Study on the Pore and Microstructure Fractal Characteristics of Alkali-Activated Coal Gangue-Slag Mortars

Abstract

1. Introduction

2. Microstructure Fractal Feature Theory Review

2.1. Calculation of Microstructure Fractal Dimension

- I.

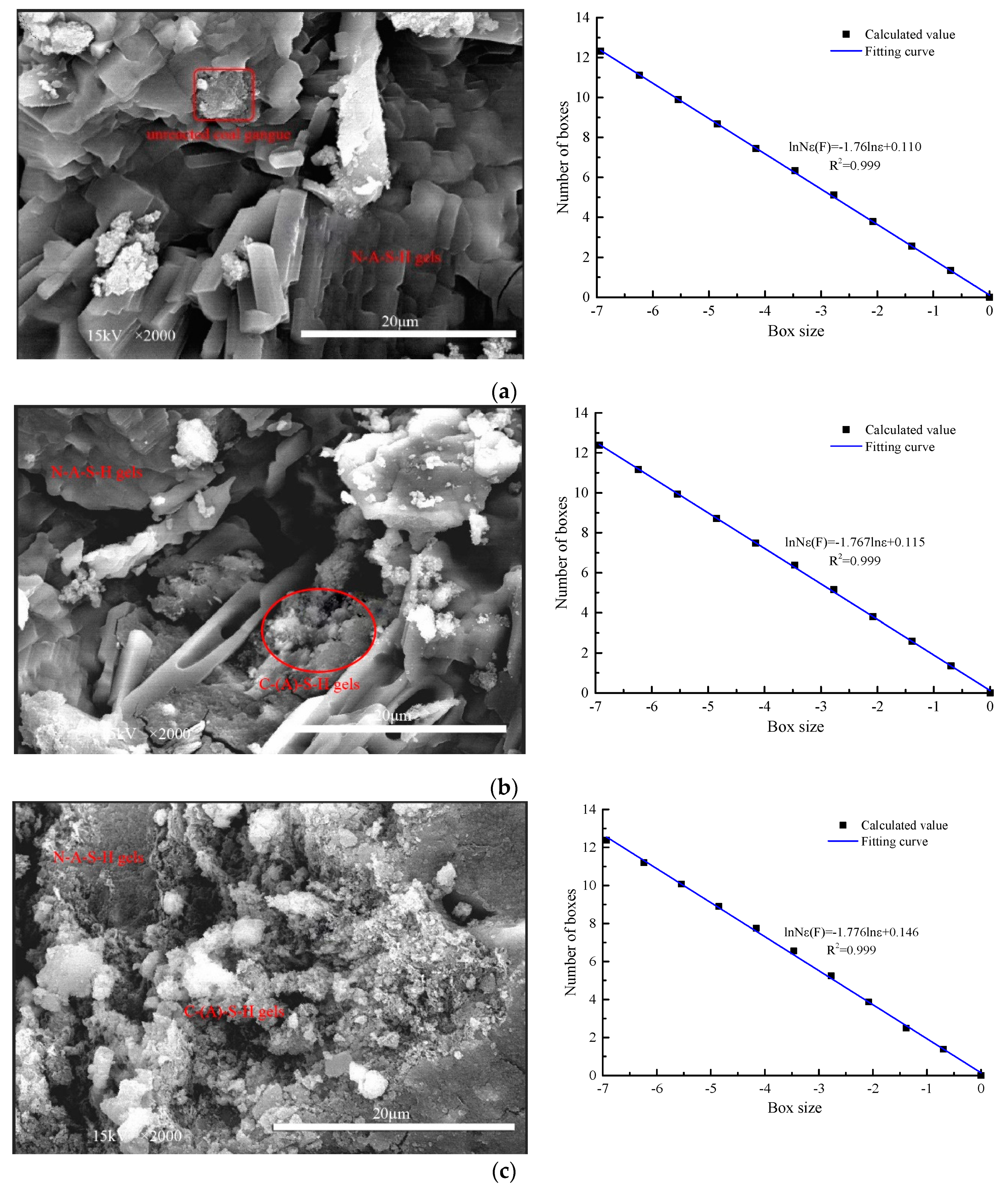

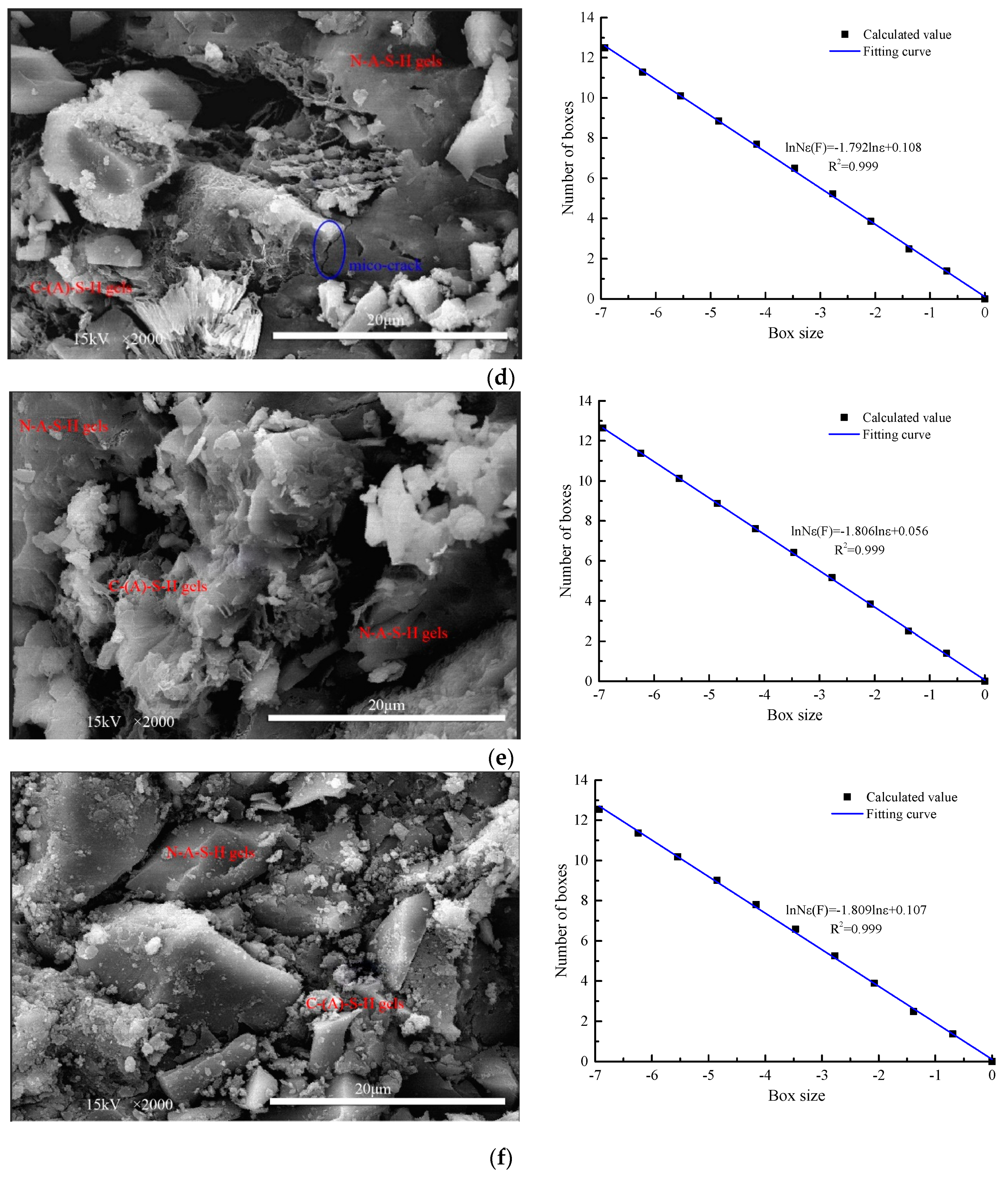

- Box dimension method. Assume that the F set is a non-empty bounded set in the Rn domain, and Nε(F) is the number of sets with a maximum diameter ε required to cover the F set. Nε(F) changes with the change of the maximum diameter. As a curve of lnNε(F)–lnε, the opposite number of the slope of the curve is the fractal box dimension value [36]. The box dimension is determined by the coverage of the same shape set. In order to quantitatively describe the internal microscopic changes of AACGS mortar under different slag content and different alkali activation modulus, the relationship between the box dimension and box quantity of SEM photos can be obtained by importing SEM photos into the computer program. After binarization processing of SEM photos, the fractal dimension program is used to calculate the fractal dimension. The opposite number of the slope of the curve is the fractal dimension value. In other words, the box dimension method is adopted in this paper to calculate the fractal dimension of SEM photos, which includes two steps: Binarization processing of SEM photos and fractal dimension numerical calculation.

- II.

- Yardstick method. The complicated curve is decomposed by unit length, in which one end of the curve is used as the starting point and a circle of unit length r is drawn with the starting point as the center. The point that intersects the curve with the starting point is connected and the intersection point is used as the new starting point to repeat the circle. The total number of measured line segments is recorded as p(r) and the unit length r is changed; p(r) will also change. The specific functional relationship can be expressed as:p(r) = L/r∝r−Dwhere L represents the length of the fractal curve. As an lnL–lnr curve, 1−D represents the slope of the straight line, which is the value of the fractal dimension.L∝r1−D

2.2. Calculation of Fractal Dimension in Mercury Intrusion Porosimetry

- I.

- Take the log of dV/dP and dP in the MIP method data and draw the dV/dP–dP curve; the fractal dimension of the pore surface according to the slope of the curve is calculated.

- II.

- Take the log of dV/dr and dr in the MIP method data and draw the dV/dr–dr curve; the fractal dimension of the pore volume according to the slope of the curve is calculated.

3. Experimental and Test Methods

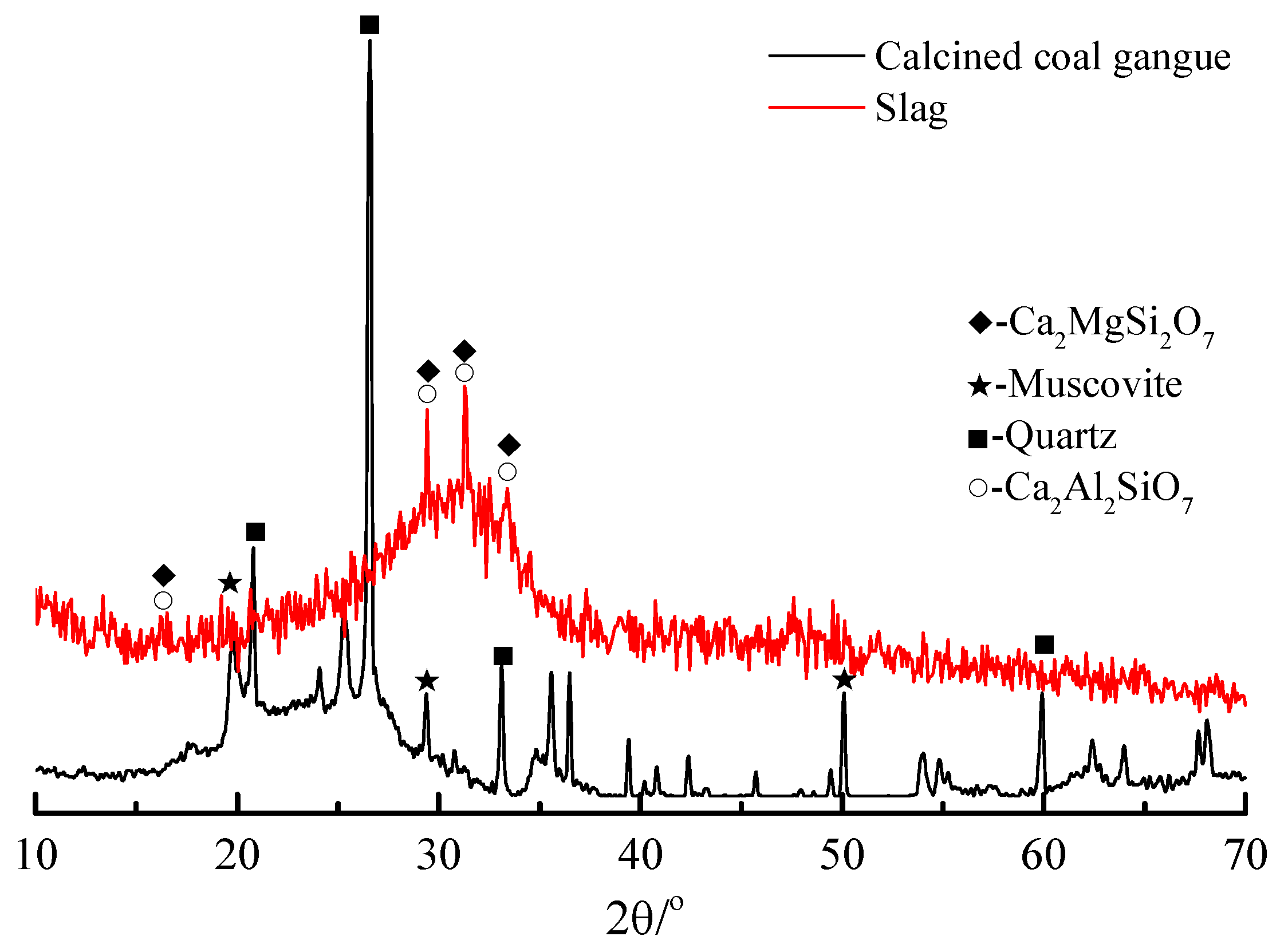

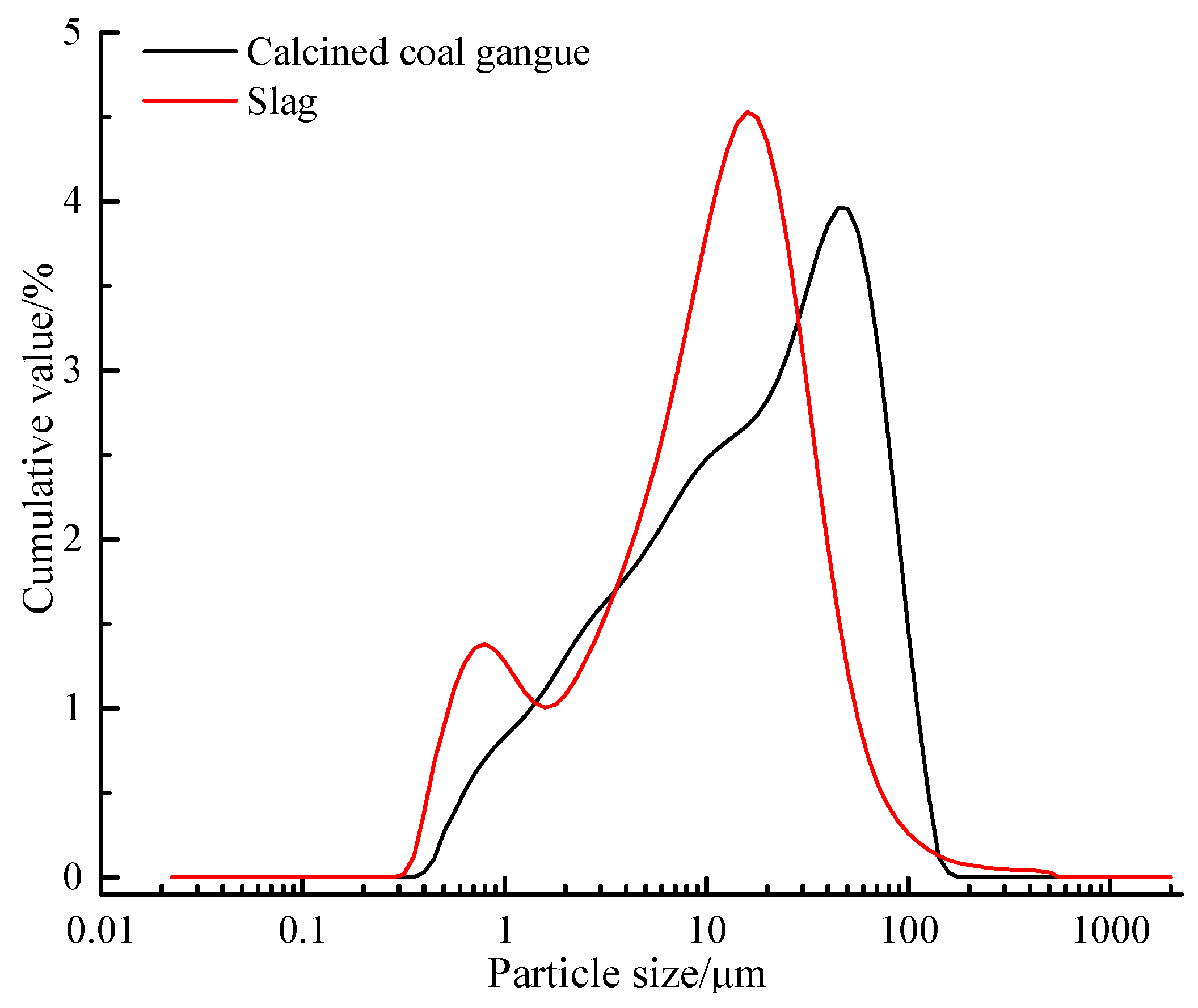

3.1. Raw Materials and Specimen Preparation

3.2. Experimental Programme

3.2.1. Compressive Strength

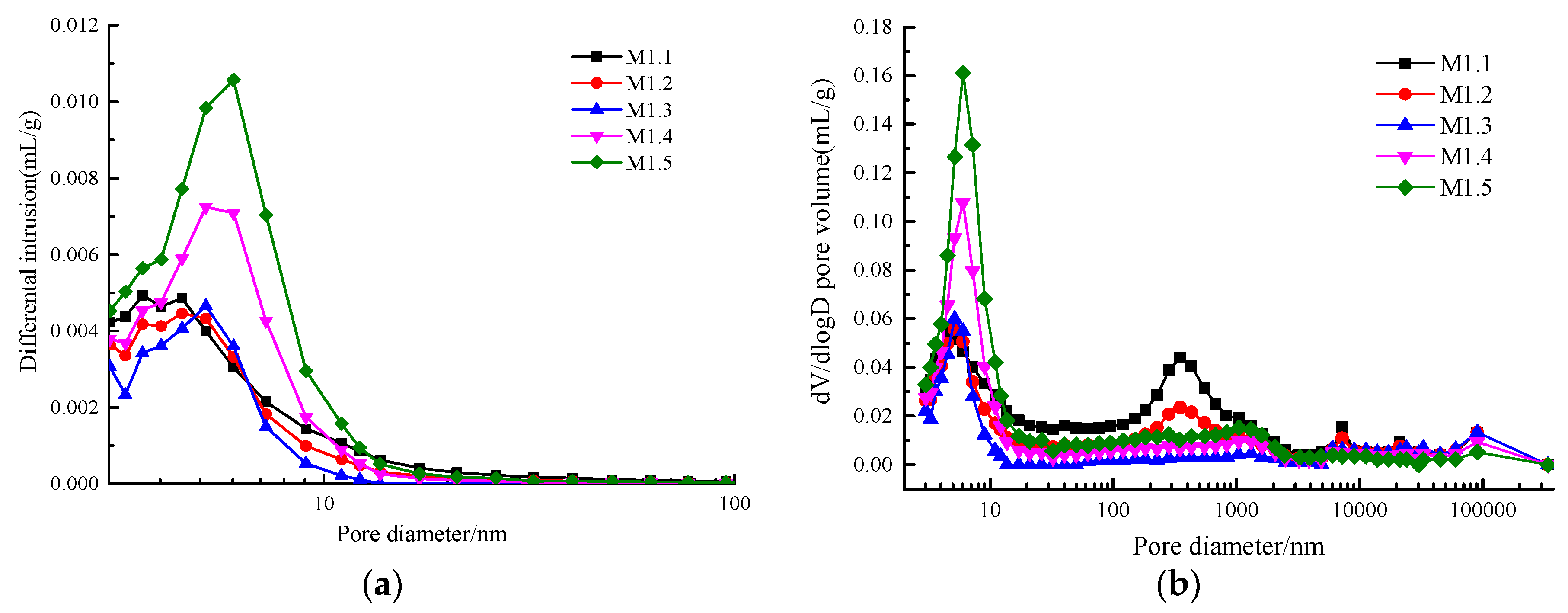

3.2.2. Pore Structure

3.2.3. Micro Morphology

4. Result and Discussion

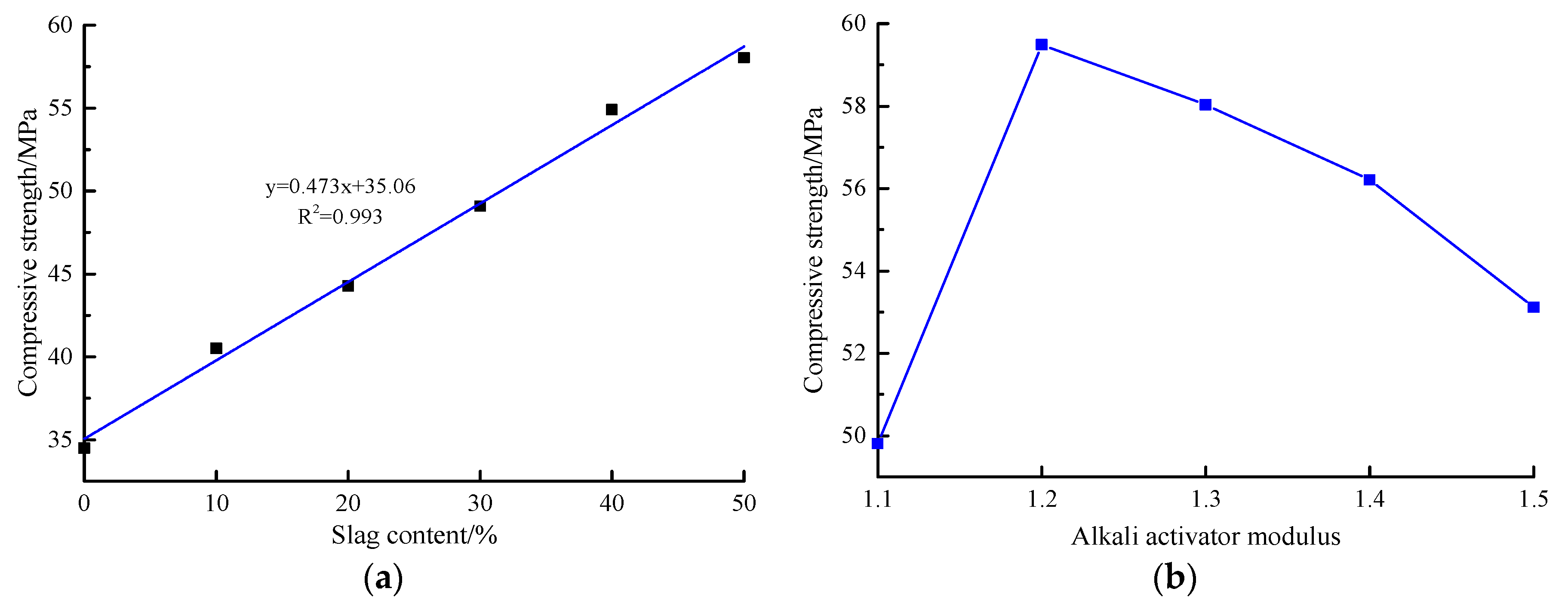

4.1. Compressive Strength Analysis

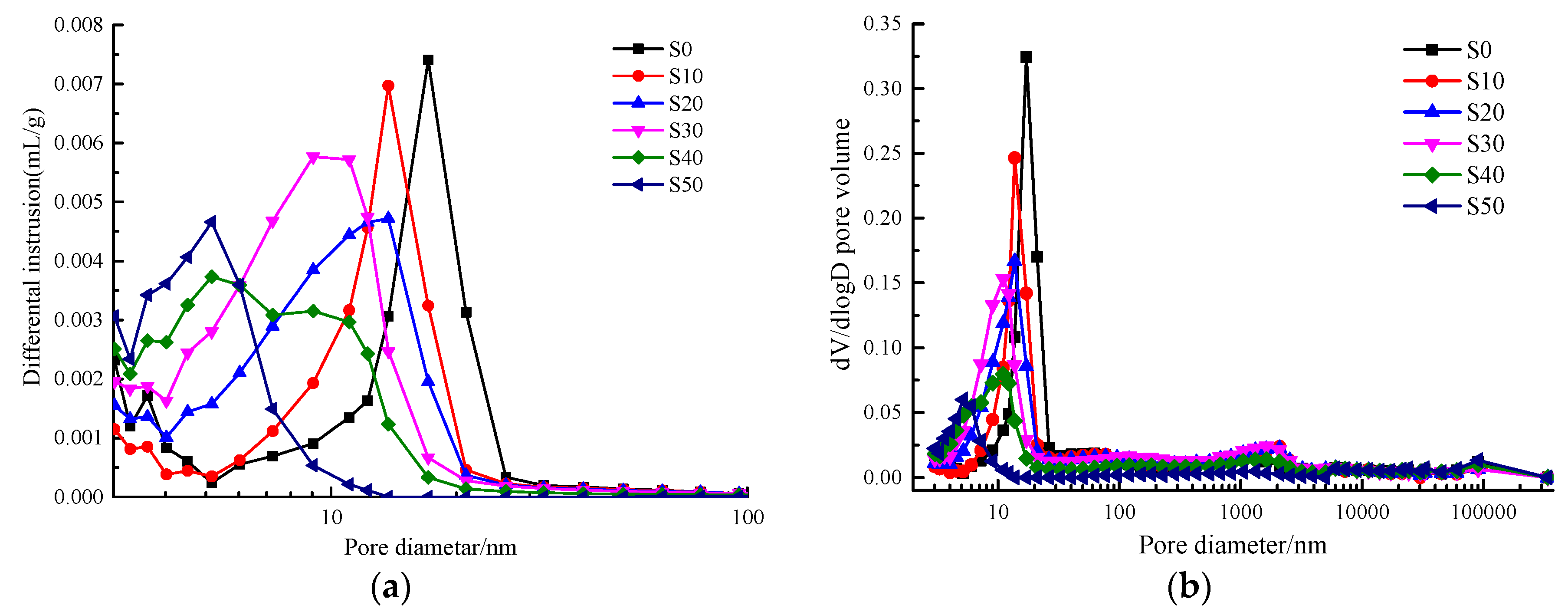

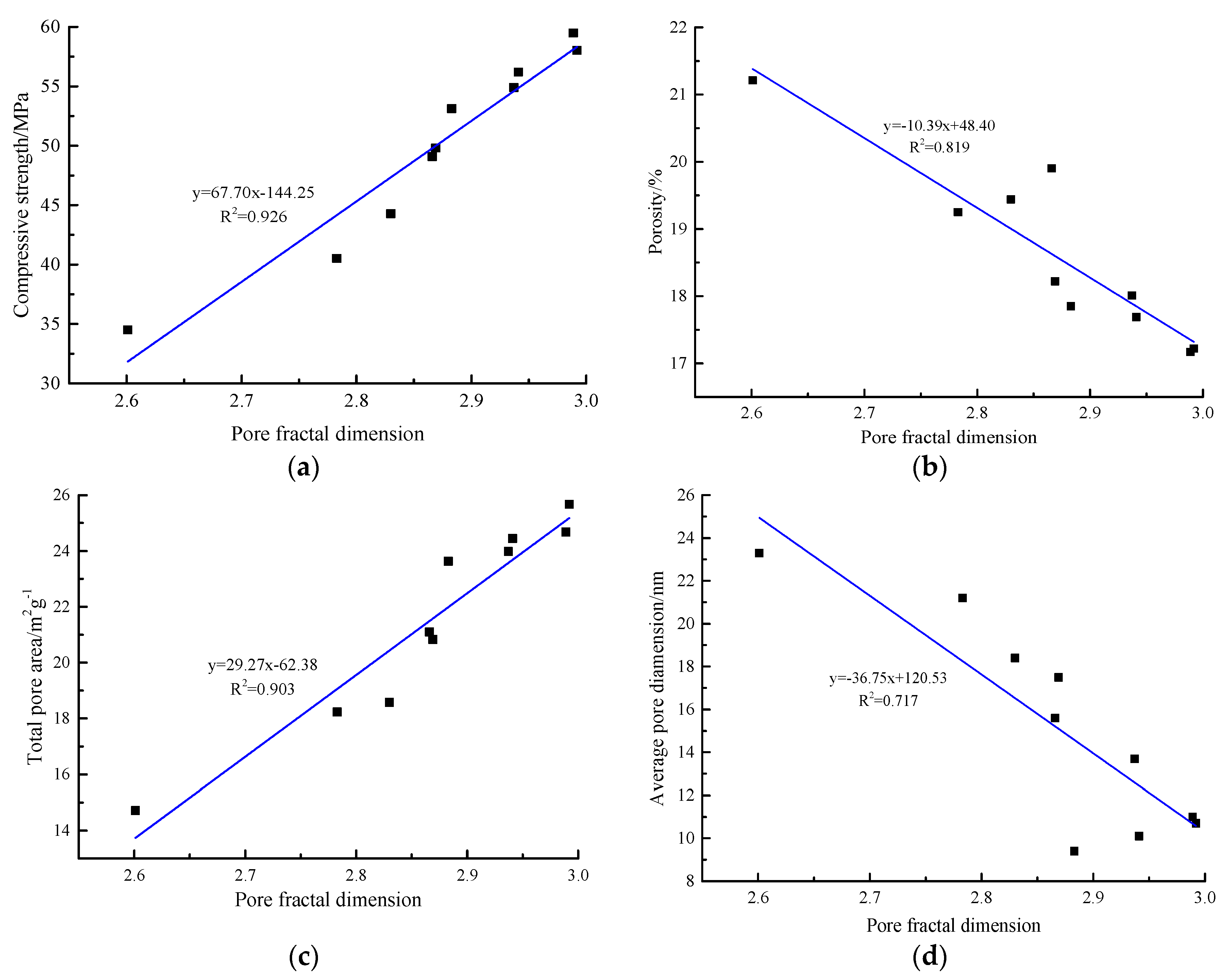

4.2. Fractal Characteristics and Fractal Dimension of AACGS Mortar Pores

4.3. Fractal Feature Analysis of SEM Photos

4.4. Discussion and Outlook

5. Conclusions

- (1).

- When the slag content is 0–50%, the compressive strength of AACGS mortar specimens increases with the increase of the slag content, and the slag content shows a significant positive linear relationship with the compressive strength.

- (2).

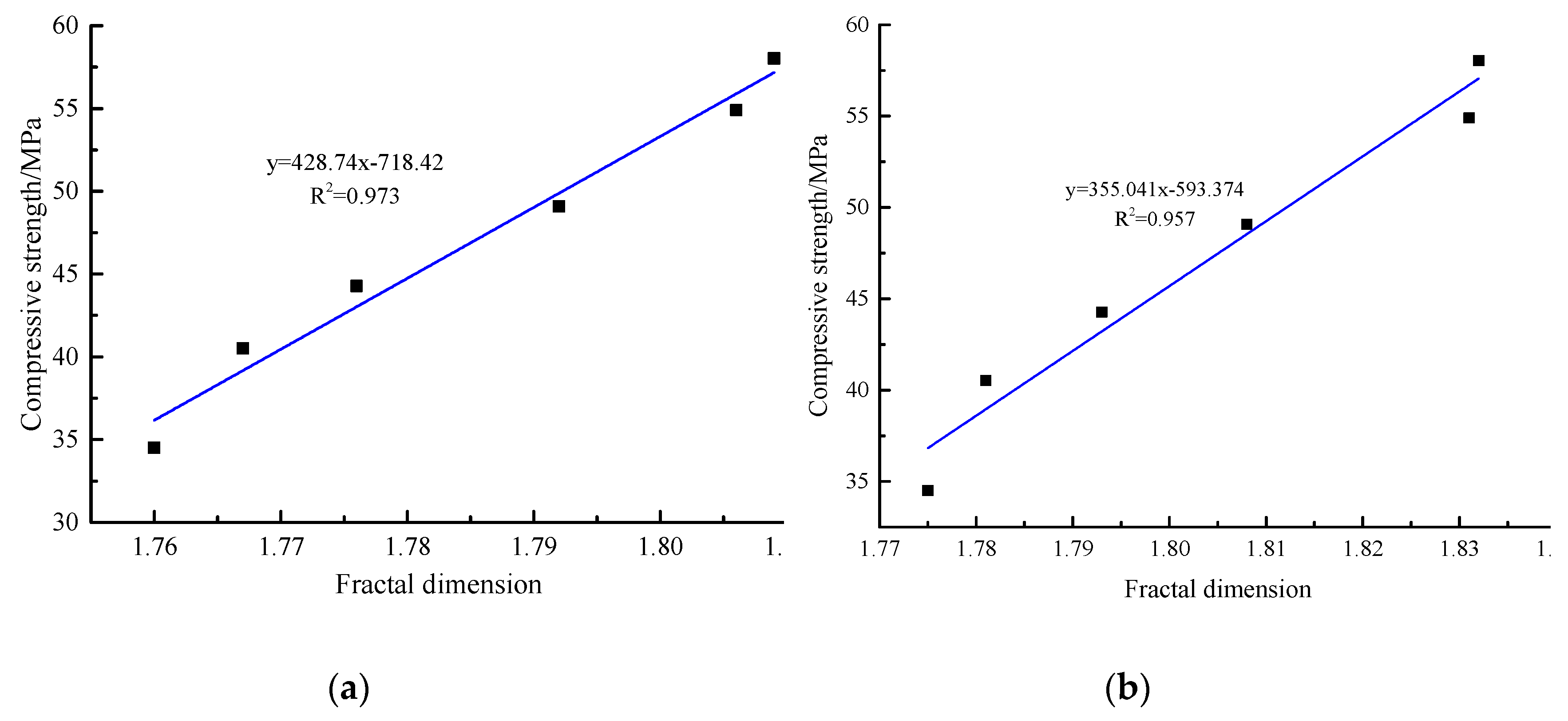

- The pore fractal dimension and compressive strength show a significant positive linear relationship, and the pore structure and pore fractal dimension have a strong correlation, through the pore fractal dimension can predict the pore characteristic parameters of the specimens. The pore fractal dimension has a strong positive linear relationship with the total pore area and has an excellent negative linear relationship with porosity and average pore dimension.

- (3).

- The binarization image of the SEM image can be obtained based on computer image processing and uses the box dimension method to calculate the fractal dimension of the binarization image. With the increase of slag content, the fractal dimension of SEM photos of AACGS mortar specimens increased, and the compressive strength of AACGS mortar and fractal dimension showed a significant positive linear relationship.

- (4).

- The pore fractal model and the box dimension method were introduced into the AACGS mortar. Due to the difference between the two theories, the fractal dimension of the pore structure was quite different from the fractal dimension of SEM photos. However, both fractal dimensions could be used separately for the prediction of macroscopic performance. This study provides a basis for the application of fractal theory in the field of alkali-activated materials.

- (5).

- Different from the fractal dimension of pore structure, SEM photos have a contingency, which is affected by material type, SEM equipment, and magnification. When the same researcher calculates the fractal dimension of SEM photos, SEM equipment and magnification can be ignored. However, whether different material systems show the same variation rules still needs to be studied and discussed by research scholars together.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mahmoud, A.E.W.; Kimio, F. Early-age strength of alkali-activated municipal slag-fly ash-based geopolymer mortar. J Mater. Civ. Eng. 2018, 30, 4018040. [Google Scholar]

- Ye, H.L.; Chen, Z.J.; Huang, L. Mechanism of sulfate attack on alkali-activated slag: The role of activator composition. Cem. Concr. Res. 2019, 125, 105868. [Google Scholar] [CrossRef]

- Karahan, O.; Yakupoǧlu, A. Resistance of alkali-activated slag mortar to abrasion and fire. Adv. Cem. Res. 2011, 23, 289–297. [Google Scholar] [CrossRef]

- Myers, R.J.; Bernal, S.A.; Provis, J.L. Phase diagrams for alkali-activated slag binders. Cem. Concr. Res. 2017, 95, 30–38. [Google Scholar] [CrossRef]

- Alessandra, M.; Alberto, B.; Chiara, G.; Tiziano, B.; Francesca, T. Metakaolin and fly ash alkali-activated mortars compared with cementitious mortars at the same strength class. Cem. Concr. Res. 2016, 88, 198–210. [Google Scholar]

- Pacheco-Torgal, F.; Moura, D.; Ding, Y.N.; Said, J. Composition, Strength and Workability of alkali-activated metakaolin based mortars. Constr. Build. Mater. 2011, 25, 3732–3745. [Google Scholar] [CrossRef]

- Samarakoon, M.H.; Ranjith, P.G.; De Silva, V.R.S. Effect of soda-lime glass powder on alkali-activated binders: Rheology, strength and microstructure characterization. Constr. Build. Mater. 2020, 241, 118013. [Google Scholar]

- Kang, S.P.; Kwon, S.J. Effects of red mud and alkali-activated slag cement on efflorescence in cement mortar. Constr. Build. Mater. 2017, 133, 459–467. [Google Scholar] [CrossRef]

- Mohamad Jamali, M.; Rassoul, A.; Alborz, H. Preparation and application of alkali-activated materials based on waste glass and coal gangue: A review. Constr. Build. Mater. 2019, 221, 84–98. [Google Scholar]

- Yi, C.; Ma, H.Q.; Chen, H.Y.; Wang, J.X.; Shi, J.; Li, Z.H.; Yu, M.K. Preparation and characterization of coal gangue geopolymers. Constr. Build. Mater. 2018, 187, 318–326. [Google Scholar]

- Huang, G.D.; Ji, Y.S.; Li, J.; Hou, Z.H.; Dong, Z.C. Improving strength of calcinated coal gangue geopolymer mortars via increasing calcium content. Constr. Build. Mater. 2018, 166, 760–768. [Google Scholar] [CrossRef]

- Liang, G.W.; Zhu, H.J.; Zhang, Z.H.; Wu, Q.S.; Du, J.Z. Investigation of the waterproof property of alkali-activated metakaolin geopolymer added with rice husk ash. J. Clean. Prod. 2019, 230, 603–612. [Google Scholar] [CrossRef]

- Yi, C.; Ma, H.Q.; Zhu, H.G.; Li, W.J.; Xin, M.L.; Liu, Y.L.; Guo, Y.D. Study on chloride binding capability of coal gangue based cementitious materials. Constr. Build. Mater. 2018, 167, 649–656. [Google Scholar] [CrossRef]

- Ma, H.Q.; Zhu, H.G.; Yi, C.; Fan, J.C.; Chen, H.Y.; Xu, X.N.; Wang, T. Preparation and reaction mechanism characterization of alkali-activated coal gangue-slag materials. Materials 2019, 12, 2250. [Google Scholar] [CrossRef] [PubMed]

- Ioannidou, K.; Krakowiak, K.J.; Bauchy, M.; Hoover, C.G.; Masoero, E.; Yip, S.; Ulm, F.J.; Levitz, P.; Pellenq, R.J.M.; Gado, E.D. Mesoscale texture of cement hydrates. Proc. Natl. Acad. Sci. USA 2016, 113, 2029–2034. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.B.; Ju, Y.; Peng, R.D.; Xiao, K.L.; Tang, W.Q.; Sheng, X.H.; Ma, W.Z. Strength and fractal characteristic of meso-structure of concrete with metakaolin and low water-binder ratio. J. China Coal Soc. 2015, 40, 1820–1826. [Google Scholar]

- Martin, M. The fractal nature of particle size distributions of grounds clinker. Cem. Concr. Res. 1990, 20, 499–505. [Google Scholar]

- Liu, H.B.; Ju, Y.; Sun, H.F.; Liu, J.H.; Tian, K.P.; Wang, L.; Ge, Z.S. Investigation on the fractal characteristic of reactive powder concrete pore structure subject to high temperature. J. China Coal Soc. 2013, 38, 1583–1588. [Google Scholar]

- Gao, Y.; Jiang, J.Y.; de Schutter, G.; Ye, G.; Sun, W. Fractal and multifractal analysis on pore structure in cement paste. Constr. Build. Mater. 2014, 69, 253–261. [Google Scholar] [CrossRef]

- Nitka, M.; Tejchman, J. A three-dimensional meso-scale approach to concrete fracture based on combined DEM with X-ray μ CT images. Cem. Concr. Res. 2018, 107, 11–29. [Google Scholar] [CrossRef]

- Zarnaghi, V.N.; Fouroghi-Asl, A.; Nourani, V.; Ma, H. On the pore structures of lightweight self-compacting concrete containing silica fume. Constr. Build. Mater. 2018, 193, 557–564. [Google Scholar] [CrossRef]

- Tang, S.W.; He, Z.; Cai, X.H.; Cai, R.J.; Zhou, W.; Li, Z.J.; Shao, H.Y.; Wu, T.; Chen, E. Volume and surface fractal dimensions of pore structure by NAD and LT-DSC in calcium sulfoaluminate cement pastes. Constr. Build. Mater. 2017, 143, 395–418. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, K.; Jiang, J.Y. Examination and modeling of fractality for pore-soild structure in cement paste: Starting from the mercury intrusion porosimetry test. Constr. Build. Mater. 2016, 124, 237–243. [Google Scholar] [CrossRef]

- Gao, Y.; Feng, P.; Jiang, J.Y. Analytical and numerical modeling of elastic moduli for cement based composites with solid mass fractal model. Constr. Build. Mater. 2018, 172, 330–339. [Google Scholar] [CrossRef]

- Werner, S.; Neumann, I.; Thienel, K.C.; Heunecke, O. A fractal-based approach for the determination of concrete surfaces using laser scanning techniques: A comparison of two different measuring systems. Mater. Struct. 2013, 46, 245–254. [Google Scholar] [CrossRef]

- Nelson, I.; Béatrice, B. Fractal dimension of fumed silica: Comparison of light scattering and electron microscope methods. Powder Technol. 2010, 203, 206–210. [Google Scholar]

- Kim, J.; Choi, S.; Choi, Y.C. Fractal characteristics of pore structures in GGBFS-based cement pastes. Appl. Surf. Sci. 2018, 428, 304–314. [Google Scholar] [CrossRef]

- Winslow, D.N. Fractal character in cement and Concrete. Cem. Concr. Res. 1985, 15, 817–824. [Google Scholar] [CrossRef]

- Fernández-Martínez, M.; Sánchez-Granero, M.A. How to calculate the hausdorff dimension using fractal structures. Appl. Math. Comput. 2015, 264, 116–131. [Google Scholar] [CrossRef]

- Yang, X.; Yang, X.C.; Zhang, R.J.; Ma, S.; Wang, F.L. Fractal dimension of concrete meso-structure based on X-ray computed tomography. Powder Technol. 2019, 350, 91–99. [Google Scholar] [CrossRef]

- Yang, X.; Wang, F.L.; Yang, X.C.; Zhou, Q. Fractal dimension in concrete and implementation for meso-simulation. Constr. Build. Mater. 2017, 143, 464–472. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.L.; Zheng, J.; Wang, J.Y.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Matthew, P. Fractal dimensions of spectral measures of rank one perturbations of positive self-adjoint operator. J. Math. Anal. Appl. 2019, 475, 1803–1817. [Google Scholar]

- Lange, D.; Jennings, H.M. Image analysis techniques for characterization of pore structure of cement-based materials. Cem. Concr. Res. 1994, 24, 841–853. [Google Scholar] [CrossRef]

- Wittmann, F.H. Structure of concrete with respect to crack formation. Dev. Civ. Eng. 1983, 43, 6. [Google Scholar]

- Guo, W.; Qin, H.G.; Chen, H.S.; Sun, W. Fractal theory and its applications in the study of concrete materials. J. Chin. Ceram. Soc. 2010, 38, 1362–1368. [Google Scholar]

- Risović, D.; Mahović Poljaček, S.; Furić, K.; Gojo, M. Inferring fractal dimension of rough/porous surfaces-A comparison of SEM image analysis and electrochemical impedance spectroscopy methods. Appl. Surf. Sci. 2008, 255, 3063–3070. [Google Scholar] [CrossRef]

- Atzeni, C.; Pia, G.; Sanna, U. A geometrical fractal model for the porosity and permeability of hydraulic cement pastes. Constr. Build. Mater. 2010, 24, 1843–1847. [Google Scholar] [CrossRef]

- Song, J.W.; Fang, K.H.; Liu, D.M.; Chen, X. Research on fractal characteristics of phosphate slag-cement paste pore with MIP. Eng. J. Wuhan Univ. 2008, 41, 41–46. [Google Scholar]

- Ma, H.Q.; Chen, H.Y.; Zhu, H.G.; Shi, Y.Y.; Ni, Y.D.; Huo, Q.J.; Hang, Z.T. Study on the drying shrinkage of alkali-activated coal gangue-slag mortar and its mechanisms. Constr. Build. Mater. 2019, 225, 204–213. [Google Scholar]

- Zeng, Q.; Li, K.F. Reaction and microstructure of cement-fly-ash system. Mater. Struct. 2015, 48, 1703–1716. [Google Scholar] [CrossRef]

- Chen, X.D.; Wu, S.X. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 2013, 38, 804–812. [Google Scholar] [CrossRef]

- Jin, S.S.; Zhang, J.X.; Chen, C.Z.; Chen, W.L. Study of pore fractal characteristic of cement mortar. J. Build. Mater. 2011, 14, 92–97. [Google Scholar]

- Zhao, L.; Wang, W.; Li, Z.; Chen, Y.F. Microstructure and pore fractal dimensions of recycled thermal insulation concrete. Mater. Test. 2015, 57, 349–359. [Google Scholar] [CrossRef]

- Cui, S.; Liu, P.; Cui, E.; Su, J.; Huang, B. Experimental study on mechanical property and pore structure of concrete for shoe tree use in a hot-dry environment of high geothermal tunnels. Constr. Build. Mater. 2018, 173, 124–135. [Google Scholar] [CrossRef]

- Jin, S.S.; Zhang, J.X.; Han, S. Fractal analysis of relation between strength and pore structure of hardened mortar. Constr. Build. Mater. 2017, 135, 1–7. [Google Scholar] [CrossRef]

- Fu, J.; Yu, Y. Experimental study on pore characteristics and fractal dimension calculation of pore structure of aerated concrete block. Adv. Civ. Eng. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

| Parameters | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | Na2O | SO3 | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Coal gangue | 56.56 | 36.78 | 0.62 | 1.95 | 0.22 | 0.42 | 0.03 | 2.10 | 1.32 |

| Slag | 30.58 | 14.04 | 38.43 | 0.35 | 10.57 | 0.57 | 2.36 | 1.93 | 1.17 |

| Specimens | Coal Gangue/g | Slag/g | Standard Sand/g | NH | NS | Additional H2O | Alkali-Activator Modulus |

|---|---|---|---|---|---|---|---|

| S0 | 1000 | 0 | 2750 | 94.17 | 580.85 | 188.35 | 1.3 |

| S10 | 900 | 100 | 2750 | 94.17 | 580.85 | 188.35 | 1.3 |

| S20 | 800 | 200 | 2750 | 94.17 | 580.85 | 188.35 | 1.3 |

| S30 | 700 | 300 | 2750 | 94.17 | 580.85 | 188.35 | 1.3 |

| S40 | 600 | 400 | 2750 | 94.17 | 580.85 | 188.35 | 1.3 |

| S50 | 500 | 500 | 2750 | 94.17 | 580.85 | 188.35 | 1.3 |

| M1.5 | 500 | 500 | 2750 | 77.70 | 617.30 | 168.36 | 1.5 |

| M1.4 | 500 | 500 | 2750 | 85.60 | 599.82 | 177.94 | 1.4 |

| M1.2 | 500 | 500 | 2750 | 103.50 | 560.18 | 199.68 | 1.2 |

| M1.1 | 500 | 500 | 2750 | 113.71 | 537.57 | 212.08 | 1.1 |

| Specimens | Pore Fractal Dimension | Porosity/% | Total Pore Area/m2g−1 | Median Pore Dimension/nm | Average pore Dimension/nm |

|---|---|---|---|---|---|

| S0 | 2.601 | 21.21 | 14.710 | 21.9 | 23.3 |

| S10 | 2.783 | 19.25 | 18.229 | 18.3 | 21.2 |

| S20 | 2.830 | 19.44 | 18.575 | 17.7 | 18.4 |

| S30 | 2.866 | 19.90 | 21.094 | 15.3 | 15.6 |

| S40 | 2.937 | 18.01 | 23.977 | 13.9 | 13.7 |

| S50 | 2.992 | 17.22 | 25.665 | 11.6 | 10.7 |

| M1.5 | 2.883 | 17.85 | 23.630 | 8.5 | 9.4 |

| M1.4 | 2.941 | 17.69 | 24.446 | 9.3 | 10.1 |

| M1.2 | 2.989 | 17.17 | 24.677 | 12.9 | 11 |

| M1.1 | 2.869 | 18.22 | 20.828 | 97.3 | 17.5 |

| Magnification | S0 | S10 | S20 | S30 | S40 | S50 |

|---|---|---|---|---|---|---|

| 2000 | 1.76 | 1.767 | 1.776 | 1.792 | 1.806 | 1.809 |

| 1000 | 1.775 | 1.781 | 1.793 | 1.808 | 1.831 | 1.832 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Sun, J.; Wu, C.; Yi, C.; Li, Y. Study on the Pore and Microstructure Fractal Characteristics of Alkali-Activated Coal Gangue-Slag Mortars. Materials 2020, 13, 2442. https://doi.org/10.3390/ma13112442

Ma H, Sun J, Wu C, Yi C, Li Y. Study on the Pore and Microstructure Fractal Characteristics of Alkali-Activated Coal Gangue-Slag Mortars. Materials. 2020; 13(11):2442. https://doi.org/10.3390/ma13112442

Chicago/Turabian StyleMa, Hongqiang, Jianwei Sun, Chao Wu, Cheng Yi, and Yu Li. 2020. "Study on the Pore and Microstructure Fractal Characteristics of Alkali-Activated Coal Gangue-Slag Mortars" Materials 13, no. 11: 2442. https://doi.org/10.3390/ma13112442

APA StyleMa, H., Sun, J., Wu, C., Yi, C., & Li, Y. (2020). Study on the Pore and Microstructure Fractal Characteristics of Alkali-Activated Coal Gangue-Slag Mortars. Materials, 13(11), 2442. https://doi.org/10.3390/ma13112442