Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

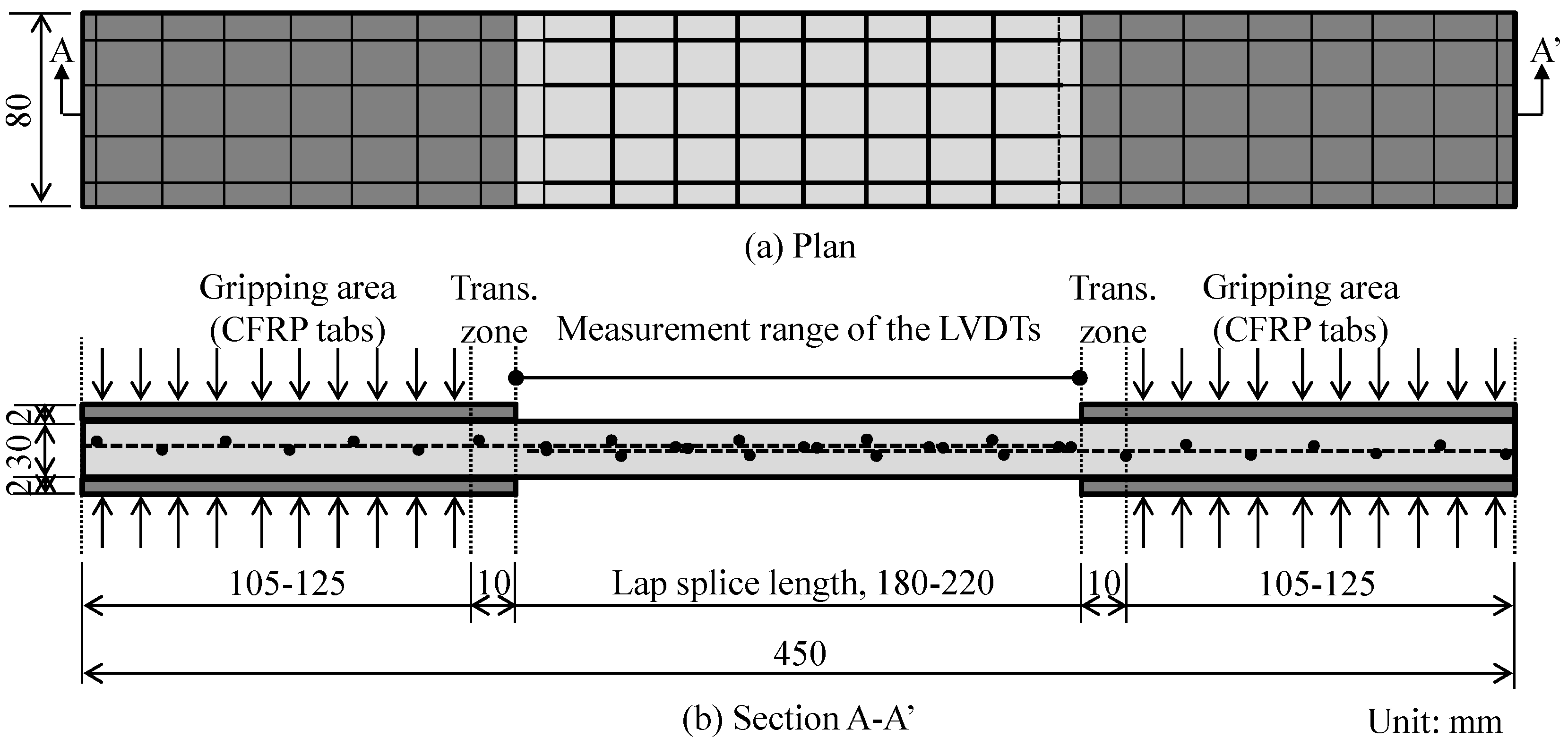

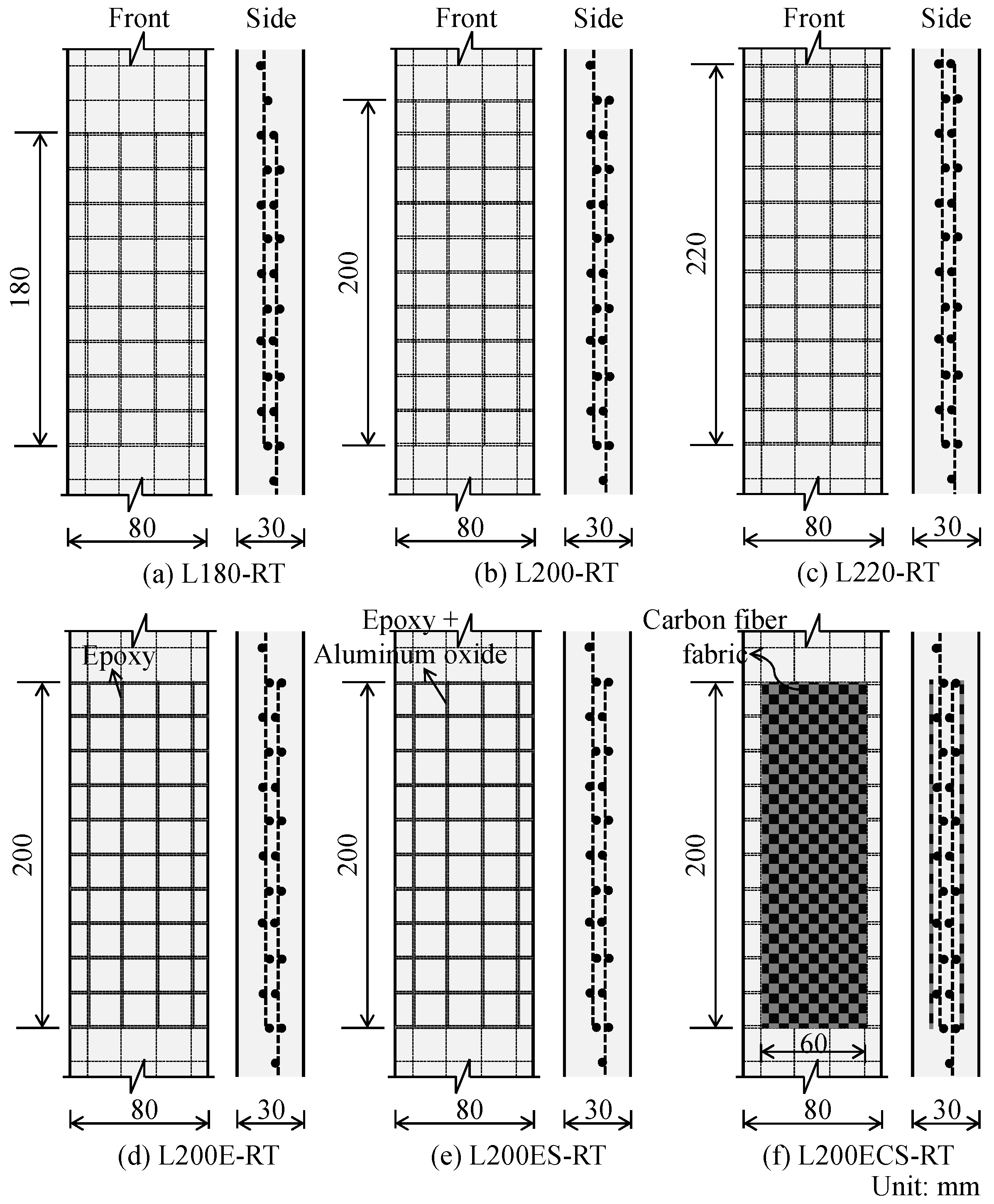

2.2. Test Specimens

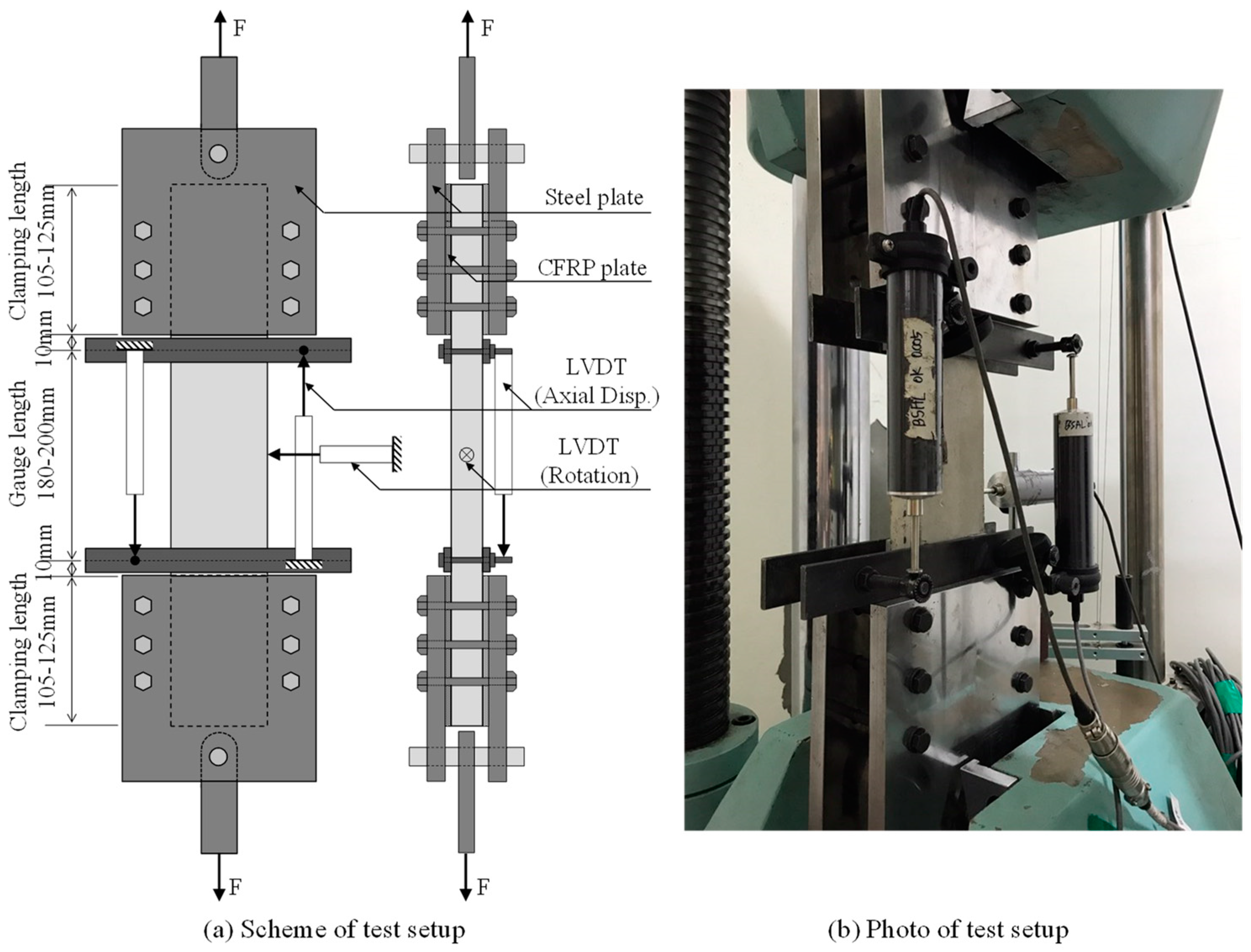

2.3. Test Setup and Measurements

3. Experimental Results and Discussions

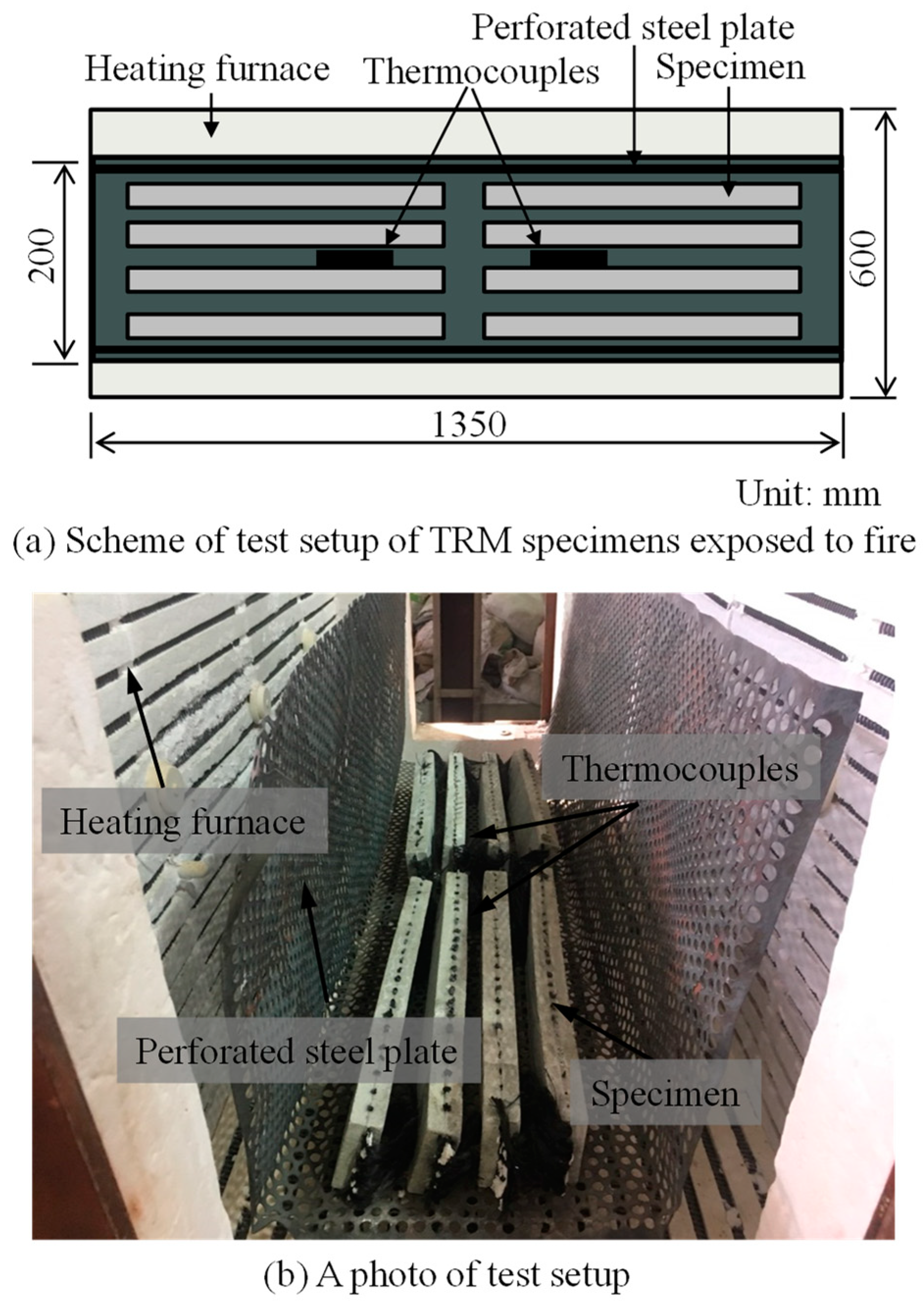

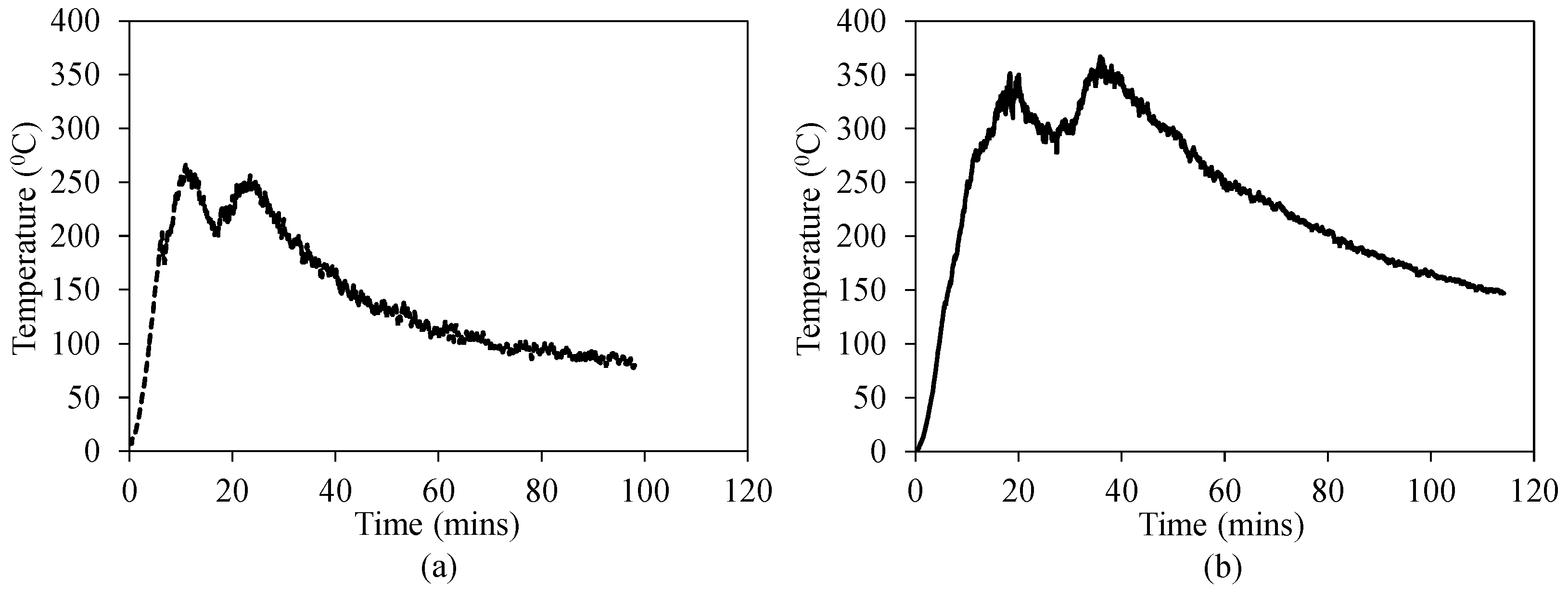

3.1. Temperature–Time Relationships

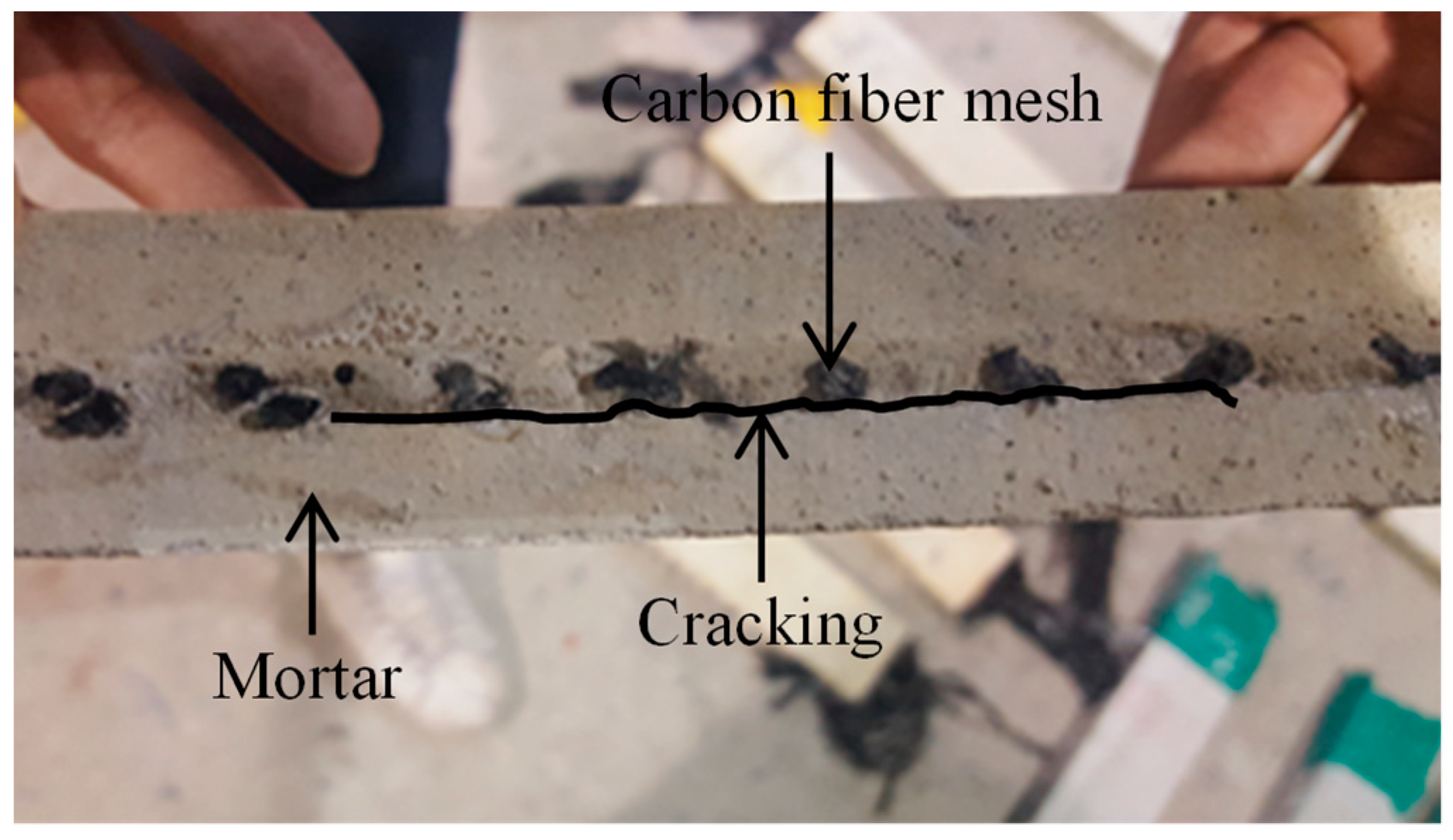

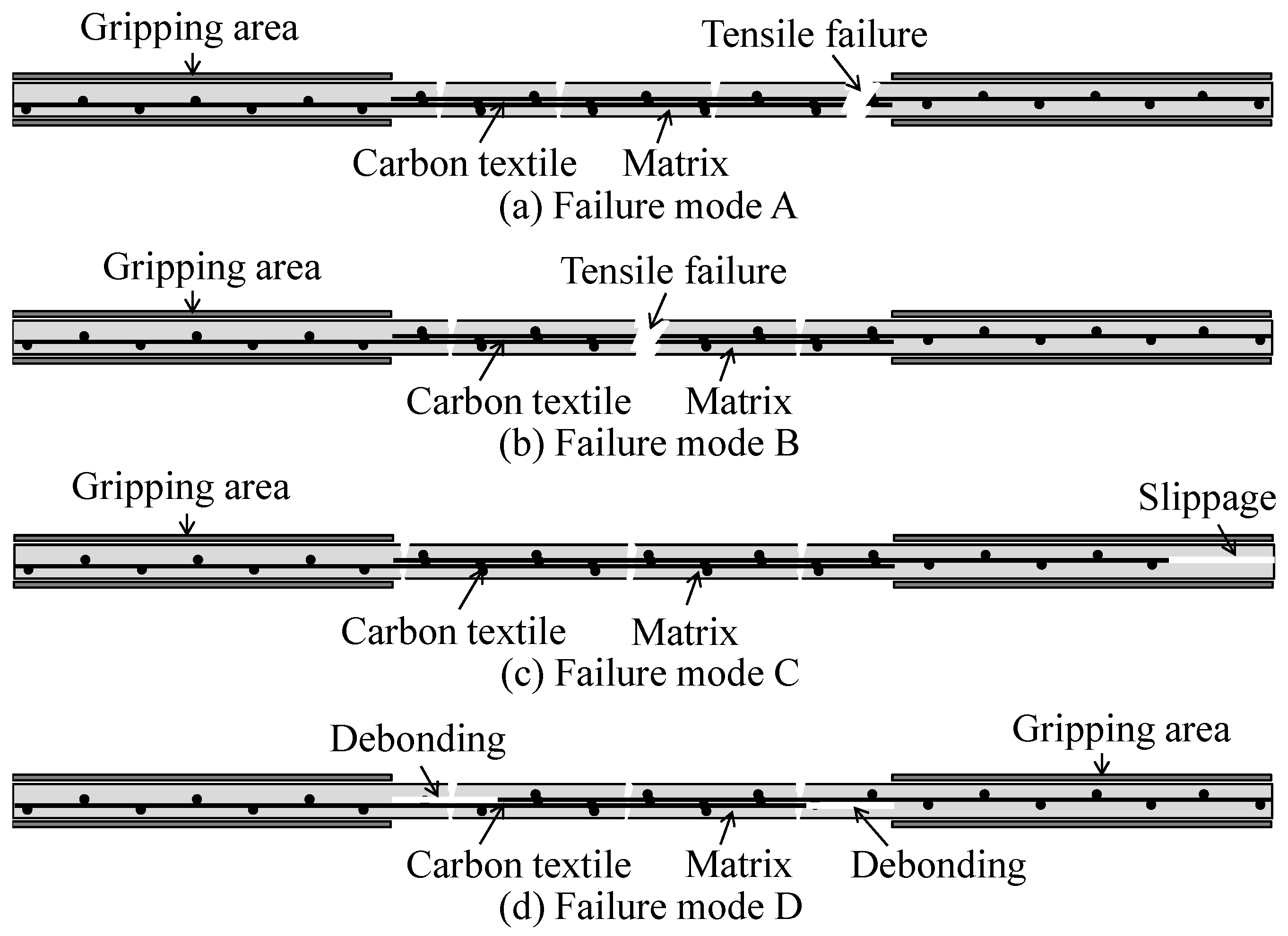

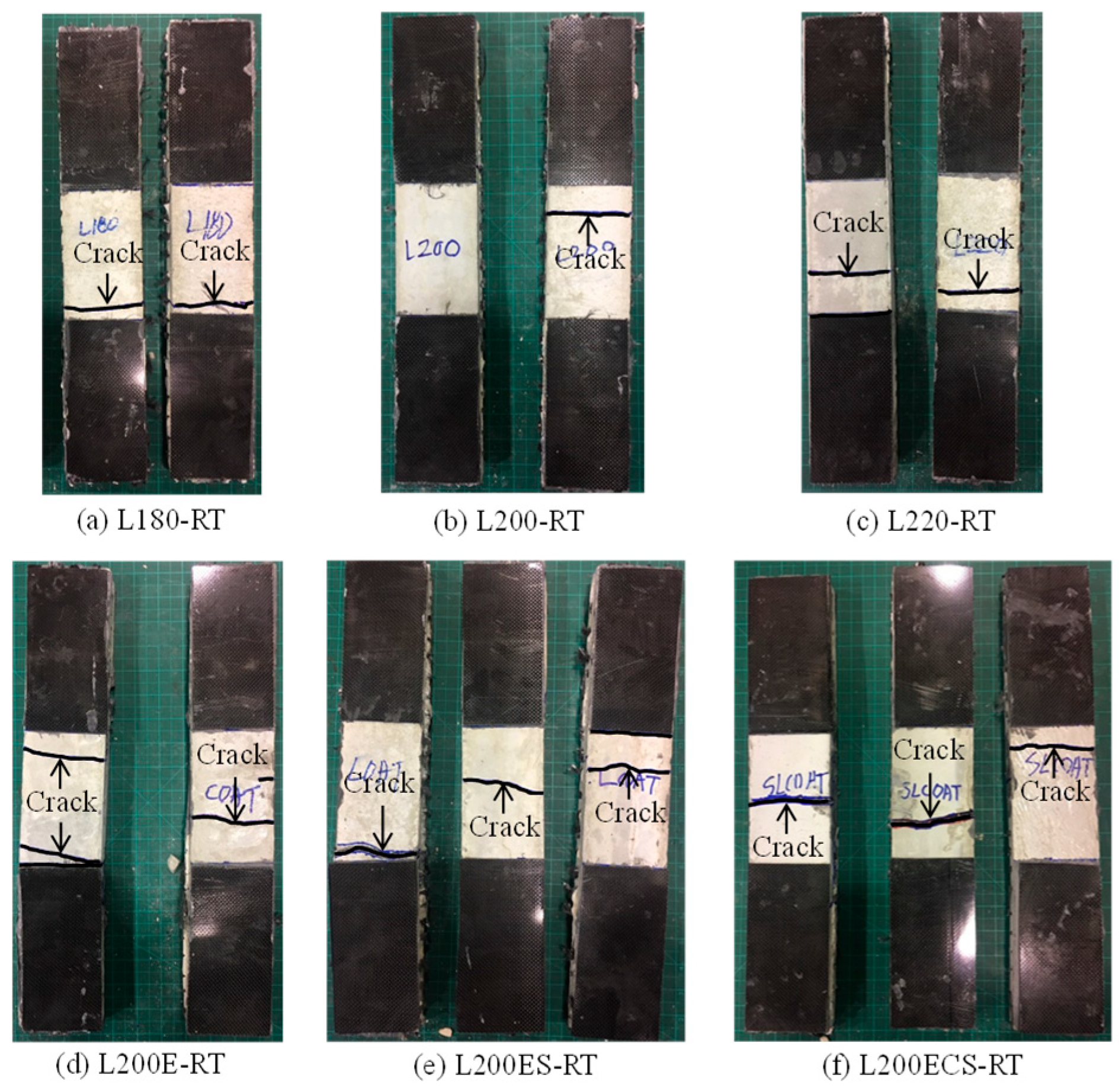

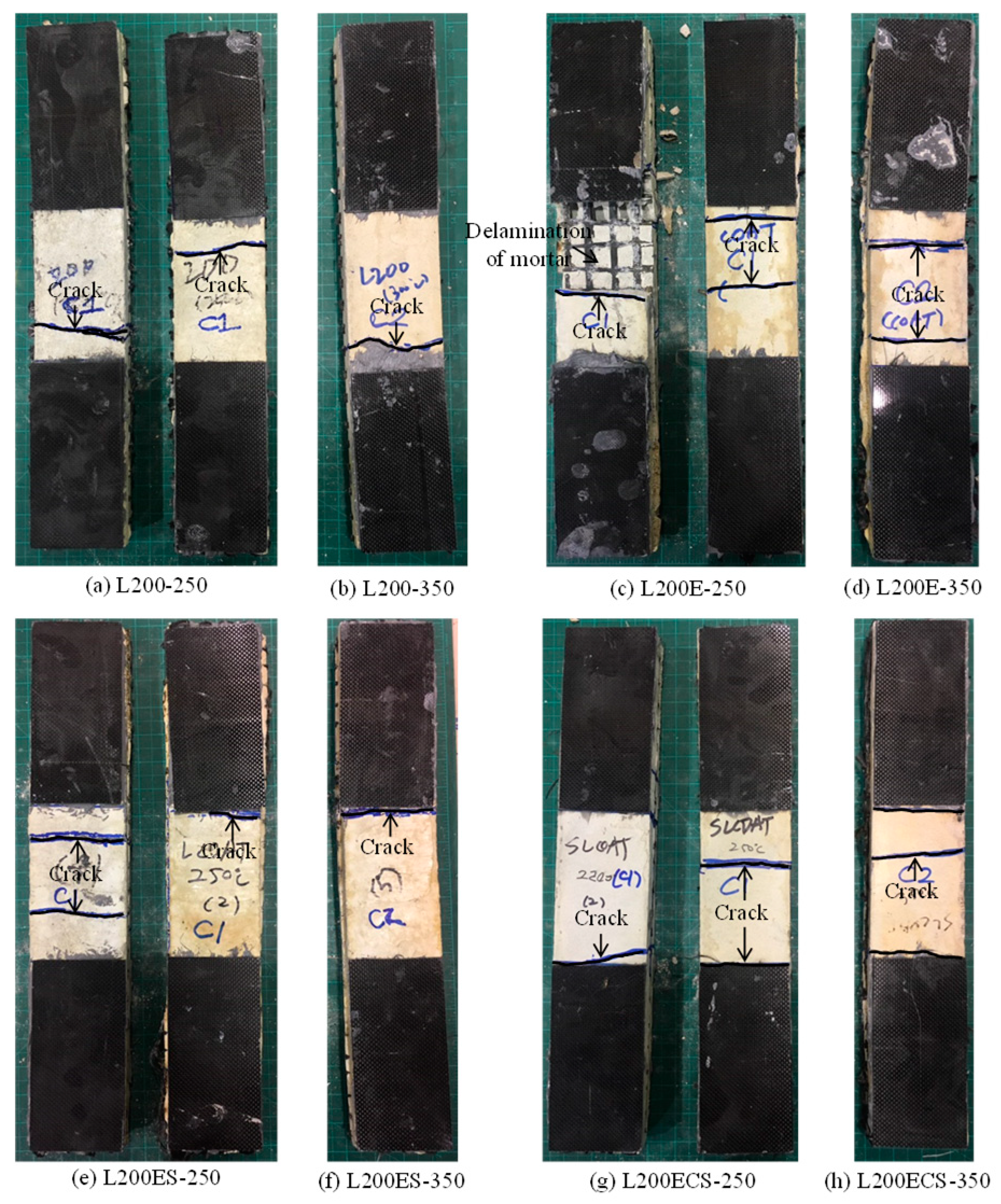

3.2. Crack Pattern and Failure Mode

3.3. Idealized Stress–Strain Curves of Textile-Reinforced Mortar (TRM) Test Specimens

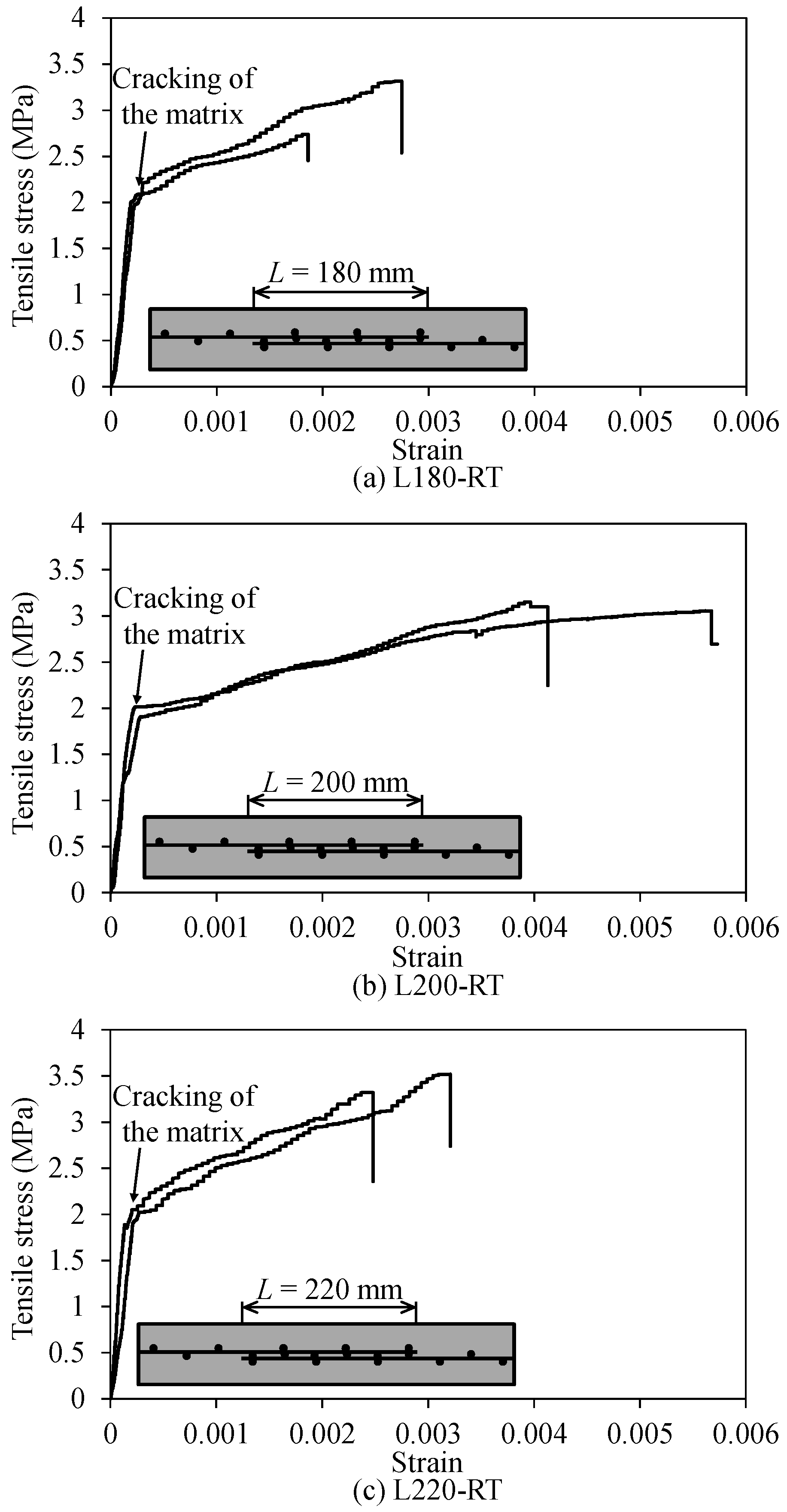

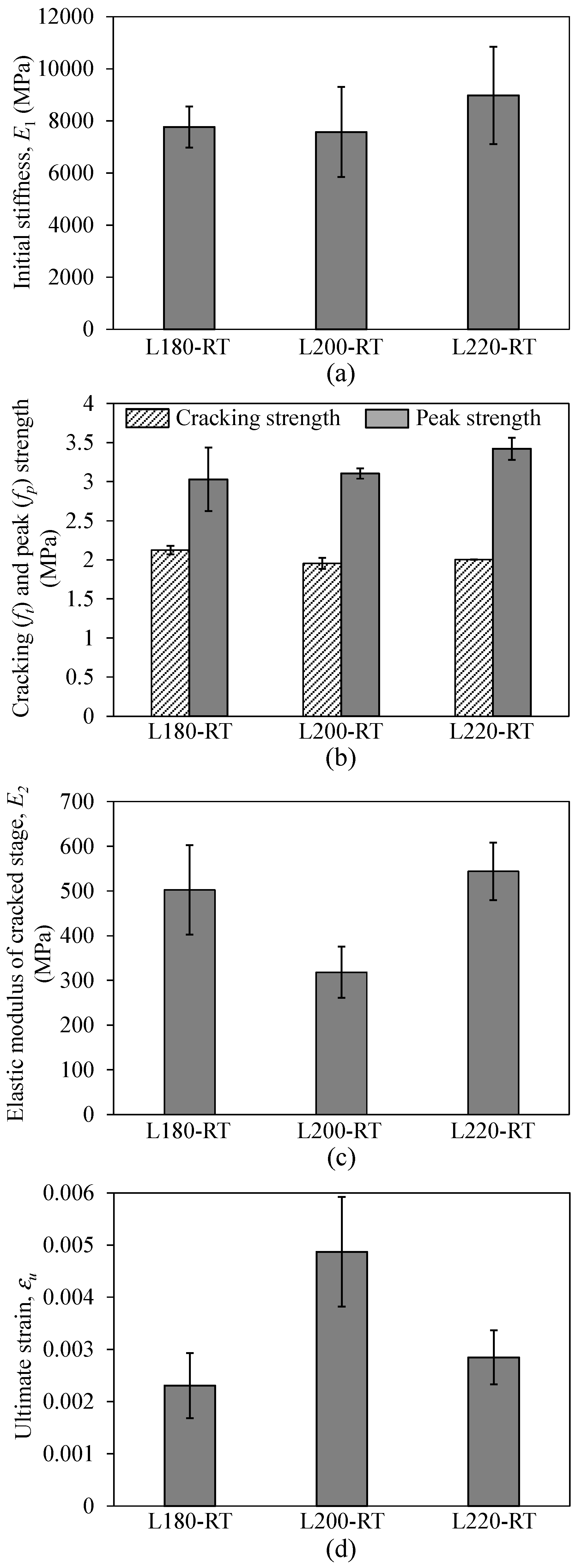

3.4. Effect of Lap Splice Length on Tensile Behavior of TRM Test Specimens

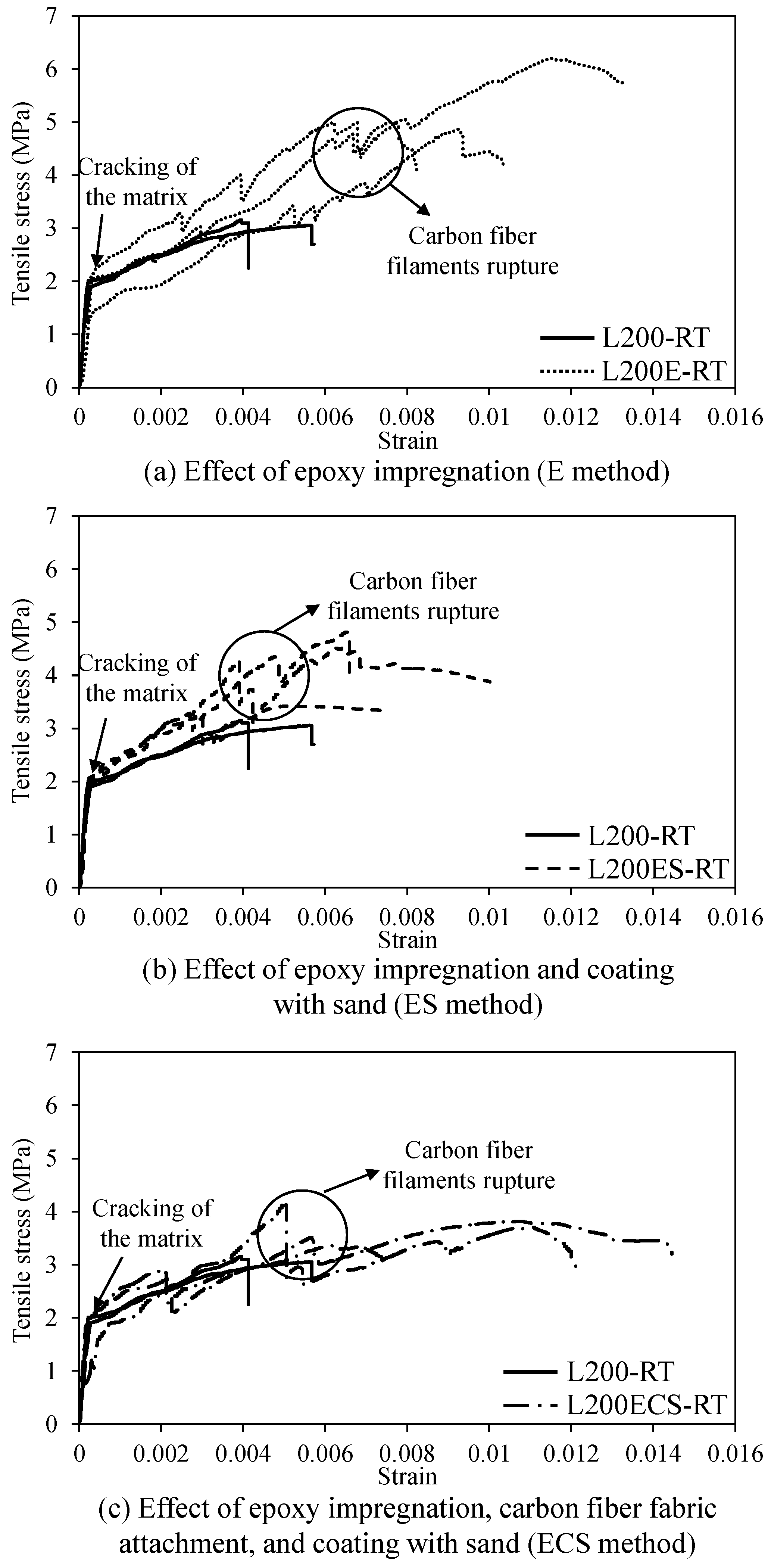

3.5. Effect of the Surface Treatment Details of Lap Splice on Tensile Behavior of TRM Test Specimens

3.6. Effect of Temperature on Tensile Behaviors of TRM Test Specimens

4. Prediction of Tensile Behaviors for TRM Composites Exposed to High Temperature

5. Conclusions

- The failure modes of the TRM test specimens in this study were essentially governed by carbon fiber rupturing after cracking occurred in the mortar matrix. In addition, the high temperature did not affect the failure modes of the test specimens despite causing strength reductions.

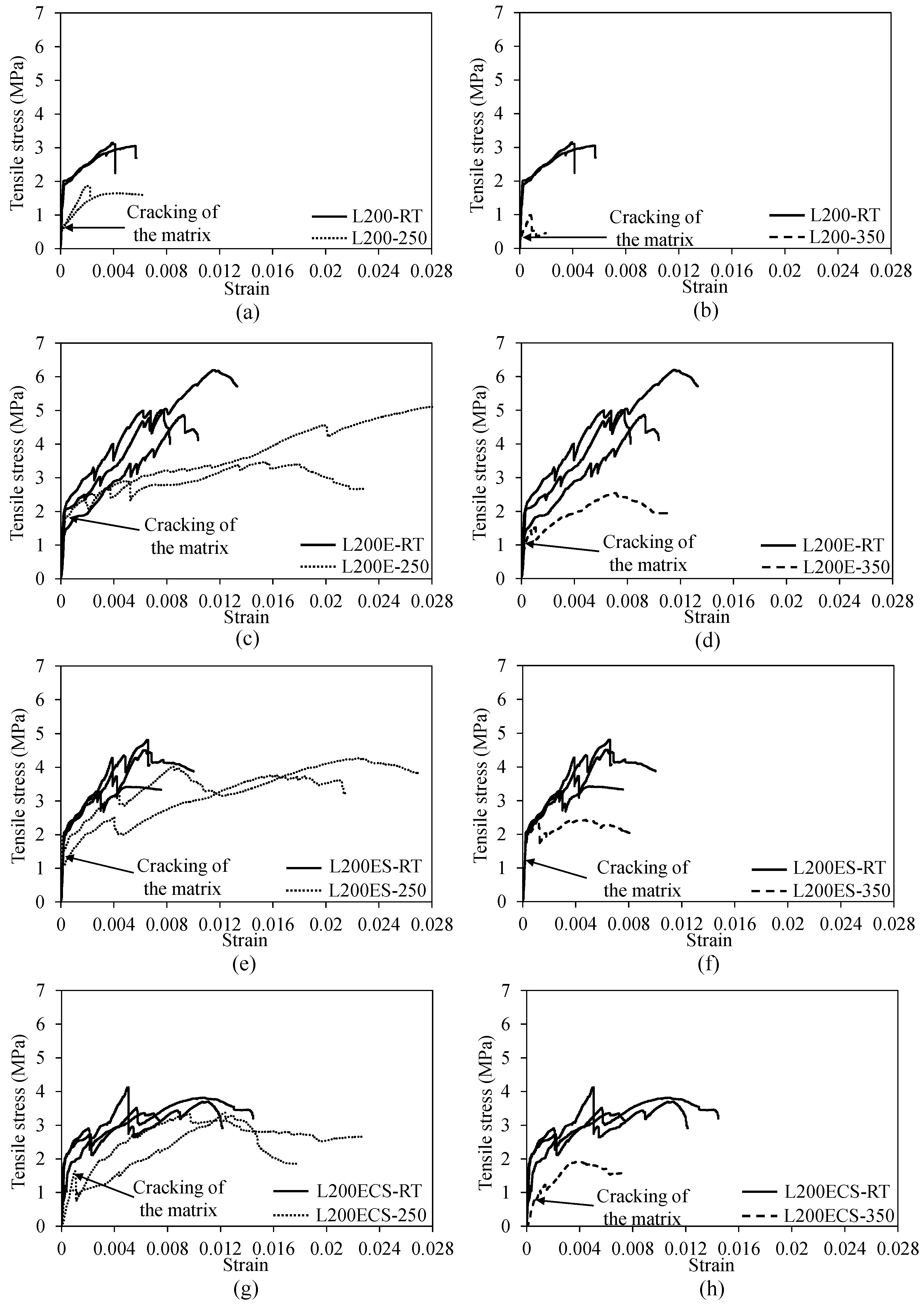

- In the case of the control specimens without surface treatment, after the cracking of the mortar matrix, the test specimens showed linear stress–strain curves up to the peak load, then a sudden load drop was observed. In contrast, the other test specimens with surface treatment in the overlapping region and/or exposure to high temperature showed non-linear behavior with fluctuation and gradual failure. However, despite showing fluctuation, the specimens with surface treatment in the overlapping region and/or exposure to high temperature displayed approximately trilinear behavior with un-cracked and cracked stages that were similar to the control specimens.

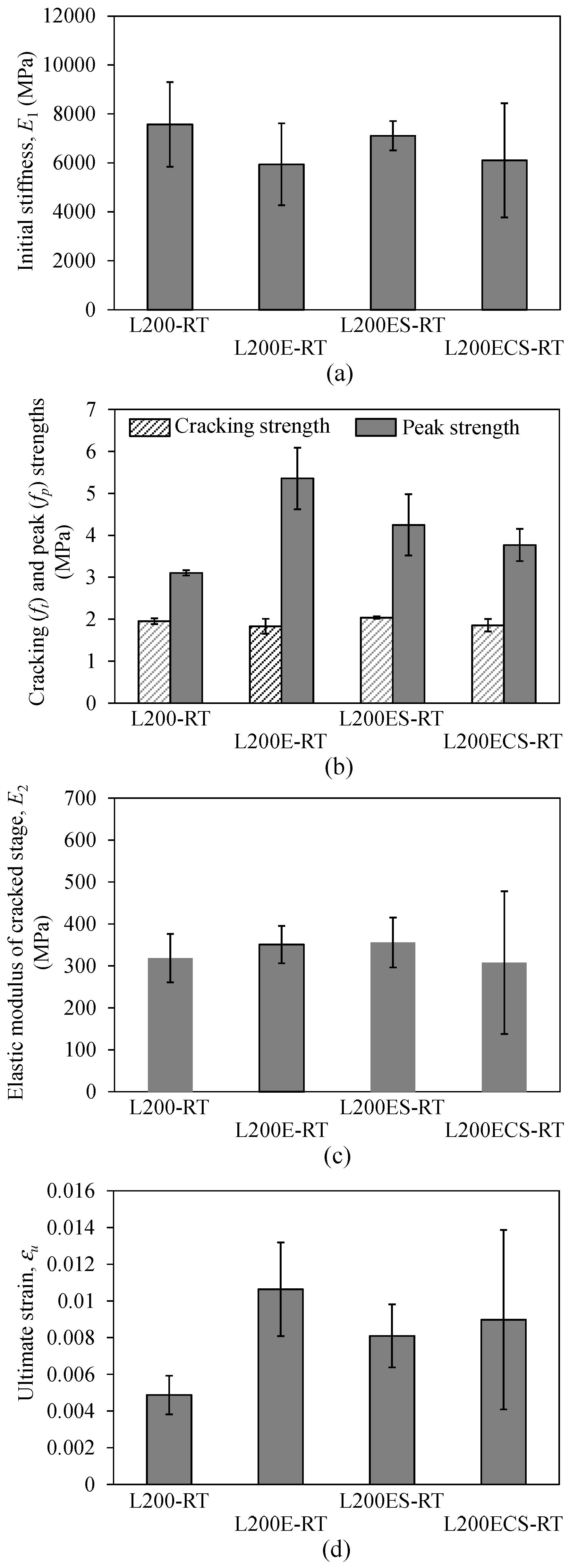

- The use of various lap splice lengths did not change the initial stiffness () or cracking strength (), but increased the peak strengths () of the TRM specimens. In addition, the elastic moduli of cracked stage () and ultimate strain () fluctuated with different lap splice lengths.

- The surface treatment in the overlapping region did not significantly change the initial stiffness, cracking strength, or elastic modulus of the cracked stage of the TRM specimens, but significantly increased the peak strength and ultimate strain compared to those of the non-detailed specimen L200-RT.

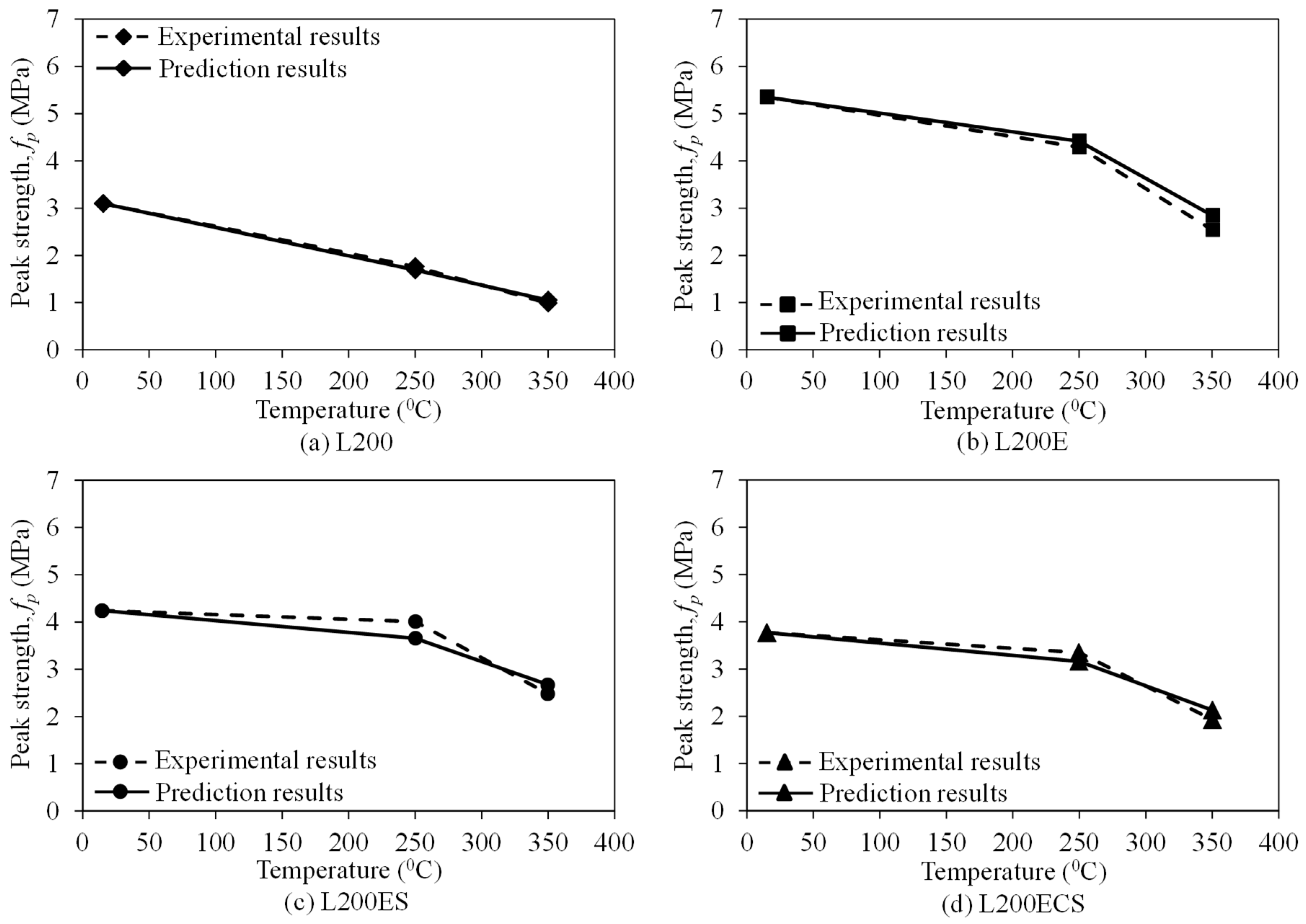

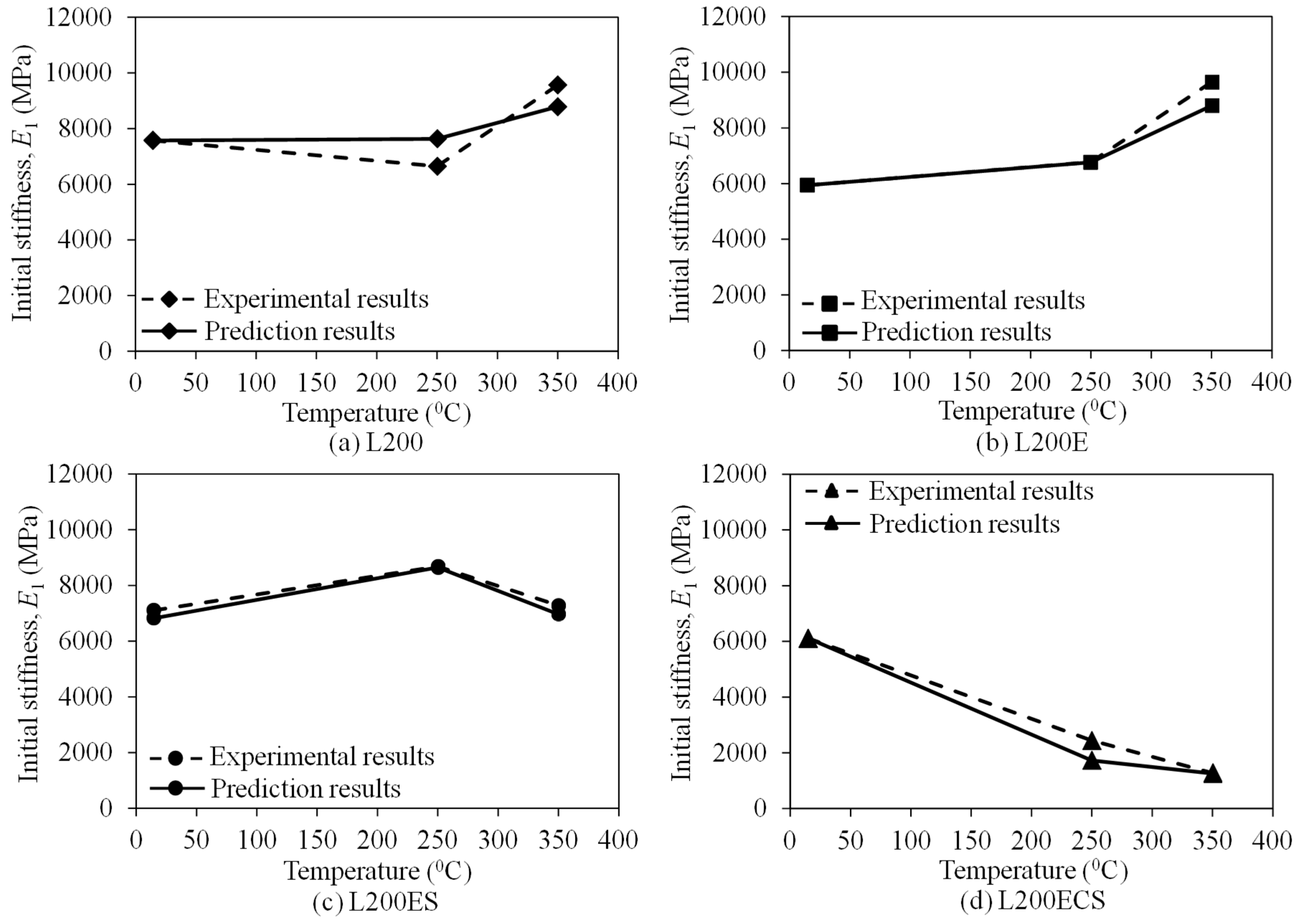

- The same trends in cracking strength, peak strength, and ultimate strain were observed for the TRM test specimens exposed to high temperature. The cracking and peak strengths decreased as the temperature increased. The ultimate strains of the test specimens using the details in the overlapping region were substantially higher than those of the test specimens in the L200 series, despite exposure to high temperature. Under high temperature, most test specimens showed nearly constant initial stiffness, except for the L200ECS specimens.

- The prediction model developed by Gibson et al. [45] was adopted to predict the tensile behaviors including peak strength, cracking strength, and initial stiffness of the TRM composites. The predicted results indicated that the Gibson model could be used to evaluate the tensile behaviors of the lap-spliced carbon fiber-textile reinforced mortar composites exposed to high temperature with a good agreement with the experimental results.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Truong, G.T.; Kim, J.-C.; Choi, K.-K. Seismic performance of reinforced concrete columns retrofitted by various methods. Eng. Struct. 2017, 134, 217–235. [Google Scholar] [CrossRef]

- Cho, C.-G.; Kim, Y.-Y.; Feo, L.; Hui, D. Cyclic responses of reinforced concrete composites columns strengthened in the plastic hinge region by HPFRC mortar. Compos. Struct. 2012, 94, 2246–2253. [Google Scholar] [CrossRef]

- Obaidat, Y.T.; Heyden, S.; Dahlblom, O.; Abu-Farsakh, G.; Abdel-Jawad, Y. Retrofitting of reinforced concrete beams using composite laminates. Constr. Build. Mater. 2011, 25, 591–597. [Google Scholar] [CrossRef]

- Toutanji, H.A. Durability characteristics of concrete columns confined with advanced composite materials. Compos. Struct. 1999, 44, 155–161. [Google Scholar] [CrossRef]

- GangaRao, H. Infrastructure applications of fiber-reinforced polymer composites. In Applied Plastics Engineering Handbook; Myer, K., Ed.; William Andrew: Burlington, MA, USA, 2011; pp. 565–584. [Google Scholar]

- Madeo, A. Fibrous composite reinforcements. In Generalized Continuum Mechanics and Engineering Applications; Madeo, A., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 19–47. [Google Scholar]

- Escrig, C.; Gil, L.; Bernat-Maso, E.; Puigvert, F. Experimental and analytical study of reinforced concrete beams shear strengthened with different types of textile-reinforced mortar. Constr. Build. Mater. 2015, 83, 248–260. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C.C. Comparison between different tensile test set-ups for the mechanical characterization of inorganic-matrix composites. Constr. Build. Mater. 2018, 171, 140–151. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G. Tensile behavior of mortar-based composites for externally bonded reinforcement systems. Compos. Part B 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Ombres, L. Analysis of the bond between fabric reinforced cementitious mortar (FRCM) strengthening systems and concrete. Compos. Part B 2015, 69, 418–426. [Google Scholar] [CrossRef]

- Awani, O.; El Refai, A.; El-Maaddawy, T. Bond characteristics of carbon fabric-reinforced cementitious matrix in double shear tests. Constr. Build. Mater. 2015, 101, 39–49. [Google Scholar] [CrossRef]

- De Santis, S.; Carozzi, F.G.; de Felice, G.; Poggi, C. Test methods for textile reinforced mortar systems. Compos. Part B 2017, 127, 121–132. [Google Scholar] [CrossRef]

- Caggegi, C.; Laoye, E.; Djama, K.; Bassil, A.; Gabor, A. Tensile behaviour of a basalt TRM strengthening system: Influence of mortar and reinforcing textile ratios. Compos. Part B 2017, 130, 90–102. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Bond between textile-reinforced mortar (TRM) and concrete substrates: Experimental investigation. Compos. Part B 2016, 98, 350–361. [Google Scholar] [CrossRef]

- Larrinaga, P.; Chastre, C.; San-Jose, J.T.; Garmendia, L. Non-linear analytical model of composites based on basalt textile reinforced mortar under uniaxial tension. Compos. Part B Eng. 2013, 55, 518–527. [Google Scholar] [CrossRef]

- Donnini, J.; De Caso y Basalo, F.; Corinaldesi, V.; Lancioni, G. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. Part B 2017, 108, 108–121. [Google Scholar] [CrossRef]

- D’Antino, T.; Sneed, L.H.; Carloni, C.; Pellegrino, C. Influence of the substrate characteristics on the bond behavior of PBO FRCM-concrete joints. Constr. Build. Mater. 2015, 101, 838–850. [Google Scholar] [CrossRef]

- Carloni, C.; Verre, S.; Sneed, L.H.; Ombres, L. Loading rate effect on the debonding phenomenon in fiber reinforced cementitious matrix-concrete joints. Compos. Part B Eng. 2017, 108, 301–314. [Google Scholar] [CrossRef]

- Messori, M.; Nobili, A.; Signorini, C.; Sola, A. Mechanical performance of epoxy coated AR-glass fabric textile reinforced mortar: Influence of coating thickness and formulation. Compos. Part B 2018, 149, 135–143. [Google Scholar] [CrossRef]

- Signorini, C.; Nobili, A.; Gonzalez, E.I.C.; Siligardi, C. Silica coating for interphase bond enhancement of carbon and AR-glass textile reinforced mortar (TRM). Compos. Part B 2018, 141, 191–202. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical properties of FRCM using carbon fabrics with different coating treatments. Compos. Part B 2016, 88, 220–228. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, M.; Zhou, F.; Zhu, D. Experimental study on basalt textile reinforced concrete under uniaxial tensile loading. Constr. Build. Mater. 2017, 138, 88–100. [Google Scholar] [CrossRef]

- Mesticou, Z.; Bui, L.; Junes, A.; Si Larbi, A. Experimental investigation of tensile fatigue behaviour of textile-reinforced concrete (TRC): Effect of fatigue load and strain rate. Compos. Struct. 2017, 160, 1136–1146. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Vu, H.X.; Si Larbi, A.; Ferrier, E. Experimental study of the effect of simultaneous mechanical and high-temperature loadings on the behaviour of textile-reinforced concrete (TRC). Constr. Build. Mater. 2016, 125, 253–270. [Google Scholar] [CrossRef]

- Kong, K.; Mesticou, Z.; Michel, M.; Si Larbi, A.; Junes, A. Comparative characterization of the durability behaviour of textile-reinforced concrete (TRC) under tension and bending. Compos. Struct. 2017, 179, 107–123. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. Bond between TRM versus FRP composites and concrete at high temperatures. Compos. Part B 2017, 127, 150–165. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Bournas, D.A. TRM and FRP jacketing in shear strengthening of concrete members subjected to high temperatures. Compos. Part B 2016, 106, 190–205. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. TRM versus FRP in flexural strengthening of RC beams: Behaviour at high temperatures. Constr. Build. Mater. 2017, 154, 424–437. [Google Scholar] [CrossRef]

- Kim, H.-S.; Truong, G.T.; Park, S.-H.; Choi, K.-K. Tensile properties of carbon fiber-textile reinforced mortar (TRM) characterized by different anchorage methods. Int. J. Concr. Struct. Mater. 2018, 12, 73. [Google Scholar] [CrossRef]

- AC434. Acceptance Criteria for Masonry and Concrete Strengthening Using Fiber-Reinforced Cementitious Matrix (FRCM) Composite Systems; A Subsidiary of the International Code Council: Birmingham, UK, 2011. [Google Scholar]

- KS L 5105. Testing Method for Compressive Strength of Hydraulic Cement Mortars; Korean Standard Association: Seoul, Korea, 2017. [Google Scholar]

- ACI 549.4R-13. Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures; American Concrete Institute: Farmington Hills, MI, USA, 2013. [Google Scholar]

- Aluminum Oxide as a Reinforcing Agent for Zinc Oxide-Eugenol-Eba Cements. Available online: https://nvlpubs.nist.gov/nistpubs/Legacy/RPT/nbsreport9804.pdf (accessed on 10 April 2019).

- Xie, Y.; Sherwood, P.M.A. Coatings of aluminum oxide and magnesium oxide on carbon fiber surfaces. Chem. Mater. 1994, 6, 650–657. [Google Scholar] [CrossRef]

- Park, J.S.; Park, Y.H.; Jung, W.T. Anchorage efficiency of mold-type anchorage for CFRP plates. Korea Concr. Inst. 2008, 20, 169–172. (In Korean) [Google Scholar]

- Karunagaran, N.; Rajadurai, A. Effect of surface treatment on mechanical properties of glass fiber/stainless steel wire mesh reinforced epoxy hybrid composites. J. Mech. Sci. Technol. 2016, 30, 2475–2482. [Google Scholar] [CrossRef]

- Leone, M.; Aiello, M.A.; Balsamo, A.; Carozzi, F.G.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P.; et al. Glass fabric reinforced cementitious matrix: Tensile properties and bond performance on masonry substrate. Compos. Part B 2017, 127, 196–214. [Google Scholar] [CrossRef]

- ASTM D3039. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Butler, M.; Mechtcherine, V.; Hempel, S. Durability of textile reinforced concrete made with AR glass fibre: Effect of the matrix composition. Mater. Struct. 2010, 43, 1351–1368. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Focacci, F.; Hojdys, L.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; et al. Experimental investigation of tensile and bond properties of carbon-FRCM composites for strengthening masonry elements. Compos. Part B 2017, 128, 100–119. [Google Scholar] [CrossRef]

- Tlaiji, T.; Vu, H.X.; Ferrier, E.; Si Larbi, A. Thermomechanical behaviour and residual properties of textile reinforced concrete (TRC) subjected to elevated and high temperature loading: Experimental and comparative study. Compos. Part B 2018, 144, 99–110. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Coskun, A. The effect of high temperature on compressive strength and splitting tensile strength of structural lightweight concrete containing fly ash. Constr. Build. Mater. 2008, 22, 2269–2275. [Google Scholar] [CrossRef]

- Cao, S.; Wu, Z.; Li, F. Effects of temperature on tensile strength of carbon fiber and carbon/epoxy composite sheets. Adv. Mater. Res. 2012, 476, 778–784. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Feih, S.; Kandare, E.; Mathys, Z.; Gibson, A.G.; Des Jardin, P.E.; Case, S.W.; Lattimer, B.Y. Review of fire structural modelling of polymer composites. Compos. Part A 2009, 40, 1800–1814. [Google Scholar] [CrossRef]

- Gibson, A.G.; Wu, Y.-S.; Evans, J.T.; Mouritz, A.P. Laminate theory analysis of composites under load in fire. J. Compos. Mater. 2006, 40, 639–658. [Google Scholar] [CrossRef]

- Homoro, O.; Vu, X.H.; Ferrier, E. Experimental and analytical study of the thermo-mechanical behaviour of textile-reinforced concrete (TRC) at elevated temperatures: Role of discontinuous short glass fibres. Constr. Build. Mater. 2018, 190, 645–663. [Google Scholar] [CrossRef]

| Specimens | Total Length (mm) | Lap Splice Length or Central Length (mm) | Gripping Length (mm) | Coating Method | Exposure to Fire | Number of Test Specimens |

|---|---|---|---|---|---|---|

| L180-RT | 450 | 180 | 125 | - (1) | - (1) | 2 |

| L200-RT | 450 | 200 | 115 | - (1) | - (1) | 2 |

| L220-RT | 450 | 220 | 105 | - (1) | - (1) | 2 |

| L200E-RT | 450 | 200 | 115 | Epoxy | - (1) | 3 |

| L200ES-RT | 450 | 200 | 115 | Epoxy + sand blasting (aluminum oxide powder) | - (1) | 3 |

| L200ECS-RT | 450 | 200 | 115 | Epoxy + carbon fiber fabric + sand blasting (aluminum oxide powder) | - (1) | 3 |

| L200-250 | 450 | 200 | 115 | - (1) | Max. temp.: 250 °C | 2 |

| L200-350 | 450 | 200 | 115 | - (1) | Max. temp.: 350 °C | 1 |

| L200E-250 | 450 | 200 | 115 | Epoxy | Max. temp.: 250 °C | 2 |

| L200E-350 | 450 | 200 | 115 | Epoxy | Max. temp.: 350 °C | 1 |

| L200ES-250 | 450 | 200 | 115 | Epoxy + sand blasting (aluminum oxide powder) | Max. temp.: 250 °C | 2 |

| L200ES-350 | 450 | 200 | 115 | Epoxy + sand blasting (aluminum oxide powder) | Max. temp.: 350 °C | 1 |

| L200ECS-250 | 450 | 200 | 115 | Epoxy + carbon fiber fabric + sand blasting (aluminum oxide powder) | Max. temp.: 250 °C | 2 |

| L200ECS-350 | 450 | 200 | 115 | Epoxy + carbon fiber fabric + sand blasting (aluminum oxide powder) | Max. temp.: 350 °C | 1 |

| Specimens | Initial Stiffness | Cracking Strength | Cracking Strain | Elastic Modulus of Cracked Stage | Peak Strength | Ultimate Strain | Failure Mode | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 (MPa) | COV | ft (MPa) | COV | εt | COV | E2 (MPa) | COV | fp (MPa) | COV | εu | COV | ||

| L180-RT | 7770.8 | 0.102 | 2.12 | 0.026 | 0.00028 | 0.129 | 502.3 | 0.197 | 3.03 | 0.134 | 0.0023 | 0.271 | A |

| L200-RT | 7573.0 | 0.229 | 1.95 | 0.036 | 0.00026 | 0.194 | 318.3 | 0.180 | 3.10 | 0.021 | 0.0049 | 0.216 | A |

| L220-RT | 8983.4 | 0.208 | 2.00 | 0.002 | 0.00023 | 0.207 | 544.0 | 0.123 | 3.42 | 0.041 | 0.0028 | 0.182 | A or B |

| L200E-RT | 5941.8 | 0.280 | 1.83 | 0.177 | 0.00032 | 0.127 | 350.9 | 0.128 | 5.35 | 0.137 | 0.0106 | 0.239 | A or B |

| L200ES-RT | 7106.5 | 0.087 | 2.04 | 0.030 | 0.00029 | 0.062 | 355.7 | 0.168 | 4.24 | 0.172 | 0.0081 | 0.212 | A or B |

| L200ECS-RT | 6104.4 | 0.410 | 1.86 | 0.219 | 0.00033 | 0.306 | 308.0 | 0.653 | 3.77 | 0.101 | 0.0090 | 0.545 | A or B |

| L200-250 | 6644.2 | 0.084 | 0.57 | 0.145 | 0.00009 | 0.228 | - | - | 1.76 | 0.084 | 0.0042 | 0.660 | A |

| L200-350 | 9562.5 | - | 0.21 | - | 0.00002 | - | - | - | 0.99 | - | 0.0008 | - | A |

| L200E-250 | 6769.4 | 0.335 | 1.90 | 0.071 | 0.00029 | 0.267 | - | - | 4.29 | 0.274 | 0.0256 | 0.232 | A or B |

| L200E-350 | 9642.9 | - | 0.75 | - | 0.00008 | - | - | - | 2.54 | - | 0.0098 | - | A |

| L200ES-250 | 8679.8 | 0.537 | 1.58 | 0.087 | 0.00019 | 0.184 | - | - | 4.01 | 0.091 | 0.0162 | 0.473 | A or B |

| L200ES-350 | 7280.5 | - | 1.66 | - | 0.00023 | - | - | - | 2.48 | - | 0.0085 | - | A |

| L200ECS-250 | 2440.9 | 0.533 | 1.32 | 0.335 | 0.00069 | 0.797 | - | - | 3.35 | 0.009 | 0.0169 | 0.181 | A or B |

| L200ECS-350 | 1278.3 | - | 0.82 | - | 0.00064 | - | - | - | 1.93 | - | 0.0063 | - | B |

| Specimens | (1) | (1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (a) Peak strength (MPa) | ||||||||||

| L200 | 3.10 | 0.99 | 0.014 | 250 | 350 | 225 | 1.69 | 1.05 | 1.04 | 0.94 |

| L200E | 5.35 | 2.54 | 0.014 | 250 | 350 | 275 | 4.42 | 2.85 | 0.97 | 0.89 |

| L200ES | 4.24 | 2.48 | 0.014 | 250 | 350 | 275 | 3.66 | 2.67 | 1.10 | 0.93 |

| L200ECS | 3.77 | 1.93 | 0.014 | 250 | 350 | 275 | 3.16 | 2.13 | 1.06 | 0.91 |

| (b) Cracking strength (MPa) | ||||||||||

| L200 | 1.95 | 0.21 | 0.014 | 250 | 350 | 175 | 0.38 | 0.21 | 1.49 | 0.98 |

| L200E | 1.83 | 0.62 (2) | 0.014 | 250 | 350 | 280 | 1.91 | 0.74 | 0.99 | 1.02 |

| L200ES | 2.04 | 1.66 | 0.014 | 250 | 350 | 125 | 1.60 | 1.59 | 0.99 | 1.04 |

| L200ECS | 1.86 | 0.82 | 0.014 | 250 | 350 | 225 | 1.12 | 0.81 | 1.18 | 1.01 |

| (c) Initial stiffness (MPa) | ||||||||||

| L200 | 7573.0 | 9562.5 | 0.014 | 250 | 350 | 300 | 7632.0 | 8783.8 | 0.87 | 1.09 |

| L200E | 5941.8 | 9642.9 | 0.014 | 250 | 350 | 280 | 6761.4 | 8800.1 | 1.00 | 1.10 |

| L200ES | 7106.5 | 6965.2 (3) | 0.014 | 250 | 350 | 250 | 8645.5 | 6965.2 | 1.00 | 1.04 |

| L200ECS | 6104.4 | 1278.3 | 0.014 | 250 | 350 | 175 | 1729.0 | 1258.8 | 1.41 | 1.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, G.T.; Park, S.-H.; Choi, K.-K. Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature. Materials 2019, 12, 1512. https://doi.org/10.3390/ma12091512

Truong GT, Park S-H, Choi K-K. Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature. Materials. 2019; 12(9):1512. https://doi.org/10.3390/ma12091512

Chicago/Turabian StyleTruong, Gia Toai, Sung-Ho Park, and Kyoung-Kyu Choi. 2019. "Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature" Materials 12, no. 9: 1512. https://doi.org/10.3390/ma12091512

APA StyleTruong, G. T., Park, S.-H., & Choi, K.-K. (2019). Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature. Materials, 12(9), 1512. https://doi.org/10.3390/ma12091512