Microstructure and Low Cycle Fatigue Properties of AA5083 H111 Friction Stir Welded Joint

Abstract

1. Introduction

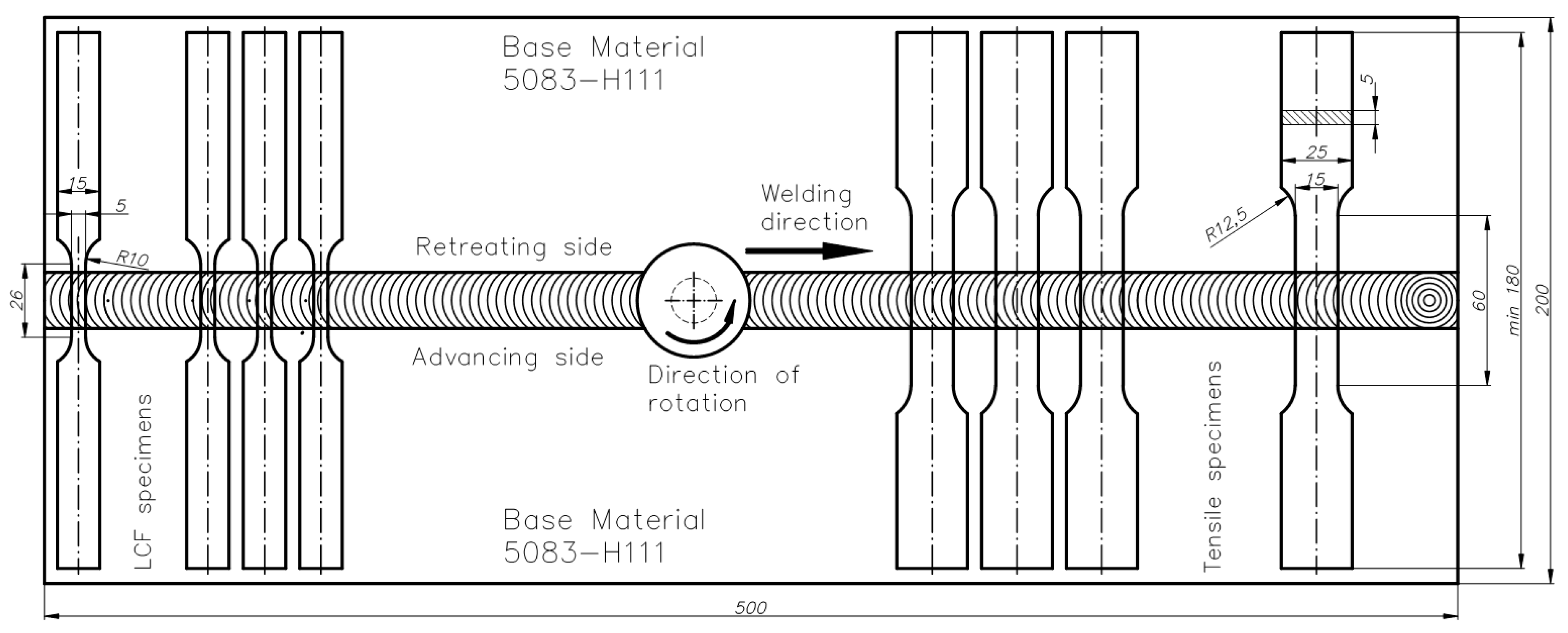

2. Materials and Methods

3. Results and Discussion

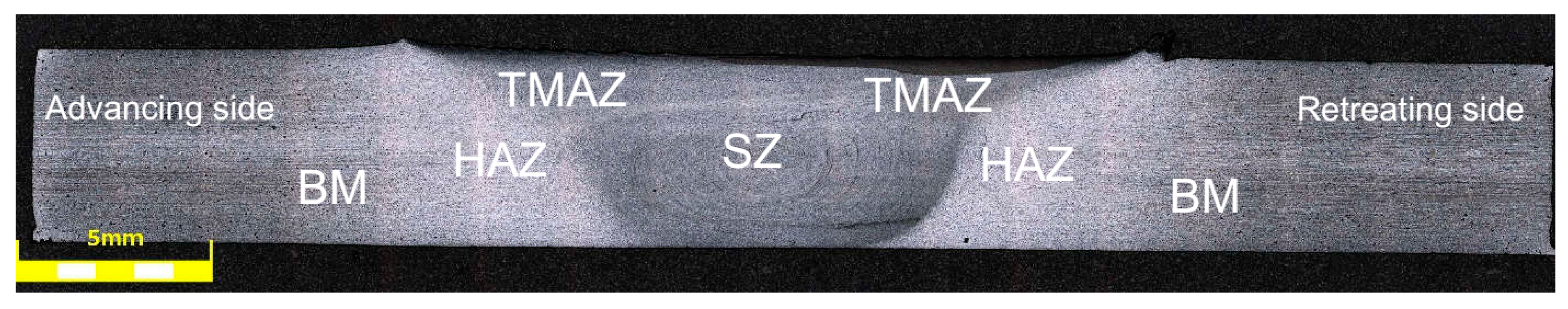

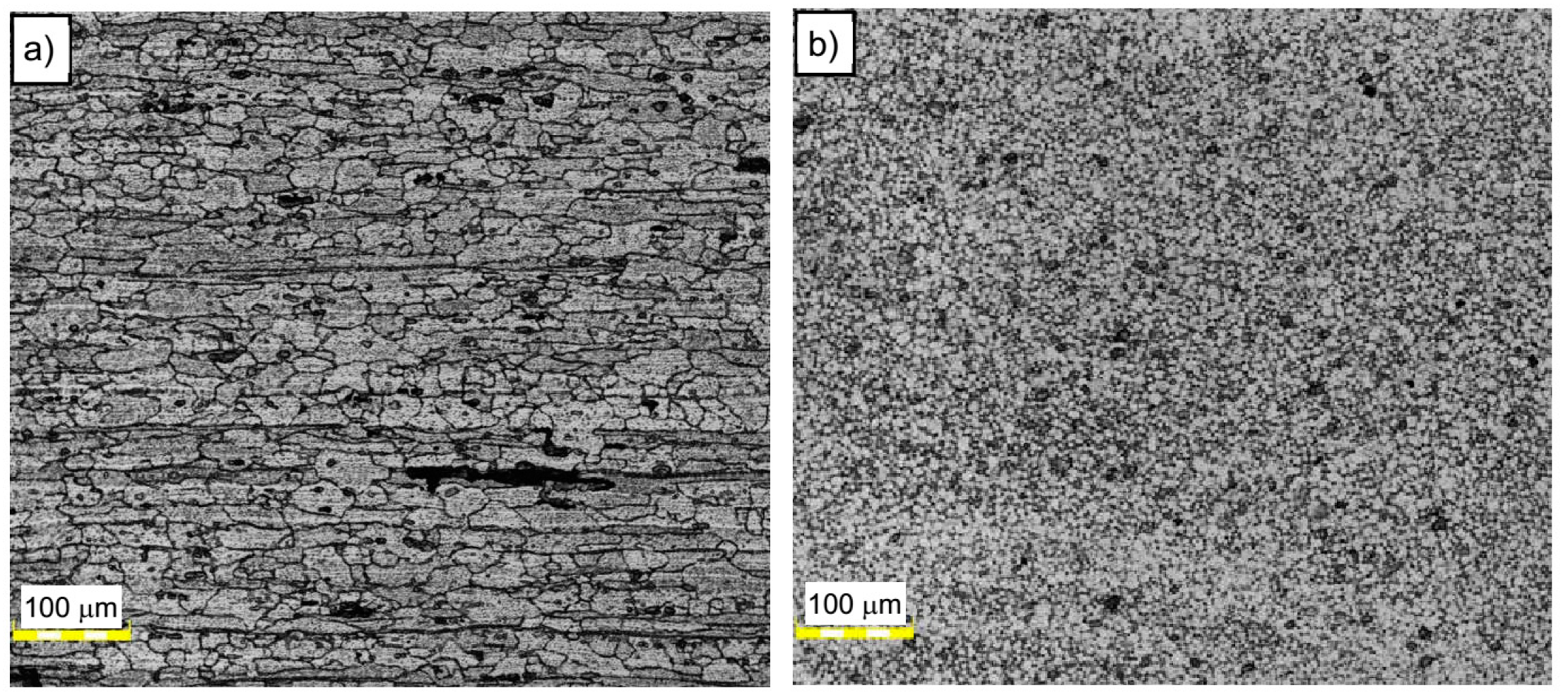

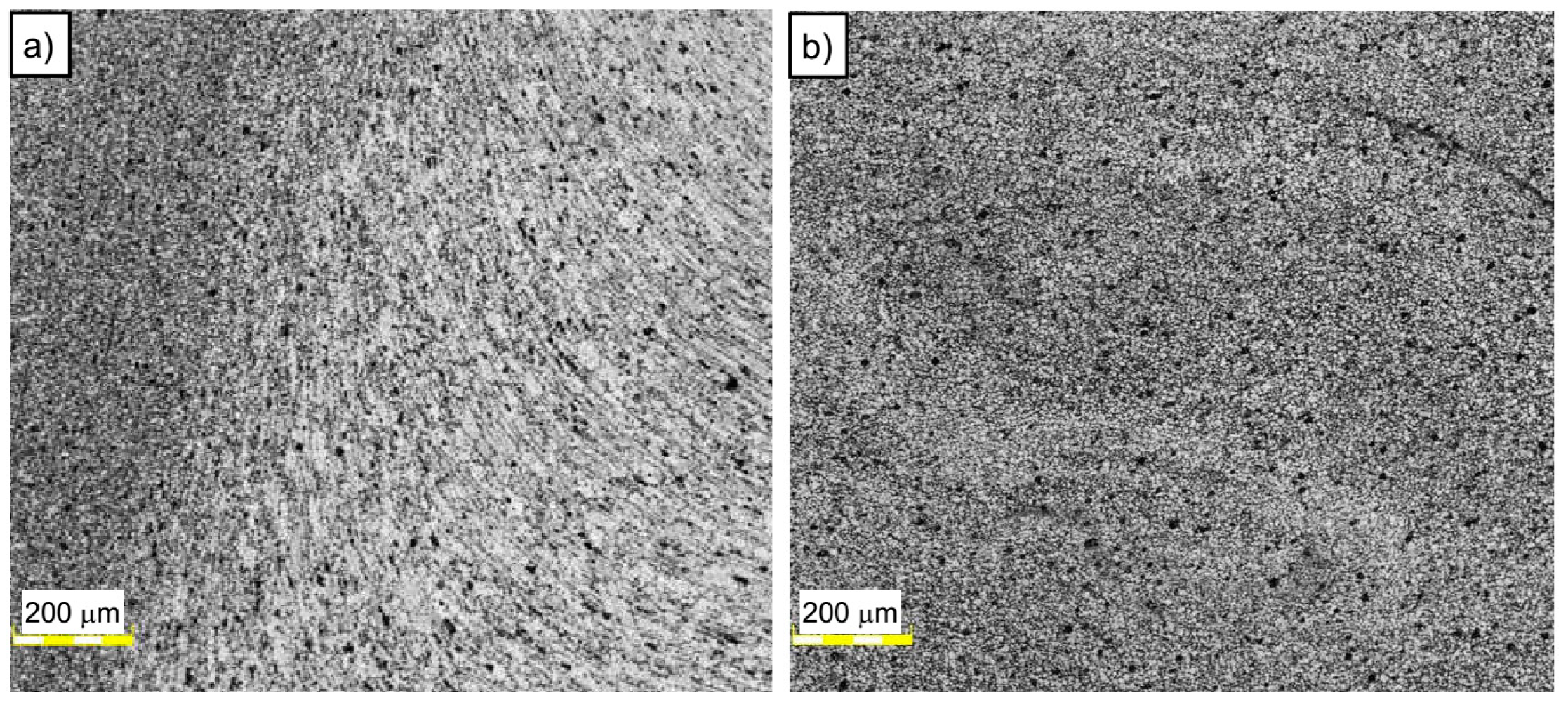

3.1. Microstructural Behavior

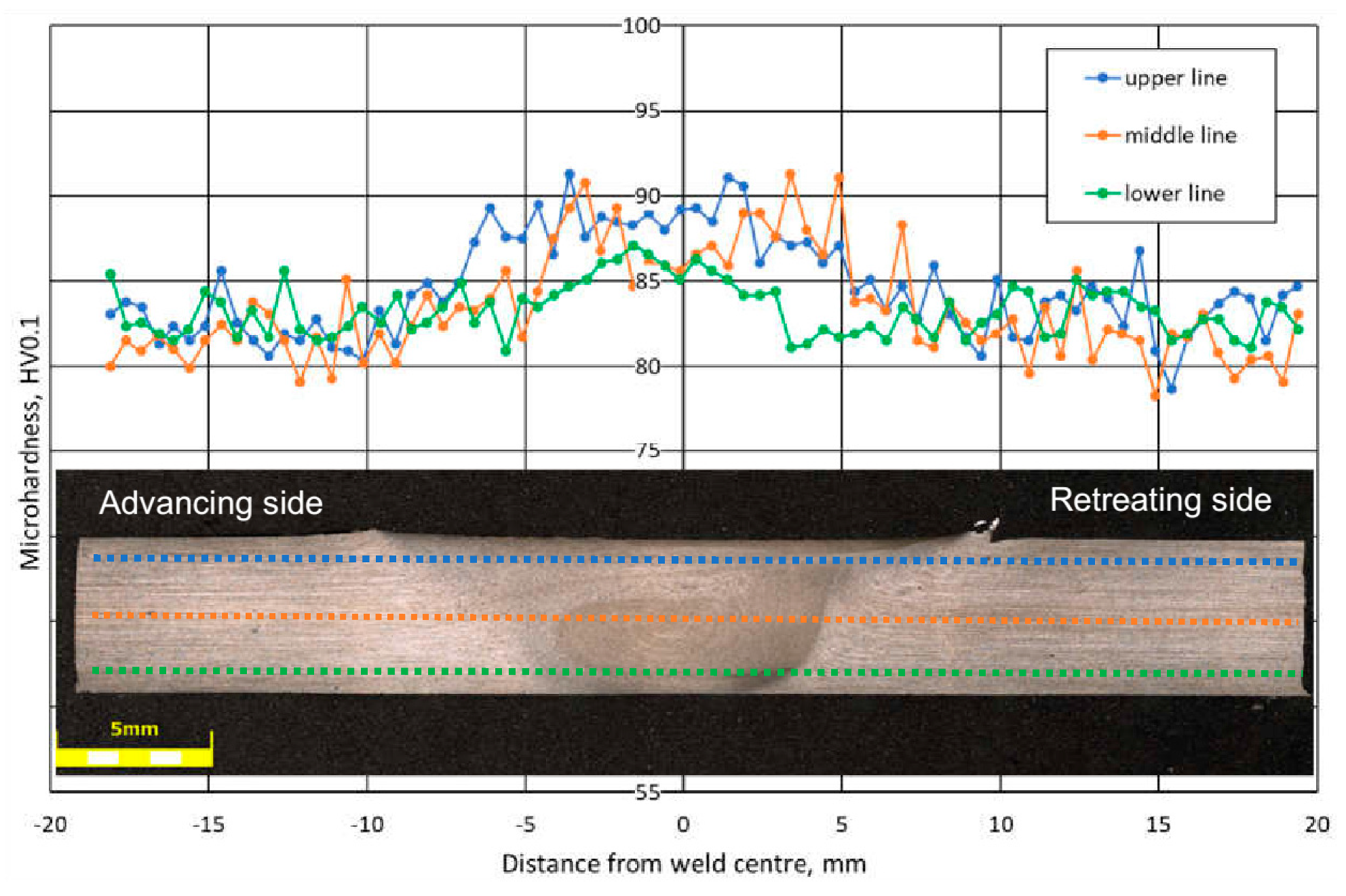

3.2. Microhardness

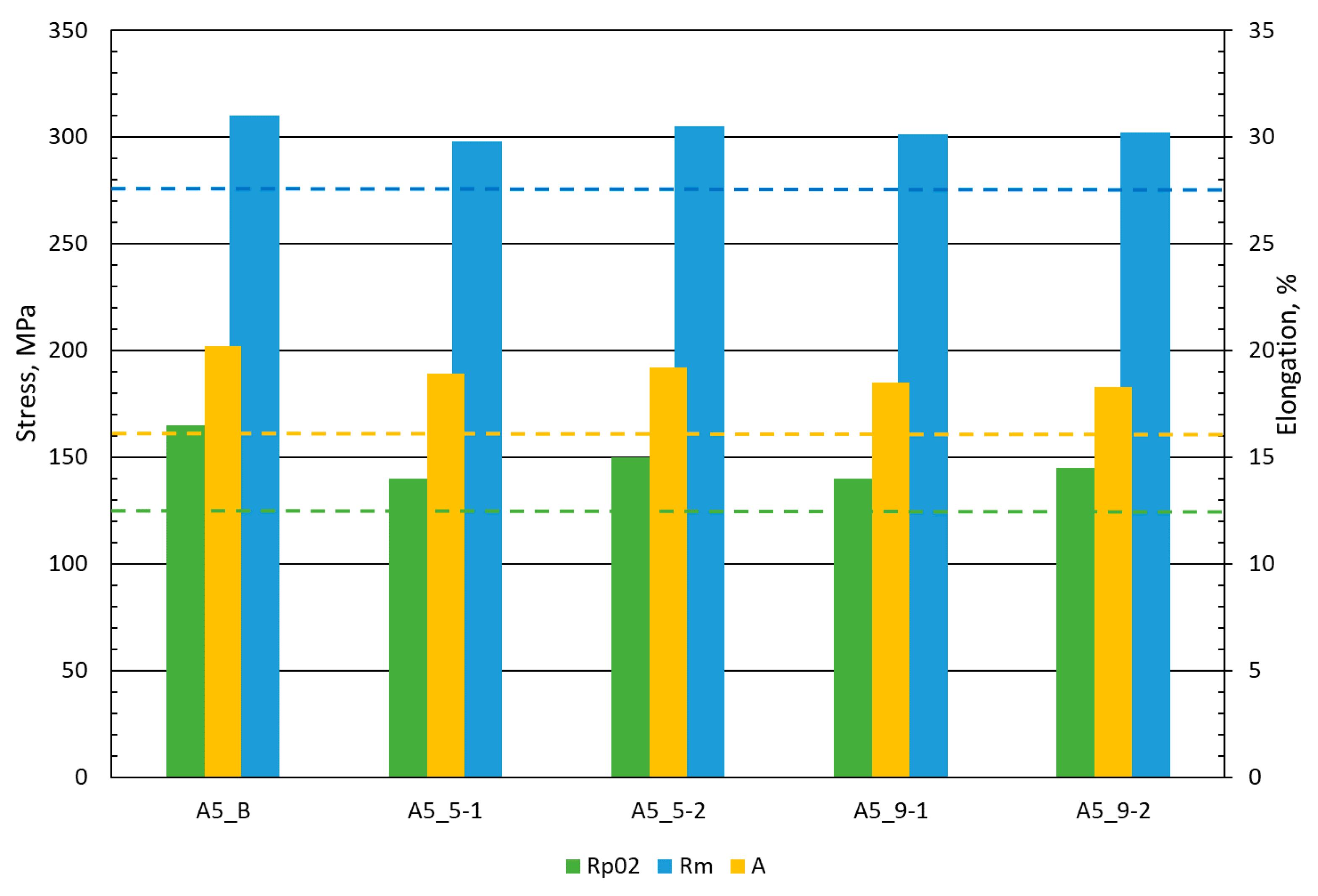

3.3. Tensile Properties

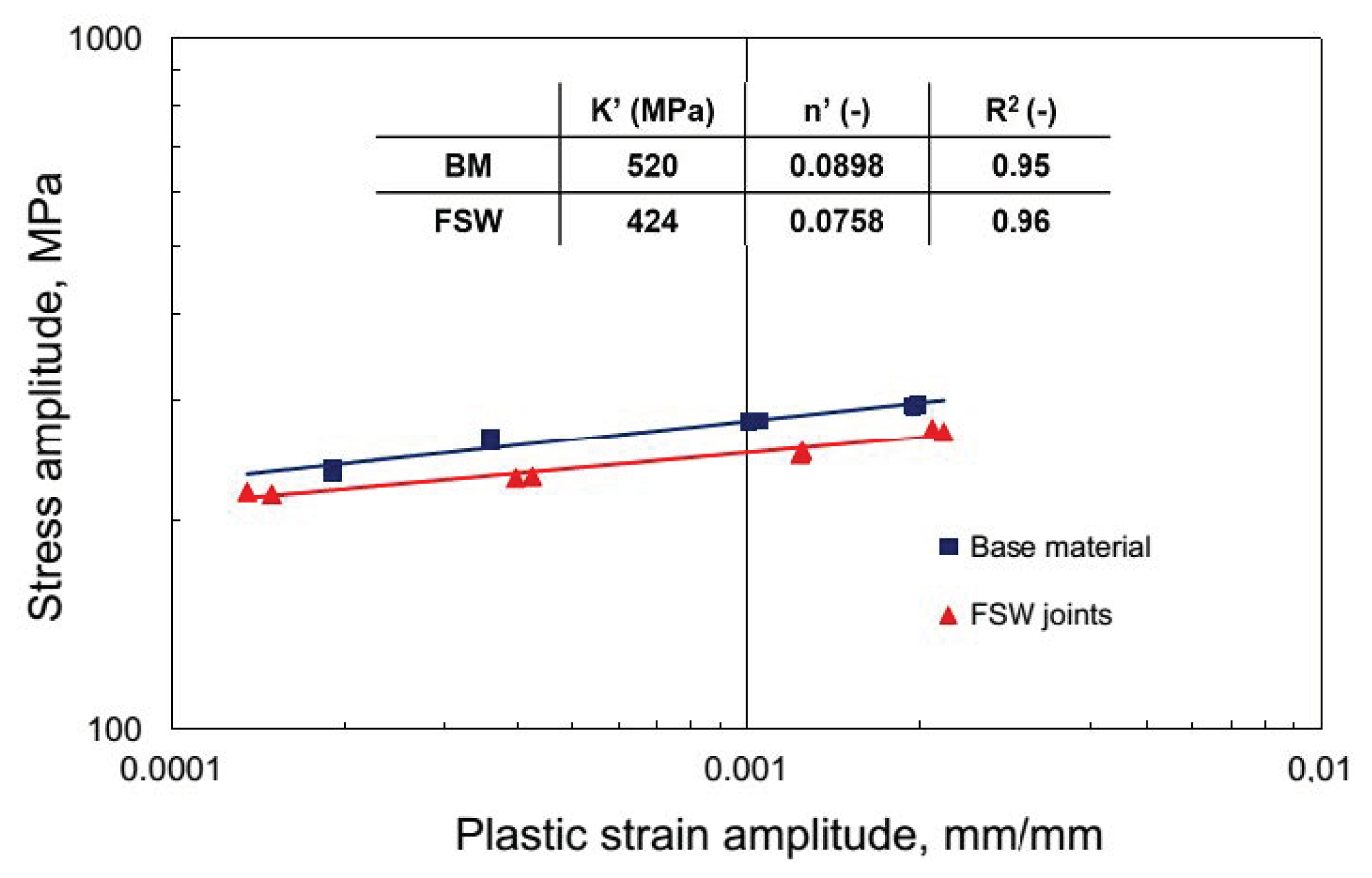

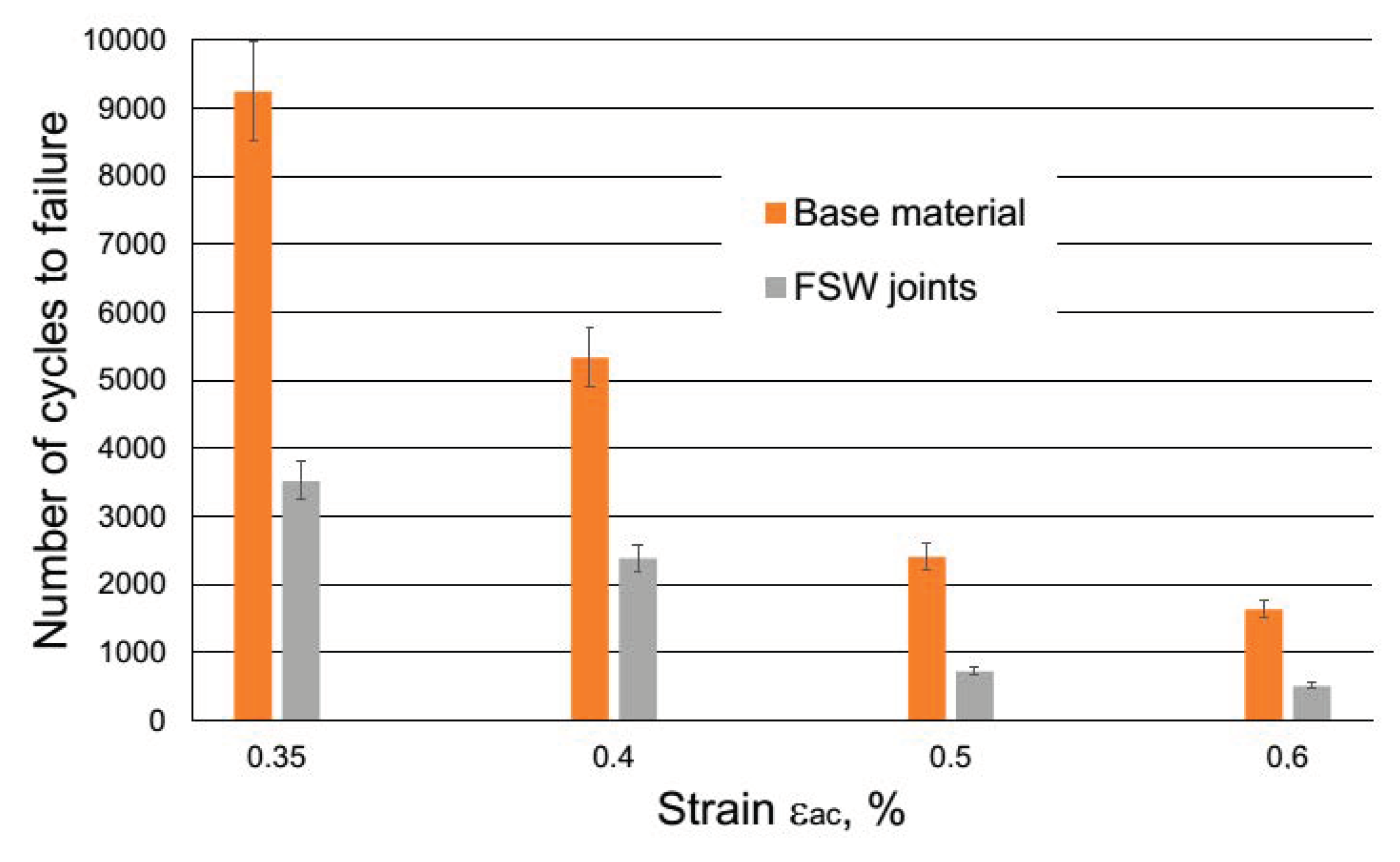

3.4. Fatigue Behavior

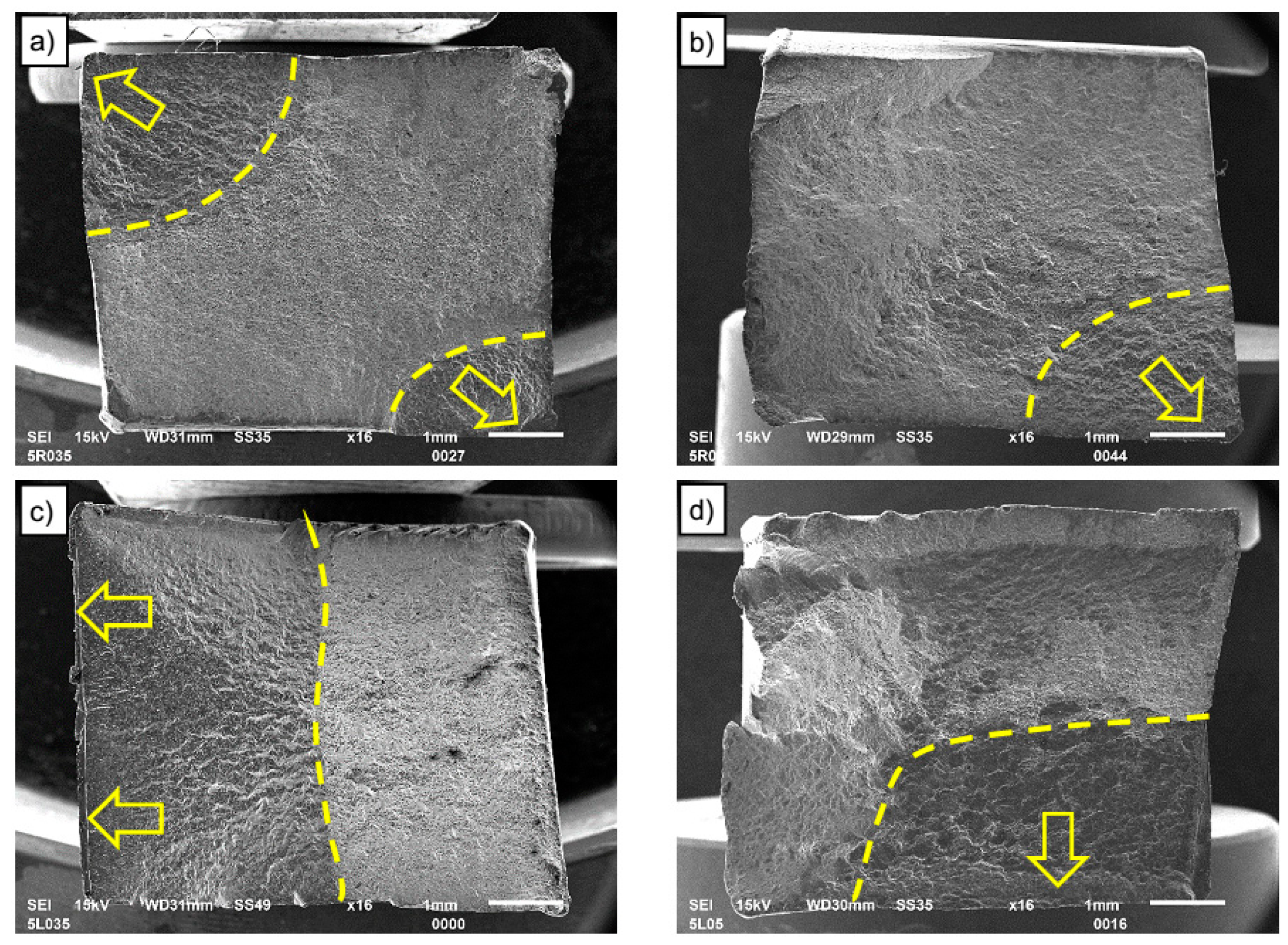

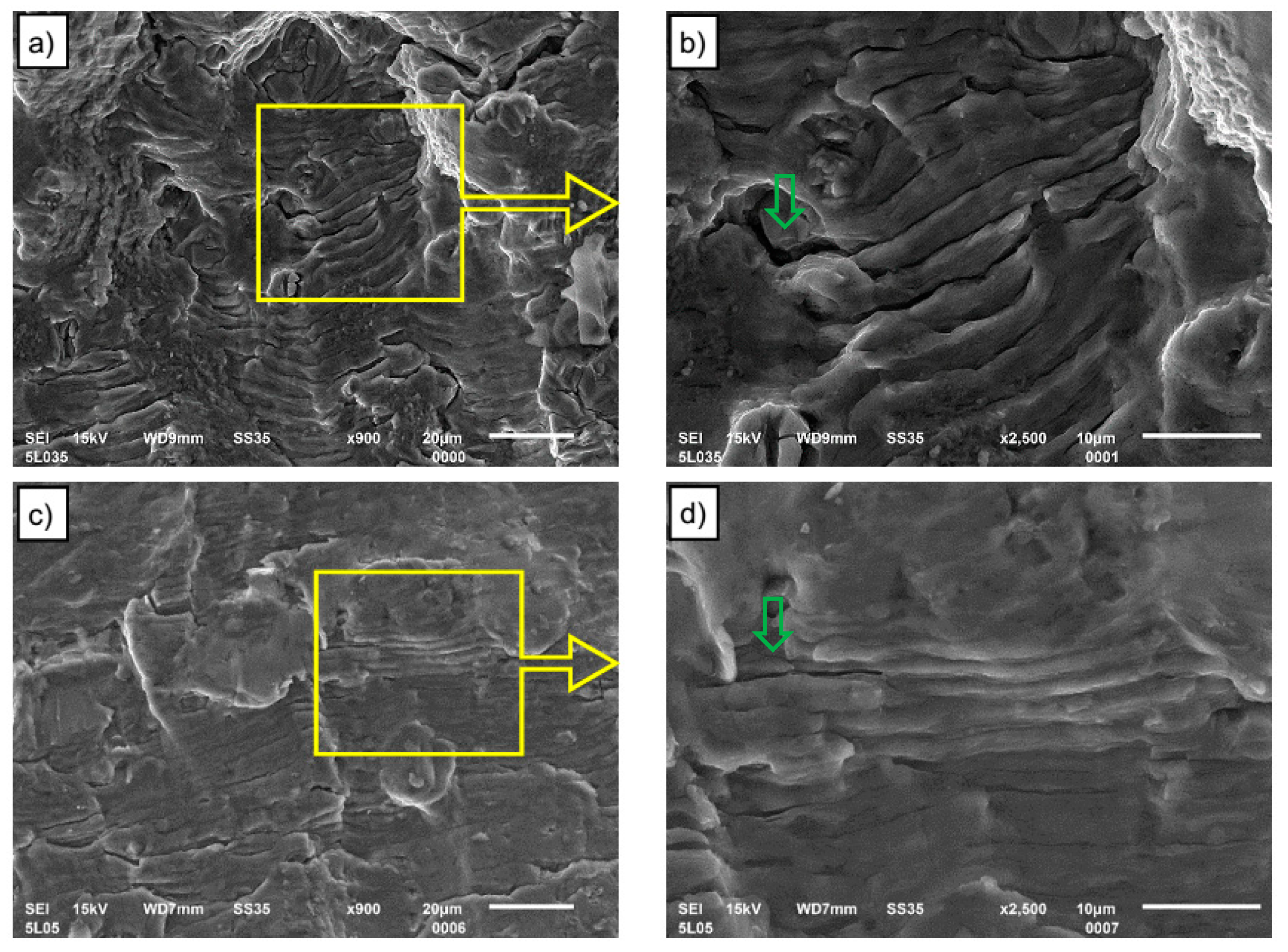

3.5. Fractography

4. Conclusions

- Macroscopic observations did not reveal any noticeable imperfections in the investigated joint. On the other hand, microscopic examinations revealed the impact of the tool on the workpiece in the friction stir zone; it results in the formation of ultrafine grain microstructure in this area due to the dynamic recrystallization phenomenon.

- As a result of the dynamic impact of the tool and changes in the microstructure, the microhardness of the joined material value of 82 HV0.1 increased to about 88 HV0.1 in the stir zone for selected friction stir welding parameters.

- It was found that the FSW joined elements subjected to low cycle fatigue may be exposed to significant efficiency deterioration reaching 66% differently than in the case of monotonic tensile load, for which the efficiency of the FSW weld exceeded 90% for this alloy both based on own research and literature.

- The process of low-cycle fatigue of 5083 H111 aluminum alloy was characterized by cyclic hardening. It was revealed by a decrease in the width of hysteresis loops during the fatigue test, with the simultaneous sharp increase in the values of the range of stress for both: base material and FSW joint.

- Failures in FSW joined specimens occurred in the heat-affected zone for both tensile and LCF testing.

- The scanning electron microscopy observations of the fatigue crack propagation region revealed the presence of fatigue striations, together with some secondary cracks for all strain amplitudes and both types of samples.

Author Contributions

Funding

Conflicts of Interest

References

- Canepa, E.; Stifanese, R.; Merotto, L.; Traverso, P. Corrosion behaviour of aluminium alloys in deep-sea environment: A review and the KM3NeT test results. Mar. Struct. 2018, 59, 271–284. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Guglielmino, E.; Mariano Sili, A. Full-field analysis of AL/FE explosive welded joints for shipbuilding applications. Mar. Struct. 2018, 57, 207–218. [Google Scholar] [CrossRef]

- Cerik, B.C. Large inelastic deformation of aluminium alloy plates in high-speed vessels subjected to slamming. J. Mar. Sci. Technol. 2017, 22, 301–312. [Google Scholar] [CrossRef]

- Paik, J.K. Recent Advances and Future Trends on Plasticity and Impact Mechanics of Ships and Offshore Structures. Procedia Eng. 2017, 173, 17–24. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Amini, A.; Asadi, P.; Zolghadr, P. Friction Stir Welding Applications in Industry; Woodhead Publishing Limited: Cambridge, UK, 2014; ISBN 9780857094551. [Google Scholar]

- Shrivastava, A.; Krones, M.; Pfefferkorn, F.E. Comparison of energy consumption and environmental impact of friction stir welding and gas metal arc welding for aluminum. CIRP J. Manuf. Sci. Technol. 2015, 9, 159–168. [Google Scholar] [CrossRef]

- Maggiolino, S.; Schmid, C. Corrosion resistance in FSW and in MIG welding techniques of AA6XXX. J. Mater. Process. Technol. 2008, 197, 237–240. [Google Scholar] [CrossRef]

- Ericsson, M.; Sandström, R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG. Int. J. Fatigue 2003, 25, 1379–1387. [Google Scholar] [CrossRef]

- Cai, C.; Wang, X.; Liang, Z.; Rao, Y.; Wang, H.; Yan, D. Effects of water-cooling on the mechanical properties and microstructure of 5083 aluminum alloy during flame straightening. Metals 2018, 8, 692. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; Sik, A. Mechanical, fatigue and microstructural properties of friction stir welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 56, 84–90. [Google Scholar] [CrossRef]

- Tronci, A.; Mckenzie, R.; Leal, R.M.; Rodrigues, D.M. Microstructural and mechanical characterization of 5XXX-H111 friction stir welded tailored blanks. Sci. Technol. Weld. Join. 2011, 16, 433–439. [Google Scholar] [CrossRef]

- Zhou, N.; Song, D.; Qi, W.; Li, X.; Zou, J.; Attallah, M.M. Influence of the kissing bond on the mechanical properties and fracture behaviour of AA5083-H112 friction stir welds. Mater. Sci. Eng. A 2018, 719, 12–20. [Google Scholar] [CrossRef]

- Doan, V.T.; Liu, B.; Garbatov, Y.; Wu, W.; Guedes Soares, C. Strength assessment of aluminium and steel stiffened panels with openings on longitudinal girders. Ocean Eng. 2020, 200, 107047. [Google Scholar] [CrossRef]

- Kosturek, R.; Śniezek, L.; Wachowski, M.; Torzewski, J. The influence of post-weld heat treatment on the microstructure and fatigue properties of Sc-modified AA2519 friction stir-welded joint. Materials 2019, 12, 583. [Google Scholar] [CrossRef]

- Sun, G.; Guo, Y.; Han, X.; Shang, D.; Chen, S. Fatigue modeling containing hardening particles and grain orientation for aluminum alloy FSW joints. Materials 2019, 12, 2024. [Google Scholar] [CrossRef] [PubMed]

- Lombard, H.; Hattingh, D.G.; Steuwer, A.; James, M.N. Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminium alloy. Eng. Fract. Mech. 2008, 75, 341–354. [Google Scholar] [CrossRef]

- Ranjan, R.; de Oliveira Miranda, A.C.; Hui Guo, S.; Walbridge, S.; Gerlich, A. Fatigue analysis of friction stir welded butt joints under bending and tension load. Eng. Fract. Mech. 2019, 206, 34–45. [Google Scholar] [CrossRef]

- D’Urso, G.; Giardini, C.; Lorenzi, S.; Pastore, T. Fatigue crack growth in the welding nugget of FSW joints of a 6060 aluminum alloy. J. Mater. Process. Technol. 2014, 214, 2075–2084. [Google Scholar] [CrossRef]

- Ilman, M.N.; Kusmono; Iswanto, P.T. T. Fatigue crack growth rate behaviour of friction-stir aluminium alloy AA2024-T3 welds under transient thermal tensioning. Mater. Des. 2013, 50, 235–243. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, H.; Li, S.; Zhao, H.; Chen, J.; Qi, L. Microstructure, mechanical properties and fatigue crack growth behavior of friction stir welded joint of 6061-T6 aluminum alloy. Int. J. Fatigue 2020, 135, 105556. [Google Scholar] [CrossRef]

- Salih, O.S.; Neate, N.; Ou, H.; Sun, W. Influence of process parameters on the microstructural evolution and mechanical characterisations of friction stir welded Al-Mg-Si alloy. J. Mater. Process. Technol. 2020, 275, 116366. [Google Scholar] [CrossRef]

- Rodriguez, R.I.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. Low-cycle fatigue of dissimilar friction stir welded aluminum alloys. Mater. Sci. Eng. A 2016, 654, 236–248. [Google Scholar] [CrossRef]

- Kosturek, R.; Śnieżek, L.; Torzewski, J.; Wachowski, M. Low cycle fatigue properties of Sc-modified AA2519-T62 extrusion. Materials 2020, 13, 220. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ding, H.; Cai, Z.; Zhao, J.; Li, J. Microstructural and mechanical characterization of a dissimilar friction stir-welded AA5083-AA7B04 butt joint. J. Mater. Eng. Perform. 2017, 26, 530–539. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Xie, J.; Sun, S.; Wang, L.; Qian, Y.; Meng, Y.; Wei, Y. Microstructure and mechanical properties of aluminum 5083 weldments by gas tungsten arc and gas metal arc welding. Mater. Sci. Eng. A 2012, 549, 7–13. [Google Scholar] [CrossRef]

- Prabha, K.A.; Putha, P.K.; Prasad, B.S. Effect of tool rotational speed on mechanical properties of aluminium alloy 5083 weldments in friction stir welding. Mater. Today Proc. 2018, 5, 18535–18543. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Krishna, K.S.V.B.R.; Sekhar, K.C.; Sivaprasad, K.; Venkateswarlu, K.; Narayanasamy, R. A study on the work hardening and the effect of triaxiality on the fracture behaviour of some cryorolled aluminium alloys. Mater. Sci. Eng. A 2016, 678, 165–177. [Google Scholar] [CrossRef]

- Svensson, L.E.; Karlsson, L.; Larsson, H.; Karlsson, B.; Fazzini, M.; Karlsson, J. Microstructure and mechanical properties of friction stir welded aluminium alloys with special reference to AA 5083 and AA 6082. Sci. Technol. Weld. Join. 2000, 5, 285–296. [Google Scholar] [CrossRef]

- Shyam, A.; Lara-Curzio, E. A model for the formation of fatigue striations and its relationship with small fatigue crack growth in an aluminum alloy. Int. J. Fatigue 2010, 32, 1843–1852. [Google Scholar] [CrossRef]

- Alatorre, N.; Ambriz, R.R.; Amrouche, A.; García, C.; Jaramillo, D. Fatigue crack growth in Al-Zn-Mg (7075-T651) welds obtained by modified indirect and gas metal arc welding techniques. J. Mater. Process. Technol. 2017, 248, 207–217. [Google Scholar] [CrossRef]

| Al | Mg | Mn | Si | Fe | Cr | Zn | Ti | Cu | Other |

|---|---|---|---|---|---|---|---|---|---|

| Bal. | 4.0–4.9 | 0.4–1.0 | max 0.4 | max 0.4 | 0.05–0.25 | max 0.25 | max 0.15 | max 0.1 | max 0.15 |

| AA5083-H111 | Rm (MPa) | Rp02 (MPa) | A (%) | HV0.1 |

|---|---|---|---|---|

| Standard | min. 275 | min. 125 | 16 | 82 |

| Research | 310 | 165 | 20 | 83 |

| Tool Rotation Speed (rpm) | |||

|---|---|---|---|

| 500 | 900 | ||

| Tool traverse speed (mm/min) | 100 | A5_5-1 | A5_9-1 |

| 200 | A5_5-2 | A5_9-2 | |

| AA5083-H111 | σ’f (MPa) | b (-) | ε’f (-) | c (-) |

|---|---|---|---|---|

| BM | 532 | −0.0859 | 9.445 | −1.1795 |

| FSW joints | 682 | −0.1312 | 2.096 | −1.1312 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torzewski, J.; Grzelak, K.; Wachowski, M.; Kosturek, R. Microstructure and Low Cycle Fatigue Properties of AA5083 H111 Friction Stir Welded Joint. Materials 2020, 13, 2381. https://doi.org/10.3390/ma13102381

Torzewski J, Grzelak K, Wachowski M, Kosturek R. Microstructure and Low Cycle Fatigue Properties of AA5083 H111 Friction Stir Welded Joint. Materials. 2020; 13(10):2381. https://doi.org/10.3390/ma13102381

Chicago/Turabian StyleTorzewski, Janusz, Krzysztof Grzelak, Marcin Wachowski, and Robert Kosturek. 2020. "Microstructure and Low Cycle Fatigue Properties of AA5083 H111 Friction Stir Welded Joint" Materials 13, no. 10: 2381. https://doi.org/10.3390/ma13102381

APA StyleTorzewski, J., Grzelak, K., Wachowski, M., & Kosturek, R. (2020). Microstructure and Low Cycle Fatigue Properties of AA5083 H111 Friction Stir Welded Joint. Materials, 13(10), 2381. https://doi.org/10.3390/ma13102381