Dendrite Morphology Evolution of Al6Mn Phase in Suction Casting Al–Mn Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results

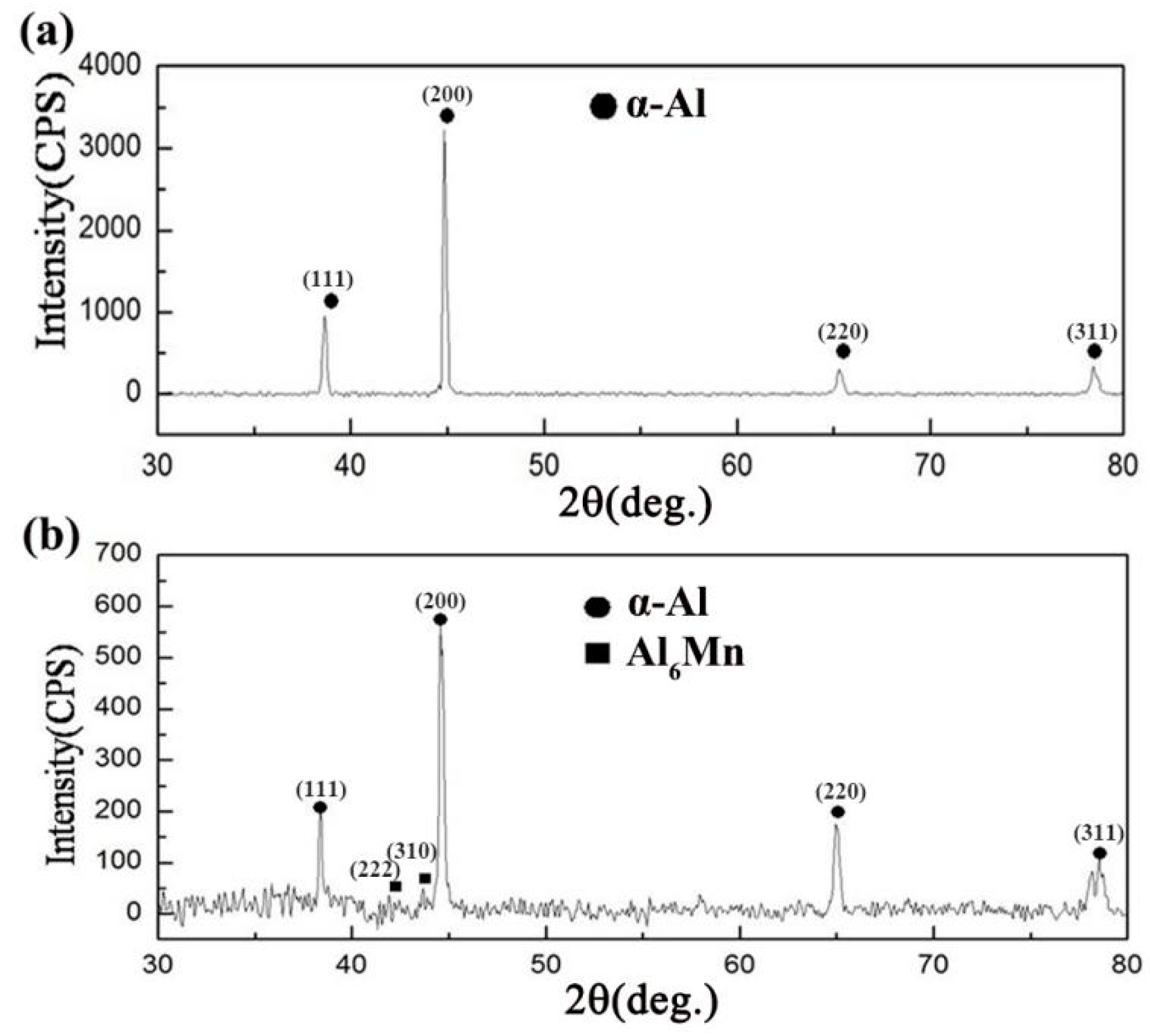

3.1. Microstructure of Suction Casting Al–1.8 wt.% Mn Alloy and Al–4 wt.% Mn Alloy

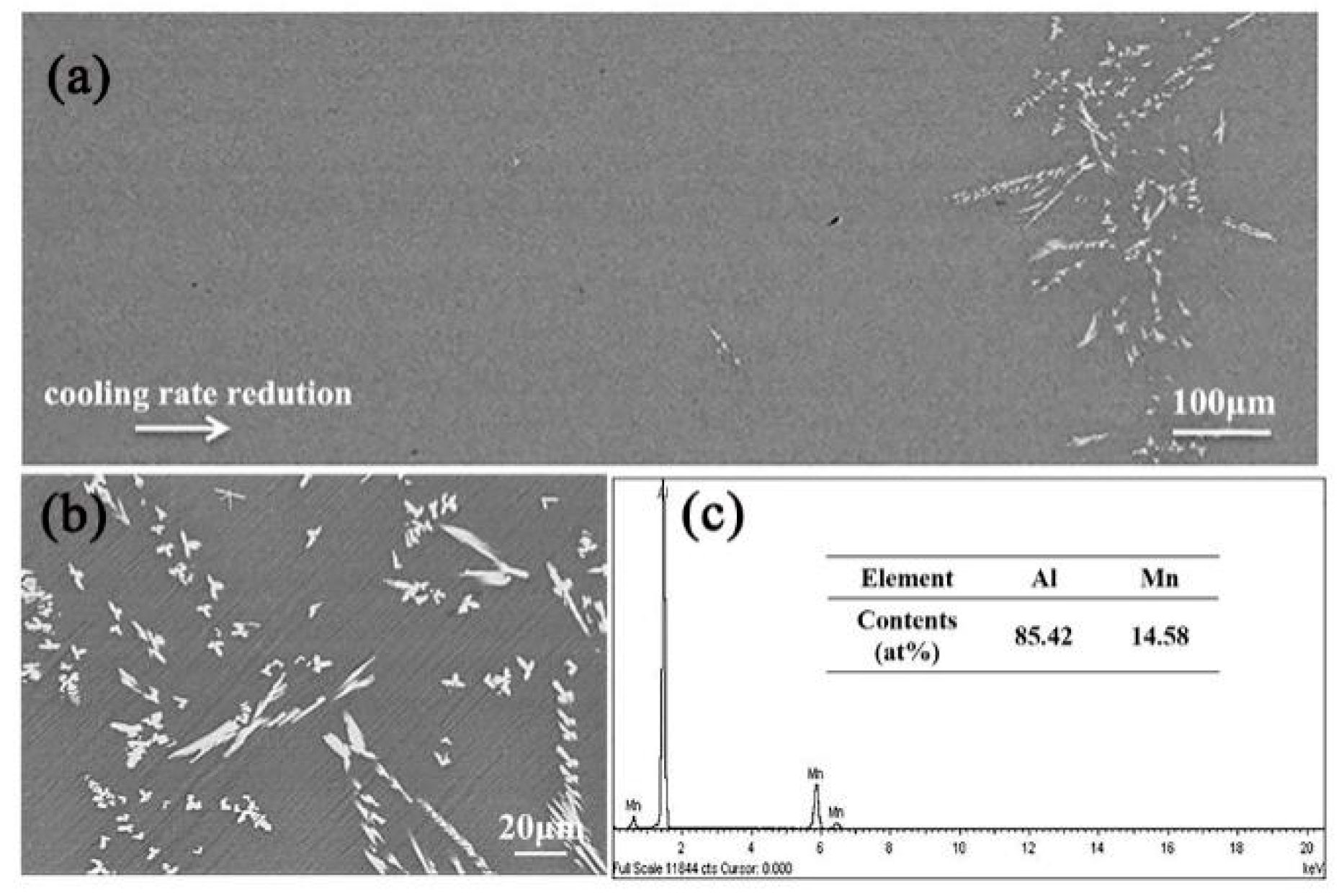

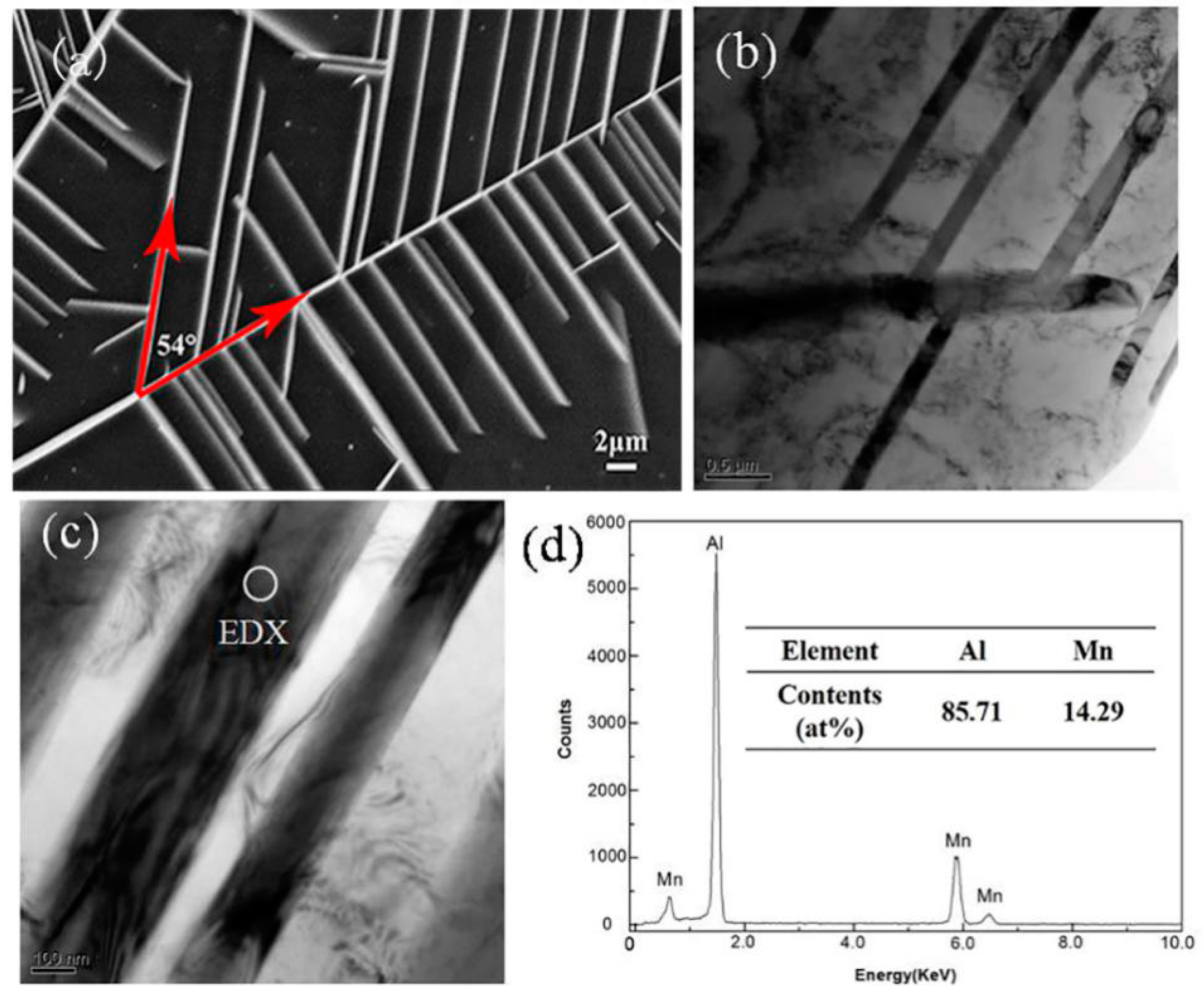

3.2. Microstructure of Suction Casting Al–6 wt.% Mn Alloy

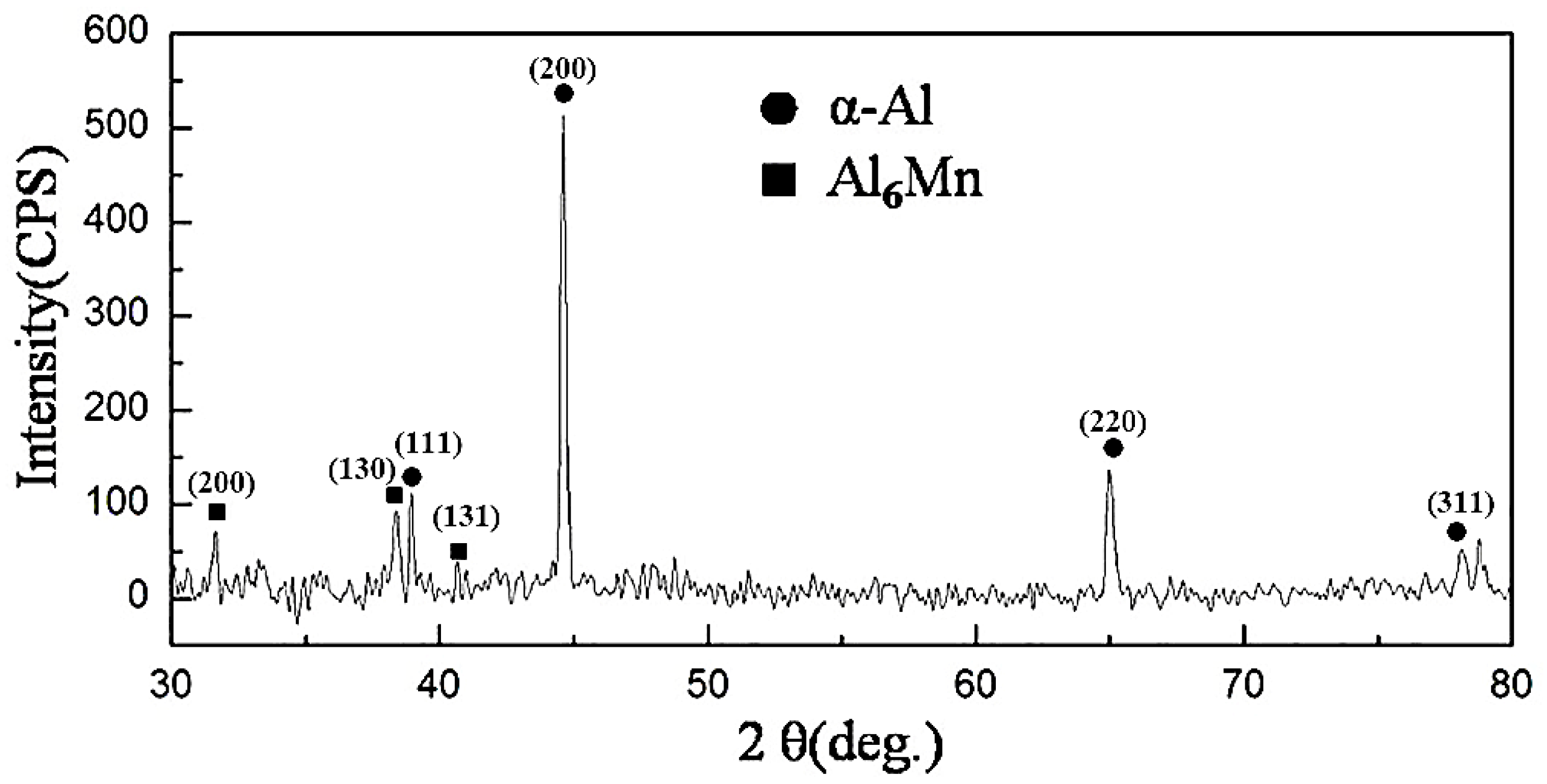

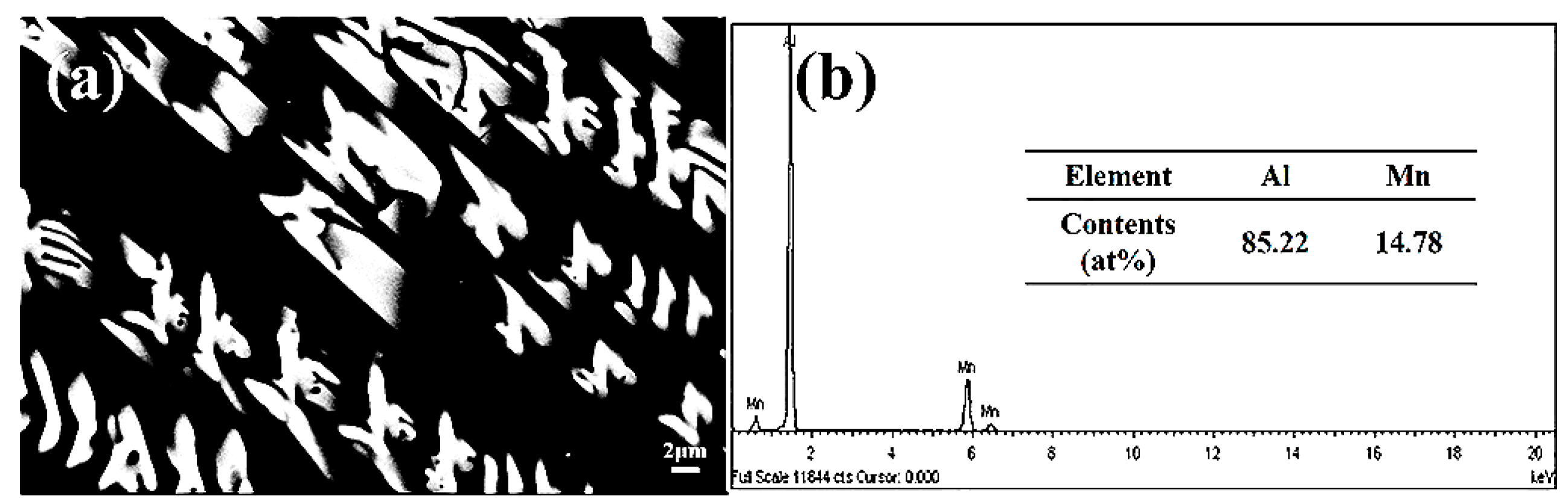

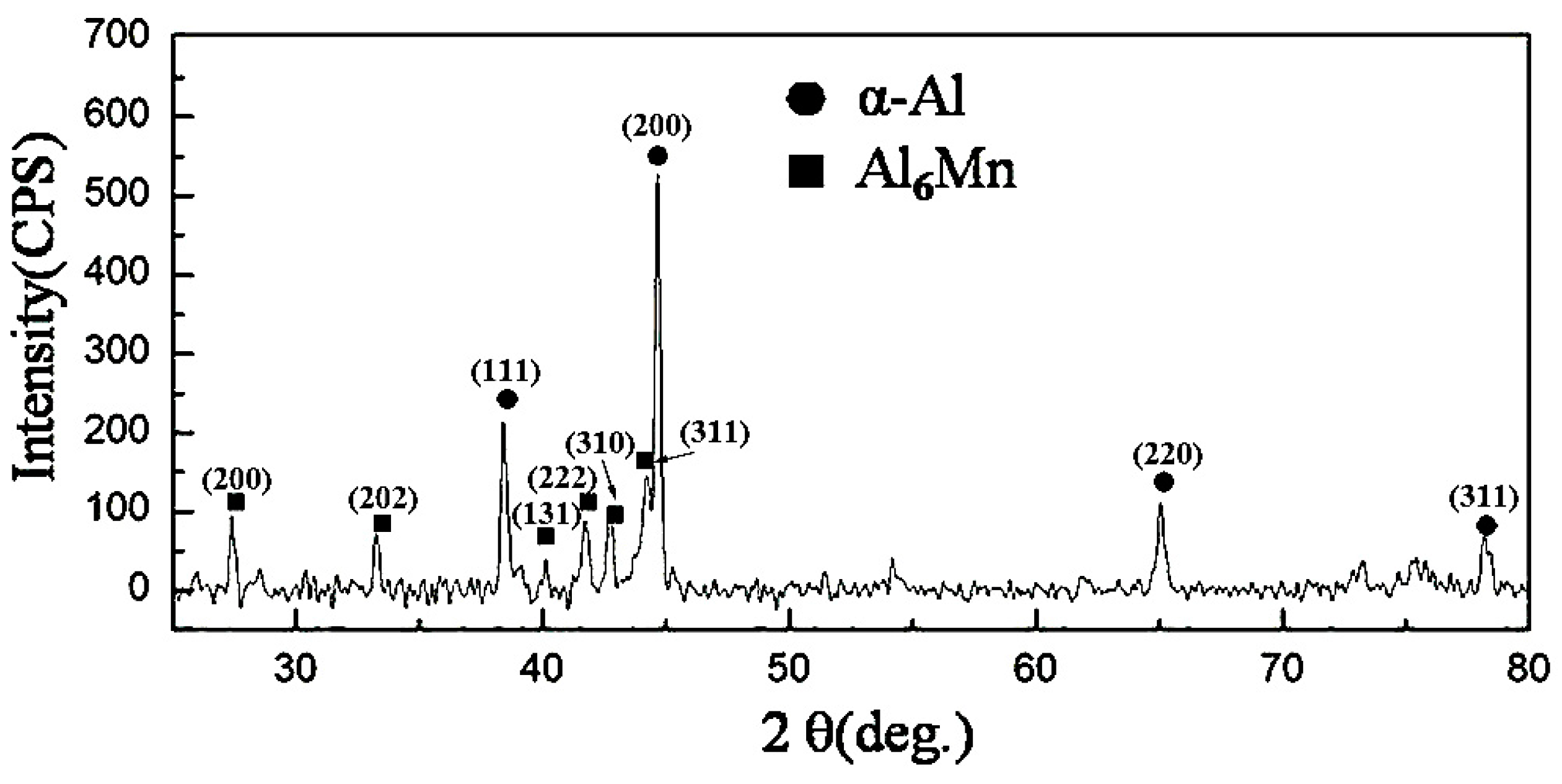

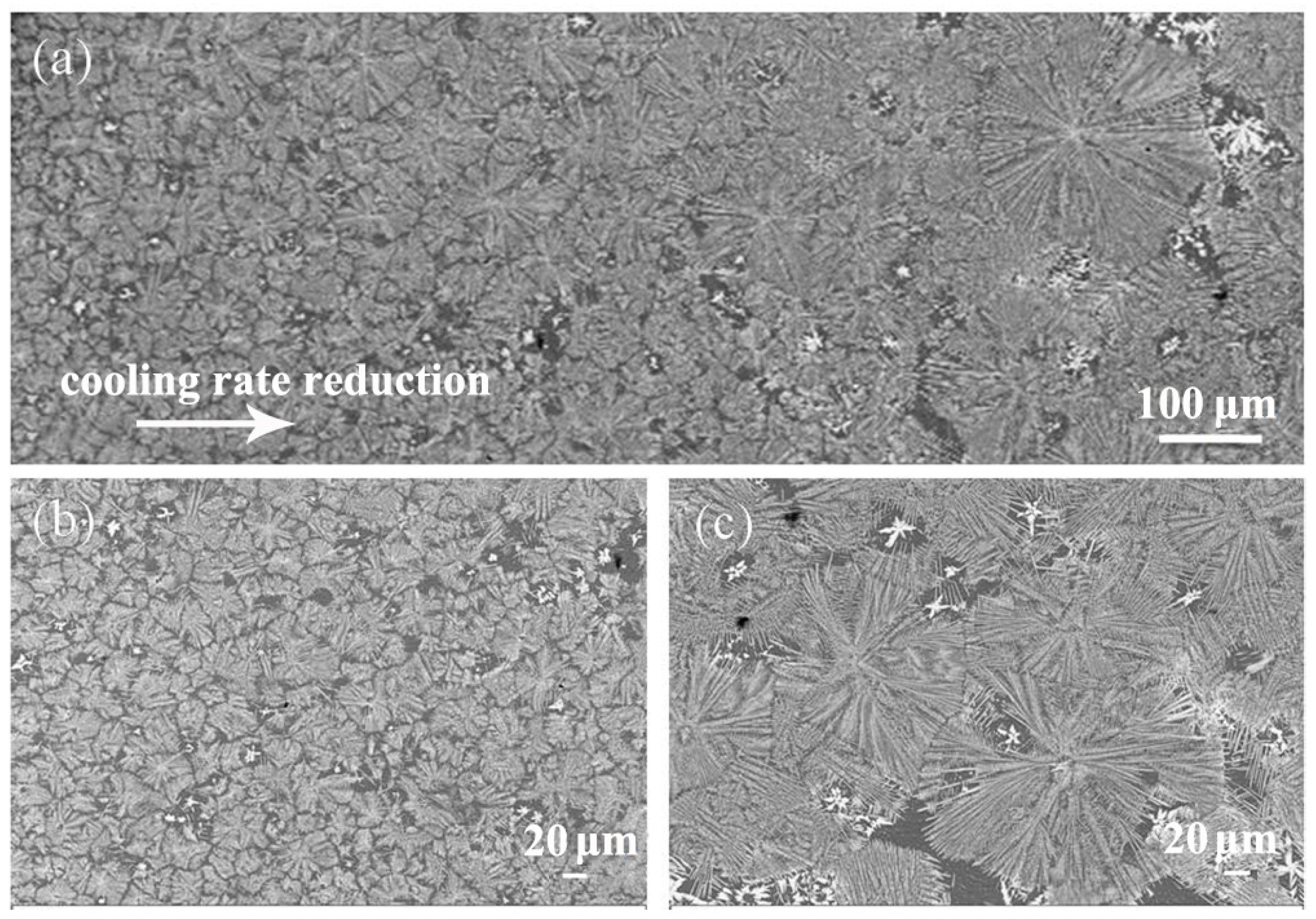

3.3. Microstructure of Suction Casting Al–8 wt.% Mn Alloy

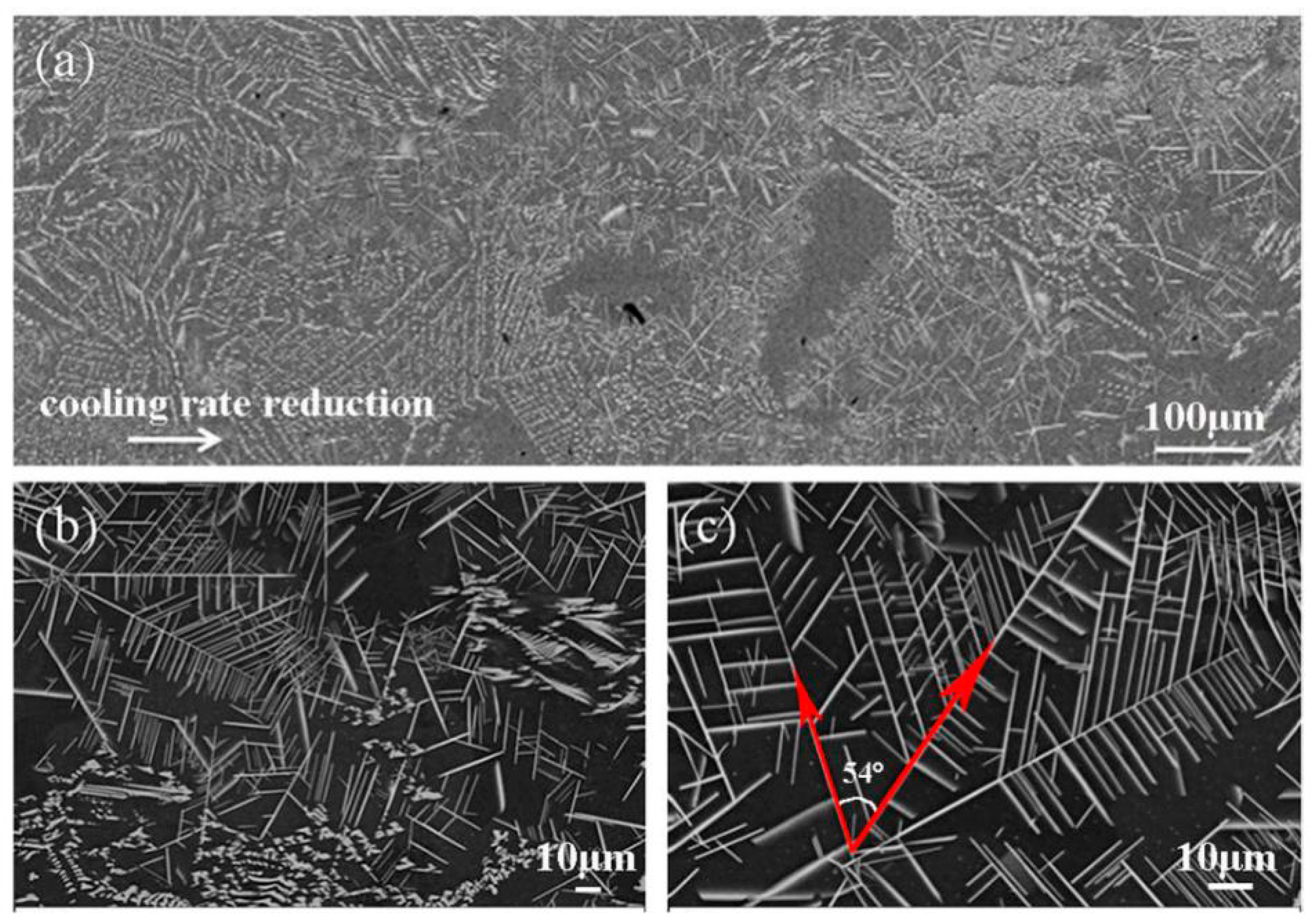

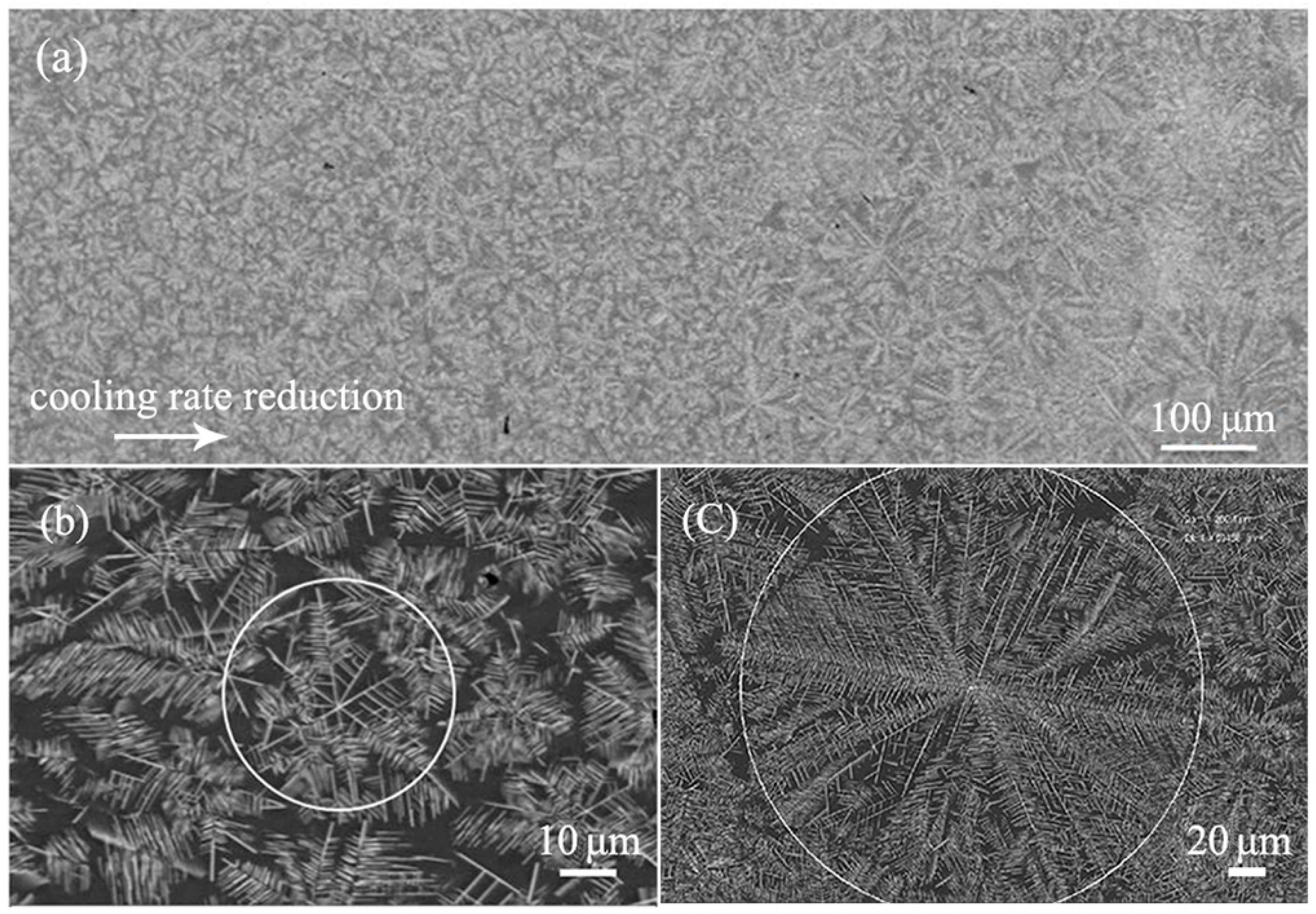

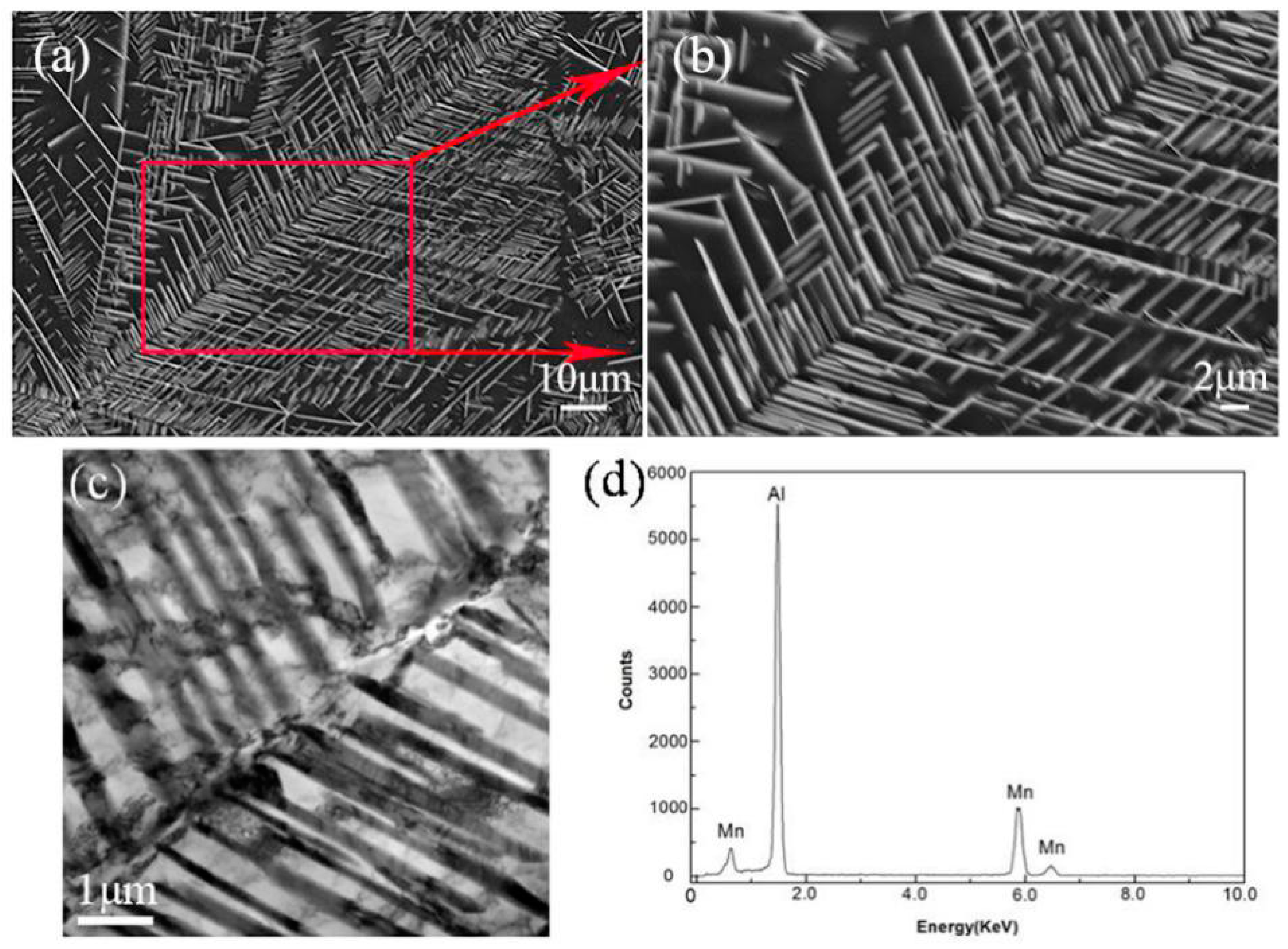

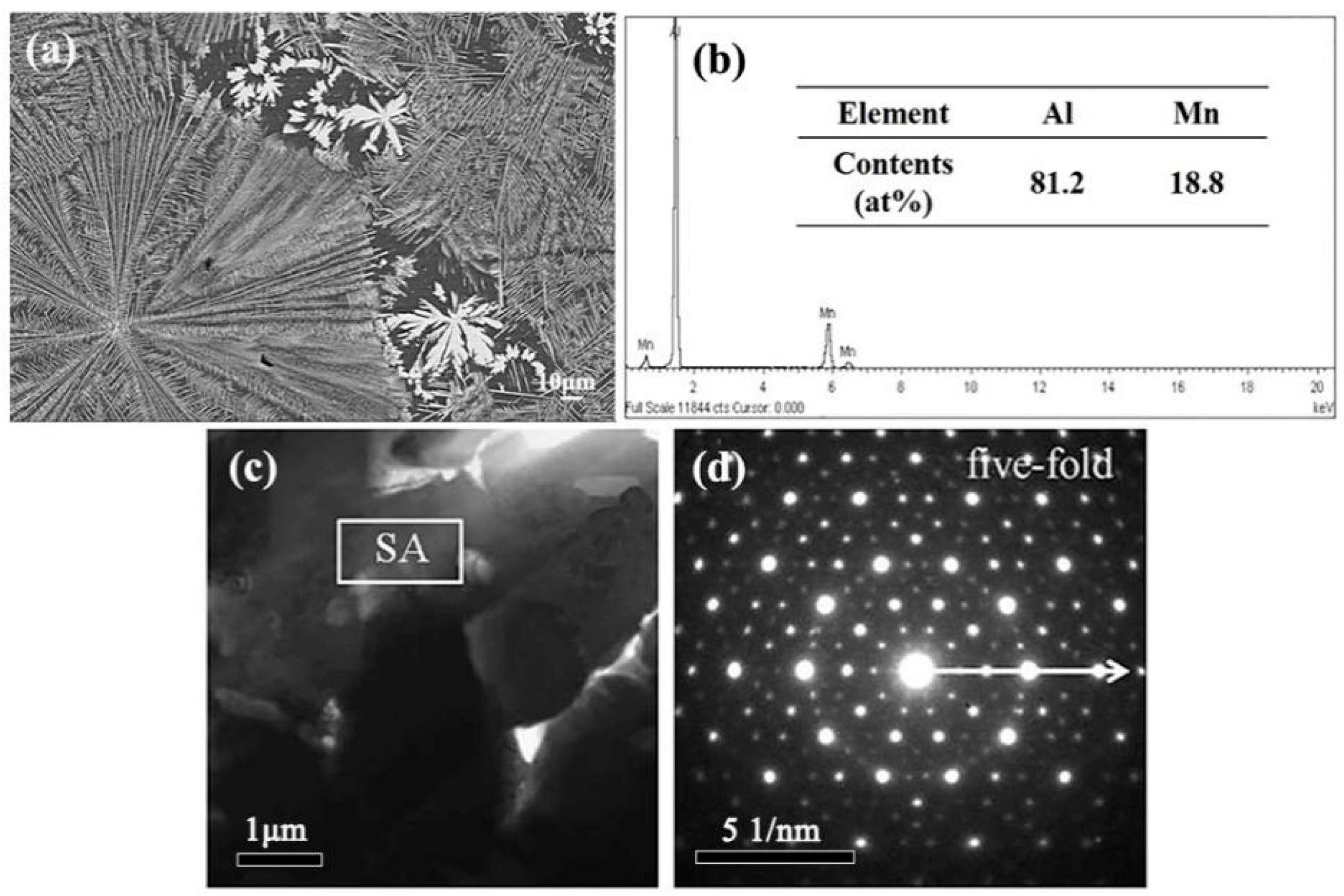

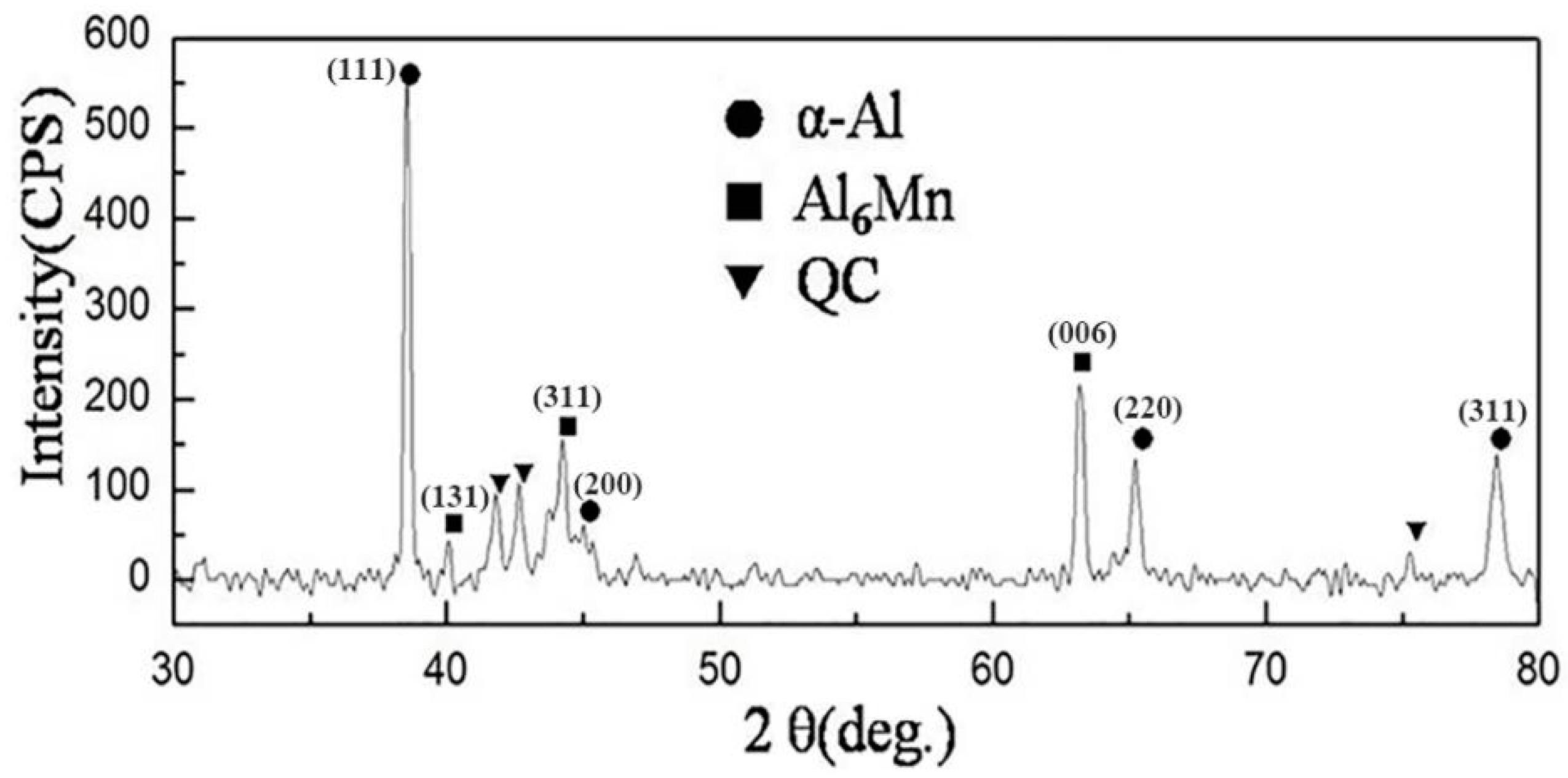

3.4. Microstructure of Suction Casting Al–10 wt.% Mn Alloy

4. Discussion

5. Conclusions

- (1)

- The microstructure in suction casting Al–Mn alloys at higher Mn content (10 wt.%) is composed of Al6Mn dendrites, Al4Mn quasicrystals, and α-Al, while that at lower Mn content (4 wt.%, 6 wt.%, and 8 wt.%) is only composed of Al6Mn phases and α-Al. The Mn content has a positive effect on improving the formation of quasicrystals.

- (2)

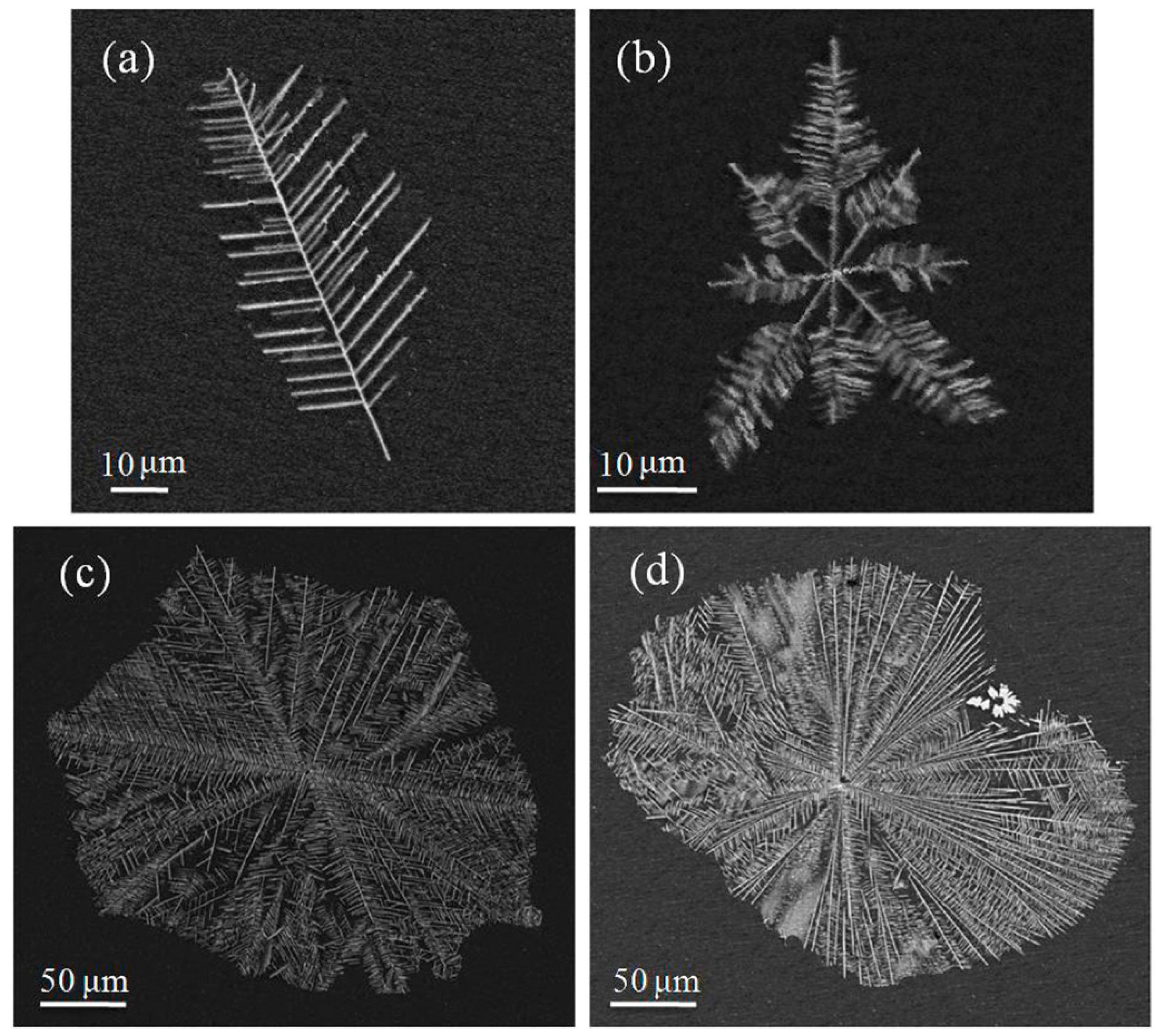

- With the increase in solute Mn content, the morphology of Al6Mn dendrites changed from a block to a feathery phase, and then to snowflake-like and the lotus leaf-like phases. The outline diameter of equiaxed dendrite decreased with the increase in cooling rate from the center to the edge of samples.

- (3)

- The formation of icosahedral quasicrystals can delay the growth of some dendrite trunks in an equiaxed dendrite.

Author Contributions

Funding

Conflicts of Interest

References

- Alexandra, V.K.; Vladimir, V.C.; Alan, T.D.; Andy, W.; Viktor, V.L.; Vadim, S.Z. Formation of metastable phases during solidification of Al-3.2wt% Mn. J. Alloys Compd. 2015, 622, 223–228. [Google Scholar]

- Yucel, B. Recrystallization of a supersaturated Al-Mn alloy. Scr. Mater. 2008, 59, 611–614. [Google Scholar]

- Mcalister, A.J.; Murray, J.L. The (Al-Mn) Aluminum-Manganese system. J. Phase Equilib. 1987, 8, 438–447. [Google Scholar] [CrossRef]

- Shechtman, D.G.; Blech, I.A.; Gratias, D.; Cahn, J.W. Metallic Phase with Long-Range Orientational Order and No Translational Symmetry. Phys. Rev. Lett. 1984, 53, 1951–1954. [Google Scholar] [CrossRef]

- Shechtman, D.; Blech, I.A. The Microstructure of Rapidly Solidified Al6Mn. Metall. Trans. A 1985, 16, 1005–1012. [Google Scholar] [CrossRef]

- Ohashi, T.; Fukatsu, N.; Asai, K. Crystallization and precipitation structures of quasicrystalline phase in rapidly solidified Al-Mn-X ternary alloys. J. Mater. Sci. 1989, 24, 3717–3724. [Google Scholar] [CrossRef]

- Juarez-Islas, J.A.; Warrington, D.H.; Jones, H. Formation of stable and metastable phases in Al-Mn alloys by the use of a gravity chill casting technique. J. Mater. Sci. 1989, 24, 2076–2080. [Google Scholar] [CrossRef]

- Song, G.S.; Fleury, E.; Lee, S.M.; Kim, W.T.; Kim, D.H. Quasicrystal-forming ability of the icosahedral phase in Al-Cu-Fe-Be alloys. Mater. Sci. Eng. A 2003, 346, 42–49. [Google Scholar] [CrossRef]

- Chang, H.J.; Fleury, E.; Song, G.S.; Kim, W.T.; Kim, D.H. Formation of quasicrystalline phases in Al-rich Al-Mn-Be alloys. J. Non-Cryst. Solids 2004, 334, 12–16. [Google Scholar] [CrossRef]

- Chen, Z.W.; Zhang, Q.; Dong, B.L.; Liu, Z.Q. Microstructure and Thermal Stability of Icosahedral Quasicrystals in Suction Casting Al-6at.%Mn(-2at.%Be) Alloys. J. Mater. Eng. Perform. 2020, 29, 447–455. [Google Scholar] [CrossRef]

- Inoue, A.; Watanabe, M.; Kimura, H.; Takahashi, F.; Nagata, A.; Masumoto, T. High mechanical strength of quasicrystalline phase surrounded by fcc-Al phase in rapidly solidified Al-Mn-Ce Alloys. Mater. Trans. JIM 1992, 33, 723–729. [Google Scholar] [CrossRef]

- Vojtěch, D.; Saksl, K.; Verner, J.; Bártová, B. Structural evolution of rapidly solidified Al-Mn and Al-Mn-Sr alloys. Mater. Sci. Eng. A 2006, 428, 188–195. [Google Scholar] [CrossRef]

- Jun, J.H.; Kim, J.M.; Kim, K.T.; Jung, W.J. Fabrication and mechanical properties of quasicrystal- reinforced Al-Mn-Mm alloys. Mater. Sci. Eng. A 2007, 449, 979–982. [Google Scholar] [CrossRef]

- Kamaeva, L.V.; Sterkhova, I.V.; Lad’yanov, V.I.; Ryltsev, R.E.; Chtchelkatchev, N.M. Phase selection and microstructure of slowly solidified Al-Cu-Fe alloys. J. Cryst. Growth 2020, 531, 1–4. [Google Scholar] [CrossRef]

- Chen, H.L.; Jansson, A. Phase formation in A3003 alloys. Mater. Today 2019, 10, 296–305. [Google Scholar] [CrossRef]

- Murray, J.L.; McAlister, A.J.; Schaefer, R.J.; Bendersky, L.A.; Biancaniello, F.S.; Moffat, D.L. Stable and metastable phase equilibria in the Al–Mn system. Mater. Trans. A 1987, 18, 385–391. [Google Scholar] [CrossRef]

- Markoli, B.; Delijic, K.; Trekelj, S.N.; Naglic, I. Influence of cooling rate and alloying elements on the microstructure of the Al-Mn-based alloy. Contemp. Mater. 2014, 1, 30–36. [Google Scholar]

- Stan-Głowińska, K.; Rogal, L.; Góral, A.; Wierzbicka-Miernik, A.; Wojewoda-Budka, J.; Schell, N.; Lityńska-Dobrzyńska, L. Formation of a quasicrystalline phase in Al-Mn base alloys cast at intermediate cooling rates. J. Mater. Sci. 2017, 52, 7794–7807. [Google Scholar] [CrossRef]

- Stan-Głowińska, K.; Lityńska-Dobrzyńska, L.; Rogal, Ł. Influence of Fe addition on the formation of a quasicrystalline phase in bulk Al-rich Al-Mn base alloys. Mater. Charact. 2017, 128, 203–208. [Google Scholar] [CrossRef]

- Jansson, A.A. Thermodynamic Evaluation of the Al-Mn System. Metall. Trans. A 1992, 23, 2953–2962. [Google Scholar] [CrossRef]

- Laissardière, G.T.; Mayou, D. Magnetism in Al(Si)-Mn quasicrystals and related phases. Phys. Rev. Lett. 2000, 85, 3273–3276. [Google Scholar] [CrossRef] [PubMed]

- Nakayasua, H.; Kobayashi, E. Orientation relationships of phase transformation in α-Al12Mn3Si pseudomorphs after plate-like Al6Mn precipitate in an AA3004 Al-Mn based alloy. Mater. Charact. 2018, 136, 367–374. [Google Scholar] [CrossRef]

- Ratchev, P.; Verlinden, B.; Houtte, P.V. Effect of Preheat Temperature On the Orientation relationship of (Mn,Fe)Al6 precipitates in an AA5182 aluminium-magnesium alloy. Acta Metall. Mater. 1995, 43, 621–629. [Google Scholar] [CrossRef]

- Liu, S.D.; Chen, J.C.; Chai, W.R.; Wang, Q. Effects of Combined Additions of Mn and Zr on Dispersoid Formation and Recrystallization Behavior in Al-Zn-Mg Alloys. Metall. Mater. Trans. A 2019, 50, 10–34. [Google Scholar] [CrossRef]

- Kang, H.J.; Li, X.Z.; Su, Y.Q.; Liu, D.M.; Guo, J.J.; Fu, H.Z. 3-D morphology and growth mechanism of primary Al6Mn intermetallic compound in directionally solidified Al-3at.%Mn alloy. Intermetallics 2012, 23, 32–38. [Google Scholar] [CrossRef]

- Zupanič, F.; Markoli, B.; Naglič, I.; Boncina, T. The experimental investigation of phase equilibria in the Al-rich corner within the ternary Al-Mn-Be system. J. Alloys Compd. 2013, 570, 125–132. [Google Scholar] [CrossRef]

- Klyueva, M.; Shulyatev, D. New stable icosahedral quasicrystal in the system Al-Cu-Co-Fe. J. Alloys Compd. 2019, 801, 478–482. [Google Scholar] [CrossRef]

- Wu, H.R.; Du, W.B. Microstructure and mechanical properties of AZ31 magnesium alloy reinforced by I-phase. Rare Met. 2019, 38, 733–738. [Google Scholar] [CrossRef]

- Sunagawa, I. Growth and morphology of crystals. Forma 1999, 14, 147–166. [Google Scholar]

- Stephens, P.W.; Goldman, A.I. Sharp diffraction maxima from an icosahedral glass. Phys. Rev. Lett. 1986, 56, 1167–1171. [Google Scholar] [CrossRef]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification, 4th ed.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 1998; pp. 22–34. [Google Scholar]

- Stan-Głowińska, K. Formation of quasicrystalline phases and their close approximants in cast Al-Mn base alloys modified by transition metals. Crystals 2018, 8, 61. [Google Scholar] [CrossRef]

- Wang, C.Y.; Beckermann, C. Prediction of columnar to equiaxed transition during diffusion-controlled dendritic alloy solidification. Metall. Mater. Trans. A 1994, 25, 1081–1093. [Google Scholar] [CrossRef]

- Witten, T.A.; Sander, L.M. Diffusion-limited aggregation, a kinetic critical phenomenon. Phys. Rev. Lett. 1980, 47, 1400–1403. [Google Scholar] [CrossRef]

- Thangaraj, N.; Subbanna, G.N.; Ranganathan, S.; Chattopadhyay, K. Electron microscopy and diffraction of icosahedral and decagonal quasicrystals in aluminium-manganese alloys. J. Microsc. 1987, 146, 287–302. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Hou, Y.; Xie, B.; Zhang, Q. Dendrite Morphology Evolution of Al6Mn Phase in Suction Casting Al–Mn Alloys. Materials 2020, 13, 2388. https://doi.org/10.3390/ma13102388

Chen Z, Hou Y, Xie B, Zhang Q. Dendrite Morphology Evolution of Al6Mn Phase in Suction Casting Al–Mn Alloys. Materials. 2020; 13(10):2388. https://doi.org/10.3390/ma13102388

Chicago/Turabian StyleChen, Zhongwei, Yue Hou, Bin Xie, and Qi Zhang. 2020. "Dendrite Morphology Evolution of Al6Mn Phase in Suction Casting Al–Mn Alloys" Materials 13, no. 10: 2388. https://doi.org/10.3390/ma13102388

APA StyleChen, Z., Hou, Y., Xie, B., & Zhang, Q. (2020). Dendrite Morphology Evolution of Al6Mn Phase in Suction Casting Al–Mn Alloys. Materials, 13(10), 2388. https://doi.org/10.3390/ma13102388