Experimental Behavior of Cracked Reinforced Concrete Columns Strengthened with Reinforced Concrete Jacketing

Abstract

1. Introduction

2. Experimental Tests

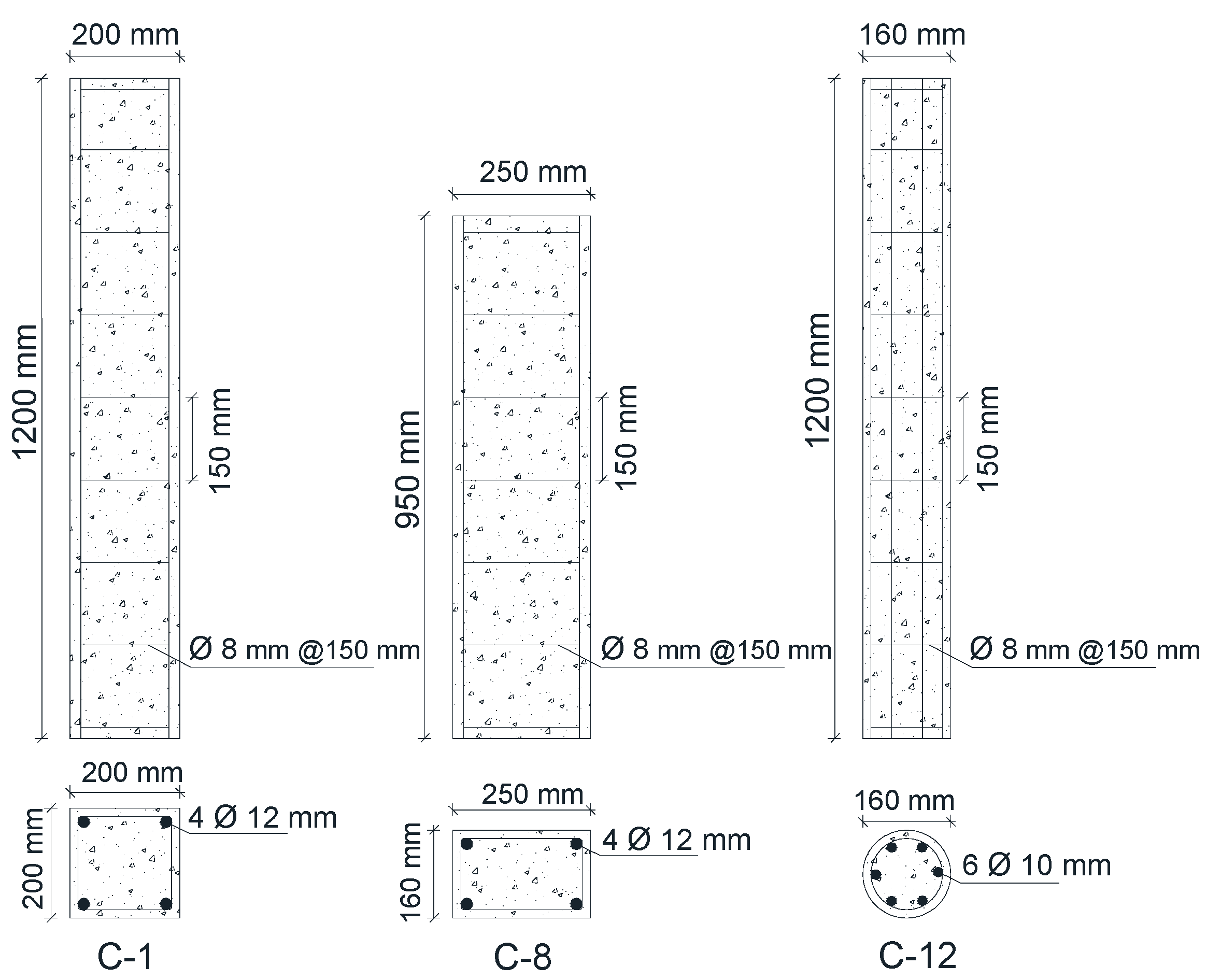

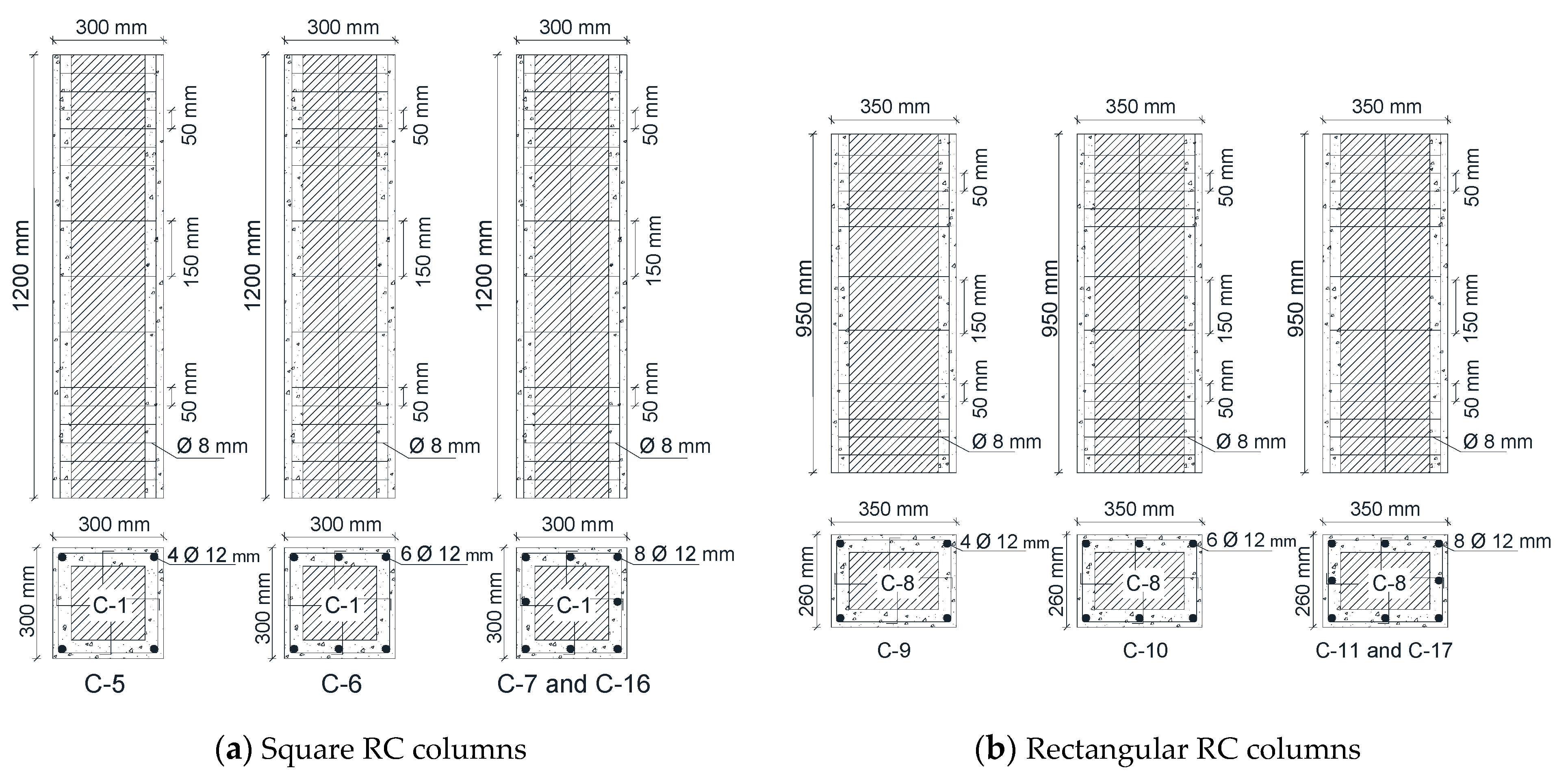

2.1. Specimen Details

2.2. Instrumentation and Test Setup

3. Results and Discussion

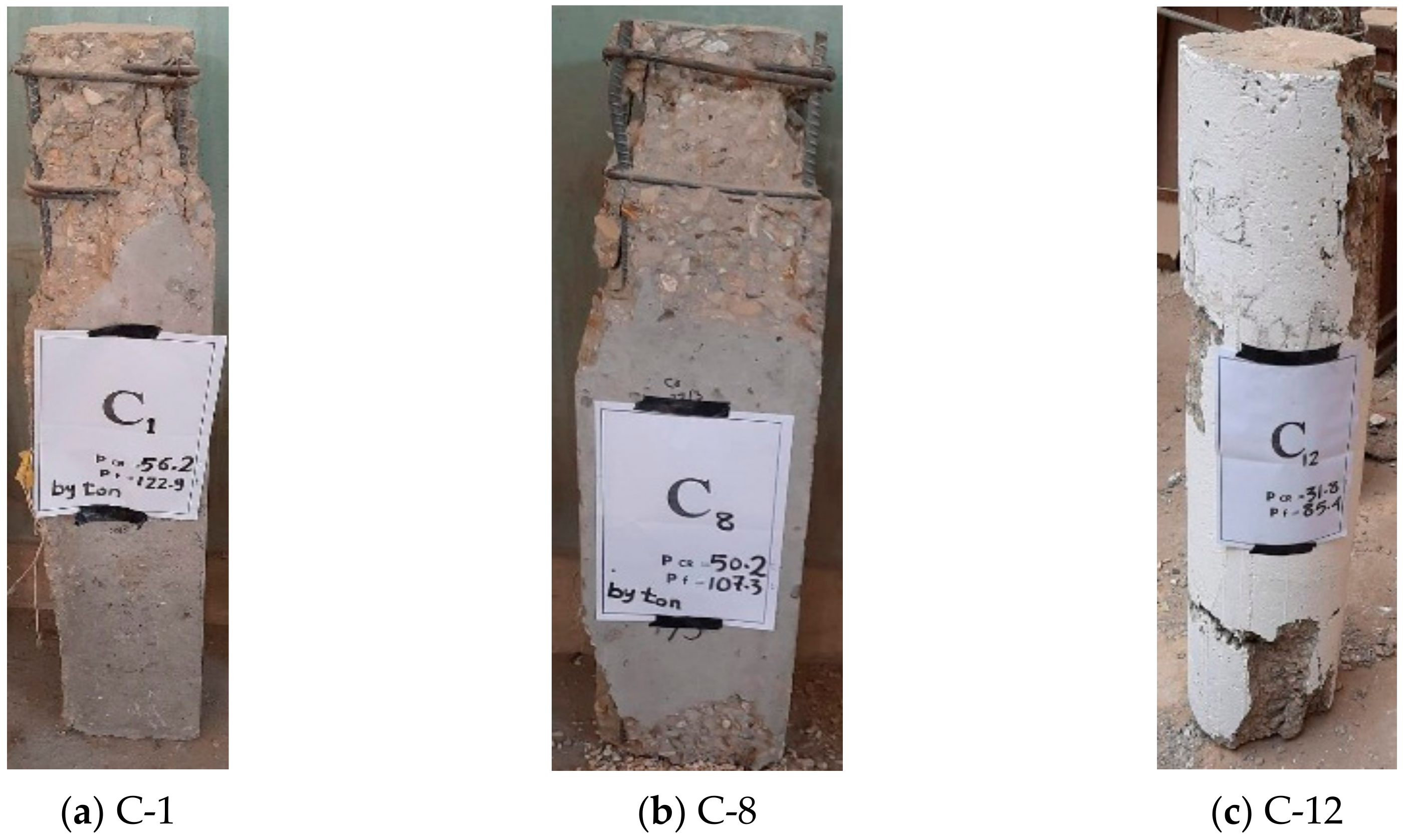

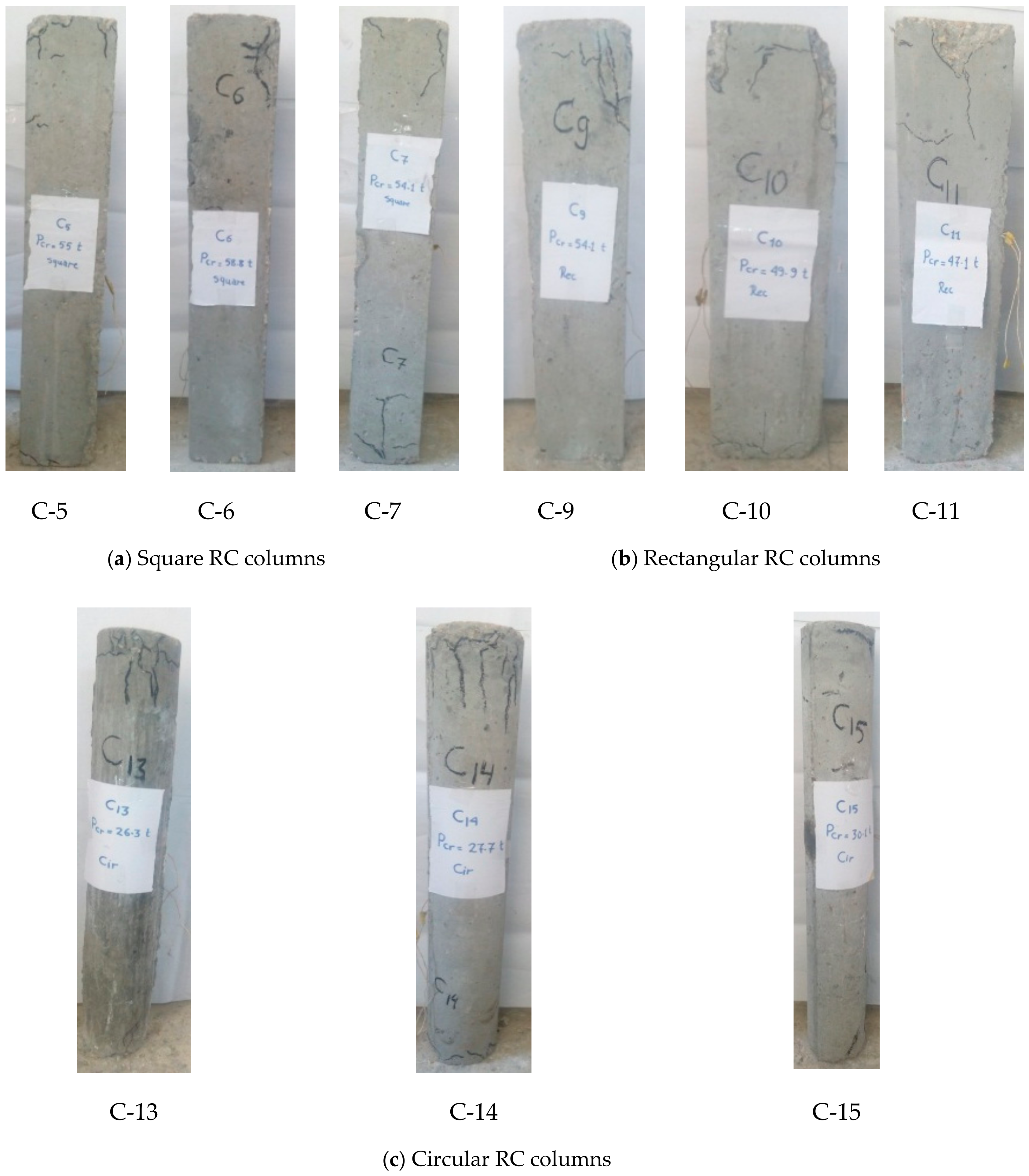

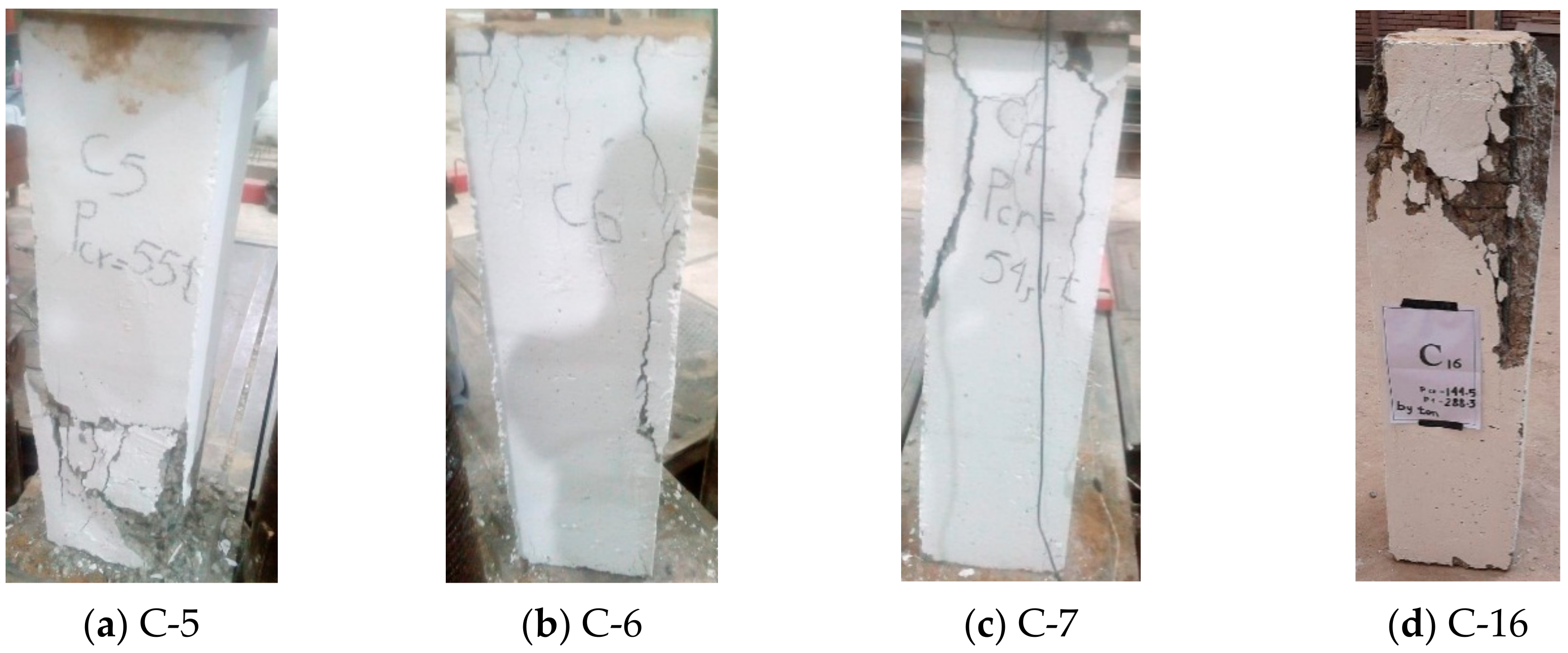

3.1. Crack Patterns and the Axial Load Capacity of Control Columns

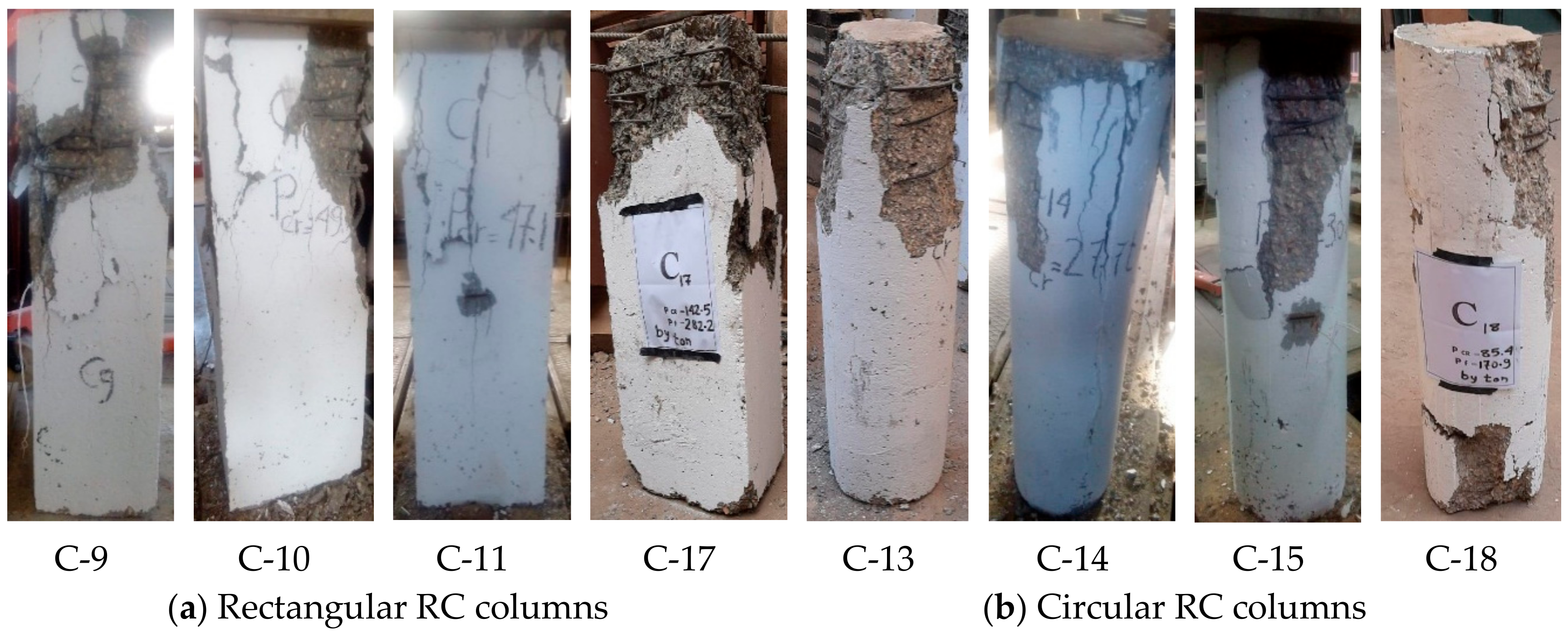

3.2. Crack Patterns and the Failure Loads of the Strengthened Columns

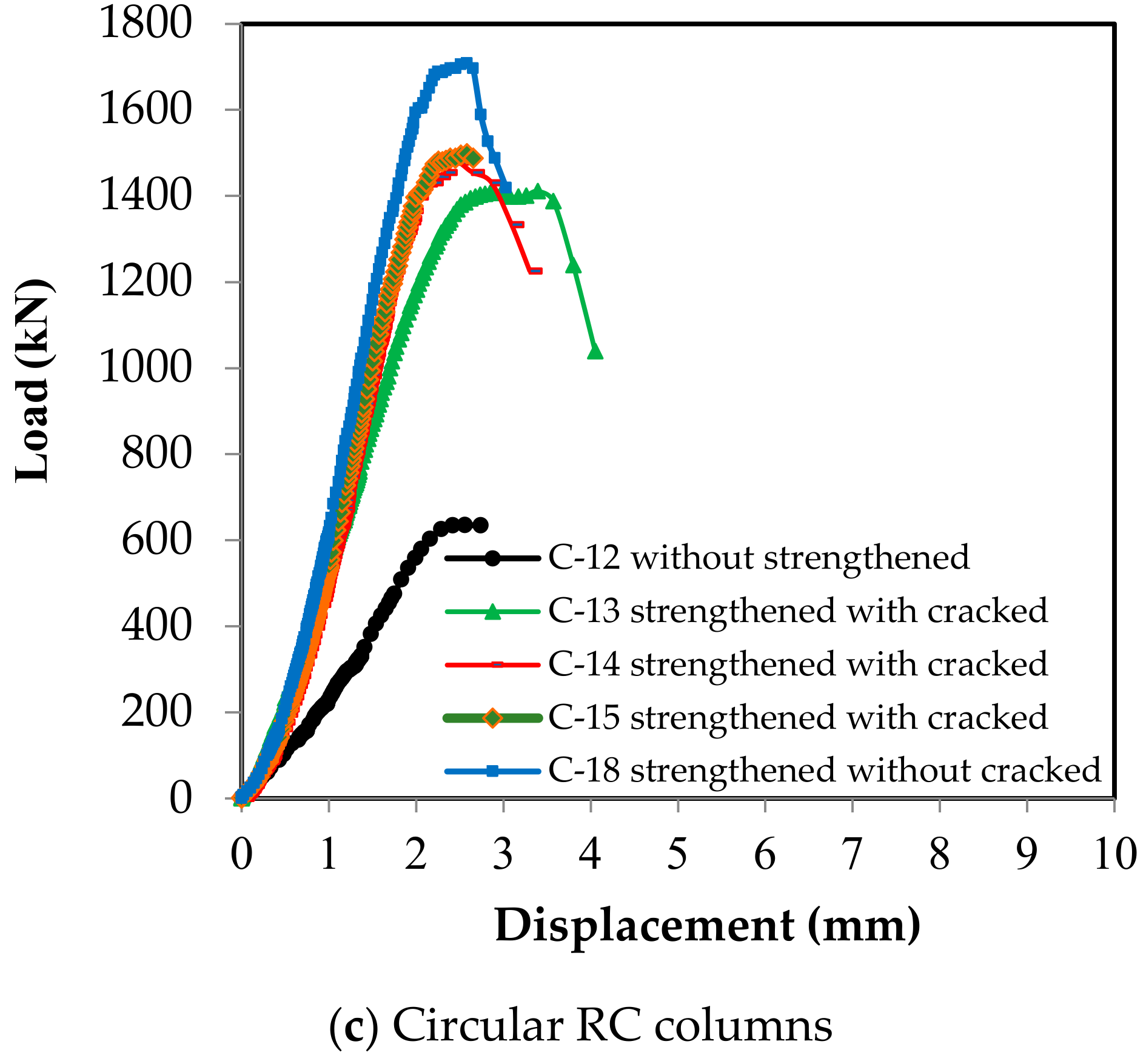

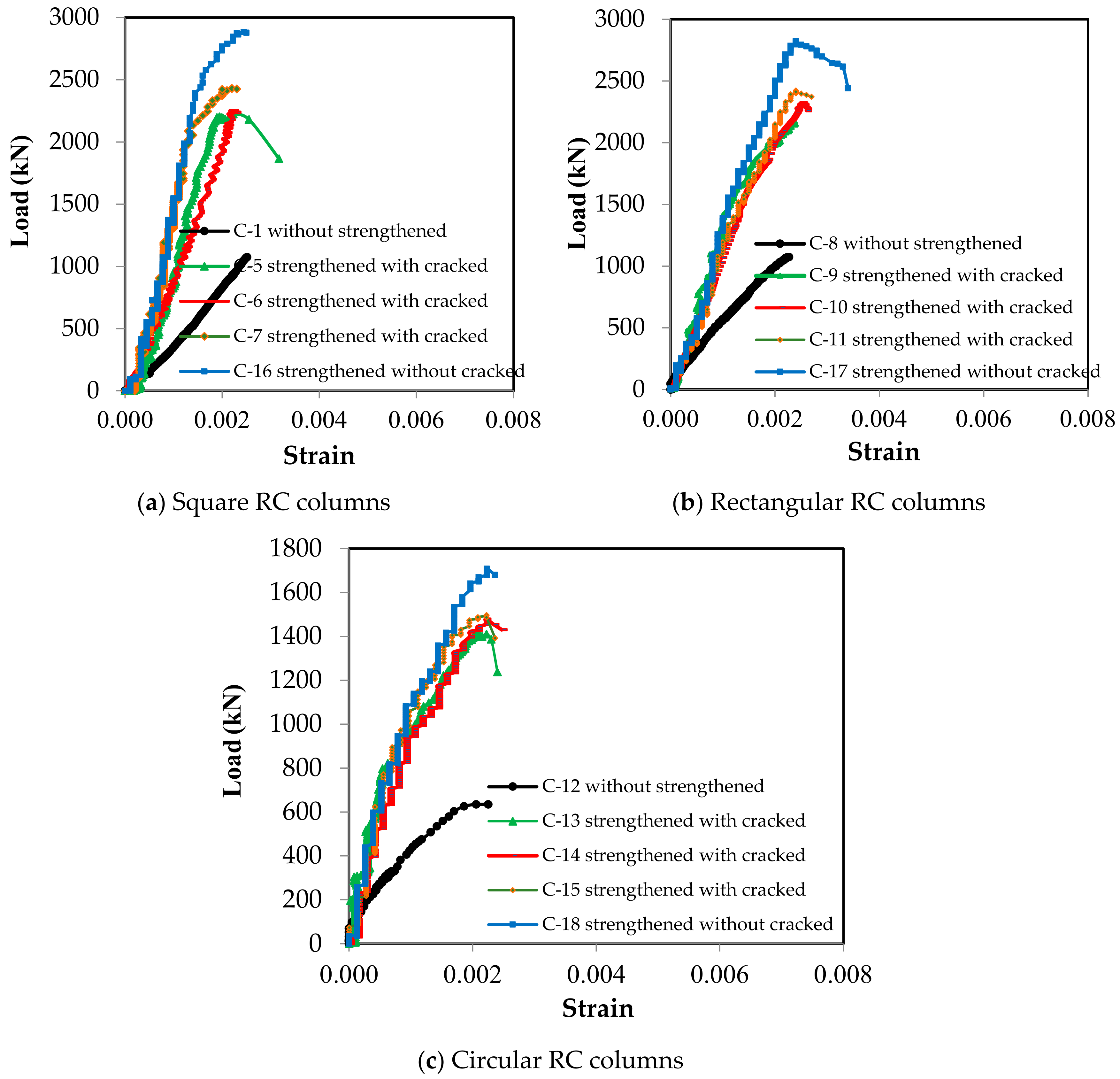

3.3. Load–Displacement Relationships

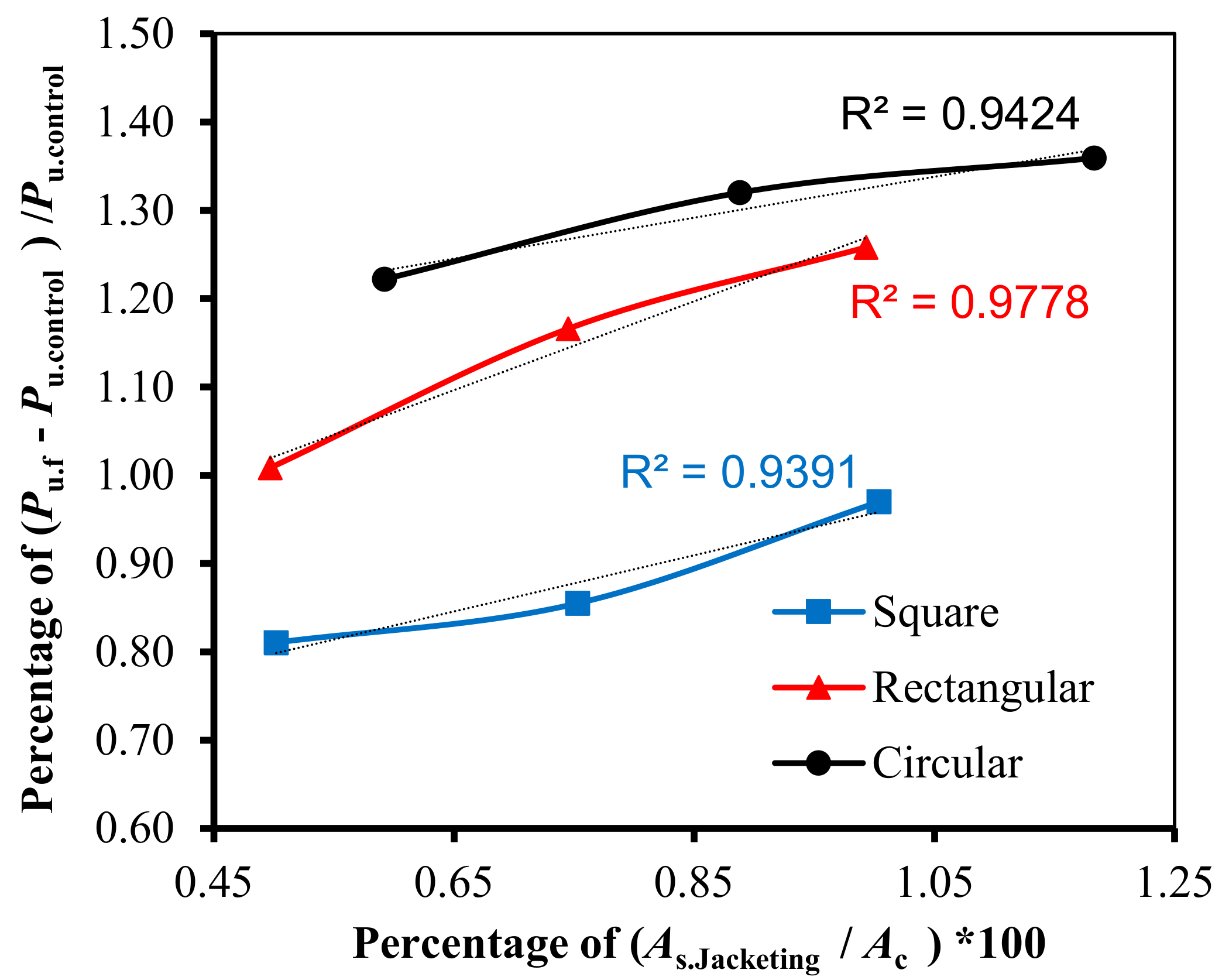

3.4. Effect of Longitudinal Steel Reinforcement in RC Jacketing

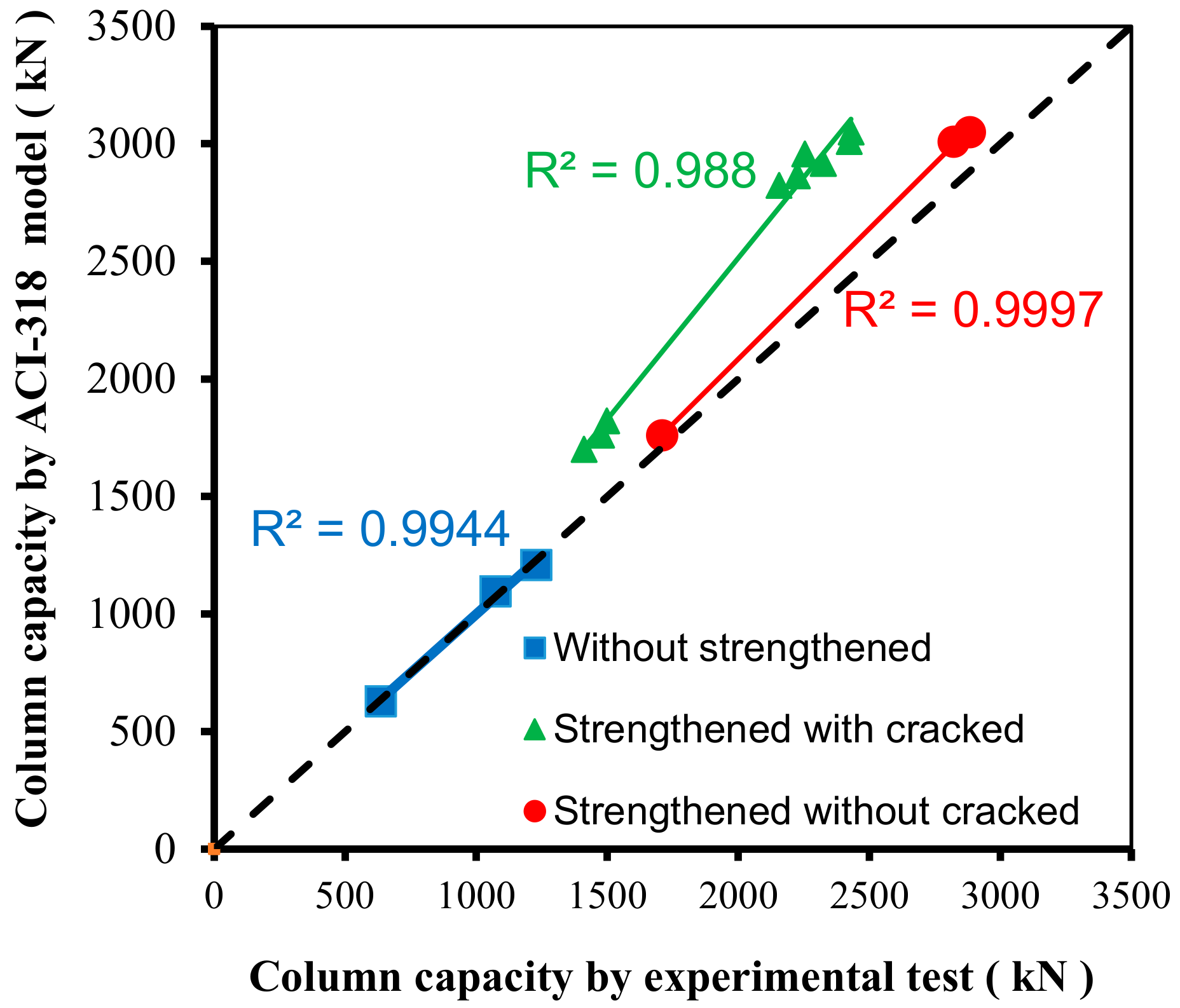

4. Comparison of the Results with the Existing Design Models

5. Conclusions

- The presence of cracks before strengthening affects the maximum load capacity of RC columns. The capacities of square, rectangular, and circular RC columns strengthened after cracking were 15.7%, 14.1%, and 13.5% lower than those of columns strengthened before cracking, respectively.

- The ACI-318 model [43] can predict the ultimate load capacity with higher accuracy and higher material efficiency. However, it requires reduction factors of up to 0.94 and 0.76 when applied to columns strengthened without and with cracks, before all RC columns are considered safe, respectively.

- The effect of the ratio of vertical steel reinforcement in the RC jacketing on the ultimate load capacity of the RC columns is linear.

- The effect of the vertical steel reinforcement ratio in the RC jacketing on the ultimate load capacity of the RC column is linear, regardless of whether the column was strengthened before or after cracking.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Ac | The concrete cross-section area |

| Ag | The concrete cross-section area inside the stirrups |

| As | The total longitudinal steel reinforcement cross-section |

| Ast | The steel reinforcement cross-section |

| Asj | The cross-section area of steel reinforcement in RC jacketing |

| fc′ | The concrete compressive strength |

| fy | The longitudinal steel yield strength |

| Pn.max | The design axial load capacity of the RC column |

| Pu.Ex | The experimental ultimate axial load capacity of the RC column |

| Pu.ACI | The ultimate axial load capacity of the RC column from the ACI-318 model |

| ϕ | The capacity safety factor |

References

- Vandoros, K.G.; Dritsos, S.E. Concrete jacket construction detail effectiveness when strengthening RC columns. Constr. Build. Mater. 2008, 22, 264–276. [Google Scholar] [CrossRef]

- Chang, S.Y.; Chen, T.W.; Tran, N.C.; Liao, W.I. Seismic retrofitting of RC columns with RC jackets and wing walls with different structural details. Earthq. Eng. Vib. 2014, 13, 279–292. [Google Scholar] [CrossRef]

- Liu, C.Y.; Ma, H.; Chen, L.; Li, Z.B.; Yang, D.B. Experimental study on seismic performance of reinforced concrete column retrofitted by asymmetric increased single lateral section. Adv. Struct. Eng. 2017, 20, 1325–1339. [Google Scholar] [CrossRef]

- Ou, Y.C.; Truong, A.N. Cyclic behavior of reinforced concrete L-and T-columns retrofitted from rectangular columns. Eng. Struct. 2018, 177, 147–159. [Google Scholar] [CrossRef]

- Deng, M.K.; Zhang, Y.X.; Li, Q.Q. Shear strengthening of RC short columns with ECC jacket: Cyclic behavior tests. Eng. Struct. 2018, 160, 535–545. [Google Scholar] [CrossRef]

- Choi, E.; Chung, Y.S.; Park, C.; Kim, D.J. Seismic performance of circular RC columns retrofitted with prefabricated steel wrapping jackets. Mag. Concr. Res. 2013, 65, 1429–1440. [Google Scholar] [CrossRef]

- Wang, L.; Su, R.K.L.; Cheng, B.; Li, L.Z.; Wan, L.; Shan, Z.W. Seismic behavior of preloaded rectangular RC columns strengthened with precambered steel plates under high axial load ratios. Eng. Struct. 2017, 152, 683–697. [Google Scholar] [CrossRef]

- Colomb, F.; Tobbi, H.; Ferrier, E.; Hamelin, P. Seismic retrofit of reinforced concrete short columns by CFRP materials. Compos. Struct. 2008, 82, 475–487. [Google Scholar] [CrossRef]

- Ozcan, O.; Binici, B.; Ozcebe, G. Seismic strengthening of rectangular reinforced concrete columns using fibre reinforced polymers. Eng. Struct. 2010, 32, 964–973. [Google Scholar] [CrossRef]

- Meda, A.; Mostosi, S.; Rinaldi, Z.; Riva, P. Corroded RC columns repair and strengthening with high performance fibre reinforced concrete jacket. Mater. Struct. 2016, 49, 1967–1978. [Google Scholar] [CrossRef]

- Abdullah, A.; Takiguchi, K. An investigation into the behavior and strength of reinforced concrete columns strengthened with ferrocement jackets. Cem. Concr. Compos. 2003, 25, 233–242. [Google Scholar] [CrossRef]

- Ma, R.; Xiao, Y.; Li, K.N. Full-scale testing of a parking structure column retrofitted with carbon fibre reinforced composites. Constr. Build. Mater. 2000, 14, 63–71. [Google Scholar] [CrossRef]

- Galal, K.; Arafa, A.; Ghobarah, A. Retrofit of RC square short columns. Eng. Struct. 2005, 27, 801–813. [Google Scholar] [CrossRef]

- Del Zoppo, M.; Di Ludovico, M.; Balsamo, A.; Prota, A. Comparative analysis of existing RC columns jacketed with CFRP or FRCC. Polymers 2018, 10, 361. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Kim, S.J.; Park, D.; Choi, S. Experimental investigation of reinforced concrete columns retrofitted with polyester sheet. Earthq. Struct. 2014, 6, 237–250. [Google Scholar] [CrossRef]

- Napoli, A.; Realfonzo, R. RC columns strengthened with novel CFRP systems: An experimental study. Polymers 2015, 7, 2044–2060. [Google Scholar] [CrossRef]

- Lee, H.S.; Kage, T.; Noguchi, T.; Tomosawa, F. An experimental study on the retrofitting effects of reinforced concrete columns damaged by rebar corrosion strengthened with carbon fibre sheets. Cem. Concr. Res. 2003, 33, 563–570. [Google Scholar] [CrossRef]

- Mahmoud, F.B.; Hatem, M.M.; Sherif, A.M. Behavior of reinforced concrete columns strengthened by steel jacket. HBRC J. 2015, 11, 201–212. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Naja, M.; Shihada, S.; Arafa, M. Repairing and strengthening of damaged RC columns using thin concrete jacketing. Adv. Civil Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Araujo, C.V.D.S.; Silva, R.J.C. Experimental and analytical analysis of reinforced concrete columns strengthened with CFRP. J. Build. Pathol. Rehabilit. 2016, 1, 4. [Google Scholar] [CrossRef]

- Campione, G.; Fossetti, M.; Giacchino, C.; Minafo, G. RC columns externally strengthened with RC jackets. Mater. Struct. 2014, 47, 1715–1728. [Google Scholar] [CrossRef]

- Julio, E.S.; Branco, F.; Silva, V.D. Structural rehabilitation of columns with reinforced concrete jacketing. Prog. Struct. Eng. Mater. 2003, 5, 29–37. [Google Scholar] [CrossRef]

- Campione, G. Load carrying capacity of RC compressed columns strengthened with steel angles and strips. Eng. Struct. 2012, 40, 457–465. [Google Scholar] [CrossRef]

- Jose, M.A.; Salvador, I.; Francisco, J.P.; Ester, G.; Pedro, A.C. Axially loaded RC columns strengthened by steel caging. Finite element modeling. Constr. Build. Mater. 2009, 23, 2265–2276. [Google Scholar] [CrossRef]

- Eunsoo, C.; Young, S.C.; Joonam, P.; Baik, S.C. Behavior of reinforced concrete columns confined by new steel-jacketing method. ACI Struct. J. 2010, 107, 654–662. [Google Scholar]

- Ester, G.; Jose, M.A.; Salvador, I.; Pedro, A.C. Influence of strips configuration on the behaviour of axially loaded RC columns strengthened by steel angles and strips. Mater. Des. 2009, 30, 4103–4111. [Google Scholar] [CrossRef]

- Vrettos, I.; Kefala, E.; Triantafillou, T.C. Innovative flexural strengthening of reinforced concrete columns using carbon-fibre anchors. ACI Struct. J. 2013, 110, 63–70. [Google Scholar]

- Kotynia, R.; Baky, H.A.; Neale, K.W.; Ebead, U.A. Flexural strengthening of RC beams with externally bonded CFRP systems: Test results and 3D nonlinear FE analysis. J. Compos. Construct. 2008, 12, 190–201. [Google Scholar] [CrossRef]

- Ye, L.P.; Yue, Q.R.; Zhao, S.H.; Li, Q.W. Shear strength of reinforced concrete columns strengthened with carbon-fibre-reinforced plastic sheet. J. Struct. Eng. 2002, 128, 1527–1534. [Google Scholar] [CrossRef]

- Sause, R.; Harries, K.A.; Walkup, S.L.; Pessiki, S.; Ricles, J.M. Flexural behavior of concrete columns retrofitted with carbon fibre-reinforced polymer jackets. ACI Struct. J. 2004, 101, 708–716. [Google Scholar]

- Bournas, D.A.; Triantafillou, T.C. Flexural strengthening of reinforced concrete columns with near-surface-mounted FRP or stainless steel. ACI Struct. J. 2009, 106, 495–505. [Google Scholar]

- Sarafraz, M.E.; Danesh, F. New technique for flexural strengthening of RC columns with NSM FRP bars. Mag. Concr. Res. 2012, 64, 151–161. [Google Scholar] [CrossRef]

- Rodrigues, H.; Furtado, A.; Arede, A.; Vila-Pouca, N.; Varum, H. Experimental study of repaired RC columns subjected to uniaxial and biaxial horizontal loading and variable axial load with longitudinal reinforcement welded steel bars solutions. Eng. Struct. 2018, 155, 371–386. [Google Scholar] [CrossRef]

- Wu, Y.F.; Griffith, M.C.; Oehlers, D.J. Improving the strength and ductility of rectangular reinforced concrete columns through composite partial interaction: Tests. J. Struct. Eng. 2003, 129, 1183–1190. [Google Scholar] [CrossRef]

- Pudjisuryadi, P.; Tavio, T.; Suprobo, P. Performance of square reinforced concrete columns externally confined by steel angle collars under combined axial and lateral load. Proc. Eng. 2015, 125, 1043–1049. [Google Scholar] [CrossRef]

- Paultre, P.; Boucher-Trudeau, M.; Eid, R.; Roy, N. Behavior of circular reinforced-concrete columns confined with carbon fibre-reinforced polymers under cyclic flexure and constant axial load. J. Compos. Constr. 2016, 20. [Google Scholar] [CrossRef]

- Rodrigues, H.; Furtado, A.; Arede, A. Experimental evaluation of energy dissipation and viscous damping of repaired and strengthened RC columns with CFRP jacketing under biaxial load. Eng. Struct. 2017, 145, 162–175. [Google Scholar] [CrossRef]

- Montuori, R.; Piluso, V.; Tisi, A. Ultimate behaviour of FRP wrapped sections under axial force and bending: Influence of stress–strain confinement model. Compos. Part B: Eng. 2013, 54, 85–96. [Google Scholar] [CrossRef]

- Raza, S.; Khan, M.K.I.; Menegon, S.J.; Tsang, H.H.; Wilson, J.L. Strengthening and repair of reinforced concrete columns by jacketing: State-of-the-art review. Sustainability 2019, 11, 3208. [Google Scholar] [CrossRef]

- Sayed, A.M.; Diab, H.M. Modeling of the axial load capacity of RC columns strengthened with steel jacketing under preloading based on FE simulation. Model. Simul. Eng. 2019, 3, 1–8. [Google Scholar] [CrossRef]

- Martin, V.; Miroslav, B. Strengthening under load: The effect of preload magnitudes. Proc. Eng. 2016, 161, 343–348. [Google Scholar] [CrossRef]

- Martin, V.; Miroslav, B. Strengthening under load: Numerical study of flexural buckling of columns. Proc. Eng. 2017, 190, 118–125. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirement for Structural Concrete (ACI 318-14) and Commentary; Farmington Hills American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Eurocode 4—ENV 1994-1-1. Design of Composite Steel and Concrete Structures, Part 1–1: General Rules and Rules for Buildings; Thomas Telford BSI: London, UK, 2004. [Google Scholar]

- Takeuti, A.R.; Hanai, J.B.; Mirmiran, A. Preloaded RC columns strengthened with high-strength concrete jackets under uniaxial compression. Mater. Struct. 2008, 41, 1251–1262. [Google Scholar] [CrossRef]

| Column Shape | Column Specimens | Concrete Dimension (mm) | As | As/Ac | Concrete fc’ (MPa) | ||

|---|---|---|---|---|---|---|---|

| b | t | h | |||||

| Square | C-1, 5, 6, 7 and 16 | 200 | 200 | 1200 | 4Ø12 | 1.13% | 25.5 |

| Rectangular | C-8, 9, 10, 11 and 17 | 160 | 250 | 950 | 4Ø12 | 1.13% | 22.7 |

| Circular | C-12, 13, 14, 15 and 18 | 160 Diameter | 1200 | 6Ø10 | 2.34% | 22.1 | |

| Column Shape | Column Specimens | Initial Concrete Dimensions (mm) | RC Jacketing | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| b | t | h | As | Concrete fc’ (MPa) | Thickness (mm) | New Dimension (mm) | Asj | As/Ac | |||

| b | t | ||||||||||

| Square | C-16 | 200 | 200 | 1200 | 4Ø12 | 29.4 | 50 | 300 | 300 | 8ø12 | 1.50% |

| C-5 | 4ø12 | 1.00% | |||||||||

| C-6 | 6ø12 | 1.25% | |||||||||

| C-7 | 8ø12 | 1.50% | |||||||||

| Rectangular | C-17 | 160 | 250 | 950 | 4Ø12 | 30.2 | 50 | 260 | 350 | 8ø12 | 1.50% |

| C-9 | 4ø12 | 1.00% | |||||||||

| C-10 | 6ø12 | 1.24% | |||||||||

| C-11 | 8ø12 | 1.50% | |||||||||

| Circular | C-18 | 160 Diameter | 1020 | 6Ø10 | 28.9 | 50 | 260 Diameter | 6Ø10 | 1.78% | ||

| C-13 | 4Ø10 | 1.48% | |||||||||

| C-14 | 6ø10 | 1.78% | |||||||||

| C-15 | 8ø10 | 2.07% | |||||||||

| Column Shape | Column Specimen | Cracking Load (kN) | Ultimate Load (kN) |

|---|---|---|---|

| Square | C-1 | 562 | 1229 |

| C-16 | 1445 | 2883 | |

| C-5 | 550 | - | |

| C-6 | 588 | - | |

| C-7 | 541 | - | |

| Rectangular | C-8 | 502 | 1073 |

| C-17 | 1425 | 2822 | |

| C-9 | 541 | - | |

| C-10 | 499 | - | |

| C-11 | 471 | - | |

| Circular | C-12 | 318 | 635 |

| C-18 | 854 | 1709 | |

| C-13 | 263 | - | |

| C-14 | 277 | - | |

| C-15 | 301 | - |

| Column Shape | Column Specimen | Ultimate Load (kN) | % Increase | % Decrease |

|---|---|---|---|---|

| Square | C-1 | 1229 | --- | --- |

| C-16 | 2883 | 134.5 | --- | |

| C-5 | 2225 | 81.0 | --- | |

| C-6 | 2253 | 83.3 | --- | |

| C-7 | 2430 | 97.7 | 15.7 | |

| Rectangular | C-8 | 1073 | --- | --- |

| C-17 | 2822 | 163.0 | --- | |

| C-9 | 2155 | 100.8 | --- | |

| C-10 | 2324 | 116.6 | --- | |

| C-11 | 2423 | 125.8 | 14.1 | |

| Circular | C-12 | 635 | --- | --- |

| C-18 | 1709 | 169.1 | --- | |

| C-13 | 1411 | 122.2 | --- | |

| C-14 | 1479 | 132.9 | 13.5 | |

| C-15 | 1498 | 135.9 | --- |

| Column Shape | Column Specimen | Ultimate Load (kN) | Pu.f. ACI-318 (kN) | Ratio of Pu.Ex/Pu.ACI |

|---|---|---|---|---|

| Square | C-1 | 1229 | 1208 | 1.02 |

| C-16 | 2883 | 3050 | 0.95 | |

| C-5 | 2225 | 2864 | 0.78 | |

| C-6 | 2253 | 2957 | 0.76 | |

| C-7 | 2430 | 3050 | 0.80 | |

| Rectangular | C-8 | 1073 | 1097 | 0.98 |

| C-17 | 2822 | 3009 | 0.94 | |

| C-9 | 2155 | 2823 | 0.76 | |

| C-10 | 2324 | 2916 | 0.80 | |

| C-11 | 2423 | 3009 | 0.81 | |

| Circular | C-12 | 635 | 628 | 1.01 |

| C-18 | 1709 | 1761 | 0.97 | |

| C-13 | 1411 | 1701 | 0.83 | |

| C-14 | 1479 | 1761 | 0.84 | |

| C-15 | 1498 | 1821 | 0.82 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed Sayed, A.; Mohamed Rashwan, M.; Emad Helmy, M. Experimental Behavior of Cracked Reinforced Concrete Columns Strengthened with Reinforced Concrete Jacketing. Materials 2020, 13, 2832. https://doi.org/10.3390/ma13122832

Mohamed Sayed A, Mohamed Rashwan M, Emad Helmy M. Experimental Behavior of Cracked Reinforced Concrete Columns Strengthened with Reinforced Concrete Jacketing. Materials. 2020; 13(12):2832. https://doi.org/10.3390/ma13122832

Chicago/Turabian StyleMohamed Sayed, Ahmed, Mohamed Mohamed Rashwan, and Mohamed Emad Helmy. 2020. "Experimental Behavior of Cracked Reinforced Concrete Columns Strengthened with Reinforced Concrete Jacketing" Materials 13, no. 12: 2832. https://doi.org/10.3390/ma13122832

APA StyleMohamed Sayed, A., Mohamed Rashwan, M., & Emad Helmy, M. (2020). Experimental Behavior of Cracked Reinforced Concrete Columns Strengthened with Reinforced Concrete Jacketing. Materials, 13(12), 2832. https://doi.org/10.3390/ma13122832