Extrusion-Based Additive Manufacturing with Carbon Reinforced Concrete: Concept and Feasibility Study

Abstract

1. Introduction

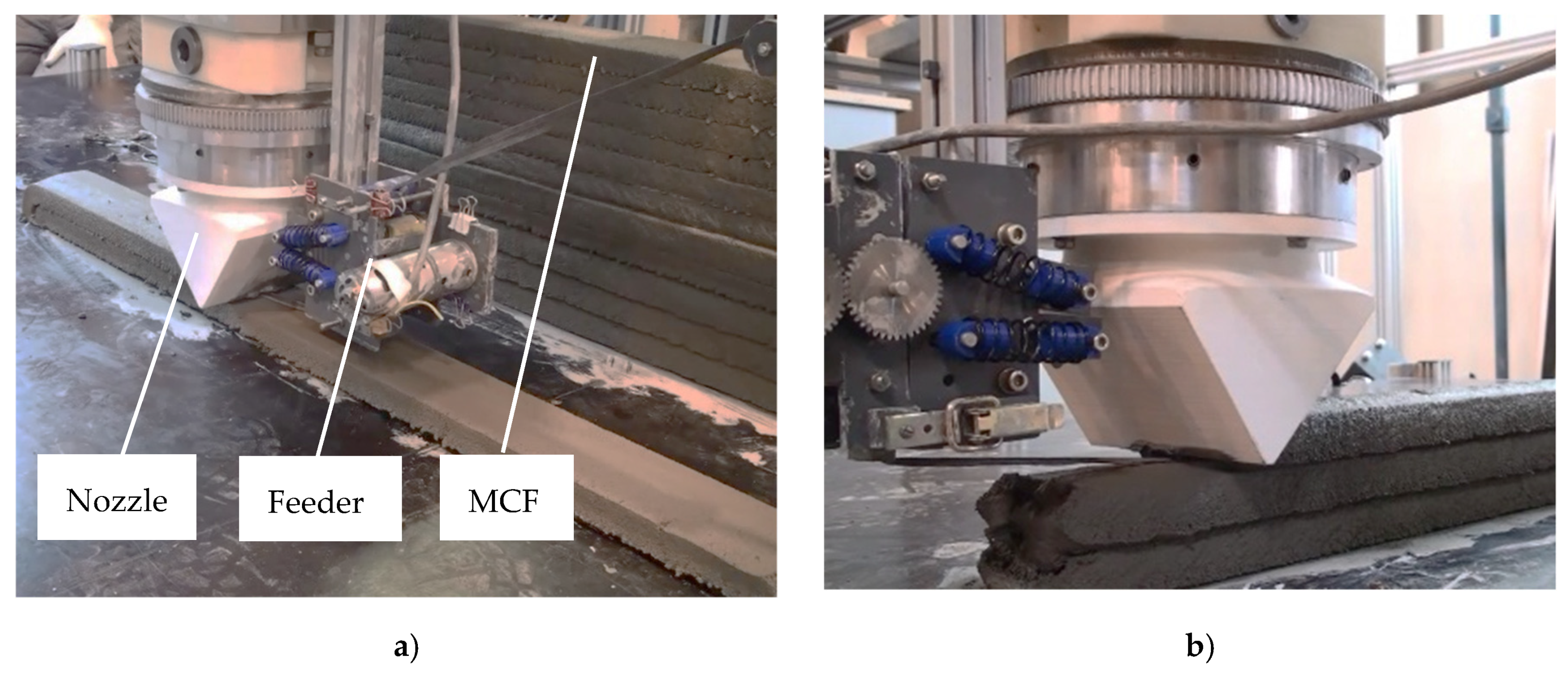

2. Concepts for a Direct Implementation of MCF Reinforcements in 3D Concrete Printing

2.1. MCF Production and Supply to the Printhead

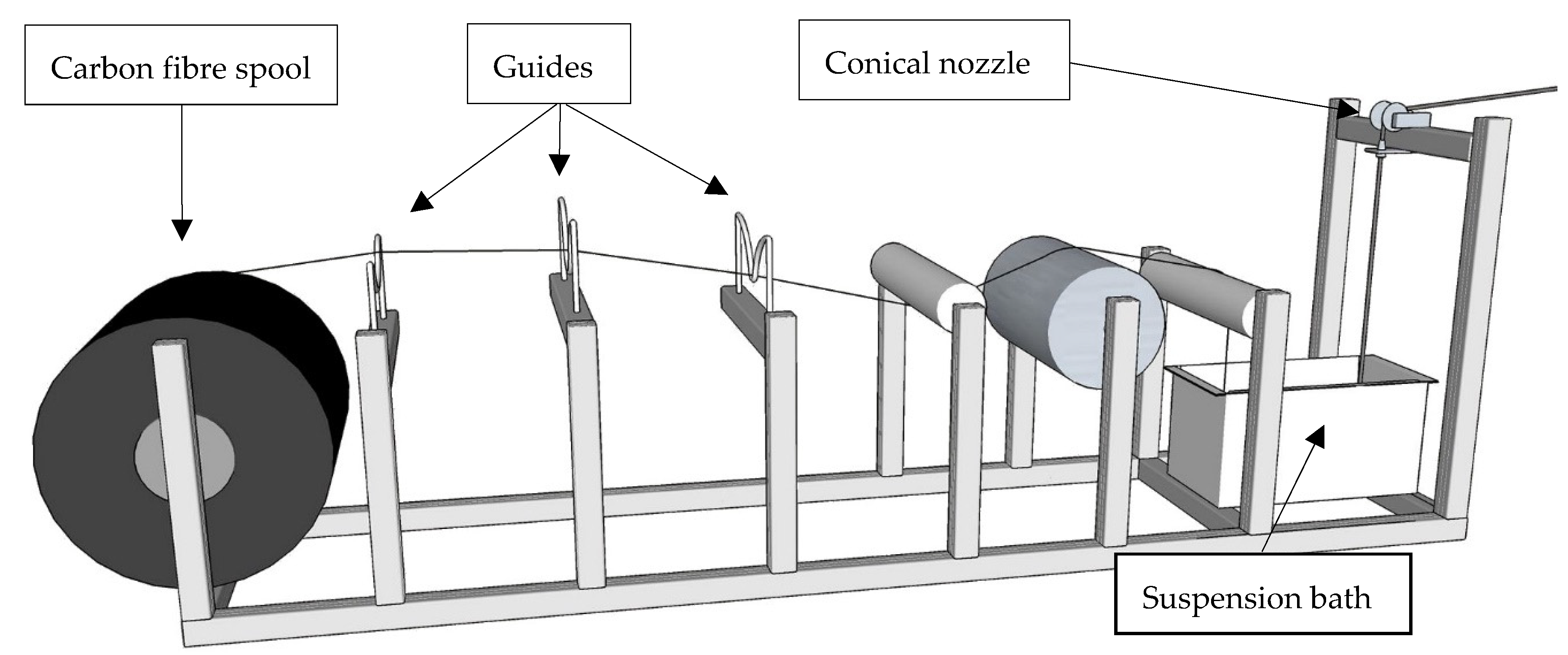

2.1.1. Stationary Impregnation Process

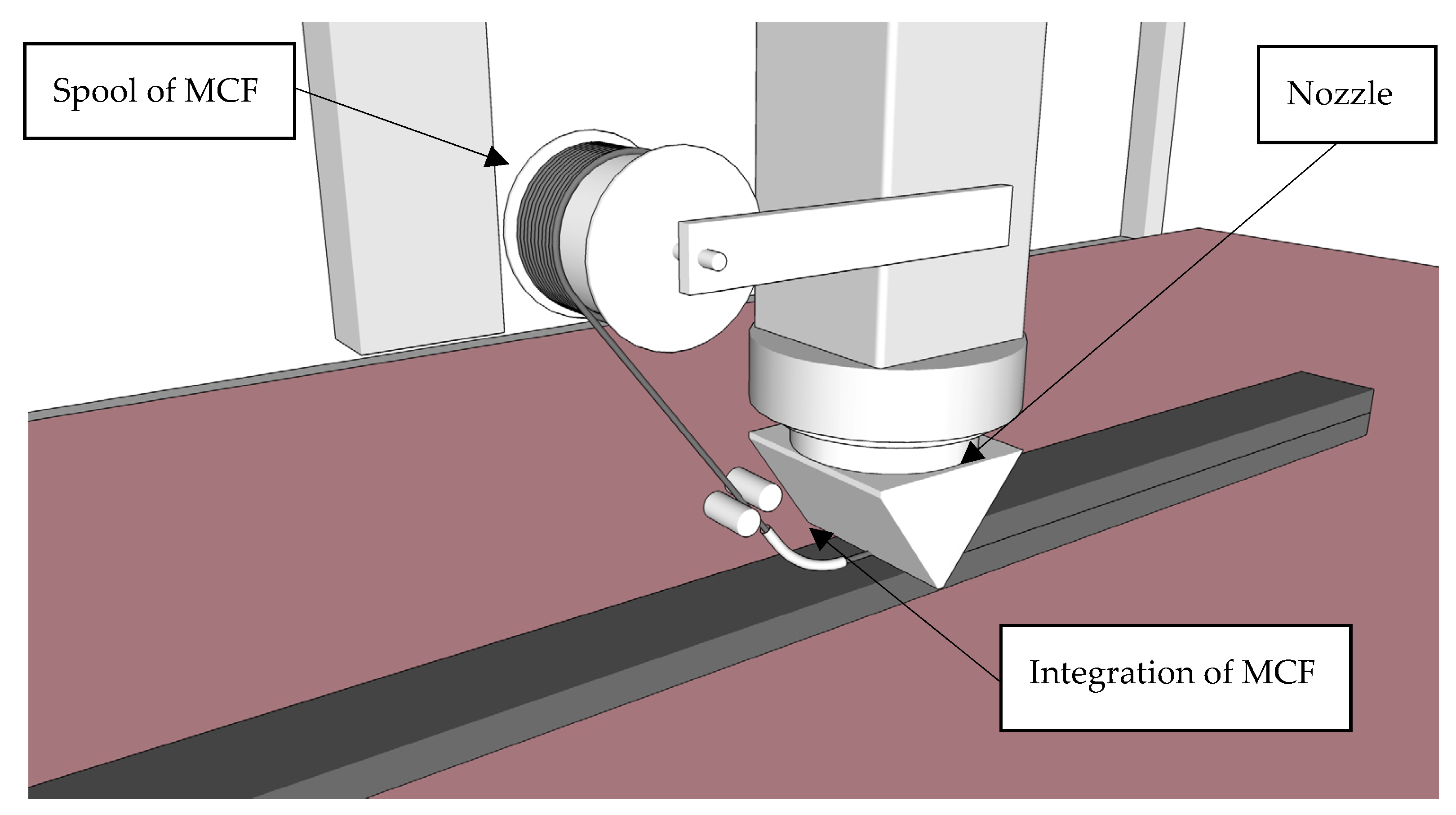

2.1.2. MCF Supply from a Spool (Two-Step Process)

2.1.3. MCF Supply from a Continuous, Stationary Impregnation Line (One-Step Process)

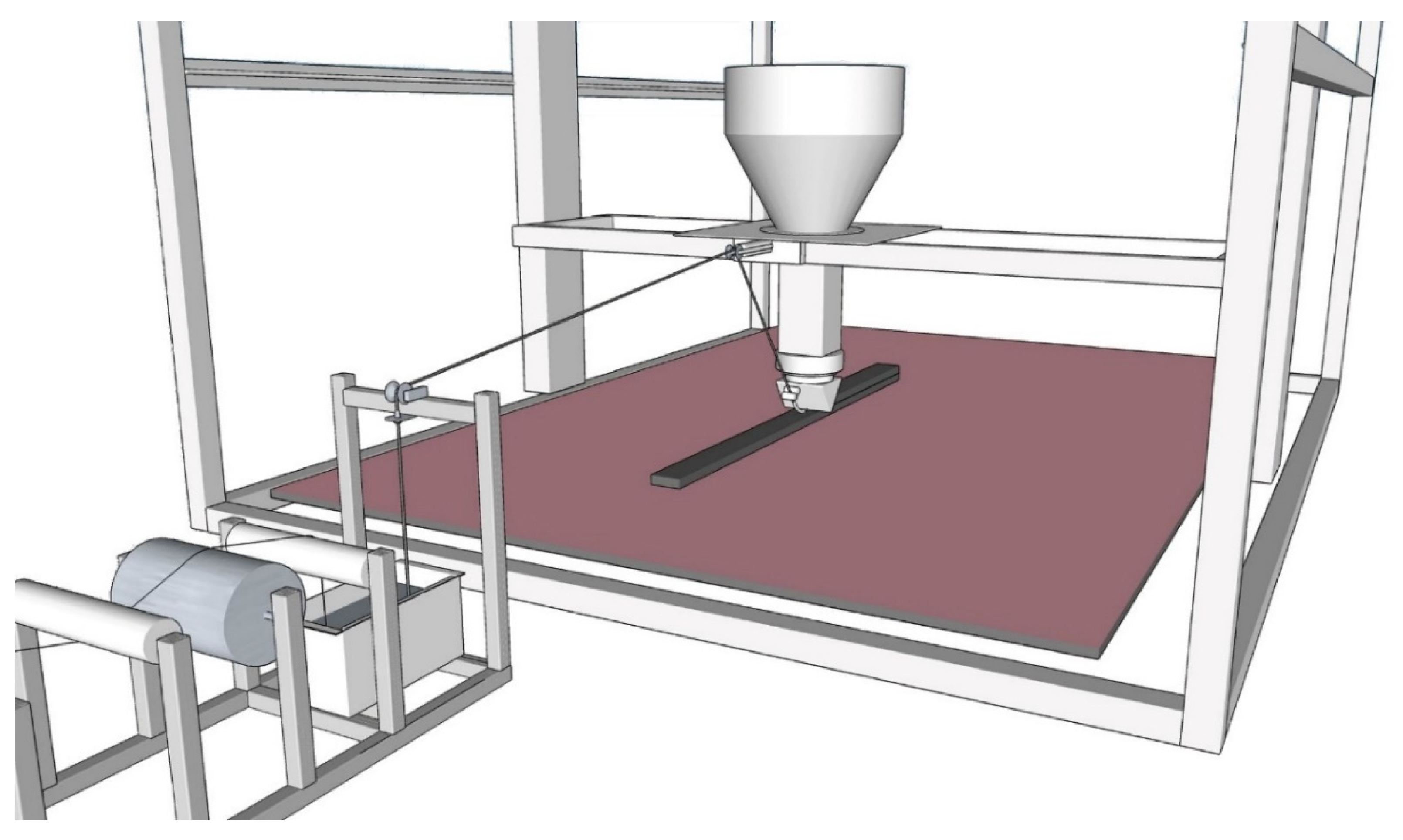

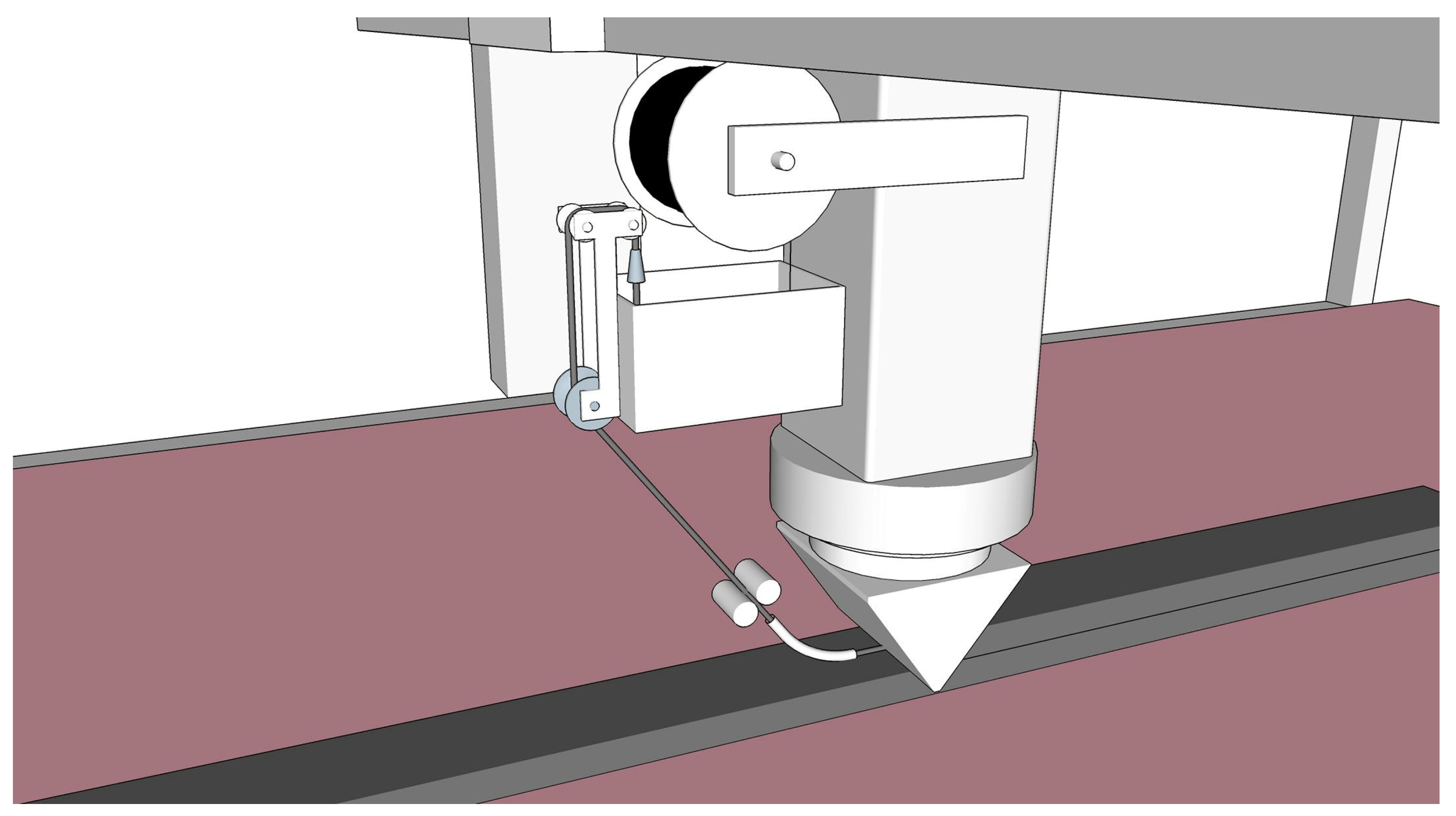

2.1.4. MCF Supply from a Mobile Impregnating Device (One-Step Process)

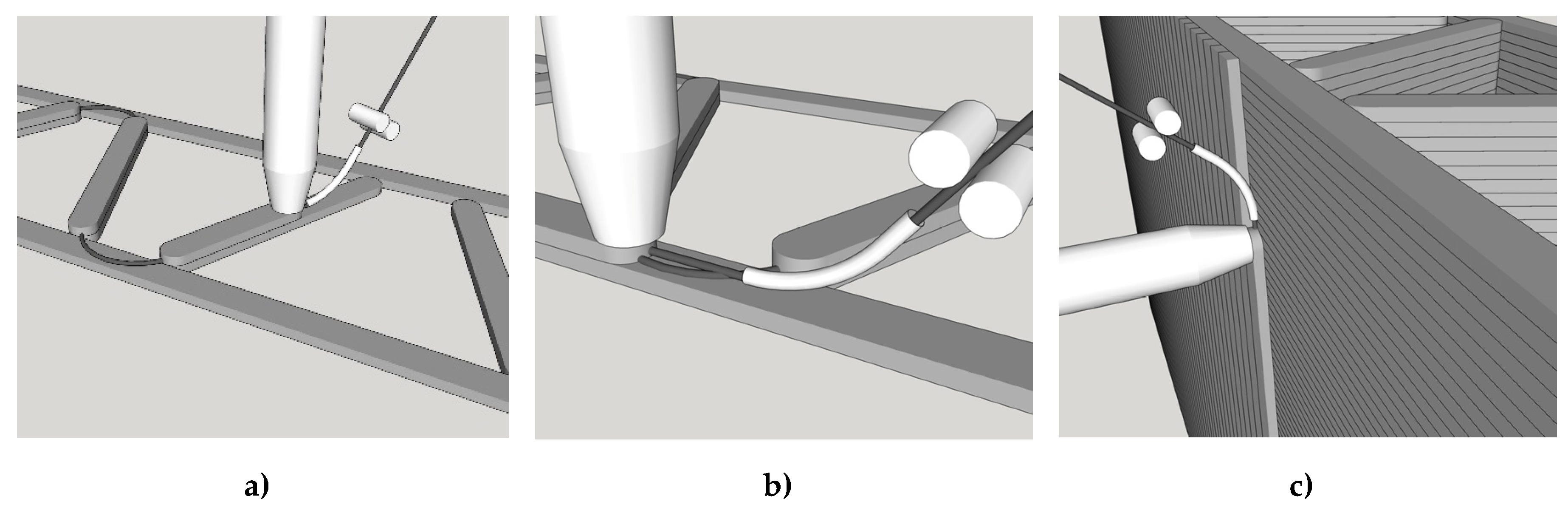

2.2. Integrating MCF into Concrete Elements

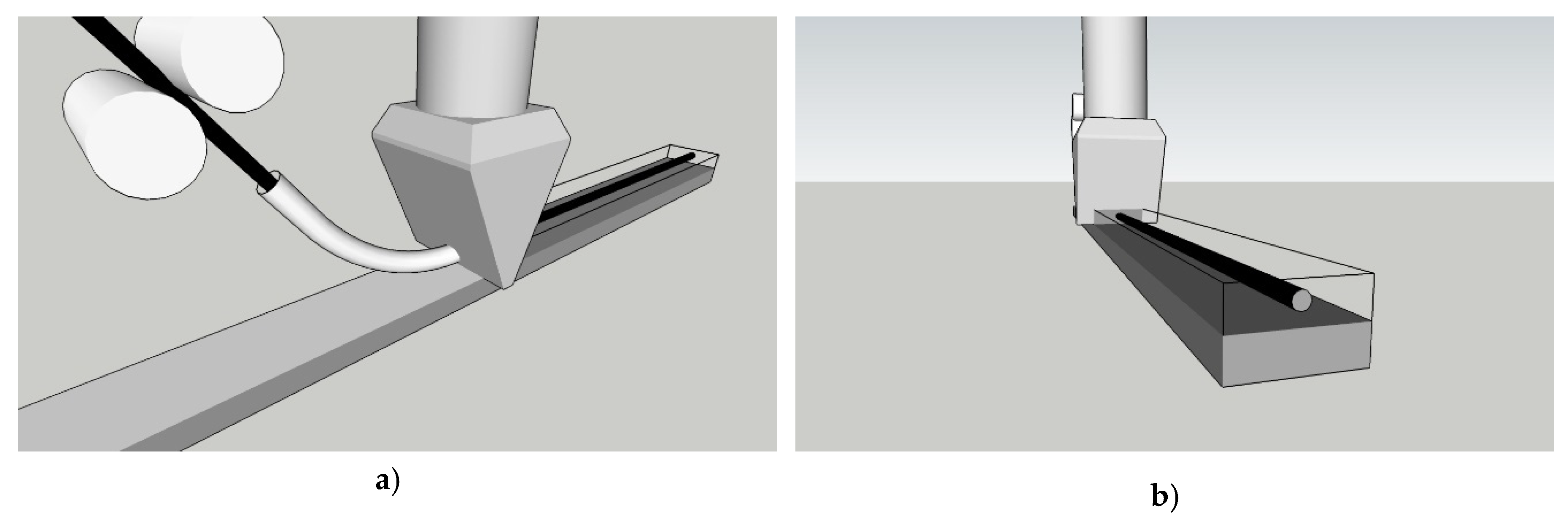

2.2.1. Integrating MCF into the Concrete Filament

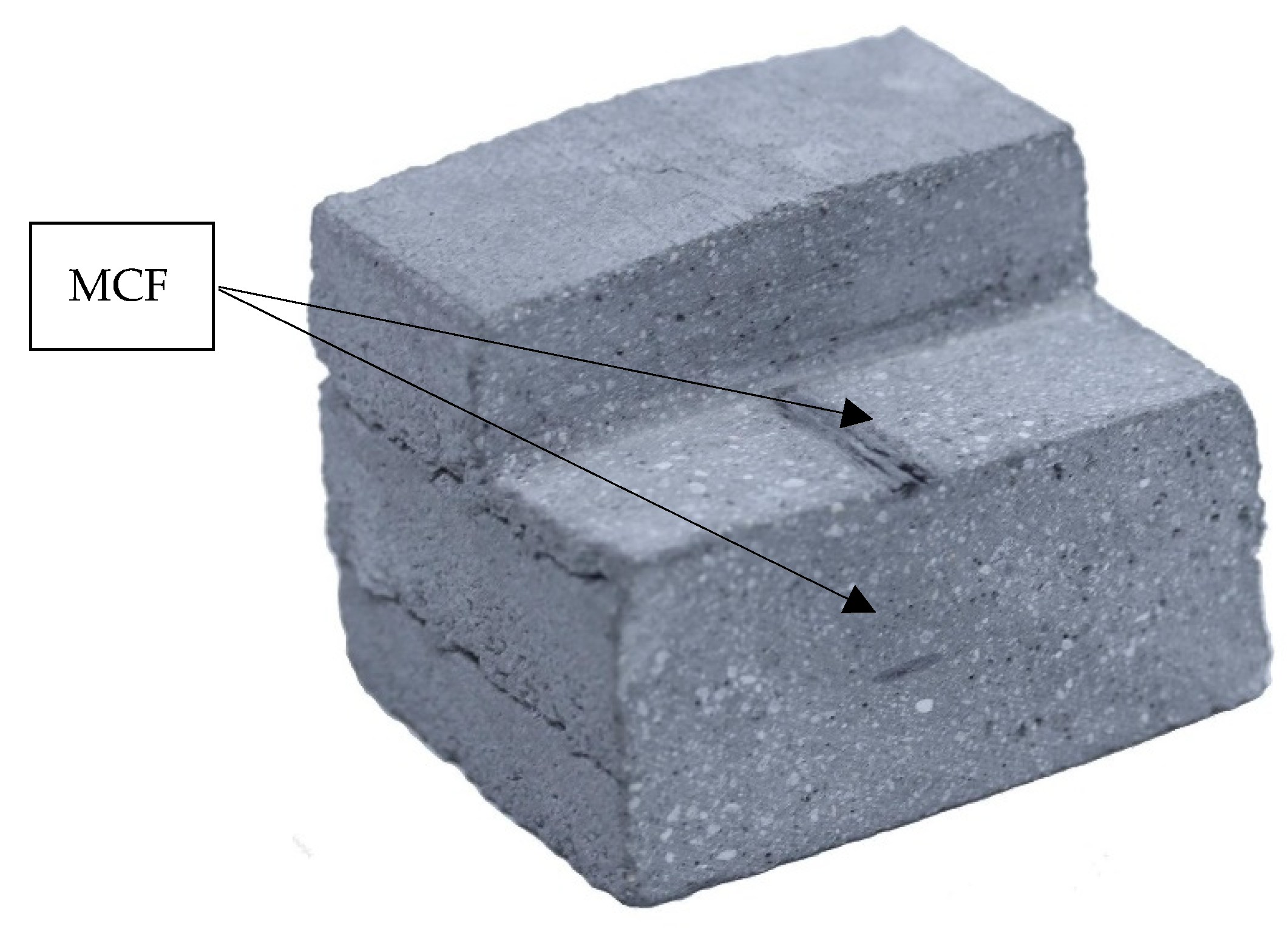

2.2.2. Integrating MCF between Concrete Filaments

2.2.3. Further Implementation Aspects

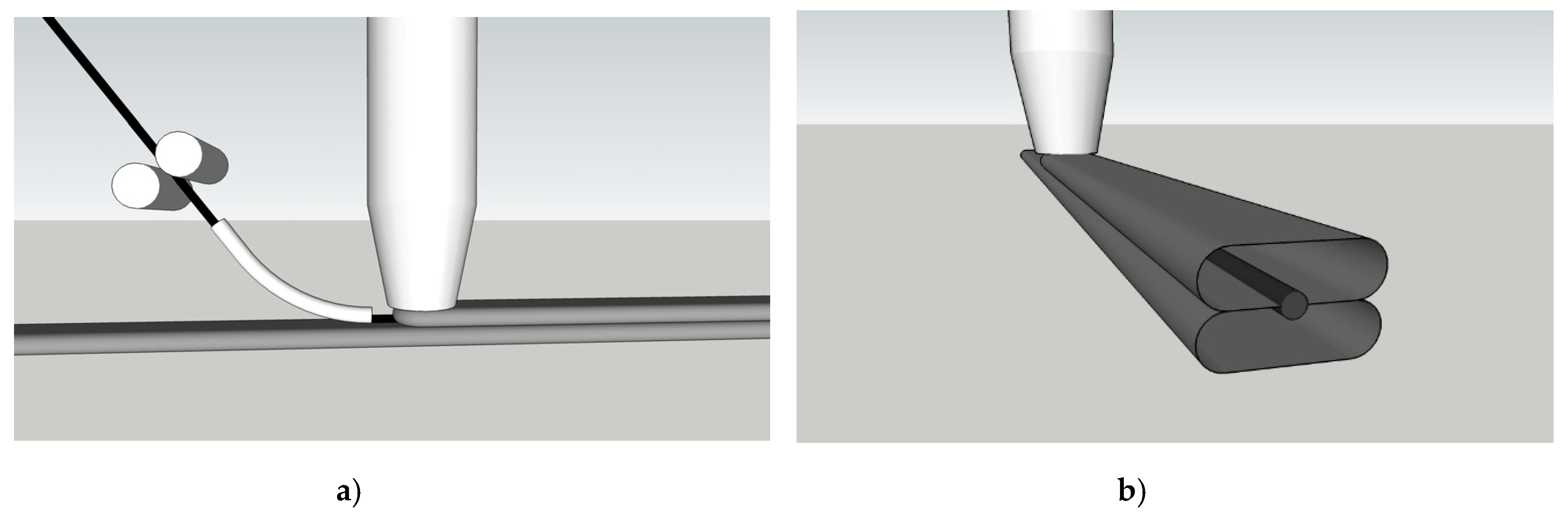

- deposition of one, two, or several rovings next to each other,

- bundling of several rovings into a thicker strand before integrating them into concrete,

- use of CF yarns with different fineness,

- variation of concrete filament dimensions, etc.

3. Feasibility Study—Materials and Methods

3.1. Raw Materials

3.2. Fabrication of the MCF and Concrete Mixing

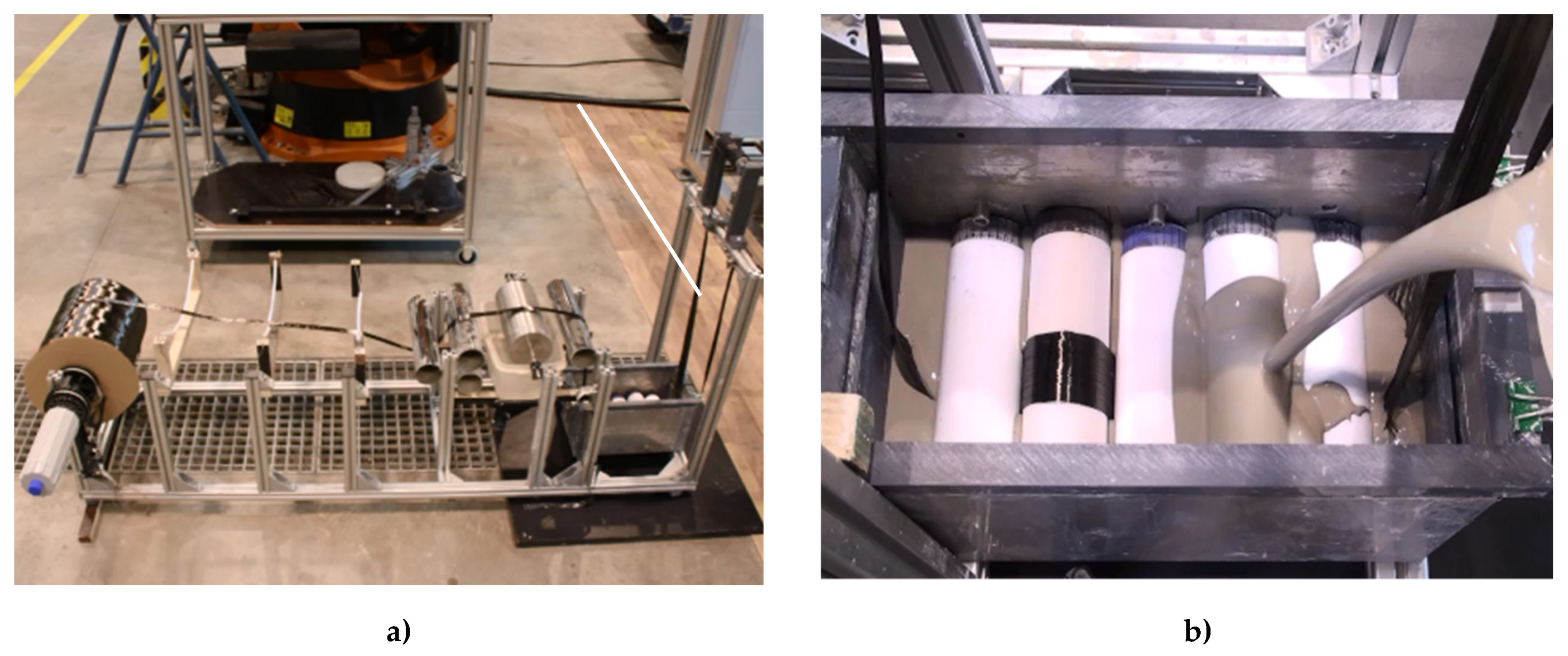

3.3. 3D Printing of Carbon-Reinforced Concrete Elements

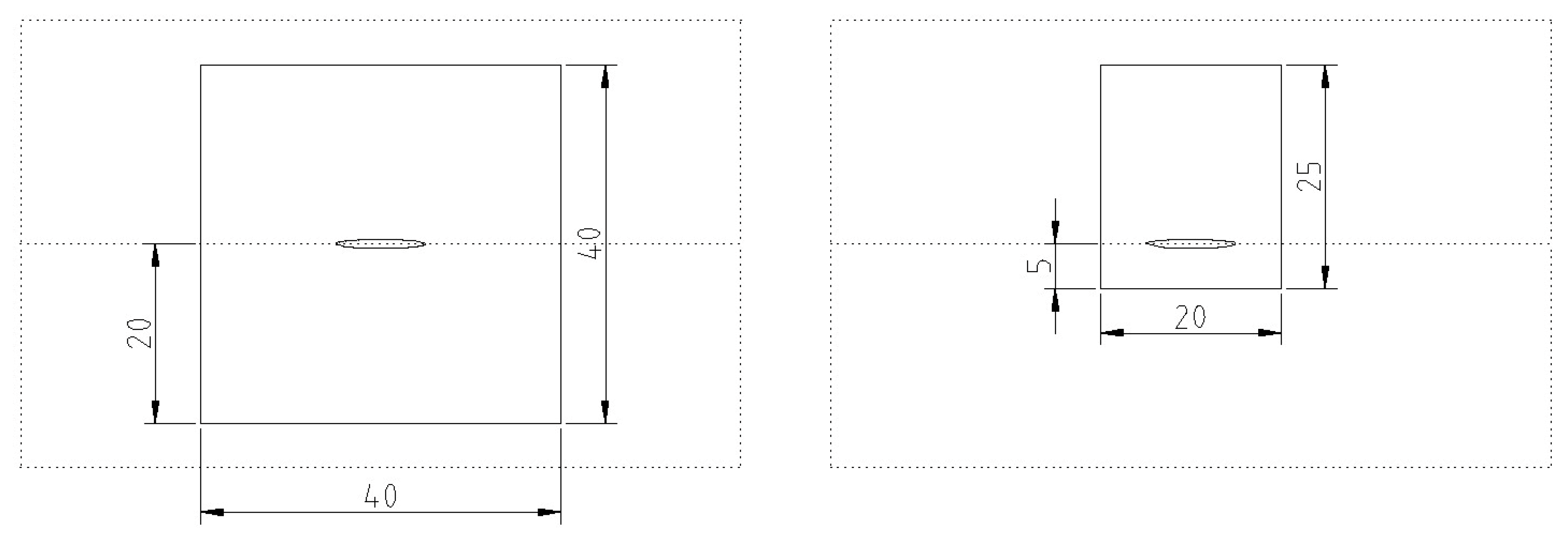

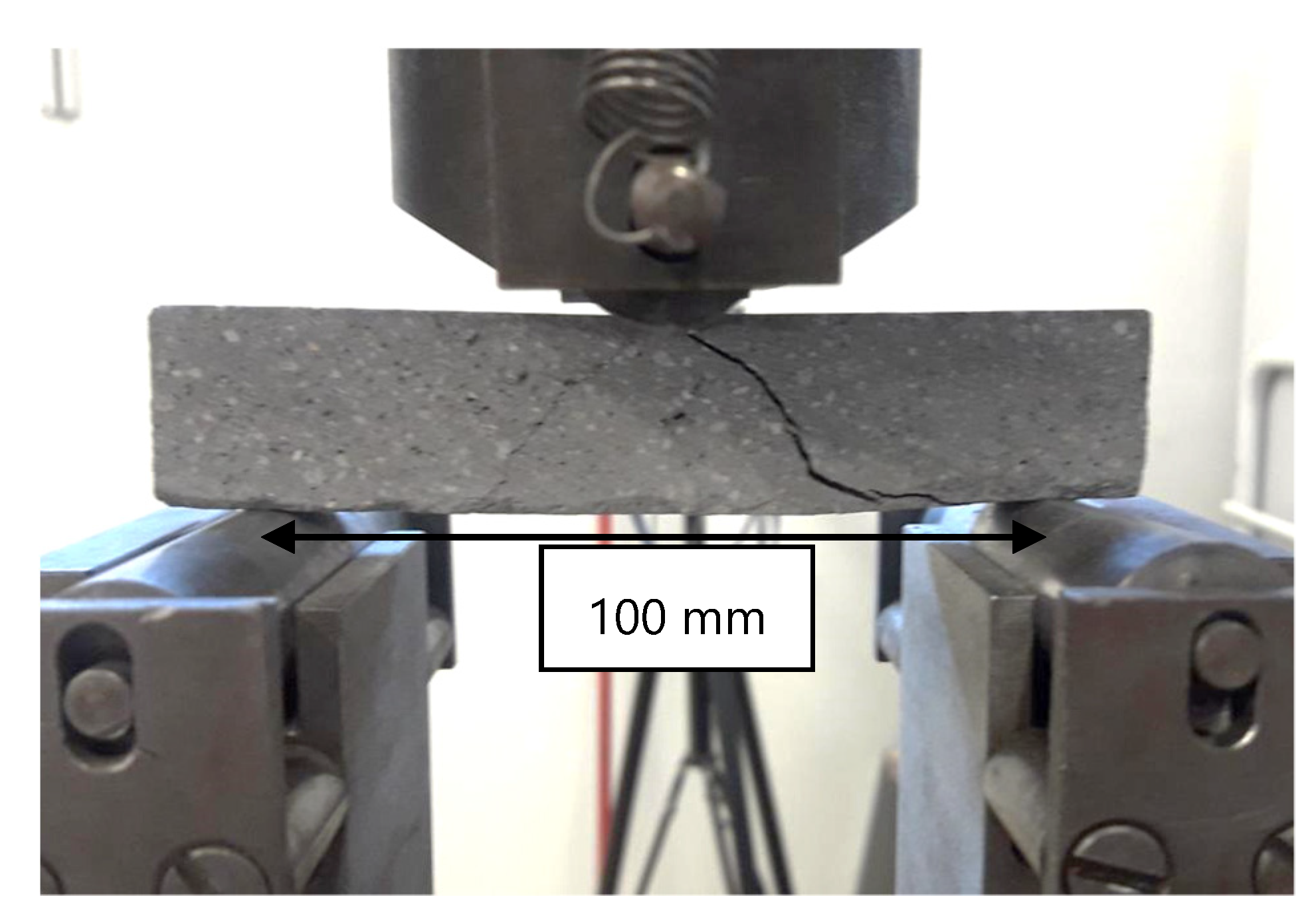

3.4. Specimen Preparation and Mechaniical Testing

4. Feasibility Study: Results and Discussion

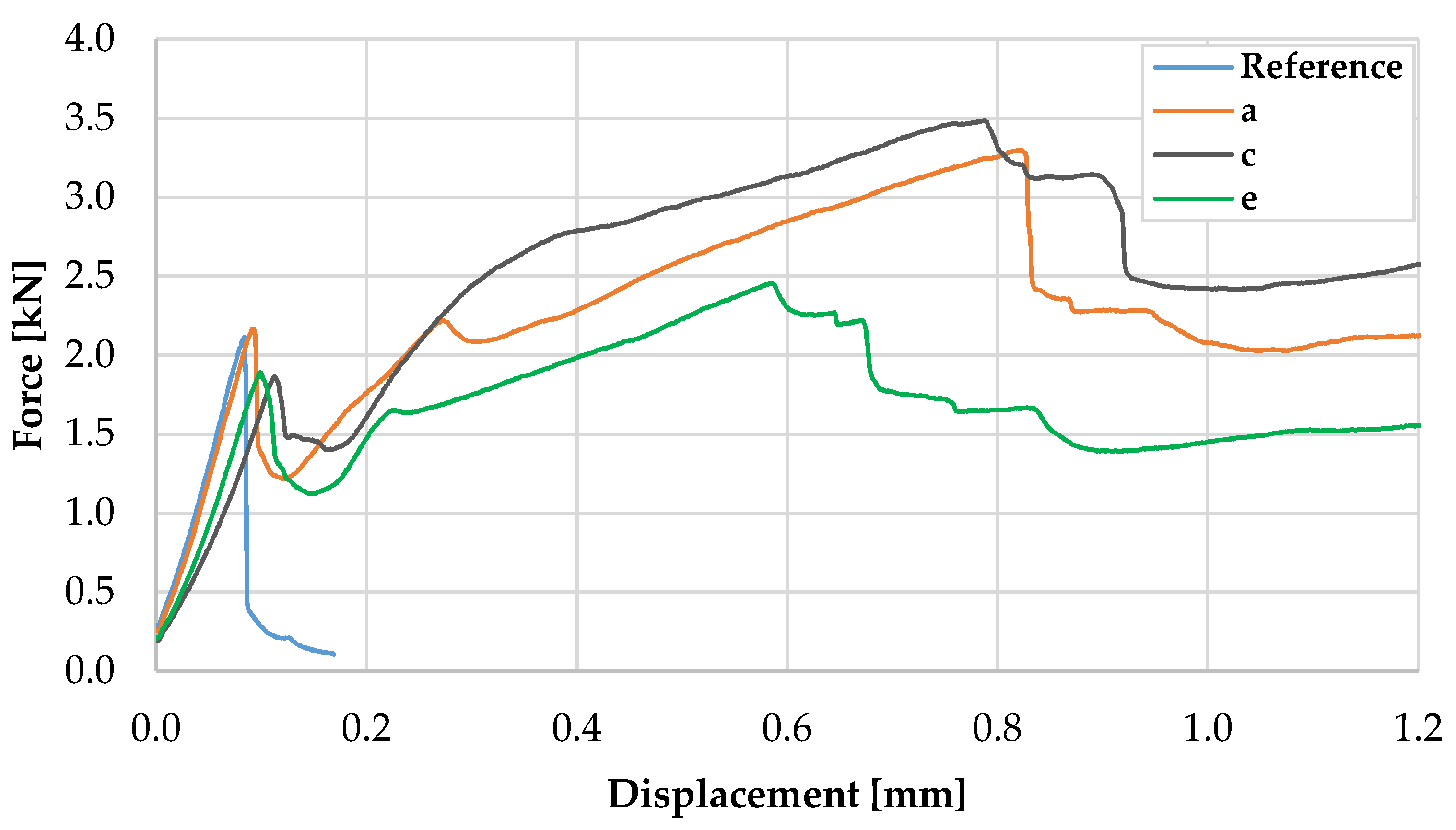

4.1. Speciemens with a Cross-Section of 40 mm × 40 mm and Centrally Positioned MCF Reinforcement

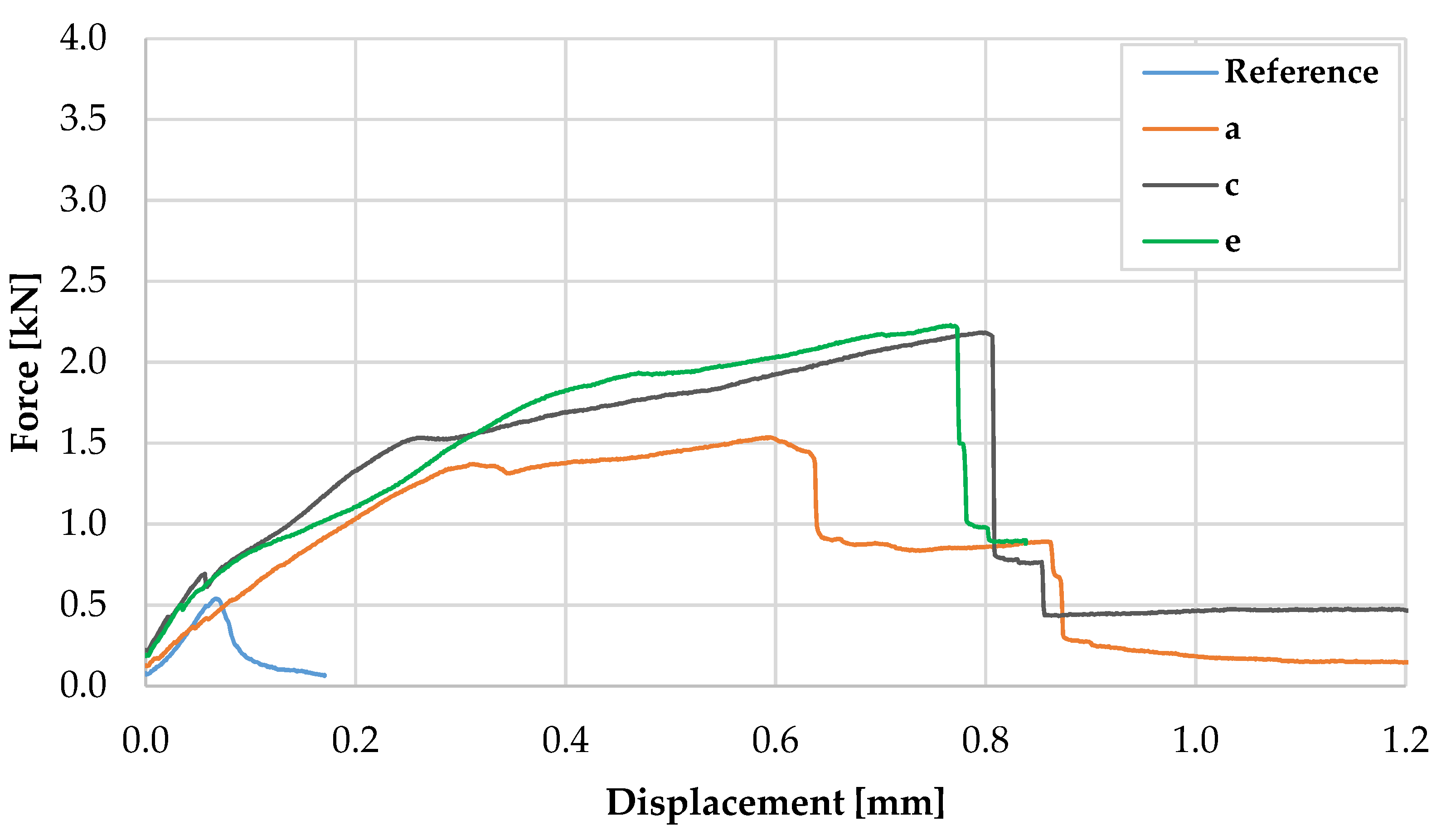

4.2. Specimens with a Cross-Section of 20 mm × 25 mm and MCF located in the Tension Zone

5. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Salet, T.A.M.; Ahmed, Z.Y.; Bos, F.P.; Laagland, H.L.M. Design of a 3D printed concrete bridge by testing. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Buswell, R.A.; Soar, R.; Gibb, A.; Thorpe, A. Freeform Construction: Mega-scale Rapid Manufacturing for construction. Autom. Constr. 2007, 16, 224–231. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.; Mata-Falcón, J.; Kaufmann, W. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N. Incorporating reinforcement in 3D-printing with concrete. Beton Stahlbetonbau 2018, 113, 496–504. [Google Scholar] [CrossRef]

- Hamidi, F.; Aslani, F. Additive manufacturing of cementitious composites: Materials, methods, potentials, and challenges. Constr. Build. Mater. 2019, 218, 582–609. [Google Scholar] [CrossRef]

- Rudenko, A. 3D Printed Castle. 2020. Available online: http://totalkustom.com/photo.html (accessed on 9 April 2020).

- Apis Cor 3D printed in Dubai, Apis Cor. Available online: https://www.apis-cor.com/dubai-project (accessed on 9 April 2020).

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Hack, N.; Lauer, W.V. Mesh-Mould: Robotically Fabricated Spatial Meshes as Reinforced Concrete Formwork. Archit. Des. 2014, 84, 44–53. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Grafe, J.; Nerella, V.N.; Spaniol, E.; Hertel, M.; Füssel, U. 3D-printed steel reinforcement for digital concrete construction—Manufacture, mechanical properties and bond behaviour. Constr. Build. Mater. 2018, 179, 125–137. [Google Scholar] [CrossRef]

- Ogura, H.; Nerella, V.N.; Mechtcherine, V. Developing and testing of Strain-Hardening Cement-Based Composites (SHCC) in the context of 3D-printing. Materials 2018, 11, 1375. [Google Scholar] [CrossRef] [PubMed]

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J.; et al. On the emergence of 3D printable Engineered, Strain Hardening Cementitious Composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Zhang, Y.; Sanjayan, J. Development of 3D printable engineered cementitious composites with ultra-high tensile ductility for digital construction. Mater. Des. 2019, 181, 108088. [Google Scholar] [CrossRef]

- Hambach, M.; Möller, H.; Neumann, T.; Volkmer, D. Portland cement paste with aligned carbon fibres exhibiting exceptionally high flexural strength (>100 MPa). Cem. Concr. Res. 2016, 89, 80–86. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fibre-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmann, C.; Michel, S. Tensile behavior of high-strength strain-hardening cement-based composites (HS-SHCC) made with high-performance polyethylene, aramid and PBO fibres. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

- Bos, F.; Ahmed, Z.; Jutinov, E.; Salet, T. Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete. Materials 2017, 10, 1314. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-cable reinforced geopolymer composite for extrusion-based 3D printing. Mater. Lett. 2019, 235, 144–147. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Mechanical improvement of continuous steel microcable reinforced geopolymer composites for 3D printing subjected to different loading conditions. Compos. Part B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2020, 109, 102992. [Google Scholar] [CrossRef]

- Schneider, K.; Lieboldt, M.; Liebscher, M.; Fröhlich, M.; Hempel, S.; Butler, M.; Schröfl, C.; Mechtcherine, V. Mineral-Based Coating of Plasma-Treated Carbon Fibre Rovings for Carbon Concrete Composites with Enhanced Mechanical Performance. Materials 2017, 10, 360. [Google Scholar] [CrossRef]

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77. [Google Scholar] [CrossRef]

- Schneider, K.; Michel, A.; Liebscher, M.; Mechtcherine, V. Bond behavior of mineral-impregnated and polymer-impregnated reinforcement structures made of carbon fibres at temperatures up to 500 °C. Beton Stahlbetonbau 2018, 113, 886–894. [Google Scholar] [CrossRef]

- Ehlig, D.; Schladitz, F.; Frenzel, M.; Curbach, M. Textile concrete—An overview of executed projects. Beton Stahlbetonbau 2012, 107, 777–785. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel cement-based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Liu, T.; Liu, X.; Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fibre composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- Incremental3d, Incremental3d. Available online: https://www.incremental3d.eu/ (accessed on 9 April 2020).

- Priest, I. 3D-Printed Concrete Components. Available online: https://www.ribaj.com/products/3d-printing (accessed on 9 April 2020).

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N. 3D-concrete-printing by selective deposition—Requirements for fresh concrete and testing. Beton Stahlbetonbau 2019, 114, 24–32. [Google Scholar] [CrossRef]

- Karihaloo, B.L.; Abdalla, H.M.; Xiao, Q.Z. Size effect in concrete beams. Eng. Fract. Mech. 2003, 70, 979–993. [Google Scholar] [CrossRef]

| Number of Filaments | 50,000 |

|---|---|

| Fineness of yarn [tex] | 3450 |

| Density [g/cm³] | 1.8 |

| Filament diameter [μm] | 6.9 |

| Filament tensile strength [MPa] | 4400 |

| Filament modulus of elasticity [GPa] | 255 |

| Sizing type | Epoxy |

| Sizing level [% by mass] | 1.0 |

| (a) | (b) | ||

| CEM I 52.5 R Opterra [kg] | 538 | Mikrodur R-X [g] | 417.5 |

| Fly ash steament H4 [kg] | 215 | Mikrodur P-U [g] | 417.5 |

| Silica suspension Emsac 500 SE [kg] | 162 | Centritit Fume SX [g] | 417.5 |

| Sand 0.006–0.2 (BCS 413) [kg] | 656 | Superplasticizer MSH flüssig [g] | 37.6 |

| Sand 0–2 [kg] | 979 | Water [g] | 387.5 |

| Sand 0–4 [kg] | 652 | ||

| Superplasticizer Sky 593 BASF [kg] | 16 | ||

| Water [kg] | 276 | ||

| Specimen | Reference | Reinforced Samples | ||||

|---|---|---|---|---|---|---|

| Max. Force [kN] | First Crack [kN] | Max. Force [kN] | Increase | No. of Cracks | Failure Mode | |

| a | 2.09 | 2.17 | 3.30 | 69% | 1 | Slip |

| b | 2.12 | 1.98 | 2.17 | 11% | 1 | Slip |

| c | 2.21 | 1.87 | 3.49 | 78% | 1 | Slip |

| d | 1.70 | 1.56 | 2.17 | 11% | 1 | Slip |

| e | 1.93 | 1.89 | 2.46 | 26% | 1 | Slip |

| f | 1.69 | 2.17 | 2.57 | 32% | 1 | Slip |

| Average | 1.96 | 1.94 | 2.69 | 38% | - | - |

| Coeff. of var. | 11% | 12% | 21% | 77% | - | - |

| Specimen | Reference | Reinforced Samples | ||||

|---|---|---|---|---|---|---|

| Max. Force [kN] | First Crack [kN] | Max. Force [kN] | Increase | No. of Cracks | Failure Mode | |

| a | 0.60 | - | 1.54 | 174% | 2 | Del. |

| b | 0.62 | 0.50 | 1.51 | 169% | 2 | Del. |

| c | 0.49 | 0.69 | 2.18 | 289% | 3 | Del./Slip |

| d | 0.56 | - | 2.02 | 260% | 2 | Del./Slip |

| e | 0.56 | - | 2.23 | 297% | 2 | Del./Slip |

| f | 0.54 | 0.70 | 1.92 | 241% | 1 | Del. |

| Average | 0.56 | 0.63 | 1.90 | 238% | - | - |

| Coeff. of var. | 8% | 18% | 16% | 23% | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mechtcherine, V.; Michel, A.; Liebscher, M.; Schmeier, T. Extrusion-Based Additive Manufacturing with Carbon Reinforced Concrete: Concept and Feasibility Study. Materials 2020, 13, 2568. https://doi.org/10.3390/ma13112568

Mechtcherine V, Michel A, Liebscher M, Schmeier T. Extrusion-Based Additive Manufacturing with Carbon Reinforced Concrete: Concept and Feasibility Study. Materials. 2020; 13(11):2568. https://doi.org/10.3390/ma13112568

Chicago/Turabian StyleMechtcherine, Viktor, Albert Michel, Marco Liebscher, and Tobias Schmeier. 2020. "Extrusion-Based Additive Manufacturing with Carbon Reinforced Concrete: Concept and Feasibility Study" Materials 13, no. 11: 2568. https://doi.org/10.3390/ma13112568

APA StyleMechtcherine, V., Michel, A., Liebscher, M., & Schmeier, T. (2020). Extrusion-Based Additive Manufacturing with Carbon Reinforced Concrete: Concept and Feasibility Study. Materials, 13(11), 2568. https://doi.org/10.3390/ma13112568