Directly Printed Low-Cost Nanoparticle Sensor for Vibration Measurement during Milling Process

Abstract

1. Introduction

2. Fabrication of a Low-Cost Vibration Sensor

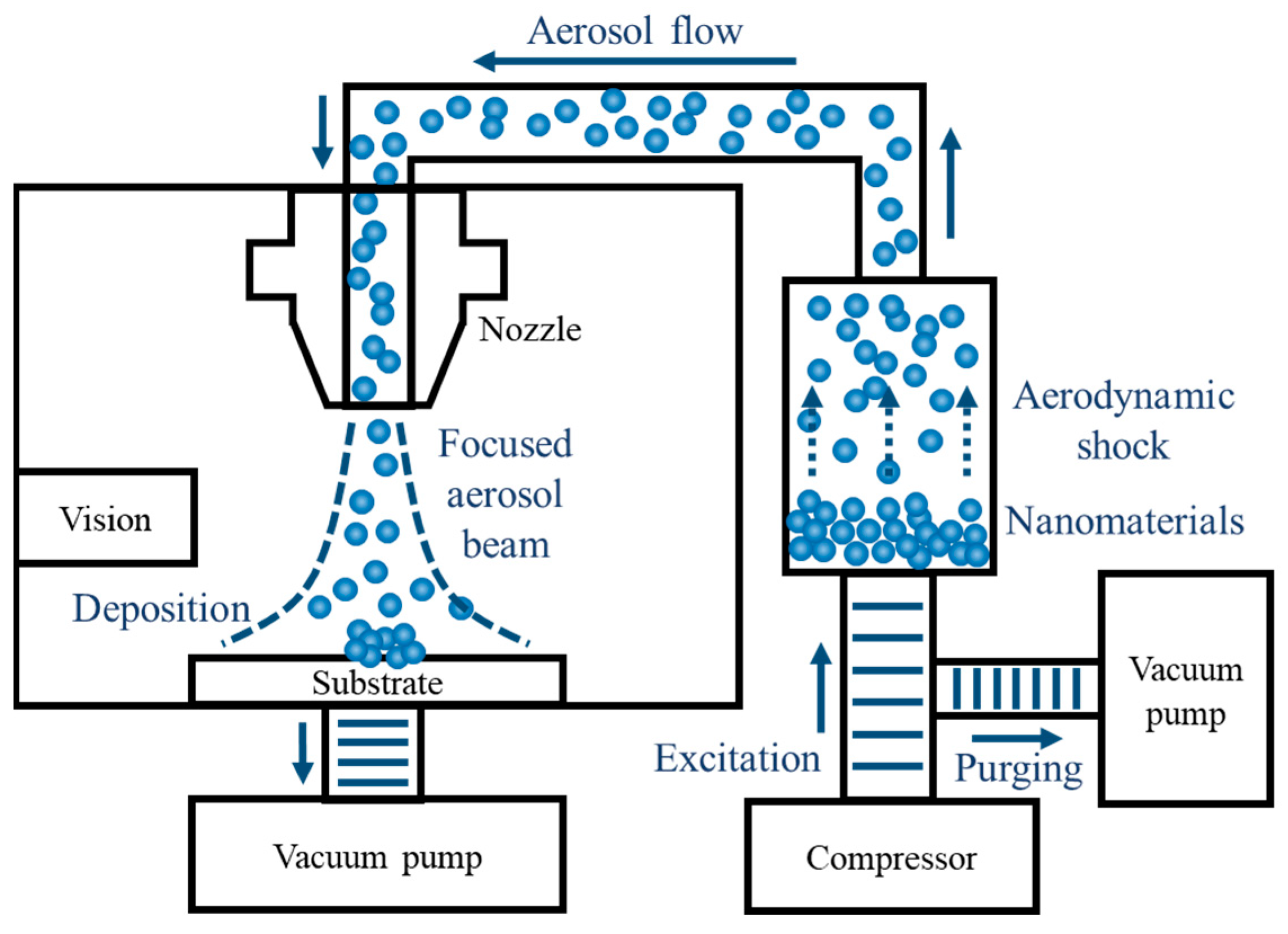

2.1. AFN Printing System

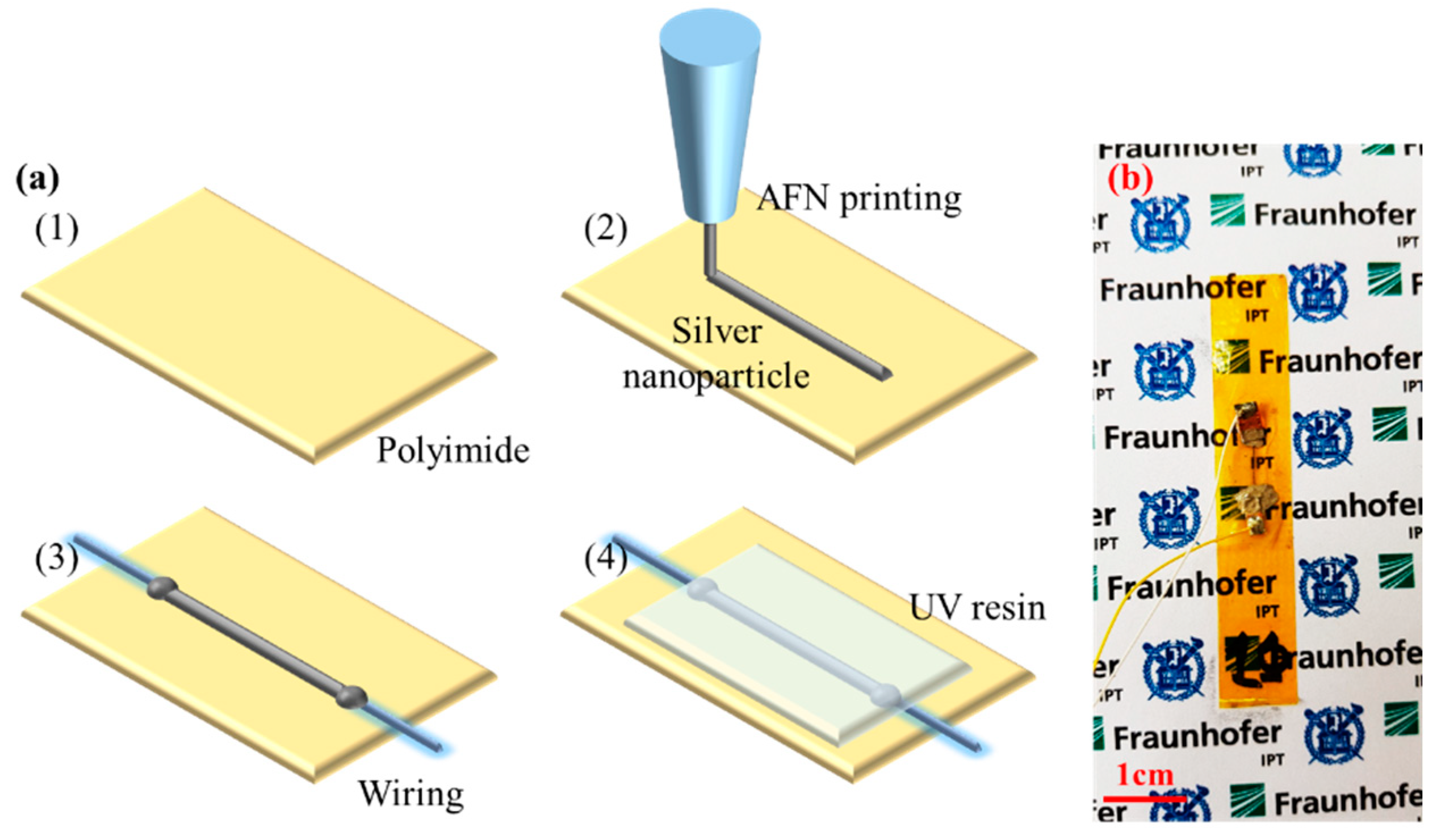

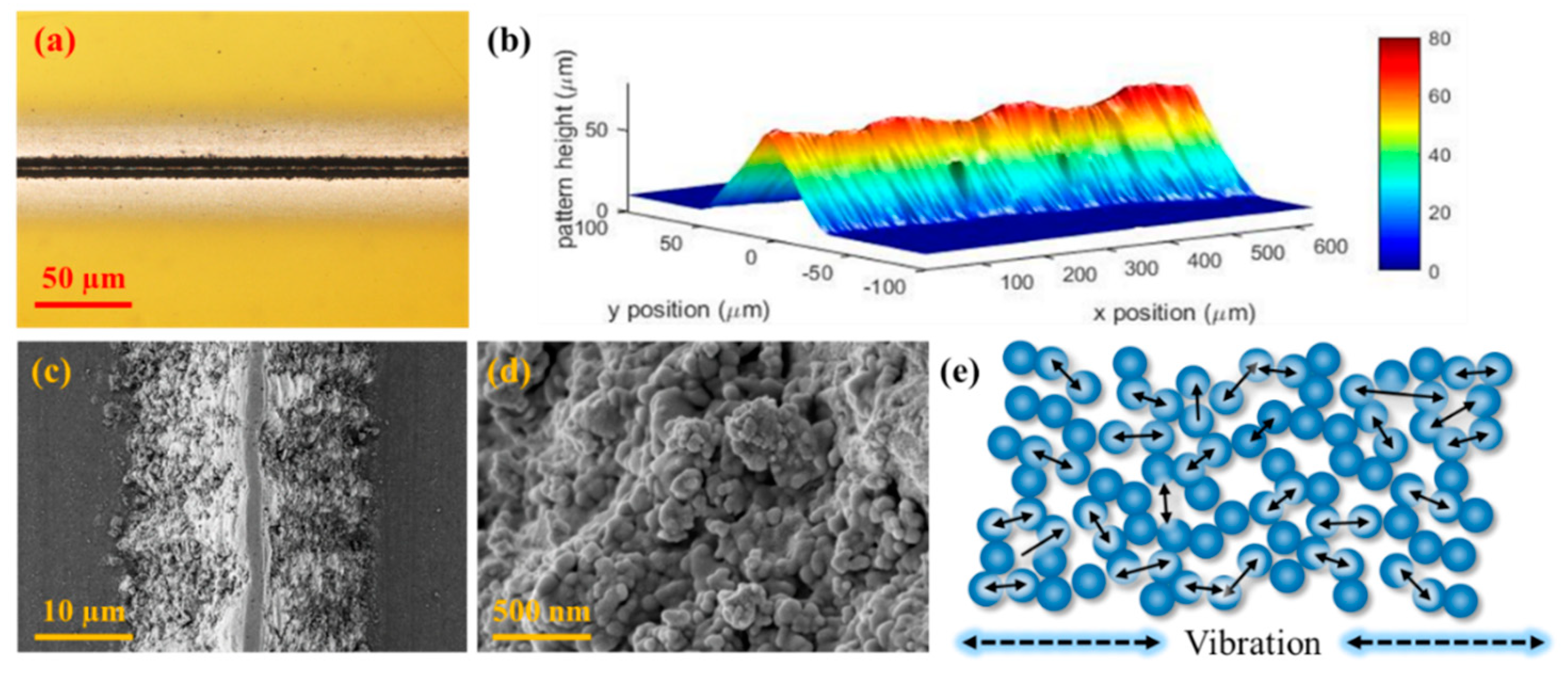

2.2. Vibration Sensor Fabrication

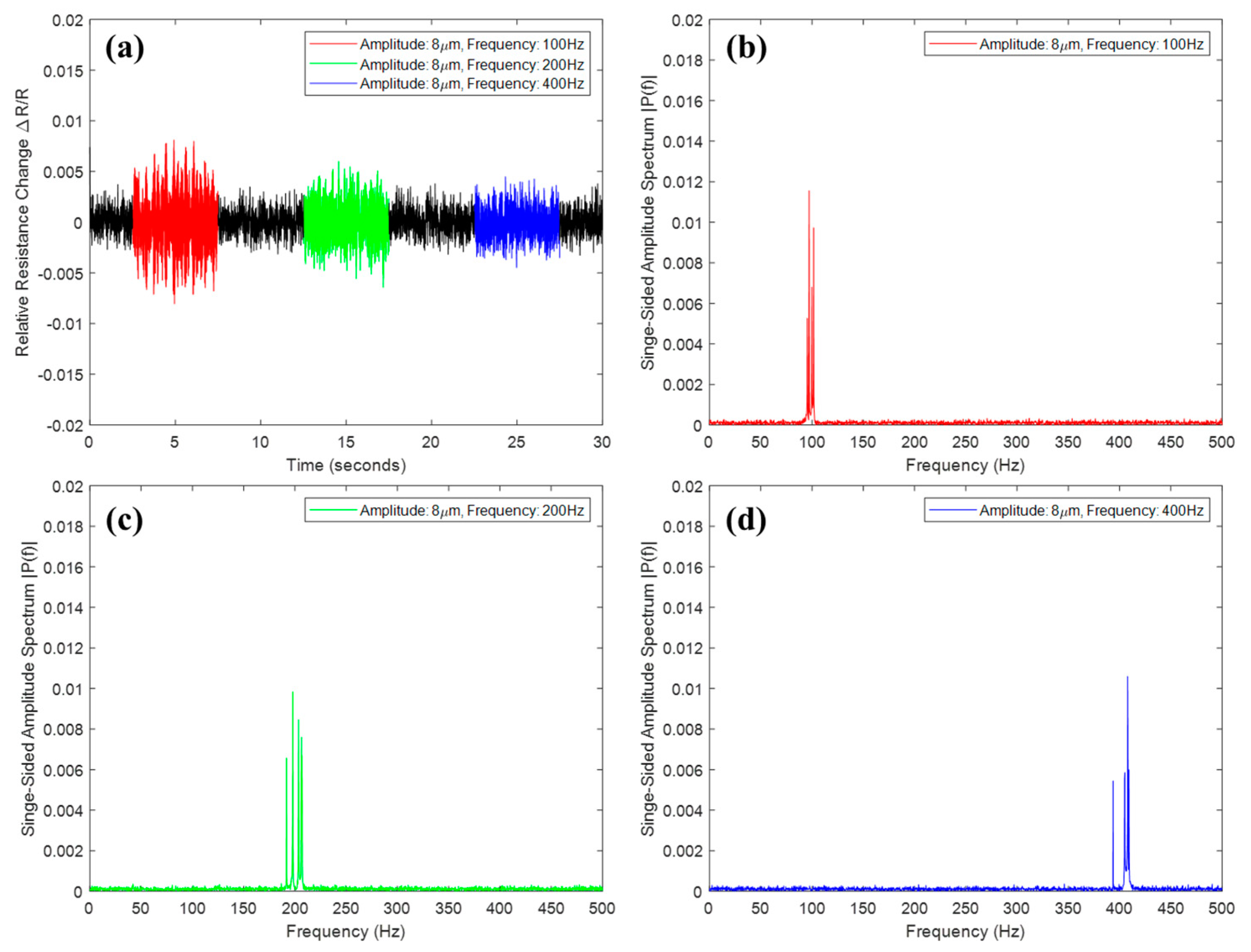

2.3. Validation of Vibration Measurement Performance

3. Milling Process Monitoring

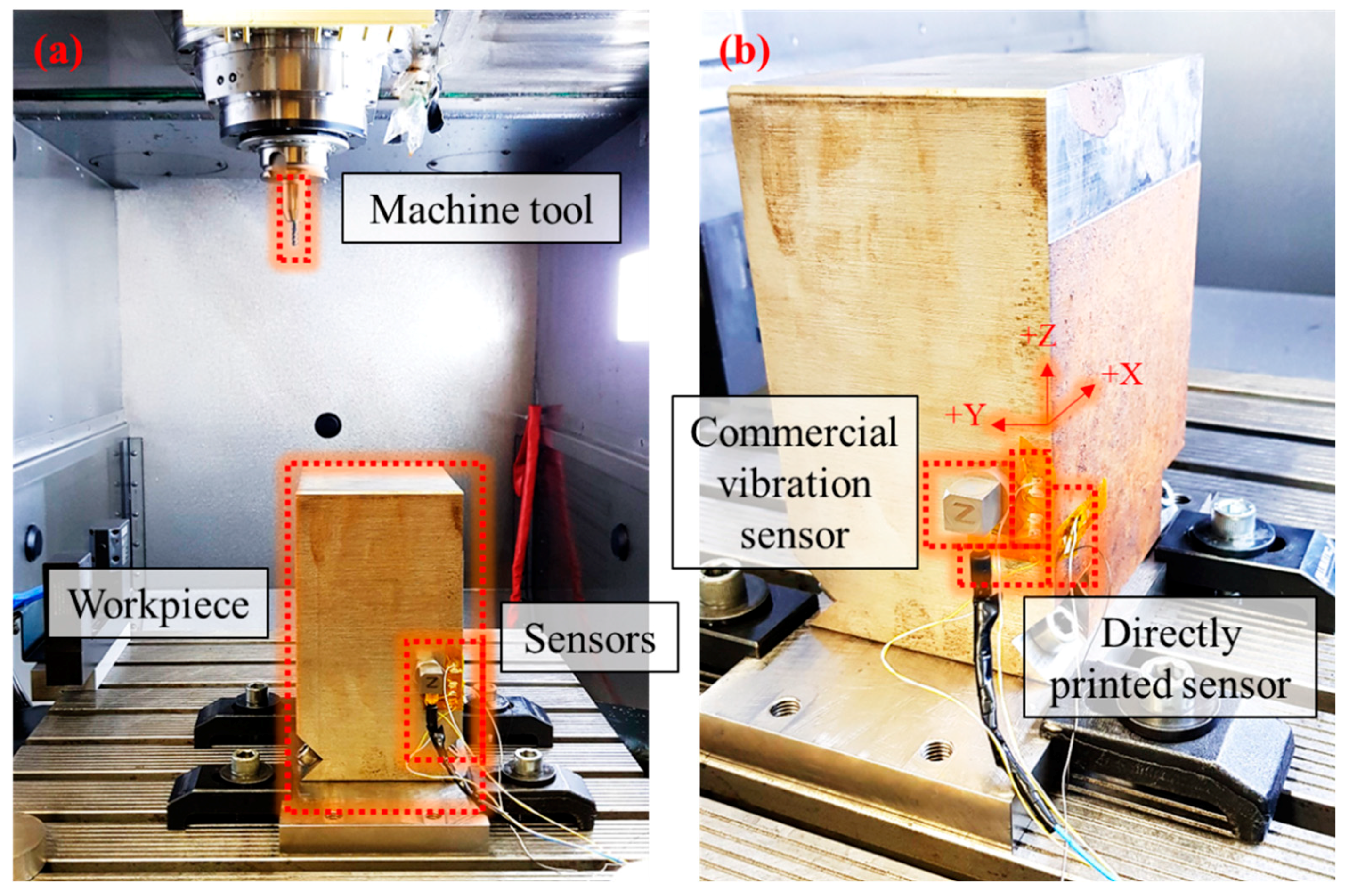

3.1. Workpiece Attached Vibration Measurement

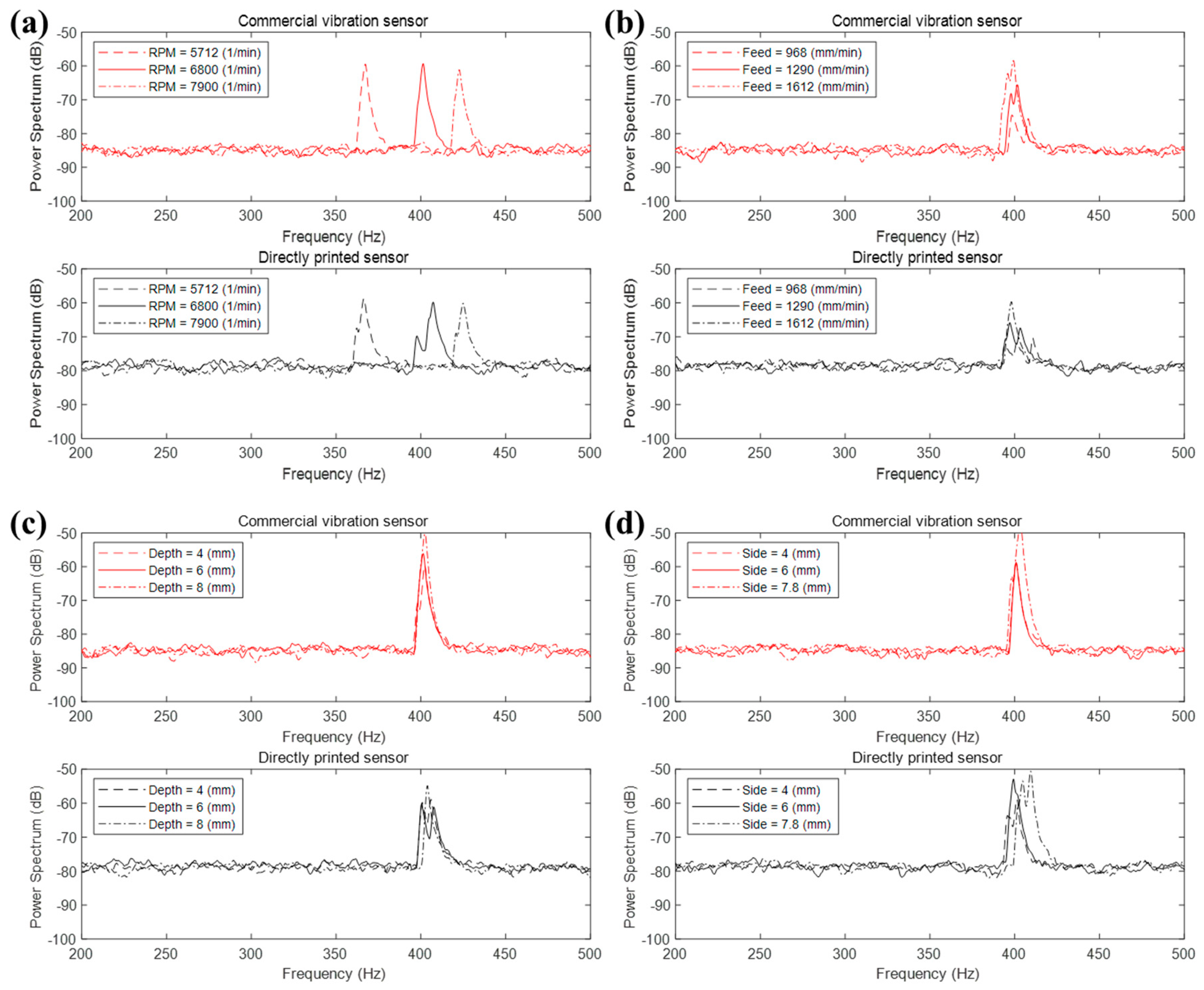

3.2. Process Parametrisation

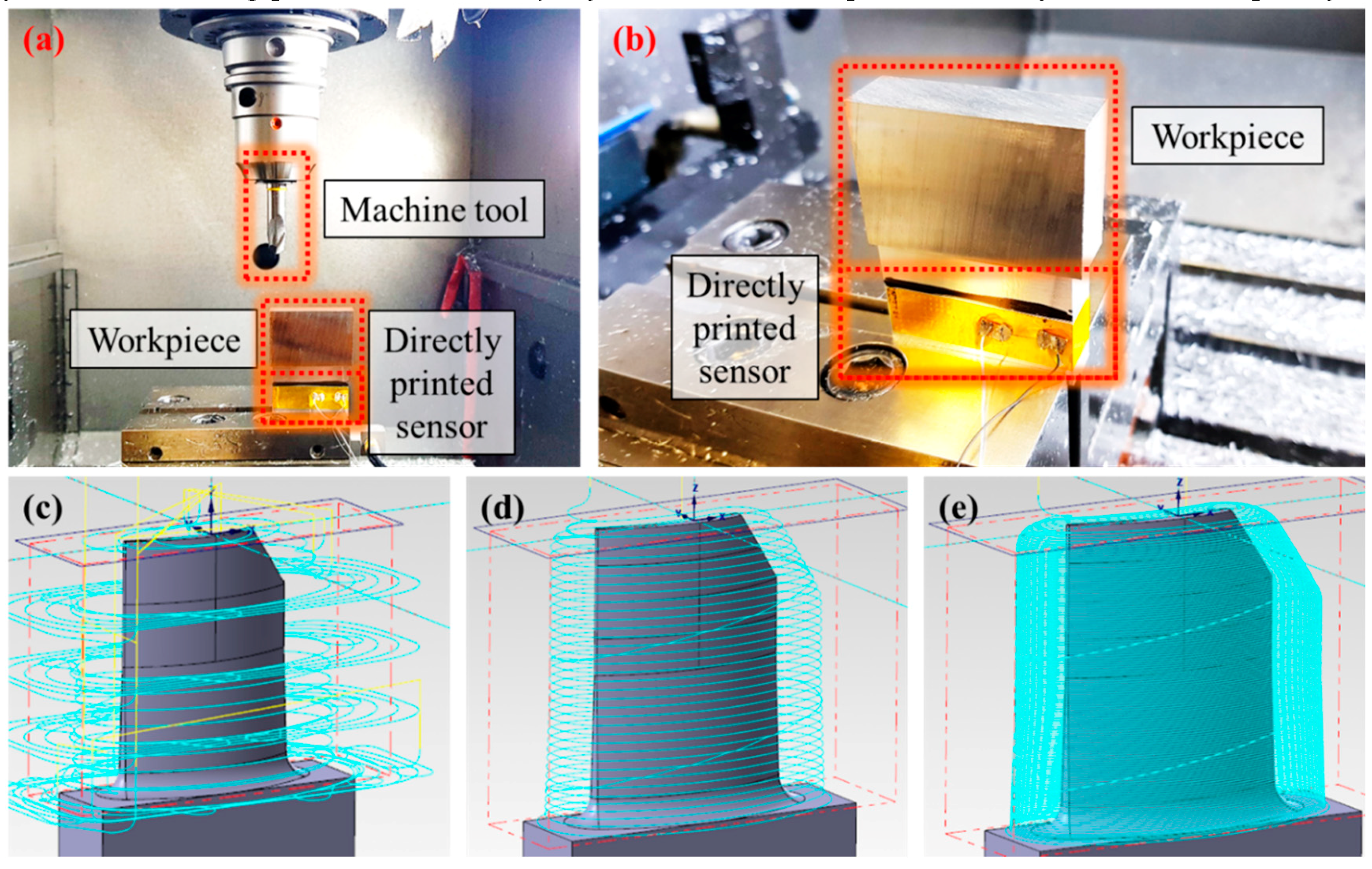

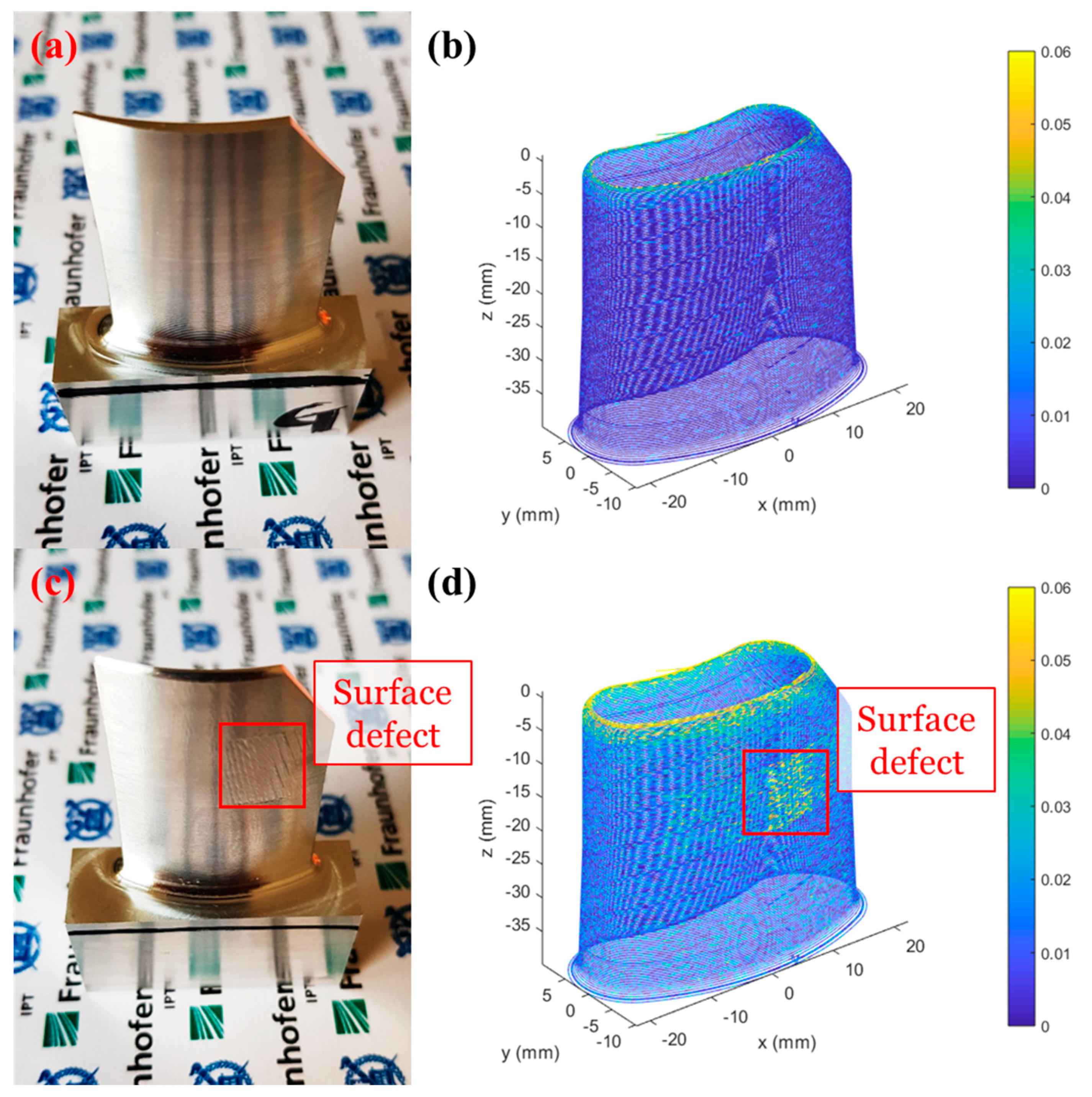

4. Application to Digital Twins

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jeschke, S.; Brecher, C.; Meise, T.; Özdemir, D.; Eschert, T. Industrial internet of things and cyber manufacturing systems. In Industrial Internet of Things; Springer: Cham, Switzerland, 2017; pp. 3–19. [Google Scholar]

- Stark, R.; Kind, S.; Neumeyer, S. Innovations in digital modelling for next generation manufacturing system design. CIRP Ann. 2017, 66, 169–172. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Brecher, C.; Jeschke, S.; Schuh, G.; Aghassi, S.; Arnoscht, J.; Bauhoff, F.; Fuchs, S.; Jooß, C.; Karmann, W.O.; Kozielski, S.S.; et al. Integrative production technology for high-wage countries. In Integrative Production Technology for High-Wage Countries; Springer: Berlin/Heidelberg, Germany, 2012; pp. 17–76. [Google Scholar]

- Park, S.S.; Parmar, K.; Shajari, S.; Sanati, M. Polymeric carbon nanotube nanocomposite-based force sensors. CIRP Ann. 2016, 65, 361–364. [Google Scholar] [CrossRef]

- Drossel, W.G.; Gebhardt, S.; Bucht, A.; Kranz, B.; Schneider, J.; Ettrichrätz, M. Performance of a new piezoceramic thick film sensor for measurement and control of cutting forces during milling. CIRP Ann. 2018, 67, 45–48. [Google Scholar] [CrossRef]

- Nguyen, V.; Fernandez-Zelaia, P.; Melkote, S.N. PVDF sensor based characterization of chip segmentation in cutting of Ti-6Al-4V alloy. CIRP Ann. 2017, 66, 73–76. [Google Scholar] [CrossRef]

- Yun, H.T.; Heo, S.; Lee, M.K.; Min, B.K.; Lee, S.J. Ploughing detection in micromilling processes using the cutting force signal. Int. J. Mach. Tools Manuf. 2011, 51, 377–382. [Google Scholar] [CrossRef]

- Hong, Y.S.; Yoon, H.S.; Moon, J.S.; Cho, Y.M.; Ahn, S.H. Tool-wear monitoring during micro-end milling using wavelet packet transform and Fisher’s linear discriminant. Int. J. Precis. Eng. Manuf. 2016, 17, 845–855. [Google Scholar] [CrossRef]

- Möhring, H.C.; Litwinski, K.M.; Gümmer, O. Process monitoring with sensory machine tool components. CIRP Ann. 2010, 59, 383–386. [Google Scholar] [CrossRef]

- Yao, Q.; Luo, M.; Zhang, D.; Wu, B. Identification of cutting force coefficients in machining process considering cutter vibration. Mech. Syst. Signal Process. 2018, 103, 39–59. [Google Scholar] [CrossRef]

- Xie, Z.; Li, J.; Lu, Y. An integrated wireless vibration sensing tool holder for milling tool condition monitoring. Int. J. Adv. Manuf. Technol. 2018, 95, 2885–2896. [Google Scholar] [CrossRef]

- Munoa, J.; Beudaert, X.; Kaan, E.; Iglesias, A.; Barrios, A.; Zatarain, M. Active suppression of structural chatter vibrations using machine drives and accelerometers. CIRP Ann. 2015, 64, 385–388. [Google Scholar] [CrossRef]

- Marinescu, I.; Axinte, D.A. A critical analysis of effectiveness of acoustic emission signals to detect tool and workpiece malfunctions in milling operations. Int. J. Mach. Tools Manuf. 2008, 48, 1148–1160. [Google Scholar] [CrossRef]

- Lee, J.Y.; Shin, Y.J.; Kim, M.S.; Kim, E.S.; Yoon, H.S.; Kim, S.Y.; Yoon, Y.C.; Ahn, S.H.; Min, S. A simplified machine-tool power consumption measurement procedure and methodology for estimating total energy consumption. J. Manuf. Sci. Eng. 2016, 138, 051004. [Google Scholar] [CrossRef]

- Ma, L.; Melkote, S.N.; Morehouse, J.B.; Castle, J.B.; Fonda, J.W.; Johnson, M.A. Thin-film PVDF sensor-based monitoring of cutting forces in peripheral end milling. J. Dyn. Syst. Meas. Control 2012, 134, 051014. [Google Scholar] [CrossRef]

- Luo, M.; Luo, H.; Axinte, D.; Liu, D.; Mei, J.; Liao, Z. A wireless instrumented milling cutter system with embedded PVDF sensors. Mech. Syst. Signal Process. 2018, 110, 556–568. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Z.; Zhou, Z.; Peng, S.; Tan, Y. A new method based on Fiber Bragg grating sensor for the milling force measurement. Mechatronics 2015, 31, 22–29. [Google Scholar] [CrossRef]

- Mian, A.J.; Drive, N.; Mativenga, P.T. Chip formation in microscale milling and correlation with acoustic emission signal. Int. J. Adv. Manuf. Technol. 2011, 56, 63–78. [Google Scholar] [CrossRef]

- Ahn, S.H.; Yoon, H.S.; Jang, K.H.; Kim, E.S.; Lee, H.T.; Lee, G.Y.; Kim, C.S.; Cha, S.W. Nanoscale 3D Printing Process Using Aerodynamically Focused Nanoparticle (AFN) Printing, Micro-Machining, and Focused Ion Beam (FIB). CIRP Ann. 2015, 64, 523–526. [Google Scholar] [CrossRef]

- Min, S.H.; Lee, G.Y.; Ahn, S.H. Direct printing of highly sensitive, stretchable, and durable strain sensor based on silver nanoparticles/multi-walled carbon nanotubes composites. Compos. Part B Eng. 2019, 161, 395–401. [Google Scholar] [CrossRef]

- Herrmann, J.; Müller, K.H.; Reda, T.; Baxter, G.R.; Raguse, B.; de Groot, G.J.J.B.; Chai, R.; Roberts, M.; Wieczorek, L. Nanoparticle films as sensitive strain gauges. Appl. Phys. Lett. 2007, 91, 183105. [Google Scholar] [CrossRef]

- Pelton, M.; Sader, J.E.; Burgin, J.; Liu, M.; Guyot-Sionnest, P.; Gosztola, D. Damping of acoustic vibrations in gold nanoparticles. Nat. Nanotechnol. 2009, 4, 492. [Google Scholar] [CrossRef] [PubMed]

- Yi, L.; Jiao, W.; Wu, K.; Qian, L.; Yu, X.; Xia, Q.; Mao, K.; Yuan, S.; Wang, S.; Jiang, Y. Nanoparticle monolayer-based flexible strain gauge with ultrafast dynamic response for acoustic vibration detection. Nano Res. 2015, 8, 2978–2987. [Google Scholar] [CrossRef]

- Lee, G.Y.; Kim, M.S.; Min, S.H.; Kim, H.S.; Kim, H.J.; Keller, R.; Ihn, J.B.; Ahn, S.H. Highly Sensitive Solvent-free Silver Nanoparticle Strain Sensors with Tunable Sensitivity Created Using and Aerodynamically Focused Nanoparticle Printer. ACS Appl. Mater. Interfaces 2019, 11, 26421–26432. [Google Scholar] [CrossRef] [PubMed]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Kádár, B.; Egri, P.; Pedone, G.; Chida, T. Smart, simulation-based resource sharing in federated production networks. CIRP Ann. 2018, 67, 503–506. [Google Scholar] [CrossRef]

| RPM (1/min) | Feed Rate (mm/min) | Cutting Depth (mm) | Cutting Side (mm) |

|---|---|---|---|

| 5712 | 968 | 4 | 4 |

| 6800 | 1290 | 6 | 6 |

| 7900 | 1612 | 8 | 7.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, S.-H.; Lee, T.H.; Lee, G.-Y.; Zontar, D.; Brecher, C.; Ahn, S.-H. Directly Printed Low-Cost Nanoparticle Sensor for Vibration Measurement during Milling Process. Materials 2020, 13, 2920. https://doi.org/10.3390/ma13132920

Min S-H, Lee TH, Lee G-Y, Zontar D, Brecher C, Ahn S-H. Directly Printed Low-Cost Nanoparticle Sensor for Vibration Measurement during Milling Process. Materials. 2020; 13(13):2920. https://doi.org/10.3390/ma13132920

Chicago/Turabian StyleMin, Soo-Hong, Tae Hun Lee, Gil-Yong Lee, Daniel Zontar, Christian Brecher, and Sung-Hoon Ahn. 2020. "Directly Printed Low-Cost Nanoparticle Sensor for Vibration Measurement during Milling Process" Materials 13, no. 13: 2920. https://doi.org/10.3390/ma13132920

APA StyleMin, S.-H., Lee, T. H., Lee, G.-Y., Zontar, D., Brecher, C., & Ahn, S.-H. (2020). Directly Printed Low-Cost Nanoparticle Sensor for Vibration Measurement during Milling Process. Materials, 13(13), 2920. https://doi.org/10.3390/ma13132920