An Investigation on the Microstructure and Texture of an AZ80 Cup-Shaped Piece Processed by Rotating Backward Extrusion

Abstract

1. Introduction

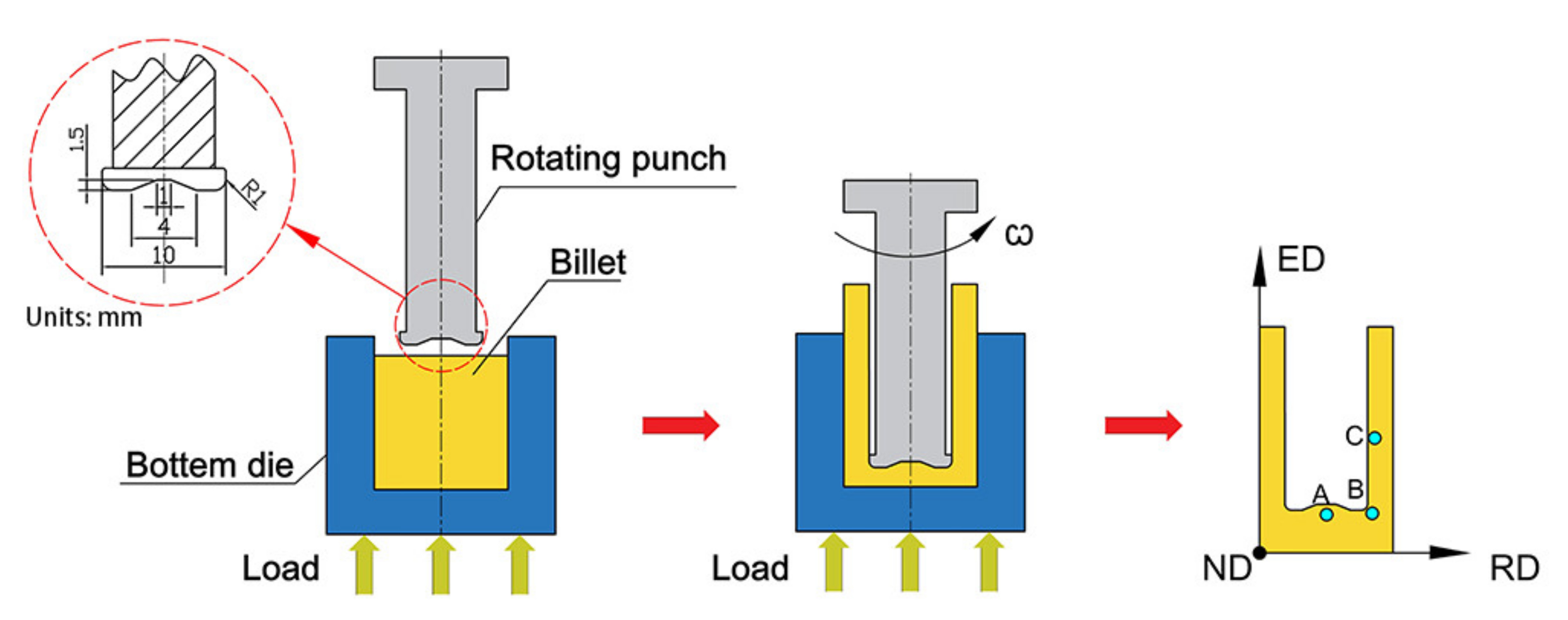

2. Materials and Methods

3. Results and Discussion

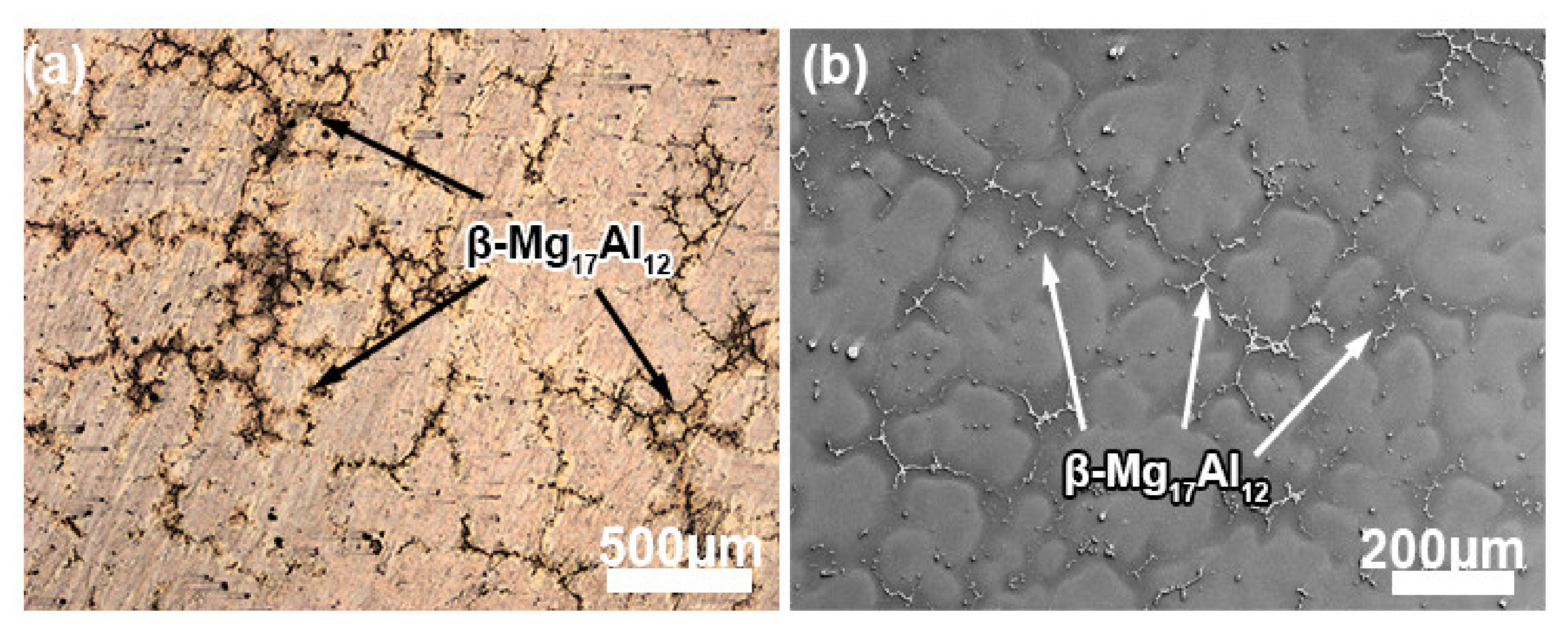

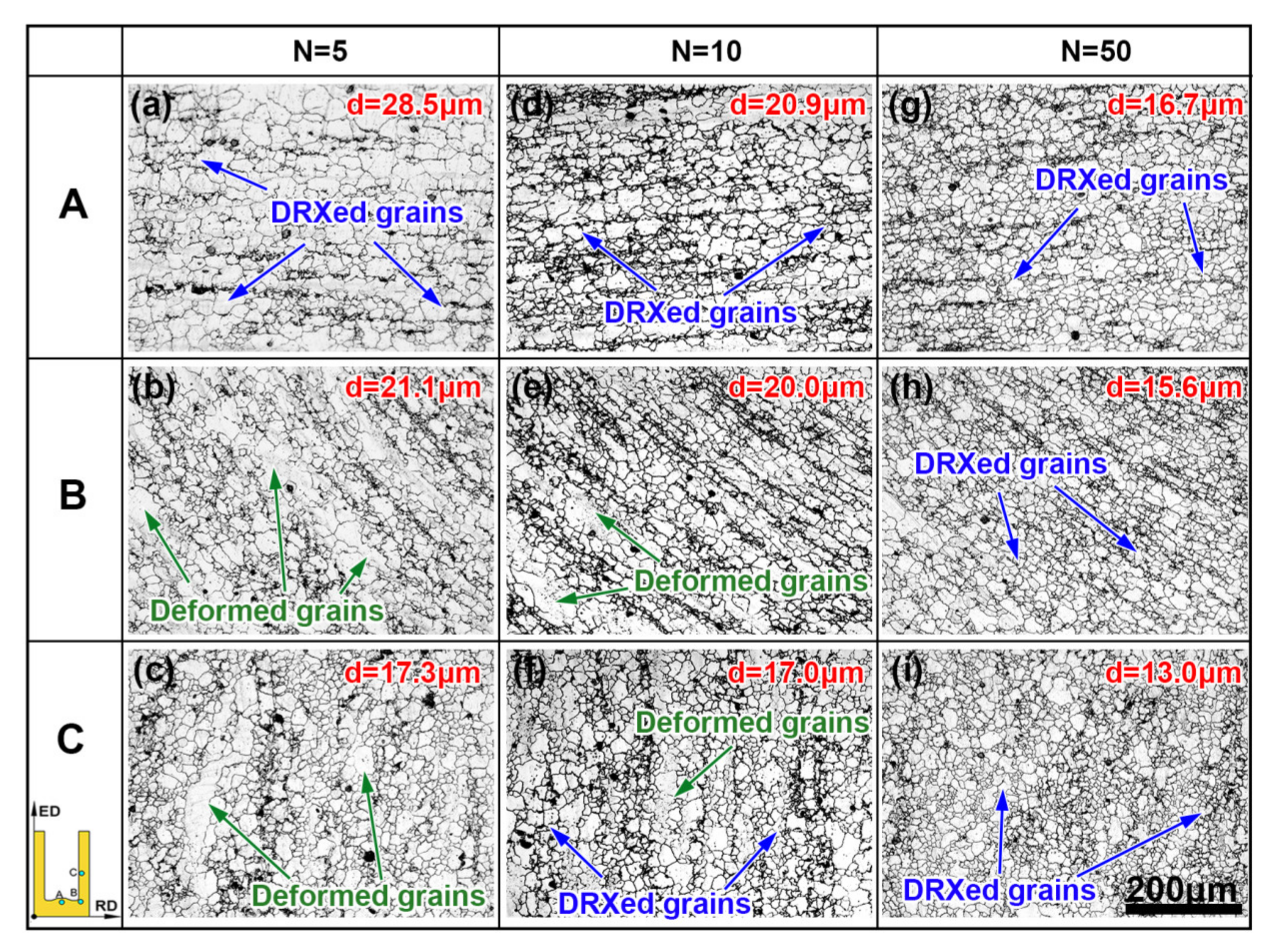

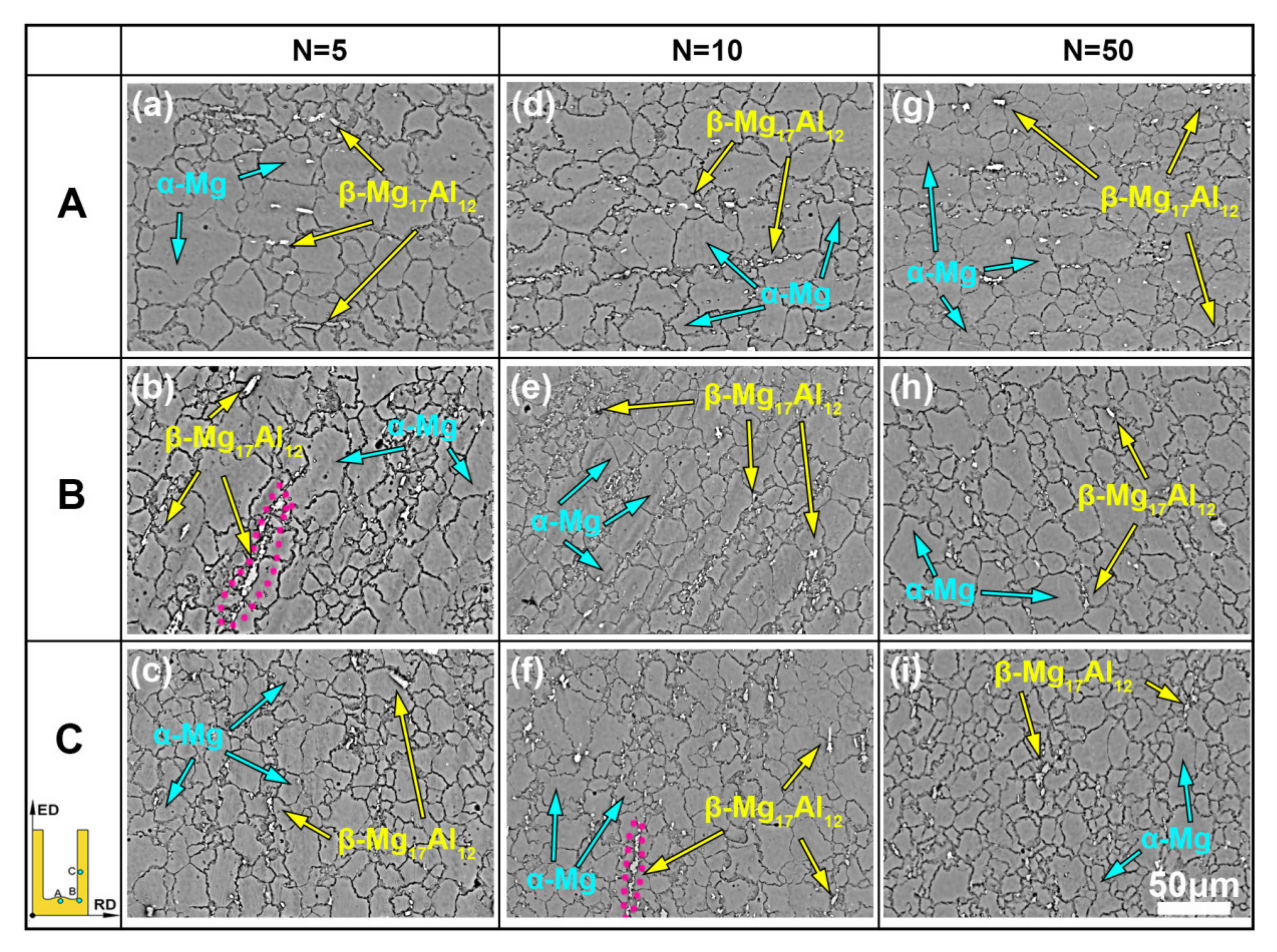

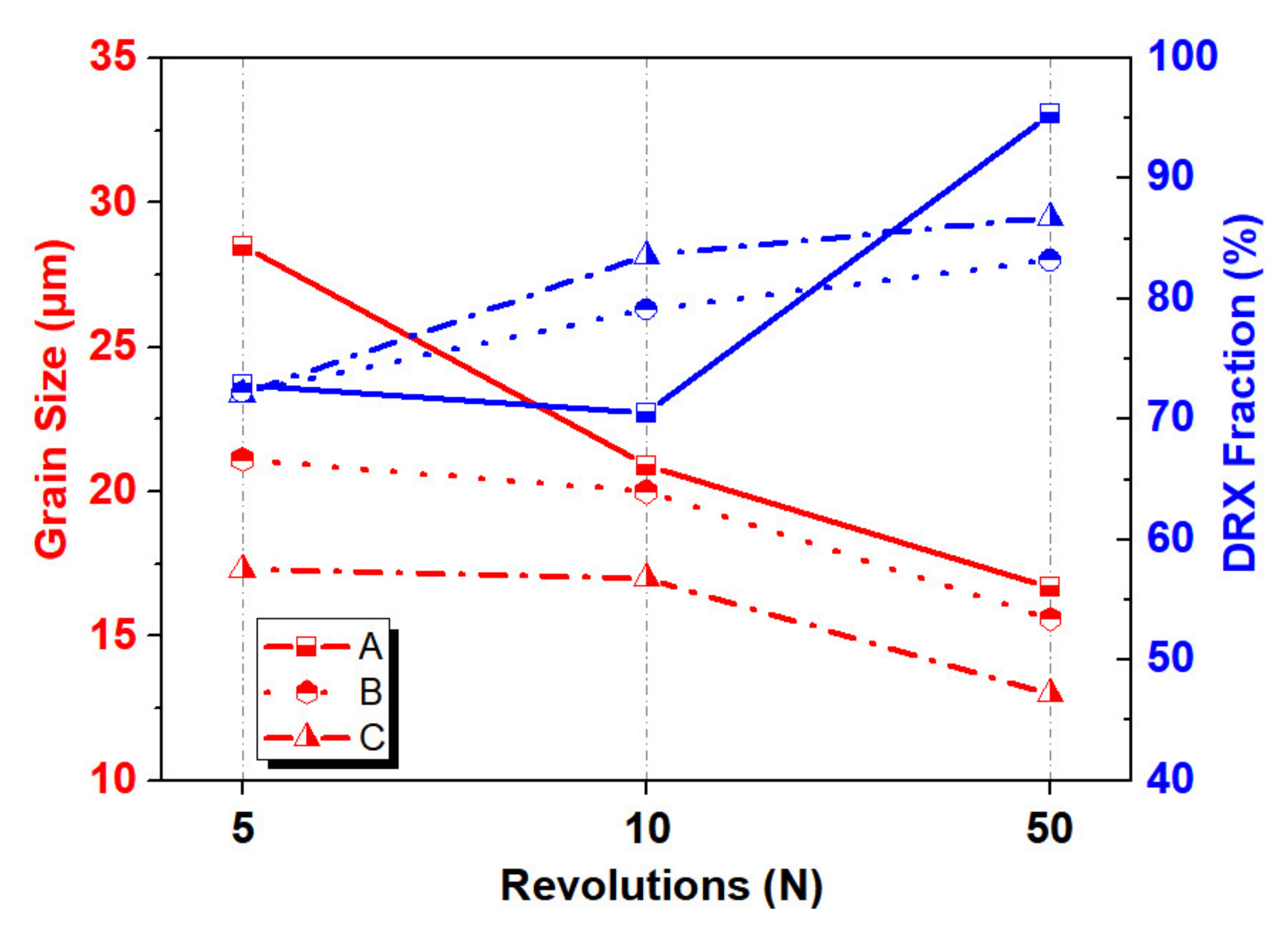

3.1. Microstructure Evolution

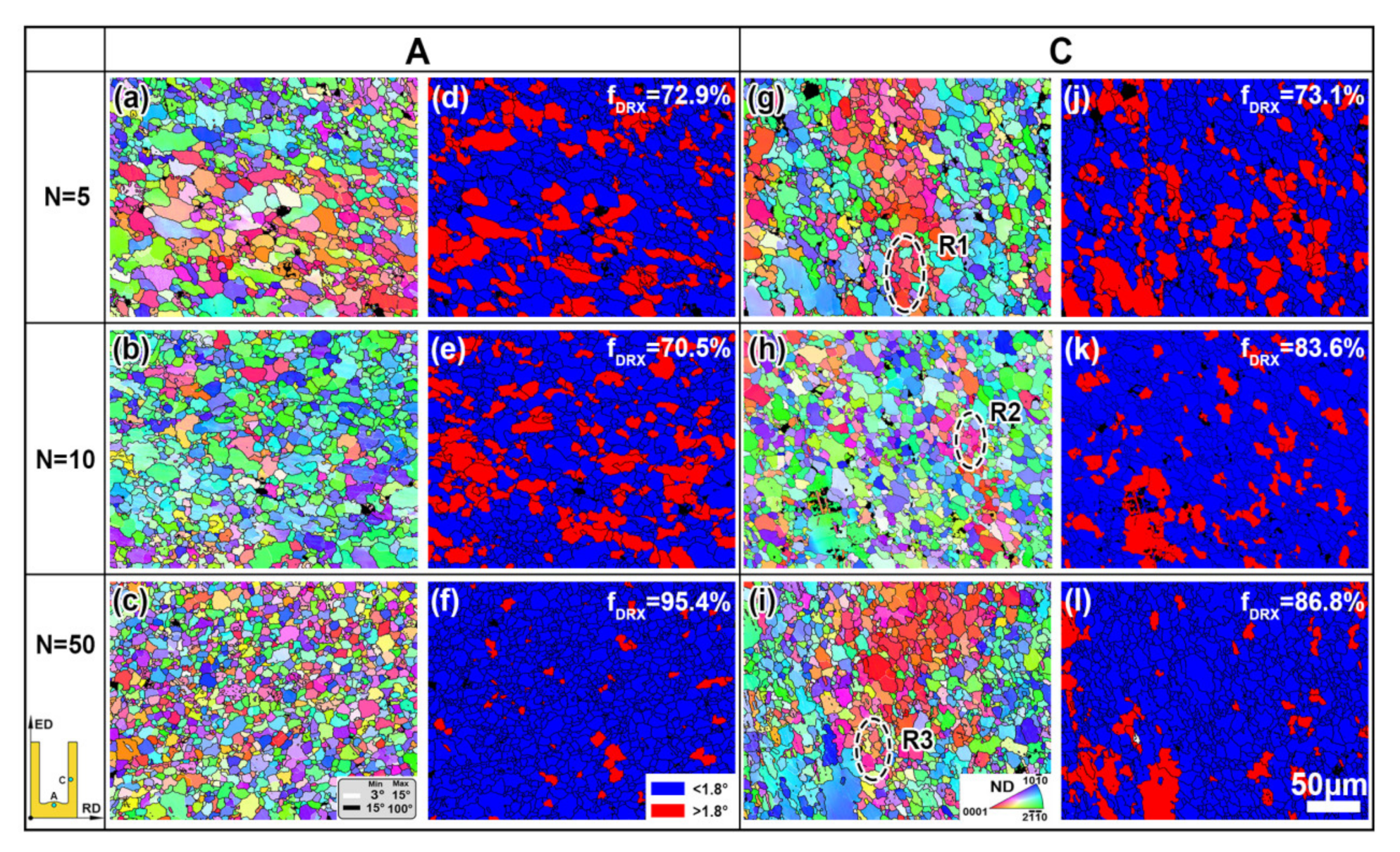

3.2. DRX Behaviors during the RBE Process

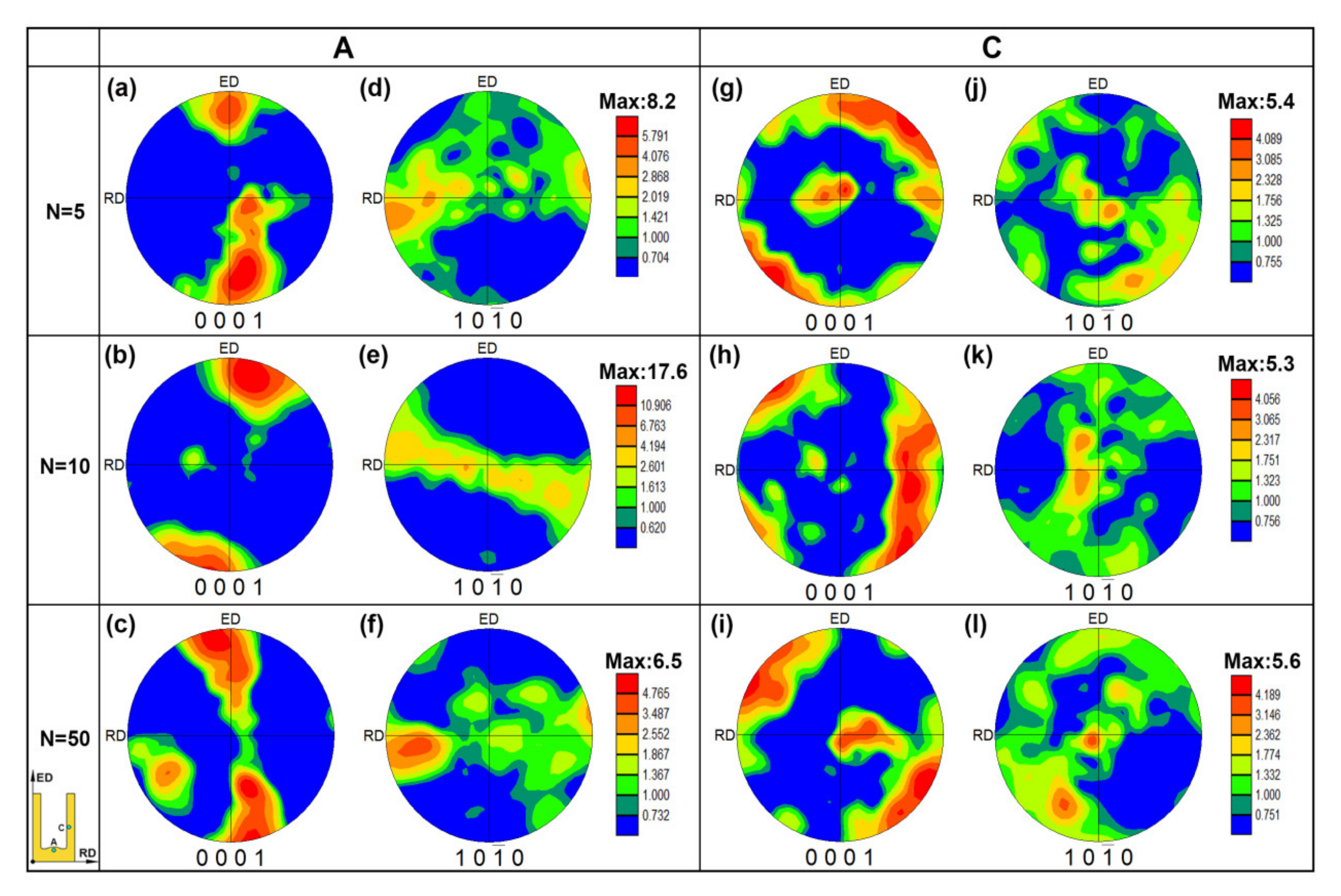

3.3. Texture Development

4. Outlook

5. Conclusions

- The grain refinement and microstructure uniformity can be enhanced by increasing the rotating revolutions. Furthermore, the large β phase can be broken into a small size phase with the increase of revolutions.

- The DRX fraction of the alloy can be increased with the revolutions increasing, and the main deformation mechanism of the RBE process is the CDRX and DDRX.

- Increasing the rotating revolutions can effectively weaken the texture during the RBE process, which may be ascribed to the occurrence of new DRXed grains with a random orientation.

Author Contributions

Funding

Conflicts of Interest

References

- Dong, B.B.; Che, X.; Wang, Q.; Meng, M.; Gao, Z.J.; Ma, F.L.; Yang, Z.; Zhang, M. Refining the microstructure and modifying the texture of the AZ80 alloy cylindrical tube by the rotating backward extrusion with different rotating revolutions. J. Alloys Compd. 2020, 836, 155442. [Google Scholar] [CrossRef]

- You, S.H.; Huang, Y.D.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnes. Alloy 2017, 5, 239–253. [Google Scholar] [CrossRef]

- Victoria-Hernandez, J.; Yi, S.; Letzig, D.; Hernandez-Silva, D.; Bohlen, J. Microstructure and texture development in hydrostatically extruded Mg-Al-Zn alloys during tensile testing at intermediate temperatures. Acta Mater. 2013, 61, 2179–2193. [Google Scholar] [CrossRef]

- Lei, J.Y.; Ma, L.F.; Jia, W.T.; Zhu, Y.C.; Huang, Z.Q.; Lin, J.B. Microstructure and properties of Mg-Al-Mn magnesium alloy under shear deformation coupled tension rolling. Mater. Res. Express 2019, 6, 106584. [Google Scholar] [CrossRef]

- Wang, C.P.; Mei, H.S.; Li, R.Q.; Li, D.F.; Wang, L.; Hua, Z.H.; Zhao, L.J.; Pen, F.F.; Li, H. Microstructure evolution and grain coarsening behaviour during partial remelting of cyclic extrusion compression formed AZ61 magnesium alloy. Acta Metall. Sin. 2013, 26, 149–156. [Google Scholar] [CrossRef]

- Du, B.N.; Hu, Z.Y.; Sheng, L.Y.; Xu, D.K.; Zheng, Y.F.; Xi, T.F. Influence of Zn content on microstructure and tensile properties of Mg-Zn-Y-Nd alloy. Acta Metall. Sin. 2018, 31, 1–11. [Google Scholar] [CrossRef]

- Cheng, W.L.; Wang, L.F.; Zhang, H.; Cao, X.Q. Enhanced stretch formability of AZ31 magnesium alloy thin sheet by pro-crossed twinning lamellas induced static recrystallization. J. Mater. Process. Technol. 2018, 254, 302–309. [Google Scholar] [CrossRef]

- Zhiyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Biswas, S.; Suwas, S. Evolution of sub-micron grain size and weak texture in magnesium alloy Mg-3Al-0.4Mn by a modified multi-axial forging process. Scr. Mater. 2012, 66, 89–92. [Google Scholar] [CrossRef]

- Roostaei, A.A.; Zarei-Hanzaki, A.; Abedi, H.R.; Rokni, M.R. An investigation into the mechanical behavior and microstructural evolution of the accumulative roll bonded AZ31 Mg alloy upon annealing. Mater. Des. 2011, 32, 2963–2968. [Google Scholar] [CrossRef]

- Fatemi-Varzaneh, S.M.; Zarei-Hanzaki, A. Accumulative back extrusion (ABE) processing as a novel bulk deformation method. Mater. Sci. Eng. A 2009, 504, 104–106. [Google Scholar] [CrossRef]

- Razmpoosh, M.H.; Zarei-Hanzaki, A.; Imandoust, A. Effect of the Zenere Hollomon parameter on the microstructure evolution of dual phase TWIP steel subjected to friction stir processing. Mater. Sci. Eng. A 2015, 638, 15–19. [Google Scholar] [CrossRef]

- del Valle, J.A.; Carreno, F. Influence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling. Acta Mater. 2016, 54, 4247–4259. [Google Scholar] [CrossRef]

- Kim, W.J.; Park, J.D.; Kim, W.Y. Effect of differential speed rolling on microstructure and mechanical properties of an AZ91 magnesium alloy. J. Magnes. Alloy 2008, 460, 289–293. [Google Scholar] [CrossRef]

- Zhang, G.S.; Zhang, Z.M.; Li, X.B.; Yan, Z.M.; Che, X.; Yu, J.M.; Meng, Y.Z. Effects of repetitive upsetting-extrusion parameters on microstructure and texture evolution of Mg-Gd-Y-Zn-Zr alloy. J. Alloys Compd. 2019, 790, 48–57. [Google Scholar] [CrossRef]

- Mizunuma, S. Large straining behavior and microstructure refinement of several metals by torsion extrusion process. Mater. Sci. Forum 2006, 503–504, 185–192. [Google Scholar] [CrossRef]

- Kong, L.X.; Lin, L.; Hodgson, P.D. Material properties under drawing and extrusion with cyclic torsion. Mater. Sci. Eng. A 2001, 308, 209–215. [Google Scholar] [CrossRef]

- Korbel, A.; Pospiech, J.; Bochniak, W.; Tarasek, A.; Ostachowski, P.; Bonarski, J. New structural and mechanical features of hexagonal materials after room temperature extrusion using the KoBo method. Int. J. Mater. Res. 2011, 102, 464–473. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, Z.; Wang, Q.; Hao, H.; Cui, J.; Li, L. Rotary extrusion as a novel severe plastic deformation method for cyclindrical tubes. Mater. Lett. 2018, 215, 195–199. [Google Scholar] [CrossRef]

- Che, X.; Wang, Q.; Dong, B.B.; Meng, M.; Zhang, Z.M. Numerical and experimental analysis of rotating backward extrusion as a new SPD process. Met. Mater. Int. 2020. [Google Scholar] [CrossRef]

- Chapuis, A.; Driver, J.H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Koike, J.; Kobayashi, T.; Watanabe, H.; Suzuki, M.; Maruyama, K.; Higashi, K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys. Acta Mater. 2003, 51, 2055–2065. [Google Scholar] [CrossRef]

- Li, N.L.; Huang, G.J.; Xin, R.L.; Liu, Q. Effect of initial texture on dynamic recrystallization and deformation mechanisms in AZ31 Mg alloy extruded at 573 K. Mater. Sci. Eng. A 2013, 569, 18–26. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, S.W.; Moon, B.G.; Kim, H.S.; Park, S.H. Influence of extrusion temperature on dynamic deformation behaviors and mechanical properties of Mg-8Al-0.5Zn-0.2Mn-0.3Ca-0.2Y alloy. J. Mater. Res. Technol. 2019, 8, 5254–5270. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, M.Y.; Xu, S.W.; Wu, K.; Wang, E.D.; Fan, G.H.; Kamado, S.; Liu, X.D.; Wang, G.J.; Lv, X.Y. Microstructure and mechanical properties of Mg-Gd-Y-Zn-Zr alloy sheets processed by combined processes of extrusion hot rolling and ageing. Mater. Sci. Eng. A 2013, 559, 844–851. [Google Scholar] [CrossRef]

- Jiang, M.G.; Xu, C.; Yan, H.; Fan, G.H.; Nakata, T.; Lao, C.S. Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion. Acta Mater. 2018, 157, 53–71. [Google Scholar] [CrossRef]

- Huang, K.; Loge, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Hadorn, J.P.; Hantzsche, K.; Yi, S.; Bohlen, J.; Letzig, D.; Wollmershauser, J.A.; Agnew, S.R. Role of solute in the texture modification during hot deformation of Mg-rare earth alloys. Metall. Mater. Trans. A 2012, 43, 1347–1362. [Google Scholar] [CrossRef]

- Hadorn, J.P.; Sasaki, T.T.; Nakata, T.; Ohkubo, T.; Kamado, S.; Hono, K. Solute clustering and grain boundary segregation in extruded dilute Mg-Gd alloys. Scr. Mater. 2014, 93, 28–31. [Google Scholar] [CrossRef]

- Al-Samman, T.; Gottstein, G. Dynamic recrystallization during high temperature deformation of magnesium. Mater. Sci. Eng. A 2008, 490, 411–420. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, B.; Liu, C. An investigation of dynamic recrystallization behavior of ZK60-Er magnesium alloy. Mater. Sci. Eng. A 2014, 612, 253–266. [Google Scholar] [CrossRef]

- Torbati-Sarraf, S.A.; Sabbaghianrad, S.; Figueiredo, R.B.; Langdona, T.G. Orientation imaging microscopy and microhardness in a ZK60 magnesium alloy processed by high-pressure torsion. J. Alloy. Compds 2017, 712, 185–193. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Cu | Fe | Ni | Si | Mg |

|---|---|---|---|---|---|---|---|

| 8.43 | 0.60 | 0.19 | <0.05 | <0.05 | <0.05 | <0.05 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, X.; Dong, B.; Liu, K.; Wang, Q.; Meng, M.; Gao, Z.; Ma, J.; Yang, F.; Zhang, Z. An Investigation on the Microstructure and Texture of an AZ80 Cup-Shaped Piece Processed by Rotating Backward Extrusion. Materials 2020, 13, 3690. https://doi.org/10.3390/ma13173690

Che X, Dong B, Liu K, Wang Q, Meng M, Gao Z, Ma J, Yang F, Zhang Z. An Investigation on the Microstructure and Texture of an AZ80 Cup-Shaped Piece Processed by Rotating Backward Extrusion. Materials. 2020; 13(17):3690. https://doi.org/10.3390/ma13173690

Chicago/Turabian StyleChe, Xin, Beibei Dong, Kai Liu, Qiang Wang, Mu Meng, Zhi Gao, Jin Ma, Fulai Yang, and Zhimin Zhang. 2020. "An Investigation on the Microstructure and Texture of an AZ80 Cup-Shaped Piece Processed by Rotating Backward Extrusion" Materials 13, no. 17: 3690. https://doi.org/10.3390/ma13173690

APA StyleChe, X., Dong, B., Liu, K., Wang, Q., Meng, M., Gao, Z., Ma, J., Yang, F., & Zhang, Z. (2020). An Investigation on the Microstructure and Texture of an AZ80 Cup-Shaped Piece Processed by Rotating Backward Extrusion. Materials, 13(17), 3690. https://doi.org/10.3390/ma13173690