Effects of MgO Expansive Agent and Steel Fiber on Crack Resistance of a Bridge Deck

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

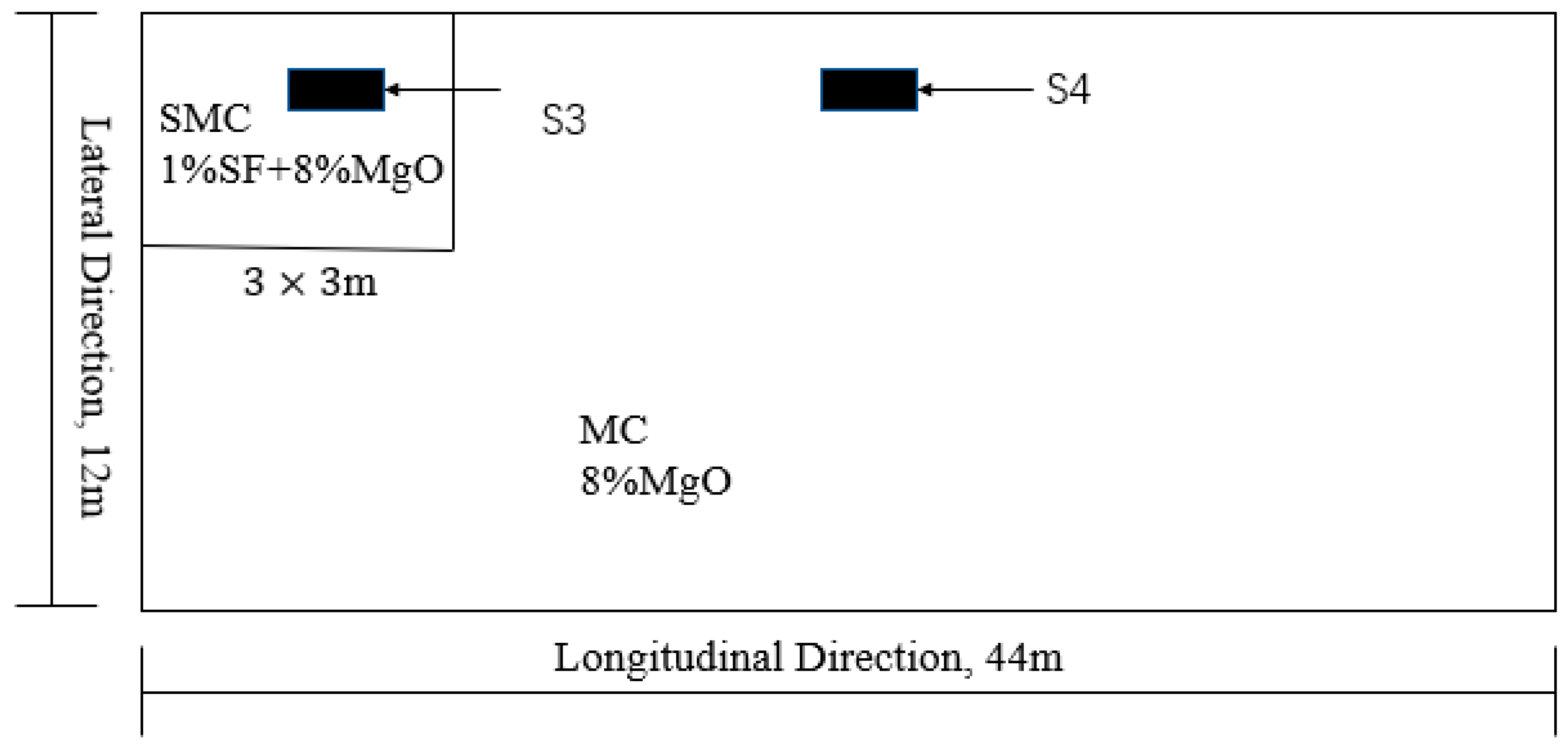

2.2. Experimental

2.2.1. Temperature and Deformation Test

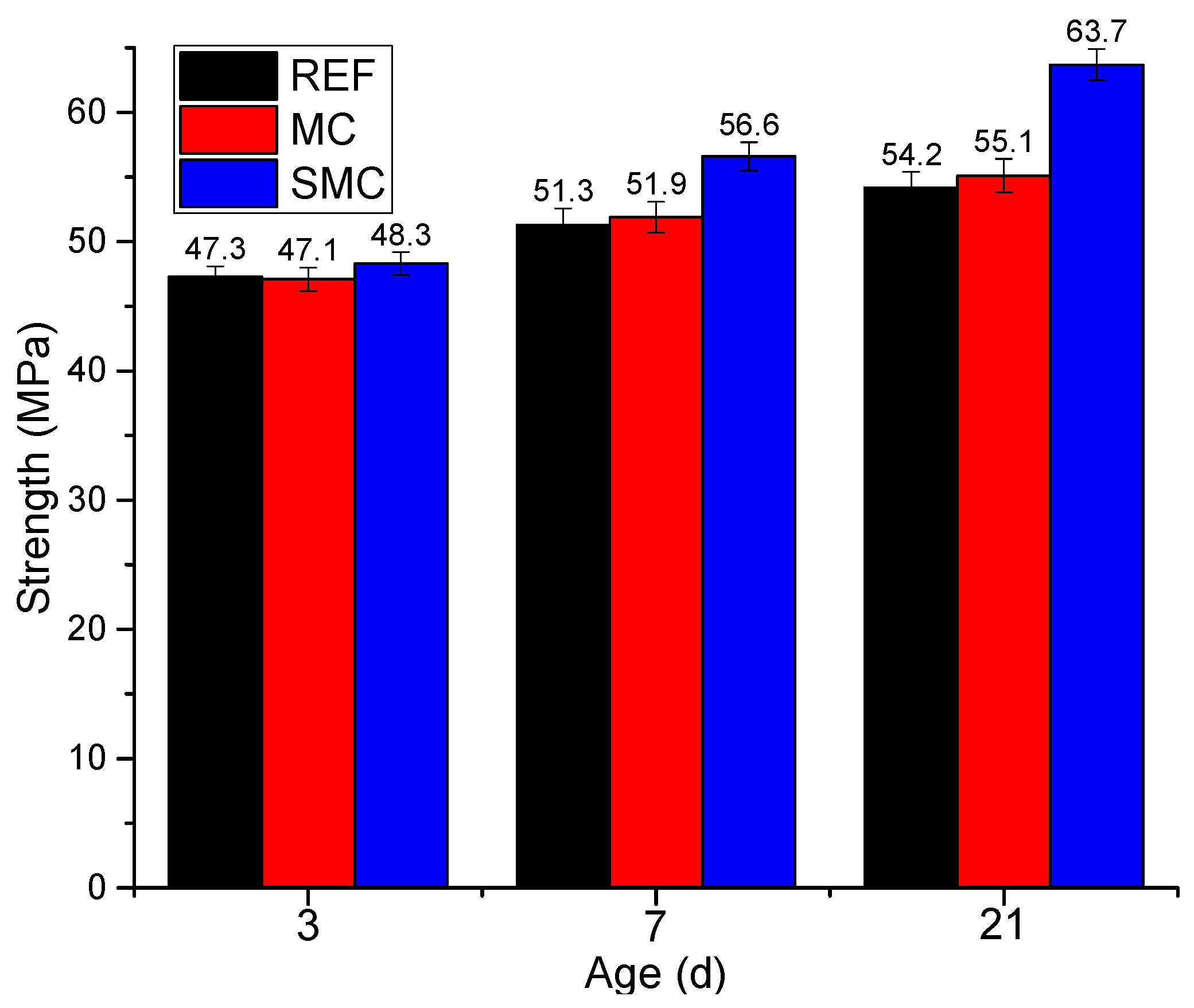

2.2.2. Strength Test

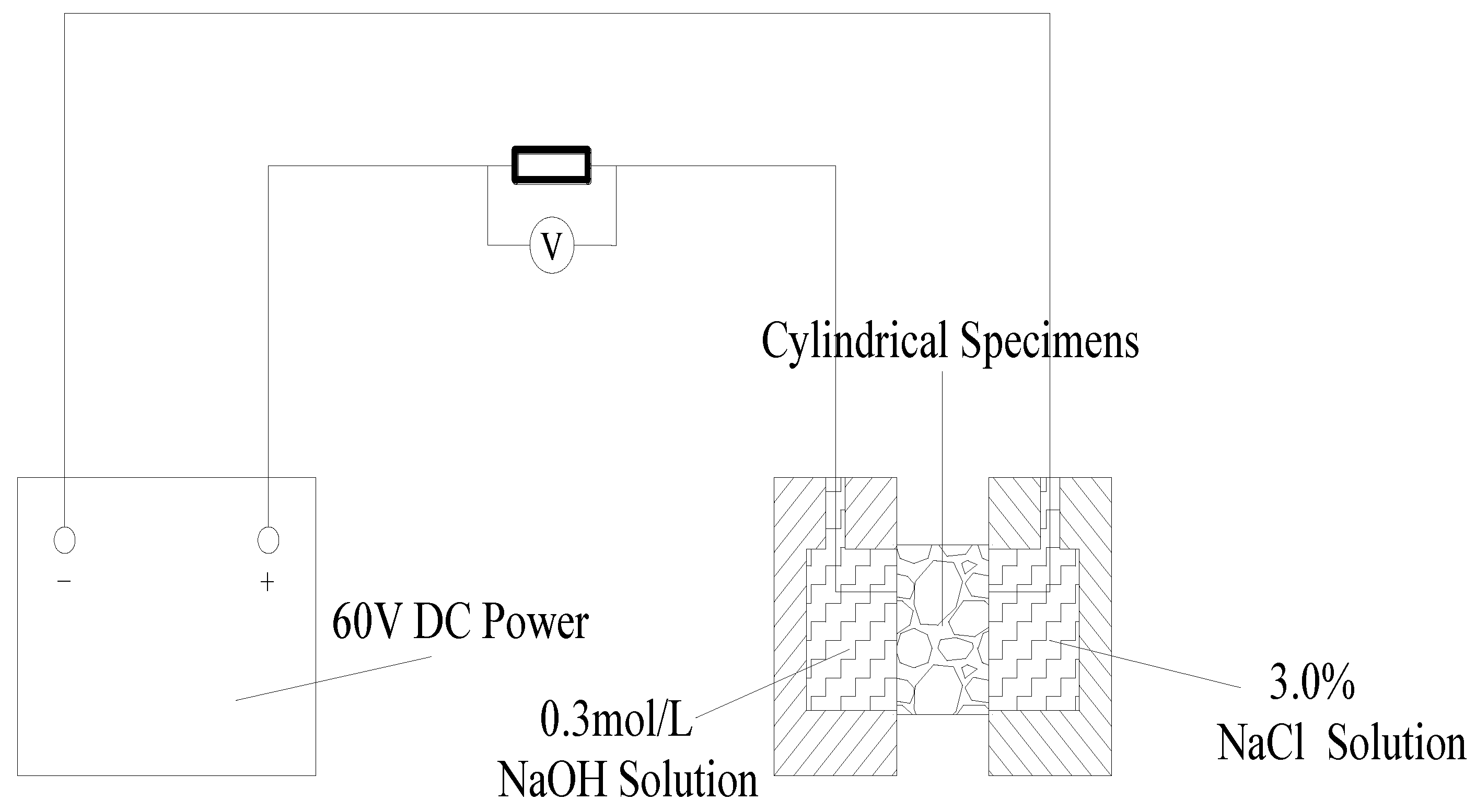

2.2.3. Permeability Test

2.2.4. Pore Structure Test

3. Results

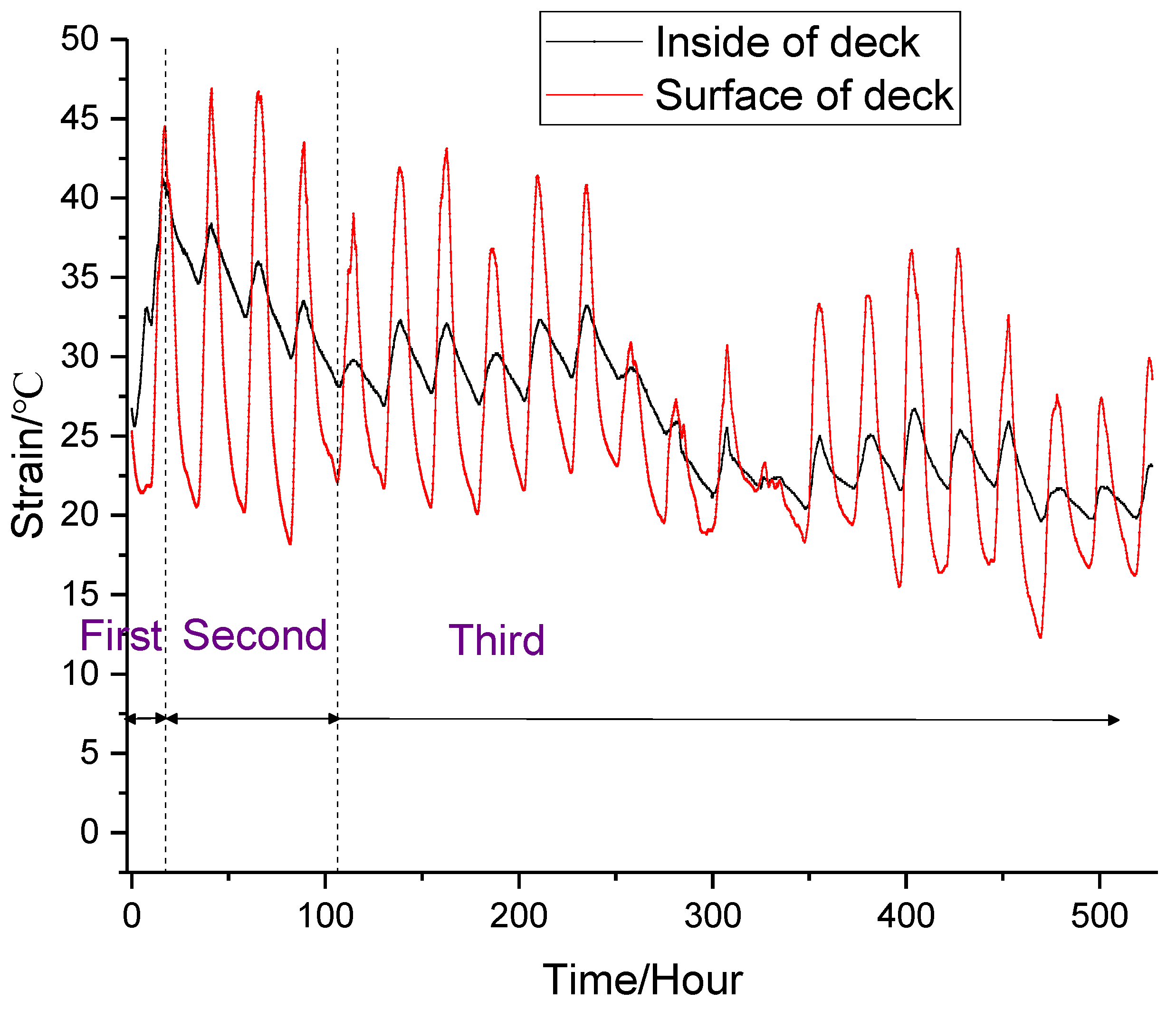

3.1. Temperature Variation

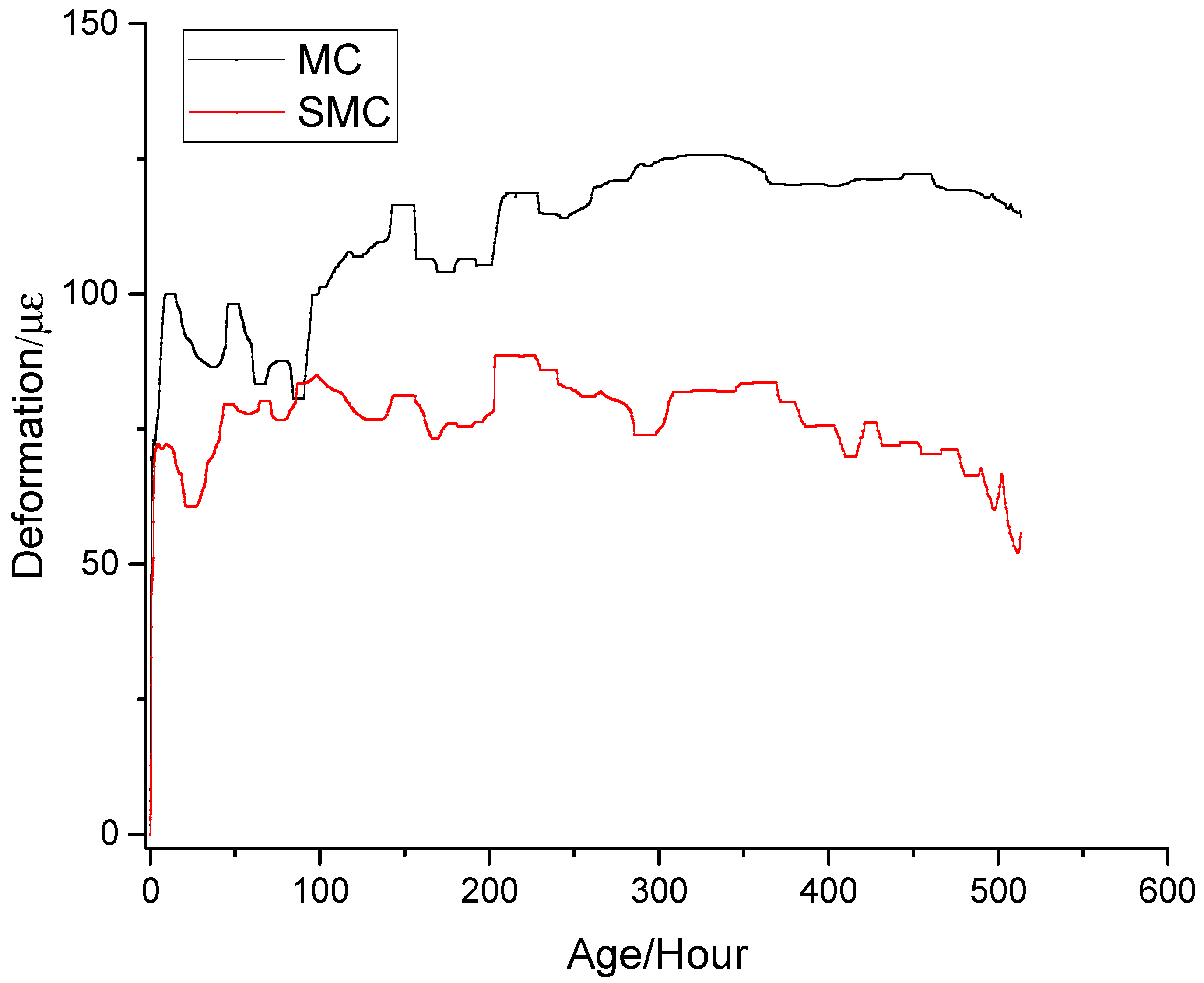

3.2. Volume Deformation

3.3. Expansion Caused by MgO Hydration

3.4. Strength Test

3.5. Chloride Permeability of Concrete

3.6. Performance Enhancement Mechanism of Concrete

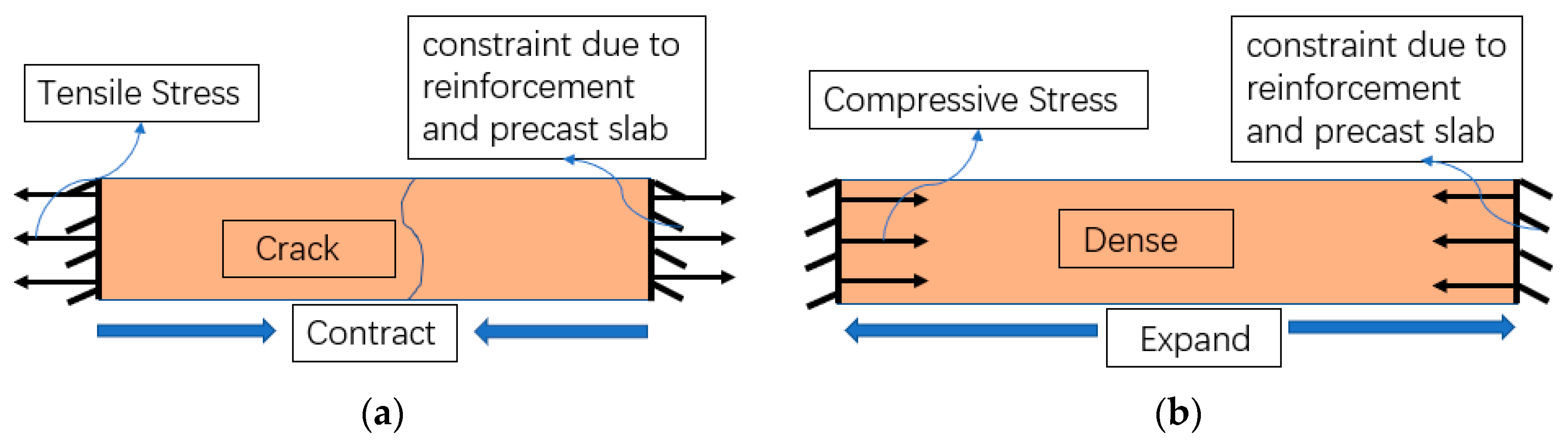

3.6.1. The Relationship between Deformation and Stress

3.6.2. Pore Structure of Concrete

4. Conclusions

- (1)

- With the increase of bridge spans, the cement content of modern concrete is increasing, which significantly increases the early shrinkage. The shrinkage of REF measured at the Xiaoqing River Bridge in 520 h reached −88.3 μ ε. If no measures are taken to reduce shrinkage, the shrinkage under the constraint of the precast slab below will produce tensile stress, which will lead to shrinkage cracks.

- (2)

- Due to the radiation of the sun, the temperature of the bridge deck is very high during the daytime, but at night the temperature will quickly drop. In this process, the bridge deck is subjected to repeated tension and compression. Because the concrete is not completely hardened in the early stage, the strength is low, and it is easy to produce temperature cracks. Therefore, in the early stage of construction, it is necessary to strengthen the maintenance of the bridge deck.

- (3)

- After adding MgO to concrete, the expansion of MgO hydration compensated the shrinkage, and the expansion of MC in 520 h was 24.9 × 10−6, preventing shrinkage cracks of the deck. The later expansion of MgO tended to a stable value, and there was no backward shrinkage. In addition, the strength test showed that MgO did not reduce the strength of the deck.

- (4)

- Due to the restraint of steel fibers, Ca(OH)2 was generated in the restricted space, resulting in pre-pressure, which improved the performance of concrete. When MgO and steel fiber were used at the same time, the expansion of SMC decreased to 9.1 × 10−6 in 520 h, and the strength increased by 17.5% in 21 days. The test results showed that the combined action not only prevented shrinkage cracking of the slab, but also improved the strength of the concrete. In this way, temperature cracks and shrinkage cracks could be effectively prevented.

- (5)

- The use of MgO alone had little effect on the resistance to chloride penetration of concrete, with a maximum increase of only 4.6%. On the other hand, the combined effect of MgO and steel fibers at the same time significantly improved the resistance to chloride penetration of concrete, with a maximum increase of 40.7%.

- (6)

- The combined effect of MgO and steel fiber significantly improved the pore structure of concrete, which reduced the total porosity of SMC by 32.2% and the harmful pore by 50.7%, which also explained the reason for the increase of rebound strength of SMC from the micro level.

- (7)

- Through in-situ tests at the construction site, this study clearly shows that the combined application of MgO and steel fiber can still maintain good performance in outdoor environments. Therefore, SMC, a new type of cement-based material, should be widely promoted and applied to bridge decks of long-span bridges, which has great significance in improving the durability of bridges.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shan, J.H.; Zhou, M.; Li, B.X.; Cai, J.W.; Xu, F. Application of polypropylene fiber concrete in bridge deck pavement. Key Eng. Mater. 2006, 418–423. [Google Scholar] [CrossRef]

- Su, L.; Wang, S.; Gao, Y.; Liu, J.; Shao, X. In Situ experimental study on the behavior of UHPC composite orthotropic steel bridge deck. Materials 2020, 13, 253. [Google Scholar] [CrossRef] [PubMed]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Ferdous, W.; Nguyen, K.T.Q.; Hota, G. Ageing of particulate-filled epoxy resin under hygrothermal conditions. Constr. Build. Mater. 2020, 249, 118846. [Google Scholar] [CrossRef]

- Manalo, A.; Maranan, G.; Benmokrane, B.; Cousin, P.; Alajarmeh, O.; Ferdous, W.; Liang, R.; Hota, G. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem. Concr. Compos. 2020, 109, 103564. [Google Scholar] [CrossRef]

- Abousnina, R.; Manalo, A.; Ferdous, W.; Lokuge, W.; Al-Jabri, K.S. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Constr. Build. Mater. 2020, 252, 13. [Google Scholar] [CrossRef]

- Bazant, Z. Advances in material modelling of concrete. In Proceedings of the Tenth International Conference on Structural Mechanics in Reactor Technology (SMiRT 10), Anaheim, CA, USA, 14–18 August 1989; pp. 301–330. [Google Scholar]

- Craeye, B.; Geirnaert, M.; Schutter, G.D. Super absorbing polymers as an internal curing agent for mitigation of early-age cracking of high-performance concrete bridge decks. Constr. Build. Mater. 2011, 25, 1–13. [Google Scholar] [CrossRef]

- Shen, D.; Liu, X.; Zeng, X.; Zhao, X.; Jiang, G. Effect of polypropylene plastic fibers length on cracking resistance of high-performance concrete at early age. Constr. Build. Mater. 2020, 244, 117874. [Google Scholar] [CrossRef]

- Yang, L.; Shi, C.; Wu, Z. Mitigation techniques for autogenous shrinkage of ultra-high-performance concrete—A review. Compos. Part B Eng. 2019, 178, 107456. [Google Scholar] [CrossRef]

- Shen, D.; Jiang, J.; Wang, W.; Shen, J.; Jiang, G. Tensile creep and cracking resistance of concrete with different water-to-cement ratios at early age. Constr. Build. Mater. 2017, 146, 410–418. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Y.; Yan, J.; Guo, X. Shear behaviour of steel-UHPC composite beams in waffle bridge deck. Compos. Struct. 2020, 234, 111678. [Google Scholar] [CrossRef]

- Hajibabaee, A.; Moradllo, M.K.; Behravan, A.; Ley, M.T. Quantitative measurements of curing methods for concrete bridge decks. Constr. Build. Mater. 2018, 162, 306–313. [Google Scholar] [CrossRef]

- You, J.; Park, J.; Lee, C.; Park, S.; Hong, S. Analysis of expressway bridge deck slab deterioration. In Proceedings of the AIP Conference Proceedings, Okinawa, Japan, 20 April 2018. [Google Scholar]

- Su, Q.; Dai, C.; Jiang, X. Bending performance of composite bridge deck with T-shaped ribs. Front. Struct. Civil. Eng. 2019, 13, 990–997. [Google Scholar] [CrossRef]

- Alizadeh, E. Efficient composite bridge deck consisting of GFRP, steel, and concrete. J. Sandw. Struct. Mater. 2019, 21, 154–174. [Google Scholar] [CrossRef]

- Pei, B.; Li, L.; Shao, X.; Wang, L.; Zeng, Y. Field Measurement and practical design of a lightweight composite bridge deck. J. Constr. Steel Res. 2018, 147, 564–574. [Google Scholar] [CrossRef]

- Bajzecerováa, V.; Kanóczb, J. The Effect of environment on timber-concrete composite bridge deck. In Proceedings of the Bridges in Danube Basin 2016—New Trends in Bridge Engineering and Efficient Solution for Large and Medium Span Bridges, Zilina, Slovakia, 30 September–1 October 2016; pp. 32–39. [Google Scholar]

- Elsanadedy, H.M.; Abbas, H.; Al-Salloum, Y.A.; Almusallam, T.H. Prediction of intermediate crack debonding strain of externally bonded FRP laminates in RC beams and one-way slabs. J. Compos. Constr. 2014, 18, 04014008. [Google Scholar] [CrossRef]

- Mayencourt, P.; Mueller, C. Structural optimization of cross-laminated timber panels in one-way bending. Structures 2019, 18, 48–59. [Google Scholar] [CrossRef]

- Rabinovitch, O.; Frostig, Y. High-order analysis of refine concrete slabs strengthened with circular composite laminated patches of general layup. J. Eng. Mech. ASCE 2004, 127, 1334–1345. [Google Scholar] [CrossRef]

- Teguedy, M.C.; Joly-Lapalice, C.; Sorelli, L.; Conciatori, D. Optical fiber sensors implementation for monitoring the early-age behavior of full-scale timber-concrete composite slabs. Constr. Build. Mater. 2019, 226, 564–578. [Google Scholar] [CrossRef]

- Zhang, J.Z.J.; Hou, D.H.D.; Gao, Y.G.Y. Calculation of shrinkage stress in early-age concrete pavements. II: Calculation of shrinkage stress. J. Transp. Eng. 2013, 139, 971–980. [Google Scholar] [CrossRef]

- Huang, K.; Shi, X.; Zollinger, D.; Mirsayar, M.; Wang, A.; Mo, L. Use of MgO expansion agent to compensate concrete shrinkage in jointed reinforced concrete pavement under high-altitude environmental conditions. Constr. Build. Mater. 2019, 202, 528–536. [Google Scholar] [CrossRef]

- Yousefieh, N.Y.N.; Joshaghani, A.J.A.; Hajibandeh, E.H.E.; Shekarchi, M.S.M. Influence of fibers on drying shrinkage in restrained concrete. Constr. Build. Mater. 2017, 148, 833–845. [Google Scholar] [CrossRef]

- Hu, Y.; Li, H.; Wang, Q.; Zhang, J.; Song, Q. Characterization of LDHs prepared with different activity MgO and resisting Cl− attack of concrete in salt lake brine. Constr. Build. Mater. 2019, 229, 116921. [Google Scholar] [CrossRef]

- Heidari, A.; Hashempour, M.; Chermahini, M.D. Influence of reactive MgO hydration and cement content on C&DW aggregate concrete characteristics. Int. J. Civ. Eng. 2019, 17, 1095–1106. [Google Scholar]

- Dung, N.T.; Unluer, C. Performance of reactive MgO concrete under increased CO2 dissolution. Cem. Concr. Res. 2019, 118, 92–101. [Google Scholar] [CrossRef]

- Pu, L.; Unluer, C. Durability of carbonated MgO concrete containing fly ash and ground granulated blast-furnace slag. Constr. Build. Mater. 2018, 192, 403–415. [Google Scholar] [CrossRef]

- Zhang, R.; Panesar, D.K. Mechanical properties and rapid chloride permeability of carbonated concrete containing reactive MgO. Constr. Build. Mater. 2018, 172, 77–85. [Google Scholar] [CrossRef]

- Ruan, S.; Unluer, C. Influence of mix design on the carbonation, mechanical properties and microstructure of reactive MgO cement-based concrete. Cem. Concr. Compos. 2017, 80, 104–114. [Google Scholar] [CrossRef]

- Dung, N.T.; Unluer, C. Development of MgO concrete with enhanced hydration and carbonation mechanisms. Cem. Concr. Res. 2018, 103, 160–169. [Google Scholar] [CrossRef]

- Jiang, F.; Mao, Z.; Deng, M.; Li, D. Deformation and compressive strength of steel fiber reinforced MgO concrete. Materials 2019, 12, 3617. [Google Scholar] [CrossRef]

- Chemical Analysis Method of Cement; GB/T 176-2017; Standards Press: Beijing, China, 29 December 2017.

- Huang, K.; Deng, M.; Mo, L.; Wang, Y. Early Age stability of concrete pavement by using hybrid fiber together with MgO expansion agent in high altitude locality. Constr. Build. Mater. 2013, 48, 685–690. [Google Scholar] [CrossRef]

- Technical Specification for Testing the Compressive Strength of Concrete by the Rebound Method; JTJ/T 23-2011; Architecture & Building Press: Beijing, China, 1 December 2011.

- Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration, ASTM C1202; ASTM International: West Conshohocken, PA, USA, 2012.

- Salmasi, F.; Mostofinejad, D. Investigating the effects of bacterial activity on compressive strength and durability of natural lightweight aggregate concrete reinforced with steel fibers. Constr. Build. Mater. 2020, 251, 119032. [Google Scholar] [CrossRef]

- Provete Vincler, J.; Sanchez, T.; Turgeon, V.; Conciatori, D.; Sorelli, L. A modified accelerated chloride migration tests for UHPC and UHPFRC with PVA and steel fibers. Cem. Concr. Res. 2019, 117, 38–44. [Google Scholar] [CrossRef]

- Lehner, P.; Konečný, P.; Ponikiewski, T. Comparison of material properties of SCC concrete with steel fibres related to ingress of chlorides. Crystals 2020, 10, 220. [Google Scholar] [CrossRef]

- Lee, C.; Kim, S.; Kim, Y.; Kim, S.; Hwang, J.; Park, J. Experimental study on thermal conductivity of concrete using ferronickel slag powder. KSCE J. Civ. Eng. 2020, 24, 219–227. [Google Scholar] [CrossRef]

- Wang, W.; Wang, H.; Chang, K.; Wang, S. Effect of high temperature on the strength and thermal conductivity of glass fiber concrete. Constr. Build. Mater. 2020, 245, 118387. [Google Scholar] [CrossRef]

- Marie, I.M.I. Thermal conductivity of hybrid recycled aggregate—Rubberized concrete. Constr. Build. Mater. 2017, 133, 516–524. [Google Scholar] [CrossRef]

- Bradbury, R.D. Reinforced Concrete Pavement; Wire Reinforcement Institute: Washington, DC, USA, 1938. [Google Scholar]

- Darter, M.I. Design of Zero-Maintenance Plain Jointed Concrete Pavement, Volume 1: Development of Design Procedures; Report No. FHWA-RD-77-III; Federal Highway Administration: Washington, DC, USA, 1977.

- Chidighikaobi, P.C. Thermal effect on the flexural strength of expanded clay lightweight basalt fiber reinforced concrete. Mater. Today Proc. 2019, 19, 2467–2470. [Google Scholar] [CrossRef]

- Xiaoke, L.; Changyong, L.; Minglei, Z.; Hui, Y.; Siyi, Z. Testing and prediction of shear performance for steel fiber reinforced expanded-shale lightweight concrete beams without web reinforcements. Materials 2019, 12, 1594. [Google Scholar]

- Zhao, M.; Zhang, B.; Shang, P.; Fu, Y.; Zhang, X.; Zhao, S. Complete stress-strain curves of self-compacting steel fiber reinforced expanded-shale lightweight concrete under uniaxial compression. Materials 2019, 12, 2979. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, X.; Song, W.; Li, C.; Zhao, S. Development of steel fiber-reinforced expanded-shale lightweight concrete with high freeze-thaw resistance. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Bharadwaj, K.; Glosser, D.; Moradllo, M.K.; Isgor, O.B.; Weiss, W.J. Toward the prediction of pore volumes and freeze-thaw performance of concrete using thermodynamic modelling. Cem. Concr. Res. 2019, 124, 105820. [Google Scholar] [CrossRef]

- Pacheco, F.; de Souza, R.P.; Christ, R.; Rocha, C.A.; Silva, L.; Tutikian, B. Determination of volume and distribution of pores of concretes according to different exposure classes through 3D microtomography and mercury intrusion porosimetry. Struct. Concr. 2018, 19, 1419–1427. [Google Scholar] [CrossRef]

- Mehta, P.K. Studies on blended Portland cements containing Santorin earth. Cem. Concr. Res. 1981, 11, 507–518. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.; Yin, X. Influence of pore size of concrete on its impermeability. J. Silicate 2005, 33, 97–102. (In Chinese) [Google Scholar]

- Chen, S.; Hu, C. Research trends of cement concrete durability of highway structures. Highway 2003, 5, 124–129. (In Chinese) [Google Scholar]

| No. | Chemical Composition/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | MgO | Al2O3 | SiO2 | Fe2O3 | SO3 | K2O | Na2O | Loss | Total | |

| Cement | 60.51 | 2.18 | 6.34 | 22.02 | 3.05 | 1.86 | 0.47 | 0.23 | 1.96 | 98.62 |

| Fly ash | 5.01 | 1.03 | 34.18 | 48.91 | 5.22 | 1.20 | 0.89 | 0.62 | 1.50 | 98.56 |

| Length/mm | Diameter/mm | Tensile Strength/MPa |

|---|---|---|

| 38 (±5%) | 0.58 (±5%) | 520 |

| No. | Composition/kg·m−3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Fine Aggregate | Coarse Aggregate | Water | Water Reducer | Steel Fiber | MgO | |

| Ref | 450 | 50 | 713 | 1025 | 160 | 6 | 0 | 0 |

| 8%MgO(MC) | 450 | 50 | 713 | 1025 | 160 | 7.5 | 0 | 40 |

| 1%SF + 8%MgO(SMC) | 450 | 50 | 713 | 1025 | 160 | 7.6 | 78 | 40 |

| Type | Chloride Diffusion Coefficient (10−9 cm2/s) | Reduced Extent (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 28 d | 60 d | 3 d | 7 d | 28 d | 60 d | |

| REF | 15.6 | 15.4 | 10.8 | 8.8 | 0 | 0 | 0 | 0 |

| MC | 15.4 | 15.2 | 10.7 | 8.4 | 1.3 | 1.3 | 0.9 | 4.6 |

| SMC | 13.7 | 11.2 | 6.4 | 6.2 | 12.2 | 27.3 | 40.7 | 29.6 |

| No. | Total Porosity/% | Pore Distribution/% | ||

|---|---|---|---|---|

| 0–50 nm | 50–500 nm | >500 nm | ||

| REF | 15.76 | 8.51 | 2.42 | 4.83 |

| SMC | 10.69 | 4.38 | 3.98 | 2.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, F.; Deng, M.; Mo, L.; Wu, W. Effects of MgO Expansive Agent and Steel Fiber on Crack Resistance of a Bridge Deck. Materials 2020, 13, 3074. https://doi.org/10.3390/ma13143074

Jiang F, Deng M, Mo L, Wu W. Effects of MgO Expansive Agent and Steel Fiber on Crack Resistance of a Bridge Deck. Materials. 2020; 13(14):3074. https://doi.org/10.3390/ma13143074

Chicago/Turabian StyleJiang, Feifei, Min Deng, Liwu Mo, and Wenqing Wu. 2020. "Effects of MgO Expansive Agent and Steel Fiber on Crack Resistance of a Bridge Deck" Materials 13, no. 14: 3074. https://doi.org/10.3390/ma13143074

APA StyleJiang, F., Deng, M., Mo, L., & Wu, W. (2020). Effects of MgO Expansive Agent and Steel Fiber on Crack Resistance of a Bridge Deck. Materials, 13(14), 3074. https://doi.org/10.3390/ma13143074