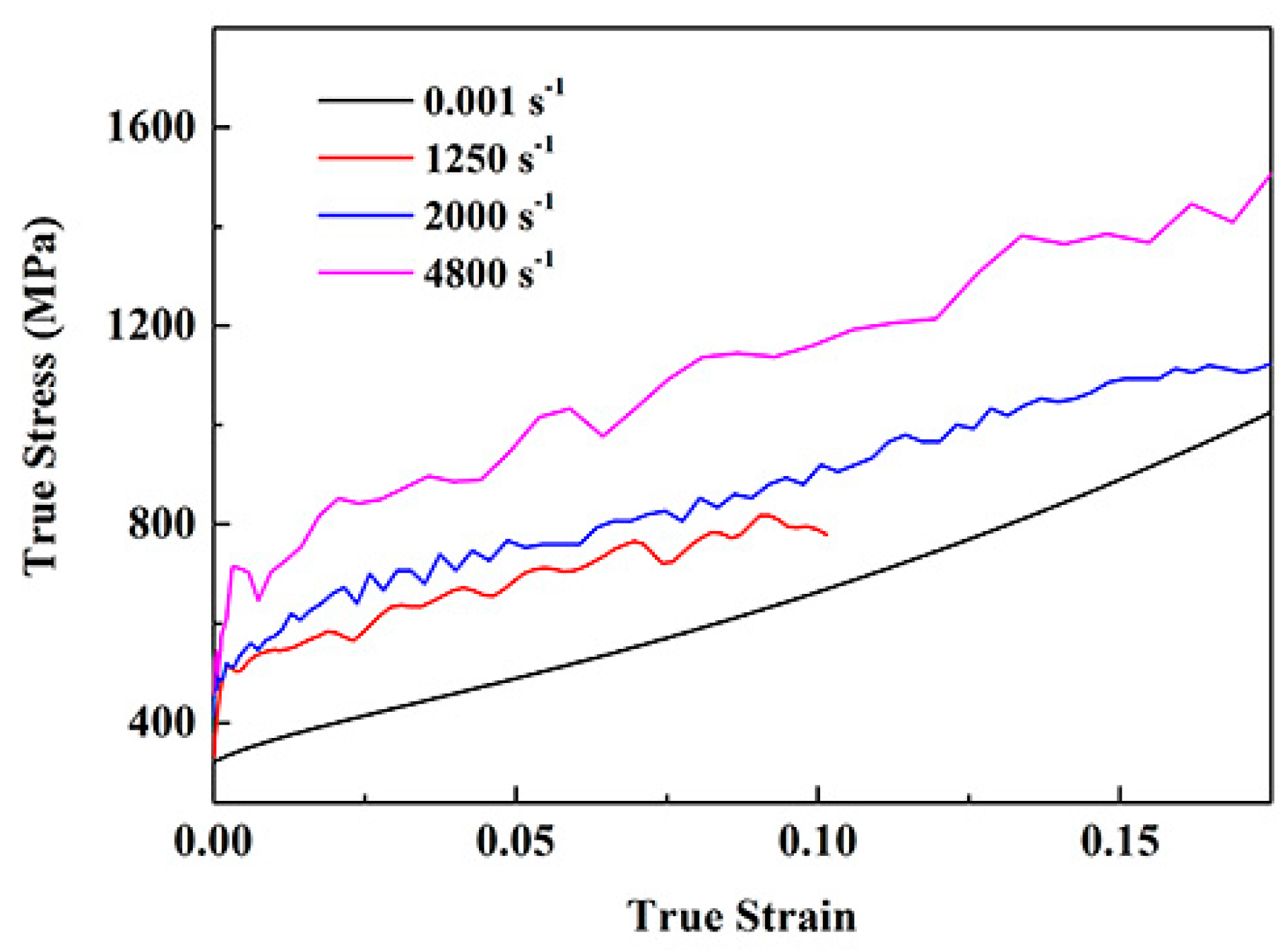

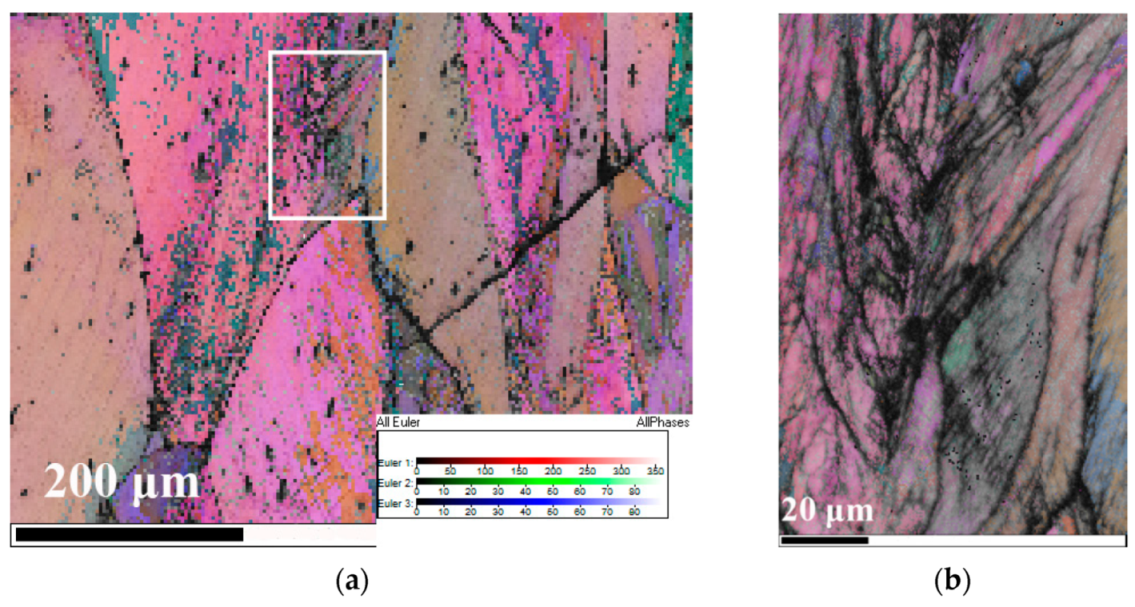

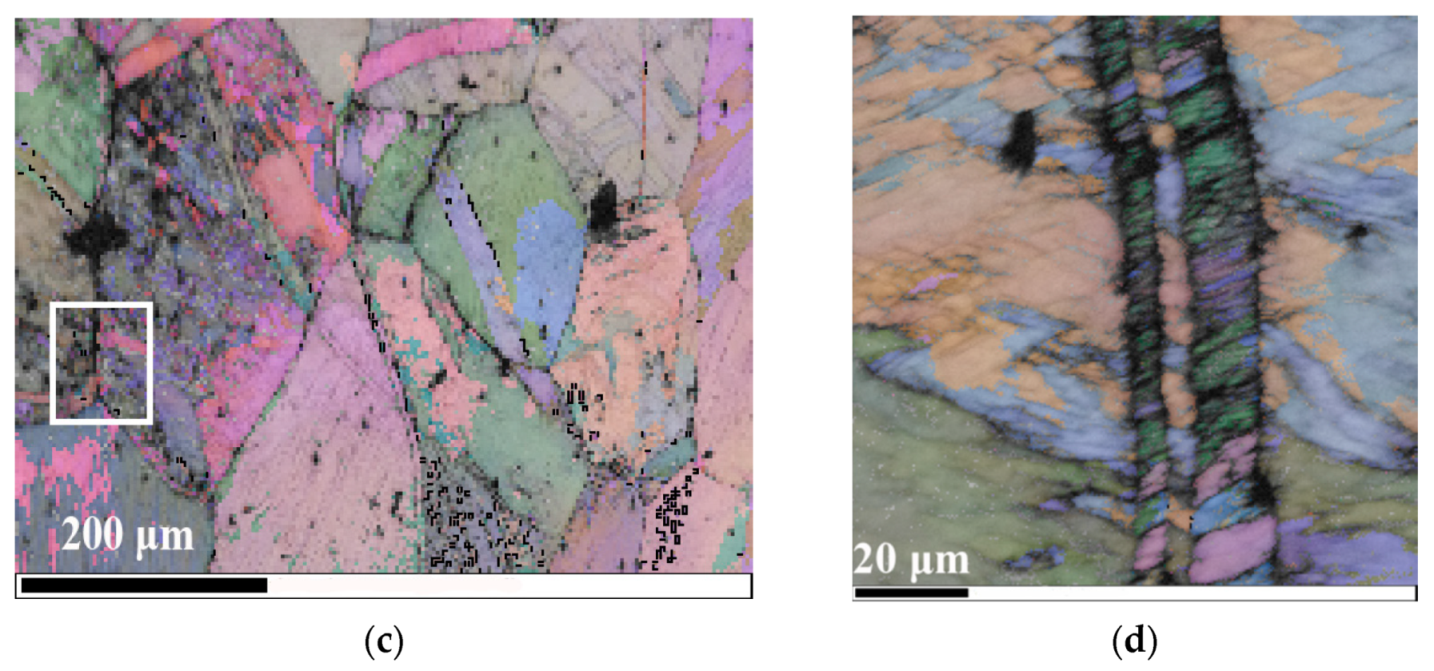

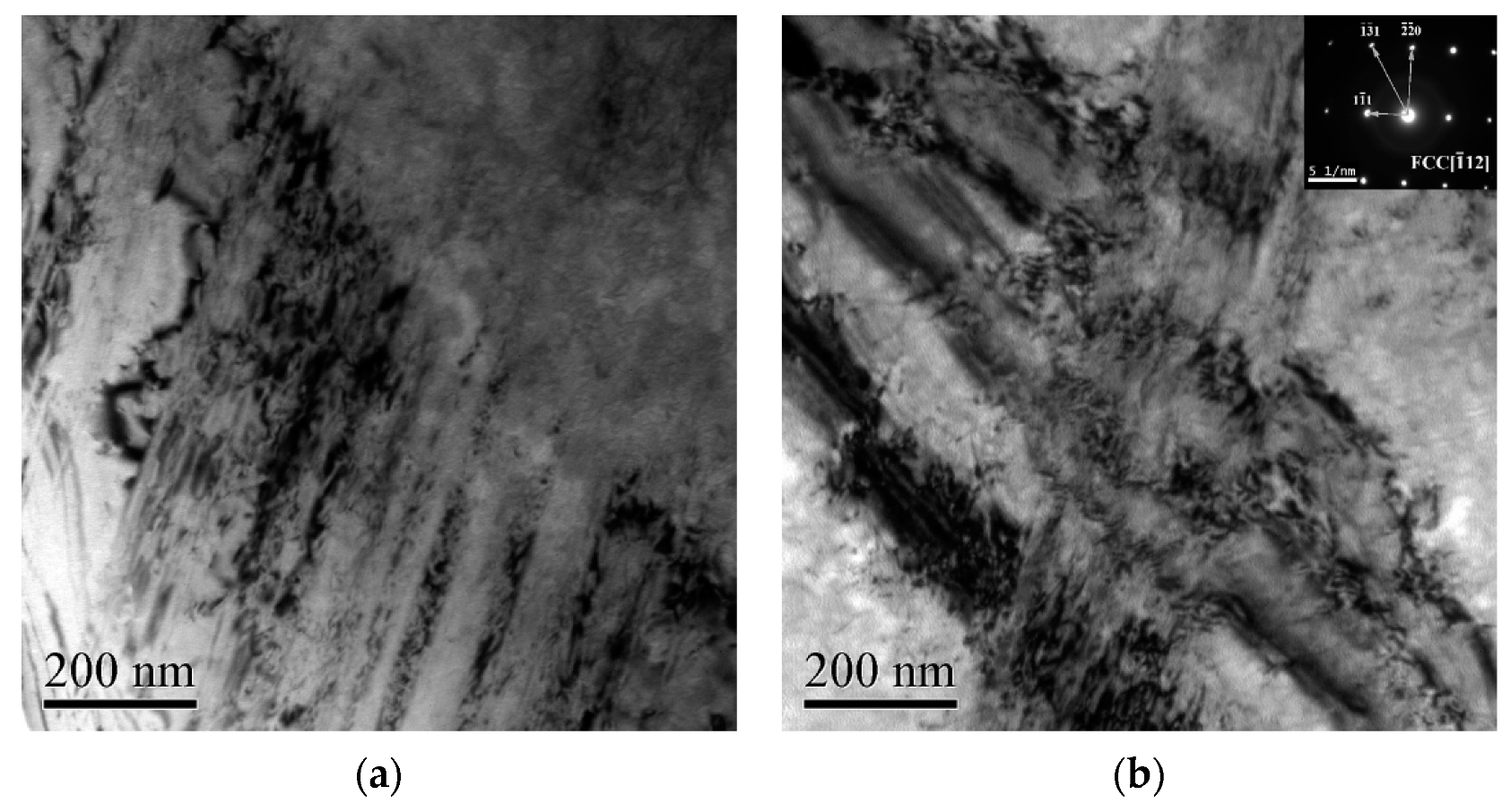

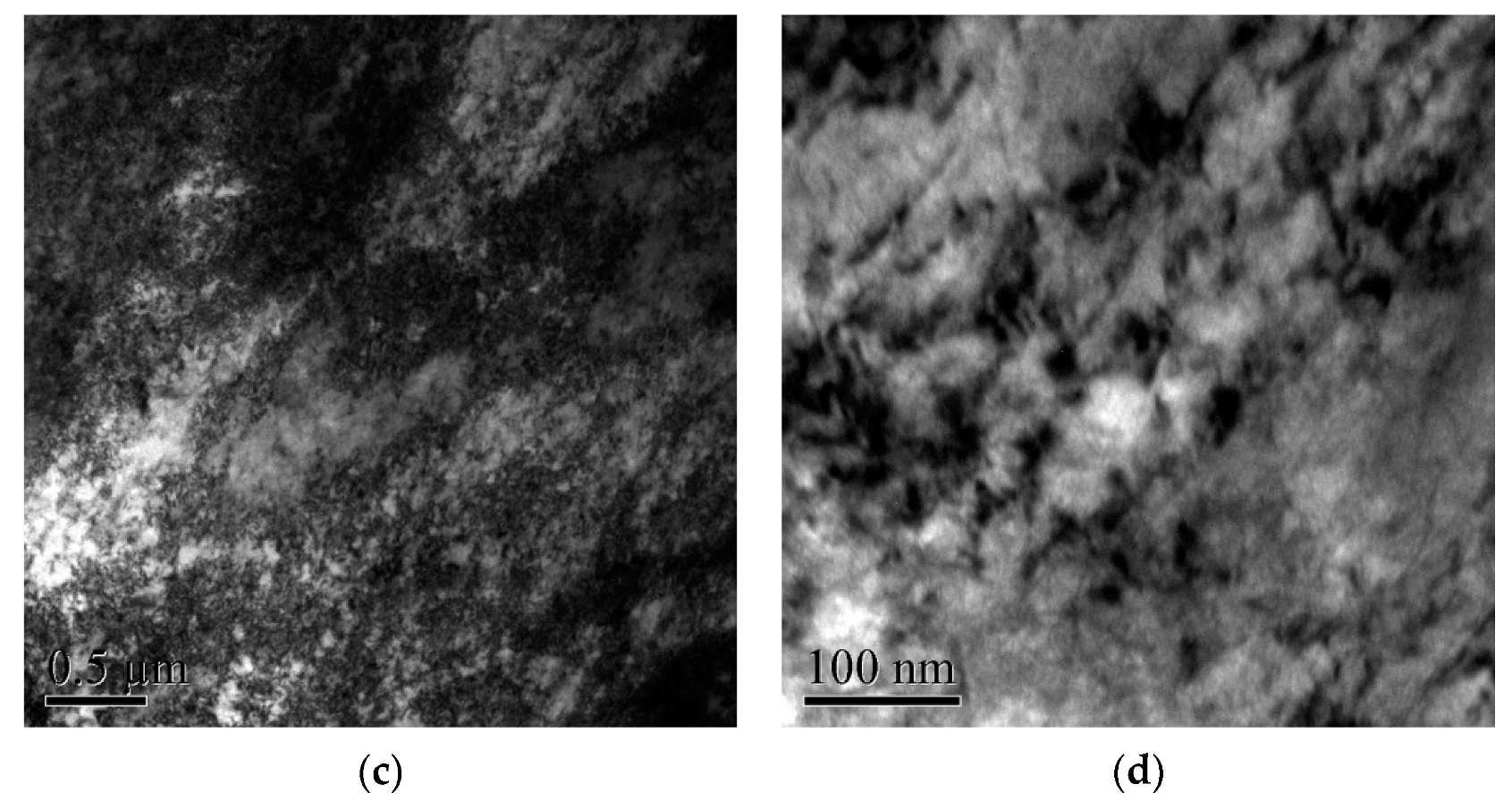

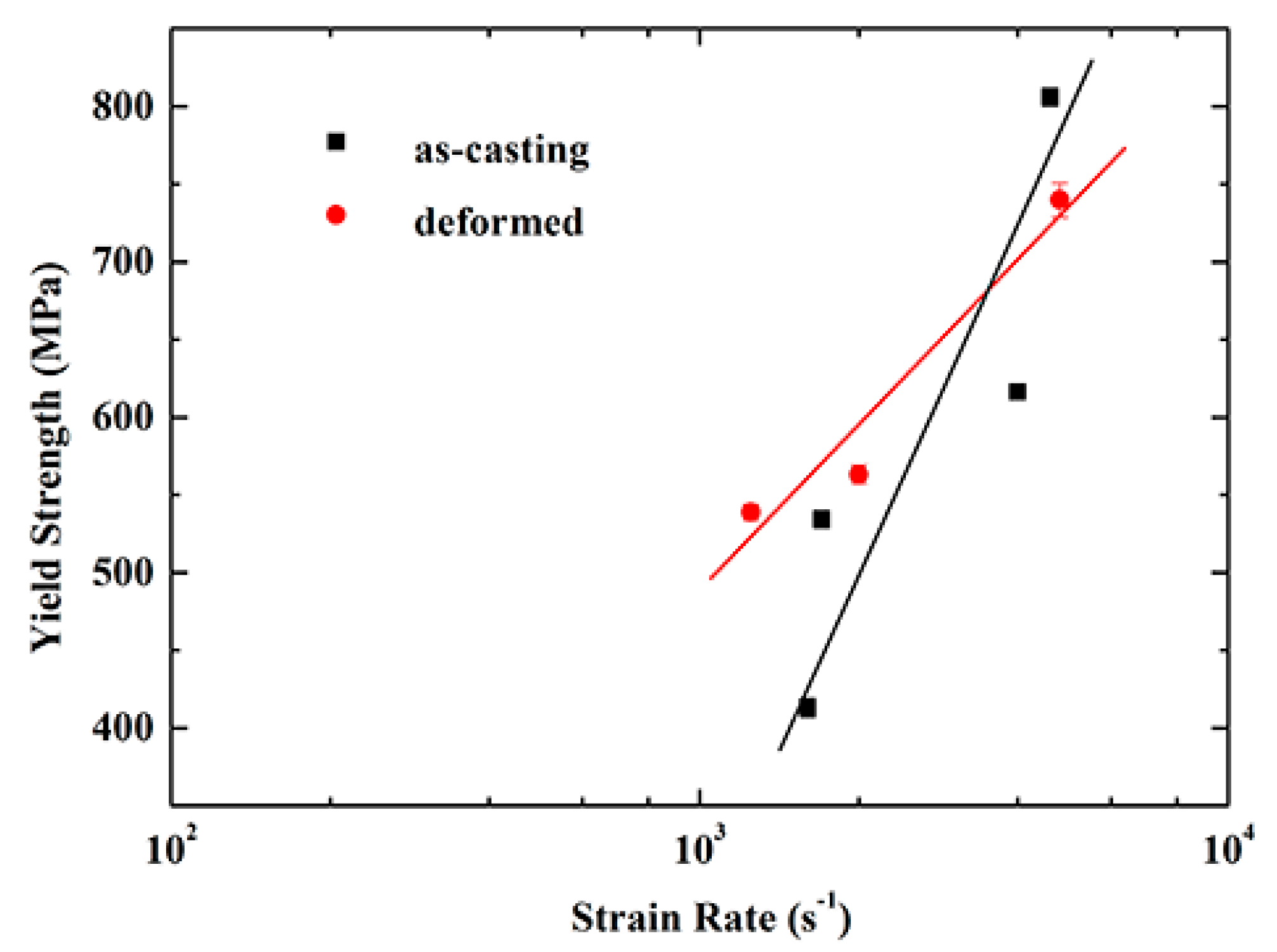

3. Results

4. Discussion

4.1. Dynamic Mechanical Properties of NiCrFeCoMn HEA

4.2. Microstructure Mechanism for Serration Behavior of the Deformed High-Entropy Alloy at High Strain Rates

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Klimova, M.; Stepanov, N.; Shaysultanov, D.; Chernichenko, R.; Zherebtsov, S. Microstructure and Mechanical Properties Evolution of the Al, C-Containing CoCrFeNiMn-Type High-Entropy Alloy during Cold Rolling. Materials 2017, 11, 53. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhy, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Mao, M.M.; Wang, J.W.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 6. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- He, J.Y.; Wang, Q.; Zhang, H.S.; Dai, L.H.; Mukai, T.; Wu, Y.; Liu, X.J.; Wang, H.; Nieh, T.G.; Lu, Z.P. Dynamic deformation behavior of a face-centered cubic FeCoNiCrMn high-entropy alloy. Sci. Bull. 2018, 63, 362–368. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.P.; Chen, S.Y.; Xie, X.; Liaw, P.K.; Dahmen, K.A.; Qiao, J.W.; Wang, Y.L. Serration and noise behaviors in materials. Prog. Mater. Sci. 2017, 90, 358–460. [Google Scholar] [CrossRef]

- Csikor, F.F.; Motz, C.; Weygand, D.; Zaiser, M.; Zapperi, S. Dislocation avalanches, strain bursts, and the problem of plastic forming at the micrometer scale. Science 2007, 318, 251–254. [Google Scholar] [CrossRef] [PubMed]

- Ispanovity, P.D.; Groma, I.; Gyorgyi, G.; Csikor, F.F.; Weygand, D. Submicron Plasticity: Yield Stress, Dislocation Avalanches, and Velocity Distribution. Phys. Rev. Lett. 2010, 105, 4. [Google Scholar] [CrossRef]

- Tsekenis, G.; Goldenfeld, N.; Dahmen, K.A. Dislocations Jam at Any Density. Phys. Rev. Lett. 2011, 106, 4. [Google Scholar] [CrossRef]

- Miguel, M.C.; Vespignani, A.; Zapperi, S.; Weiss, J.; Grasso, J.R. Intermittent dislocation flow in viscoplastic deformation. Nature 2001, 410, 667–671. [Google Scholar] [CrossRef]

- Dahmen, K.A.; Ben-Zion, Y.; Uhl, J.T. Micromechanical Model for Deformation in Solids with Universal Predictions for Stress-Strain Curves and Slip Avalanches. Phys. Rev. Lett. 2009, 102, 4. [Google Scholar] [CrossRef]

- Friedman, N.; Jennings, A.T.; Tsekenis, G.; Kim, J.Y.; Tao, M.L.; Uhl, J.T.; Greer, J.R.; Dahmen, K.A. Statistics of Dislocation Slip Avalanches in Nanosized Single Crystals Show Tuned Critical Behavior Predicted by a Simple Mean Field Model. Phys. Rev. Lett. 2012, 109, 5. [Google Scholar] [CrossRef]

- Fu, S.H.; Cheng, T.; Zhang, Q.C.; Hu, Q.; Cao, P.T. Two mechanisms for the normal and inverse behaviors of the critical strain for the Portevin-Le Chatelier effect. Acta Mater. 2012, 60, 6650–6656. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, Q.C.; Cao, P.T.; Fu, S.H. Thermal analyses and simulations of the type A and type B Portevin-Le Chatelier effects in an Al-Mg alloy. Acta Mater. 2012, 60, 1647–1657. [Google Scholar] [CrossRef]

- Cai, Y.L.; Tian, C.G.; Fu, S.H.; Han, G.M.; Cui, C.Y.; Zhang, Q.C. Influence of gamma ’ precipitates on Portevin-Le Chatelier effect of NI-based superalloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 638, 314–321. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Woo, W.; Huang, E.W.; Yeh, J.W.; Choo, H.; Lee, C.; Tu, S.Y. In-situ neutron diffraction studies on high-temperature deformation behavior in a CoCrFeMnNi high entropy alloy. Intermetallics 2015, 62, 1–6. [Google Scholar] [CrossRef]

- Wang, B.F.; Huang, X.X.; Fu, A.; Liu, Y.; Liu, B. Serration behavior and microstructure of high entropy alloy CoCrFeMnNi prepared by powder metallurgy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 726, 37–44. [Google Scholar] [CrossRef]

- Wang, B.F.; Yao, X.R.; Wang, C.; Zhang, X.Y.; Huang, X.X. Mechanical Properties and Microstructure of a NiCrFeCoMn High-Entropy Alloy Deformed at High Strain Rates. Entropy 2018, 20, 892. [Google Scholar] [CrossRef]

- Wang, B.F.; Liu, Z.L.; Li, J. Microstructure evolution in AISI201 austenitic stainless steel during the first compression cycle of multi-axial compression. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 568, 20–24. [Google Scholar] [CrossRef]

- Kato, H.; Kawamura, Y.; Inoue, A.; Chen, H.S. Transition from linear to nonlinear viscoelasticity during deformation in a Zr-based glassy alloy. Mater. Trans. JIM 2000, 41, 1202–1207. [Google Scholar] [CrossRef]

- Couzinie, J.P.; Lilensten, L.; Champion, Y.; Dirras, G.; Perriere, L.; Guillot, I. On the room temperature deformation mechanisms of a TiZrHfNbTa refractory high-entropy alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 645, 255–263. [Google Scholar] [CrossRef]

- Kubin, L.P.; Estrin, Y. The portevin-Le Chatelier effect in deformation with constant stress rate. Acta Metall. 1985, 33, 397–407. [Google Scholar] [CrossRef]

- Fu, S.H.; Cai, Y.L.; Yang, S.L.; Zhang, Q.C.; Wu, X.P. The Mechanism of Critical Strain of Serrated Yielding in Strain Rate Domain. Chin. Phys. Lett. 2016, 33, 4. [Google Scholar]

| Elements | Ni | Cr | Fe | Co | Mn |

|---|---|---|---|---|---|

| at.% | 21.24 | 17.76 | 21.79 | 20.72 | 18.49 |

| wt.% | 22.18 | 16.42 | 21.64 | 21.71 | 18.06 |

| Sample | Condition | Size (mm) | Compressive Strain Rate (s−1) |

|---|---|---|---|

| 1 | as cast | Φ4 × H5.6 | 0.001 |

| 2 | as cast | Φ4 × H5.6 | 1500 |

| 3 | as cast | Φ2 × H2.8 | 4600 |

| 4 | deformed | Φ4 × H5.6 | 0.001 |

| 5 | deformed | Φ6 × H8.4 | 1250 |

| 6 | deformed | Φ4 × H5.6 | 2000 |

| 7 | deformed | Φ2 × H2.8 | 4800 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Yao, X.; Wang, B. Mechanical Properties and Serration Behavior of a NiCrFeCoMn High-Entropy Alloy at High Strain Rates. Materials 2020, 13, 3722. https://doi.org/10.3390/ma13173722

Liu R, Yao X, Wang B. Mechanical Properties and Serration Behavior of a NiCrFeCoMn High-Entropy Alloy at High Strain Rates. Materials. 2020; 13(17):3722. https://doi.org/10.3390/ma13173722

Chicago/Turabian StyleLiu, Ruoyu, Xianrui Yao, and Bingfeng Wang. 2020. "Mechanical Properties and Serration Behavior of a NiCrFeCoMn High-Entropy Alloy at High Strain Rates" Materials 13, no. 17: 3722. https://doi.org/10.3390/ma13173722

APA StyleLiu, R., Yao, X., & Wang, B. (2020). Mechanical Properties and Serration Behavior of a NiCrFeCoMn High-Entropy Alloy at High Strain Rates. Materials, 13(17), 3722. https://doi.org/10.3390/ma13173722