Effect of MWCNTs on Wear Behavior of Epoxy Resin for Aircraft Applications

Abstract

1. Introduction

2. Materials

2.1. Raw Materials

2.2. Sample Preparation

3. Methods

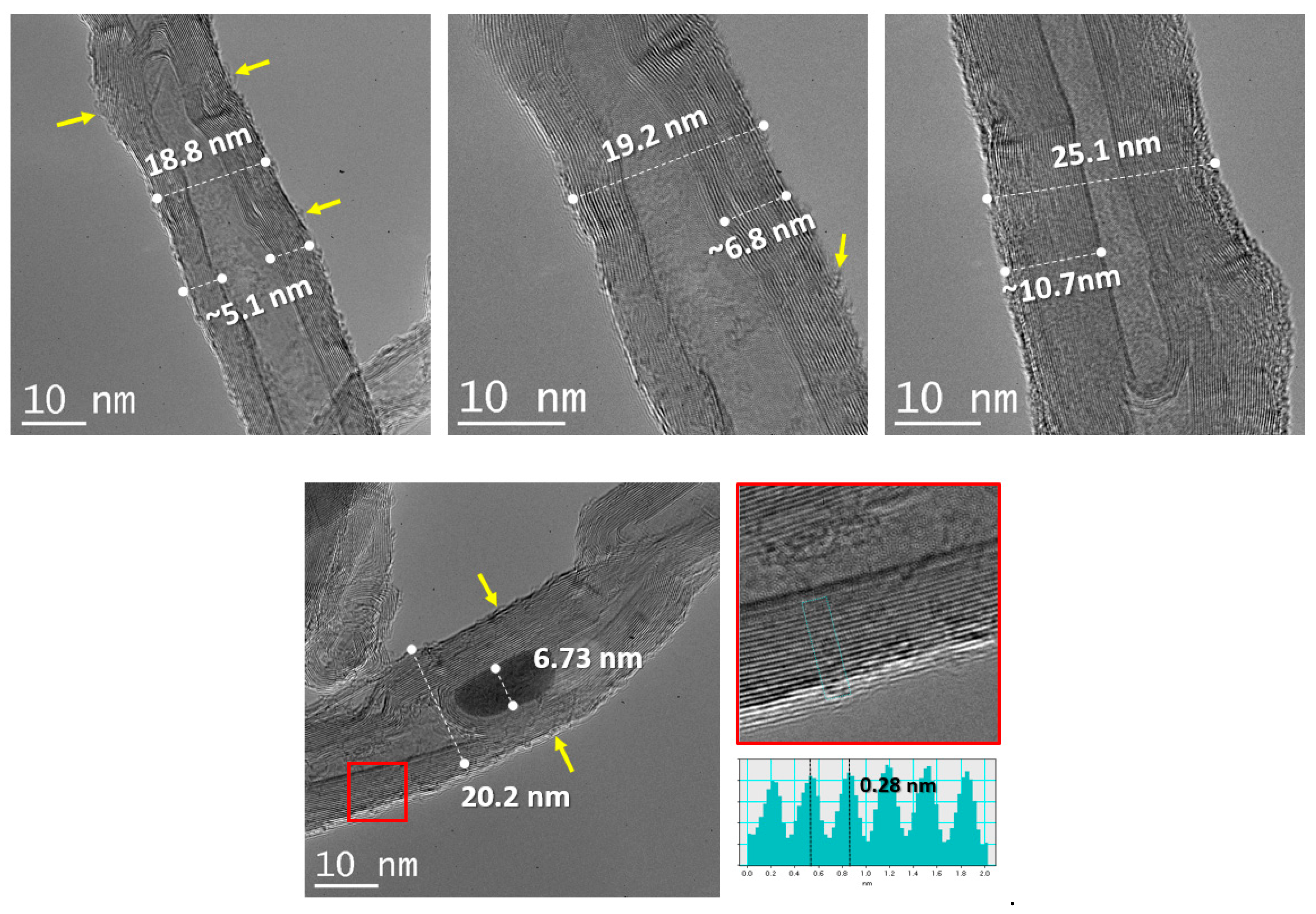

3.1. High-Resolution Transmission Electron Microscopy (HR-TEM)

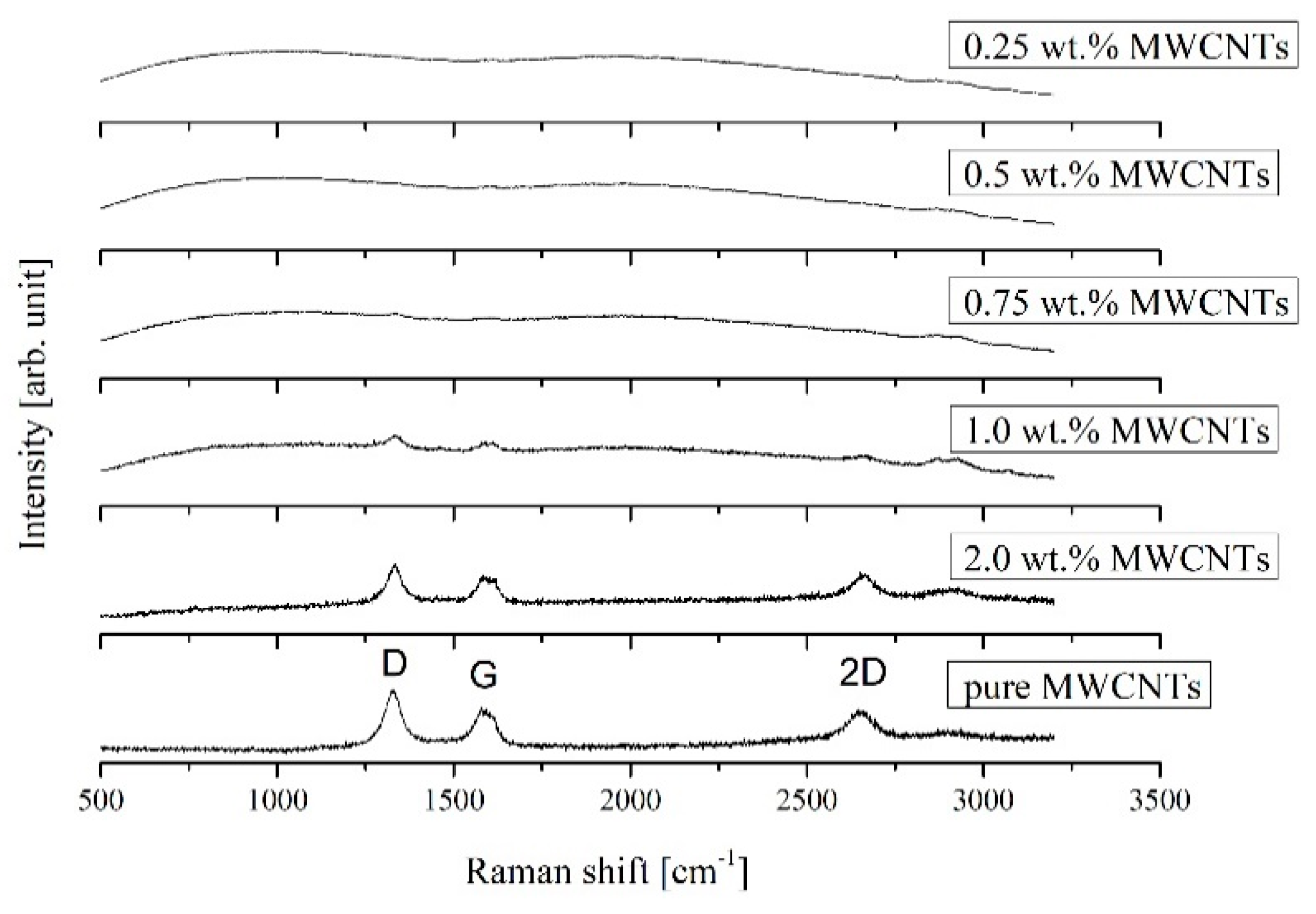

3.2. Raman Spectroscopy

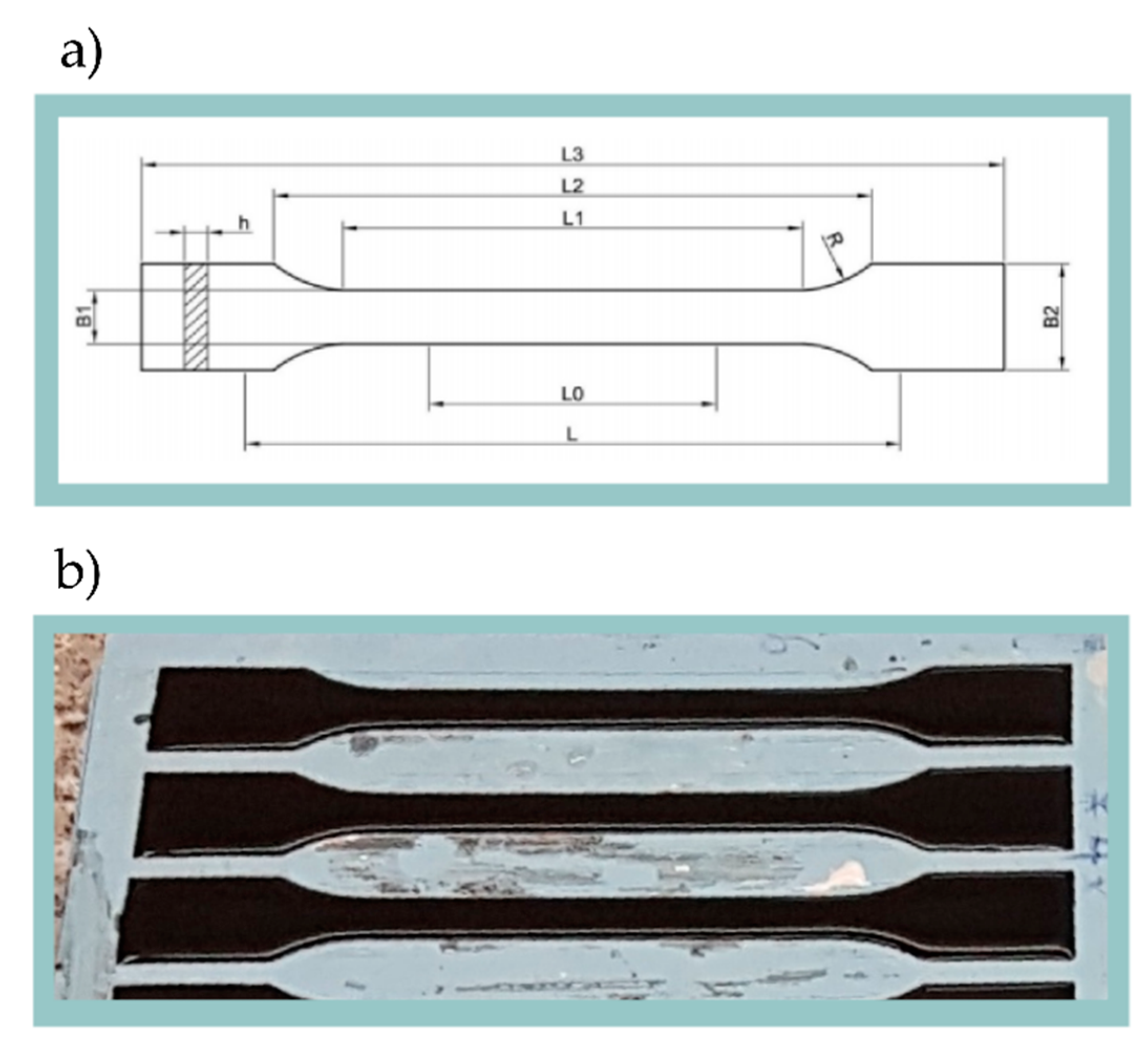

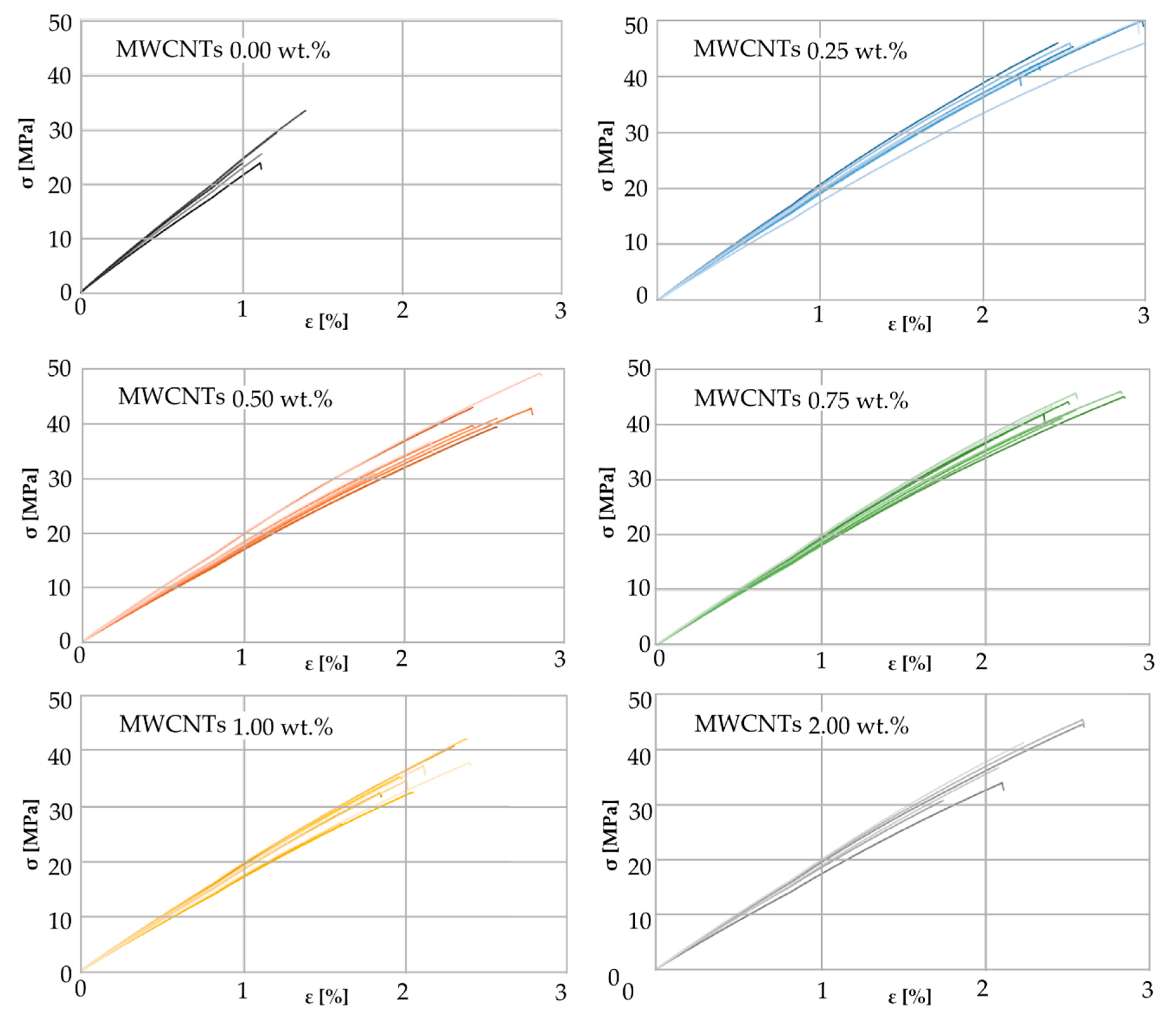

3.3. Tensile Testing

3.4. Hardness Tests

3.5. Abrasion Tests

3.6. Surface Imaging

4. Results

4.1. HR-TEM

4.2. Raman Spectroscopy

4.3. Tensile Testing

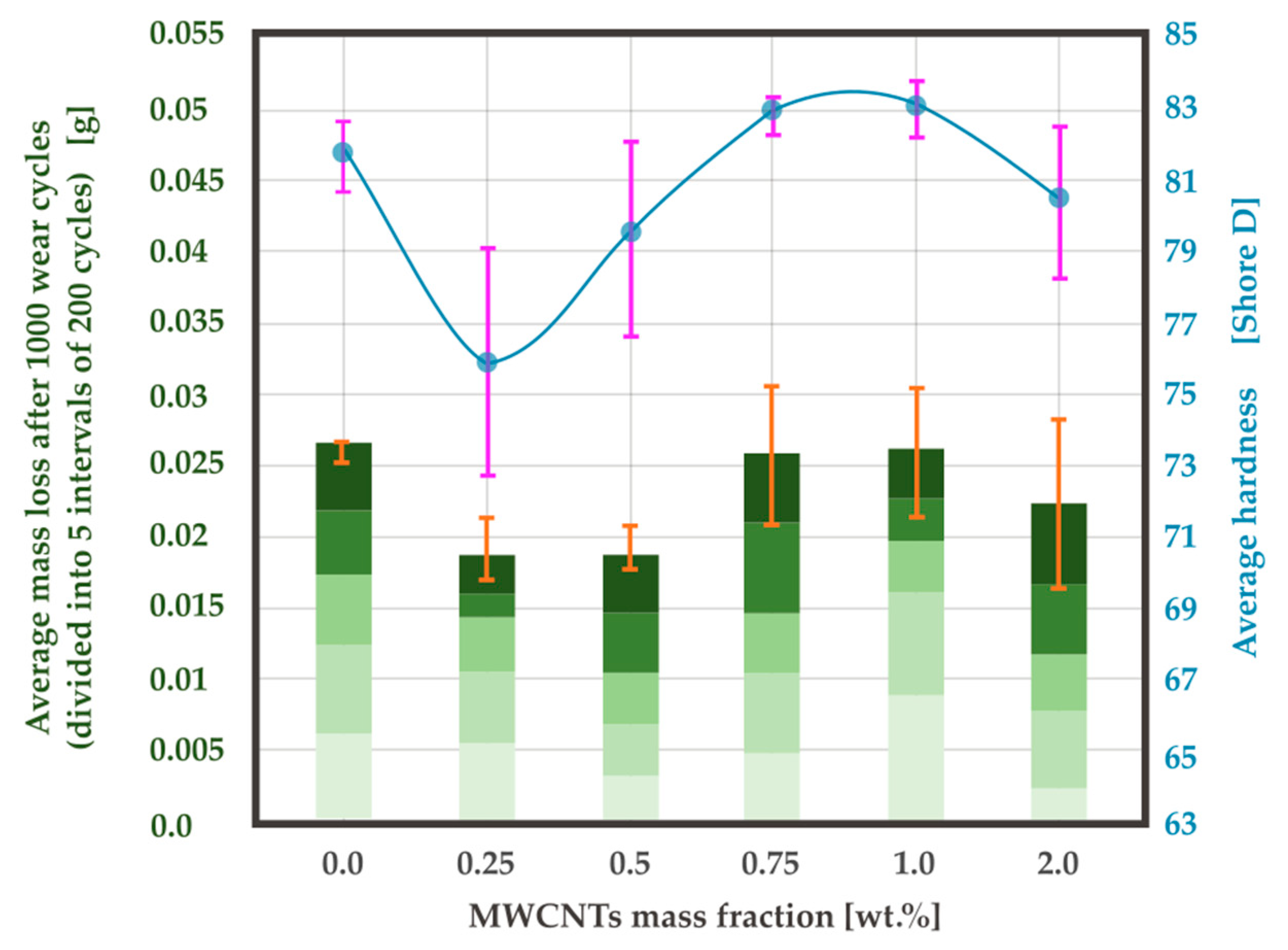

4.4. Hardness Test

4.5. Abrasion Tests

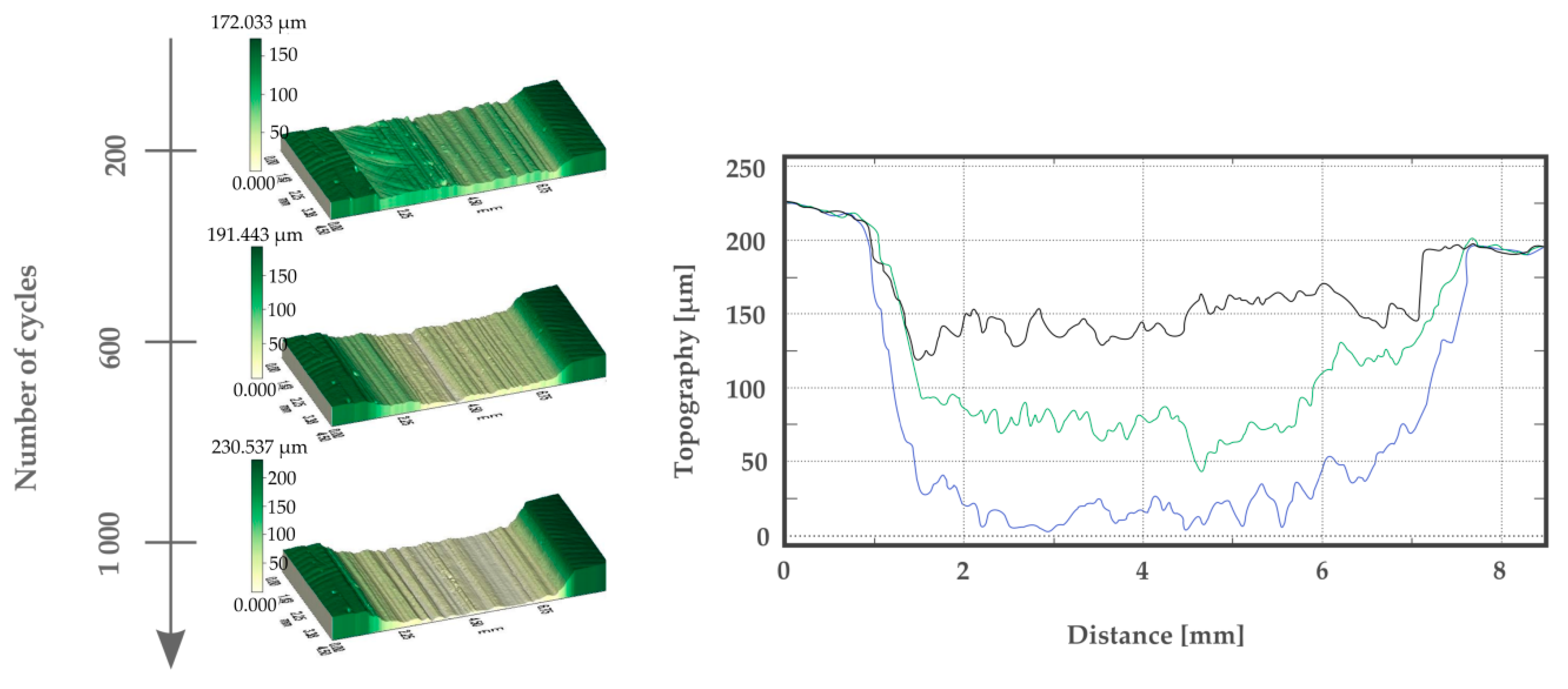

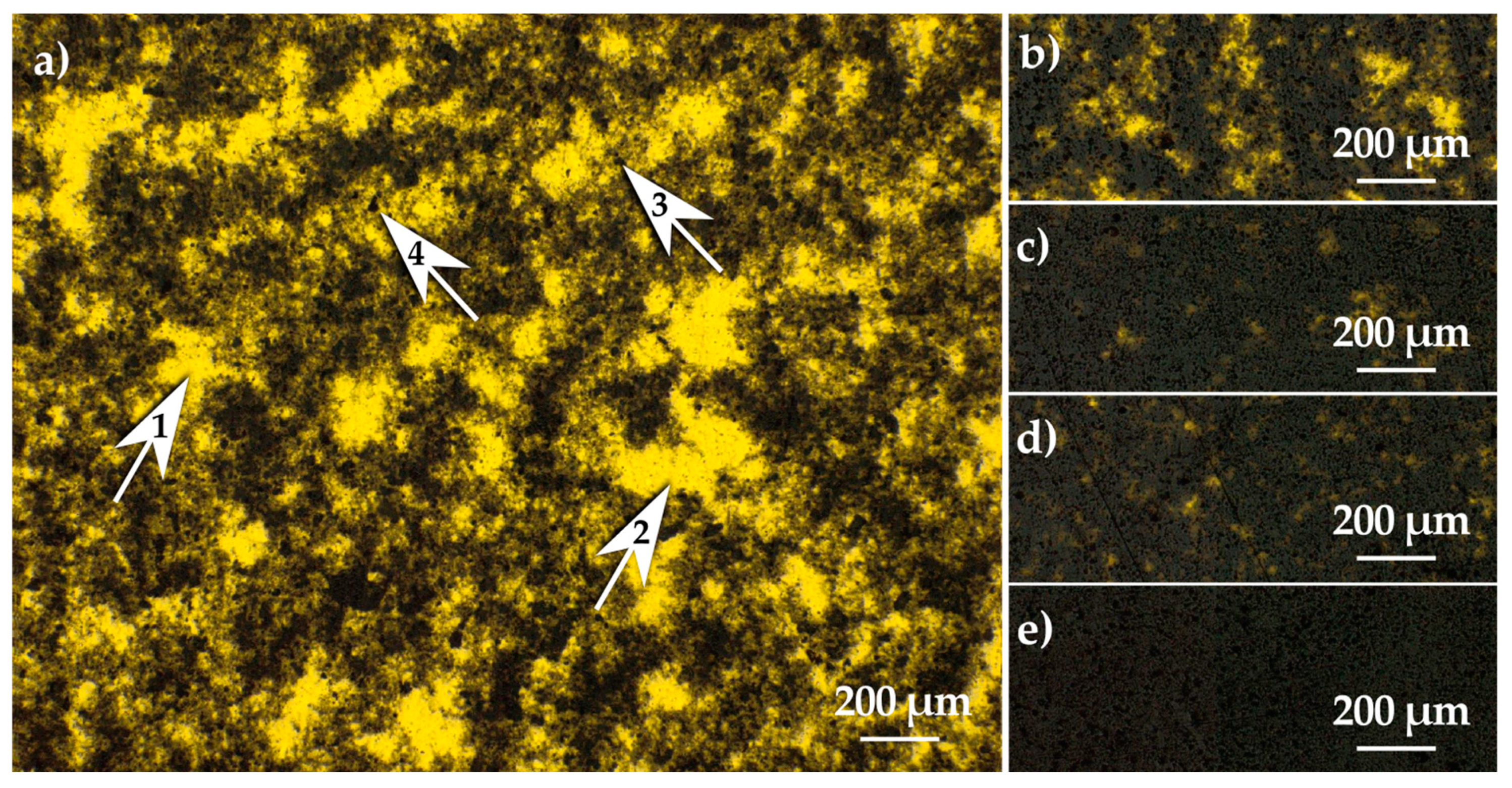

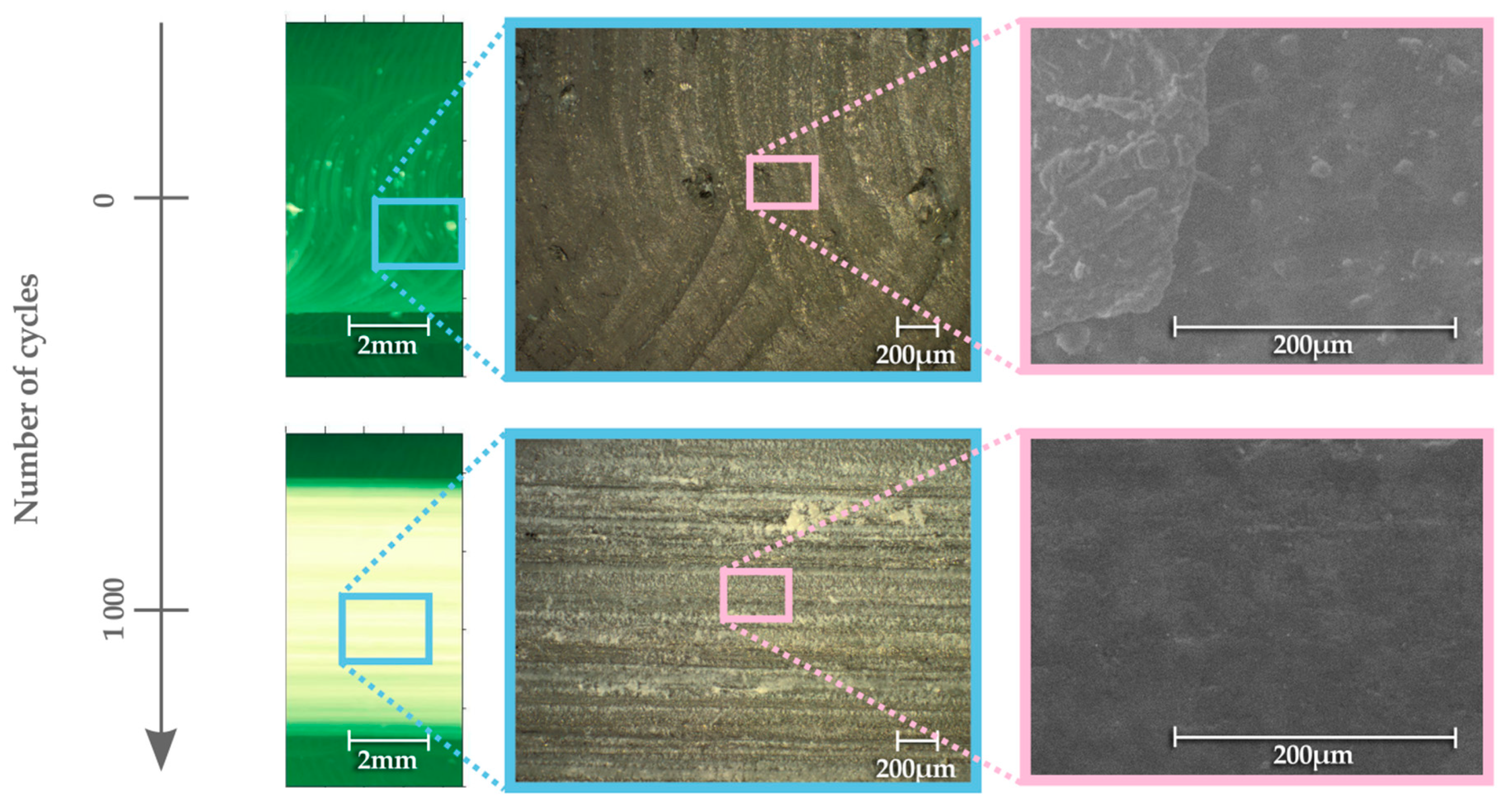

4.6. Surface Imaging

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pei, X.; Friedrich, K. Friction and Wear of Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Kumar, V.; Sinha, S.K.; Agarwal, A.K. Tribological studies of epoxy composites with solid and liquid fillers. Tribol. Int. 2017, 105, 27–36. [Google Scholar] [CrossRef]

- Bieniaś, J.; Jakubczak, P.; Majerski, K.; Ostapiuk, M.; Surowska, B. Methods of Ultrasonic Testing, as an Effective Way of Estimating Durability and Diagnosing Operational Capability of Composite Laminates Used in Aerospace Industry. Eksploatacja I Niezawodność 2013, 15, 284–289. [Google Scholar]

- Joshi, M.; Chatterjee, U. Polymer nano-composite: An advanced material for aerospace applications. In Advanced Composite Materials for Aerospace Engineering: Processing, Properties and Applications; Woodhead Publishing: Cambrige, UK, 2016; pp. 241–264. ISBN 9780081000540. [Google Scholar]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Borowiec, M.; Bochenski, M.; Gawryluk, J.; Augustyniak, M. Analysis of the Macro Fiber Composite Characteristics for Energy Harvesting Efficiency. In Dynamical Systems: Theoretical and Experimental Analysis, 2nd ed.; Awrejcewicz, J., Ed.; Springer: Łódź, Poland, 2015; Volume 182, pp. 27–37. [Google Scholar]

- Lv, M.; Zheng, F.; Wang, Q.; Wang, T.; Liang, Z. Friction and Wear Behaviours of Carbon and Aramid Fibers Reinforced Polyimide Composites in Simulated Space Environment. Tribol. Int. 2015, 92, 246–254. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Rong, M.Z.; Yu, S.L.; Wetzel, B.; Friedrich, K. Effect of particle surface treatment on the tribological performance of epoxy based nano-composites. Wear 2002, 253, 1086–1093. [Google Scholar] [CrossRef]

- Suresha, B.; Chandramohan, G.; Renukappa, N.M. Siddaramaiah Mechanical and tribological properties of glass–epoxy composites with and without graphite particulate filler. J. Appl. Polym. Sci. 2006, 103, 2472–2480. [Google Scholar] [CrossRef]

- Hussein, S.I.; Abd-Elnaiem, A.M.; Asafa, T.B.; Jaafar, H.I. Effect of incorporation of conductive fillers on mechanical properties and thermal conductivity of epoxy resin composite. Appl. Phys. A 2018, 124, 475. [Google Scholar] [CrossRef]

- Szczepaniak, R.; Rolecki, K.; Krzyzak, A. The influence of the powder additive upon selected mechanical properties of a composite. IOP Conf. Series: Mater. Sci. Eng. 2019, 634, 012007. [Google Scholar] [CrossRef]

- Sławski, S.; Szymiczek, M.; Domin, J. Influence of the reinforcement on the destruction image of the composites panels after applying impact load. AIP Conf. Proc 2019, 020050. [Google Scholar] [CrossRef]

- Dydek, K.; Latko-Durałek, P.; Boczkowska, A.; Sałaciński, M.; Kozera, R. Carbon Fiber Reinforced Polymers modified with thermoplastic nonwovens containing multi-walled carbon nanotubes. Compos. Sci. Technol. 2019, 173, 110–117. [Google Scholar] [CrossRef]

- Bellucci, S.; Balasubramanian, C.; Micciulla, F.; Rinaldi, G. CNT composites for aerospace applications. J. Exp. Nanosci. 2007, 2, 193–206. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Isfahani, R.B.; Monfared, R.M. Effects of multi-walled carbon nanotube and nanosilica on tensile properties of woven carbon fabric-reinforced epoxy composites fabricated using VARIM. J. Compos. Mater. 2017, 51, 4177–4188. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Gospodarek, B.; Ławniczak, P.; Sterzyński, T. Influence of the conductive network creation on electrical, rheological, and mechanical properties of composites based on LDPE and EVA matrices. Adv. Polym. Technol. 2018, 37, 3542–3551. [Google Scholar] [CrossRef]

- Capanidis, D. Selected aspects of the methodology of tribological investigations of polymer materials. Arch. Civ. Mech. Eng. 2007, 7, 39–55. [Google Scholar] [CrossRef]

- Giannakopoulos, A.; Panagiotopoulos, D. Conical indentation of incompressible rubber-like materials. Int. J. Solids Struct. 2009, 46, 1436–1447. [Google Scholar] [CrossRef]

- Krzyzak, A.; Prażmo, J.; Kucharczyk, W. Effect of Natural Ageing on the Physical Properties of Polypropylene Composites. Adv. Mater. Res. 2014, 1001, 141–148. [Google Scholar] [CrossRef]

- Valis, D.; Krzyzak, A. Composite materials reliability assessment and comparison. In Safety and Reliability of Complex Engineered Systems; CRC Press: Boca Raton, FL, USA, 2015; pp. 2119–2125. [Google Scholar]

- Ruzicka, M.; Dvořák, M.; Schmidová, N.; Šašek, L.; Štěpánek, M. Health and usage monitoring system for the small aircraft composite structure. AIP Conf. Proc. 2017, 1862, 20007. [Google Scholar] [CrossRef]

- Oliwa, R.; Oleksy, M.; Oliwa, J.; Wegier, A.; Krauze, S.; Kowalski, M. Fire resistant glass fabric-epoxy composites with reduced smoke emission. Polimery 2019, 64, 290–293. [Google Scholar] [CrossRef]

- Oliwa, R.; Oleksy, M.; Czech-Polak, J.; Płocińska, M.; Krauze, S.; Kowalski, M. Powder-epoxy resin/glass fabric composites with reduced flammability. J. Fire Sci. 2019, 37, 155–175. [Google Scholar] [CrossRef]

- Policandriotes, T.; Filip, P. Efects of selected nanoadditives on the friction and wear performance of carbon-carbon aircraft brake composites. Wear 2011, 271, 2280–2289. [Google Scholar] [CrossRef]

- Karaeva, A.R.; Kazennov, N.V.; Urvanov, S.A.; Zhukova, E.A.; Mordkovich, V. Carbon Fiber-Reinforced Polyurethane Composites with Modified Carbon–Polymer Interface. Proc. Sci. Prac. Conf. Res. Dev. 2017, 415–420. [Google Scholar] [CrossRef]

- Setua, D.K.; Mordina, B.; Srivastava, A.K.; Roy, D.; Prasad, N.E. Carbon nanofibers-reinforced polymer nanocomposites as efficient microwave absorber. In Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Elsevier Science: Amsterdam, The Netherlands, 2020; pp. 395–430. [Google Scholar] [CrossRef]

- Jia, Z.; Hao, C.; Yan, Z.; Yang, Y. Effects of Nanoscale Expanded Graphite on the Wear and Frictional Behaviours of Polyimide-Based Composites. Wear 2015, 338–339, 282–287. [Google Scholar] [CrossRef]

- Jacobs, O.; Xu, W.; Schadel, B.; Wu, W. Wear behaviour of carbon nanotube reinforced epoxy resin composites. Tribol. Lett. 2006, 23, 65–75. [Google Scholar] [CrossRef]

- Sakka, M.M.; Antar, Z.; Elleuch, K.; Feller, J.F. Tribological response of an epoxy matrix filled with graphite and/or carbon nanotubes. Friction 2017, 5, 171–182. [Google Scholar] [CrossRef]

- Singh, N.P.; Gupta, V.; Singh, A.P. Graphene and carbon nanotube reinforced epoxy nanocomposites: A review. Polymer 2019, 180, 121724. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Kövér, L.; Toth, J.; Biniak, S.; Trykowski, G.; Judek, J. Multiwall carbon nanotubes purification and oxidation by nitric acid studied by the FTIR and electron spectroscopy methods. J. Alloy. Compd. 2010, 501, 77–84. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Zemek, J.; Jiricek, P.; Biniak, S.; Trykowski, G. Studies of oxidized carbon nanotubes in temperature range RT–630°C by the infrared and electron spectroscopies. J. Alloy. Compd. 2010, 505, 379–384. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Zemek, J.; Jiricek, P. Time dependent thermal treatment of oxidized MWCNTs studied by the electron and mass spectroscopy methods. Appl. Surf. Sci. 2012, 258, 7912–7917. [Google Scholar] [CrossRef]

- Tjong, S.C. Structural and mechanical properties of polymer nanocomposites. Mater. Sci. Eng. R: Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Dai, L.; Sun, J. Mechanical Properties of Carbon Nanotubes-Polymer Composites. In Carbon Nanotubes—Current Progress of Their Polymer Composites; InTechOpen: London, UK, 2016; Available online: https://www.intechopen.com/books/carbon-nanotubes-current-progress-of-their-polymer-composites/mechanical-properties-of-carbon-nanotubes-polymer-composites (accessed on 12 May 2020).

- Kashyap, A.; Singh, N.P.; Arora, S.; Singh, V.; Gupta, V. Effect of amino-functionalization of MWCNTs on the mechanical and thermal properties of MWCNTs/epoxy composites. Bull. Mater. Sci. 2020, 43, 1–9. [Google Scholar] [CrossRef]

- Francisco, W.; Ferreira, F.V.; Cividanes, L.D.S.; Coutinho, A.D.R.; Thim, G. Functionalization of Multi-Walled Carbon Nanotube and Mechanical Property of Epoxy-Based Nanocomposite. J. Aerosp. Technol. Manag. 2015, 7, 289–293. [Google Scholar] [CrossRef]

- Pötschke, P.; Mothes, F.; Krause, B.; Voit, B. Melt-Mixed PP/MWCNT Composites: Influence of CNT Incorporation Strategy and Matrix Viscosity on Filler Dispersion and Electrical Resistivity. Polymer 2019, 11, 189. [Google Scholar] [CrossRef] [PubMed]

- Paun, C.; Obreja, C.; Comanescu, F.; Tucureanu, V.; Tutunaru, O.; Romanitan, C.; Ionescu, O. Epoxy nanocomposites based on MWCNT. In Proceedings of the 2019 International Semiconductor Conference (CAS), Sinaia, Romania, 9–11 October 2019; pp. 237–240. [Google Scholar]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Aruniit, A.; Antonov, M.; Kers, J.; Krumme, A. Determination of Resistance to Wear of Particulate Composite. Key Eng. Mater. 2014, 604, 188–191. [Google Scholar] [CrossRef]

- Kharitonov, A.; Tkachev, A.; Blohin, A.; Dyachkova, T.; Kobzev, D.; Maksimkin, A.; Mostovoy, A.; Alekseiko, L. Reinforcement of Bisphenol-F epoxy resin composites with fluorinated carbon nanotubes. Compos. Sci. Technol. 2016, 134, 161–167. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, T.; Xie, Y.; Liu, J. Effect of carbon nanotubes on friction and wear of a piston ring and cylinder liner system under dry and lubricated conditions. Friction 2016, 5, 147–154. [Google Scholar] [CrossRef]

- Ren, Z.; Yangyu, Y.; Lin, Y.; Guo, Z. Tribological Properties of Molybdenum Disulfide and Helical Carbon Nanotube Modified Epoxy Resin. Materials 2019, 12, 903. [Google Scholar] [CrossRef]

- Oliwa, R.; Oliwa, J.; Bulanda, K.; Oleksy, M.; Budzik, G. Effect of modified bentonites on the crosslinking process of epoxy resin with alifphatic amine as curing agent. Polimery 2019, 64, 499–503. [Google Scholar] [CrossRef]

- Kozioł, M.; Jesionek, M.; Szperlich, P. Addition of a small amount of multiwalled carbon nanotubes and flaked graphene to epoxy resin. J. Reinf. Plast. Compos. 2017, 36, 640–654. [Google Scholar] [CrossRef]

- Smith, D.J. High Resolution Transmission Electron Microscopy. In Handbook of Microscopy for Nanotechnology; Yao, N., Wang, Z.L., Eds.; Springer: Boston, MA, USA, 2015; pp. 427–453. [Google Scholar]

- Özden, S.; Narayanan, T.N.; Tiwary, C.S.; Dong, P.; Hart, A.H.C.; Vajtai, R.; Ajayan, P.M. 3D Macroporous Solids from Chemically Cross-linked Carbon Nanotubes. Small 2014, 11, 688–693. [Google Scholar] [CrossRef]

- Image Modes in TEM—Lattice Images. Available online: https://www.microscopy.ethz.ch/TEM_HRTEM.htm (accessed on 10 October 2019).

- Manrique, J.A.; Marí, B.; Ribes-Greus, A.; Monreal, L.; Teruel, R.; Gascon, M.L.; Sans, J.; Marí-Guaita, J. Study of the Degree of Cure through Thermal Analysis and Raman Spectroscopy in Composite-Forming Processes. Materials 2019, 12, 3991. [Google Scholar] [CrossRef] [PubMed]

- Rycewicz, M.; Macewicz, Ł.; Kratochvil, J.; Stanisławska, A.; Ficek, M.; Sawczak, M.; Stranak, V.; Szkodo, M.; Bogdanowicz, R. Physicochemical and Mechanical Performance of Freestanding Boron-Doped Diamond Nanosheets Coated with C:H:N:O Plasma Polymer. Materials 2020, 13, 1861. [Google Scholar] [CrossRef] [PubMed]

- Krishna, R.; Unsworth, T.; Edge, R. Raman Spectroscopy and Microscopy. In Reference Module in Materials Science and Materials Engineering; Elsevier BV: Oxford, UK, 2016. [Google Scholar]

- Lawson, E.E.; Barry, B.W.; Williams, A.C.; Edwards, H.G.M. Biomedical Applications of Raman Spectroscopy. J. Raman Spectrosc. 1997, 28, 111–117. [Google Scholar] [CrossRef]

- Kline, N.J.; Treado, P.J. Raman Chemical Imaging of Breast Tissue. J. Raman Spectrosc. 1997, 28, 119–124. [Google Scholar] [CrossRef]

- Smith, G.D.; Clark, R. Raman microscopy in archaeological science. J. Archaeol. Sci. 2004, 31, 1137–1160. [Google Scholar] [CrossRef]

- Nasdala, L.; Smith, D.C.; Kaindl, R.; Ziemann, M.A. Raman Spectroscopy: Analytical Perspectives in Mineralogical Research; Eötvös University Press: Budapest, Hungary, 2004; ISBN-10:352728138X. [Google Scholar] [CrossRef]

- Edwards, H.G. Spectroscopy, Raman. In Digital Encyclopedia of Applied Physics; Wiley: Hoboken, NJ, USA, 2005; ISBN-10:352728138X. [Google Scholar]

- Ramana, G.V.; Padya, B.; Kumar, R.N.; Prabhakar, K.V.P.; Jain, P.K. Mechanical properties of multi-walled carbon nanotubes reinforced polymer nanocomposites. Indian J. Eng. Mater. Sci. 2010, 17, 331–337. [Google Scholar]

- Liu, L.; Wagner, H.D. Rubbery and glassy epoxy resins reinforced with carbon nanotubes. Compos. Sci. Technol. 2005, 65, 1861–1868. [Google Scholar] [CrossRef]

- Blokhin, A.N.; Dyachkova, T.P.; Maksimkin, A.V.; Stolyarov, R.A.; Suhorukov, A.K.; Burmistrov, I.N.; Kharitonov, A.P. Polymer composites based on epoxy resin with added carbon nanotubes. Full Nanotub. Carbon Nanostruct. 2019, 28, 45–49. [Google Scholar] [CrossRef]

- Shokrieh, M.; Saeedi, A.; Chitsazzadeh, M. Mechanical properties of multi-walled carbon nanotube/polyester nanocomposites. J. Nanostruct. Chem. 2013, 3, 20. [Google Scholar] [CrossRef]

- Marouf, B.T.; Mai, Y.-W.; Bagheri, R.; Pearson, R.A. Toughening of Epoxy Nanocomposites: Nano and Hybrid Effects. Polym. Rev. 2016, 56, 70–112. [Google Scholar] [CrossRef]

- Hosur, M.; Mahdi, T.H.; E Islam, M.; Jeelani, S. Mechanical and viscoelastic properties of epoxy nanocomposites reinforced with carbon nanotubes, nanoclay, and binary nanoparticles. J. Reinf. Plast. Compos. 2017, 36, 667–684. [Google Scholar] [CrossRef]

- Lin, Y.; Lafarie-Frenot, M.C.; Bai, J.; Gigliotti, M. Numerical simulation of the thermoelectric behaviour of CNTs/CFRP aircraft composite laminates. Adv. Aircr. Space Sci. 2018, 5, 633–652. [Google Scholar]

- Shen, S.; Yang, L.; Wang, C.; Wei, L. Effect of CNT orientation on the mechanical property and fracture mechanism of vertically aligned carbon nanotube/carbon composites. Ceram. Int. 2020, 46, 4933–4938. [Google Scholar] [CrossRef]

- Krzyzak, A.; Mucha, M.; Pindych, D.; Racinowski, D. Analysis of abrasive wear of selected Aircraft materials in various abrasion conditions. J. KONES Powertrain Transp. 2018, 25, 217–222. [Google Scholar]

- Musiał, J.; Horiashchenko, S.; Polasik, R.; Musiał, J.; Kałaczyński, T.; Matuszewski, M.; Śrutek, M. Abrasion Wear Resistance of Polymer Constructional Materials for Rapid Prototyping and Tool-Making Industry. Polymer 2020, 12, 873. [Google Scholar] [CrossRef]

- Maciejewska, B.M.; Jasiurkowska-Delaporte, M.; Vasylenko, A.I.; Koziol, K.K.; Jurga, S. Experimental and theoretical studies on the mechanism for chemical oxidation of multiwalled carbon nanotubes. RSC Adv. 2014, 4, 28826–28831. [Google Scholar] [CrossRef]

- Kumar, M.; Ando, Y. Chemical vapor deposition of carbon nanotubes: A review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 2010, 10, 3739–3758. [Google Scholar] [CrossRef]

- Brostow, W.; Lobland, H.E.H.; Narkis, M. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef]

- Brostow, W.; Lobland, H.E.H.; Narkis, M. The concept of materials brittleness and its applications. Polym. Bull. 2011, 67, 1697–1707. [Google Scholar] [CrossRef]

- Al Shaabania, Y.A. Wear and Friction Properties of Epoxy- Polyamide Blend Nanocomposites Reinforced by MWCNTs. Energy Procedia 2019, 157, 1561–1567. [Google Scholar] [CrossRef]

- Kalacska, G. An engineering approach to dry friction behaviour of numerous engineering plastics with respect to the mechanical properties. Express Polym. Lett. 2013, 7, 199–210. [Google Scholar] [CrossRef]

- Krzyzak, A.; Kosicka, E.; Szczepaniak, R.; Szymczak, T. Evaluation of the properties of polymer composites with carbon nanotubes in the aspect of their abrasive wear. J. Achiev. Mat. Manu. Eng. 2019, 1, 5–12. [Google Scholar] [CrossRef]

- Kato, K. Classification of wear mechanisms/models. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 349–355. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mucha, M.; Krzyzak, A.; Kosicka, E.; Coy, E.; Kościński, M.; Sterzyński, T.; Sałaciński, M. Effect of MWCNTs on Wear Behavior of Epoxy Resin for Aircraft Applications. Materials 2020, 13, 2696. https://doi.org/10.3390/ma13122696

Mucha M, Krzyzak A, Kosicka E, Coy E, Kościński M, Sterzyński T, Sałaciński M. Effect of MWCNTs on Wear Behavior of Epoxy Resin for Aircraft Applications. Materials. 2020; 13(12):2696. https://doi.org/10.3390/ma13122696

Chicago/Turabian StyleMucha, Mateusz, Aneta Krzyzak, Ewelina Kosicka, Emerson Coy, Mikołaj Kościński, Tomasz Sterzyński, and Michał Sałaciński. 2020. "Effect of MWCNTs on Wear Behavior of Epoxy Resin for Aircraft Applications" Materials 13, no. 12: 2696. https://doi.org/10.3390/ma13122696

APA StyleMucha, M., Krzyzak, A., Kosicka, E., Coy, E., Kościński, M., Sterzyński, T., & Sałaciński, M. (2020). Effect of MWCNTs on Wear Behavior of Epoxy Resin for Aircraft Applications. Materials, 13(12), 2696. https://doi.org/10.3390/ma13122696