Modeling and Experimental Study of the Localized Electrochemical Micro Additive Manufacturing Technology Based on the FluidFM

Abstract

1. Introduction

2. Experimental Section

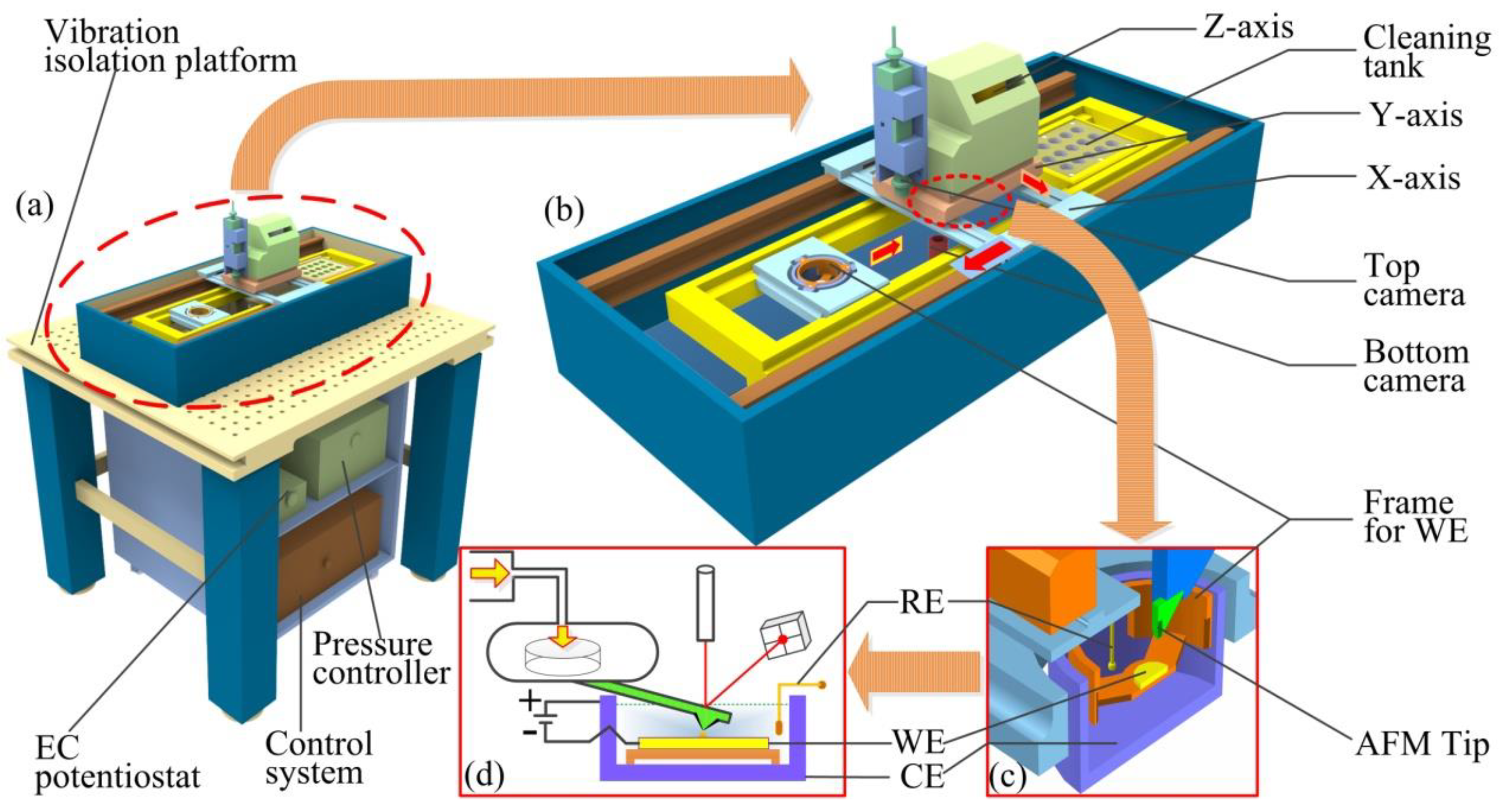

2.1. Experimental Equipment

2.2. Experimental Parameters

2.3. Characterizations

3. Results and Discussion

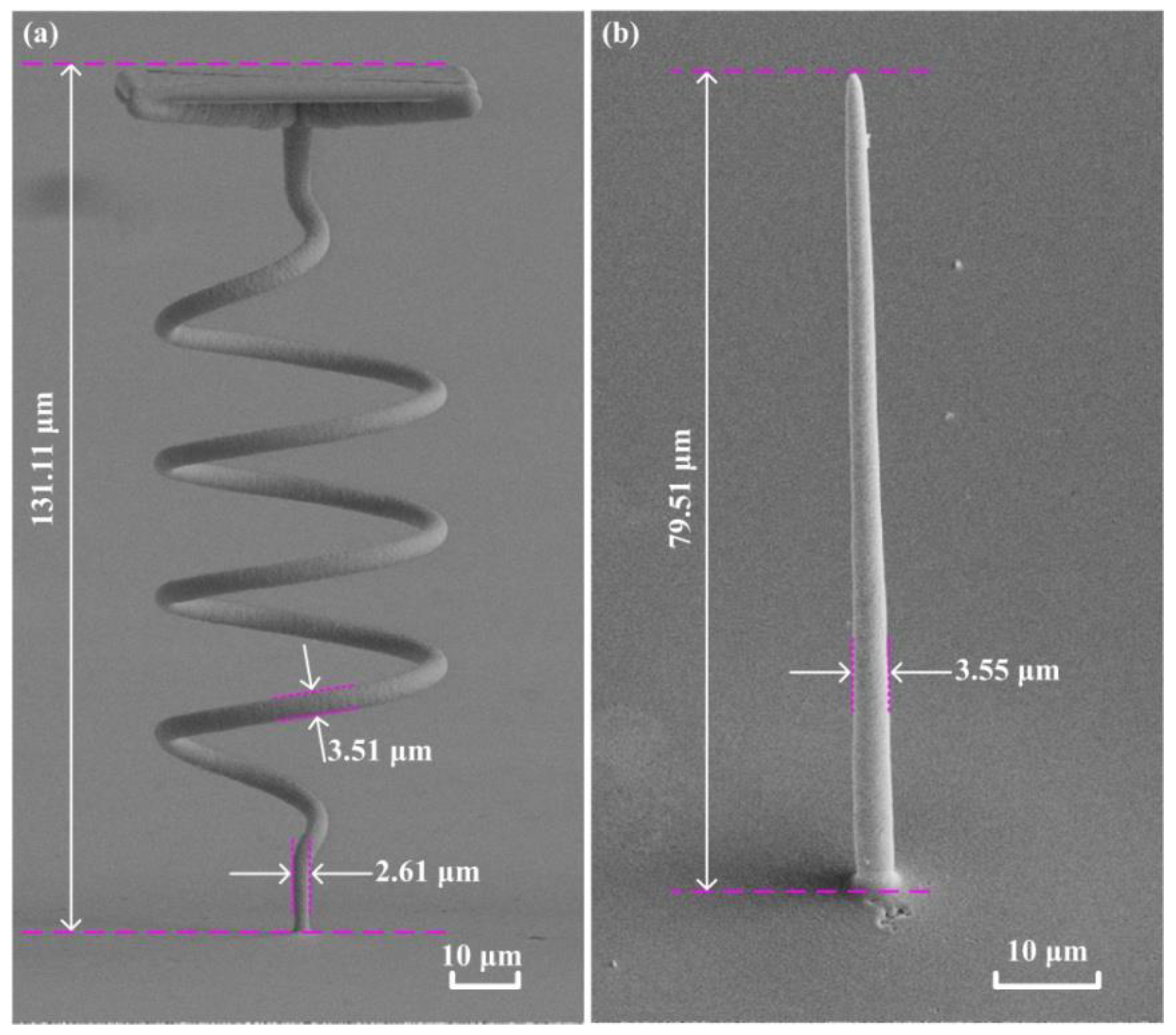

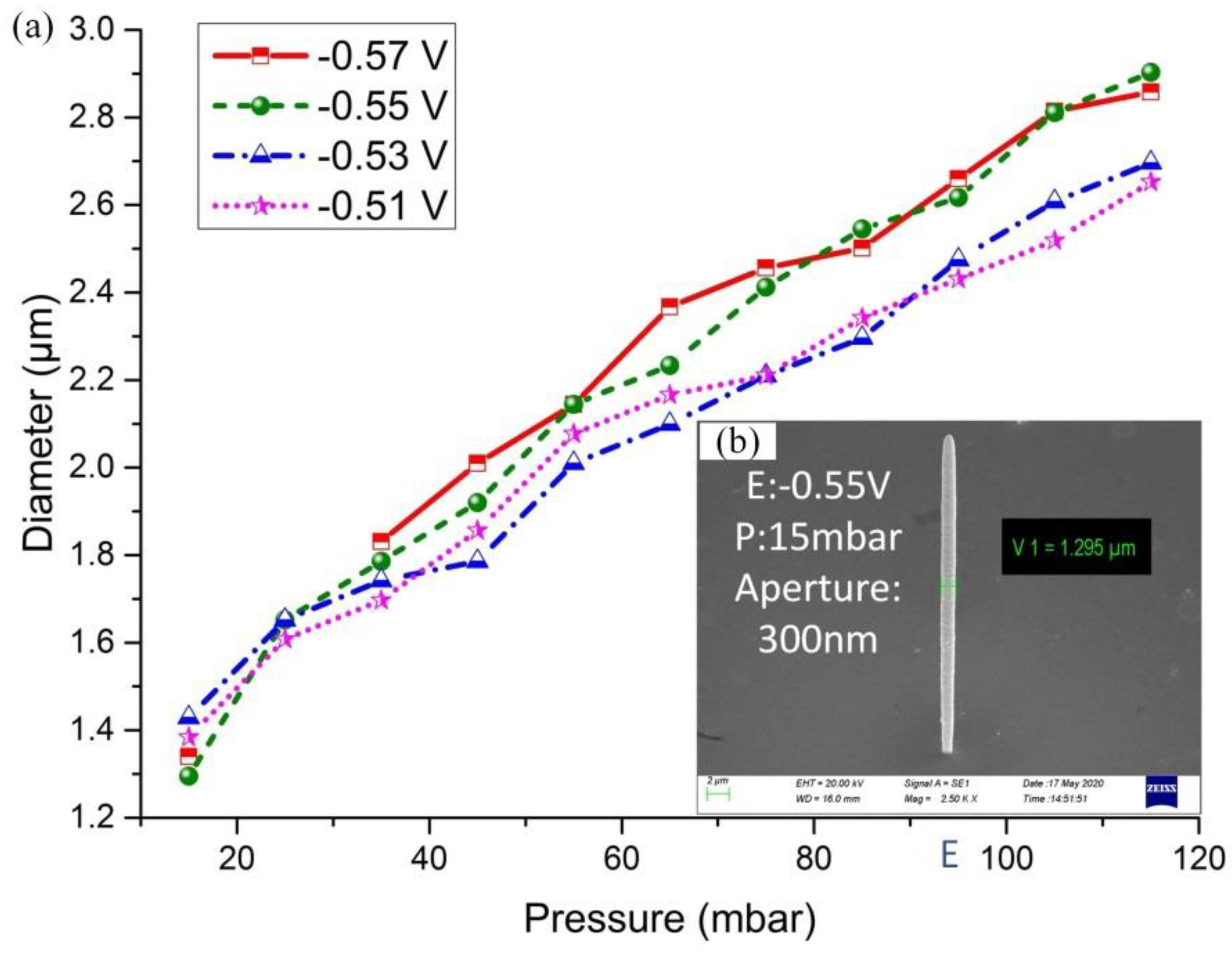

3.1. Wire Structure

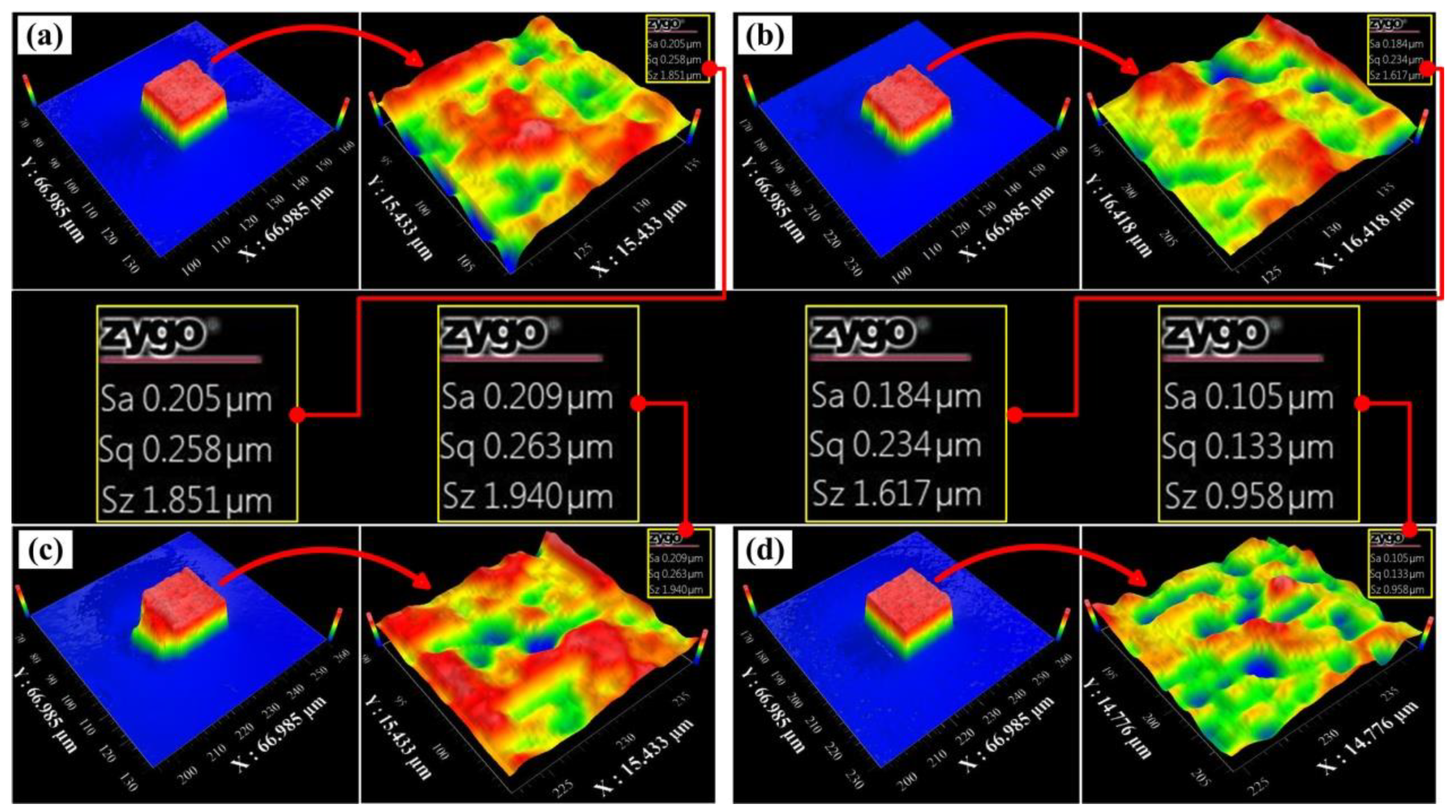

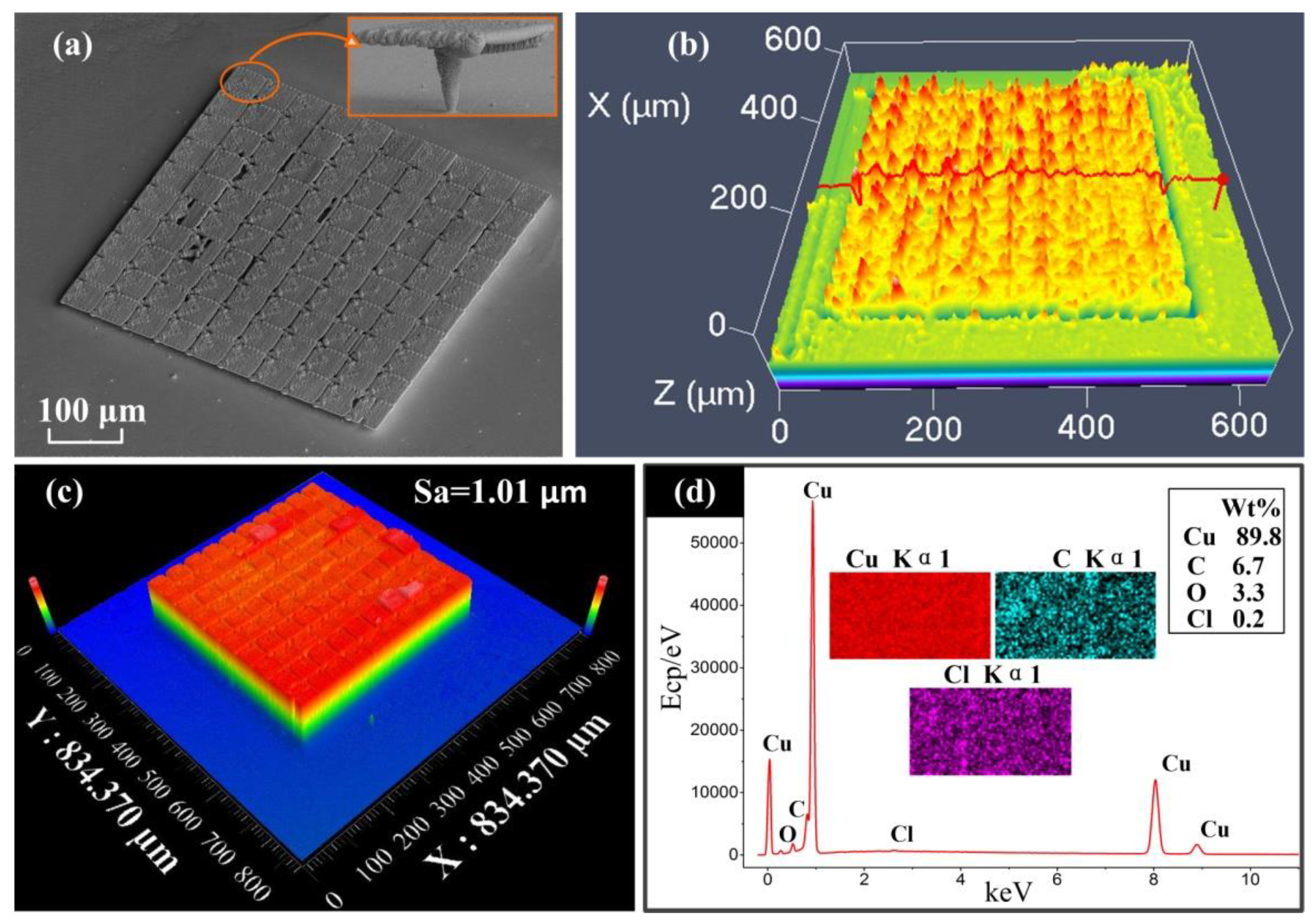

3.2. Volume Structure

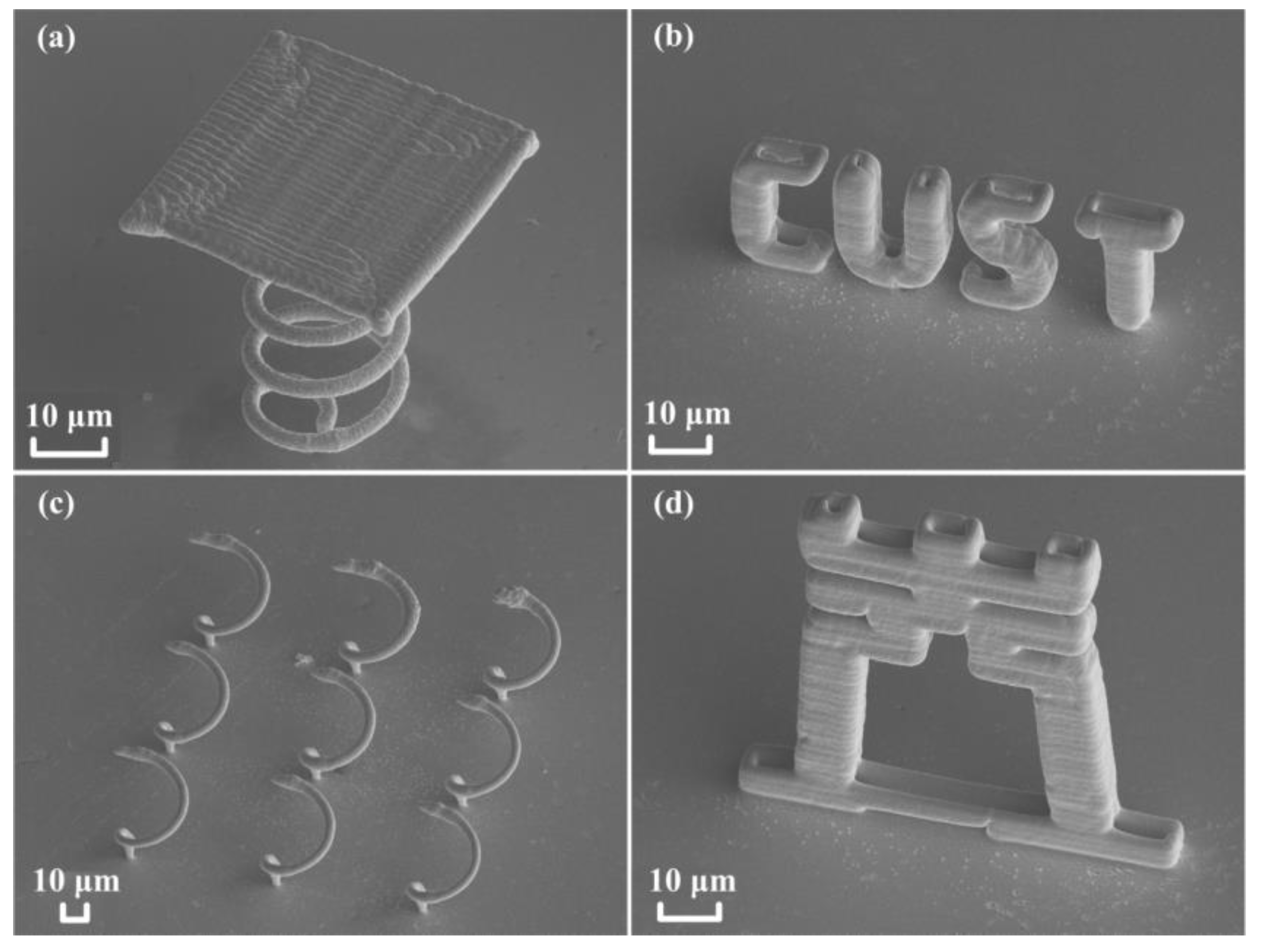

3.3. Complex Structure

3.4. Big Area Structure

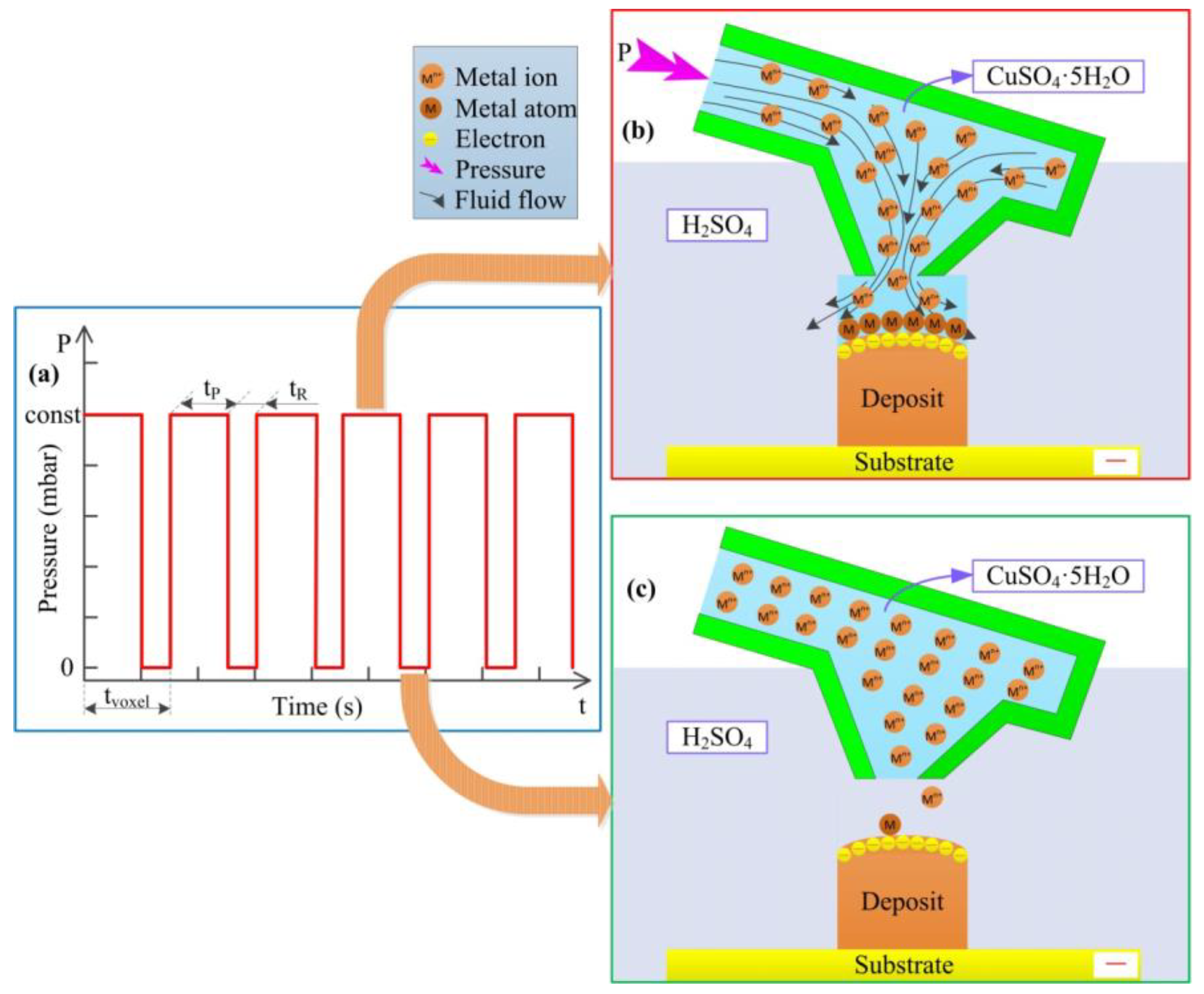

3.5. Principles of Deposition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rajput, M.S.; Pandey, P.M.; Jha, S. Micromanufacturing by selective jet electrodeposition process. Int. J. Adv. Manuf. Technol. 2013, 76, 61–67. [Google Scholar] [CrossRef]

- Seol, S.K.; Kim, D.; Lee, S.; Kim, J.H.; Chang, W.S.; Kim, J.T. Electrodeposition-based 3D Printing of Metallic Microarchitectures with Controlled Internal Structures. Small 2015, 11, 3896–3902. [Google Scholar] [CrossRef] [PubMed]

- Tseng, Y.T.; Lin, J.C.; Ciou, Y.J.; Hwang, Y.R. Fabrication of a novel microsensor consisting of electrodeposited ZnO nanorod-coated crossed Cu micropillars and the effects of nanorod coating morphology on the gas sensing. ACS Appl. Mater. Interfaces 2014, 6, 11424–11438. [Google Scholar] [CrossRef]

- Aebersold, M.J.; Dermutz, H.; Saenz Cogollo, J.F.; Han, H.; Demkó, L.; Zambelli, T.; Vörös, J. Local Chemical Stimulation Of Neurons Using Fluidfm Technology Combined With Microelectrode Arrays. In Proceedings of the 19th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Gyeongju-si, Korea, 25–29 October 2015; pp. 653–655. [Google Scholar]

- Dermutz, H.; Gruter, R.R.; Truong, A.M.; Demko, L.; Voros, J.; Zambelli, T. Local polymer replacement for neuron patterning and in situ neurite guidance. Langmuir 2014, 30, 7037–7046. [Google Scholar] [CrossRef] [PubMed]

- Jansson, A.; Thornell, G.; Johansson, S. High Resolution 3D Microstructures Made by LocalizedElectrodeposition of Nickel. J. Electrochem. Soc. 2000, 147, 1810–1817. [Google Scholar] [CrossRef]

- Amarouch, M.Y.; El Hilaly, J.; Mazouzi, D. AFM and FluidFM Technologies: Recent Applications in Molecular and Cellular Biology. Scanning 2018, 2018, 7801274. [Google Scholar] [CrossRef]

- Nageswaran, T.A.; Tomas, B.; Philipp, H.; Uta, K.; Anders, W. Influence of surface features for increased heat dissipation on tool wear. Materials 2018, 11, 664. [Google Scholar]

- Lian, Z.; Xu, J.; Yu, Z.; Yu, P.; Ren, W.; Wang, Z.; Yu, H. Bioinspired reversible switch between underwater superoleophobicity/superaerophobicity and oleophilicity/aerophilicity and improved antireflective property on the nanosecond laser-ablated superhydrophobic titanium surfaces. ACS Appl. Mater. Interfaces 2020, 12, 6573–6580. [Google Scholar] [CrossRef]

- Yusof, M.Q.M.; Harun, H.N.S.B.; Bahar, R. Experimental investigation of minimum quantity lubrication in meso-scale milling with varying tool diameter. IOP Conf. Ser. Mater. Sci. Eng. 2018, 290, 012035. [Google Scholar] [CrossRef]

- Han, J.; Lin, J.; Li, Z.; Lu, M.; Zhang, J. Design and computational optimization of elliptical vibration-assisted cutting system with a novel flexure structure. IEEE Trans. Ind. Electron. 2018, 66, 1151–1161. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Yu, H.; Yu, Z.; Li, Y.; Du, Q. Process characteristics of laser-assisted micro machining of SiCp/2024Al composites. Int. J. Adv. Manuf. Technol. 2018, 94, 3679–3690. [Google Scholar] [CrossRef]

- He, Z.R.; Luo, S.T.; Liu, C.S.; Jie, X.H.; Lian, W.Q. Hierarchical micro/nano structure surface fabricated by electrical discharge machining for anti-fouling application. J. Mater. Res. Technol. 2019, 8, 3878–3890. [Google Scholar] [CrossRef]

- Zhao, X.; Iyer, A.; Promoppatum, P.; Yao, S.-C. Numerical modeling of the thermal behavior and residual stress in the direct metal laser sintering process of titanium alloy products. Addit. Manuf. 2017, 14, 126–136. [Google Scholar] [CrossRef]

- Roy, N.K.; Behera, D.; Dibua, O.G.; Foong, C.S.; Cullinan, M.A. A novel microscale selective laser sintering (μ-SLS) process for the fabrication of microelectronic parts. Microsyst. Nanoeng. 2019, 5, 1–14. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Gunasekaran, S.; Lewis, J.A. Laser-assisted direct ink writing of planar and 3D metal architectures. Proc. Natl. Acad. Sci. USA 2016, 113, 6137–6142. [Google Scholar] [CrossRef] [PubMed]

- Park, J.U.; Hardy, M.; Kang, S.J.; Barton, K.; Adair, K.; Mukhopadhyay, D.K.; Lee, C.Y.; Strano, M.S.; Alleyne, A.G.; Georgiadis, J.G.; et al. High-resolution electrohydrodynamic jet printing. Nat. Mater. 2007, 6, 782–789. [Google Scholar] [CrossRef]

- Fowlkes, J.D.; Winkler, R.; Lewis, B.B.; Stanford, M.G.; Plank, H.; Rack, P.D. Simulation-Guided 3D Nanomanufacturing via Focused Electron Beam Induced Deposition. ACS Nano 2016, 10, 6163–6172. [Google Scholar] [CrossRef]

- Losilla, N.S.; Oxtoby, N.S.; Martinez, J.; Garcia, F.; Garcia, R.; Mas-Torrent, M.; Veciana, J.; Rovira, C. Sub-50 nm positioning of organic compounds onto silicon oxide patterns fabricated by local oxidation nanolithography. Nanotechnology 2008, 19, 455308. [Google Scholar] [CrossRef]

- Garcia, R.; Knoll, A.W.; Riedo, E. Advanced scanning probe lithography. Nat. Nanotechnol. 2014, 9, 577. [Google Scholar] [CrossRef]

- Zheng, X.; Deotte, J.; Alonso, M.P.; Farquar, G.R.; Weisgraber, T.H.; Gemberling, S.; Lee, H.; Fang, N.; Spadaccini, C.M. Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Rev. Sci. Instrum. 2012, 83, 125001. [Google Scholar] [CrossRef]

- Born, D.; Wagner, T.; Krech, W.; Hubner, U.; Fritzsch, L. Fabrication of Ultrasmall Tunnel Junctions by Electron Beam Direct-Writing. IEEE Trans. Appl. Supercond. 2001, 11, 373–376. [Google Scholar] [CrossRef]

- Kawata, S.; Sun, H.B.; Tanaka, T.; Takada, K. Finer features for functional microdevices. Nature 2001, 412, 697–698. [Google Scholar] [CrossRef] [PubMed]

- Suryavanshi, A.P.; Yu, M.-F. Probe-based electrochemical fabrication of freestanding Cu nanowire array. Appl. Phys. Lett. 2006, 88, 083103. [Google Scholar] [CrossRef]

- Kamaraj, A.; Lewis, S.; Sundaram, M. Numerical Study of Localized Electrochemical Deposition for Micro Electrochemical Additive Manufacturing. Procedia CIRP 2016, 42, 788–792. [Google Scholar] [CrossRef]

- Brant, A.M.; Sundaram, M. A Fundamental Study of Nano Electrodeposition Using a Combined Molecular Dynamics and Quantum Mechanical Electron Force Field Approach. Procedia Manuf. 2017, 10, 253–264. [Google Scholar] [CrossRef]

- Said, R.A. Localized electro-deposition (LED): The march toward process development. Nanotechnology 2004, 15, S649–S659. [Google Scholar] [CrossRef]

- Lin, J.C.; Jang, S.B.; Lee, D.L.; Chen, C.C.; Yeh, P.C.; Chang, T.K.; Yang, J.H. Fabrication of micrometer Ni columns by continuous and intermittent microanode guided electroplating. J. Micromech. Microeng. 2005, 15, 2405–2413. [Google Scholar] [CrossRef]

- Nelson, J.B.; Wisecarver, Z.; Schwartz, D.T. Electrochemical printing: Mass transfer effects. J. Micromech. Microeng. 2007, 17, 1192–1199. [Google Scholar] [CrossRef]

- Hu, J.; Yu, M.F. Meniscus-confined three-dimensional electrodeposition for direct writing of wire bonds. Science 2010, 329, 313–316. [Google Scholar] [CrossRef]

- Hirt, L.; Grüter, R.R.; Berthelot, T.; Cornut, R.; Vörös, J.; Zambelli, T. Local surface modification via confined electrochemical deposition with FluidFM. RSC Adv. 2015, 5, 84517–84522. [Google Scholar] [CrossRef]

- Ventrici de Souza, J.; Liu, Y.; Wang, S.; Dorig, P.; Kuhl, T.L.; Frommer, J.; Liu, G.Y. Three-Dimensional Nanoprinting via Direct Delivery. J. Phys. Chem. B 2018, 122, 956–962. [Google Scholar] [CrossRef] [PubMed]

- Ercolano, G.; van Nisselroy, C.; Merle, T.; Voros, J.; Momotenko, D.; Koelmans, W.W.; Zambelli, T. Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers. Micromachines 2019, 11, 6. [Google Scholar] [CrossRef] [PubMed]

- Ercolano, G.; Zambelli, T.; van Nisselroy, C.; Momotenko, D.; Vörös, J.; Merle, T.; Koelmans, W.W. Multiscale Additive Manufacturing of Metal Microstructures. Adv. Eng. Mater. 2020, 22, 1900961. [Google Scholar] [CrossRef]

- Kamaraj, A.B.; Sundaram, M. A study on the effect of inter-electrode gap and pulse voltage on current density in electrochemical additive manufacturing. J. Appl. Electrochem. 2018, 48, 463–469. [Google Scholar] [CrossRef]

- Kamaraj, A.B.; Sundaram, M. A mathematical model of the deposition rate and layer height during electrochemical additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 2367–2374. [Google Scholar] [CrossRef]

- Volgin, V.M.; Kabanova, T.B.; Davydov, A.D. Modeling of local maskless electrochemical deposition of metal microcolumns. Chem. Eng. Sci. 2018, 183, 123–135. [Google Scholar] [CrossRef]

| Technology | Deposition Rate (μm/s) | Minimum Deposition Diameter | High Aspect Ratio | Complex Structure | Formation Quality of Surface | Environmental Requirements | Subsequent Processing |

|---|---|---|---|---|---|---|---|

| LECD-FluidFM | ★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★ | No |

| LECD | ★★★ | ★★★ | ★★★★ | ★★ | ★★★ | ★★★★ | No |

| MCED | ★★ | ★★★★★ | ★★★★ | ★★★★ | ★★★★ | ★★★★★ | No |

| EcP | ★★★ | ★★★★ | ★★★ | ★★★ | ★★★ | ★★★★ | No |

| u-SLS | ★★★★ | ★★★ | ★★★ | ★★★ | ★★★ | ★★★★★ | Yes |

| FEBID | ★ | ★★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ | Yes |

| DIW | ★★★★ | ★★ | ★★★ | ★★★ | ★★★★★ | ★★★★ | Yes |

| MSL | ★★★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | Yes |

| TPA | ★★★ | ★★★★ | ★★★ | ★★★★★ | ★★★★★ | ★★★★★ | Yes |

| Parameter | Value |

|---|---|

| Voltage (V) | −0.52 (Applied on the substrate) |

| Approaching voltage (mV) | 50 |

| Pressure (mbar) | 20 |

| Printing copper solution | CuSO4 (0.5 M); H2SO4 (51 mM); HCl (0.48 mM). |

| Supporting solution | H2SO4 (54 mM); HCl (0.5 mM) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, W.; Xu, J.; Lian, Z.; Yu, P.; Yu, H. Modeling and Experimental Study of the Localized Electrochemical Micro Additive Manufacturing Technology Based on the FluidFM. Materials 2020, 13, 2783. https://doi.org/10.3390/ma13122783

Ren W, Xu J, Lian Z, Yu P, Yu H. Modeling and Experimental Study of the Localized Electrochemical Micro Additive Manufacturing Technology Based on the FluidFM. Materials. 2020; 13(12):2783. https://doi.org/10.3390/ma13122783

Chicago/Turabian StyleRen, Wanfei, Jinkai Xu, Zhongxu Lian, Peng Yu, and Huadong Yu. 2020. "Modeling and Experimental Study of the Localized Electrochemical Micro Additive Manufacturing Technology Based on the FluidFM" Materials 13, no. 12: 2783. https://doi.org/10.3390/ma13122783

APA StyleRen, W., Xu, J., Lian, Z., Yu, P., & Yu, H. (2020). Modeling and Experimental Study of the Localized Electrochemical Micro Additive Manufacturing Technology Based on the FluidFM. Materials, 13(12), 2783. https://doi.org/10.3390/ma13122783