The Role of Polypropylene Microfibers in Thermal Properties and Post-Heating Behavior of Cementitious Composites

Abstract

1. Introduction

2. Experimental Details

2.1. Materials and Mix Proportions

2.2. Mortar Casting and Specimen Preparation

2.3. Heating and Test Procedures

3. Results and Discussion

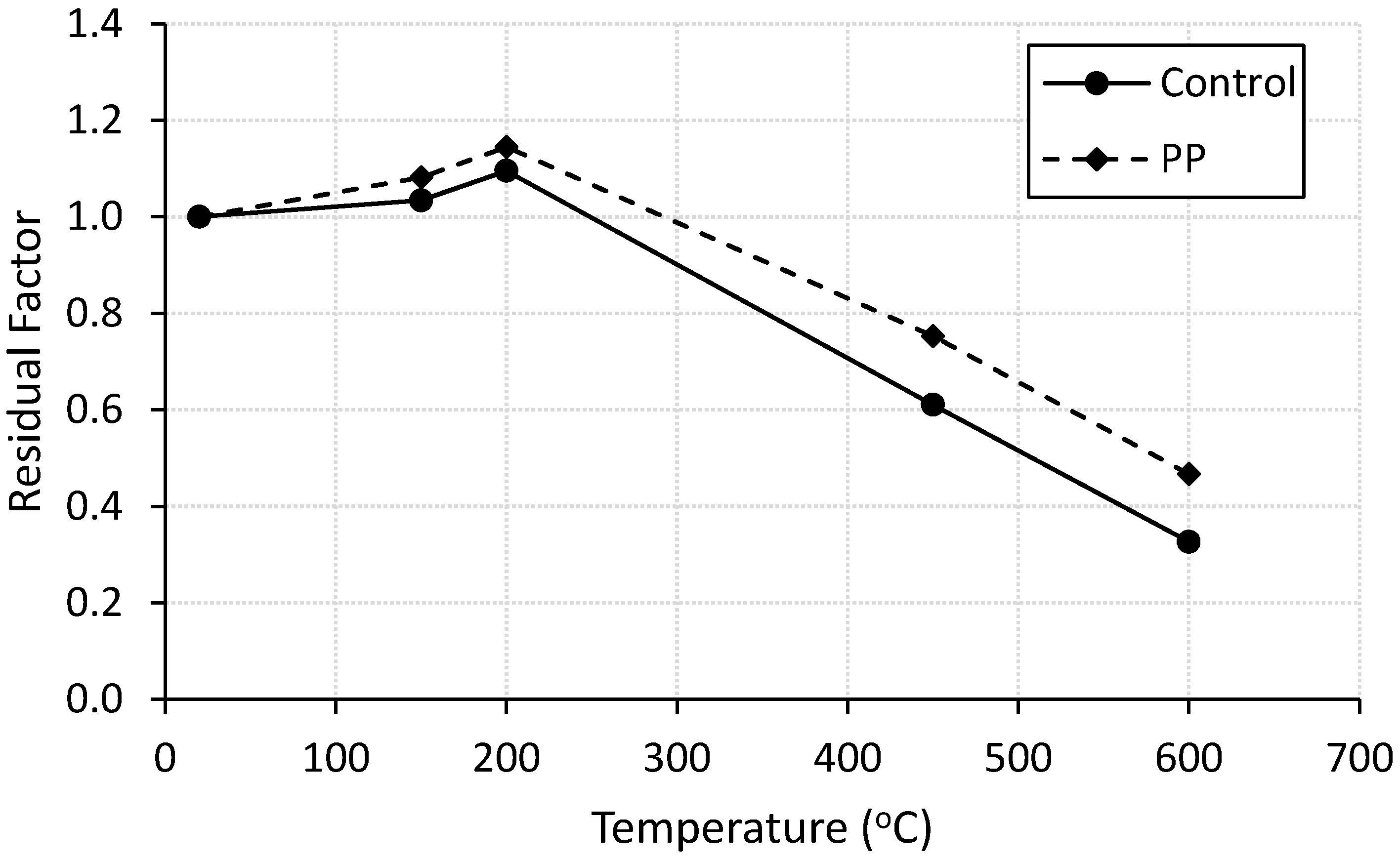

3.1. Degradation in Compressive Strength

3.2. Flexural Behavior Characteristics

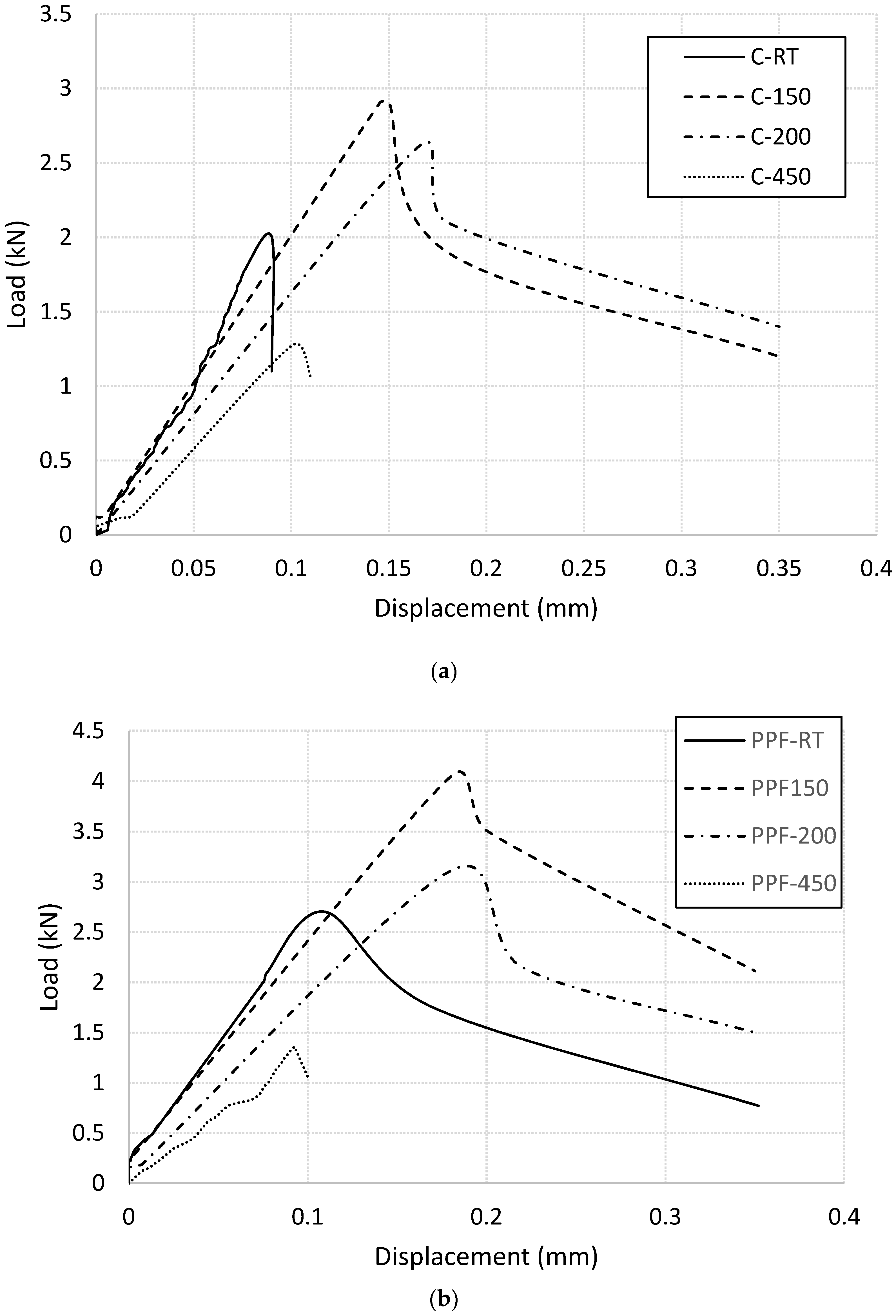

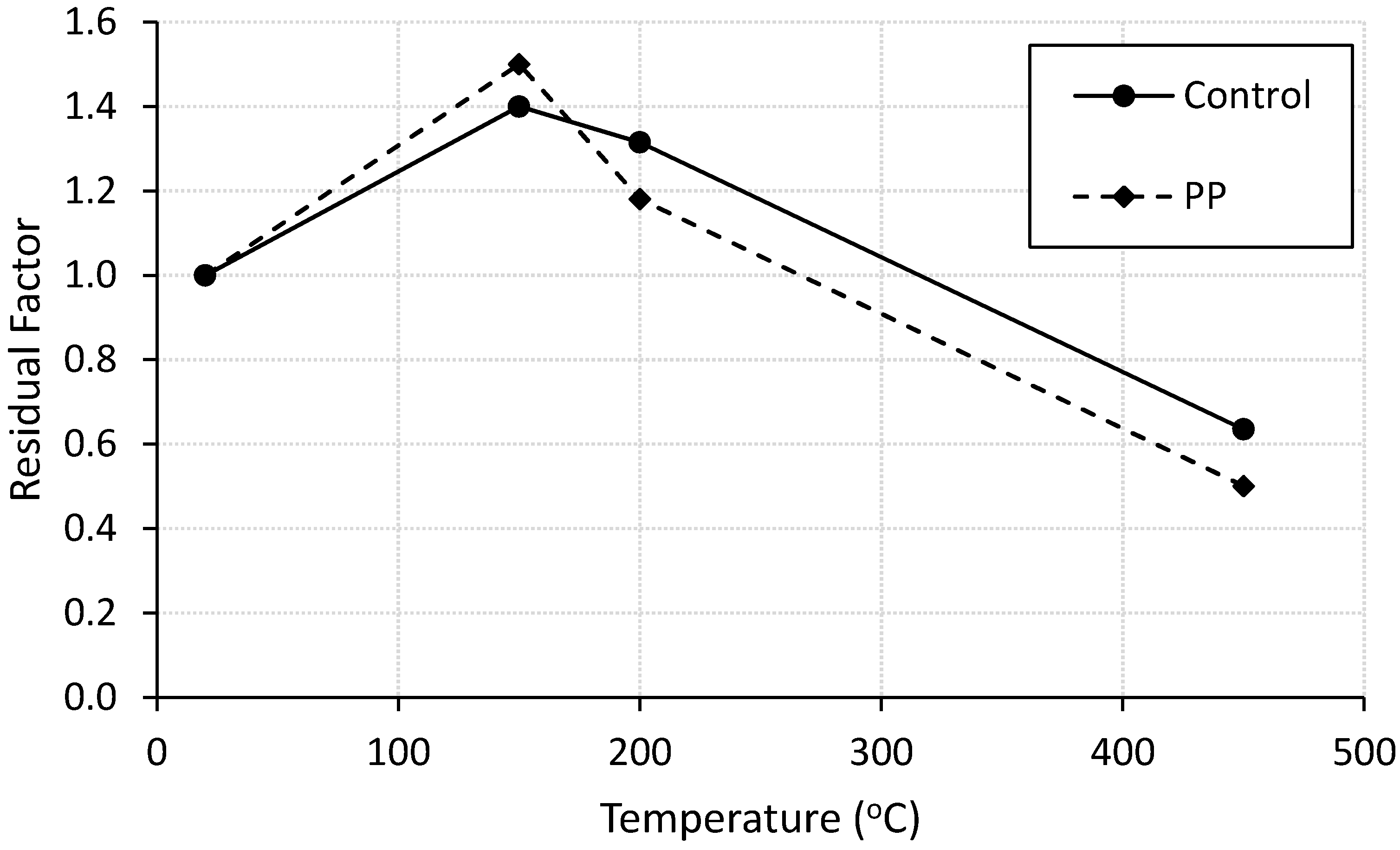

3.2.1. Residual Flexural Strength

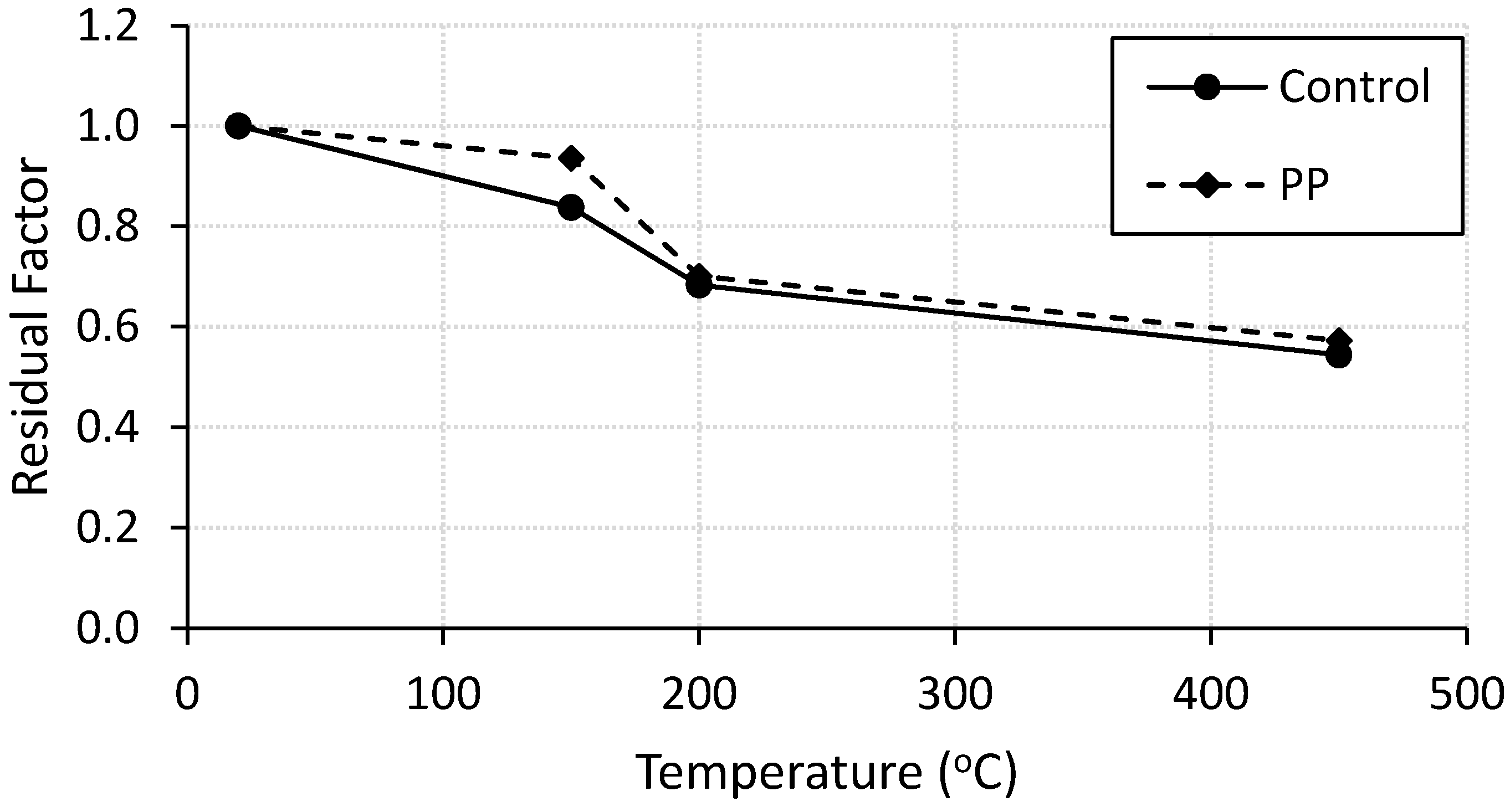

3.2.2. Residual Modulus of Elasticity

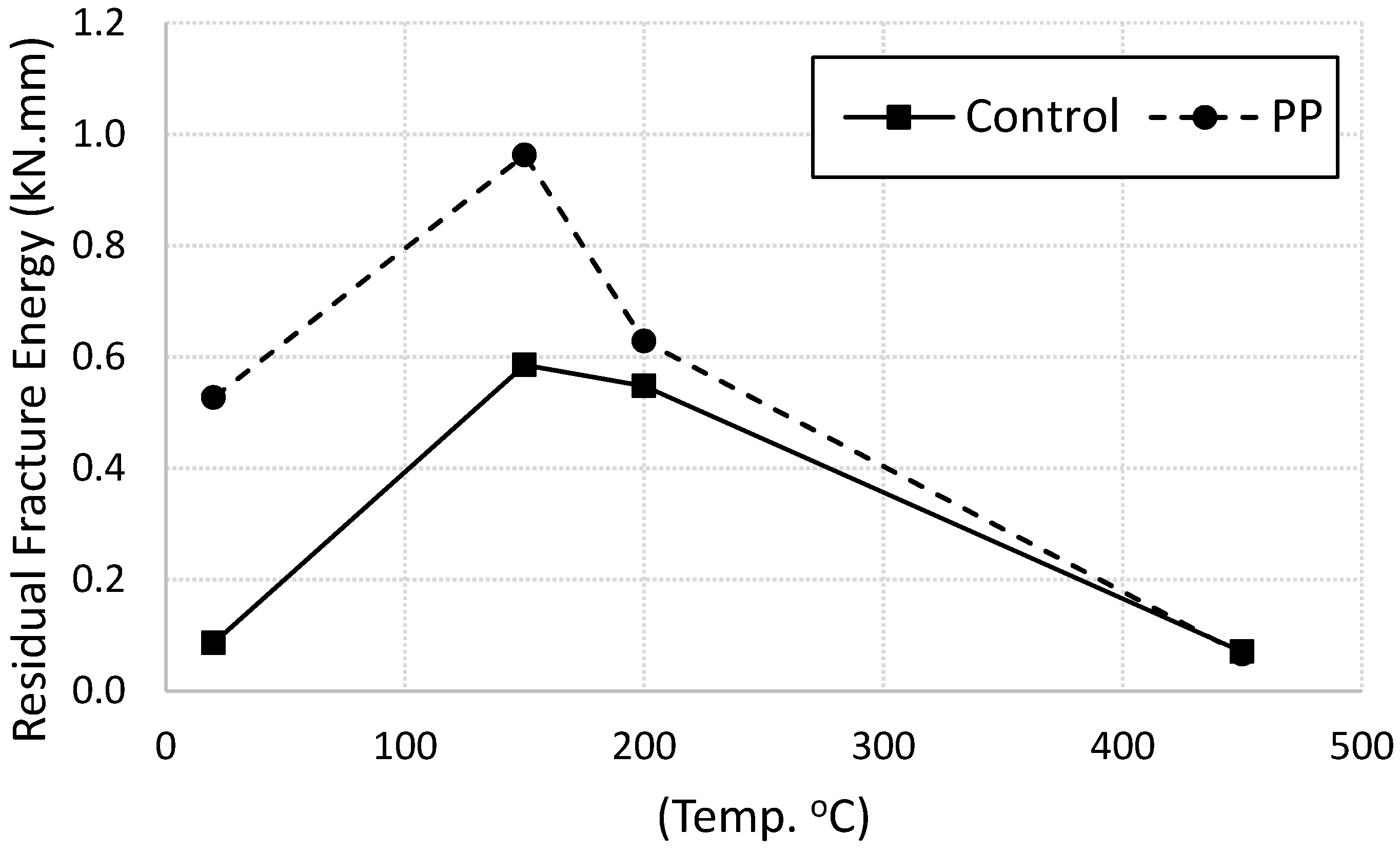

3.2.3. Residual Fracture Energy

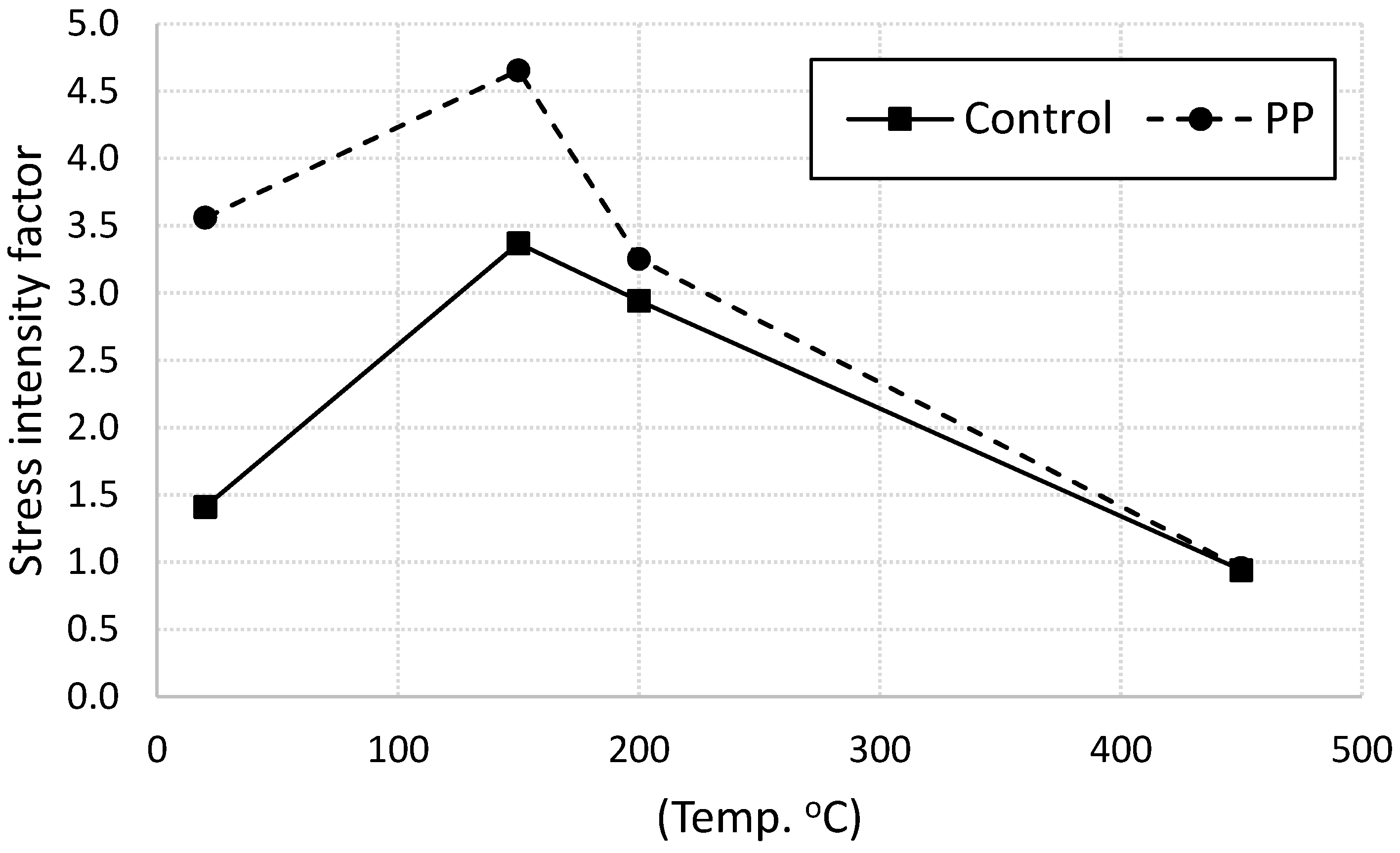

3.2.4. Stress Intensity Factor

3.2.5. Flexural Damage Behavior

3.3. Thermal Behavior

3.3.1. Thermal Conductivity

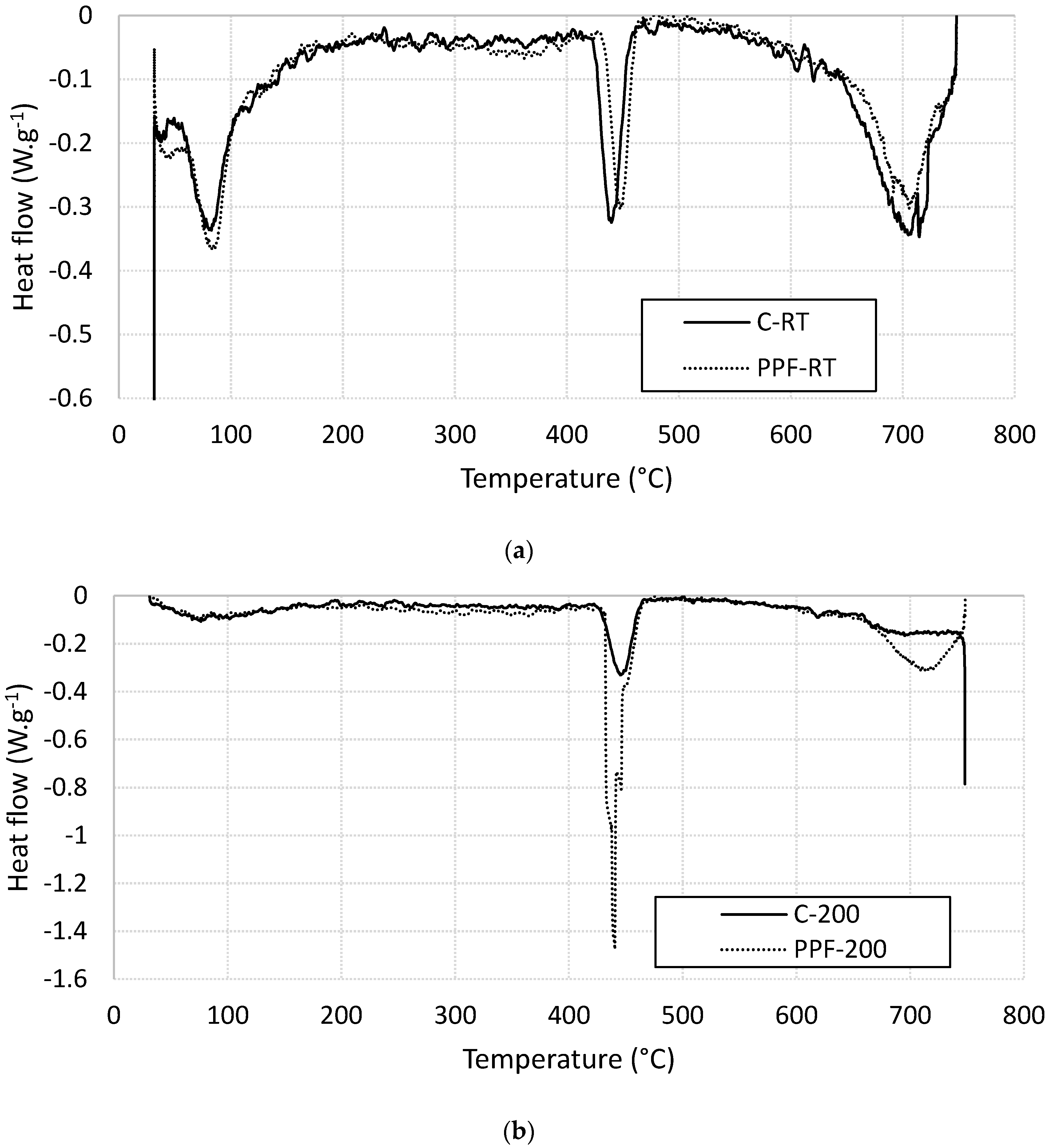

3.3.2. Heat Flow Analysis Using Differential Scanning Calorimetry (DSC)

3.3.3. Mass Loss Analysis Using Thermogravimetric Analysis (TGA)

3.4. Chemical Composition Using X-ray Diffraction (XRD)

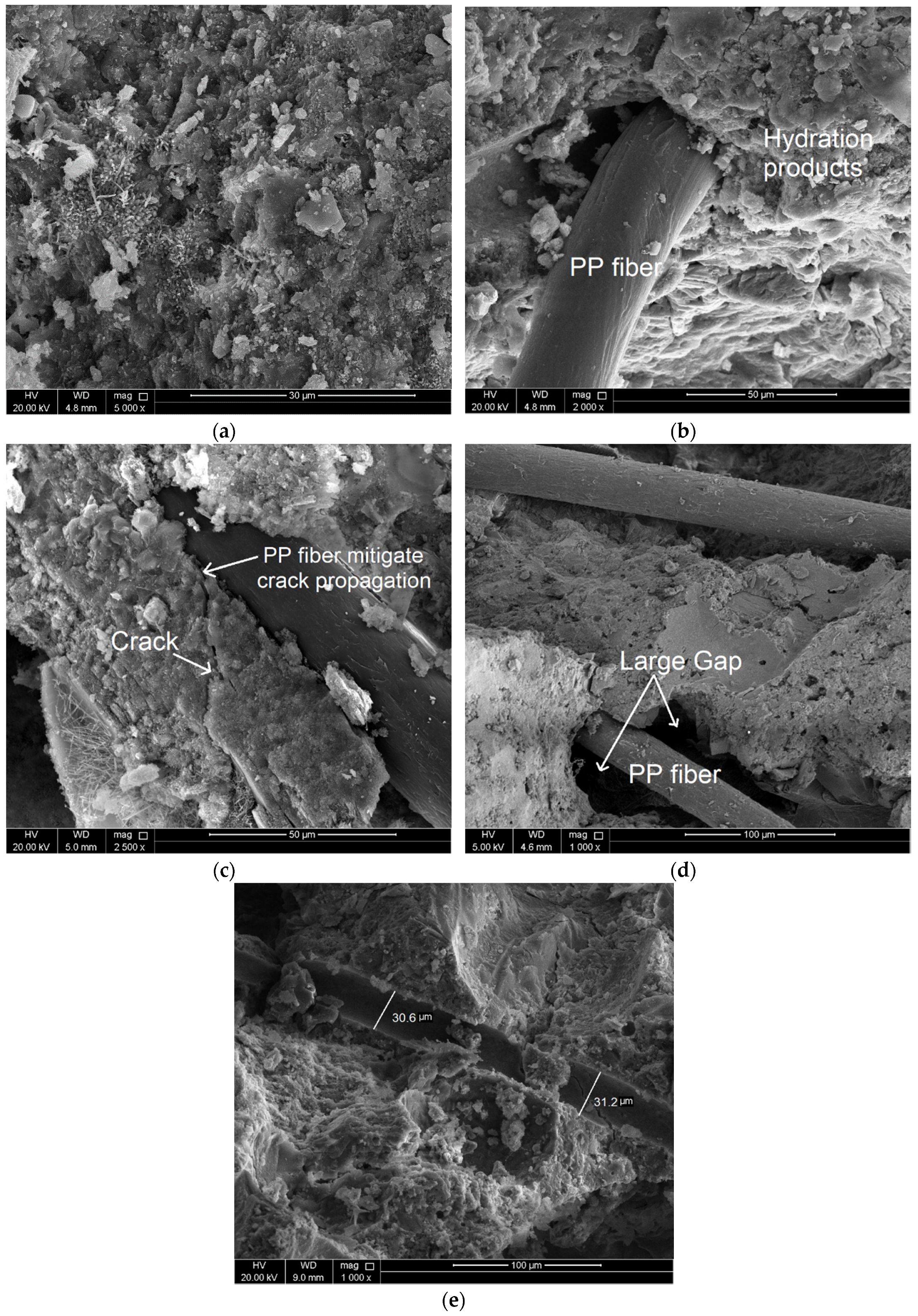

3.5. Microstructure Investigation Using Scanning Electron Microscopy (SEM)

4. Conclusions

- Adding small dosage of polypropylene (PP) microfibers into cementitious composites enhances their mechanical properties at ambient temperature. Compressive strength, flexural strength, ductility, and elastic modulus of cement mortar are clearly improved by incorporating the PP fibers.

- Incorporating PP fibers enhances the residual compressive strength of cement mortar when exposed to elevated temperatures. The enhancement is more pronounced for heating level beyond 200 °C.

- Polypropylene microfiber addition enhances the post-heating flexural behavior of cement mortar. The enhancement is less visible when the heating level exceeds the melting temperature of the fibers (170 °C).

- Thermal conductivity of cement mortar decreases with heating regardless the presence of the fibers. Beyond 200 °C, the thermal conductivity of fiber-reinforced mortar is greater than that of plain mortar.

- The presence of PP fibers does not affect the heat flow and the mass loss of cement mortar at room temperature. Heating cement mortar at temperature beyond the melting point of the fibers negatively affect its thermal behavior.

- The presence of PP fibers plays a major role in bridging the cracks and mitigating their propagation. Once the melting point of the polypropylene fibers is exceeded, the fibers melt and create extra voids in the microstructure of concrete. These extra voids negatively affect the mechanical strengths of the mortar but could enhance spalling resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, L.G.; Zhao, Z.W.; Zhu, J.; Kwan, A.K.H.; Zeng, K.L. Combined effects of water film thickness and polypropylene fibre length on fresh properties of mortar. Constr. Build. Mater. 2018, 174, 586–593. [Google Scholar] [CrossRef]

- Flores Medina, N.; Barluenga, G.; Hernández-Olivares, F. Enhancement of durability of concrete composites containing natural pozzolans blended cement through the use of Polypropylene fibers. Compos. Part B Eng. 2014, 61, 214–221. [Google Scholar] [CrossRef]

- Szeląg, M. Evaluation of cracking patterns of cement paste containing polypropylene fibers. Compos. Struct. 2019, 220, 402–411. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Ezziane, M.; Kadri, T.; Molez, L.; Jauberthie, R.; Belhacen, A. High temperature behaviour of polypropylene fibres reinforced mortars. Fire Saf. J. 2015, 71, 324–331. [Google Scholar] [CrossRef]

- Li, L.G.; Chu, S.H.; Zeng, K.L.; Zhu, J.; Kwan, A.K.H. Roles of water film thickness and fibre factor in workability of polypropylene fibre reinforced mortar. Cem. Concr. Compos. 2018, 93, 196–204. [Google Scholar] [CrossRef]

- Müller, P.; Novák, J.; Holan, J. Destructive and non-destructive experimental investigation of polypropylene fibre reinforced concrete subjected to high temperature. J. Build. Eng. 2019, 26, 100906. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Yu, B.; Solhmirzaei, R. A simplified approach for predicting temperatures in insulated RC members exposed to standard fire. Fire Saf. J. 2017, 92, 80–90. [Google Scholar] [CrossRef]

- Maluk, C.; Bisby, L.; Terrasi, G.P. Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Eng. Struct. 2017, 141, 584–595. [Google Scholar] [CrossRef]

- Bilodeau, A.; Kodur, V.K.R.; Hoff, G.C. Optimization of the type and amount of polypropylene fibres for preventing the spalling of lightweight concrete subjected to hydrocarbon fire. Cem. Concr. Compos. 2004, 26, 163–174. [Google Scholar] [CrossRef]

- Kodur, V. Properties of Concrete at Elevated Temperatures. ISRN Civ. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Amancio, F.A.; de Carvalho Rafael, M.F.; de Oliveira Dias, A.R.; Bezerra Cabral, A.E. Behavior of concrete reinforced with polypropylene fiber exposed to high temperatures. Proc. Struct. Integr. 2018, 11, 91–98. [Google Scholar] [CrossRef]

- Signorini, C.; Sola, A.; Malchiodi, B.; Nobili, A.; Gatto, A. Failure mechanism of silica coated polypropylene fibres for Fibre Reinforced Concrete (FRC). Constr. Build. Mater. 2020, 236, 117549. [Google Scholar] [CrossRef]

- Noumowe, A. Mechanical properties and microstructure of high strength concrete containing polypropylene fibres exposed to temperatures up to 200 °C. Cem. Concr. Res. 2005, 35, 2192–2198. [Google Scholar] [CrossRef]

- Eidan, J.; Rasoolan, I.; Rezaeian, A.; Poorveis, D. Residual mechanical properties of polypropylene fiber-reinforced concrete after heating. Constr. Build. Mater. 2019, 198, 195–206. [Google Scholar] [CrossRef]

- Choumanidis, D.; Badogiannis, E.; Nomikos, P.; Sofianos, A. The effect of different fibres on the flexural behaviour of concrete exposed to normal and elevated temperatures. Constr. Build. Mater. 2016, 129, 266–277. [Google Scholar] [CrossRef]

- Aydın, S.; Yazıcı, H.; Baradan, B. High temperature resistance of normal strength and autoclaved high strength mortars incorporated polypropylene and steel fibers. Constr. Build. Mater. 2008, 22, 504–512. [Google Scholar] [CrossRef]

- C01 Committee. Specification for Standard Sand; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Irshidat, M.R.; Al Nuaimi, N.; Salim, S.; Rabie, M. Dosage Optimization of Polypropylene Fiber for Strength Enhancement of Cementitious Composites. In Proceedings of the International Conference on Civil Infrastructure and Construction (CIC 2020), Doha, Qatar, 2–5 February 2020. [Google Scholar]

- C01 Committee. Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- C01 Committee. Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- C01 Committee. Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- C09 Committee. Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Zhang, H.; Wang, L.; Zheng, K.; Bakura, T.J.; Totakhil, P.G. Research on compressive impact dynamic behavior and constitutive model of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2018, 187, 584–595. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H. Thermal performance and fire resistance of nanoclay modified cementitious materials. Constr. Build. Mater. 2018, 159, 213–219. [Google Scholar] [CrossRef]

- Cülfik, M.S.; Özturan, T. Effect of elevated temperatures on the residual mechanical properties of high-performance mortar. Cem. Concr. Res. 2002, 32, 809–816. [Google Scholar] [CrossRef]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Yermak, N.; Pliya, P.; Beaucour, A.-L.; Simon, A.; Noumowé, A. Influence of steel and/or polypropylene fibres on the behaviour of concrete at high temperature: Spalling, transfer and mechanical properties. Constr. Build. Mater. 2017, 132, 240–250. [Google Scholar] [CrossRef]

- Pavlík, Z.; Trník, A.; Kulovaná, T.; Scheinherrová, L.; Rahhal, V.; Irassar, E.; Černý, R. DSC and TG Analysis of a Blended Binder Based on Waste Ceramic Powder and Portland Cement. Int. J. Thermophys. 2016, 37, 32. [Google Scholar] [CrossRef]

- Elkatatny, S.; Gajbhiye, R.; Ahmed, A.; Mahmoud, A.A. Enhancing the cement quality using polypropylene fiber. J. Pet. Explor. Prod. Technol. 2020, 10, 1097–1107. [Google Scholar] [CrossRef]

- Pakravan, H.; Jamshidi, M.; Latifi, M. Investigation on polymeric fibers as reinforcement in cementitious composites: Flexural performance. J. Ind. Text. 2012, 42, 3–18. [Google Scholar] [CrossRef]

- Ehsan, M.; Ali, Y.M.; Mehdizadeh, M.B.; Mehdi, Z.; Mohammad, R.M. Combined Effects of Metakaolin, Rice Husk Ash, and Polypropylene Fiber on the Engineering Properties and Microstructure of Mortar. J. Mater. Civ. Eng. 2017, 29, 04017025. [Google Scholar] [CrossRef]

| Compound Name | CaO | SiO2 | Fe2O3 | SO3 | Al2O3 | MgO | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|

| Content Percentage | 66.4% | 18.4% | 6.1% | 3.0% | 2.2% | 1.4% | 0.8% | 1.7% |

| Mortar Batch | Cement (Kg/m3) | Sand (Kg/m3) | Water (Kg/m3) | PP Fibers (Kg/m3) | Superplasticizer (Kg/m3) |

|---|---|---|---|---|---|

| 1 | 706.67 | 1943.33 | 342.67 | - | 7.06 |

| 2 | 706.67 | 1943.33 | 342.67 | 0.706 | 7.06 |

| 3 | 706.67 | 1943.33 | 342.67 | 0.353 | 7.06 |

| Specimen | Compressive Strength (MPa) | Flexural Strength (kN) | Elastic Modulus (Gpa) | Fracture Energy (kN.mm) | Stress Intensity Factor |

|---|---|---|---|---|---|

| C-RT | 30.3 (29.2–31.4) | 2.00 (1.88–2.12) | 23.134 | 0.086 | 1.41 |

| C-150 | 31.3 (30.4–32.2) | 2.80 (2.7–2.9) | 19.38 | 0.586 | 3.37 |

| C-200 | 33.2 (32.0–34.4) | 2.63 (2.52–2.74) | 15.8 | 0.548 | 2.94 |

| C-450 | 18.5 (16.8–20.2) | 1.27 (1.07–1.47) | 12.58 | 0.070 | 0.94 |

| C-600 | 9.9 (8.6–11.2) | 0.21 (0.06–0.36) | NA | NA | NA |

| PPF-RT | 38.5 (37.5–39.5) | 2.70 (2.59–2.81) | 24.04 | 0.527 | 3.56 |

| PPF-150 | 41.7 (40.4–43.0) | 4.05 (3.86–4.24) | 22.5 | 0.963 | 4.65 |

| PPF-200 | 44.1 (42.6–45.6) | 3.19 (3.04–3.34) | 16.85 | 0.628 | 3.25 |

| PPF-450 | 29.0 (27.6–30.4) | 1.35 (1.23–1.47) | 13.77 | 0.066 | 0.96 |

| PPF-600 | 18.0 (16.2–19.8) | NA | NA | NA | NA |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irshidat, M.R.; Al-Nuaimi, N.; Rabie, M. The Role of Polypropylene Microfibers in Thermal Properties and Post-Heating Behavior of Cementitious Composites. Materials 2020, 13, 2676. https://doi.org/10.3390/ma13122676

Irshidat MR, Al-Nuaimi N, Rabie M. The Role of Polypropylene Microfibers in Thermal Properties and Post-Heating Behavior of Cementitious Composites. Materials. 2020; 13(12):2676. https://doi.org/10.3390/ma13122676

Chicago/Turabian StyleIrshidat, Mohammad R., Nasser Al-Nuaimi, and Mohamed Rabie. 2020. "The Role of Polypropylene Microfibers in Thermal Properties and Post-Heating Behavior of Cementitious Composites" Materials 13, no. 12: 2676. https://doi.org/10.3390/ma13122676

APA StyleIrshidat, M. R., Al-Nuaimi, N., & Rabie, M. (2020). The Role of Polypropylene Microfibers in Thermal Properties and Post-Heating Behavior of Cementitious Composites. Materials, 13(12), 2676. https://doi.org/10.3390/ma13122676