Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition

Abstract

:1. Introduction

2. Materials and Methods

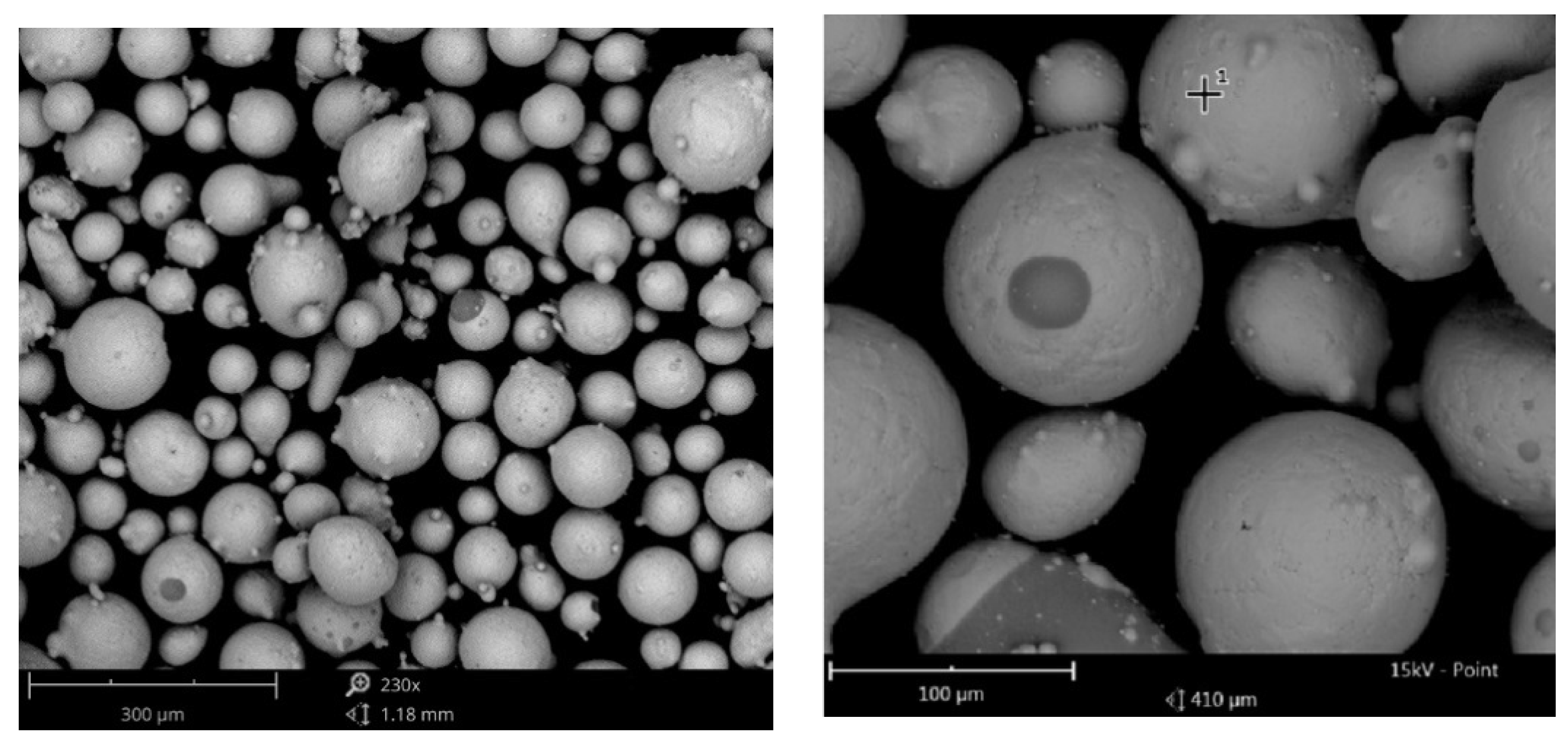

2.1. Materials

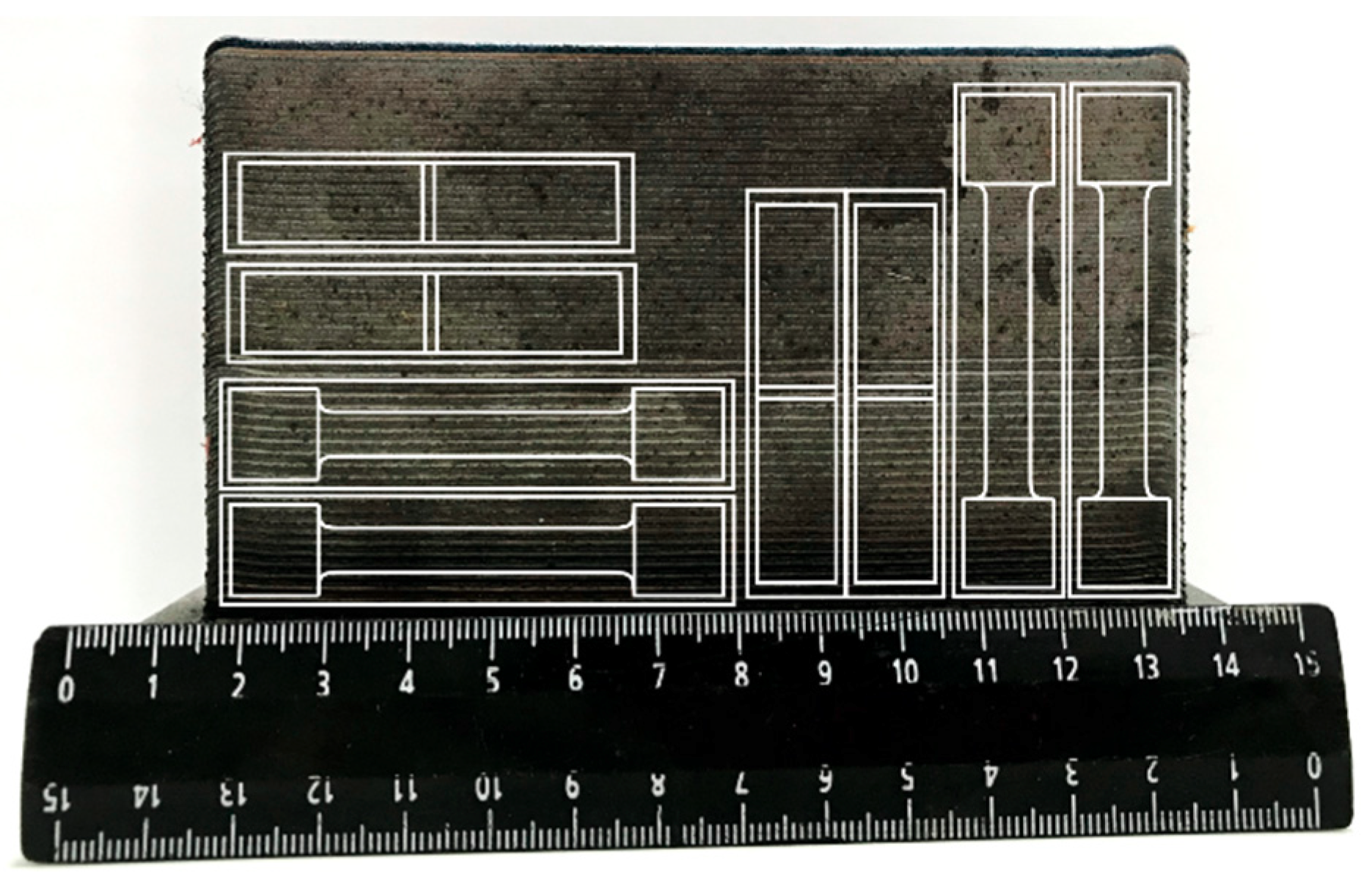

2.2. Fabrication of Samples Using DLD and Their Heat Treatment

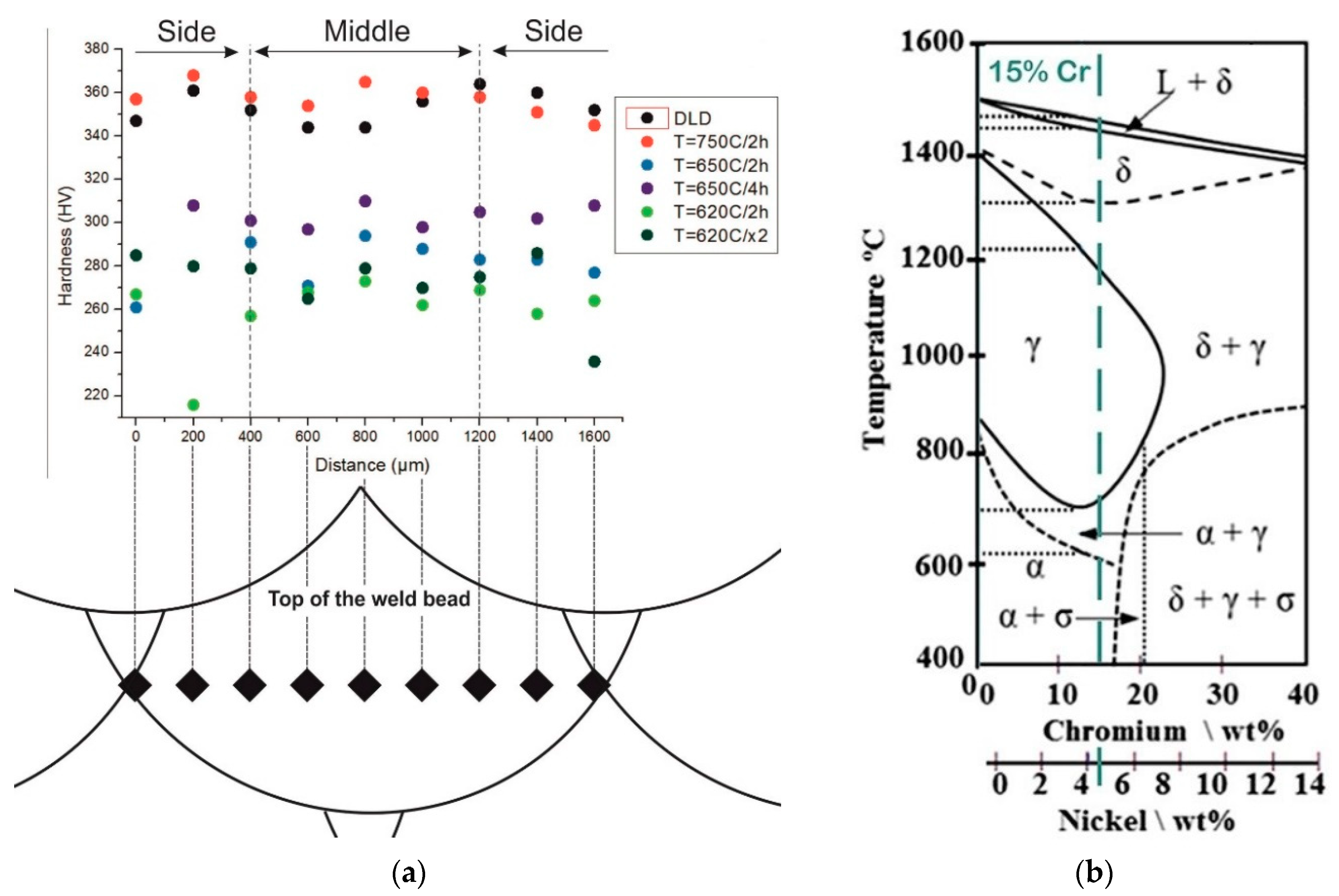

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Khodabakhshi, F.; Farshidianfar, M.; Gerlich, A.; Nosko, M.; Trembošová, V.; Khajepour, A. Microstructure, strain-rate sensitivity, work hardening, and fracture behavior of laser additive manufactured austenitic and martensitic stainless steel structures. Mater. Sci. Eng. A 2019, 756, 545. [Google Scholar] [CrossRef]

- Promakhov, V.; Zhukov, A.; Ziatdinov, M.; Zhukov, I.; Schulz, N.; Kovalchuk, S.; Dubkova, Y.; Korsmik, R.; Klimova-Korsmik, O.; Turichin, G.; et al. Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition. Metals 2019, 9, 141. [Google Scholar] [CrossRef] [Green Version]

- Winck, L.B.; Ferreira, J.; Araújo, J.; Manfrinato, M.D.; Silva, C. Surface nitriding influence on the fatigue life behavior of ASTM A743 steel type CA6NM. Surf. Coat. Technol. 2013, 232, 844. [Google Scholar] [CrossRef]

- Wen, P.; Cai, Z.; Feng, Z.; Wang, G. Microstructure and mechanical properties of hot wire laser clad layers for repairing precipitation hardening martensitic stainless steel. Opt. Laser Technol. 2015, 75, 207. [Google Scholar] [CrossRef]

- Promakhov, V.; Khmeleva, M.; Zhukov, I.A.; Platov, V.V.; Khrustalyov, A.; Vorozhtsov, A.B. Influence of Vibration Treatment and Modification of A356 Aluminum Alloy on Its Structure and Mechanical Properties. Metals 2019, 9, 87. [Google Scholar] [CrossRef] [Green Version]

- Mirakhorli, F.; Cao, X.; Pham, X.-T.; Wanjara, P.; Fihey, J. Phase structures and morphologies of tempered CA6NM stainless steel welded by hybrid laser-arc process. Mater. Charact. 2017, 123, 264. [Google Scholar] [CrossRef]

- Zhukov, I.A.; Kozulin, A.A.; Khrustalyov, A.; Matveev, A.E.; Platov, V.V.; Vorozhtsov, A.B.; Zhukova, T.V.; Promakhov, V. The Impact of Particle Reinforcement with Al2O3, TiB2, and TiC and Severe Plastic Deformation Treatment on the Combination of Strength and Electrical Conductivity of Pure Aluminum. Metals 2019, 9, 65. [Google Scholar] [CrossRef] [Green Version]

- Turichin, G.; Zemlyakov, E.; Babkin, K.; Ivanov, S.; Vildanov, A. Analysis of distortion during laser metal deposition of large parts. Procedia CIRP 2017, 74, 154. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Kuznetsov, M.; Babkin, K.; Kurakin, A.; Vildanov, A. Direct laser deposition with transversal oscillating of laser radiation. In Proceedings of the International Conference Laser Optics, St. Petersburg, Russia, 4–8 June 2018; p. 124. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetsov, M.; Tsibulskiy, I.; Firsova, A. Hybrid Laser-Arc Welding of the High-Strength Shipbuilding Steels: Equipment and Technology. Phys. Procedia 2017, 89, 156. [Google Scholar] [CrossRef]

- Rahman, N.U.; Capuano, L.; Cabeza, S.; Feinaeugle, M.; Garcia-Junceda, A.; De Rooij, M.; Matthews, D.; Walmag, G.; Gibson, I.; Römer, G. Directed energy deposition and characterization of high-carbon high speed steels. Addit. Manuf. 2019, 30. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, S.; Yan, S.; Liu, X.; Liu, Y.; Xia, D.; Lv, Y.; He, P.; Xu, B.; Han, H. The effect of different scanning strategies on microstructural evolution to 24CrNiMo alloy steel during direct laser deposition. Mater. Sci. Eng. A 2019. [Google Scholar] [CrossRef]

- Turichin, G.; Klimova, O.; Zemlyakov, E.; Babkin, K.; Kolodyazhnyy, D.; Shamray, F.; Travyanov, A.; Petrovskiy, P. Technological aspects of high speed direct laser deposition based on heterophase powder metallurgy. Phys. Procedia 2015, 78, 397. [Google Scholar] [CrossRef] [Green Version]

- Turichin, G.A.; Zemlyakov, E.V.; Klimova, O.G.; Babkin, K.D. Hydrodynamic instability in high-speed direct laser deposition for additive manufacturing. Phys. Procedia 2016, 83, 674. [Google Scholar] [CrossRef] [Green Version]

- Glukhov, V.; Turichin, G.; Klimova-Korsmik, O.; Zemlyakov, E.; Babkin, K. Quality Management of Metal Products Prepared by High-Speed Direct Laser Deposition Technology. Key Eng. Mater. 2016, 684, 461. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetsov, M.; Pozdnyakov, A.; Gook, S.; Gumenyuk, A.; Rethmeier, M. Influence of heat input and preheating on the cooling rate, microstructure and mechanical properties at the hybrid laser-arc welding of API 5L X80 steel. Procedia CIRP 2018, 74, 748. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Babkin, K.; Ivanov, S.; Vildanov, A. Laser metal deposition of Ti-6Al-4V alloy with beam oscillation. Procedia CIRP 2018, 74, 184. [Google Scholar] [CrossRef]

- Klimova-Korsmik, O.; Turichin, G.; Zemlyakov, E.; Babkin, K.; Petrovsky, P.; Travyanov, A. Structure formation in Ni superalloys during high-speed direct laser deposition. Mater. Sci. Forum 2017, 879, 978. [Google Scholar] [CrossRef]

- Trudel, A.; Lévesque, M.; Brochu, M. Microstructural effects on the fatigue crack growth resistance of a stainless steel CA6NM weld. Eng. Fract. Mech. 2014, 115, 60. [Google Scholar] [CrossRef]

- Fang, J.; Dong, S.; Li, S.; Wang, Y.; Xu, B.; Li, J.; Liu, B.; Jiang, Y. Direct laser deposition as repair technology for a low transformation temperature alloy: Microstructure, residual stress, and properties. Mater. Sci. Eng. A 2019, 748, 119. [Google Scholar] [CrossRef]

- Guan, T.; Chen, S.; Chen, X.; Liang, J.; Liu, C.; Wang, M. Effect of laser incident energy on microstructures and mechanical properties of 12CrNi2Y alloy steel by direct laser deposition. J. Mater. Sci. Technol. 2019, 35, 395. [Google Scholar] [CrossRef]

- Wei, S.; Wang, G.; Yu, J.; Rong, Y. Competitive failure analysis on tensile fracture of laser-deposited material for martensitic stainless steel. Mater. Des. 2017, 118, 1. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Champliaud, H.; Thibault, D. Characteristics of an autogenous single pass electron beam weld in thick gage CA6NM steel. Int. J. Adv. Manuf. Technol. 2015, 78, 1523. [Google Scholar] [CrossRef]

- Barros, R.; Silva, F.J.G.; Gouveia, R.M.; Saboori, A.; Marchese, G.; Biamino, S.; Salmi, A.; Atzeni, E. Laser Powder Bed Fusion of Inconel 718: Residual Stress Analysis Before and After Heat Treatment. Materials 2020, 13, 2248. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, A.; Cheng, X.; Zhang, S.; Wang, H. Effects of heat treatment on microstructure and tensile properties of laser melting deposited AISI 431 martensitic stainless steel. Mater. Sci. Eng. A 2016, 666, 27. [Google Scholar] [CrossRef]

- Gouveia, R.M.; Silva, F.J.G.; Atzeni, E.; Sormaz, D.; Alves, J.L.; Pereira, A.B. Effect of Scan Strategies and Use of Support Structures on Surface Quality and Hardness of L-PBF AlSi10Mg Parts. Materials 2020, 13, 2248. [Google Scholar] [CrossRef]

- Rashid, R.A.R.; Nazari, K.; Barr, C.; Palanisamy, S.; Orchowski, N.; Matthews, N.; Dargusch, M. Effect of laser reheat post-treatment on the microstructural characteristics of laser-cladded ultra-high strength steel. Surf. Coat. Technol. 2019, 372, 93. [Google Scholar] [CrossRef]

- Tsukanov, V.V.; Tsyganko, L.K.; Petrov, S.N.; Shandyba, G.A.; Ziza, A.I. Structural transformations during heat treatment of cast corrosion-resistant martensitic steel. Metallobrabotka 2016, 3, 42. [Google Scholar]

- Folkhard, E.; Rabensteiner, G.; Perteneder, E. Welding Metallurgy of Stainless Steels; Springer: Vienna, Austria, 1988; p. 98. [Google Scholar]

- Korsmik, R.; Rodionov, A.; Korshunov, V.; Ponomarev, D.; Prosychev, I.; Promakhov, V. Topological optimization and manufacturing of vessel propeller via LMD-method. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

| Material Grade | Elements Mass Ratio, % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ni | Mo | S | P | Fe | Cu | |

| 06Cr15Ni4CuMo | ≤0.06 | 0.40 | 0.60–0.90 | 14.0–15.5 | 4.0–4.4 | 0.11–0.28 | 0.015 | 0.015 | Bal. | 1.0–1.5 |

| P (W) | V (mm/s) | Yield Strength, σв, (MPa) | Ultimate Strength, σ0.2, (MPa) | Relative Elongation, δs, (%) | Impact Toughness, KV−10, (J) | |

|---|---|---|---|---|---|---|

| Technical specifications | N/A | N/A | ≥790 | ≥620 | ≥19 | ≥40 |

| DLD | 2300 | 25 | 1088 | 792 | 8 | 17 |

| b/Т = 750 °С, t = 2 h | ||||||

| Mode 1 | 1840 | 20 | 1114 | 798 | 7.5 | 16 |

| c/Т = 650 °С, t = 2 h | ||||||

| Mode 2 | 1840 | 20 | 863 | 530 | 15 | 39 |

| d/Т = 650 °С, t = 4 h | ||||||

| Mode 3 | 2300 | 25 | 891.7 | 587.2 | 12 | 29 |

| e/Т = 620 °С, t = 2 h | ||||||

| Mode 4 | 2300 | 20 | 816.4 | 698.3 | 16 | 42 |

| f/Т = 620 °С, t = 2 h/x2 the cycle is repeated twice | ||||||

| Mode 5 | 2300 | 20 | 804.4 | 666.8 | 19 | 42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendagaliev, R.; Klimova-Korsmik, O.; Promakhov, V.; Schulz, N.; Zhukov, A.; Klimenko, V.; Olisov, A. Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition. Materials 2020, 13, 2738. https://doi.org/10.3390/ma13122738

Mendagaliev R, Klimova-Korsmik O, Promakhov V, Schulz N, Zhukov A, Klimenko V, Olisov A. Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition. Materials. 2020; 13(12):2738. https://doi.org/10.3390/ma13122738

Chicago/Turabian StyleMendagaliev, Ruslan, Olga Klimova-Korsmik, Vladimir Promakhov, Nikita Schulz, Alexander Zhukov, Viktor Klimenko, and Andrey Olisov. 2020. "Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition" Materials 13, no. 12: 2738. https://doi.org/10.3390/ma13122738

APA StyleMendagaliev, R., Klimova-Korsmik, O., Promakhov, V., Schulz, N., Zhukov, A., Klimenko, V., & Olisov, A. (2020). Heat Treatment of Corrosion Resistant Steel for Water Propellers Fabricated by Direct Laser Deposition. Materials, 13(12), 2738. https://doi.org/10.3390/ma13122738