Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

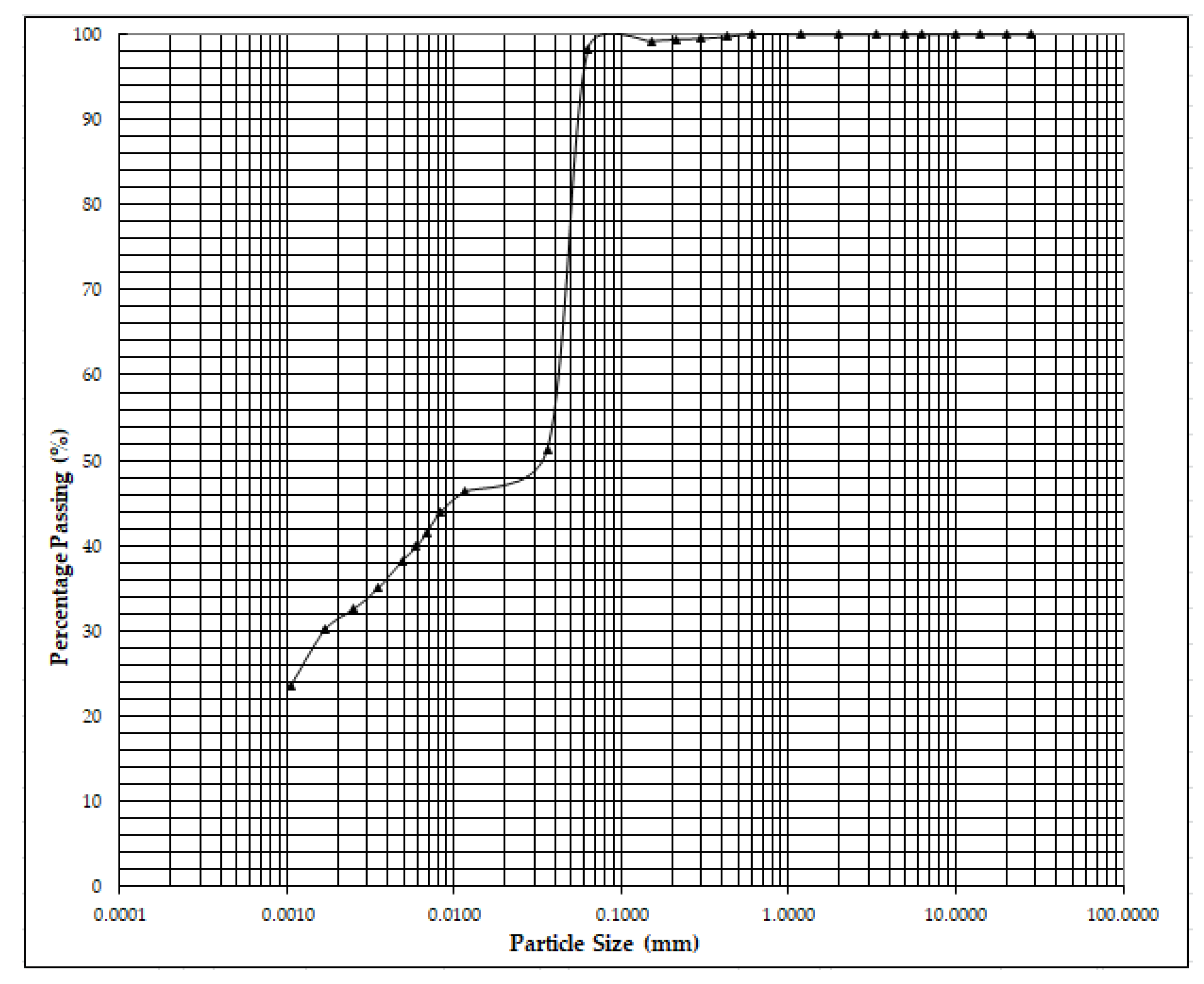

2.1.1. Soils

2.1.2. Coir Fiber

2.1.3. Lime

2.1.4. Fly Ash

2.1.5. Activator

2.2. Method

2.2.1. Sample Preparation

2.2.2. Experimental Procedure

Unconfined Compression Strength Test

Durability Test

Durability Index, Dry Density, Moisture Content, and Weight Loss

2.2.3. Microstructural Analysis

3. Results

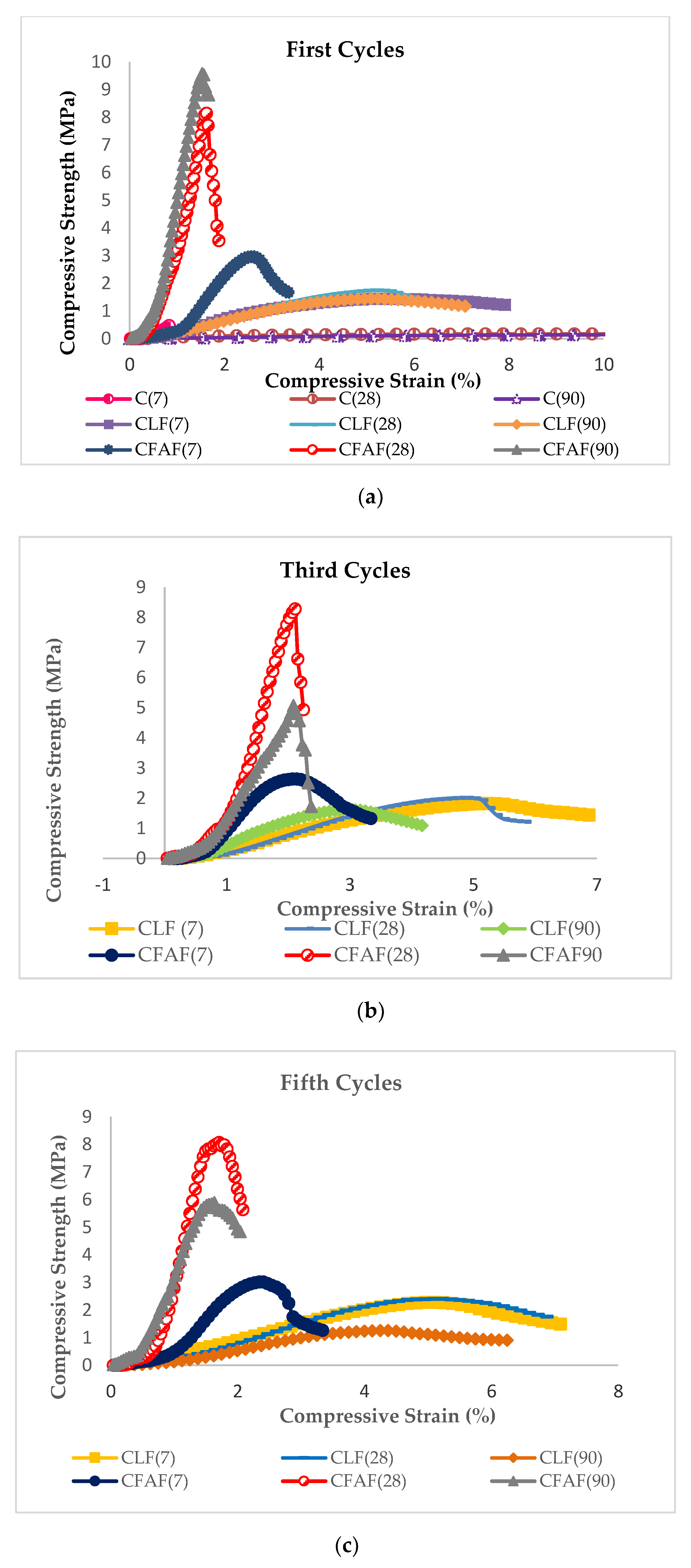

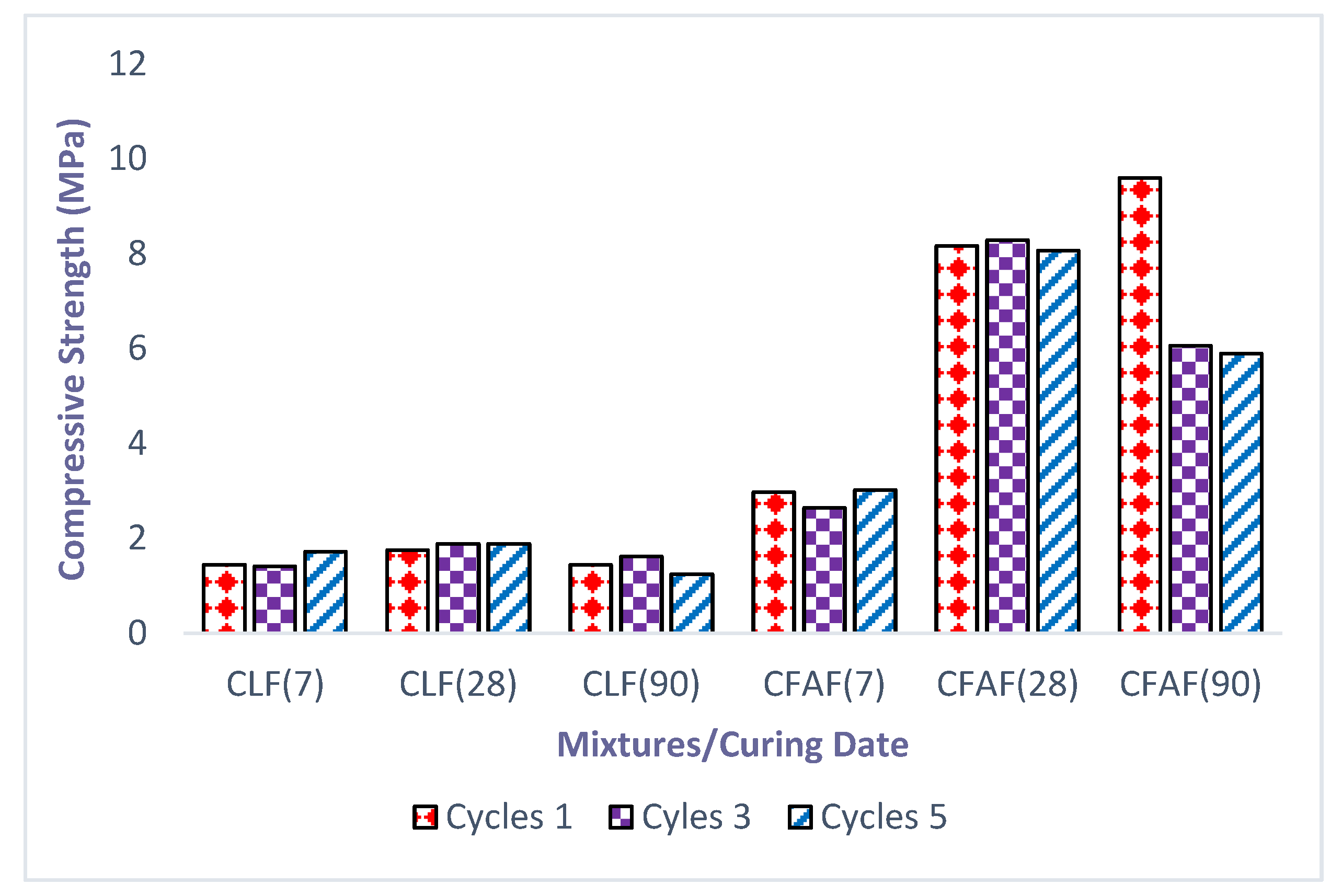

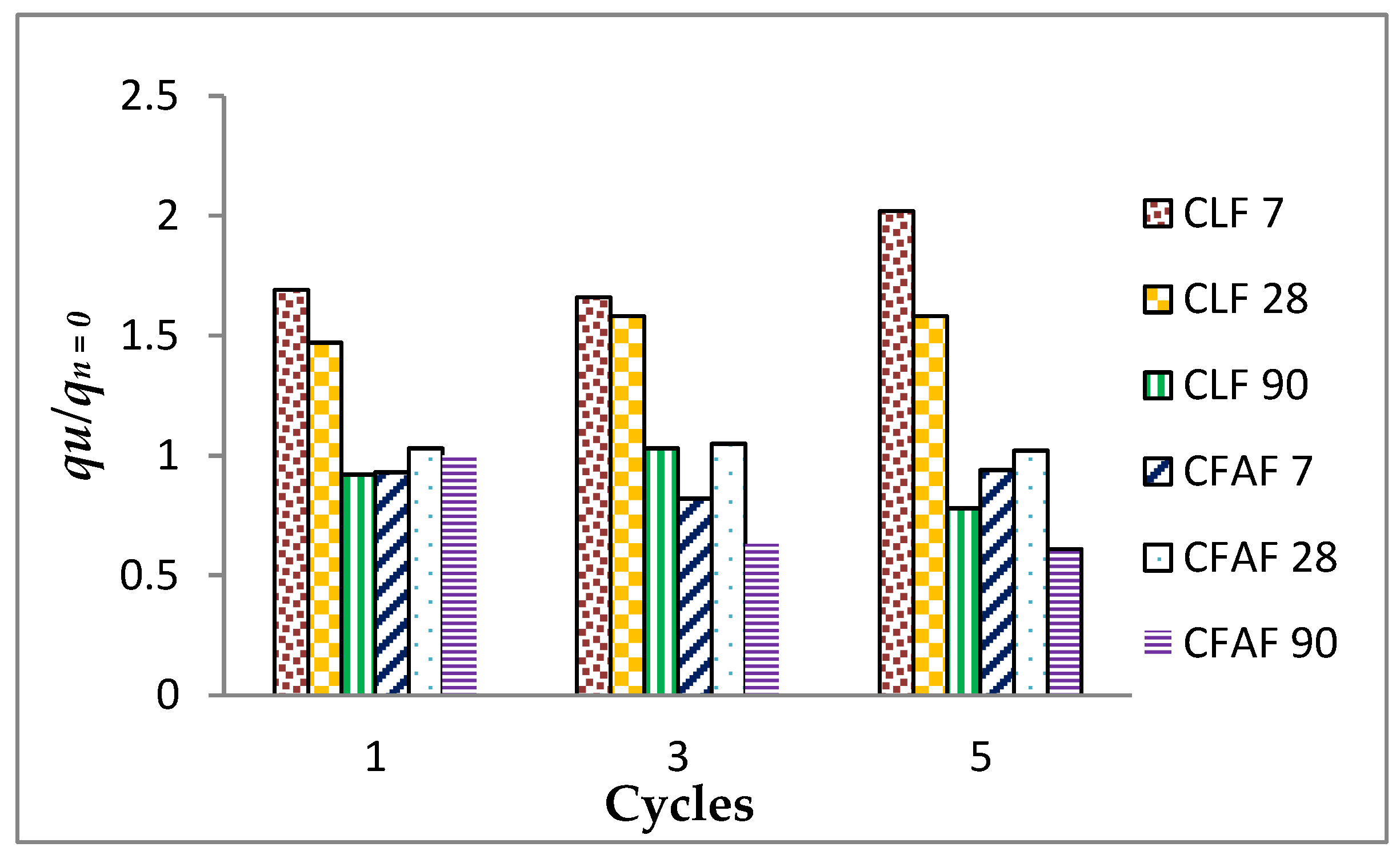

3.1. Effect of Wetting and Drying Cycles on Soil Strength

3.2. Effect of the Durability Index, Wetting/Drying Cycles on Dry Density, Moisture Content, and Weight Loss Percentage

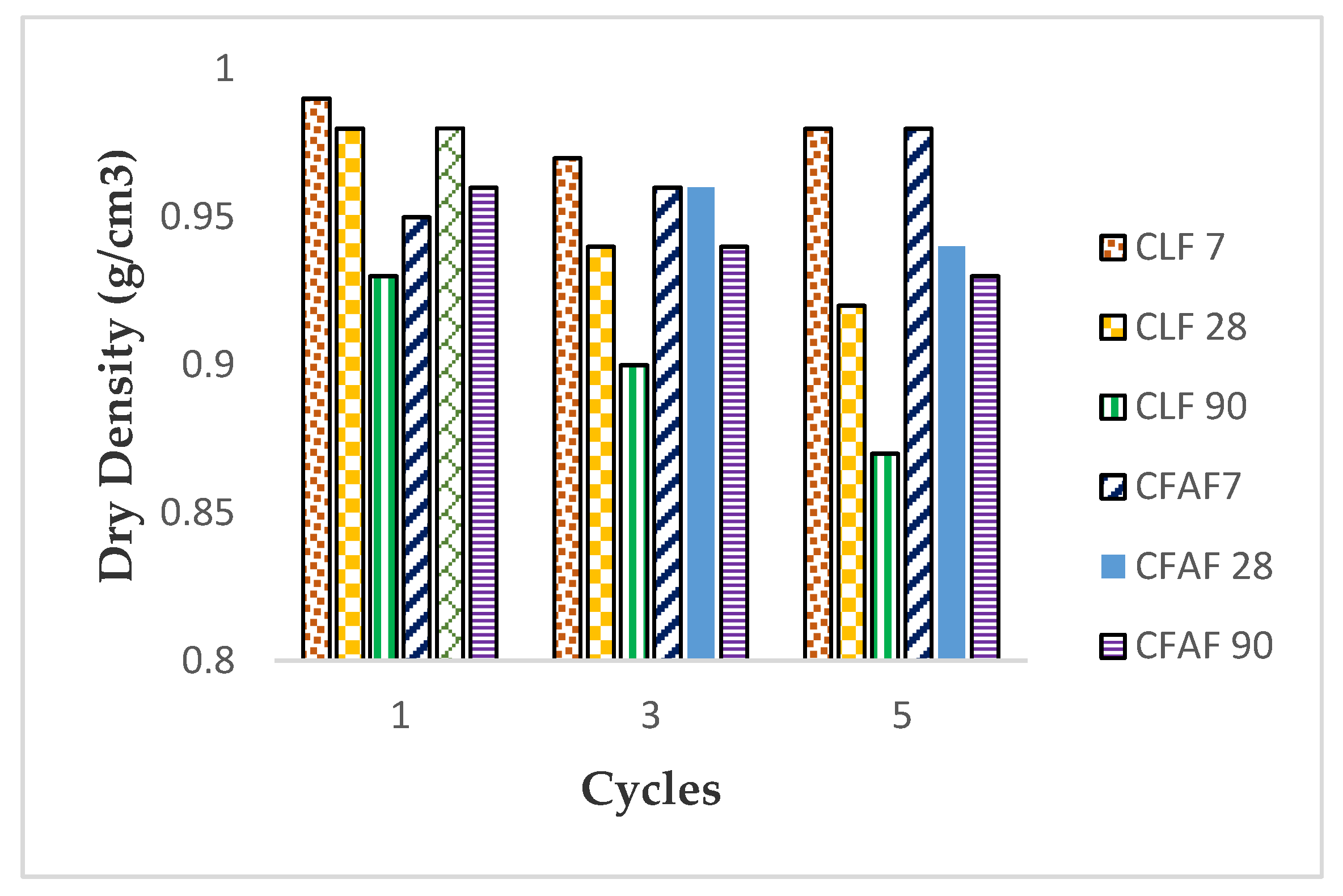

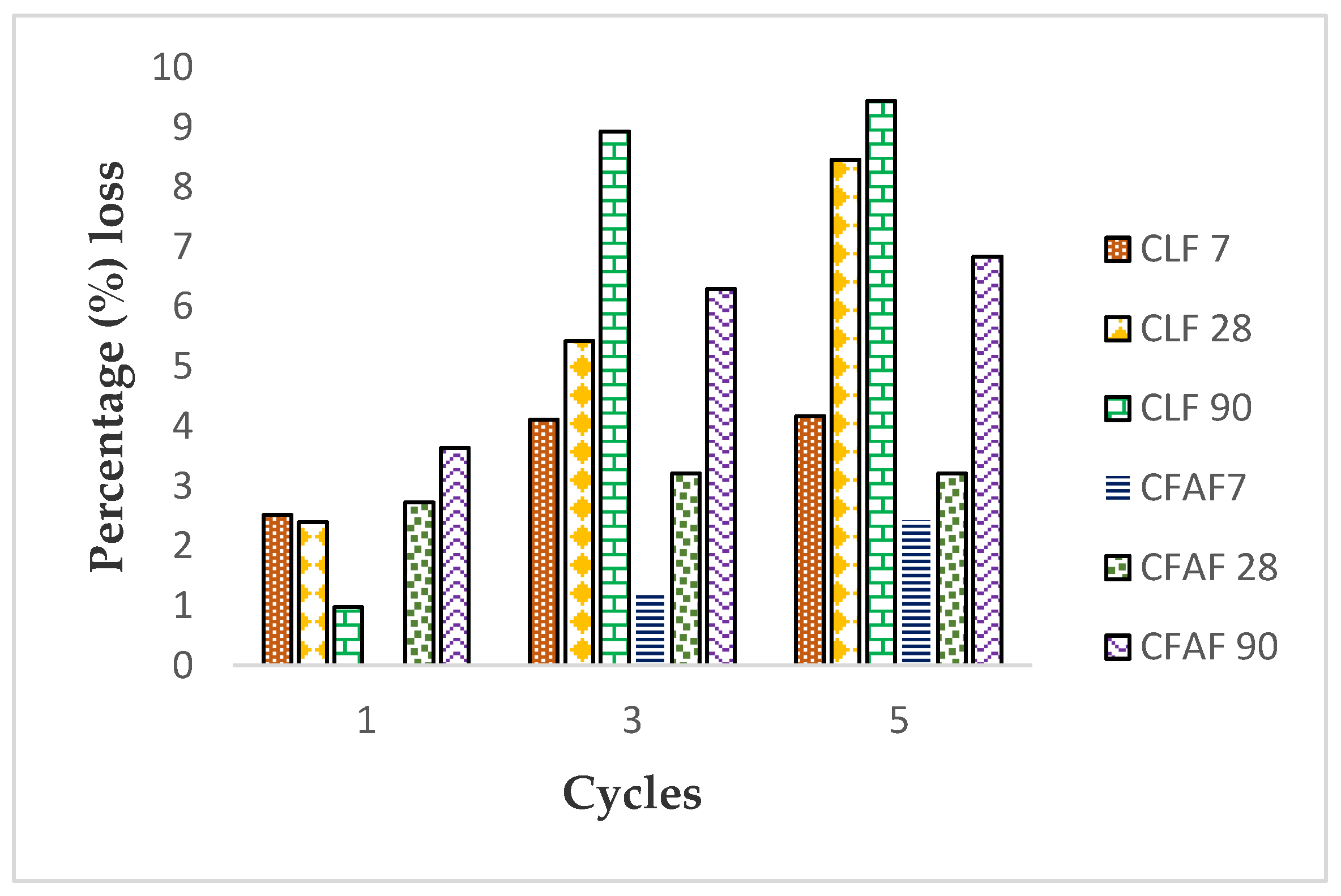

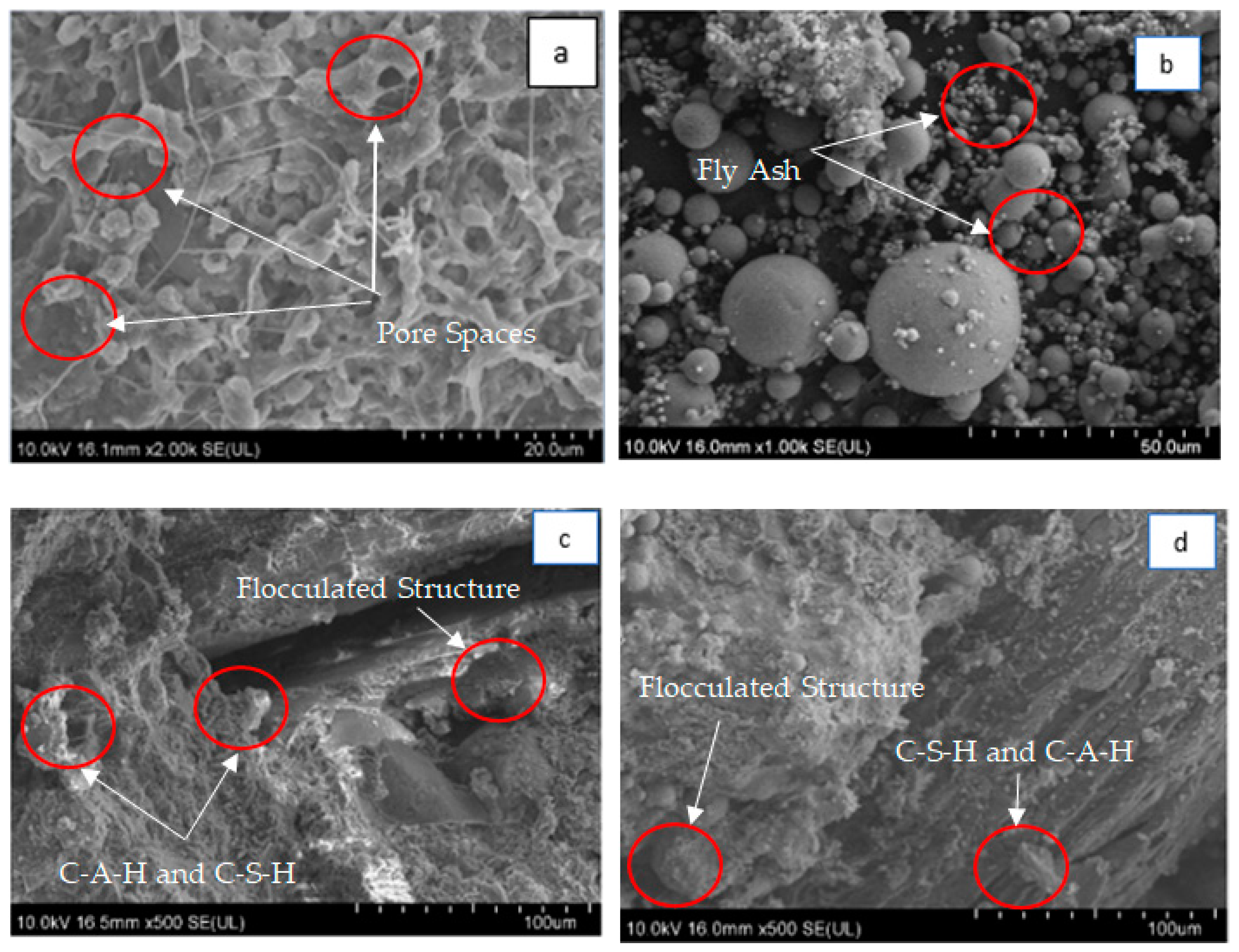

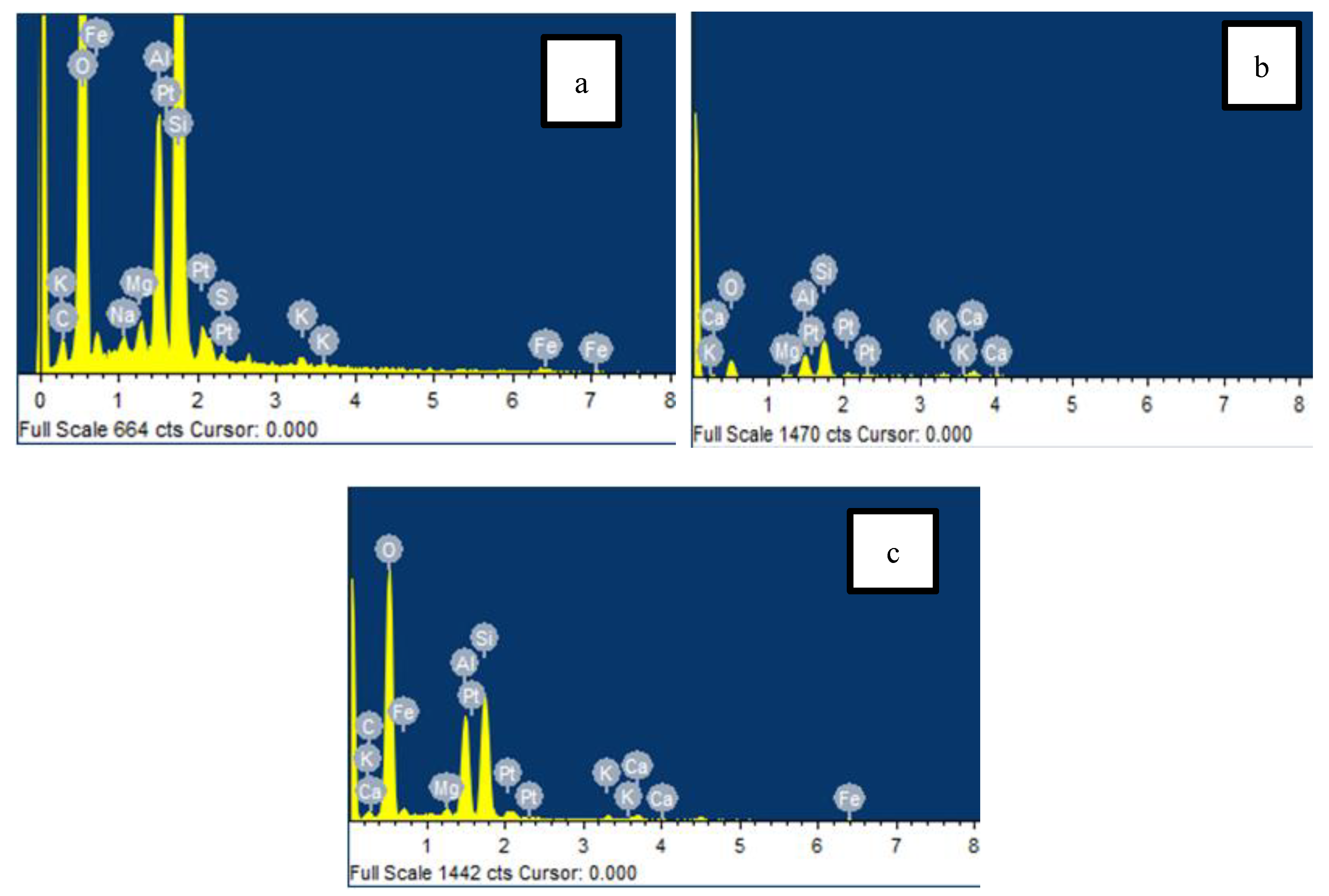

3.3. Microstructural Analysis

4. Conclusions

- The effects of the wetting/drying test on the strength of the soil (for both stabilized lime and AA) for all different curing dates and cycles show a less significant fluctuation of increment and decrement except for a curing period of 90 days, where there is a sharp decrement that occurs at the first three cycles. This may be attributed to the effect of the wetting and drying that changes the formation of the soil occurring within the material with the increase of curing periods;

- The strength of treated soil with lime and AA started to decrease after a curing period of 28 days where the decrements were 13.19% and 38.64%, respectively, notable mostly at the fifth cycle. This is due to the interfacial bonding caused by a chemical reaction that occurred between the soil particles and the stabilizer being reduced, which resulted in loosening the soil particles as the cycle period increased. It is also due to the conditions where the specimens with dried conditions for a long-term duration were then exposed to a wetting/drying cycles, which tends to cause the soil to be in a moist condition, thus attributing to a decrease in soil strength;

- Dry density and water content versus cycles show a similar trend for both soils stabilized with lime and AA where decrement occurs for dry density and increment of the water content for all specimens, respectively. This may be due to the usage of the stabilizer and the fiber inclusion that helps in lowering the dry density of the soil and the ability of the stabilizer to absorb a large amount of water, as for lime and alkaline activation;

- An increasing trend of the soil percentage loss was observed with the increase of the wetting/drying cycles for both soil stabilization treatments with an accumulation of 3% to 5% increment, except for the first cycles of treatment with lime. This is due to the absorption of water into the soil voids that forms between the binders, thus leading to soil loss;

- Analysis of the FESEM and EDX results shows a dense and compacted soil with fewer visible pores after a curing period of 90 days. The admixtures help in filling the pores and strengthen the soil. From the EDX result, it is also confirmed that there is a formation of CSH and CAH (Figure 8) gels that contributes to the interlocking between the soil particles and thus strengthens the soil although there is some decrement and increment of the physical and mechanical properties of the soil.

Author Contributions

Funding

Conflicts of Interest

References

- Rahman, Z.A.; Yaacob, W.Z.W.; Rahim, S.A.; Lihan, T.; Idris, W.M.R.; Sani, W.M. Geotechnical characterization of marine clay as potential liner material. Sains Malays. 2013, 42, 1081–1089. [Google Scholar]

- Emmanuel, E.; Lau, C.C.; Anggraini, V.; Pasbakhsh, P. Stabilization of a soft marine clay using halloysite nanotubes: A multi-scale approach. Appl. Clay Sci. 2019, 173, 65–78. [Google Scholar] [CrossRef]

- Zainuddin, N.; Yunus, N.Z.M.; Al-Bared, M.A.M.; Marto, A.; Harahap, I.S.H.; Rashid, A.S.A. Measuring the engineering properties of marine clay treated with disposed granite waste. Measurement 2019, 131, 50–60. [Google Scholar] [CrossRef]

- Jiang, N.J.; Du, Y.J.; Liu, S.Y.; Wei, M.K.; Horpibulsuk, S.; Arulrajah, A. Multi-scale laboratory evaluation of the physical, mechanical and microstructural properties of soft highway subgrade soil stabilized with calcium carbide residue. Can. Geotech. J. 2016, 53, 373–383. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physiochemical, microstructural and mechanical characteristic of a plastic silt. Eng. Geol. 2013, 16, 255–261. [Google Scholar] [CrossRef]

- Pomakhina, E.; Deneele, D.; Gaillot, A.C.; Paris, M.; Ouvrard, G. Solid state nmr investigation of pozzolanic reaction occuring in lime-treated Ca-bentonite. Cem. Concr. Res. 2012, 42, 626–632. [Google Scholar] [CrossRef]

- Alsafi, S.; Farzadnia, N.; Asadi, A.; Huat, B.K. Collapsibility potential of gypseous soil stabilized with fly ash geopolymer; characterization and assessment. Constr. Build. Mater. 2017, 137, 390–409. [Google Scholar] [CrossRef]

- Cristelo, N.; Cunha, V.M.; Dias, M.; Gomes, A.T.; Miranda, T.; Araújo, N. Influence of discrete fibre reinforcement on the uniaxial compression response and seismic wave velocity of a cement stabilised sandy-clay. Geotext. Geomembr. 2015, 43, 1–13. [Google Scholar] [CrossRef]

- Sargent, P.; Hughes, P.N.; Rouainia, M.; White, M.L. The use of alkali activated waste binders in enhancing the mechanical properties and durability of soft alluvial soils. Eng. Geol. 2013, 152, 96–108. [Google Scholar] [CrossRef]

- Teing, T.T.; Huat, B.B.K.; Anggraini, V.; Shukla, S. Improving the engineering behaviour of residual soil with fly ash and treated natural fibres in alkaline condition. Int. J. Geotech. Eng. 2019, 1–14. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Syamsir, A.; Huat, B.B. Three point bending flexural strength of cement treated tropical marine soil reinforced by lime treated natural fiber. Measurement 2017, 111, 158–166. [Google Scholar] [CrossRef]

- Correia, A.A.; Oliveira, P.J.V.; Cust’odio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamsawang, P. Use of steel and polypropylene fibers to improve flexural performance of deep soil-cement column. Constr. Build. Mater. 2012, 29, 201–205. [Google Scholar] [CrossRef]

- Botero, E.; Ossa, A.; Sherwell, G.; Ovando-Shelley, E. Stress strain behavior of a silty soil reinforced with polyethylene terephthalate (PET). Geotext. Geomembr. 2015, 43, 363–369. [Google Scholar] [CrossRef]

- Consoli, N.C.; De Moraes, R.R.; Festugato, L. Variables controlling strength of fibre-reinforced cemented soils. Proc. ICE-Ground Improv. 2013, 166, 221–232. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Kamaruddin, F.A.; Nahazanan, H.; Huat, B.B.K.; Anggraini, V. Improvement of marine clay soil using lime and alkaline activation stabilized with inclusion of treated coir fibre. Appl. Sci. 2020, 10, 2129. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Mohamed, M.; Arulrajah, A.; Horpibulsuk, S.; Anggraini, V. Practical approach to predict the shear strength of fibre-reinforced clay. Geosynth. Int. 2017, 25, 50–66. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. J. Elsevier (Compos.) Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Adekunle, K.F. Surface treatments of natural fibres—A review: Part 1. J. Polym. Chem. 2015, 5, 41–46. [Google Scholar] [CrossRef]

- Yew, B.S.; Muhamad, M.; Mohamed, S.B.; Wee, F.H. Effect of alkaline treatment on structural characterisation, thermal degradation and water absorption of coir fibre polymer composites. Sains Malays. 2019, 48, 653–659. [Google Scholar] [CrossRef]

- Haque, M.M.; Ali, M.E.; Hasan, M.; Islam, M.N.; Kim, H. Chemical treatment of coir fiber reinforced polypropylene composites. Ind. Eng. Chem. Res. 2012, 51, 3958–3965. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Durability studies of surface-modified coir geotextiles. Geotext. Geomembr. 2018, 46, 699–706. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Sarker, P.K.; Kelly, S.; Yao, Z. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef]

- Rajan, A.; Senan, R.C.; Pavithran, C.; Emilia Abraham, T. Biosoftening of coir fiber using selected microorganisms. Bioprocess Biosyst. Eng. 2005, 28, 165. [Google Scholar] [CrossRef] [PubMed]

- Vishnudas, S.; Hubert, H.G.; Savenije, P.; Der Zaag, V.; Anil, K.R. Coir geotextile for slope stabilization and cultivation—A case study in a highland region of Kerala, South India. Phys. Chem. Earth Parts A/B/C 2012, 47–48, 135–138. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, H.J.; Yu, W.R. Fabrication of long and discontinuous natural fiber reinforced polypropylene biocomposites and their mechanical properties. Fibers Polym. 2009, 10, 83–90. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, Y. Evaluation of statistical strength of bamboo fiber and mechanical properties of fiber reinforced green composites. J. Cent. South Univ. Technol. 2008, 15, 564–567. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Mehta, G.; Mohanty, A.K.; Thayer, K.; Misra, M.; Drzal, L.T. Novel biocomposites sheet molding compounds for low cost housing panel applications. J. Polym. Environ. 2005, 13, 169–175. [Google Scholar] [CrossRef]

- Bordoloi, S.; Hussain, R.; Sen, S.; Garg, A.; Sreedeep, S. Chemically altered natural fiber impregnated soil for improving subgrade strength of pavements. Adv. Civ. Eng. Mater. 2017, 7, 48–63. [Google Scholar] [CrossRef]

- Lee, C.C.; Amaylia, C.A. Effect of treatment on surface modifier and water retention value (WRV) of natural fiber. Aust. J. Basic Appl. Sci. 2015, 9, 101–104. [Google Scholar]

- Saha, P.; Roy, D.; Manna, S.; Adhikari, B.; Sen, R.; Roy, S. Durability of transesterified jute geotextiles. Geotext. Geomembr. 2012, 35, 69–75. [Google Scholar] [CrossRef]

- Adekunle, K.; Åkesson, D.; Skrifvars, M. Biobased composites prepared by compression molding with a novel thermoset resin from soybean oil and a natural-fiber reinforcement. J. Appl. Polym. Sci. 2010, 116, 1759–1765. [Google Scholar] [CrossRef]

- Torres, F.G.; Cubillas, M.L. Study of the interfacial properties of natural fibre reinforced polyethylene. Polym. Test. 2005, 24, 694–698. [Google Scholar] [CrossRef]

- BS 1377-2: 1990. Methods of Test for: Soils for Civil Engineering Purposes-Part 2-Classification Tests; British Standards Institution: London, UK, 1990. [Google Scholar]

- Anggraini, V. Reinforcement Effects of Nano-Modified Coir Fibres on Lime-Treated Marine Clay. Ph.D. Thesis, Universiti Putra Malaysia (UPM), Seri Kembangan, Selangor, Malaysia, 2015. [Google Scholar]

- Sivakumar Babu, G.; Vasudevan, A.; Sayida, M. Use of coir fibers for improving the engineering properties of expansive soils. J. Nat. Fibers 2008, 5, 61–75. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, B.; Ng, C.W.; Tang, C.-S. Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng. Geol. 2006, 87, 230–240. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Kamaruddin, F.A.; Huat, B.B.K.; Anggraini, V.; Nahazanan, H. The tensile strength of coir fiber treated with chemicals. In Proceedings of the 5th GEGEU International Research Seminar, Universiti Putra, Seri Kembangan, Malaysia, 30 October 2018; pp. 1–3. [Google Scholar]

- Anggraini, V.; Asadi, A.; Farzadnia, N.; Jahangirian, H.; Huat, B.B.K. Effects of coir fibers modified with Ca (OH)2 and Mg (OH)2 nanoparticles on mechanical properties of lime-treated marine clay. Geosynth. Int. (ICE) 2016, 23, 206–218. [Google Scholar] [CrossRef]

- Dash, S.K.; Hussain, M. Lime stabilization of soils: Reappraisal. J. Mater. Civ. Eng. 2011, 24, 707–714. [Google Scholar] [CrossRef]

- ASTM C 618. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Pourakbar, S.; Huat, B.B.K.; Asadi, A.; Fasihnikoutalab, M.H. Model study of alkali-activated waste binder for soil stabilization. Int. J. Geosynth. Ground Eng. 2016, 2, 35. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer past. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Kamaruddin, F.A.; Huat, B.B.K.; Anggraini, V.; Nahazanan, H. Modified natural fiber on soil stabilization with lime and alkaline activation treated marine clay. Int. J. 2019, 16, 69–75. [Google Scholar] [CrossRef]

- BS 1377-7: 1990. Methods of Test for: Soils for Civil Engineering Purposes—Part 7—Shear Strength Tests (Total Stress); British Standards Institution: London, UK, 1990. [Google Scholar]

- ASTM D 2166-06. Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; American Society for Testing and Materials (ASTM): Philadelphia, PA, USA, 2003. [Google Scholar]

- EuroSoilStab. Design Guide Soft Soil Stabilisation: Development of Design and Construction Methods to Stabilize Soft Organic Soils; BRE Press: Watford, UK, 2002. [Google Scholar]

- Kamei, T.; Ahmed, A.; Ugai, K. Durability of soft clay stabilized with recycled bassanite and furnace cement mixtures. Jpn. Geotech. Soc. (Soils Found.) 2013, 53, 155–165. [Google Scholar] [CrossRef]

- Muntohar, A.; Hartono, E.; Widianti, A. Engineering properties of silty soil stabilized with lime and rice husk ash and reinforced with waste plastic fiber. J. Mater. Civ. Eng. 2013, 25, 1260–1270. [Google Scholar] [CrossRef]

- ASTM D 559. Standard Test Method for Wetting and Drying Compacted Soil-Cement Mixture; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Cai, Y.; Shi, B.; Gao, W.; Chen, F.J.; Tang, C.S. Experimental study on engineering properties of fibre-lime treated soils. Yantu Gongcheng Xuebao (Chin. J. Geotech. Eng.) 2006, 28, 1283–1287. [Google Scholar]

- Japan Highway Society. JHS Method of Wetting and Drying Test for Water Absorption of Rocks—Method for Soil Testing; Japan Highway Society Handbook; Japan Highway Society: Tokyo, Japan, 2001; pp. 284–286. [Google Scholar]

- Ahmed, A.; Ugai, K. Environmental effects on durability of soil stabilized with recycled gypsum. Cold Reg. Sci. Technol. 2011, 66, 84–92. [Google Scholar] [CrossRef]

- Ramesh, H.; Krishna, K.M.; Mamatha, H. Compaction and strength behavior of lime-coir fiber treated black cotton soil. Geomech. Eng. 2010, 2, 19–28. [Google Scholar] [CrossRef]

- Ravishankar, U.; Raghavan, S. Coir stabilised lateritic soil for pavements. In Proceedings of the Indian Geotechnical Conference, Ahmedabad, India, 14–16 December 2004. [Google Scholar]

- Jiang, N.J.; Du, Y.J.; Kiu, K. Durability of lightweight alkali-activated ground granulated blast furnace slag (GGBS) stabilized clayey soils subjected to sulfate attack. Appl. Clay Sci. 2018, 161, 70–75. [Google Scholar] [CrossRef]

- Seco, A.; Garcia, B.; Prieto, E.; Ramirez, F.; Miqueleiz, L.; Urmeneta, P.; Oroz, V. Types of Waste for the Production of Pozzolanic Materials—A Review; Intech Press: Rijeka, Croatia, 2012. [Google Scholar]

- Dermatas, D.; Meng, X. Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng. Geol. 2003, 70, 377–394. [Google Scholar] [CrossRef]

- Latifi, N.; Meehan, C.L.; Abd Majid, M.Z.; Horpibulsuk, S. Strengthening monmorillionitic and kaolinitic clays using a calcium-based nontraditional additive: A micro-level study. Appl. Clay Sci. 2016, 132–133, 182–193. [Google Scholar] [CrossRef]

- García, S.; Trejo, P.; Ramírez, O.; López-Molina, J.; Hernández, N. Influence of nanosilica on compressive strength of lacustrine soft clays. In Proceedings of the 19th International Conference on Soil Mechanics and Geotechnical Engineering, Seoul, Korea, 17–21 September 2017; pp. 369–372. [Google Scholar]

- Du, Y.J.; Bo, Y.L.; Jin, F.; Liu, C.Y. Durability of reactive magnesia-activated slag stabilized low plasticity clay subjected to drying-wetting cycle. Eur. J. Environ. Civ. Eng. 2016, 20, 215–230. [Google Scholar] [CrossRef]

- Hoy, M.; Rachan, R.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M. Effect of wetting-drying cycles on compressive strength and microstructure of recycled asphalt pavement—Fly ash geopolymer. Constr. Build. Mater. 2017, 144, 624–634. [Google Scholar] [CrossRef]

| Parameter | MC (%) | SG | LL (%) | PL (%) | OC (%) | pH | XRD |

|---|---|---|---|---|---|---|---|

| Value | 72 | 2.57 | 52–72 | 32–40 | 6.88 | 7.5 | Montmorillionite, illite, quartz, kaolinite, and halloysite |

| Coir Fiber | Value |

|---|---|

| Length (cm) | 17–22 |

| Diameter (mm) | 0.18–0.38 |

| Tensile Strength (MPa) | 60–130 |

| Breaking Elongation (%) | 30 |

| Lignin (%) | 44 |

| Cellulose (%) | 48 |

| Ash (%) | 2 |

| Water Soluble (%) | 6 |

| Chemical Composition | SiO2 | Fe2O3 | Al2O3 | CaO |

|---|---|---|---|---|

| % by weight | 57.47 | 4.71 | 15.37 | 3.32 |

| Types of Soil | Designation Mix | Curing Period (Days) | Repetitive Sample | Number of Samples |

|---|---|---|---|---|

| C | Untreated clay soil | 72,890 | 3 | 3 × 3 = 9 |

| CLF | Clay, 5% of lime, 1% of fiber | 72,890 | 3 | 3 × 3 = 9 |

| CFAF | Clay, 60% of FA, 1% of fiber | 72,890 | 3 | 3 × 3 = 9 |

| Total No of Sample | 27 | |||

| Mixture | Curing Period (Days) | Element (Wt %) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Si | Al | Ca | Mg | Na | C | O | Si/Al Al/Si | ||

| Clay | 90 | 9.35 | 4.74 | - | 1.52 | 0.91 | 2.82 | 18.37 | 1.97 0.51 |

| CLF | 90 | 28.18 | 12.46 | 11.96 | 1.33 | - | - | 30.13 | 2.26 0.43 |

| CFAF | 90 | 22.15 | 6.55 | 3.27 | 0.74 | - | 9.43 | 43.58 | 3.37 0.29 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamaruddin, F.A.; Anggraini, V.; Kim Huat, B.; Nahazanan, H. Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber. Materials 2020, 13, 2753. https://doi.org/10.3390/ma13122753

Kamaruddin FA, Anggraini V, Kim Huat B, Nahazanan H. Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber. Materials. 2020; 13(12):2753. https://doi.org/10.3390/ma13122753

Chicago/Turabian StyleKamaruddin, Fatin Amirah, Vivi Anggraini, Bujang Kim Huat, and Haslinda Nahazanan. 2020. "Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber" Materials 13, no. 12: 2753. https://doi.org/10.3390/ma13122753

APA StyleKamaruddin, F. A., Anggraini, V., Kim Huat, B., & Nahazanan, H. (2020). Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber. Materials, 13(12), 2753. https://doi.org/10.3390/ma13122753