Effect of Different Rheological Models on the Distress Prediction of Composite Pavement

Abstract

1. Introduction

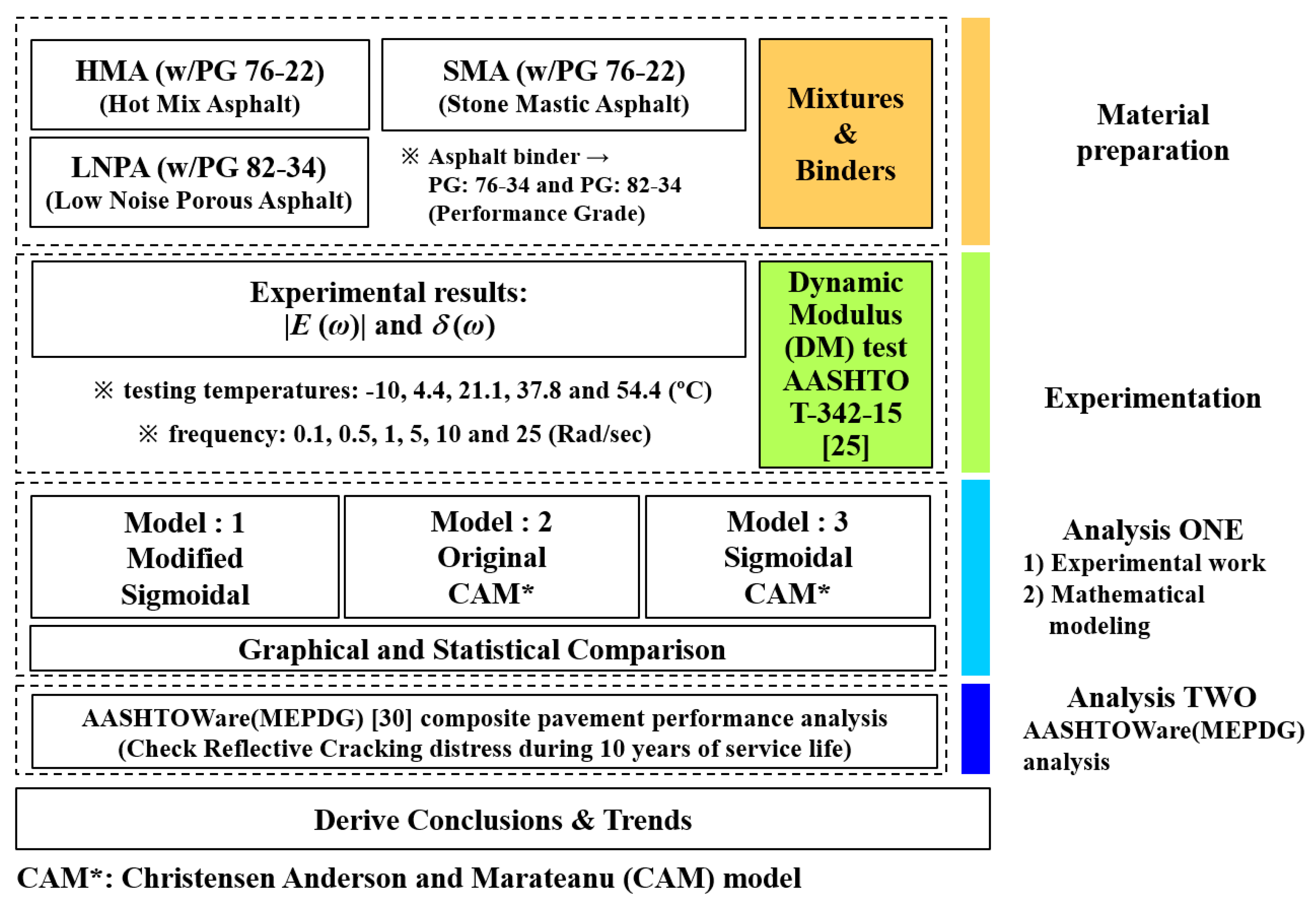

2. Objective and Research Approach

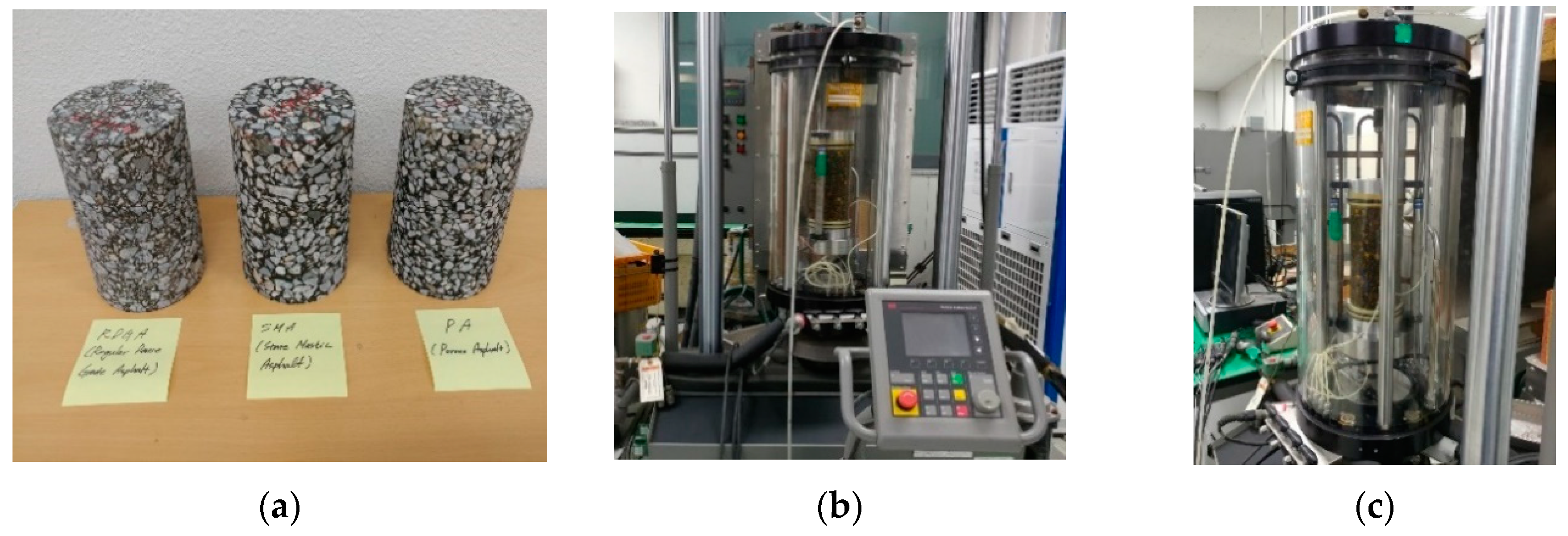

3. Experimentation

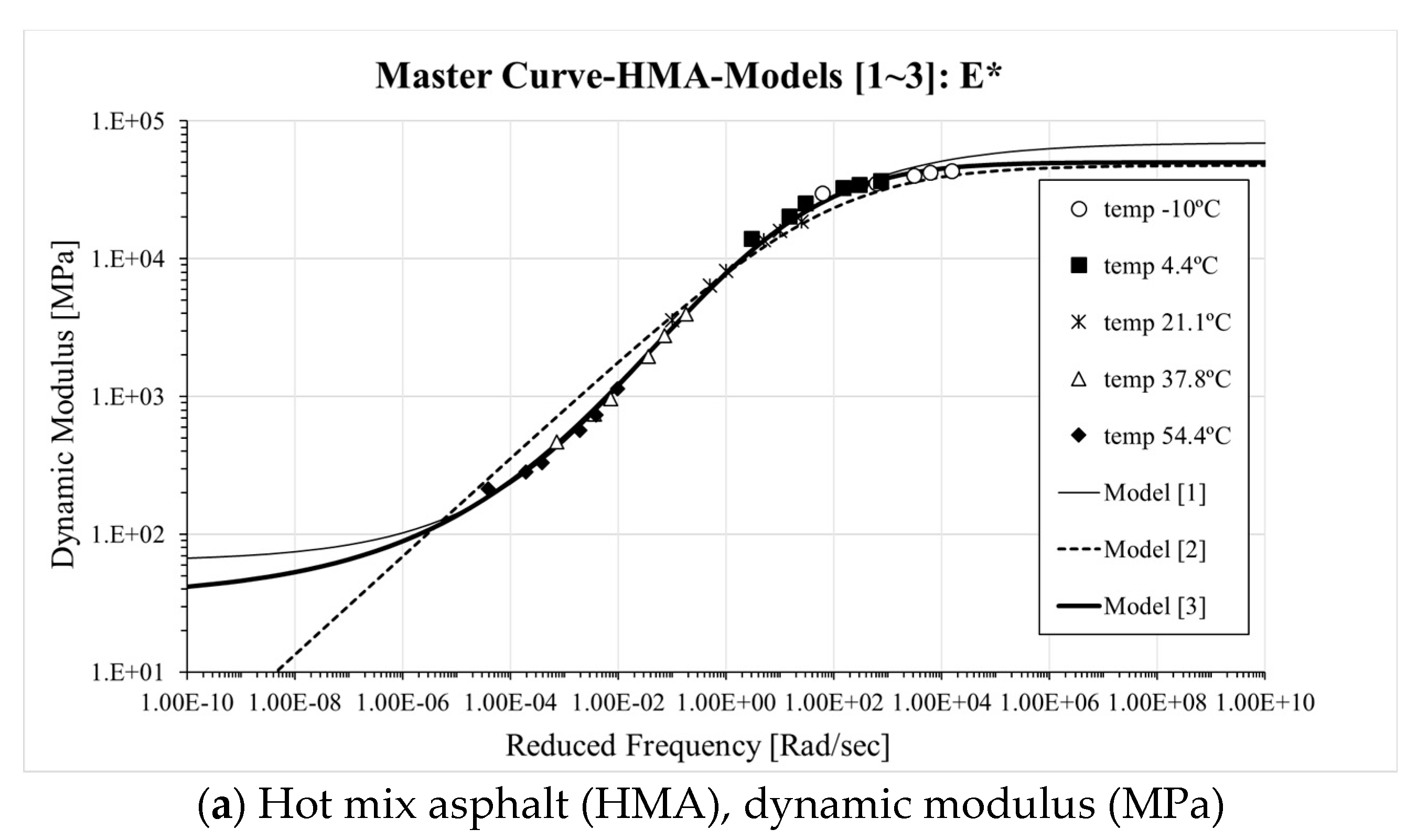

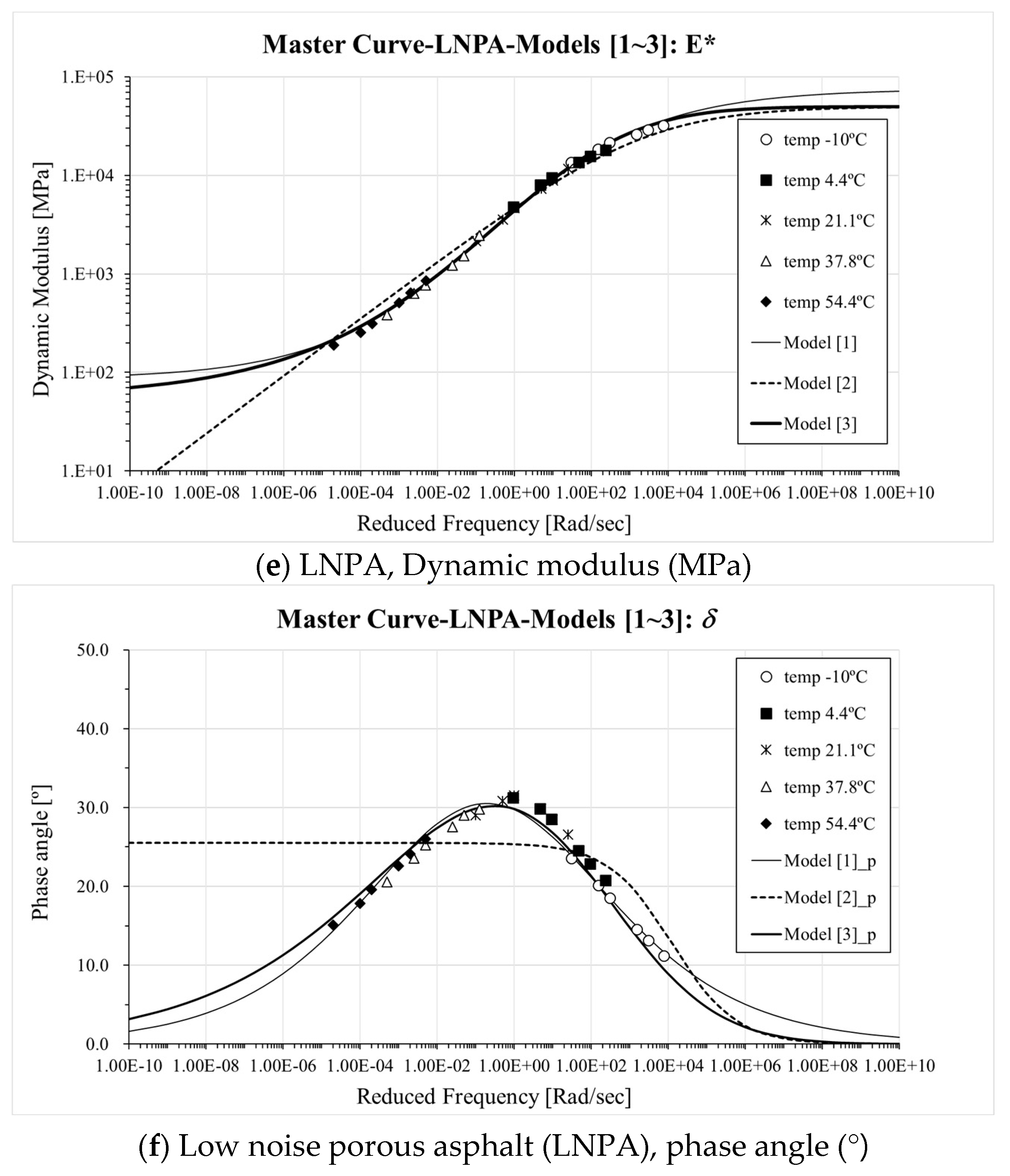

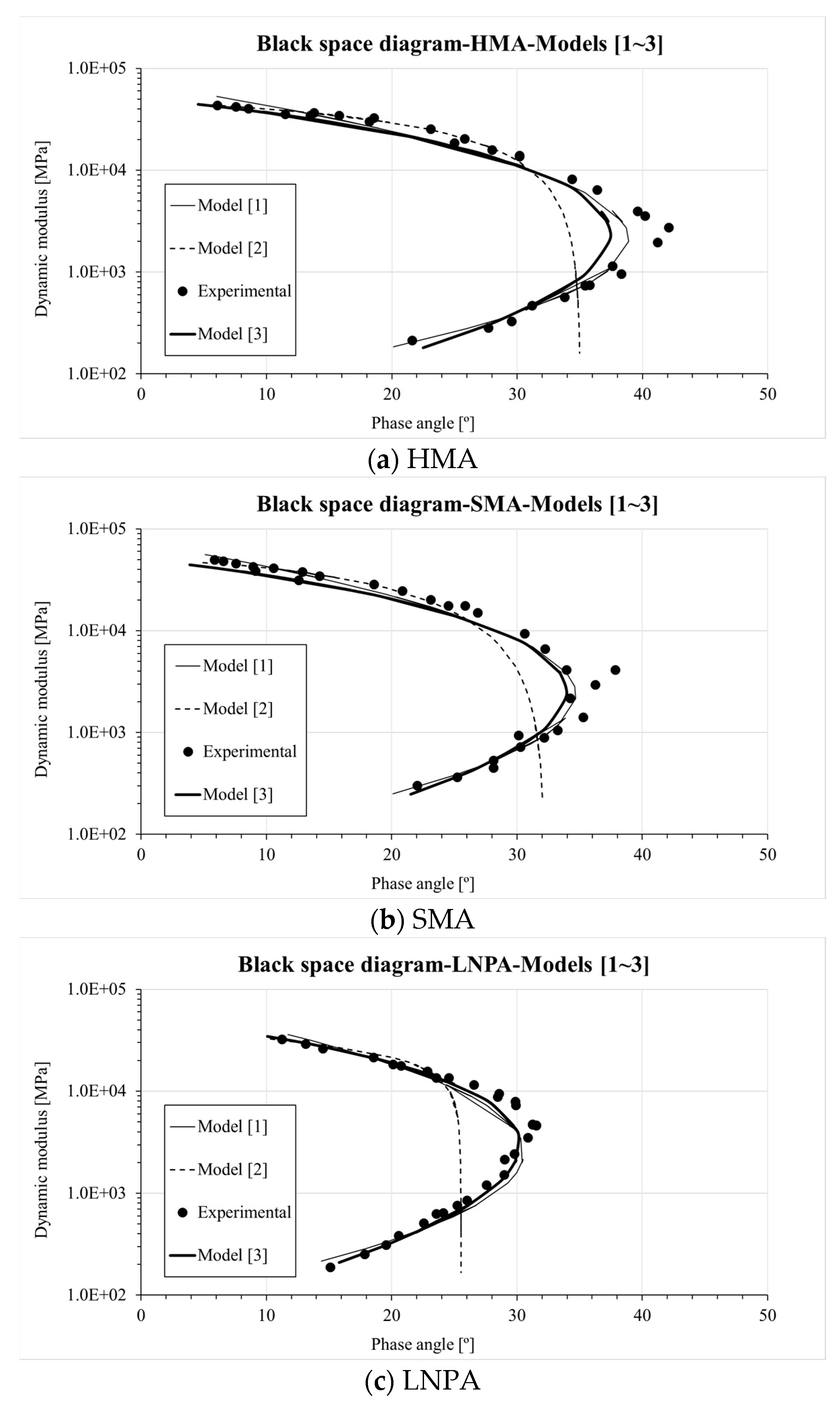

4. Master Curves Models

5. Data Analysis

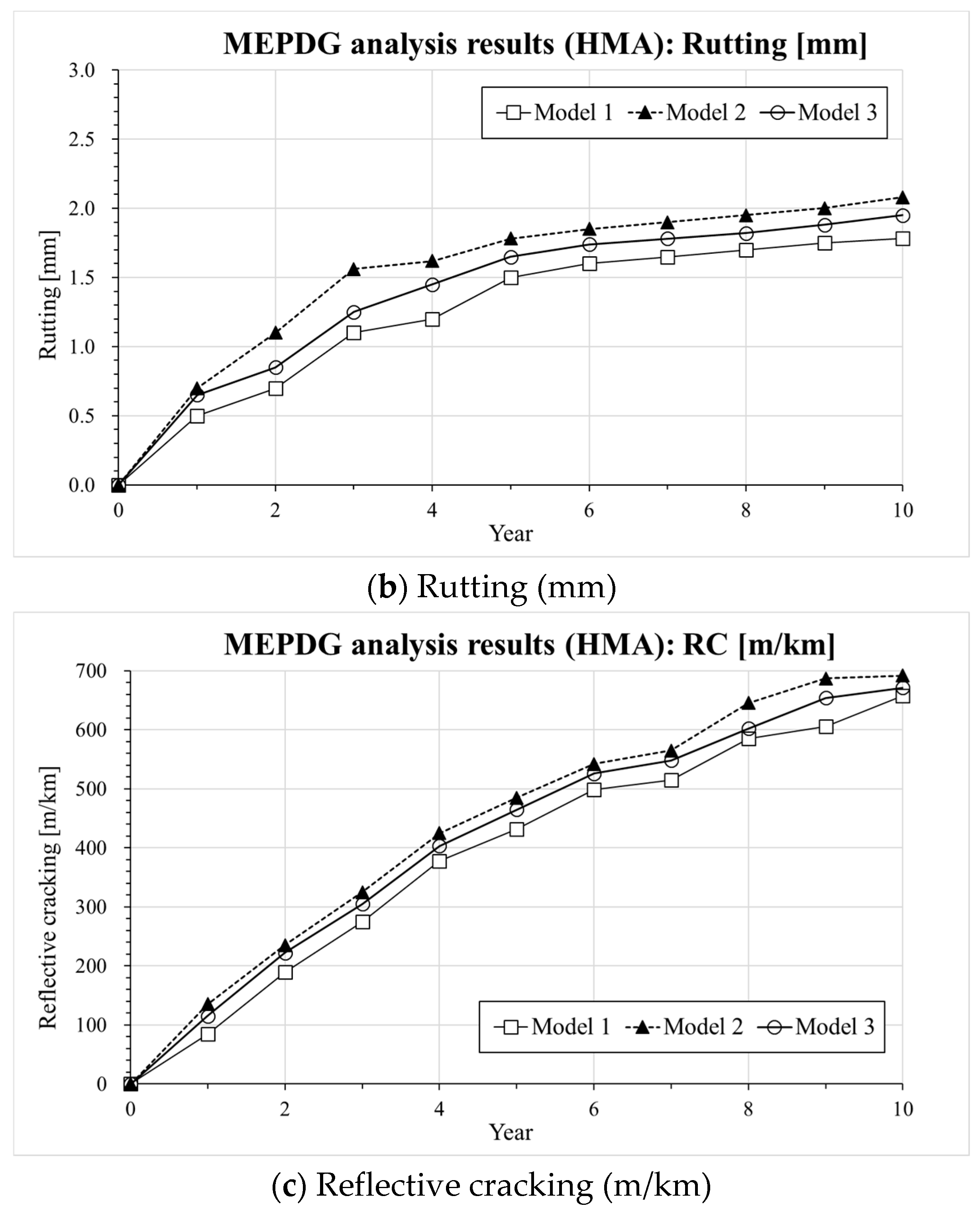

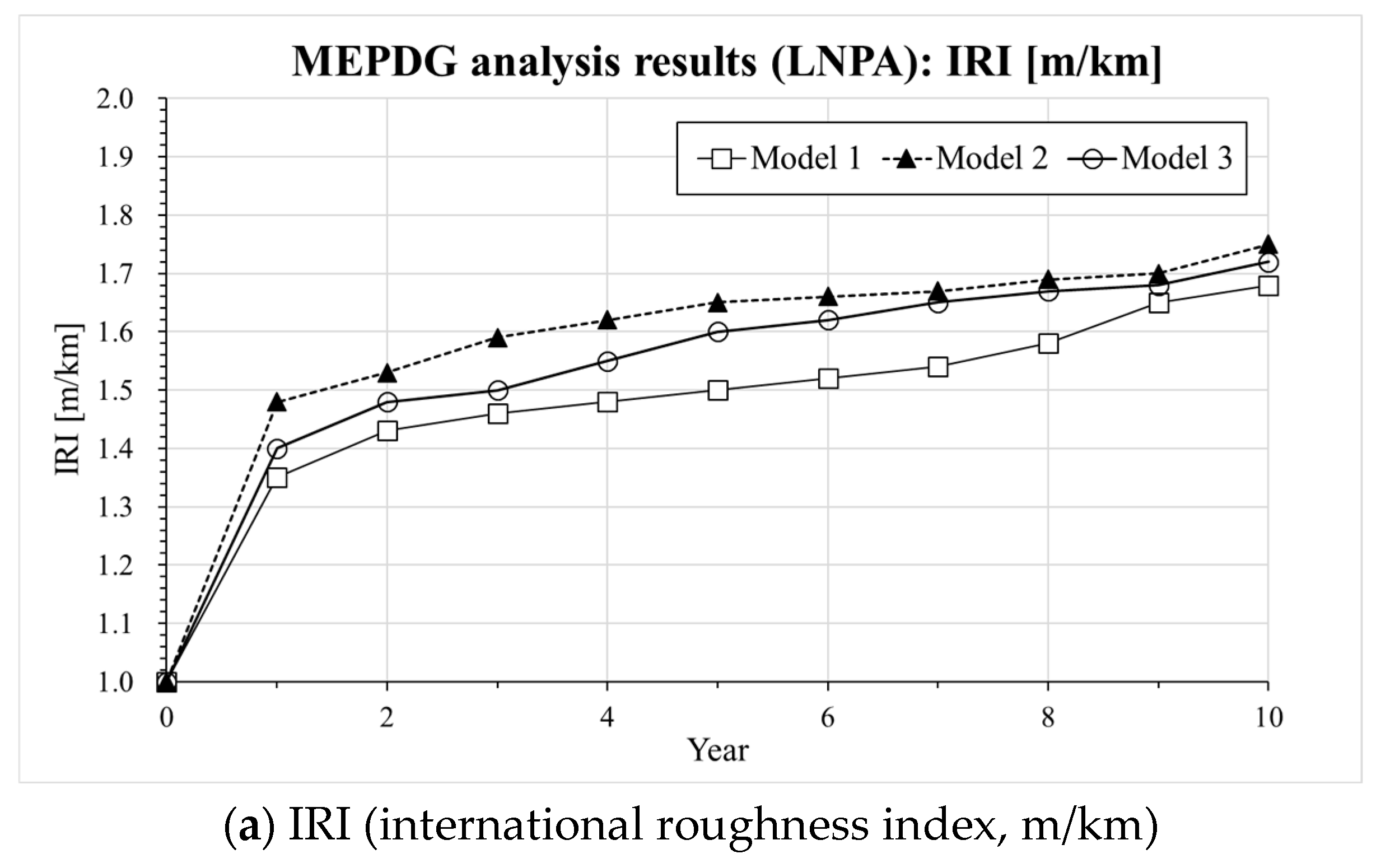

6. Composite Pavement Performance Simulations

- (1)

- Input pavement analysis type (e.g., newly pavement or overlay; asphalt, concrete or composite pavement layer) and expected service life along with pavement performance criteria (e.g., smoothness, cracking resistance, rutting resistance, etc.)

- (2)

- Input traffic, climate, pavement layer bondage effects

- (3)

- Input material properties of asphalt, concrete pavement layer along with cemented base layer (if exists). In this step, dynamic modulus of asphalt pavement layer with three different models is used as crucial input parameter (e.g., MEPDG input parameter Level 1)

- (4)

- Perform analysis and evaluate the computed results

7. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, D.H.; Lee, J.M.; Moon, K.H.; Park, J.S.; Suh, Y.C.; Jeong, J.H. Development of Remodeling Index Model to Predict Priority of Large-Scale Repair Works of Deteriorated Expressway Concrete Pavements in Korea. KSCE J. Civ. Eng. 2019, 23, 2096–2107. [Google Scholar] [CrossRef]

- Lee, J.H.; Baek, S.B.; Lee, K.H.; Kim, J.S.; Jeong, J.H. Long-term performance of fiber-grid-reinforced asphalt overlay pavements: A case study of Korean national highways. J. Traffic Transp. Eng. 2019, 6, 366–382. [Google Scholar] [CrossRef]

- Mun, S.; Kim, Y.R. Determination of subgrade stiffness under intact portland cement concrete slabs for rubblization projects. KSCE J. Civ. Eng. 2004, 8, 527–533. [Google Scholar] [CrossRef]

- Lee, S.W.; Bae, J.M.; Han, S.H.; Stoffels, S.M. Evaluation of optimum rubblized depth to prevent reflection cracks. J. Transp. Eng. 2007, 133, 355–361. [Google Scholar] [CrossRef]

- Lee, K.H.; Ock, C.G.; Lee, G.P. Optimizing SMA (Stone Mastic Asphalt) pavement technology into expressway construction in South Korea. KSCE Proc. 1998, 4, 97–100. (In Korean) [Google Scholar]

- Ock, C.G.; Kim, J.W.; Lee, J.S. Performance evaluation of Stone Mastic Asphalt (SMA) and Low Noise Porous Asphalt (LNPA) in South Korea expressway. J. Korean Soc. Road Eng. 2010, 12, 29–37. (In Korean) [Google Scholar]

- Moghaddam, T.B.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Yalcin, E.; Hudson-Griffiths, R.; García, A. Mechanical and Self-Healing Properties of Stone Mastic Asphalt Containing Encapsulated Rejuvenators. J. Mater. Civ. Eng. 2019, 31, 04019052. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, B.; Cao, D. Comparative Analysis of Performance of Porous Asphalt Pavement and SMA Pavement Based on Deck Pavement Structure. IOP Conf. Ser. Earth Environ. Sci. 2019, 283, 012053. [Google Scholar] [CrossRef]

- Ock, C.G.; Kim, J.W.; Ahn, J.H. Noise reduction evaluation of Low Noise Porous Asphalt (LNPA) developed from Stone Mastic Asphalt (SMA) on expressway in South Korea. In Proceedings of the KSCE Annual Conference Proceedings, Daegu, Korea, 10 May 2007; pp. 1833–1836. (In Korean). [Google Scholar]

- Kim, C.H.; Kang, H.J.; Jang, T.S.; Cheon, B.H. Effectiveness of Low Noise Porous Asphalt (LNPA) for reduction of noise compared to conventional pavement types. In Proceedings of the KSNVE Annual Conference Proceedings, Pyeongchang, Korea, 20–23 February 2019; p. 260. (In Korean). [Google Scholar]

- AASHTO. M320-10. Standard Specification for Performance—Graded Asphalt Binder; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2010. [Google Scholar]

- Baek, J.; Al-Qadi, I.L. Finite element method modeling of reflective cracking initiation and propagation: Investigation of the effect of steel reinforcement interlayer on retarding reflective cracking in hot-mix asphalt overlay. Transp. Res. Rec. 2006, 1949, 32–42. [Google Scholar] [CrossRef]

- Baek, J.; Al-Qadi, I.L. Finite element modeling of reflective cracking under moving vehicular loading: Investigation of the mechanism of reflective cracking in hot-mix asphalt overlays reinforced with interlayer systems. In Airfield and Highway Pavements: Efficient Pavements Supporting Transportation’s Future; ASCE: Reston, VA, USA, 2008; pp. 74–85. [Google Scholar] [CrossRef]

- Maurer, D.A.; Malasheskie, G.J. Field performance of fabrics and fibers to retard reflective cracking. Geotext. Geomembr. 1989, 8, 239–267. [Google Scholar] [CrossRef]

- Sousa, J.B.; Pais, J.C.; Saim, R.; Way, G.B.; Stubstad, R.N. Mechanistic-empirical overlay design method for reflective cracking. Transp. Res. Rec. 2002, 1809, 209–217. [Google Scholar] [CrossRef]

- Zhou, F.; Scullion, T. Overlay Tester: A Simple Performance Test for Thermal Reflective Cracking (With Discussion and Closure). J. Assoc. Asph. Paving Technol. 2005, 74, 443–484. [Google Scholar]

- Bennert, T.; Worden, M.; Turo, M. Field and laboratory forensic analysis of reflective cracking on Massachusetts interstate 495. Transp. Res. Rec. 2009, 2126, 27–38. [Google Scholar] [CrossRef]

- Dave, E.V.; Buttlar, W.G. Thermal reflective cracking of asphalt concrete overlays. Int. J. Pavement Eng. 2010, 11, 477–488. [Google Scholar] [CrossRef]

- Pasquini, E.; Pasetto, M.; Canestrari, F. Geocomposites against reflective cracking in asphalt pavements: Laboratory simulation of a field application. Road Mater. Pavement Des. 2015, 16, 815–835. [Google Scholar] [CrossRef]

- Wang, X.; Zhong, Y. Reflective crack in semi-rigid base asphalt pavement under temperature-traffic coupled dynamics using XFEM. Constr. Build. Mater. 2019, 214, 280–289. [Google Scholar] [CrossRef]

- Walubita, L.F.; Mahmoud, E.; Lee, S.I.; Komba, J.J.; Nyamuhokya, T.P. Grid Reinforcement in HMA Overlays-A Field Case Study of Highway US 59 in Atlanta District of Texas (No. 19-02991). In Proceedings of the Transportation Research Board 98th Annual Meeting, Washington, DC, USA, 13–17 January 2019. [Google Scholar] [CrossRef]

- Noory, A.; Nejad, F.M.; Khodaii, A. Evaluation of geocomposite-reinforced bituminous pavements with Amirkabir University Shear Field Test. Road Mater. Pavement Des. 2019, 20, 259–279. [Google Scholar] [CrossRef]

- AASHTO. T 342-15. Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt Concrete Mixtures; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015. [Google Scholar]

- Rahman, A.S.M.A.; Tarefder, R.A. Dynamic modulus and phase angle of warm-mix versus hot-mix asphalt concrete. Constr. Build. Mater. 2016, 126, 434–441. [Google Scholar] [CrossRef]

- Corrales-Azofeifa, J.P.; Archilla, A.R. Dynamic Modulus Model of Hot Mix Asphalt: Statistical Analysis Using Joint Estimation and Mixed Effects. J. Infrastruct. Syst. 2018, 24, 04018012. [Google Scholar] [CrossRef]

- Nemati, R.; Dave, E.V. Nominal property based predictive models for asphalt mixture complex modulus (dynamic modulus and phase angle). Constr. Build. Mater. 2018, 158, 308–319. [Google Scholar] [CrossRef]

- MOLIT. Guideline for Production and Construction of Asphalt Mixture (Specification, Korean); Ministry of Land Infrastructure and Transportation: Seoul, South Korea, 2017. (In Korean)

- AASHTO. User Manual of AASHTOWare-Pavement (SI Unit Version)(Software Manual); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018. [Google Scholar]

- AASHTO. M323. Standard Specification for Superpave Volumetric Mix Design; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017. [Google Scholar]

- Pellinen, T.K.; Witczak, M.W.; Bonaquist, R.F. Asphalt mix master curve construction using sigmoidal fitting function with non-linear least squares optimization. Recent Adv. Mater. Charact. Model. Pavement Syst. 2004, 83–101. [Google Scholar] [CrossRef]

- Marasteanu, M.O.; Anderson, D.A. Improved model for bitumen rheological characterization. In Eurobitume Workshop on Performance-Related Properties for Bituminous Binders; European Bitumen Association: Brussels, Belgium, 1999; Volume 133. [Google Scholar]

- Booij, H.C.; Thoone, G.P.J.M. Generalization of Kramers-Kronig transforms and some approximations of relations between viscoelastic quantities. Rheol. Acta 1982, 21, 15–24. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; Willey: New York, NY, USA, 1980. [Google Scholar]

- Podolsky, J.H.; Williams, R.C.; Cochran, E. Effect of corn and soybean oil derived additives on polymer-modified HMA and WMA master curve construction and dynamic modulus performance. Int. J. Pavement Res. Technol. 2018, 11, 541–552. [Google Scholar] [CrossRef]

- Yang, X.; You, Z. New predictive equations for dynamic modulus and phase angle using a nonlinear least-squares regression model. J. Mater. Civ. Eng. 2014, 27, 04014131. [Google Scholar] [CrossRef]

- Cook, R.D.; Weisberg, S. Applied Regression Including Computing and Graphics; John Wiley & Sons, Inc.: New York, NY, USA, 2009. [Google Scholar]

| Mix ID | Mixture Description (Mixture Type) | Detailed Mixture Information (Aggregate Passing Sieve %) |

|---|---|---|

| HMA (Mixture 1) | Hot Mix Asphalt (NMAS = 13 mm) (WC-1) | Air Voids = 4.3–4.5%/OAC = 4.4–4.6% VMA = 14.3–14.8%/VFA = 71–73% (Granite: 13 mm: 92%, 5 mm: 56%, 2.5 mm: 39%, 0.6 mm: 25%, 0.3 mm: 15%, 0.08 mm: 6%) |

| SMA (Mixture 2) | Stone Mastic Asphalt (NMAS = 13 mm) (SMA-13) | Air Voids = 2.2–2.5%/OAC = 6.3–6.6% VMA = 17.2–17.9%/VFA = 78.3–79.8% (Granite: 13 mm: 100%, 10 mm: 48%, 2.5 mm: 15%, 0.6 mm: 12%, 0.3 mm: 9%, 0.08 mm: 7%) |

| LNPA (Mixture 3) | Low Noise Porous Asphalt (NMAS = 10 mm) (LNPA-10) | Air Voids = 18–22%/OAC = 6.3–6.8% VMA = 31.2–31.7%/VFA = 38.9–44.2% [Granite: 13 mm: 100%, 10 mm: 90%, 5 mm: 31%, 0.6 mm: 10%, 0.3 mm: 7%, 0.08 mm: 5%] |

| Contents | Dynamic Modulus (DM) Testing Conditions |

|---|---|

| Specimen size | Diameter: 100 mm; Specimen height: 150 mm; Gauge length: 100 mm |

| # of replicates | Three specimens per mixture type (total of nine specimens) |

| Temperature | −10, 4.4, 21.1, 37.8 and 54.4 °C (21.1 °C was set as reference temperature: TS) |

| Frequency | 0.1, 0.5, 1, 5, 10 and 25 rad/s |

| Others | Three LVDT sensors are used (LVDT: Linear Variable Displacement Transducer) |

| Mixture Type | Angular Frequency (rad/s) | p-Value (Significance Level: α = 0.05) [N]: Non-Significant, [S]: Significant | ||

|---|---|---|---|---|

| Model 1 Vs. Model 2 | Model 1 Vs. Model 3 | Model 2 Vs. Model 3 | ||

| HMA (Mix 1) | 10−10 | 0.0000 [Sig] | 0.0000 [Sig] | 0.0000 [Sig] |

| 10−8 | 0.0001 [Sig] | 0.0003 [Sig] | 0.0001 [Sig] | |

| 10−6 | 0.0015 [Sig] | 0.0011 [Sig] | 0.0502 [Non] | |

| 10−4 | 0.0089 [Sig] | 0.0912 [Non] | 0.0075 [Sig] | |

| 10−2 | 0.0092 [Sig] | 0.1231 [Non] | 0.0065 [Sig] | |

| 10 | 0.0412 [Sig] | 0.1156 [Non] | 0.0252 [Sig] | |

| 102 | 0.0504 [Non] | 0.0654 [Non] | 0.0375 [Sig] | |

| 104 | 0.0075 [Sig] | 0.0098 [Sig] | 0.0482 [Sig] | |

| 106 | 0.0023 [Sig] | 0.0082 [Sig] | 0.0512 [Non] | |

| 108 | 0.0005 [Sig] | 0.0023 [Sig] | 0.0985 [Non] | |

| 1010 | 0.0001 [Sig] | 0.0005 [Sig] | 0.1123 [Non] | |

| SMA (Mix 2) | 10−10 | 0.0000 [Sig] | 0.0002 [Sig] | 0.0000 [Sig] |

| 10−8 | 0.0001 [Sig] | 0.0004 [Sig] | 0.0000 [Sig] | |

| 10−6 | 0.0004 [Sig] | 0.0013 [Sig] | 0.0002 [Sig] | |

| 10−4 | 0.0072 [Sig] | 0.1212 [Non] | 0.0058 [Sig] | |

| 10−2 | 0.0101 [Sig] | 0.1542 [Non] | 0.0061 [Sig] | |

| 10 | 0.0455 [Sig] | 0.2565 [Non] | 0.0142 [Sig] | |

| 102 | 0.0515 [Non] | 0.0512 [Non] | 0.0485 [Sig] | |

| 104 | 0.0154 [Sig] | 0.0075 [Sig] | 0.0512 [Non] | |

| 106 | 0.0012 [Sig] | 0.0062 [Sig] | 0.0684 [Non] | |

| 108 | 0.0006 [Sig] | 0.0025 [Sig] | 0.0845 [Non] | |

| 1010 | 0.0001 [Sig] | 0.0004 [Sig] | 0.1245 [Non] | |

| LNPA (Mix 3) | 10−10 | 0.0000 [Sig] | 0.0003 [Sig] | 0.0001 [Sig] |

| 10−8 | 0.0001 [Sig] | 0.0011 [Sig] | 0.0001 [Sig] | |

| 10−6 | 0.0002 [Sig] | 0.0085 [Sig] | 0.0007 [Sig] | |

| 10−4 | 0.0041 [Sig] | 0.1845 [Non] | 0.0021 [Sig] | |

| 10−2 | 0.0085 [Sig] | 0.2545 [Non] | 0.0031 [Sig] | |

| 10 | 0.0174 [Sig] | 0.3241 [Non] | 0.0285 [Sig] | |

| 102 | 0.0211 [Sig] | 0.0845 [Non] | 0.0185 [Sig] | |

| 104 | 0.0111 [Sig] | 0.0745 [Non] | 0.0345 [Sig] | |

| 106 | 0.0011 [Sig] | 0.0041 [Sig] | 0.0511 [Non] | |

| 108 | 0.0003 [Sig] | 0.0011 [Sig] | 0.1422 [Non] | |

| 1010 | 0.0001 [Sig] | 0.0002 [Sig] | 0.1674 [Non] | |

| Mixture Type | Angular Frequency (rad/s) | p-Value (Significance Level: α = 0.05) [N]: Non-Significant, [S]: Significant | ||

|---|---|---|---|---|

| Model 1 Vs. Model 2 | Model 1 Vs. Model 3 | Model 2 Vs. Model 3 | ||

| HMA (Mix 1) | 10−10 | 0.0004 [Sig] | 0.0006 [Sig] | 0.0001 [Sig] |

| 10−8 | 0.0008 [Sig] | 0.0011 [Sig] | 0.0001 [Sig] | |

| 10−6 | 0.0001 [Sig] | 0.0001 [Sig] | 0.0003 [Sig] | |

| 10−4 | 0.0021 [Sig] | 0.0232 [Sig] | 0.0009 [Sig] | |

| 10−2 | 0.0121 [Sig] | 0.0092 [Sig] | 0.0012 [Sig] | |

| 10 | 0.0545 [Non] | 0.0022 [Sig] | 0.0023 [Sig] | |

| 102 | 0.0135 [Sig] | 0.0435 [Sig] | 0.0135 [Sig] | |

| 104 | 0.0025 [Sig] | 0.0055 [Sig] | 0.0025 [Sig] | |

| 106 | 0.0825 [Non] | 0.0125 [Sig] | 0.0012 [Sig] | |

| 108 | 0.0644 [Non] | 0.0214 [Sig] | 0.0512 [Non] | |

| 1010 | 0.1221 [Non] | 0.1221 [Non] | 0.0616 [Non] | |

| SMA (Mix 2) | 10−10 | 0.0001 [Sig] | 0.0006 [Sig] | 0.0001 [Sig] |

| 10−8 | 0.0001 [Sig] | 0.0007 [Sig] | 0.0001 [Sig] | |

| 10−6 | 0.0001 [Sig] | 0.0011 [Sig] | 0.0001 [Sig] | |

| 10−4 | 0.0001 [Sig] | 0.0085 [Sig] | 0.0011 [Sig] | |

| 10−2 | 0.0085 [Sig] | 0.0512 [Non] | 0.0021 [Sig] | |

| 10 | 0.0548 [Non] | 0.0611 [Non] | 0.0008 [Sig] | |

| 102 | 0.0085 [Sig] | 0.0411 [Sig] | 0.0081 [Sig] | |

| 104 | 0.0002 [Sig] | 0.0041 [Sig] | 0.0015 [Sig] | |

| 106 | 0.0745 [Non] | 0.0032 [Sig] | 0.0011 [Sig] | |

| 108 | 0.0822 [Non] | 0.0481 [Sig] | 0.0544 [Non] | |

| 1010 | 0.1541 [Non] | 0.1154 [Non] | 0.0584 [Non] | |

| LNPA (Mix 3) | 10−10 | 0.0001 [Sig] | 0.0005 [Sig] | 0.0001 [Sig] |

| 10−8 | 0.0001 [Sig] | 0.0008 [Sig] | 0.0001 [Sig] | |

| 10−6 | 0.0001 [Sig] | 0.0010 [Sig] | 0.0001 [Sig] | |

| 10−4 | 0.0001 [Sig] | 0.0052 [Sig] | 0.0008 [Sig] | |

| 10−2 | 0.0002 [Sig] | 0.0541 [Non] | 0.0010 [Sig] | |

| 10 | 0.0005 [Sig] | 0.0712 [Non] | 0.0015 [Sig] | |

| 102 | 0.0085 [Sig] | 0.0845 [Non] | 0.0041 [Sig] | |

| 104 | 0.0002 [Sig] | 0.0021 [Sig] | 0.0011 [Sig] | |

| 106 | 0.0633 [Non] | 0.0011 [Sig] | 0.0544 [Non] | |

| 108 | 0.0912 [Non] | 0.0312 [Sig] | 0.0845 [Non] | |

| 1010 | 0.1412 [Non] | 0.0412 [Sig] | 0.0984 [Non] | |

| Contents | Descriptions | Pavement Structure |

|---|---|---|

| Considered Expressway | Ho-Nam expressway (South Korea) AADT: 31,043 (More than class 3: 6,852) -Two lanes in design direction Traffic growth rate: 1.15–7.03% -Compound increase equation was applied Climate: Jeon-Nam location (relatively hot and humid during summer and cold during winter) |  Composite pavement |

| Asphalt pavement (t = 10 cm) | Asphalt binder: PG 76-22/PG 82-34, Level 1 Creep compliance: Level 3(Aggregate gradation) Dynamic modulus: Level 1 (used estimated values with Models 1–3) -Other properties were input based on Table 1 | |

| Concrete Pavement (t = 30 cm) | Compressive strength = 34 MPa (Level 2) -ν = 0.21, ρ = 2480 kgf/m3, W/C = 0.42 -LTE = 55%, Dowel = D (32 mm)/350 mm (LTE: Load Transfer Efficiency: 0–100%) -Tie bar: Installed, Widened-slab: Installed, 0.5 m -Joints are placed every 6 m Aggregate = Granite, Cement = Type 1(Ordinary Portland Cement) | |

| Lean Concrete (t = 15 cm) | Elastic/resilient modulus = 13,800 MPa -ν = 0.20, ρ = 2390 kgf/m3 | |

| Sub grade (infinite) | AASHTO A-7-6 AASHTO A-1-A | |

| Distress level: limits in South Korea | IRI = 3.0 m/km, AC Bottom-up cracking = 25% AC Rutting/thermal cracking = 13 mm/378 m/km AC Reflective cracking = 684 m/km Pavement performance evaluation for 10 years |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, K.H.; Cannone Falchetto, A.; Park, H.W.; Wang, D. Effect of Different Rheological Models on the Distress Prediction of Composite Pavement. Materials 2020, 13, 229. https://doi.org/10.3390/ma13010229

Moon KH, Cannone Falchetto A, Park HW, Wang D. Effect of Different Rheological Models on the Distress Prediction of Composite Pavement. Materials. 2020; 13(1):229. https://doi.org/10.3390/ma13010229

Chicago/Turabian StyleMoon, Ki Hoon, Augusto Cannone Falchetto, Hae Won Park, and Di Wang. 2020. "Effect of Different Rheological Models on the Distress Prediction of Composite Pavement" Materials 13, no. 1: 229. https://doi.org/10.3390/ma13010229

APA StyleMoon, K. H., Cannone Falchetto, A., Park, H. W., & Wang, D. (2020). Effect of Different Rheological Models on the Distress Prediction of Composite Pavement. Materials, 13(1), 229. https://doi.org/10.3390/ma13010229