Optical Characterization of AsxTe100−x Films Grown by Plasma Deposition Based on the Advanced Optimizing Envelope Method

Abstract

:1. Introduction

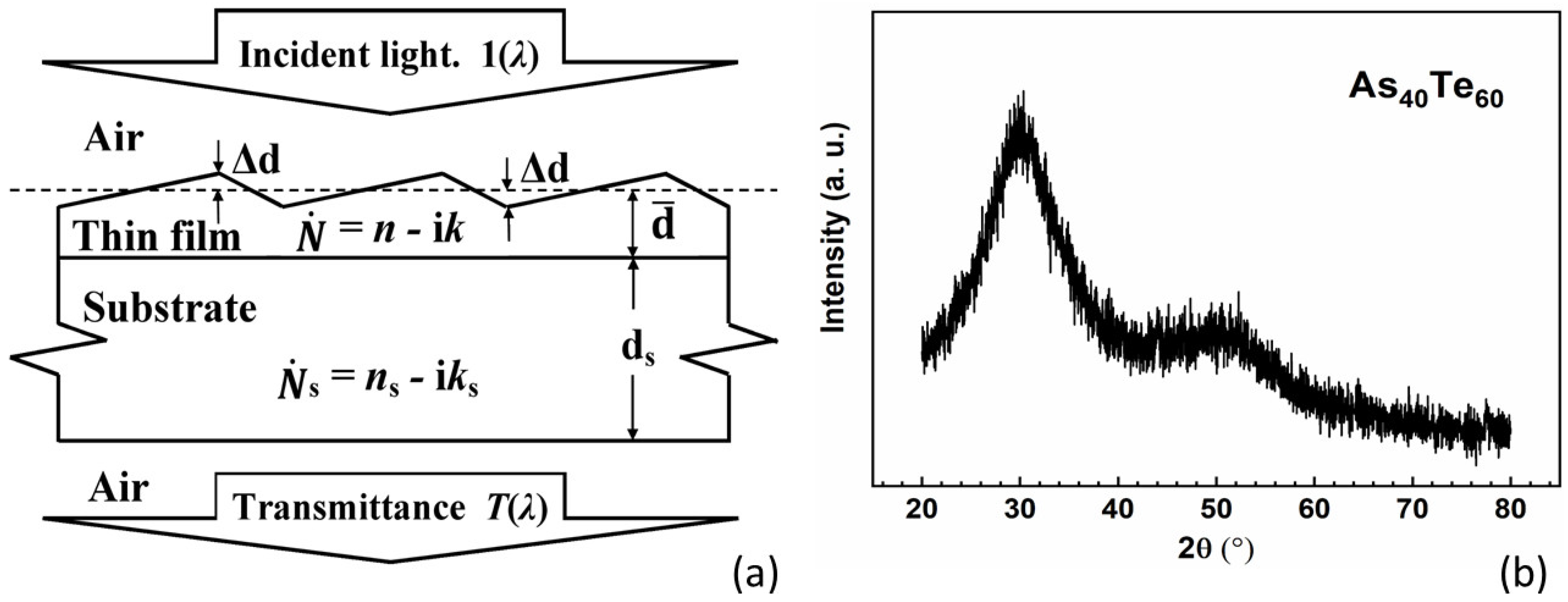

2. Materials and Methods

2.1. An Alternative Approach for Computing k (λ)

2.2. Dual Transformation Regarding Tsm (λ) Taking into Account the Substrate Absorption

2.3. Calculation of a Lower Limit of n(λ)

3. Results

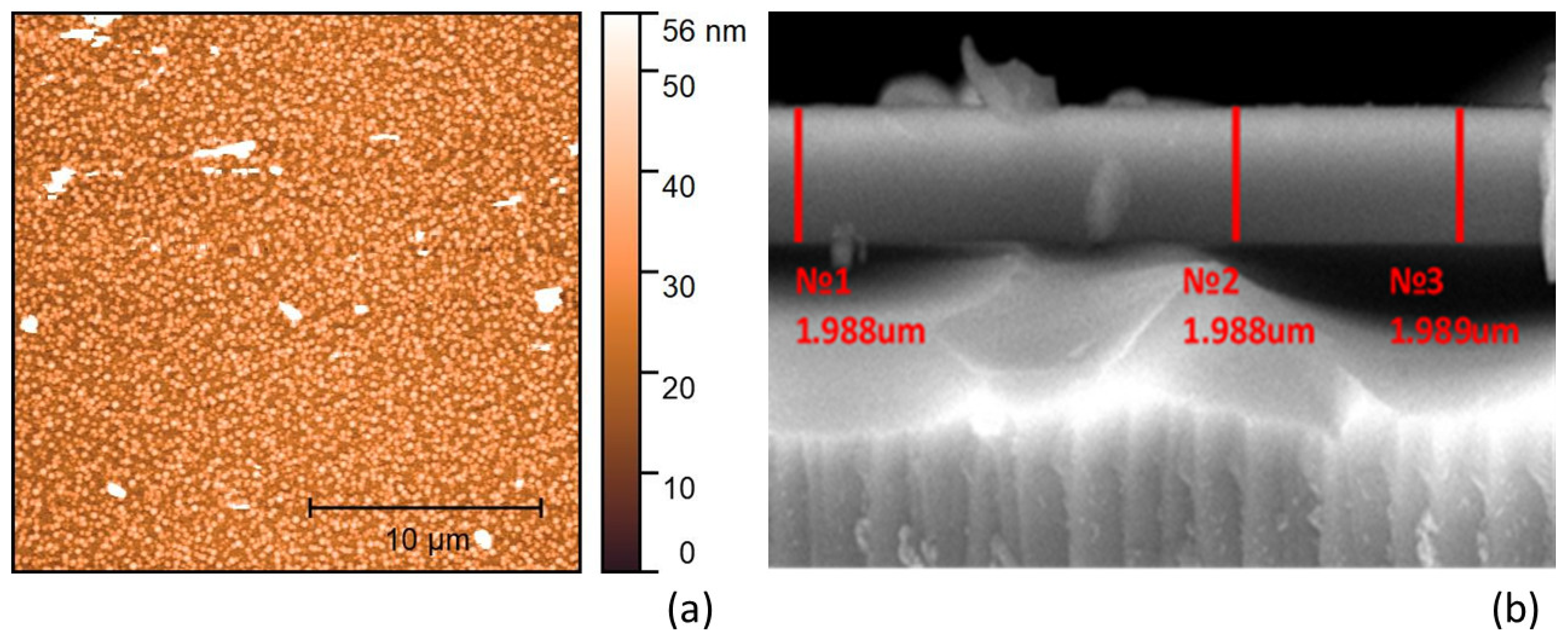

3.1. Measurements Regarding the Studied AsxTe100–X Films

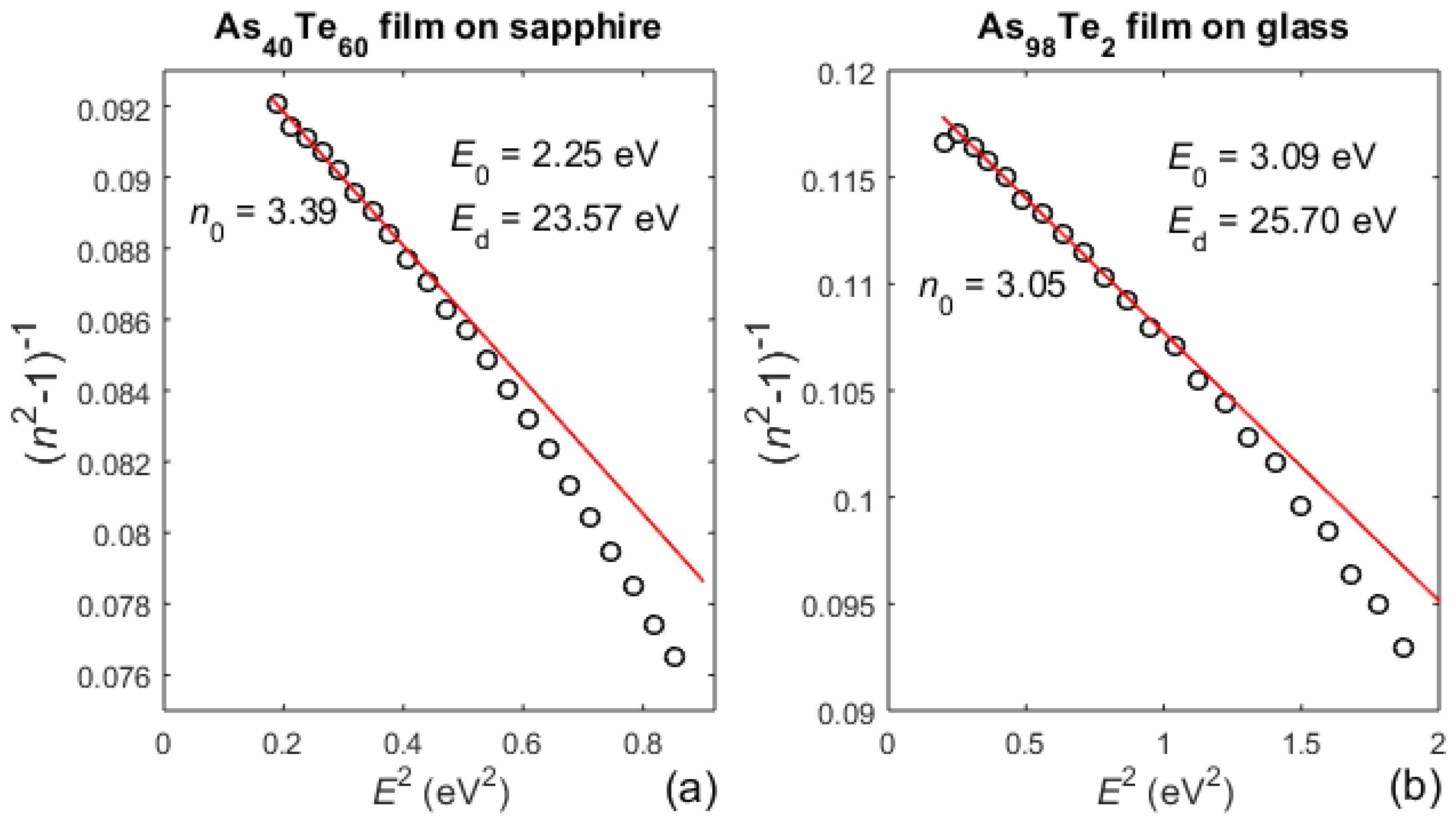

3.2. Characterization of the As40Te60 Film on Sapphire Substrate by the AOEM

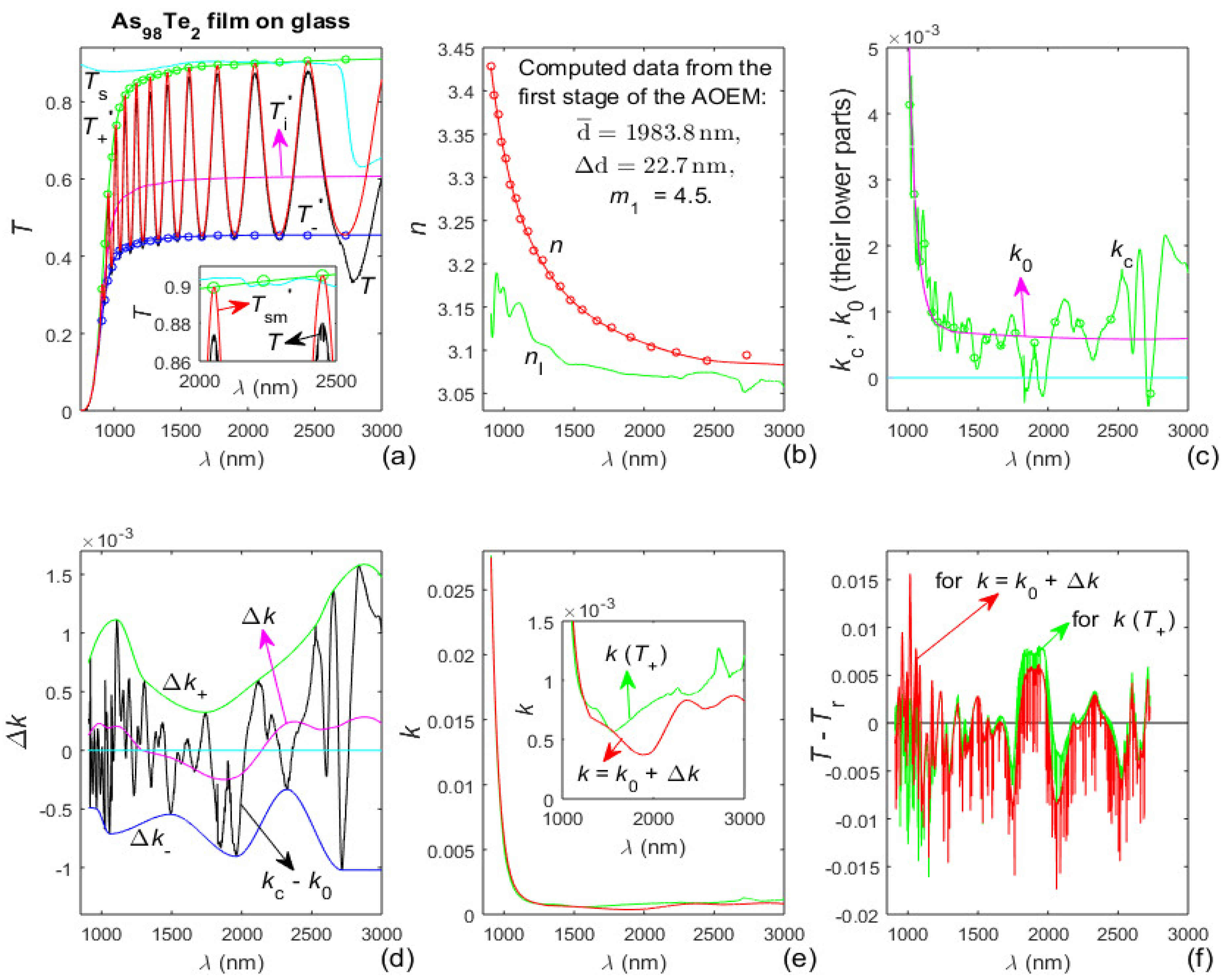

3.3. Characterization of the As98Te2 Film on Glass Substrate by the AOEM

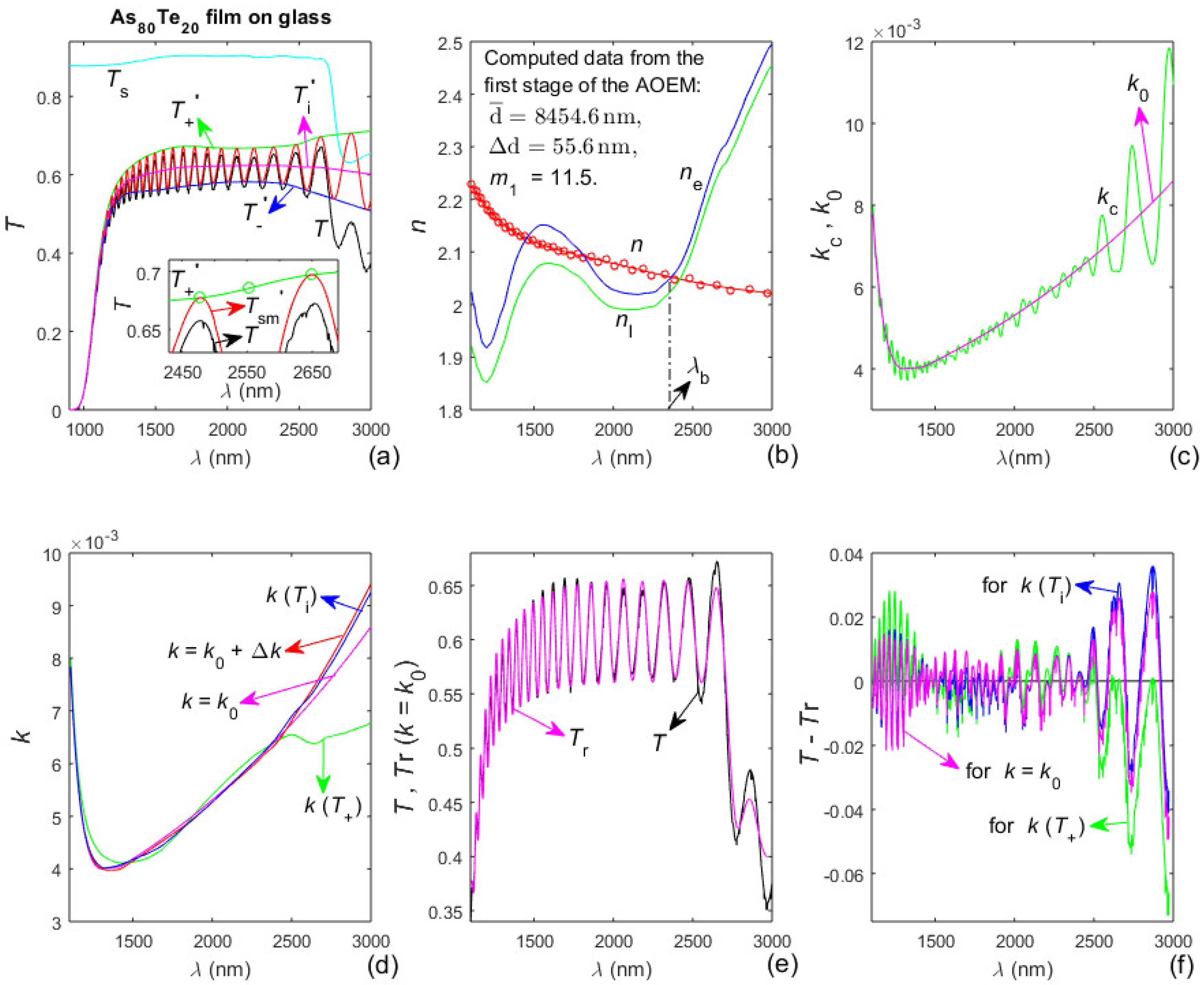

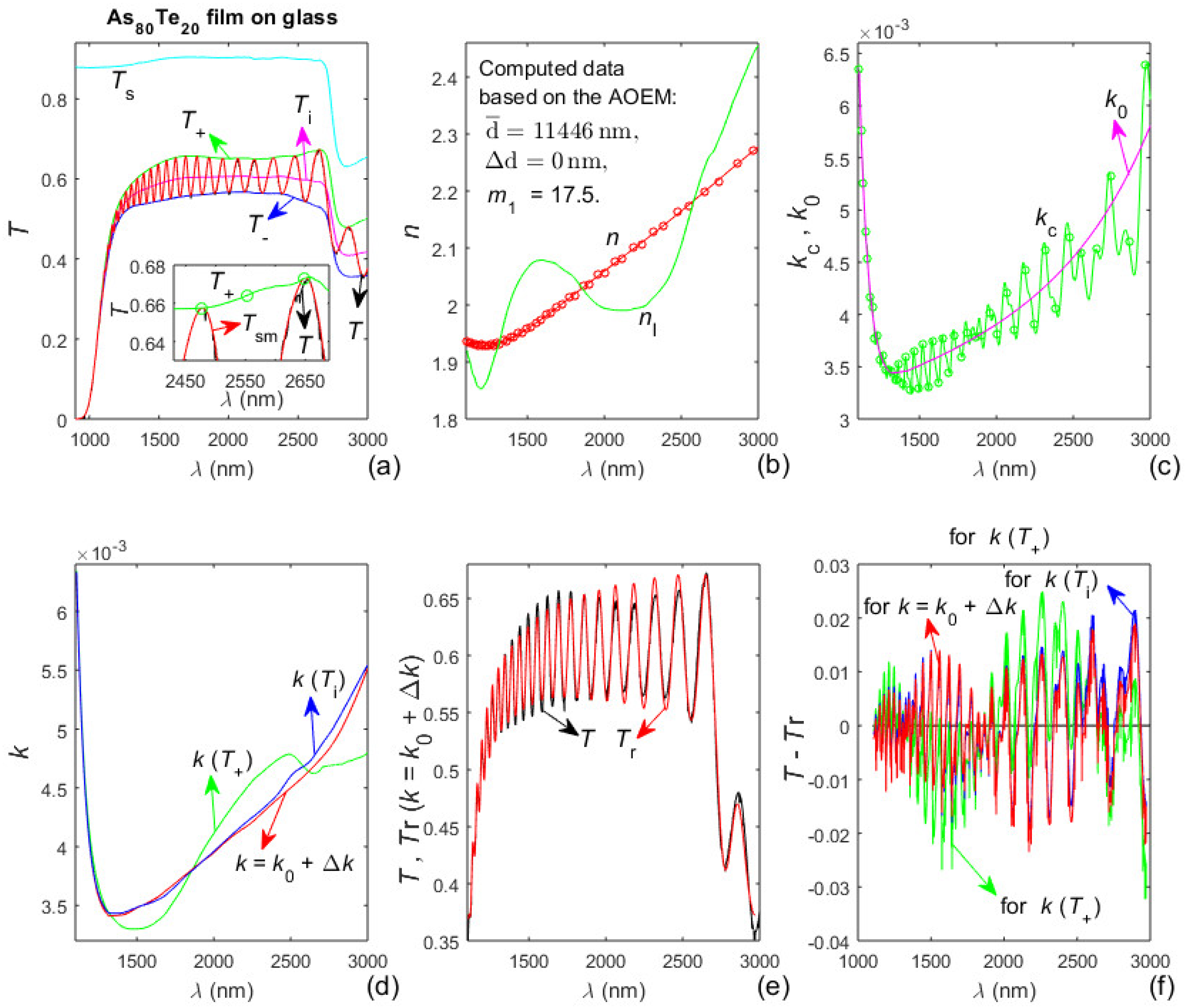

3.4. Characterization of the As80Te20 Film on Glass Substrate Based on the AOEM

3.5. Additional Results about the AsxTe100−X Films

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Soriaga, M.P.; Stickney, J.; Bottomley, L.A.; Kim, Y.G. Thin Films: Preparation, Characterization, Applications, 1st ed.; Springer: Boston, MA, USA, 2002; pp. 37–45. [Google Scholar]

- Aliofkhazraei, M. Anti-Abrasive Nanocoatings Current and Future Applications, 1st ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 543–567. [Google Scholar]

- Frey, H.; Khan, H.R. Handbook of Thin Film Technology, 1st ed.; Springer: Berlin, Germany, 2015; pp. 24–41. [Google Scholar]

- SeshanIntel, K. Handbook of Thin-Film Deposition Processes and Techniques, 2nd ed.; William Andrew Publishing: New York, NY, USA, 2002; pp. 64–76. [Google Scholar]

- Stenzel, O. Optical Coatings: Material Aspects in Theory and Practice, 1st ed.; Springer: Heidelberg, Germany, 2016; pp. 35–51. [Google Scholar]

- Poelman, D.; Smet, P.J. Methods for the determination of the optical constants of thin films from single transmission measurements: A critical review. J. Phys. D 2003, 36, 1850–1857. [Google Scholar] [CrossRef]

- Stenzel, O. The Physics of Thin Film Optical Spectra, 1st ed.; Springer: Heidelberg, Germany, 2016; pp. 79–81. [Google Scholar]

- Minkov, D.A. DSc Thesis: Characterization of Thin Films and Surface Cracks by Electromagnetic Methods and Technologies; Technical University: Sofia, Bulgaria, 2018; pp. 114–119. [Google Scholar]

- Tauc-Lorentz_Dispersion_Formula.pdf, Technical Note. Spectroscopic Ellipsometry TN11. Available online: https://www.horiba.com/fileadmin/uploads/Scientific/Downloads/OpticalSchool_CN/TN/ellipsometer/Tauc-Lorentz_Dispersion_Formula.pdf (accessed on 6 June 2020).

- Gao, L.; Lemarchand, F.; Lequime, M. Comparison of different dispersion models for single layer optical thin film index determination. Thin Solid Films 2011, 520, 501–509. [Google Scholar] [CrossRef]

- Mieghem, P.V. Theory of band tails in heavily doped semiconductors. Rev. Mod. Phys. 1992, 64, 755–793. [Google Scholar] [CrossRef]

- Fedyanin, D.Y.; Arsenin, A.V. Surface plasmon polariton amplification in metal-semiconductor structures. Opt. Express 2011, 19, 12524–12531. [Google Scholar] [CrossRef]

- Cisowski, J.; Jarzabek, B.; Jurusik, J.; Domanski, M. Direct determination of the refraction index normal dispersion for thin films of 3, 4, 9, 10-perylene tetracarboxylic dianhydride (PTCDA). Opt. Appl. 2012, 42, 181–192. [Google Scholar]

- Grassi, A.P.; Tremmel, A.J.; Koch, A.W.; El-Khozondar, H.J. On-line thickness measurement for two-layer systems on polymer electronic devices. Sensors 2013, 13, 15747–15757. [Google Scholar] [CrossRef] [Green Version]

- Brinza, M.; Emelianova, E.V.; Adriaenssens, G.Y. Nonexponential distributions of tail states in hydrogenated amorphous silicon. Phys. Rev. B 2005, 71, 115209. [Google Scholar] [CrossRef]

- Swanepoel, R. Determining refractive index and thickness of thin films from wavelength measurements only. J. Opt. Soc. Am. A 1985, 2, 1339–1343. [Google Scholar] [CrossRef]

- Minkov, D.A. Computation of the optical constants of a thin dielectric layer on a transmitting substrate from the reflection spectrum at inclined incidence of light. J. Opt. Soc. Am. A 1991, 8, 306–310. [Google Scholar] [CrossRef]

- Minkov, D.A. Calculation of the optical constants of a thin layer upon a transparent substrate from the reflection spectrum. J. Phys. D 1989, 22, 1157–1161. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of the thickness and optical constants of amorphous silicon. J. Phys. E 1983, 16, 1214–1222. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of the Thickness and Optical Constants of Amorphous Silicon. Google Scholar. Available online: https://scholar.google.com/scholar?hl=bg&as_sdt=0%2C5&q=R.+Swanepoel+1983&btnG= (accessed on 6 June 2020).

- Chiao, S.C.; Bovard, B.G.; Macleod, H.A. Optical-constant calculation over an extended spectral region: Application to titanium dioxide film. Appl. Opt. 1995, 34, 7355–7359. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, J.S.; Parralejo, A.D.; Ortiz, A.L.; Guiberteau, F. Determination of optical properties in nanostructured thin films using the Swanepoel method. Appl. Surf. Sci. 2006, 252, 6013–6017. [Google Scholar] [CrossRef]

- Gao, L.; Lemarchand, F.; Lequime, M. Refractive index determination of SiO2 layer in the UV/Vis/NIR range: Spectrophotometric reverse engineering on single and bi-layer designs. J. Europ. Opt. Soc. Rap. Public. 2013, 8, 13010. [Google Scholar] [CrossRef] [Green Version]

- Yen, S.T.; Chung, P.K. Extraction of optical constants from maxima of fringing reflectance spectra. Appl. Opt. 2015, 54, 663–668. [Google Scholar] [CrossRef]

- Jin, Y.; Song, B.; Jia, Z.; Zhang, Y.; Lin, C.; Wang, X.; Dai, S. Improvement of Swanepoel method for deriving the thickness and the optical properties of chalcogenide thin films. Opt. Express 2017, 25, 440–451. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Song, B.; Lin, C.; Zhang, P.; Dai, S.; Xu, T. Extension of the Swanepoel method for obtaining the refractive index of chalcogenide thin films accurately at an arbitrary wavenumber. Opt. Express 2017, 25, 31273–31280. [Google Scholar] [CrossRef] [PubMed]

- Leal, J.M.G.; Alcon, R.P.; Angel, J.A.; Minkov, D.A.; Marquez, E. Influence of substrate absorption on the optical and geometrical characterization of thin dielectric films. Appl. Opt. 2002, 41, 7300–7308. [Google Scholar] [CrossRef]

- Minkov, D.A.; Gavrilov, G.M.; Angelov, G.V.; Moreno, G.M.D.; Vazquez, C.G.; Ruano, S.M.F.; Marquez, E. Optimisation of the envelope method for characterisation of optical thin film on substrate specimens from their normal incidence transmittance spectrum. Thin Solid Films 2018, 645, 370–378. [Google Scholar] [CrossRef]

- Minkov, D.A.; Angelov, G.V.; Nestorov, R.N.; Marquez, E. Perfecting the dispersion model free characterization of a thin film on a substrate specimen from its normal incidence interference transmittance spectrum. Thin Solid Films 2020, 706, 137984. [Google Scholar] [CrossRef]

- Gavrilov, G.M.; Minkov, D.A.; Marquez, E.; Ruano, S.M.F. Advanced computer drawing envelopes of transmittance spectra of thin film specimens. Int. J. Adv. Res. Sci. Eng. Technol. 2016, 3, 163–168. [Google Scholar]

- McClain, M.; Feldman, A.; Kahaner, D.; Ying, X. An algorithm and computer program for the calculation of envelope curves. Comput. Phys. 1991, 5, 45–48. [Google Scholar] [CrossRef]

- Nestorov, R.N. Selection of error metric for accurate characterization of a thin dielectric or semiconductor film on glass substrate by the optimizing envelope method. Int. J. Adv. Res. Sci. Eng. Technol. 2020, 7, 1–11. [Google Scholar]

- Minkov, D. Method for determining the optical constants of a thin film on a transparent substrate. J. Phys. D 1989, 22, 199–205. [Google Scholar] [CrossRef]

- Minkov, D.A.; Angelov, G.V.; Nestorov, R.N.; Marquez, E.; Blanco, E.; Ruiz-Perez, J.J. Comparative study of the accuracy of characterization of thin films a-Si on glass substrates from their interference normal incidence transmittance spectrum by the Tauc-Lorentz-Urbach, the Cody-Lorentz-Urbach, the optimized envelopes and the optimized graphical methods. Mater. Res. Express 2019, 6, 03640. [Google Scholar]

- Minkov, D.A.; Gavrilov, G.M.; Moreno, J.M.D.; Vazquez, C.G.; Marquez, E. Optimization of the graphical method of Swanepoel for characterization of thin film on substrate specimens from their transmittance spectrum. Meas. Sci. Technol. 2017, 28, 035202. [Google Scholar] [CrossRef]

- DeMarcos, L.V.R.; Larruquert, J.I. Analytic optical-constant model derived from Tauc-Lorentz and Urbach tail. Opt. Express 2016, 24, 28561–28572. [Google Scholar]

- Ferlauto, A.S.; Ferreira, G.M.; Pearce, J.M.; Wronski, C.R.; Collins, R.W.; Deng, X.; Ganguly, G. Analytical model for the optical functions of amorphous semiconductors from the near-infrared to ultraviolet: Applications in thin film photovoltaics. J. Appl. Phys. 2002, 92, 2424–2436. [Google Scholar] [CrossRef] [Green Version]

- Mochalov, L.; Dorosz, D.; Nezhdanov, A.; Kudryashov, M.; Zelentsov, S.; Usanov, D.; Logunov, A.; Mashin, A.; Gogova, D. Investigation of the composition-structure-property relationship of AsxTe100−x films prepared by plasma deposition. Spectrochim. Acta A: Mol. Biomol. Spectrosc. 2018, 191, 211–216. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of surface roughness and optical constants of inhomogeneous amorphous silicon films. J. Phys. E: Sci. Instrum. 1984, 17, 896–903. [Google Scholar] [CrossRef]

- Scientific Instruments News. Technical Magazine of Electron Microscope and Analytical Instruments. Introduction to Model UH4150AD UV-Vis-NIR Spectrophotometer. Available online: https://www.hitachi-hightech.com/global/sinews/technical_explanation/080302/ (accessed on 6 June 2020).

- UV-3600i Plus UV-VIS-NIR Spectrophotometer. Available online: https://www.shimadzu.com/an/molecular_spectro/uv/uv-3600plus/features.html (accessed on 6 June 2020).

- Nanocrystal. Quality and Reliability. Available online: http://www.monocrystal.com/catalog/sapphire/plate/ (accessed on 6 June 2020).

- Levenhuk. Zoom&Joy. Available online: https://www.levenhuk.com/catalogue/accessories/levenhuk-n18-ng-prepared-slides-set/#.XsbUvmgzaUk (accessed on 6 June 2020).

- UV-Vis & UV-Vis-NIR Systems. Available online: https://www.agilent.com/en/products/uv-vis-uv-vis-nir/uv-vis-uv-vis-nir-systems/cary-5000-uv-vis-nir (accessed on 6 June 2020).

- Crystal Techno. Available online: http://www.crystaltechno.com/Al2O3_en.htm (accessed on 6 June 2020).

- Wemple, S.H. Refractive-index behavior of amorphous semiconductors and glasses. Phys. Rev. B. 1973, 7, 3767–3777. [Google Scholar] [CrossRef]

- Márquez, E.; Saugar, E.; Díaz, J.M.; García-Vázquez, C.; Ruano, S.M.F.; Blanco, E.; Ruiz-Pérez, J.J.; Minkov, D.A. The influence of Ar pressure on the structure and optical properties of nonhydrogenated a-Si thin films grown by rf magnetron sputtering onto room temperature glass substrates. J. Non-Cryst. Solids 2019, 517, 32–43. [Google Scholar] [CrossRef]

- Marquez, E.; Díaz, J.M.; García-Vazquez, C.; Blanco, E.; Ruiz-Perez, J.J.; Minkov, D.A.; Angelov, G.V.; Gavrilov, G.M. Optical characterization of amine-solution-processed amorphous AsS2 chalcogenide thin films by the use of transmission spectroscopy. J. Alloys Compd. 2017, 721, 363–373. [Google Scholar] [CrossRef]

- Abdel-Aal, A. The optical parameters and photoconductivity of CdxIn1Se9-x chalcogenide thin films. Physica B 2007, 392, 180–187. [Google Scholar] [CrossRef]

| As40Te60 Film, m1 Is Fixed, N = Ne = 22 | ||||

| δd/N (nm) | m1 | ∆d (nm) | (nm) | FOM (k(Ti)) |

| 3.63 × 10−2 | 6 | 47 | 2676.5 | 0.0178 |

| 1.89 × 10−2 | 7 | 44 | 2994.7 | 0.00982 |

| 0.85 × 10−2 | 8 | 38 | 3349.2 | 0.00500 |

| 1.20 × 10−2 | 9 | 25 | 3748.3 | 0.00560 |

| 2.36 × 10−2 | 10 | 1 | 4114.8 | 0.01048 |

| As98Te2 Film, m1 Is Fixed, N = Ne = 22 | ||||

| δd/N (nm) | m1 | ∆d (nm) | (nm) | FOM (k(Ti)) |

| 4.50 | 2.5 | 40 | 1355.7 | 0.0461 |

| 2.13 | 3.5 | 32 | 1671.3 | 0.0210 |

| 0.520 | 4.5 | 23 | 1981.1 | 0.00512 |

| 2.59 | 5.5 | 0 | 2286.9 | 0.0188 |

| 6.29 | 6.5 | 0 | 2523.6 | 0.0447 |

| As80Te20 Film, m1 Is Fixed, N = Ne = 46 | ||||

| δd/N (nm) | m1 | ∆d (nm) | (nm) | FOM (k(Ti)) |

| 19.83 | 4.5 | 95 | 4945.4 | 0.02441 |

| 18.03 | 5.5 | 95 | 5425.2 | 0.02265 |

| 16.43 | 6.5 | 95 | 5808.8 | 0.01909 |

| 15.11 | 7.5 | 95 | 5947.2 | 0.01544 |

| 13.83 | 8.5 | 94 | 6496.4 | 0.01398 |

| 12.79 | 9.5 | 93 | 6914.5 | 0.01243 |

| 12.10 | 10.5 | 92 | 7325.7 | 0.01130 |

| 11.80 | 11.5 | 92 | 7847.5 | 0.01035 |

| 11.92 | 12.5 | 90 | 8302.6 | 0.00981 |

| 12.27 | 13.5 | 79 | 9064.3 | 0.00937 |

| 12.14 | 14.5 | 74 | 9586.0 | 0.00898 |

| 12.11 | 15.5 | 63 | 10,195 | 0.00892 |

| 12.07 | 16.5 | 45 | 10,916 | 0.00878 |

| 11.94 | 17.5 | 0 | 11,446 | 0.00859 |

| 12.10 | 18.5 | 0 | 11,867 | 0.00889 |

| 12.63 | 19.5 | 0 | 12,288 | 0.00931 |

| Film | δd/N (nm) | p0 | FOM (k(T+)) | FOM (k(Ti)) | FOM (k0(λ)) | FOM (k0(λ) + Δk(λ)) |

|---|---|---|---|---|---|---|

| As40Te60 | 0.335 | 15 | 8.23 × 10−3 | 7.29 × 10−3 | 7.25 × 10−3 | 5.94 × 10−3 |

| As98Te20 | 0.220 | 9 | 3.96 × 10−3 | 3.74 × 10−3 | 4.36 × 10−3 | 4.26 × 10−3 |

| As80Te20, m1 = 11.5, ND | 6.89 | 6 | 1.57 × 10−2 | 1.04 × 10−2 | 1.16 × 10−2 | 1.23 × 10−2 |

| As80Te20, m1 = 11.5, AD | 6.89 | 6 | 1.96 × 10−2 | 1.92 × 10−2 | 3.39 × 10−2 | 1.90 × 10−2 |

| As80Te20, m1 = 17.5, AD | 11.94 | 7 | 1.04 × 10−2 | 8.59 × 10−3 | 9.42 × 10−3 | 8.23 × 10−3 |

| Film, Specimen Number | From | m1 | N | δd/N (nm) | ||

|---|---|---|---|---|---|---|

| a-Si, 029 | [47] | 4 | 12 | 1.010 | 1172.0 | 1.034 |

| a-Si, 074 | [47] | 4 | 14 | 1.349 | 1269.0 | 1.489 |

| a-Si, 038 | [34] | 2 | 9 | 0.341 | 785.7 | 0.391 |

| a-Si, 038 | [29] | 2 | 9 | 0.318 | 774.6 | 0.369 |

| a-Si, 041 | [34] | 12 | 17 | 0.594 | 3939.1 | 0.256 |

| a-Si, 041 | [29] | 12 | 17 | 0.567 | 3929.9 | 0.245 |

| As33S67 | [48] | 2 | 9 | 0.706 | 744.8 | 0.853 |

| As40Te60 | here | 8 | 11 | 0.335 | 3306.9 | 0.101 |

| As98Te2 | here | 4.5 | 12 | 0.220 | 1983.8 | 0.133 |

| As80Te20 | here | 17.5 | 46 | 11.94 | 11446 | 4.799 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minkov, D.; Angelov, G.; Nestorov, R.; Nezhdanov, A.; Usanov, D.; Kudryashov, M.; Mashin, A. Optical Characterization of AsxTe100−x Films Grown by Plasma Deposition Based on the Advanced Optimizing Envelope Method. Materials 2020, 13, 2981. https://doi.org/10.3390/ma13132981

Minkov D, Angelov G, Nestorov R, Nezhdanov A, Usanov D, Kudryashov M, Mashin A. Optical Characterization of AsxTe100−x Films Grown by Plasma Deposition Based on the Advanced Optimizing Envelope Method. Materials. 2020; 13(13):2981. https://doi.org/10.3390/ma13132981

Chicago/Turabian StyleMinkov, Dorian, George Angelov, Radi Nestorov, Aleksey Nezhdanov, Dmitry Usanov, Mikhail Kudryashov, and Aleksandr Mashin. 2020. "Optical Characterization of AsxTe100−x Films Grown by Plasma Deposition Based on the Advanced Optimizing Envelope Method" Materials 13, no. 13: 2981. https://doi.org/10.3390/ma13132981