1. Introduction

The low-density components made of aluminum or titanium alloys are widely used in the aircraft industries to reduce the weight of the product, without compromising quality and performance [

1]. Subsequently, the joining technologies of sheet metal parts have become a key factor affecting the assembly quality of aircraft. Among various mechanical connection methods, riveting plays the most important role in aircraft manufacturing because of its stable, easy trouble-shooting, convenient quality inspection and low cost [

2,

3]. Stress Load and cyclic temperature load have important influence on fatigue performance of a riveted joint. In this paper, the effect of stress load is analyzed under the assumption of constant temperature.

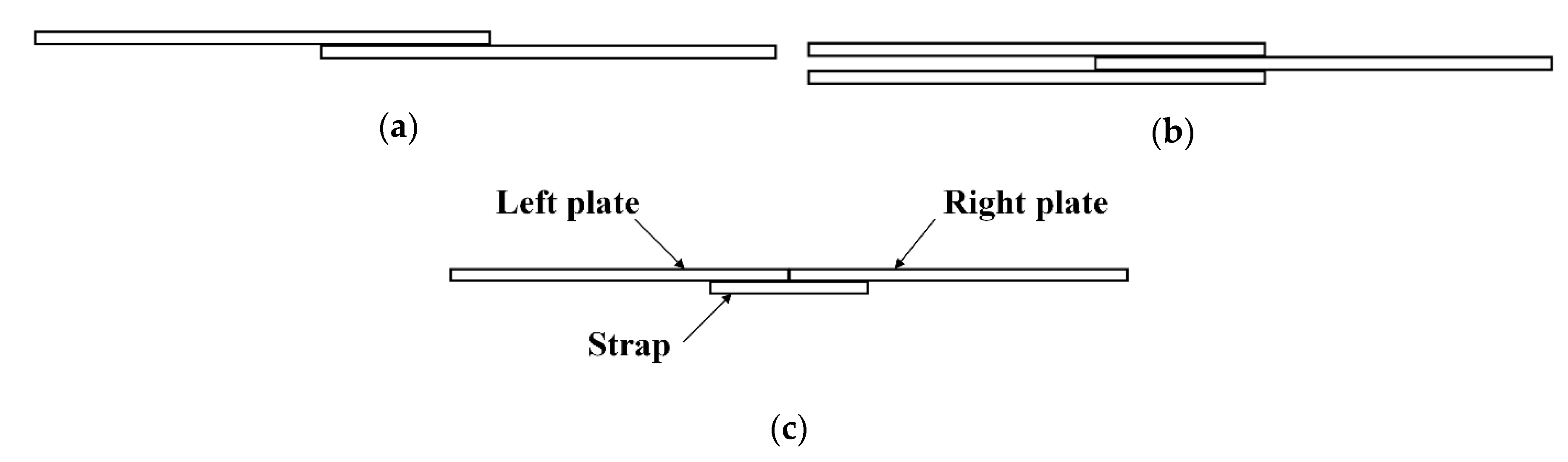

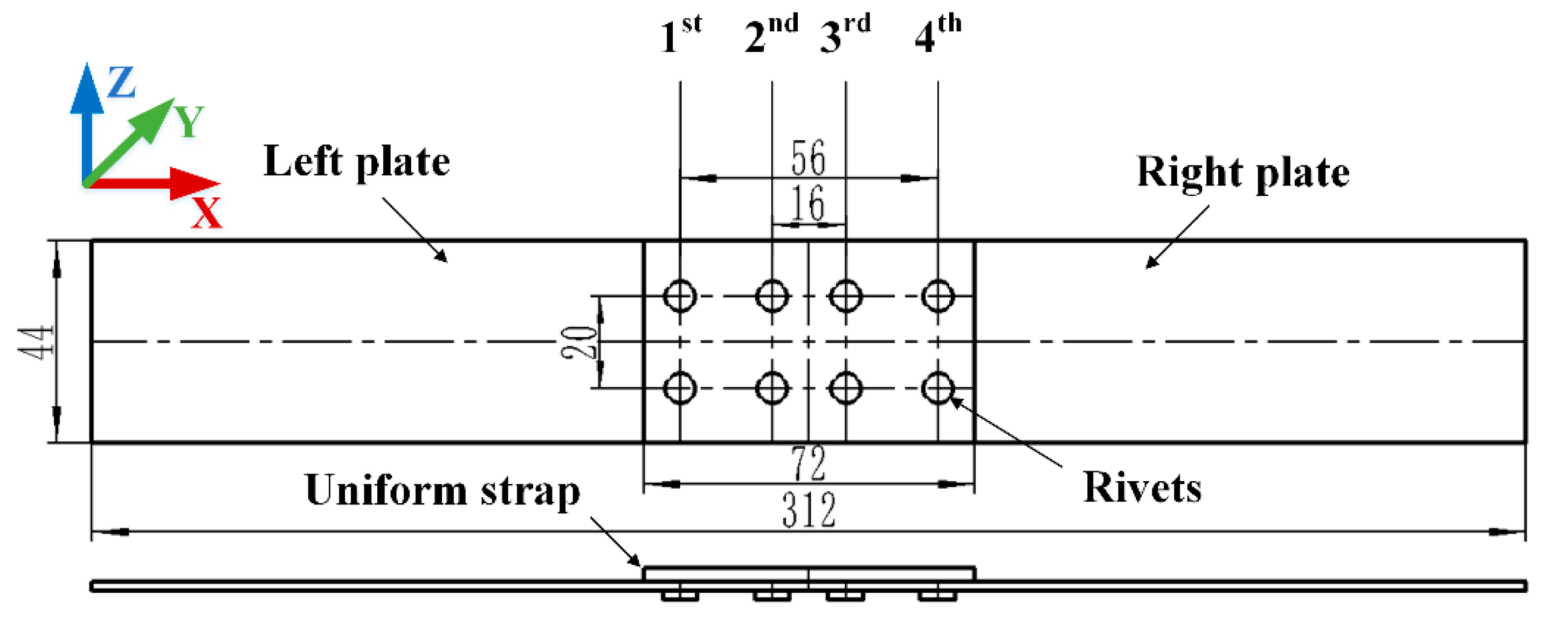

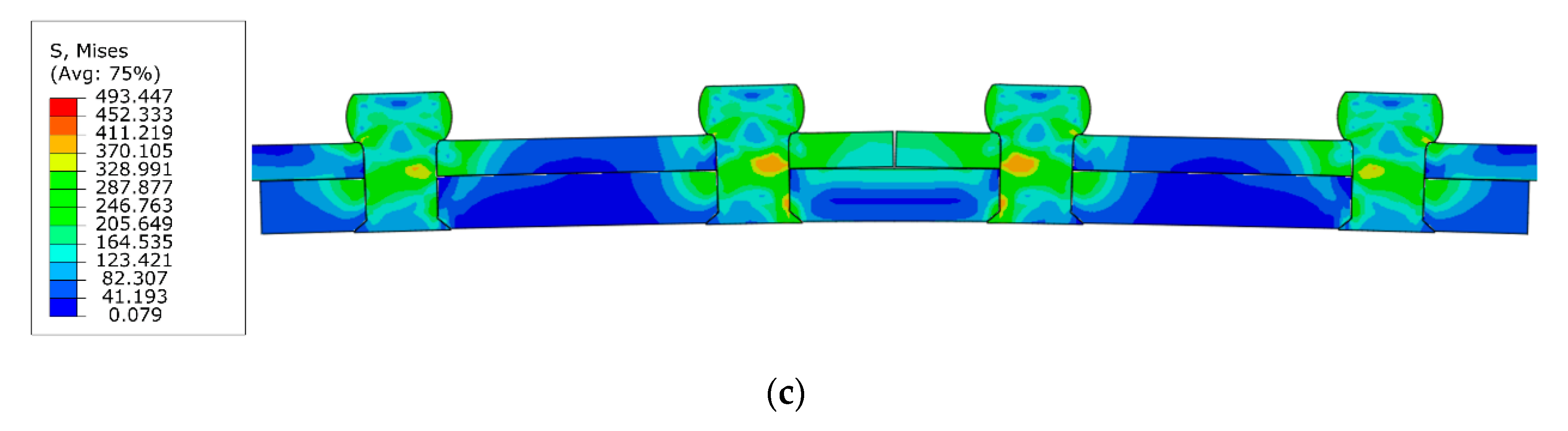

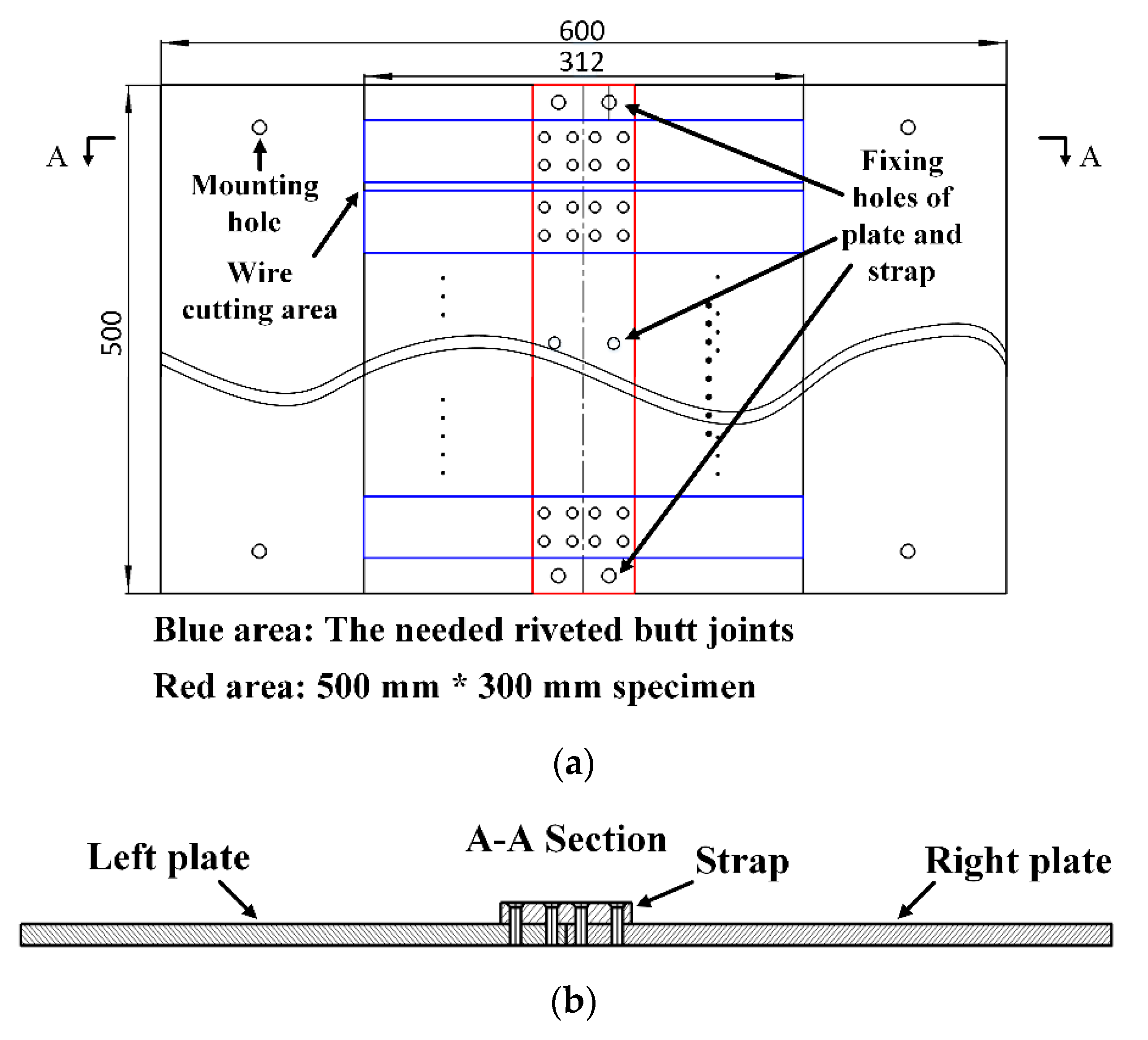

Generally, there are several typical riveted joints, such as a single-lap joint, a double-lap joint, and a single-trap butt joint, as shown in

Figure 1 [

4]. The lap joint has a shorter connection area and is lighter in weight because there are no excess connection parts. However, the overlapped panels are easy to sag, which leads to stress concentrations and affect the fatigue performance of the joints. In addition, the high-stress zone in the lap joint is on the panels, once the cracks appear, it is more difficult to maintain and control the propagation of the cracks. On the other side, the butt joint is heavier than the lap joint due to the use of straps. However, the butt joint can avoid sagging of the panels and has fewer stresses concentration. The high-stress zone in the butt joint is on the straps, which is easier to repair when cracks appear [

5].

A key step for understanding the fatigue performance of the riveted joints is to analyze the riveting process. A great deal of interest has been focused on the modeling and analysis of the riveting process by researchers. Zhang et al. [

4] studied the riveting process based on mathematical modeling and simulating to analyze the deformation of thin-walled sheet-metal parts. Aman et al. [

6] built finite element models to study the effect of riveting sequence, the distance between rivets, and the gap between sheets on the quality of riveted lap joints. A combination of riveting process parameters is found to minimize the residual stress in sheets and rivets. Chang et al. [

7] built a 3D finite element (FE) model for the riveting process and validated it by experiments. The study found that the riveting sequence has a significant effect on the distribution of riveting deformation. Furthermore, the riveting induced residual stress distribution around the riveted hole area also attracted the attention of researchers. Li et al. [

8] developed a two-dimensional axisymmetric finite element model of fuselage lap joints. Non-linear and nonhomogeneous distribution properties for the residual stress was displayed. Li et al. [

9] developed a three-dimensional numerical technique to study the residual stress and strain as well as their variations that occur during the riveting process. Manes et al. [

10] investigated the effects of squeeze force, the clearance, the rivet length, and the clamping angle in the stress field of the riveted joints by numerical technique. The results demonstrated that the squeeze force is the key parameter in the characterization of the stress field. Elajrami et al. [

11] analyzed the residual stress distribution in the riveted hole of aluminum alloy Al2024-T3 induced by a tapered pin. The results show that the residual stresses vary through the material depth, are strong at the exit face and moderate at the entrance face and maximal in mid-depth.

The fatigue life of the riveted joints mainly depends on the coupling effect of residual stress induced by the riveting process and the external load during ground-air-ground pressurization cycles [

12]. Therefore, the fatigue behavior and cracks propagation of riveted joints is a momentous aspect of riveting research. Rans et al. [

13] employed the fractographic techniques to evaluate postmortem the influence of the riveting squeeze force and resulting residual stresses on crack behavior for the riveted lap joint. The results of fatigue tests show that the fatigue life increased with increasing riveting squeeze force. Muller [

14] made an extensive investigation on riveted lap joints, including theoretical and experimental analysis. The 3D residual stress distribution was studied by FE calculations and the results agree well with observations on fatigue life enhancement in experiments. The studies indicated that the squeeze force has a significant effect on the location of fatigue crack nuclei and crack growth through or around the rivet hole. Armentani et al. [

15] conducted fatigue tests for 200 single lap multiple-riveted joint specimens and the fatigue lives and critical crack sizes for all specimens were analyzed. The results showed that the higher the applied stress, the more through-hole cracking appeared. Skorupa et al. [

16] investigated the impact of sheet thickness, rivet type and squeeze force on the fatigue response of the riveted lap joint. It was observed that the fatigue cracks always start in one of the end rivet rows of the loaded sheet. Besides, the establishment of the fatigue life prediction model has important reference significance for the practical application of riveted joints. Skorupa et al. [

17] developed a fatigue life prediction model for riveted lap joints, in which the rivet hole expansion and the load transfer distribution are unambiguously characterized by measurable quantities. The model is validated by 80 fatigue tests on aluminum alloy. De Rijck et al. [

18] investigated the relation between squeeze load and the rivet head dimension during controlled squeezing. Then the quality control of the riveting process concerning the fatigue performance of riveted joints can be achieved. Leonetti et al. [

19] proposed a system reliability model for estimating the probabilistic fatigue life of riveted shear connections. The model allows considering multiple site cracks.

However, most of the existing research is based on the lap joints, while the research of the riveted butt joint is relatively few. Maljaars et al. [

20] presented a theoretical fatigue strength prediction model for riveted double-covered butt joints. The study indicated that the plate width over rivet diameter radio and the surface finish has a large effect on the strength. Citarella et al. [

21] carried out a multi-site-damage crack growth simulation of a cracked riveted butt-joint. The equivalent crack length is proposed for a 2D analysis and the simplified bidimensional analyses are validated by fatigue test data. Galatolo et al. [

22] presented a combined experimental and numerical analysis of the residual strength of a butt-joint panel with multiple-site-damage. A crack propagation model accommodated for crack growth resistance, crack link-up and in particular restart after link-up was proposed. In fact, the effects of rivet size/arrangement and strap geometry on the fatigue life of the riveted butt joint are still scarcely understood. Moreover, the relationship between the residual stress distribution and the fatigue performance of riveted butt joint has not been revealed.

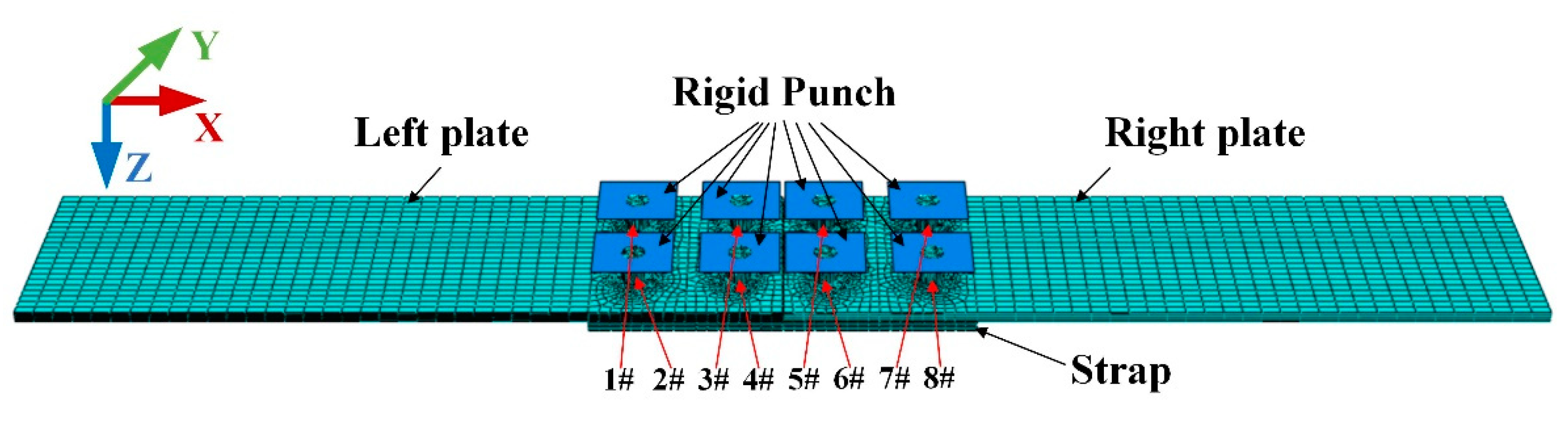

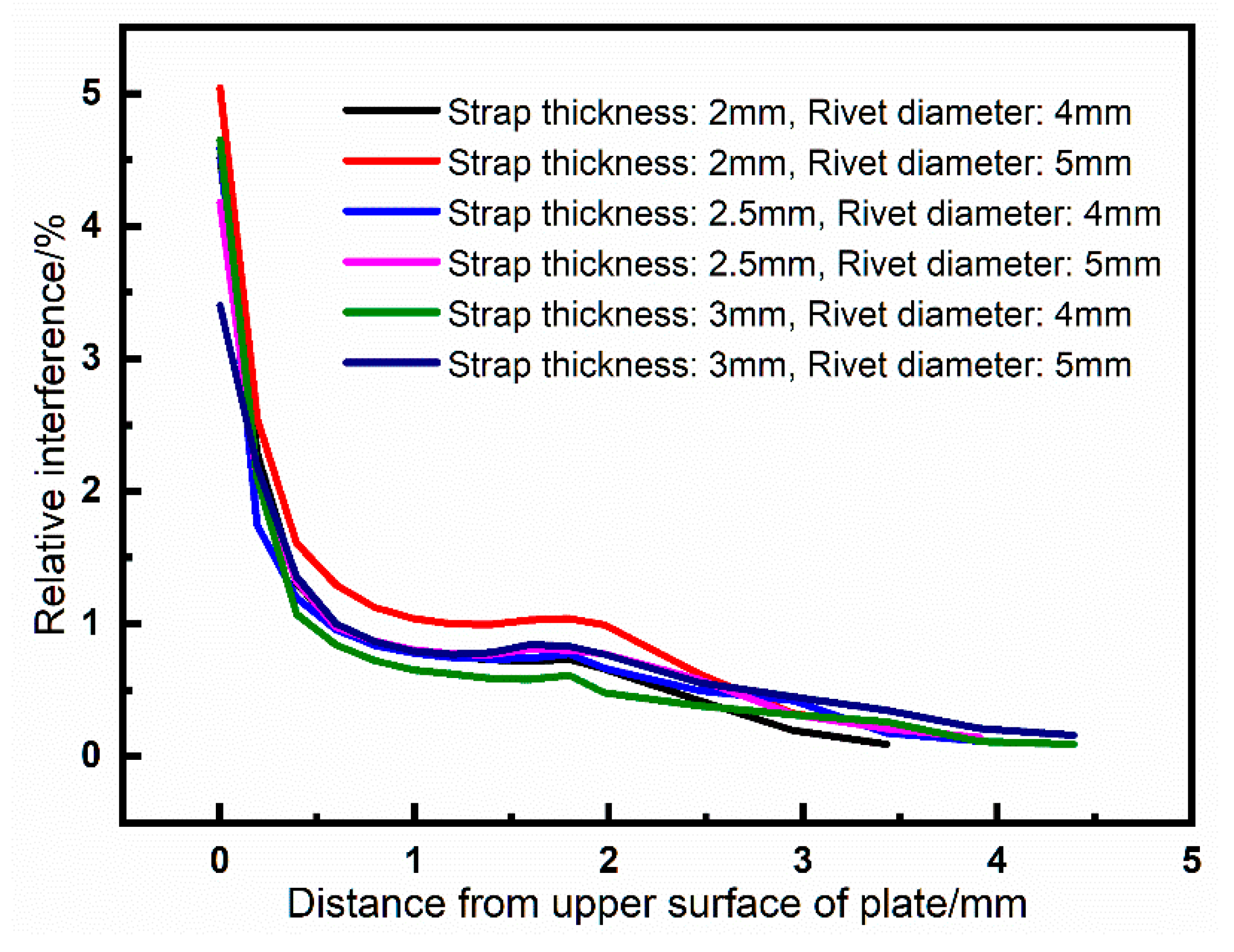

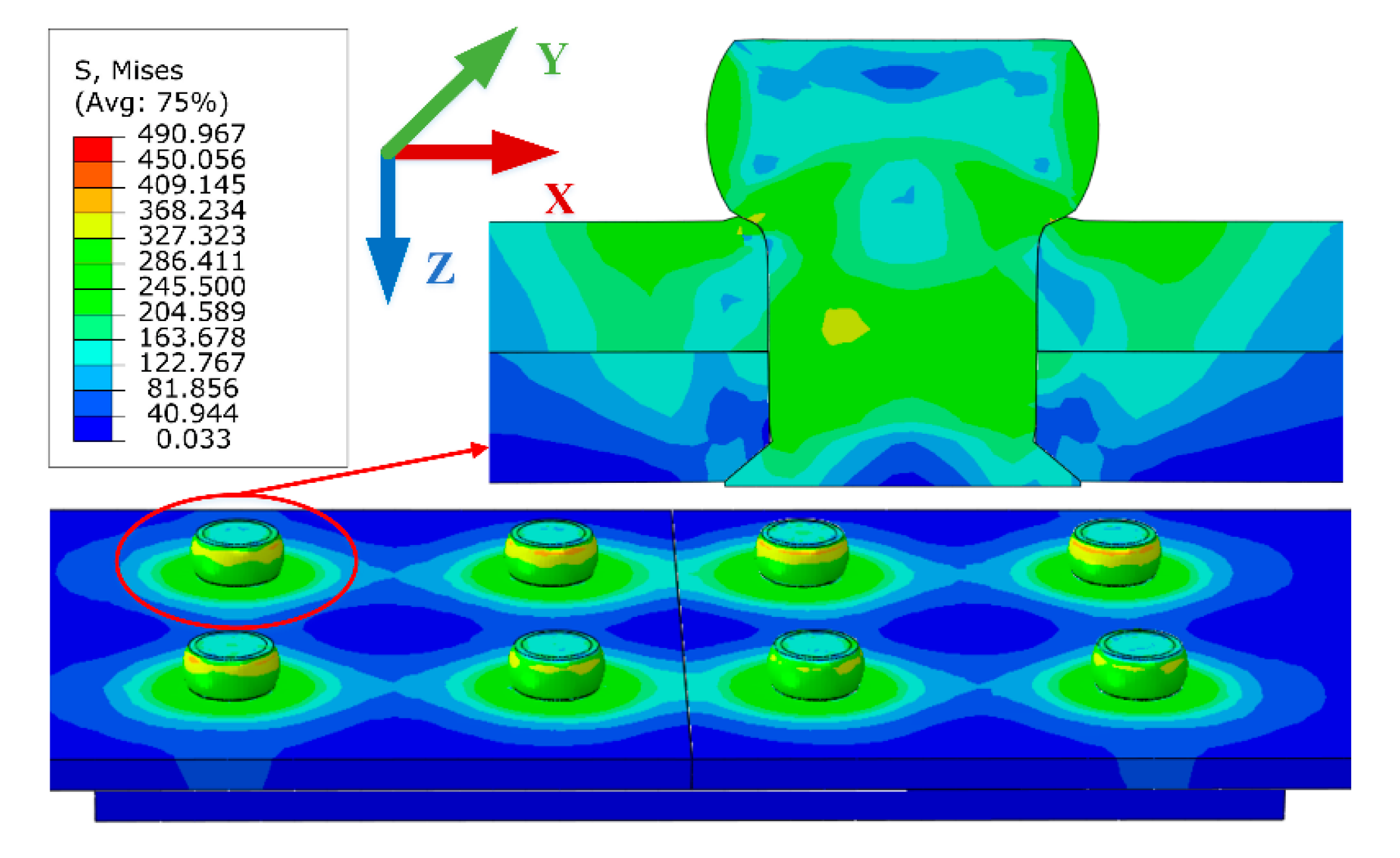

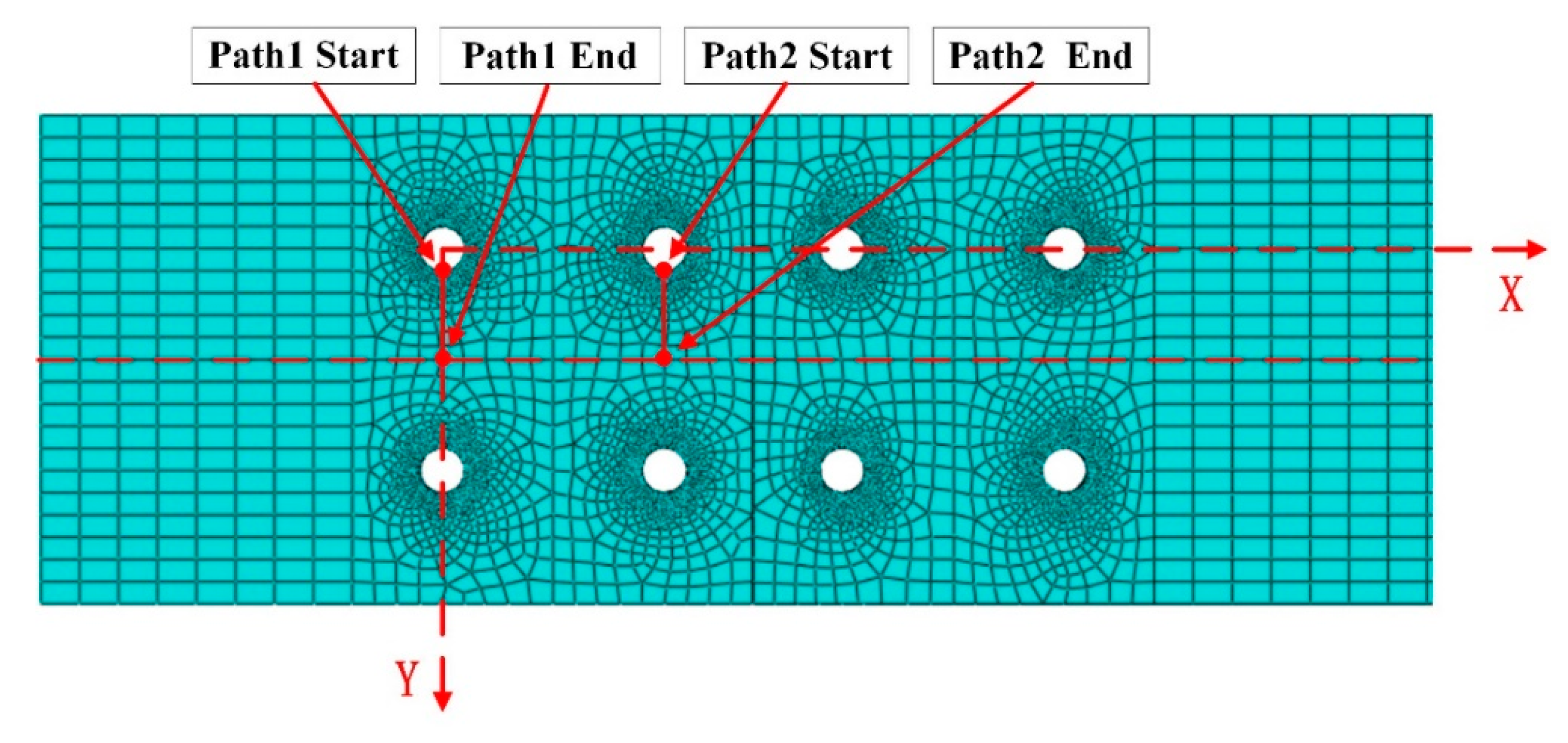

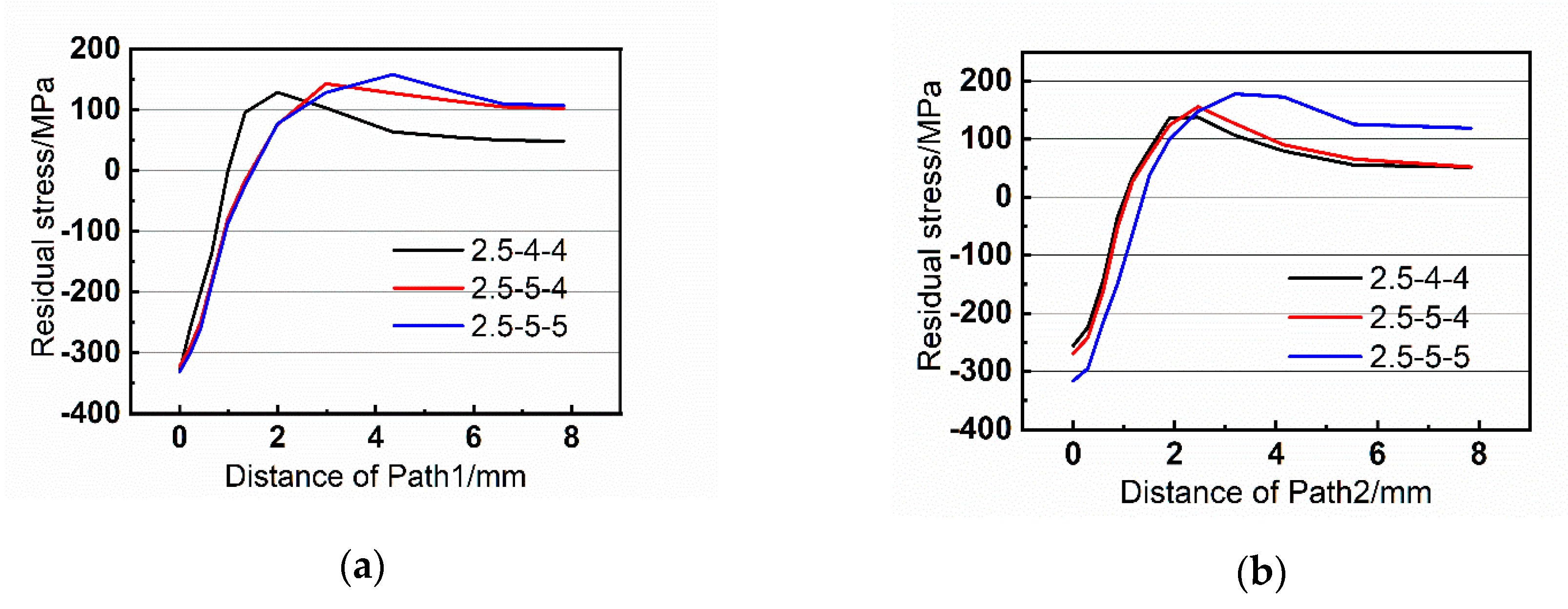

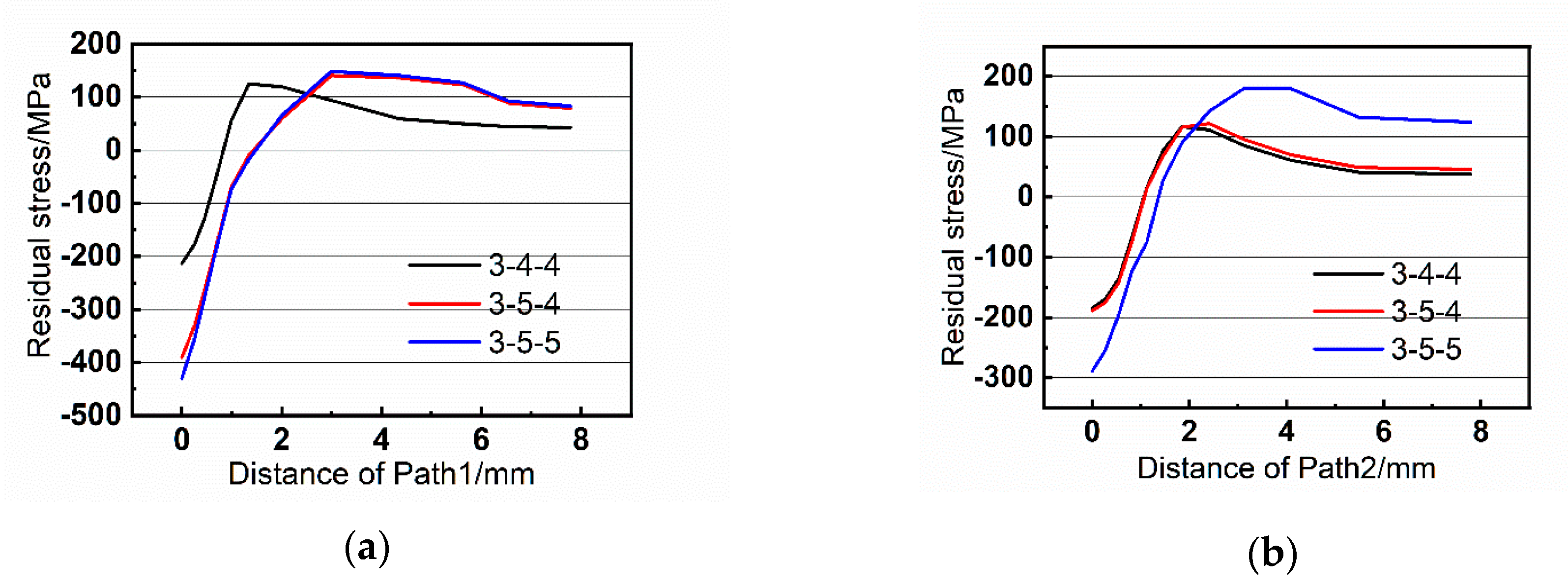

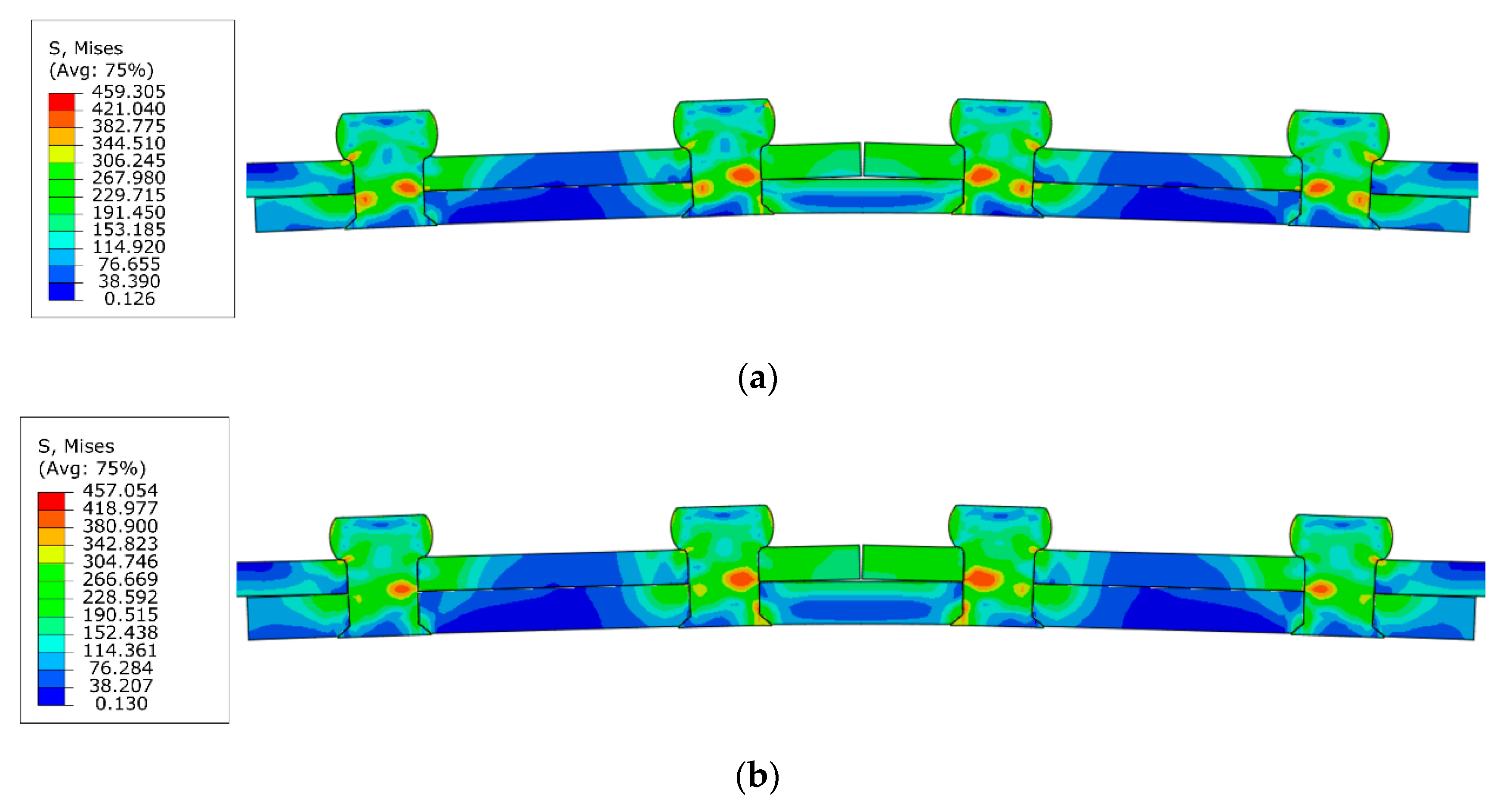

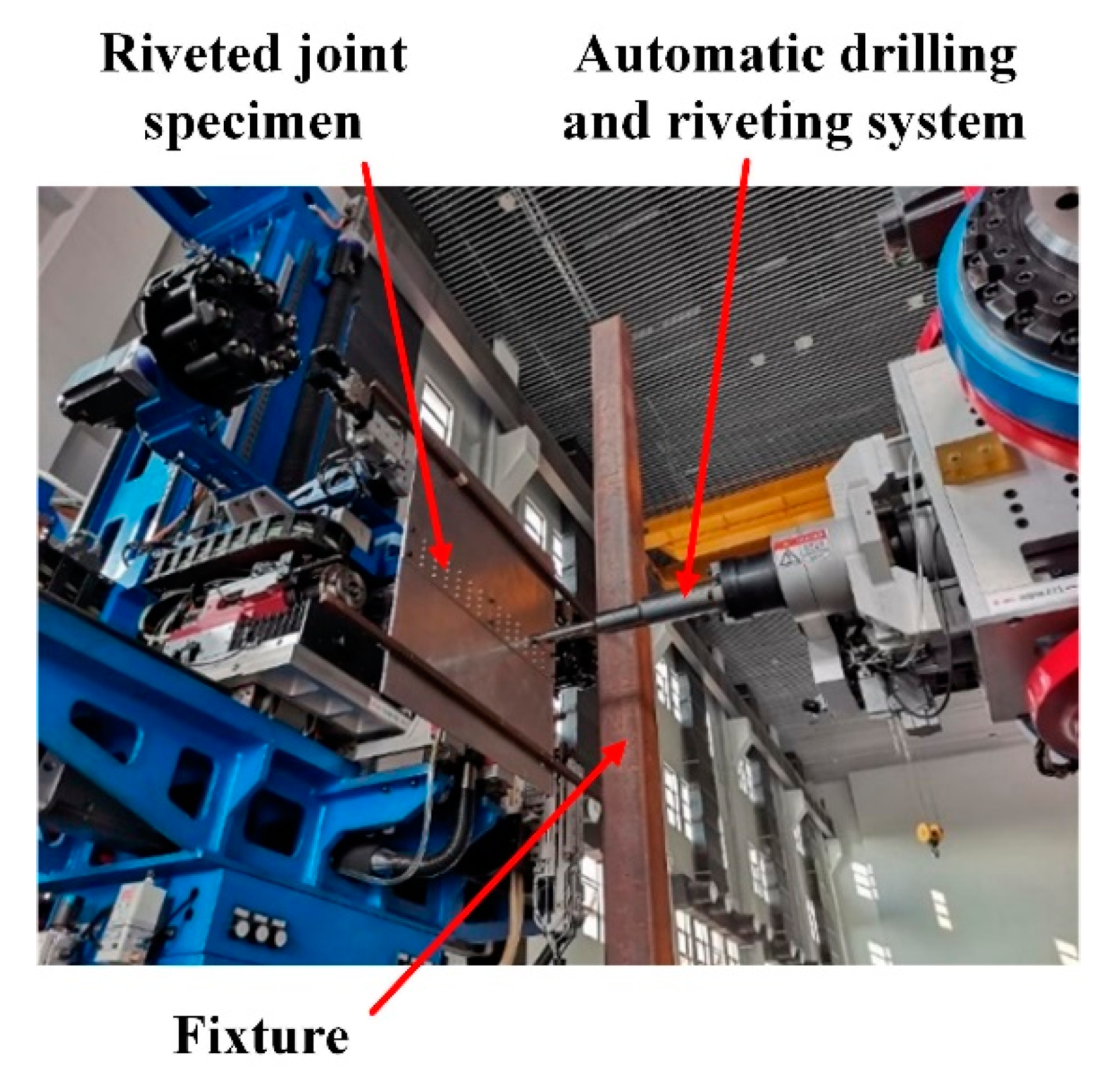

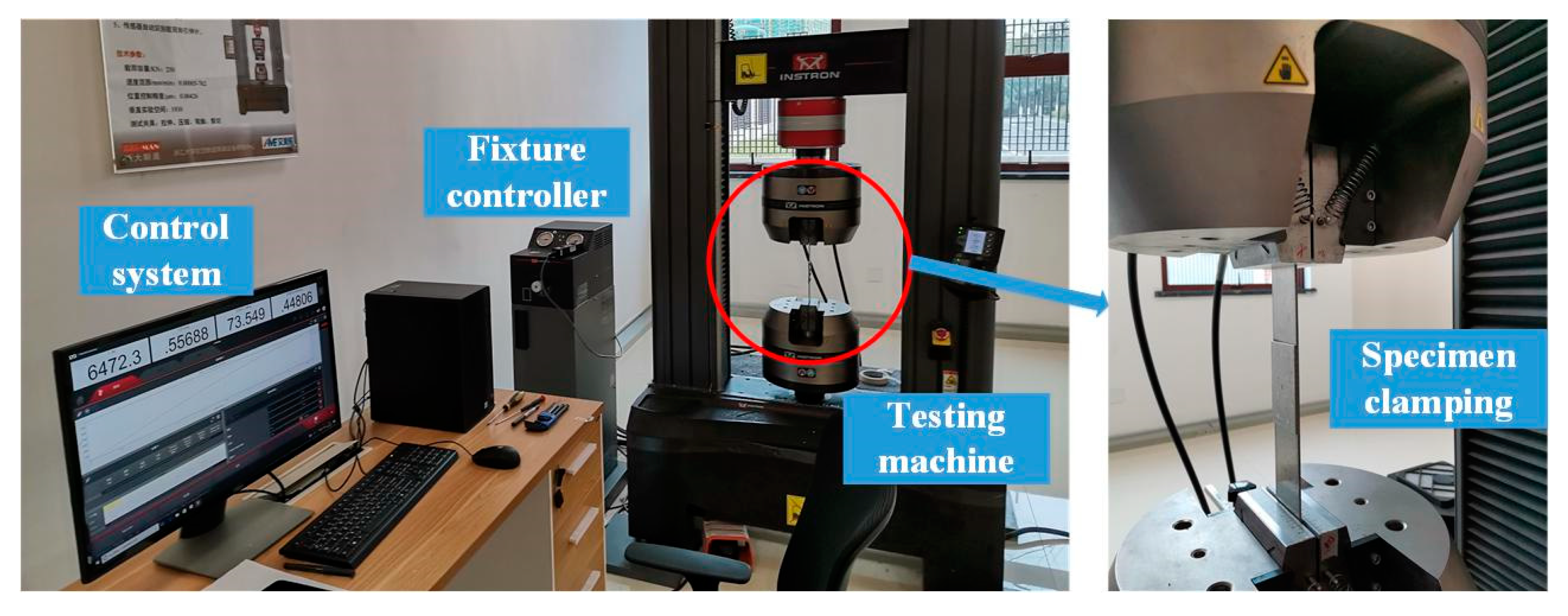

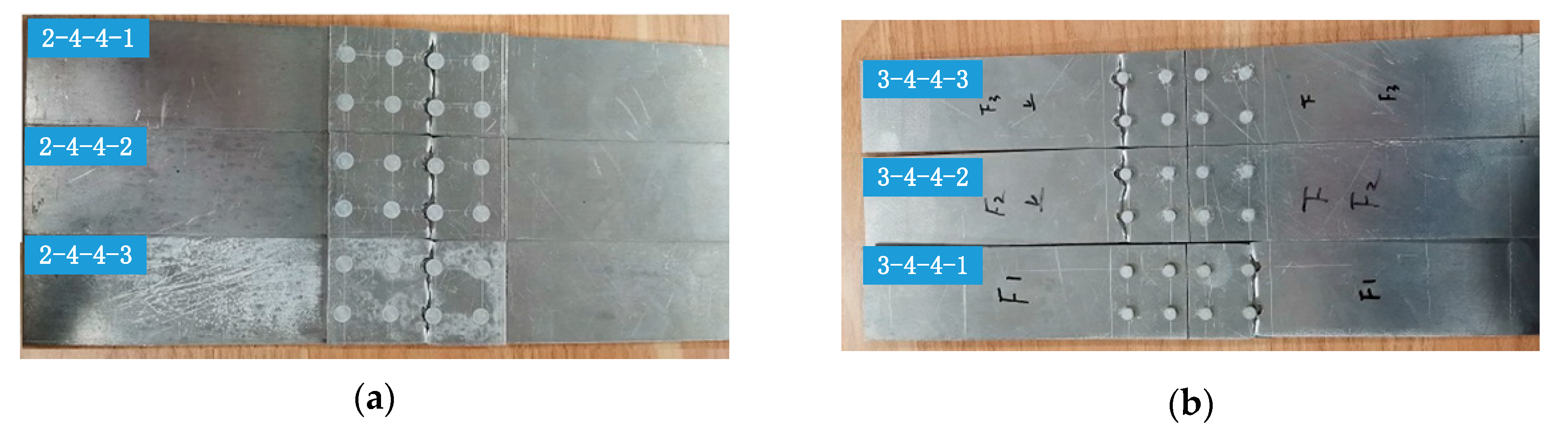

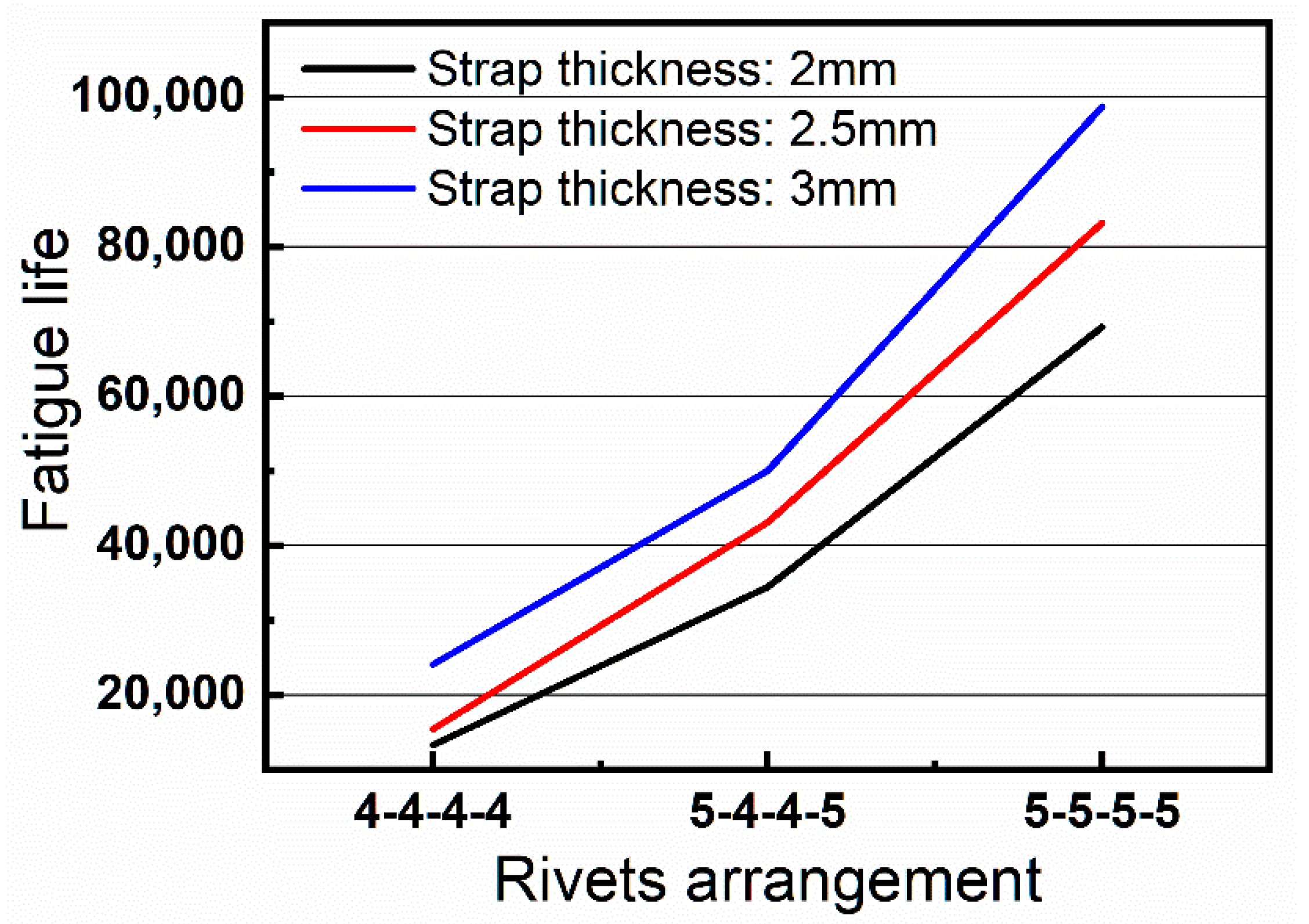

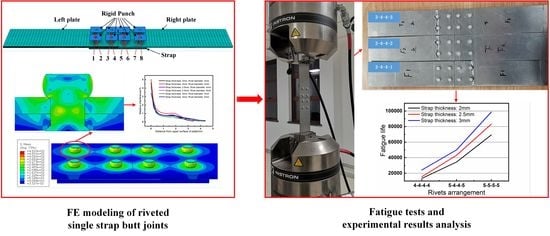

In this paper, under the assumption of constant temperature, the residual stresses of riveted single strap butt joints are numerically studied with various rivet sizes and strap thicknesses. Then, fatigue tests with cyclic loading are carried out to investigate the fatigue life of the riveted butt joint specimens with various parameters. The optimal structural design parameters of the riveted butt joint are finally determined. The remainder of the paper is organized as follows: In

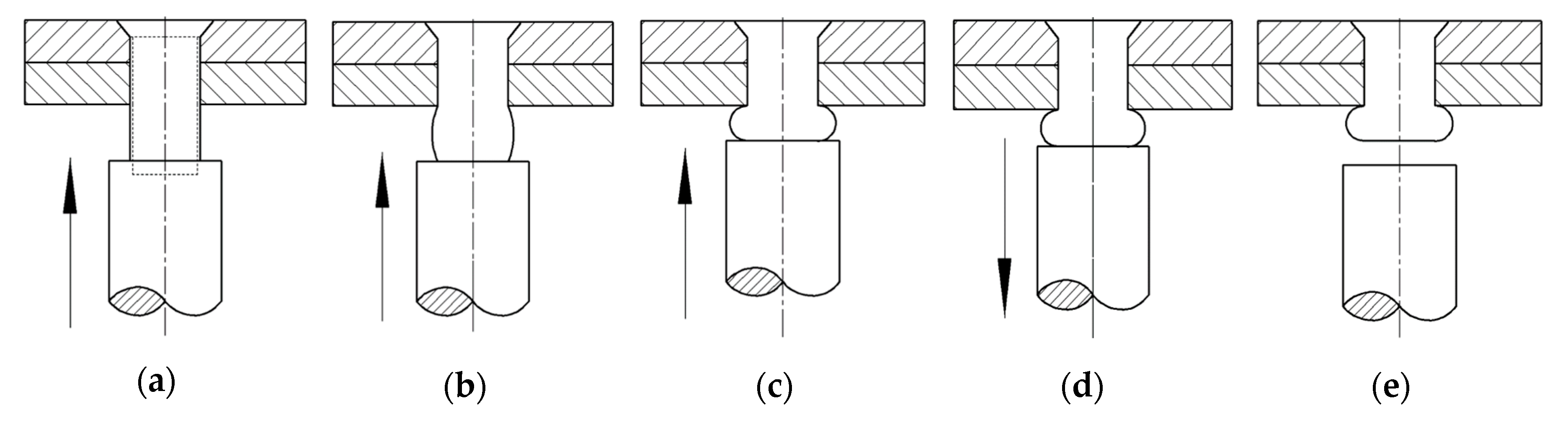

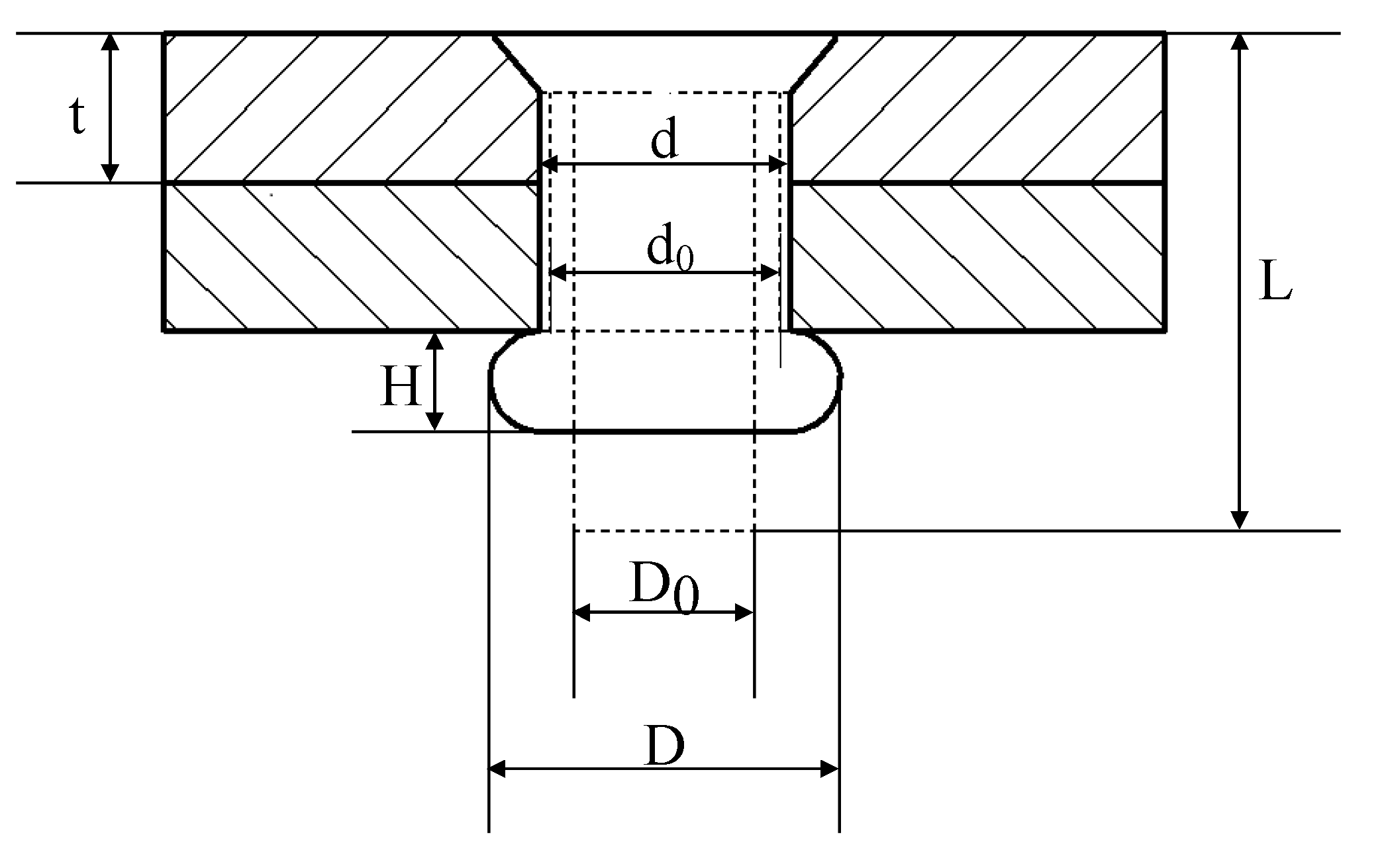

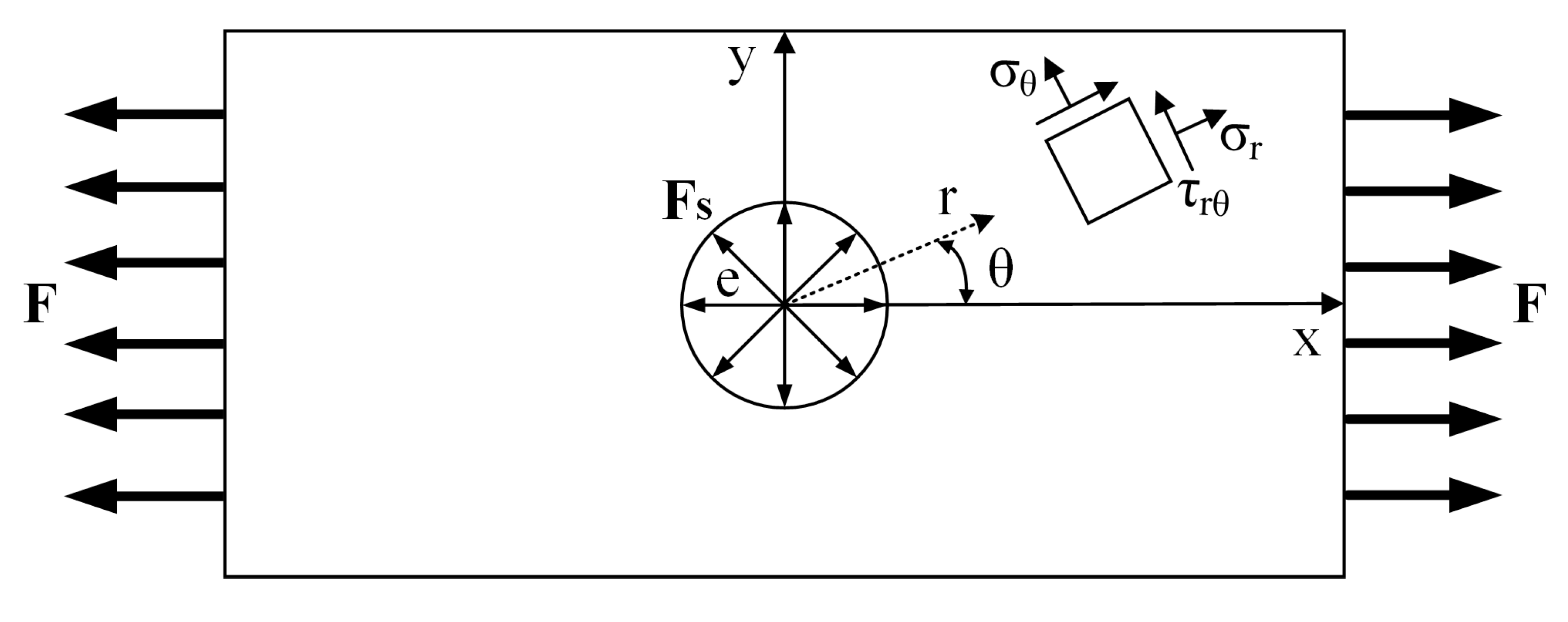

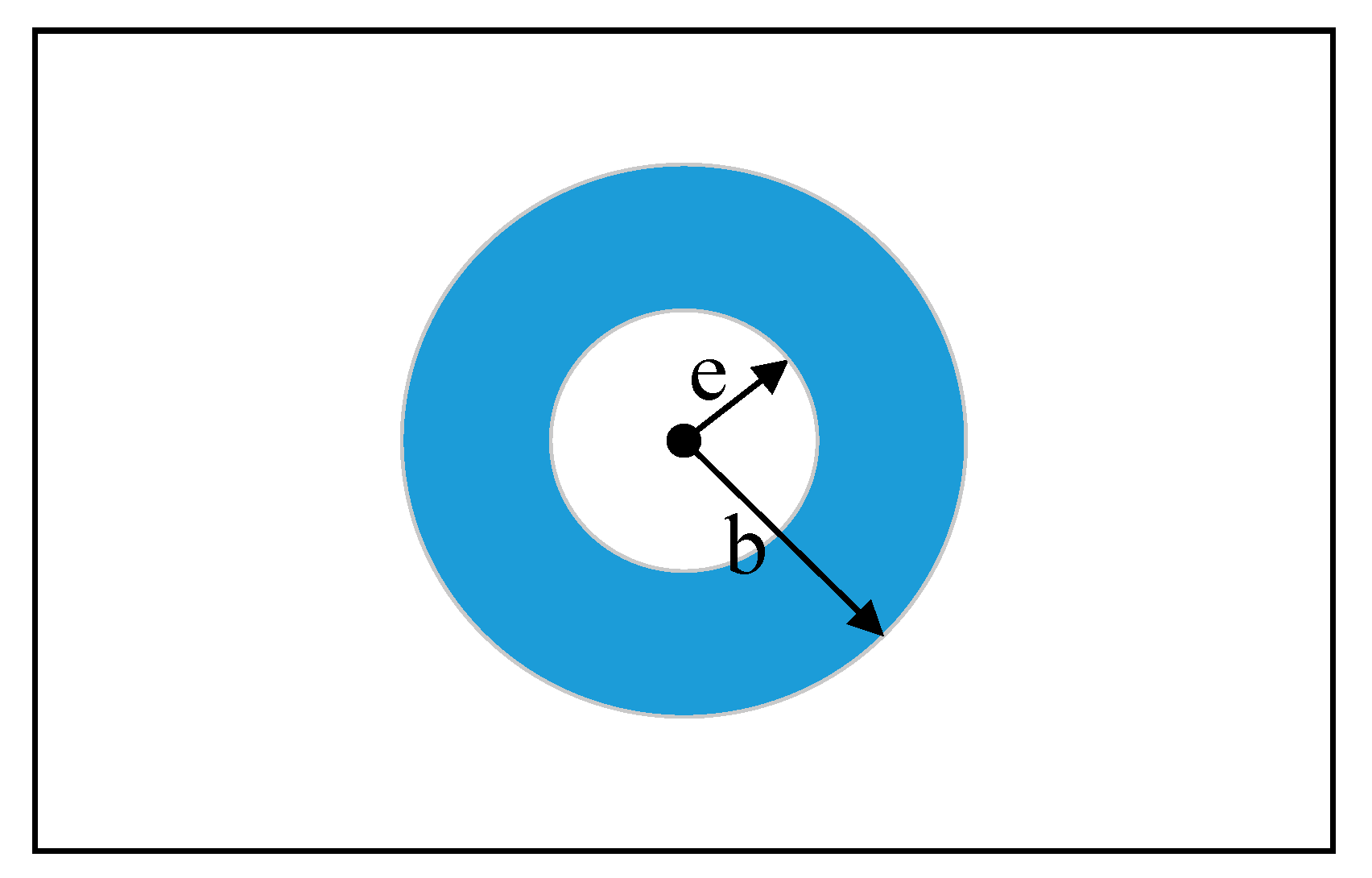

Section 2, a brief introduction of interference riveting is provided. The residual stresses distribution around the riveted hole and the fatigue strengthening mechanism are studied. In

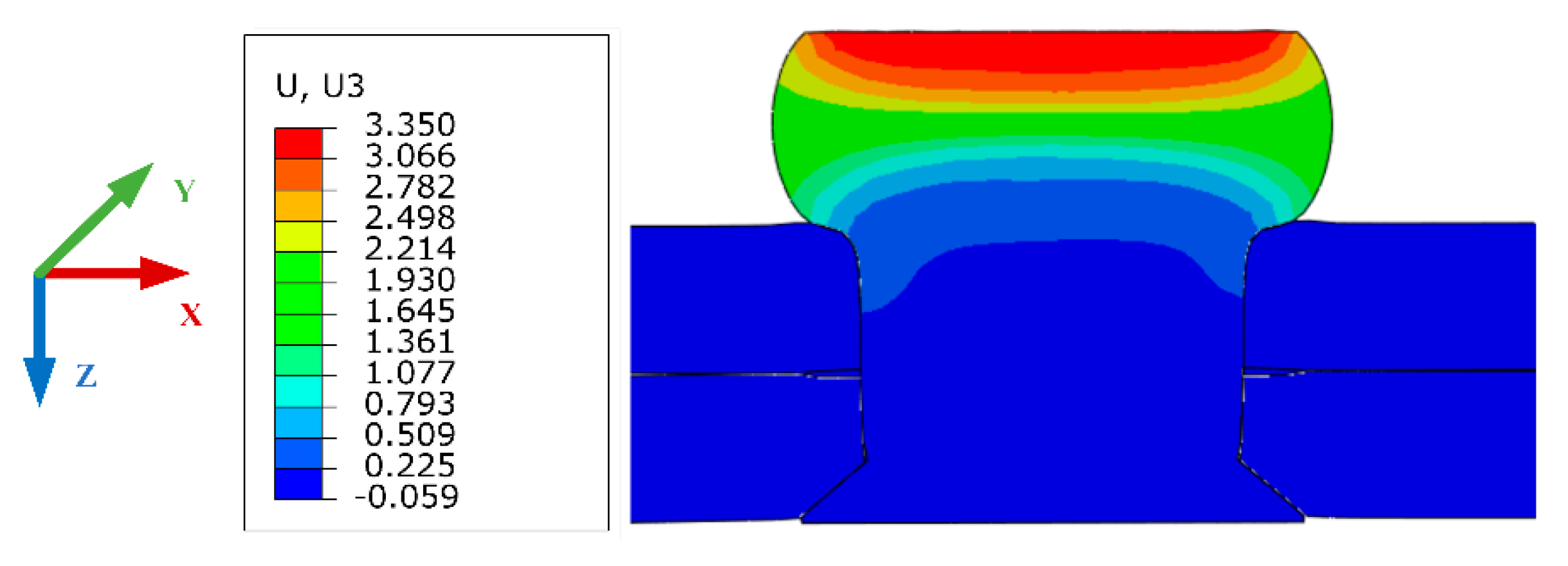

Section 3, the numerical simulation is performed, the details of the FE model are described. The driven head geometries and the residual stresses with various rivet sizes and strap thicknesses are studied. In

Section 4, fatigue tests are conducted with the automatic drilling and riveting system to verify the simulation results. The experimental results and discussion are presented. At last, the conclusion and future works are summarized in

Section 5.