Flexural Behavior of Fire-Damaged Prefabricated RC Hollow Slabs Strengthened with CFRP versus TRM

Abstract

1. Introduction

2. Specimens and Materials

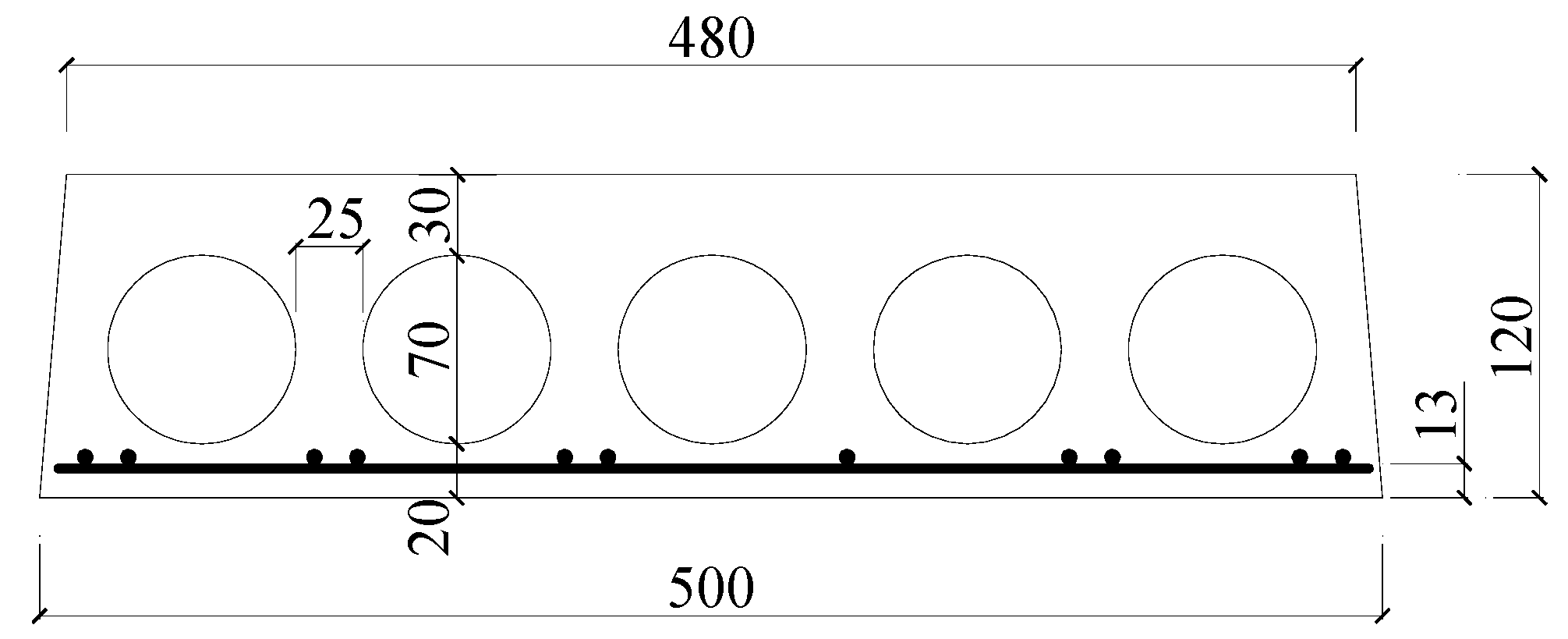

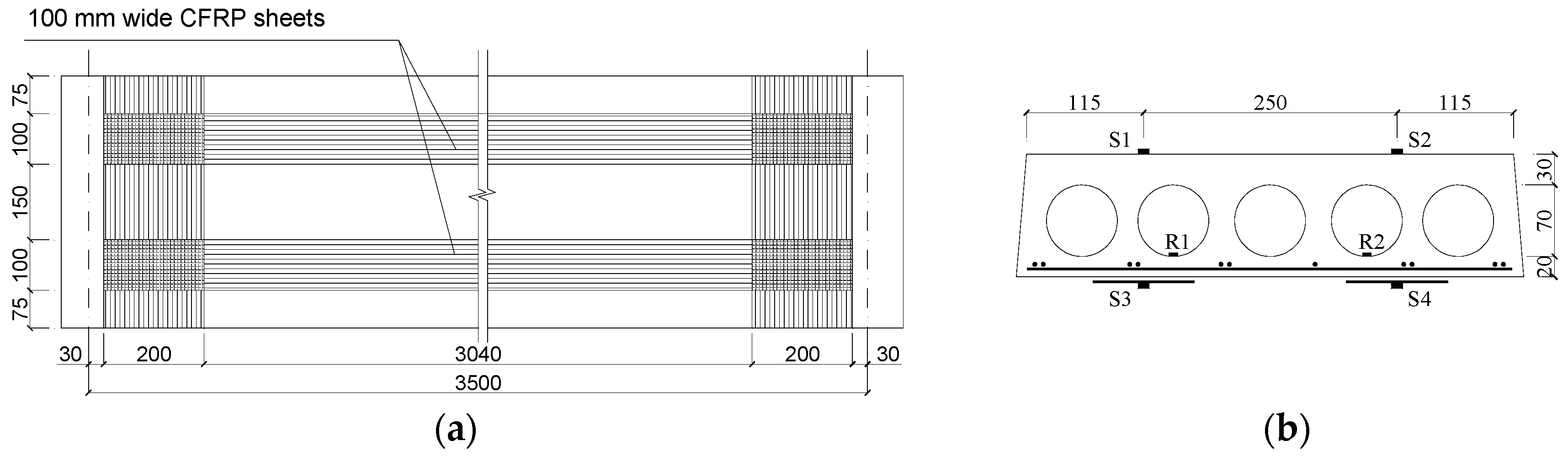

2.1. Specimens Design

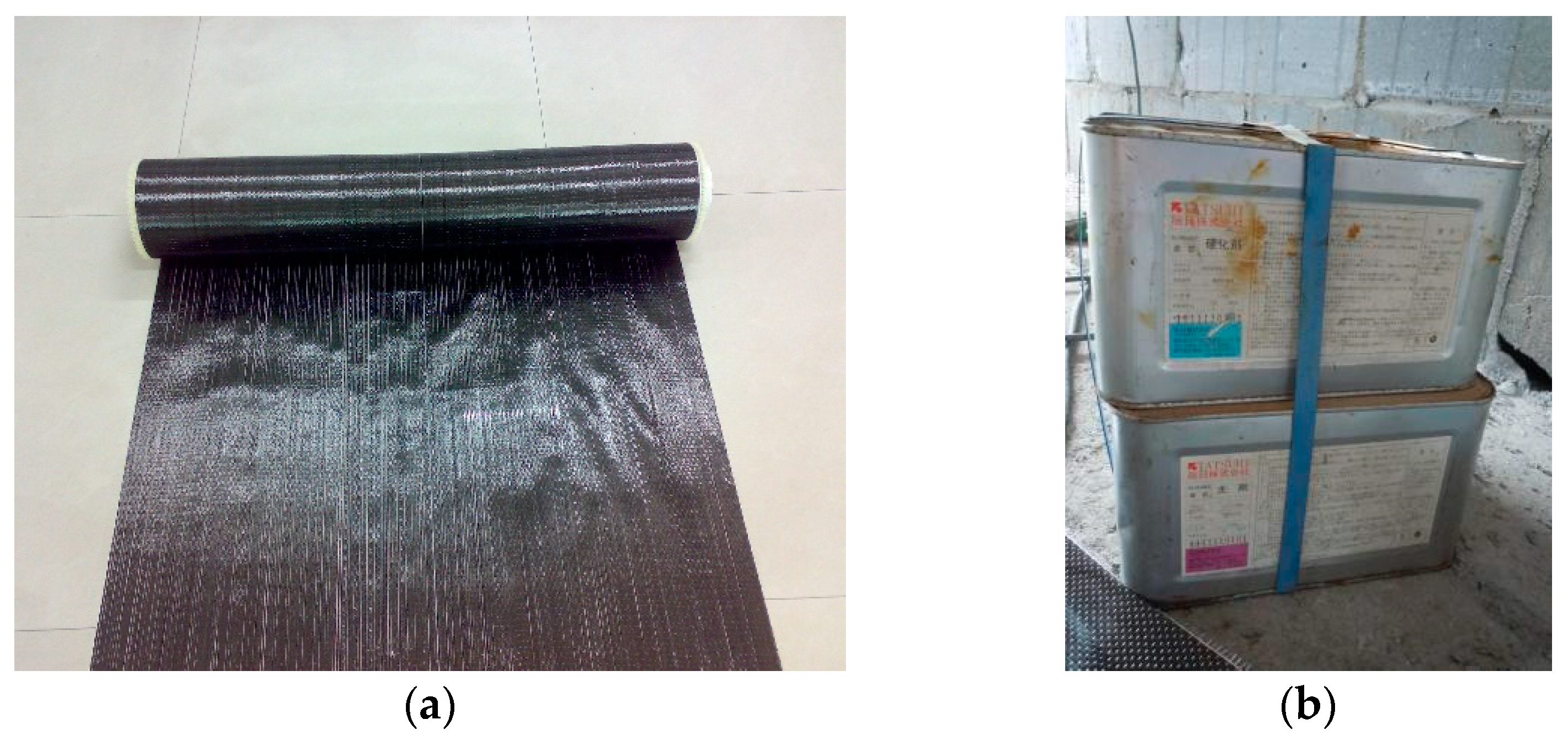

2.2. Properties of Materials

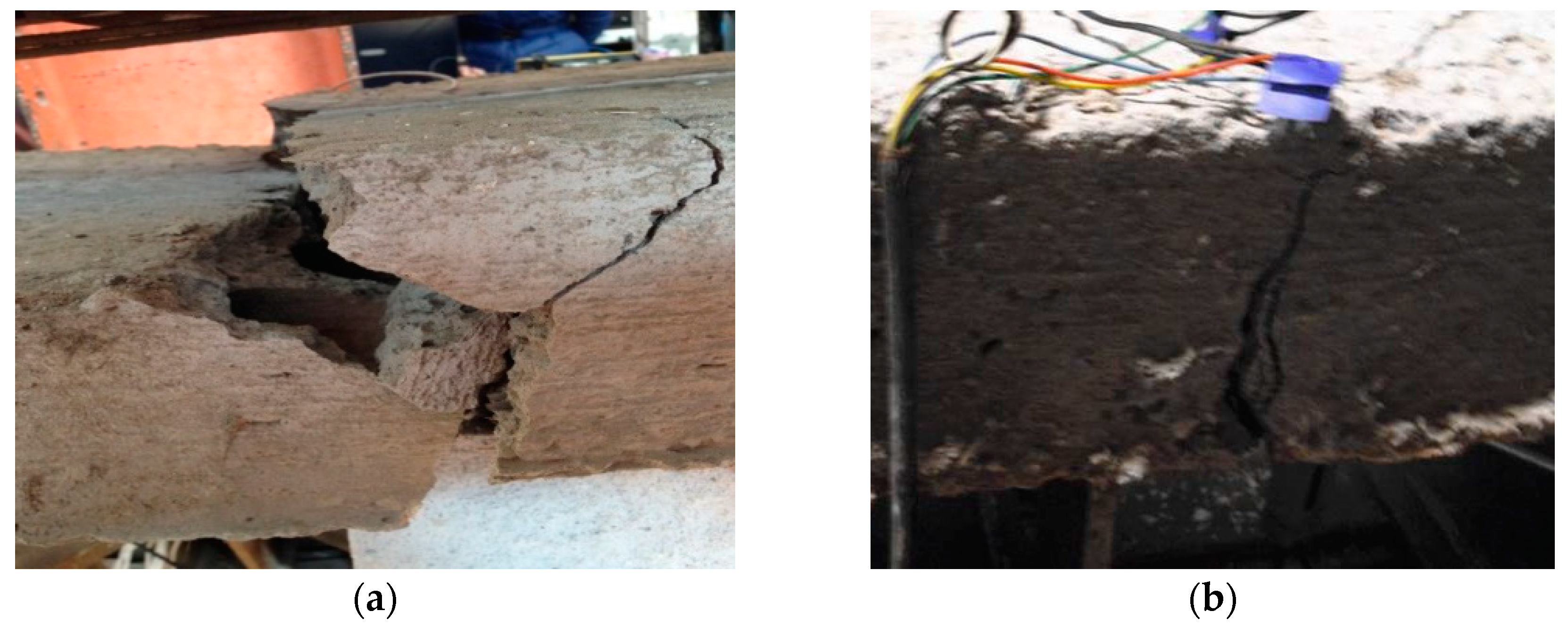

3. Fire Exposure Test

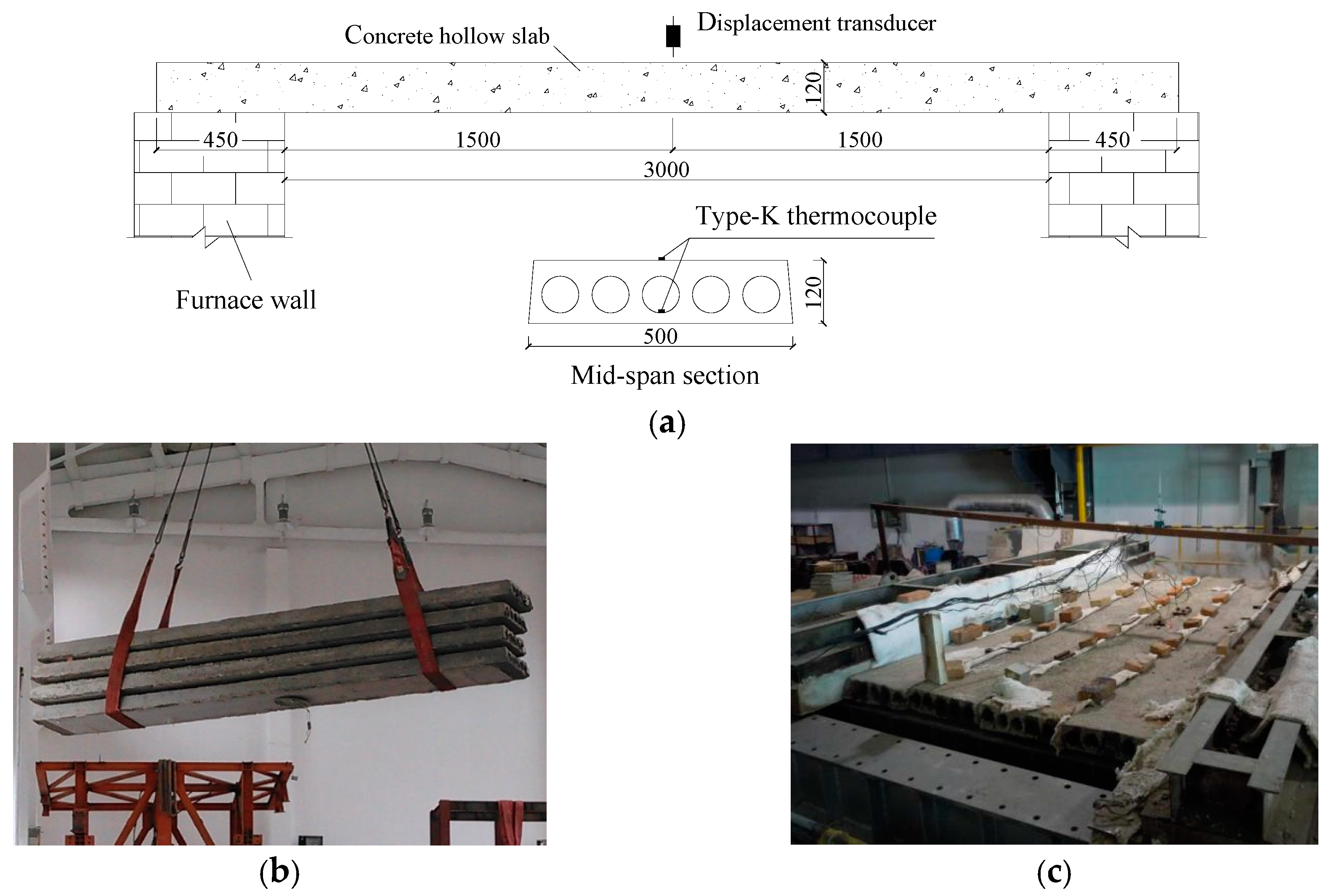

3.1. Fire Test Setup

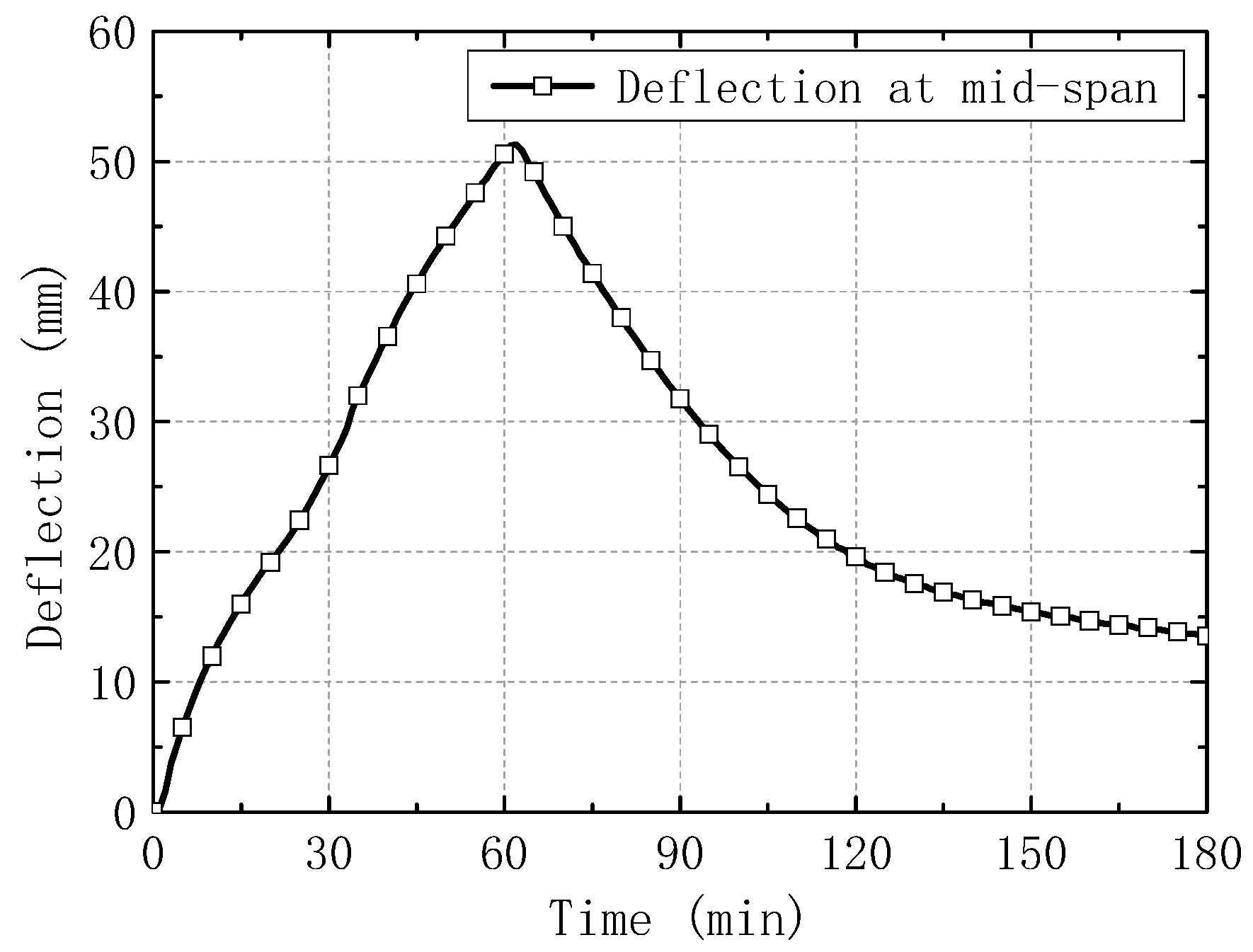

3.2. Fire Response

4. Four-Point Bending Test

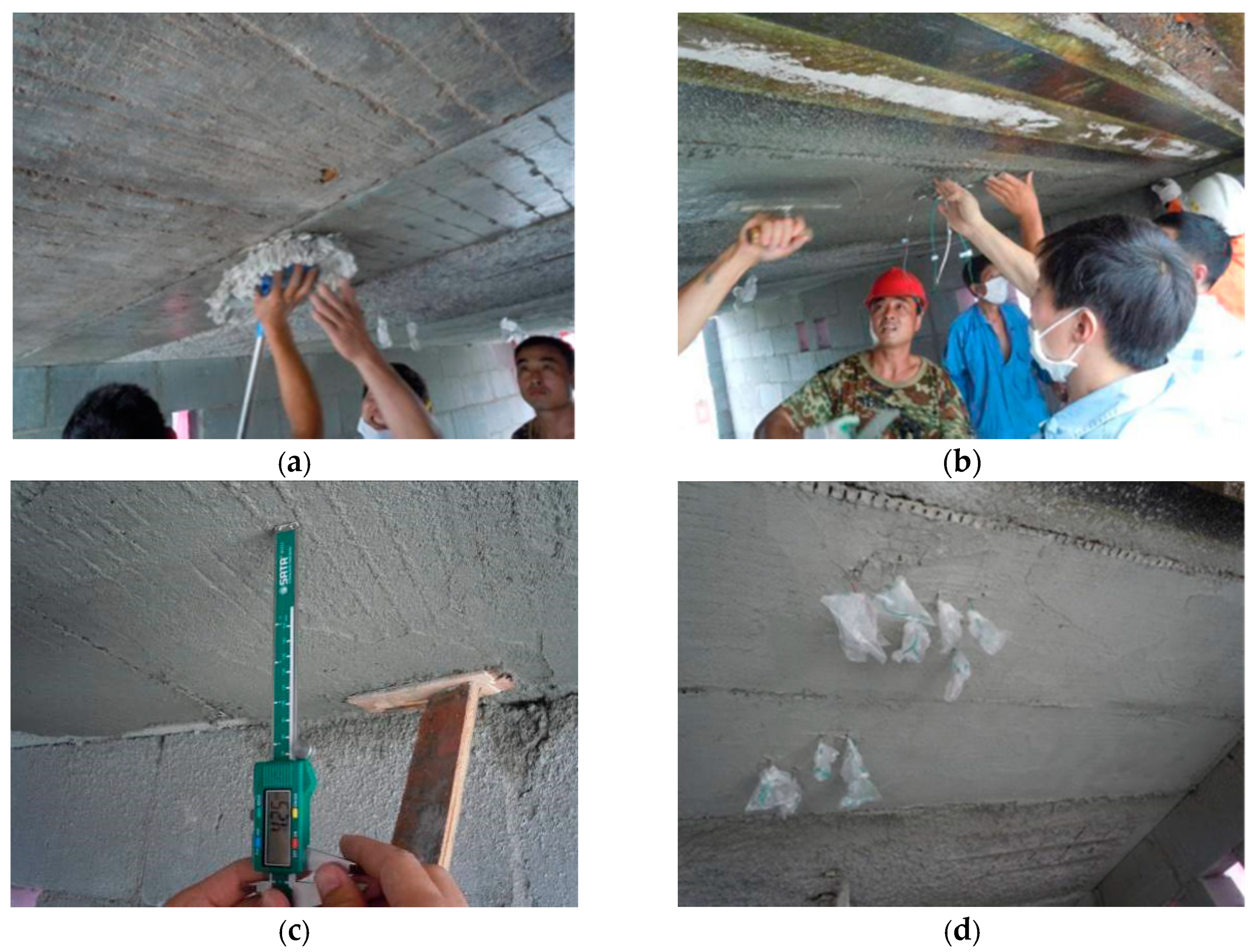

4.1. Strengthening Procedure

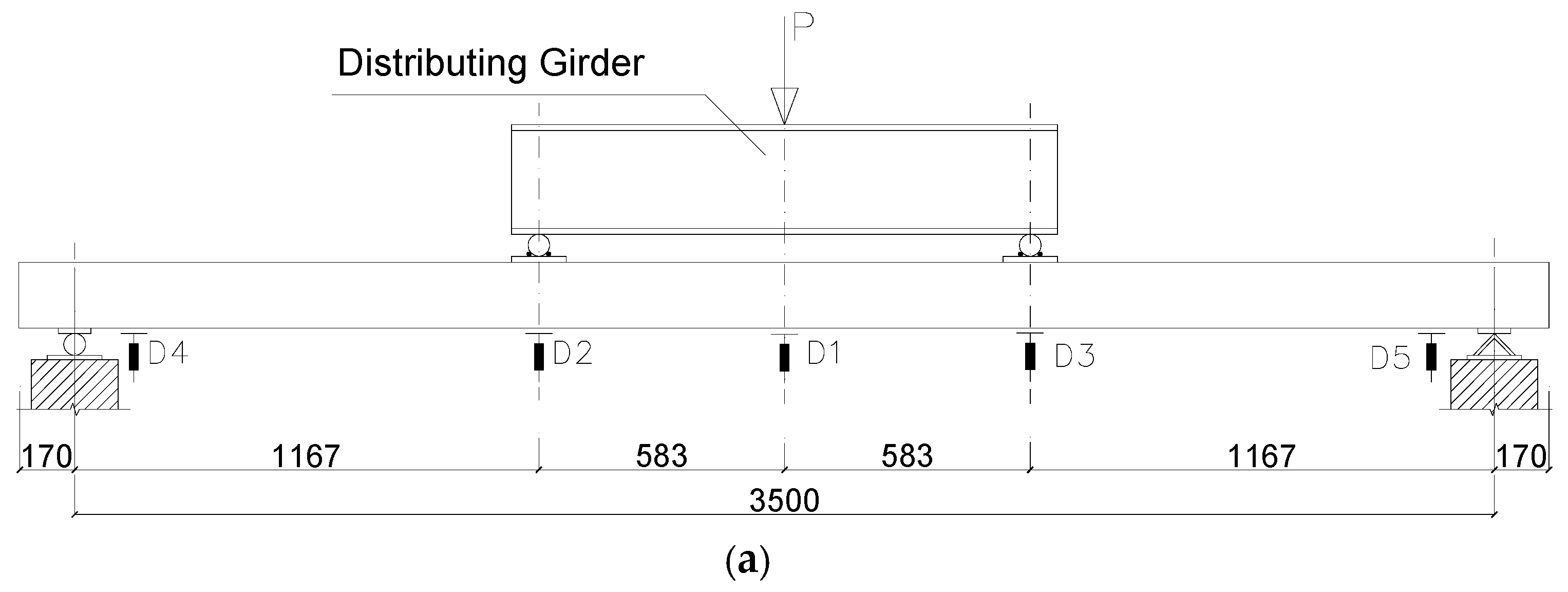

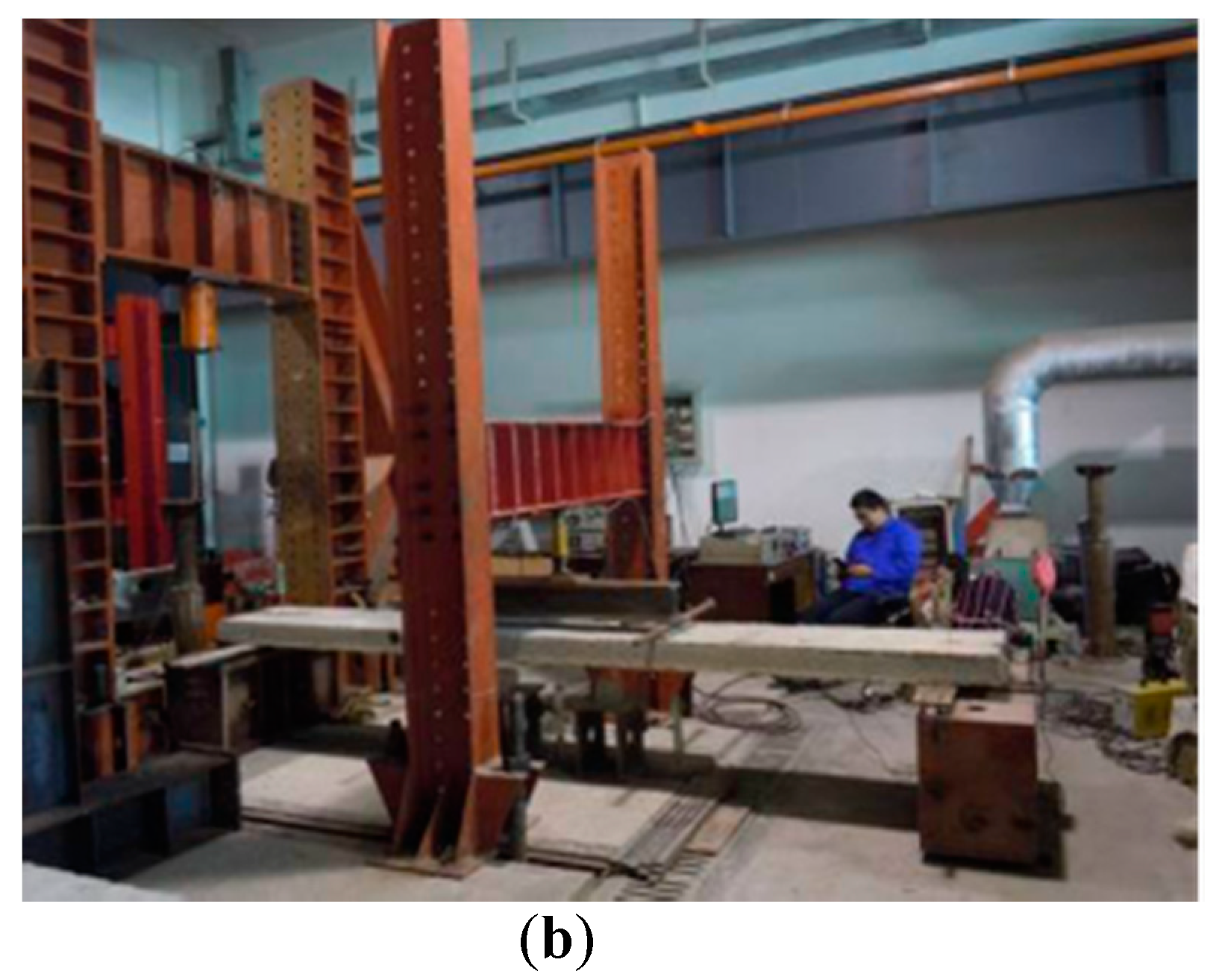

4.2. Load and Measure Arrangement

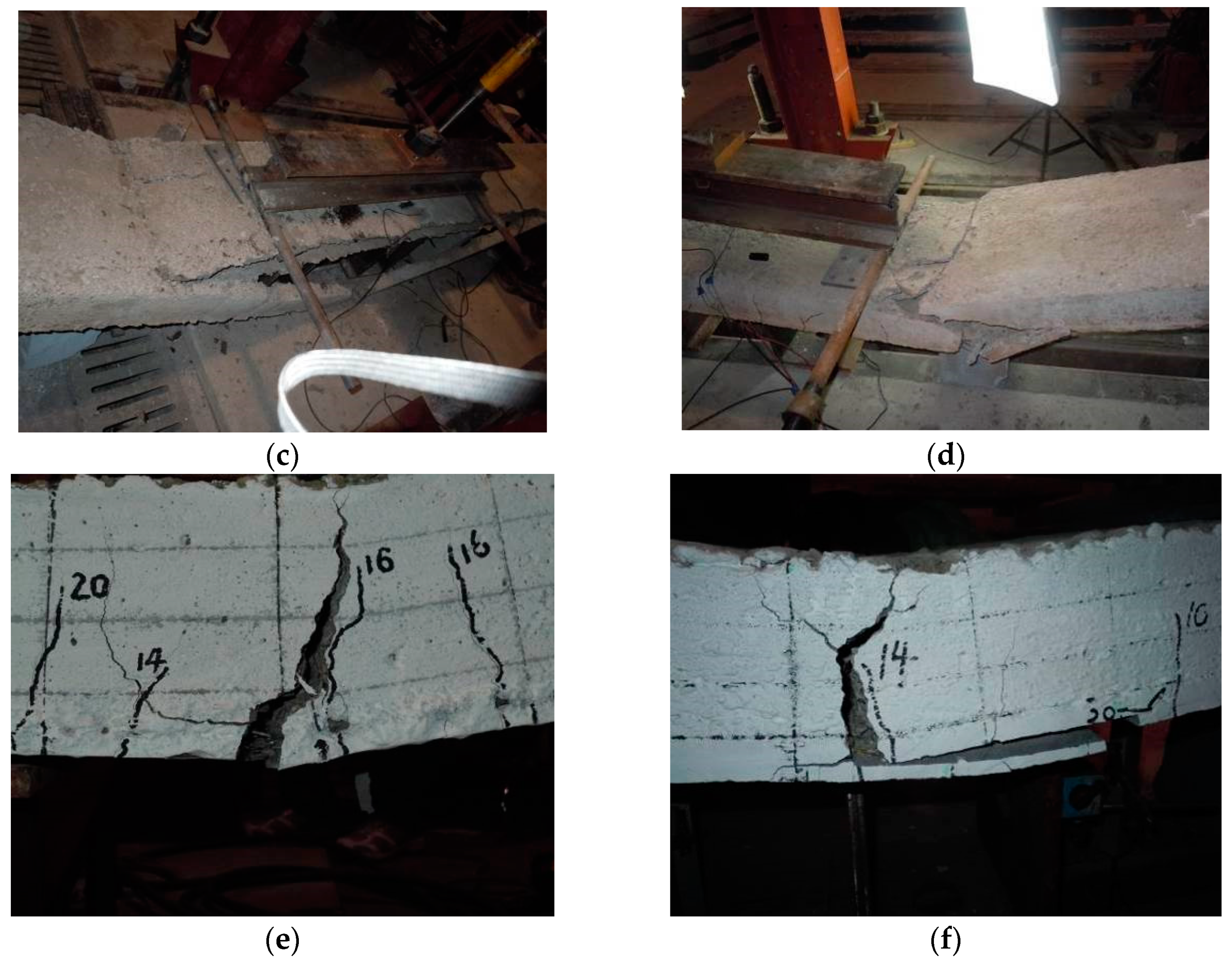

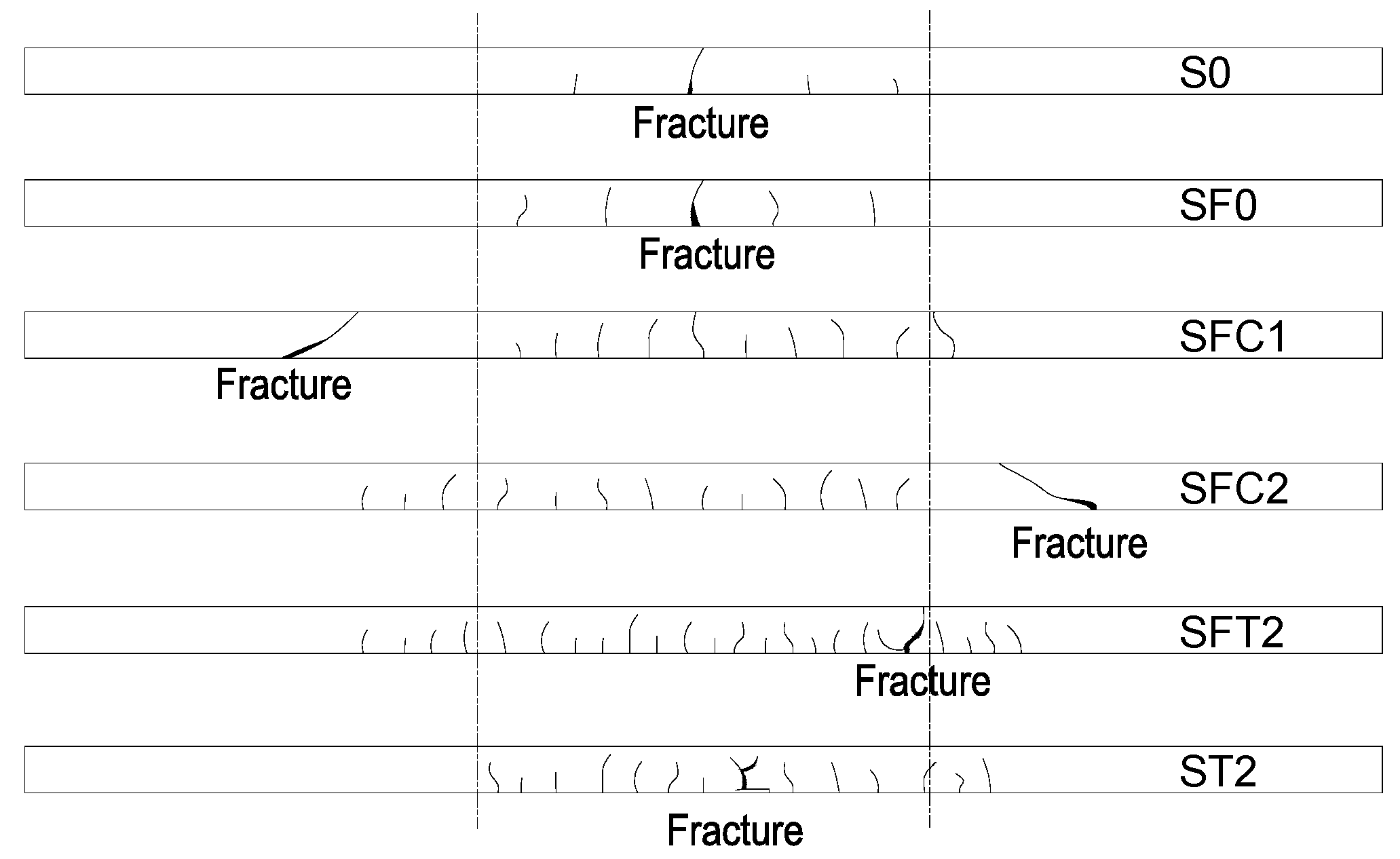

4.3. Failure Modes and Crack Distribution

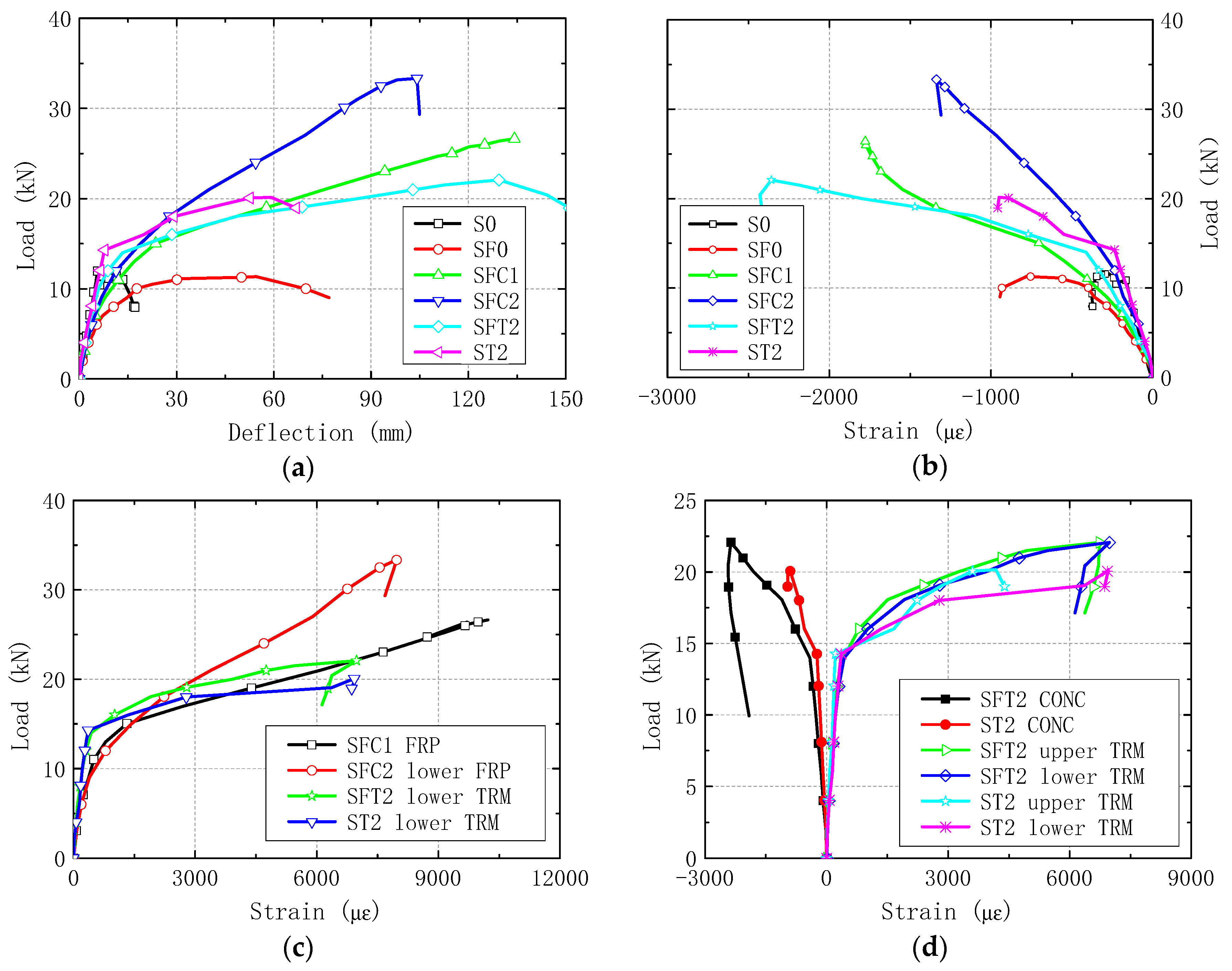

4.4. Load Response

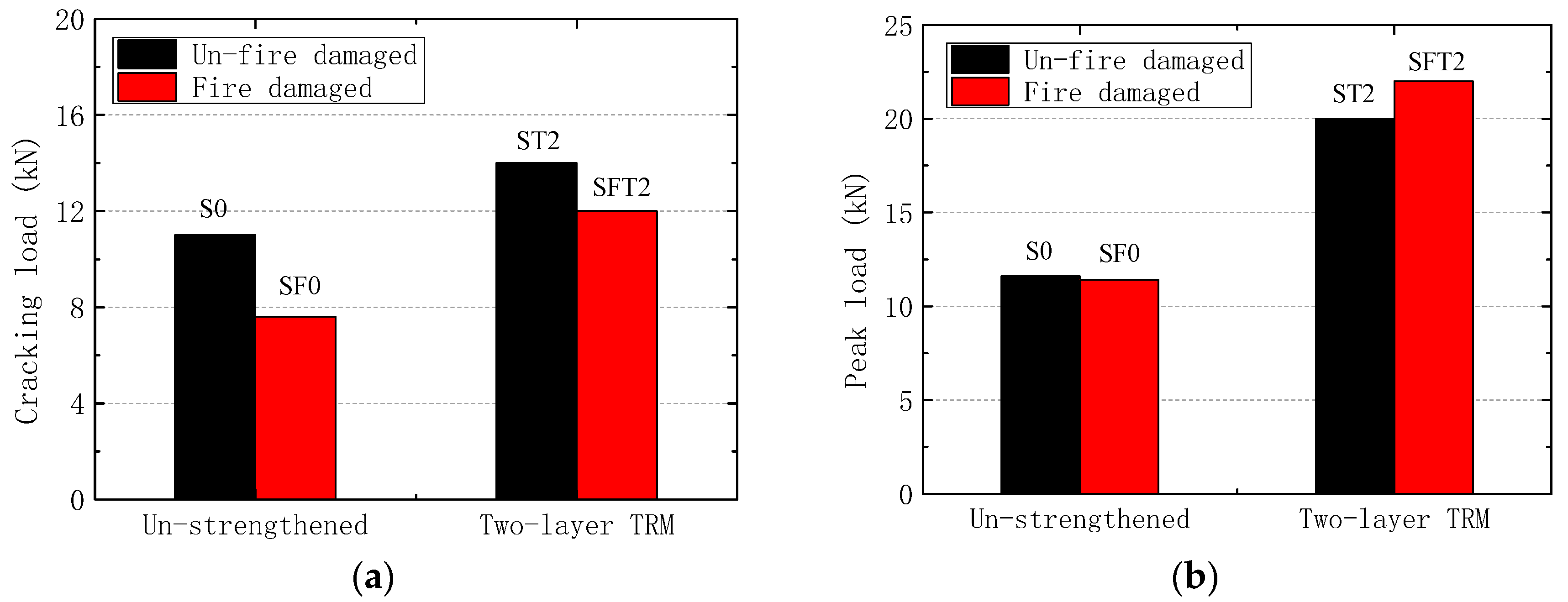

4.4.1. Effect of Fire-Damage

4.4.2. Effect of Strengthening Method and Layers

4.5. Deformation Response

5. Conclusions

- (a)

- Both the CFRP and TRM strengthening methods can significantly increase the cracking load and peak load of the fire-damaged prefabricated hollow slab, as well as the stiffness and deformation capacity. Compared to the unstrengthened fire damaged slab, the average cracking load increased by 19%, 20% and 58% respectively for one-layer CFRP, two-layer CFRP and TRM strengthening method, while the increase of peak load was 132%, 189% and 93% respectively. After strengthened, the failure deflection of hollow slabs had a more than a hundred percent increase for both methods.

- (b)

- Compared to the CFRP strengthened hollow slabs, the fire-damaged slabs strengthened with TRM exhibited a higher cracking load with a smaller cracking deflection, and a lower peak load with a larger failure deflection. The reason is that the integral flexural stiffness of the TRM strengthened hollow slab was larger than the CFRP strengthened slabs before concrete cracks appeared, and then reduced greatly due to the rapid growth of concrete cracks.

- (c)

- The cracking load of the fire-damaged specimens was generally less than that of the non-fire exposed specimens, regardless of strengthened or unstrengthened slabs, which can be attributed to the cracking of lower concrete and the yield strength degradation of steel rebars after fire exposure. However, comparing the results of the two TRM strengthened slabs, no significant effect of 60 min fire exposure was found on the peak loads of the hollow slabs, which indicated that the TRM strengthening method could restore most flexural capacity of fire-damaged hollow slabs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Julia, W.; Robert, K. Assessing concrete strength in fire-damaged structures. Constr. Build. Mater. 2020, 254, 119122. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Dwaikat, M.M.S.; Dwaikat, M.B. High-temperature properties of concrete for fire resistance modeling of structures. ACI Mater. J. 2008, 105, 517–527. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Gao, W.Y. Fire resistance of RC beams under design fire exposure. Mag. Concr. Res. 2017, 69, 402–423. [Google Scholar] [CrossRef]

- Raut, N.K.; Kodur, V.K.R. Response of high-strength concrete columns under design fire exposure. J. Struct. Eng. 2011, 137, 69–79. [Google Scholar] [CrossRef]

- Chen, Y.H.; Chang, Y.F.; Yao, G.C.; Sheu, M.S. Experimental research on post-fire behavior of reinforced concrete columns. Fire Saf. J. 2009, 44, 741–748. [Google Scholar] [CrossRef]

- Huang, Z. The behavior of reinforced concrete slabs in fire. Fire Saf. J. 2010, 45, 271–282. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, L. Repair of fire-damaged reinforced concrete members with axial load: A review. Sustainability 2019, 11, 963. [Google Scholar] [CrossRef]

- Ma, W.X.; Yin, C.X.; Zhou, J.; Lu, W. Repair of fire-damaged reinforced concrete flexural members: A review. Sustainability 2019, 11, 5199. [Google Scholar] [CrossRef]

- ACI Committee 440.2R-08. In Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2008.

- Esfahani, M.R.; Kianoush, M.R.; Tajari, A.R. Flexural behavior of reinforced concrete beams strengthened by CFRP sheets. Eng. Struct. J. 2007, 29, 2428–2444. [Google Scholar] [CrossRef]

- Dalfre, G.M.; Barros, J.A.O. NSM technique to increase the load carrying capacity of continuous RC slabs. Eng. Struct. J. 2013, 56, 137–153. [Google Scholar] [CrossRef]

- Thanoon, W.A.; Jaafar, M.S.; Kadir, M.R.A.; Noorzaei, J. Repair and structural performance of initially cracked RC slabs. Constr. Build. Mater. 2005, 19, 595–603. [Google Scholar] [CrossRef]

- Lu, W.; Ray, K.L.S. Repair of fire-exposed preloaded rectangular concrete columns by post compressed steel plates. J. Struct. Eng. 2014, 140, 04013083. [Google Scholar] [CrossRef]

- Jiang, C.J.; Lu, Z.D.; Li, L.Z. Shear performance of fire-damaged reinforced concrete beams repaired by a bolted side-plating technique. J. Struct. Eng. 2017, 143, 04017007. [Google Scholar] [CrossRef]

- Haddad, R.H.; Shannag, M.J.; Moh’d, A. Repair of heat-damaged RC shallow beams using advanced composites. Mater. Struct. 2008, 41, 287–299. [Google Scholar] [CrossRef]

- Haddad, R.H.; Al-Mekhlfy, N.; Ashteyat, A.M. Repair of heat-damaged reinforced concrete slabs using fibrous composite materials. Constr. Build. Mater. 2011, 25, 1213–1221. [Google Scholar] [CrossRef]

- Al-Kamaki, Y.S.S.; Al-Mahaidi, R.; Bennetts, I. Experimental and numerical study of the behavior of heat-damaged RC circular columns confined with CFRP fabric. Compos. Struct. 2015, 133, 679–690. [Google Scholar] [CrossRef]

- Gherdaoui, M.; Guenfoud, M.; Madi, R. Punching behavior of strengthened and repaired RC slabs with CFRP. Constr. Build. Mater. 2018, 170, 272–278. [Google Scholar] [CrossRef]

- Cao, N.T.; Pansuk, W.; Torres, L. Flexural behavior of fire-damaged reinforced concrete slabs repaired with near-surfaced mounted (NSM) carbon fiber reinforced polymer (CFRP) rods. J. Adv. Concr. Technol. 2015, 13, 15–29. [Google Scholar] [CrossRef]

- Lenwari, A.; Rungamornrat, J.; Woonprasert, S. Axial compression behavior of fire-damaged concrete cylinders confined with CFRP sheets. J. Compos. Constr. 2016, 20, 04016027. [Google Scholar] [CrossRef]

- Dong, K.; Hu, K.X. Development of bond strength model for CFRP to concrete joints at high temperatures. Compos. B Eng. 2016, 95, 264–271. [Google Scholar] [CrossRef]

- Dai, J.G.; Gao, W.Y.; Teng, J.G. Bond-slip model for FRP laminates externally bonded to concrete at elevated temperature. J. Compos. Constr. 2013, 17, 217–228. [Google Scholar] [CrossRef]

- Dong, K.; Hu, K.X.; Gao, W.Y. Fire behavior of full-scale CFRP-strengthened rc beams protected with different insulation systems. J. Asian Archit. Build. 2016, 15, 581–588. [Google Scholar] [CrossRef]

- Gao, W.Y.; Dai, J.G.; Teng, J.G. Three-level fire resistance design of FRP strengthened RC beams. J. Compos. Constr. 2018, 22, 05018001. [Google Scholar] [CrossRef]

- Schladitz, F.; Frenzel, M.; Ehlig, D.; Curbach, M. Bending load capacity of reinforced concrete slabs strengthened with textile reinforced concrete. Eng. Struct. 2012, 40, 317–326. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Triantafillou, T.C. State-of-the-art on strengthening of masonry structures with textile reinforced mortar (TRM). Constr. Build. Mater. 2018, 188, 1221–1233. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental analysis on bond between PBO-FRCM strengthening materials and concrete. Compos. B Eng. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Bond between textile-reinforced mortar (TRM) and concrete substrates: Experimental investigation. Compos. B Eng. 2016, 98, 350–361. [Google Scholar] [CrossRef]

- Donnini, J. Durability of glass FRCM systems: Effects of different environments on mechanical properties. Compos. B Eng. 2019, 174, 107047. [Google Scholar] [CrossRef]

- Donnini, J.; Basalo, F.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Composites 2017, 108, 108–121. [Google Scholar] [CrossRef]

- Ebead, U.; Shrestha, K.C.; Afzal, M.S.; El Refai, A.; Nanni, A. Effectiveness of fabric-reinforced cementitious matrix in strengthening reinforced concrete beams. J. Compos. Constr. 2016, 21, 04016084. [Google Scholar] [CrossRef]

- Gao, W.Y.; Hu, K.X.; Dai, J.G.; Dong, K.; Yu, K.Q.; Fang, L.J. Repair of fire-damaged RC slabs with basalt fabric-reinforced shotcrete. Constr. Build. Mater. 2018, 185, 79–92. [Google Scholar] [CrossRef]

- Bournas, D.A.; Triantafillou, T.C. Biaxial bending of reinforced concrete columns strengthened with externally applied reinforcement in combination with confinement. ACI Struct. J. 2013, 110, 193–203. [Google Scholar] [CrossRef]

- Koutas, L.; Bousias, S.; Triantafillou, T. Seismic strengthening of masonry-infilled RC frames with TRM: Experimental study. J. Compos. Constr. 2014, 19, 04014048. [Google Scholar] [CrossRef]

- Bournas, D.A.; Triantafillou, T.C.; Zygouris, K.; Stavropoulos, F. Textile-reinforced mortar versus FRP jacketing in seismic retrofitting of RC columns with continuous or lap-spliced deformed bars. J. Compos. Constr. 2009, 13, 360–371. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. TRM versus FRP in flexural strengthening of RC beams: Behavior at high temperatures. Constr. Build. Mater. 2017, 154, 424–437. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Bournas, D.A. TRM vs FRP jacketing in shear strengthening of concrete members subjected to high temperatures. Compos. B Eng. 2016, 106, 190–205. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. Bond between TRM versus FRP composites and concrete at high temperatures. Compos. B Eng. 2017, 127, 150–165. [Google Scholar] [CrossRef]

- Chinese Code JGJ/T 23. In Technical Specification for Inspection of Concrete Compressive Strength by Rebound Method; China Architecture & Building Press: Beijing, China, 2011.

- Chinese Code JGJ/T 70. In Standard for Test Method of Performance of Building Mortar; China Architecture & Building Press: Beijing, China, 2009.

| Specimens | Heating Period (min) | Strengthening Method | Dimensions of Strengthening Layers (mm) | |

|---|---|---|---|---|

| Width | Total Thickness | |||

| S0 | — | — | — | — |

| SF0 | 60 | — | — | — |

| SFC1 | 60 | One-layer CFRP | 100 + 100 | 0.167 |

| SFC2 | 60 | Two-layer CFRP | 100 + 100 | 0.334 |

| SFT2 | 60 | Two-layer TRM | 500 | 24 |

| ST2 | — | Two-layer TRM | 500 | 24 |

| Property | Tensile Strength (MPa) | Elastic Modulus (GPa) | Rupture Strain (%) | Bond Strength (MPa) |

|---|---|---|---|---|

| HT300 | 3379 | 242 | 1.7 | — |

| TH-RESIN | 48 | 2.68 | 1.65 | 24.5 |

| Mortar Type | PM45F |

|---|---|

| Maximum aggregate particle size (mm) | 0–2 |

| Elasticity modulus (MPa) | 22,322 (tested) |

| Compressive strength (MPa) | 43.5 (tested) |

| Tensile bond strength (MPa) | 1.2 |

| Mesh Type | BGA25 |

|---|---|

| Density (g/cm2) | 350 |

| Elasticity modulus (GPa) | 89 |

| Longitudinal tensile strength (kN/m) | 50 |

| Transverse tensile strength (kN/m) | 40 |

| Rupture strain (%) | 3.1 |

| Specimen | Cracking Load (kN) | Peak Load (kN) | Failure Deflection (mm) | Failure Mode |

|---|---|---|---|---|

| S0 | 11.0 | 11.6 | 17.4 | BF-S |

| SF0 | 7.6 | 11.4 | 55 | BF-S |

| SFC1 | 9.0 | 26.4 | 135 | SF |

| SFC2 | 9.1 | 33.0 | 105 | SF |

| SFT2 | 12.0 | 22.0 | 130 | BF-F |

| ST2 | 14.0 | 20.0 | 60 | BF-F |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, Z.-A.; Dong, K.; Jiang, J.; Yang, S.; Hu, K. Flexural Behavior of Fire-Damaged Prefabricated RC Hollow Slabs Strengthened with CFRP versus TRM. Materials 2020, 13, 2556. https://doi.org/10.3390/ma13112556

Sui Z-A, Dong K, Jiang J, Yang S, Hu K. Flexural Behavior of Fire-Damaged Prefabricated RC Hollow Slabs Strengthened with CFRP versus TRM. Materials. 2020; 13(11):2556. https://doi.org/10.3390/ma13112556

Chicago/Turabian StyleSui, Zheng-Ang, Kun Dong, Jitong Jiang, Shutong Yang, and Kexu Hu. 2020. "Flexural Behavior of Fire-Damaged Prefabricated RC Hollow Slabs Strengthened with CFRP versus TRM" Materials 13, no. 11: 2556. https://doi.org/10.3390/ma13112556

APA StyleSui, Z.-A., Dong, K., Jiang, J., Yang, S., & Hu, K. (2020). Flexural Behavior of Fire-Damaged Prefabricated RC Hollow Slabs Strengthened with CFRP versus TRM. Materials, 13(11), 2556. https://doi.org/10.3390/ma13112556