Effects of Electropolishing on Mechanical Properties and Bio-Corrosion of Ti6Al4V Fabricated by Electron Beam Melting Additive Manufacturing

Abstract

1. Introduction

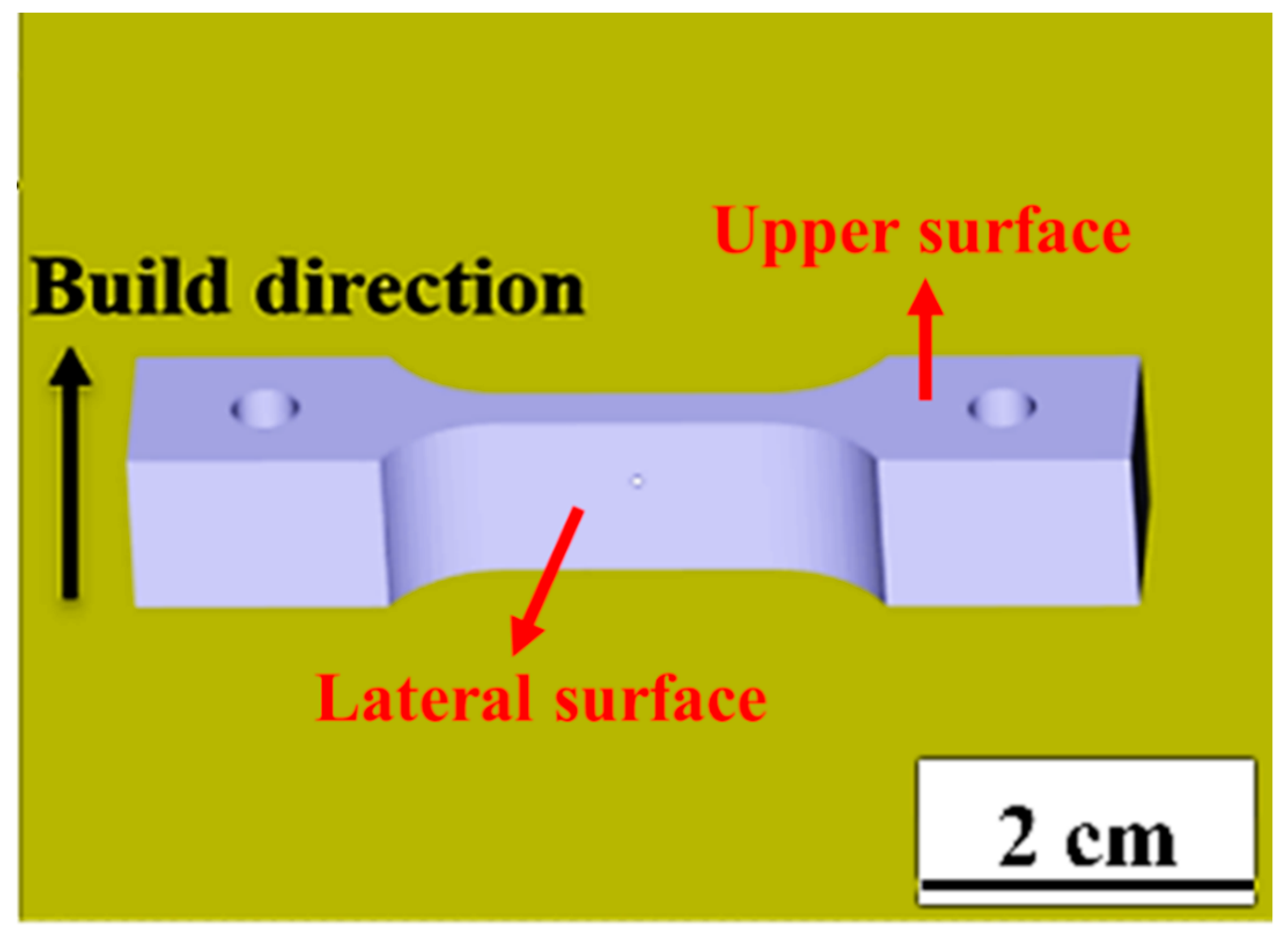

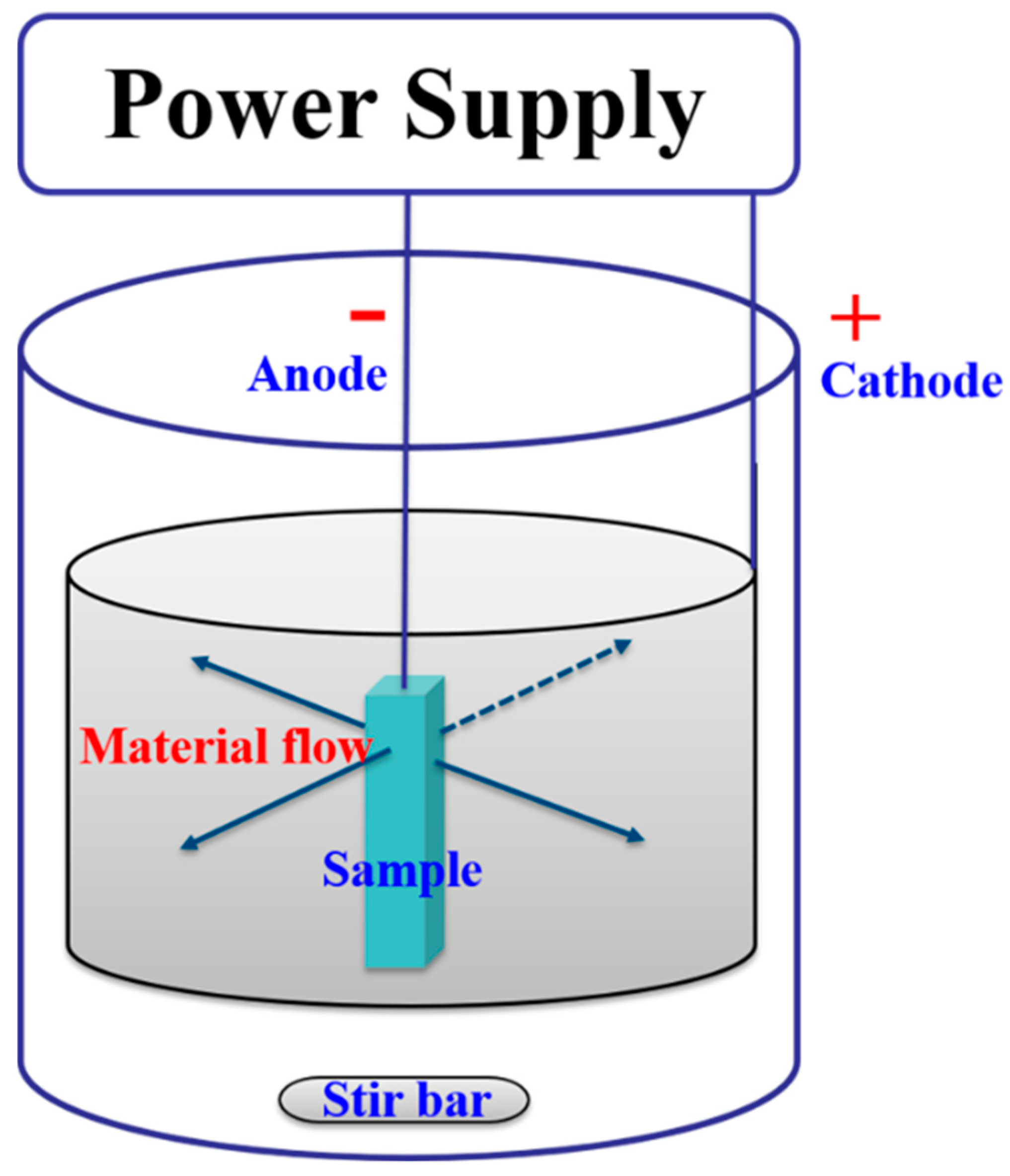

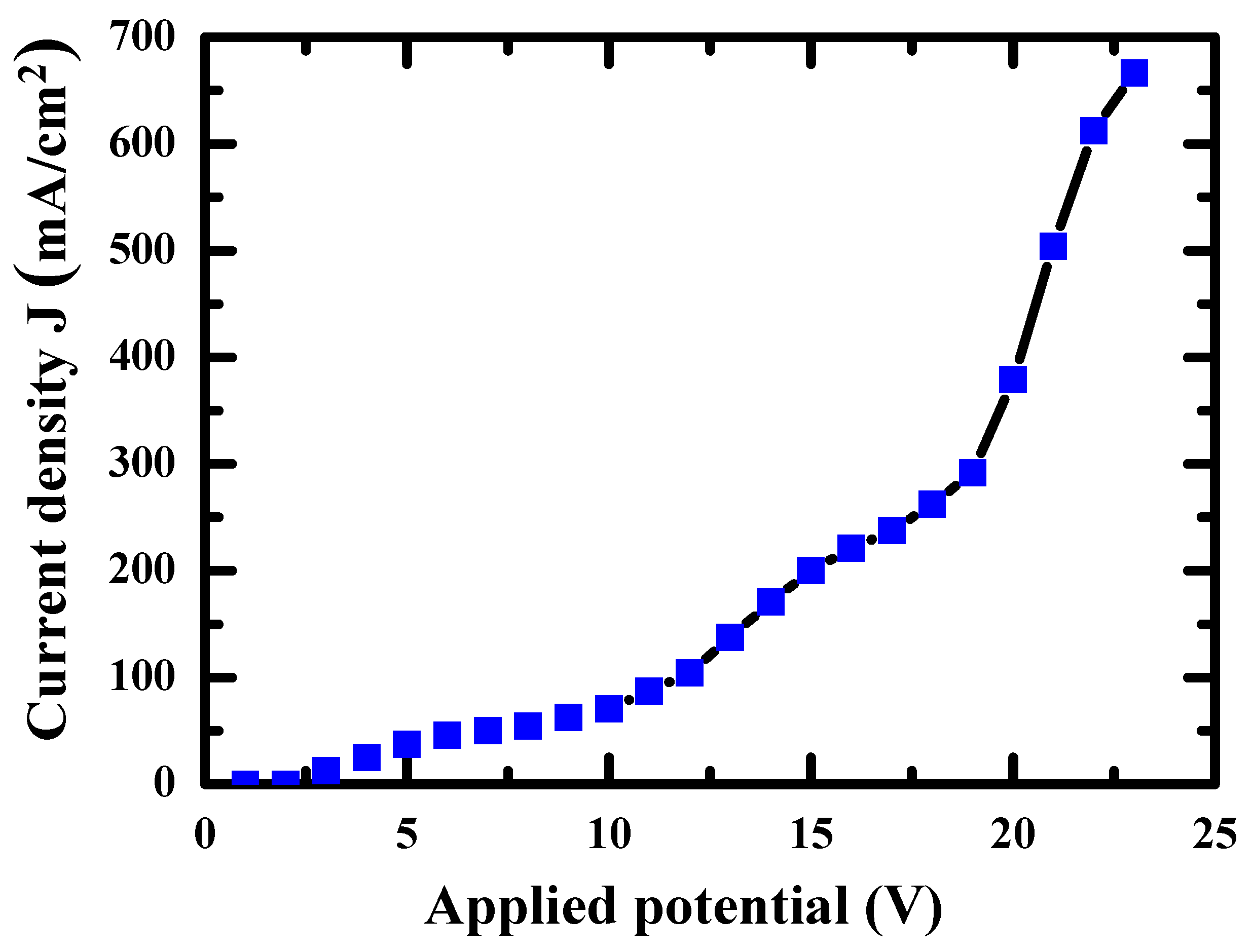

2. Material and Methods

3. Results and Discussions

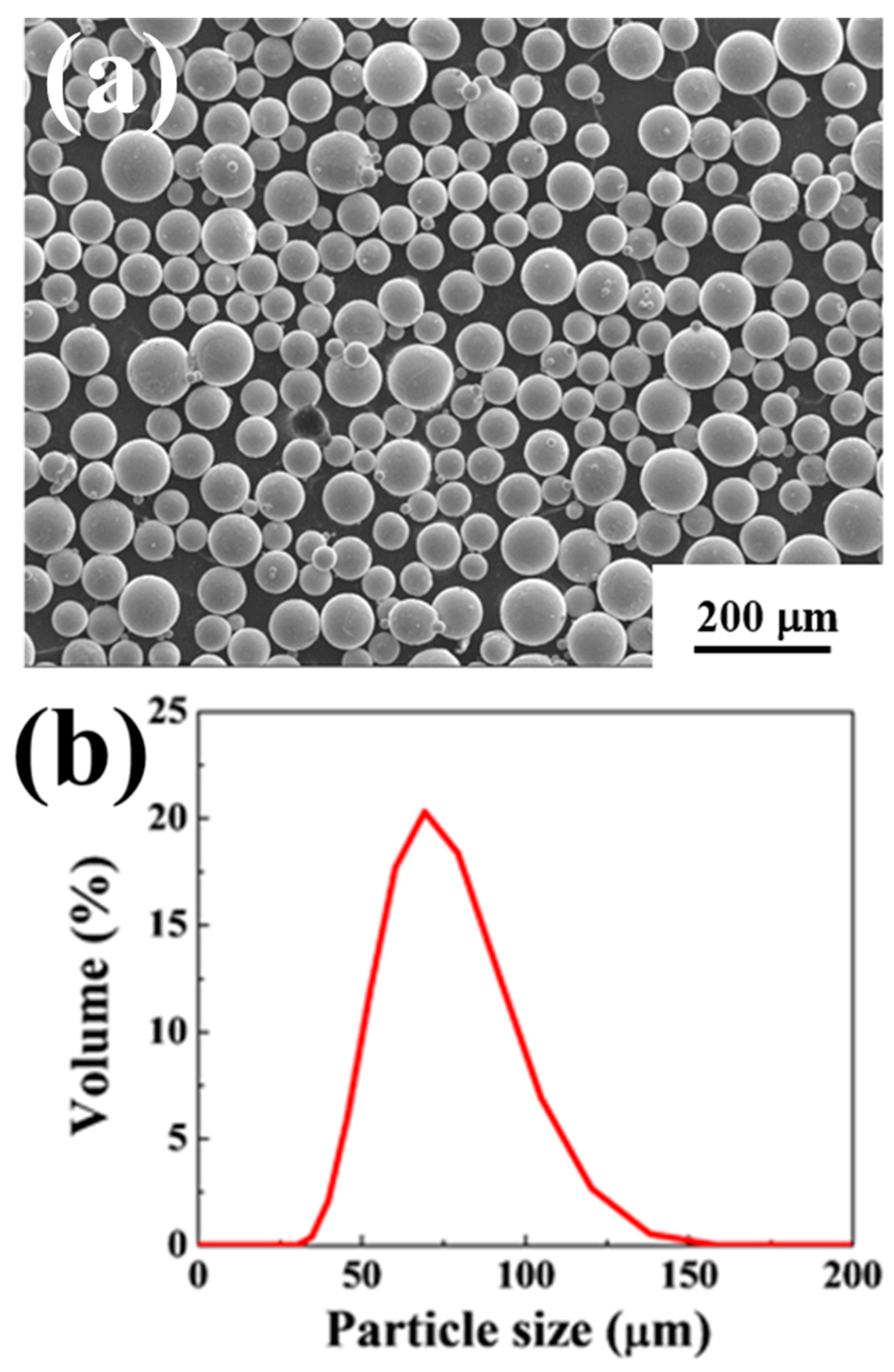

3.1. Powder Analysis

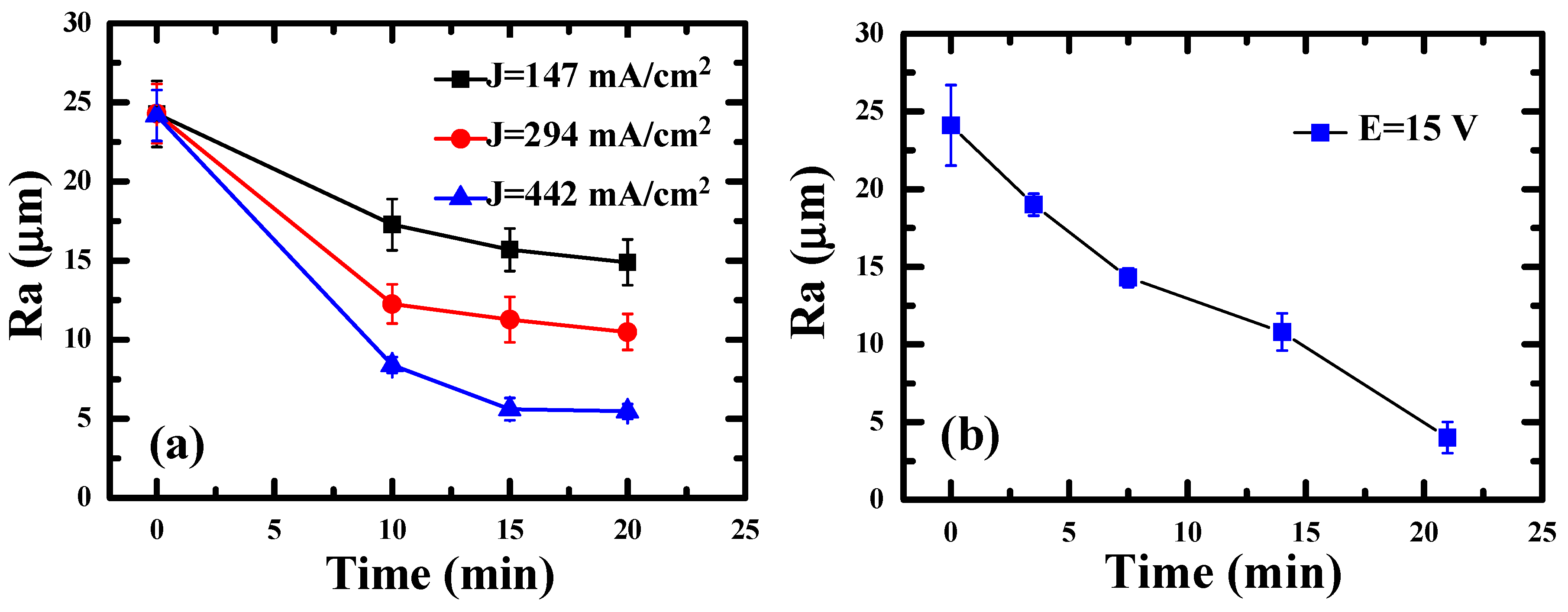

3.2. Surface Roughness

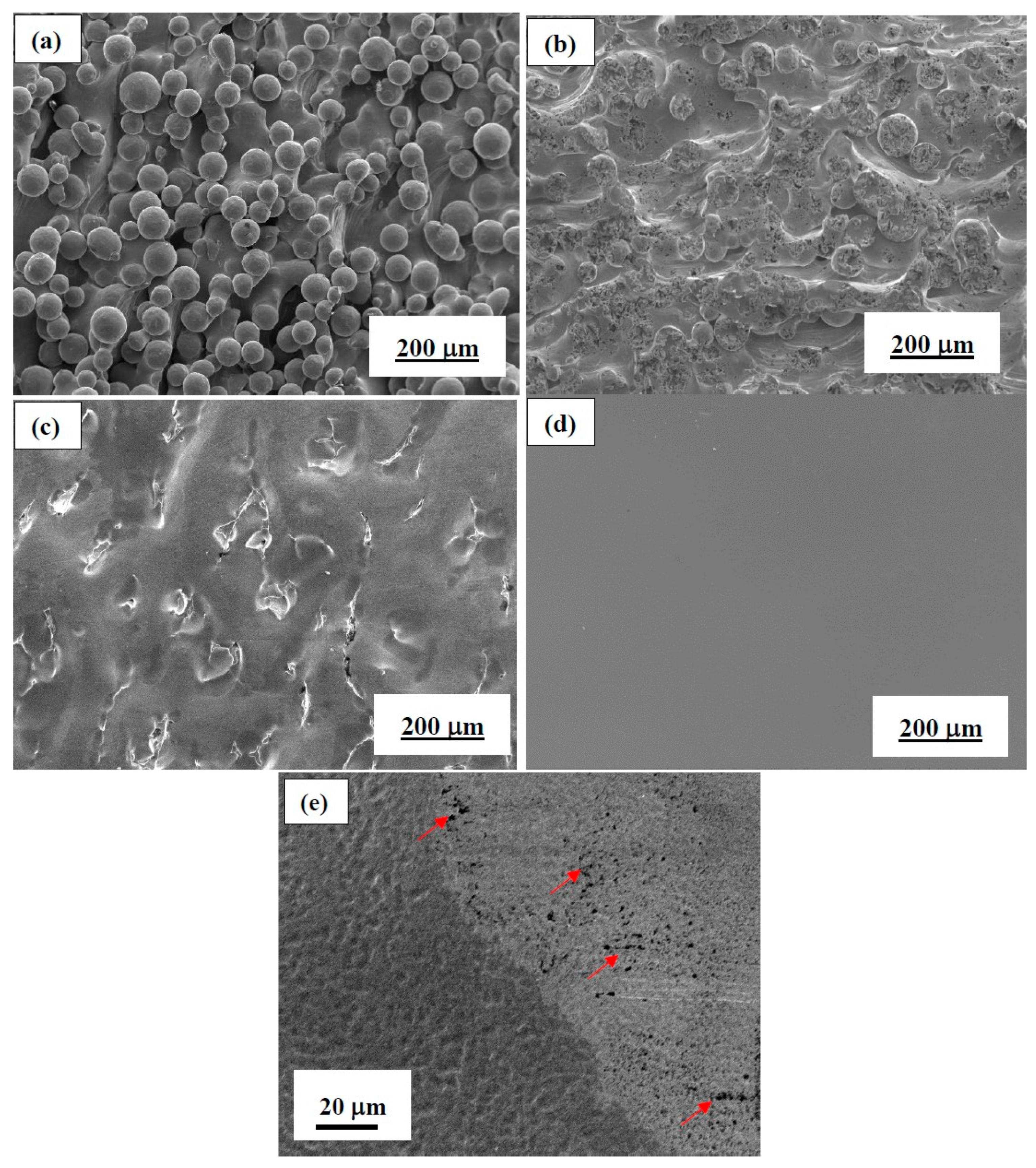

3.3. Surface Morphology

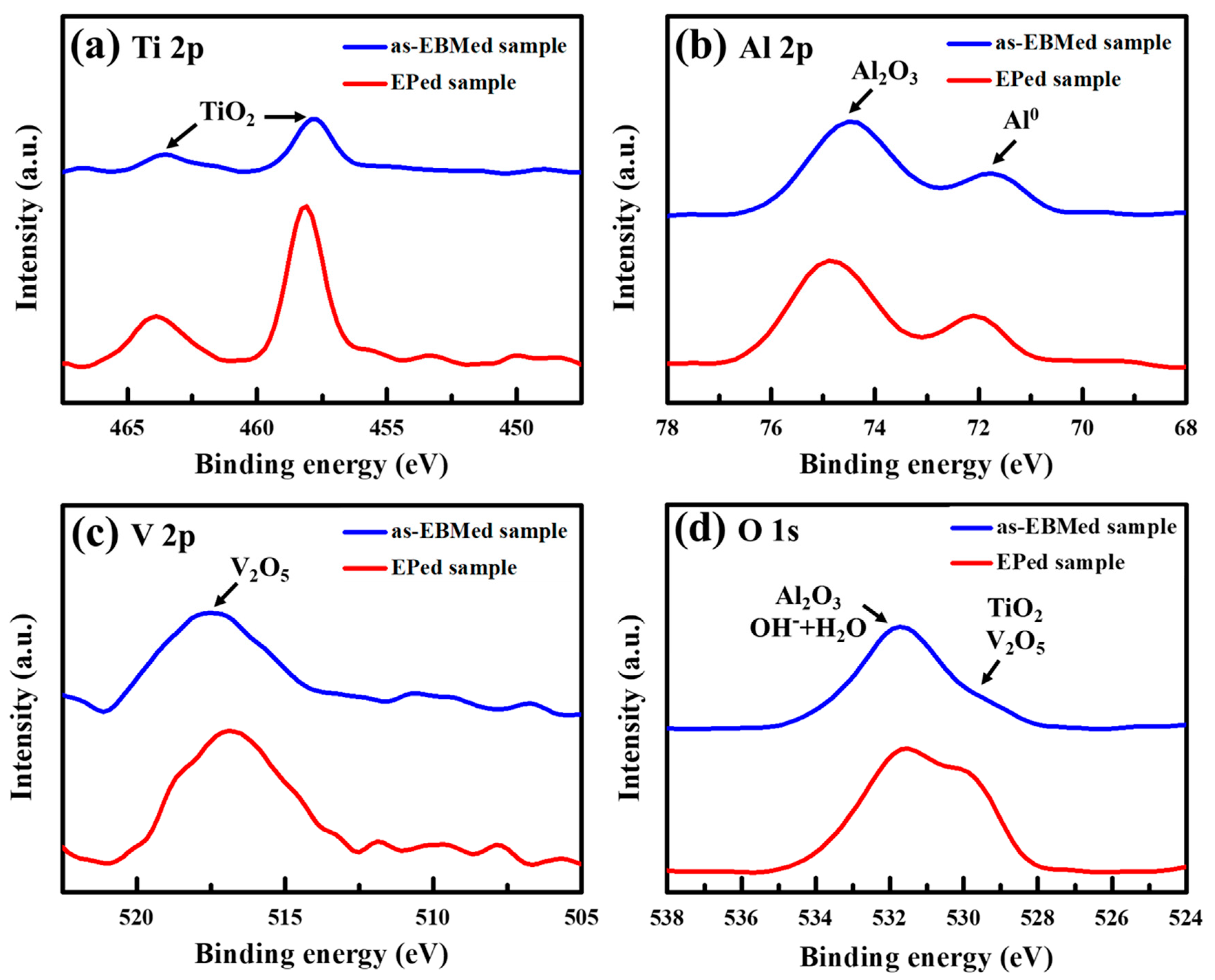

3.4. Surface Compositions Analysis

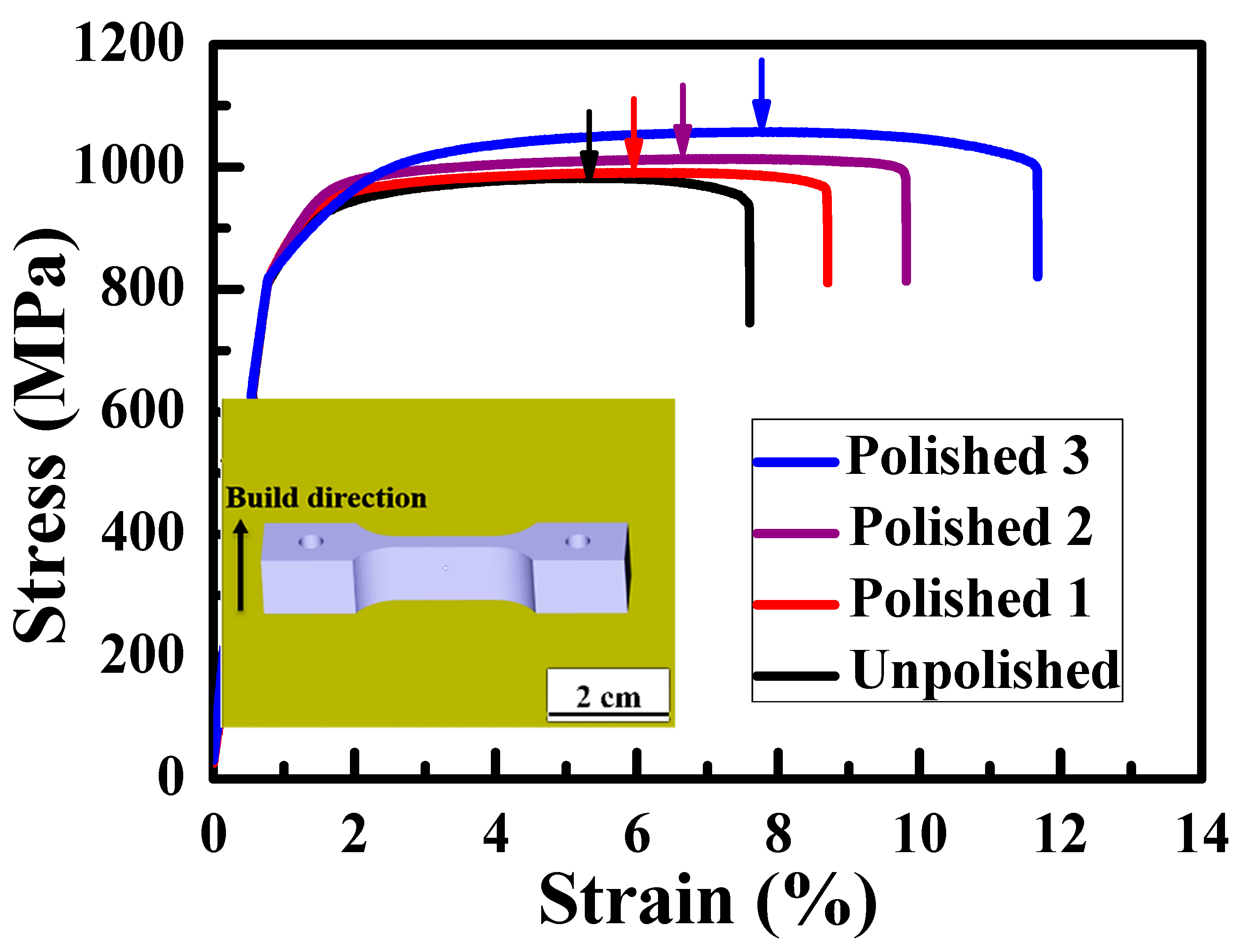

3.5. Mechanical Response

3.6. Bio-Corrosion Electrochemical Response

3.7. Closing Remarks

4. Conclusions

- (1)

- The current spherical, smooth and non-broken shape of Ti6Al4V powders can result in good powder flow and uniform powder bed during EBM. But the as-EBMed surface would contain partially melted powders, forming a rougher surface with Ra ~ 24 μm.

- (2)

- The electropolishing treatment is able to achieve surface improvement from Ra over ~24 μm down to about 4.5 μm with proper EP solution, voltage, current density, temperature and duration time.

- (3)

- Via the proper EP, the stress concentration effect can be pronouncedly reduced, upgrading the subsequent tensile performance to raise the UTS by 6% and tensile elongation by 53%. With decreasing Ra values, the mechanical response is continuously upgraded in this study.

- (4)

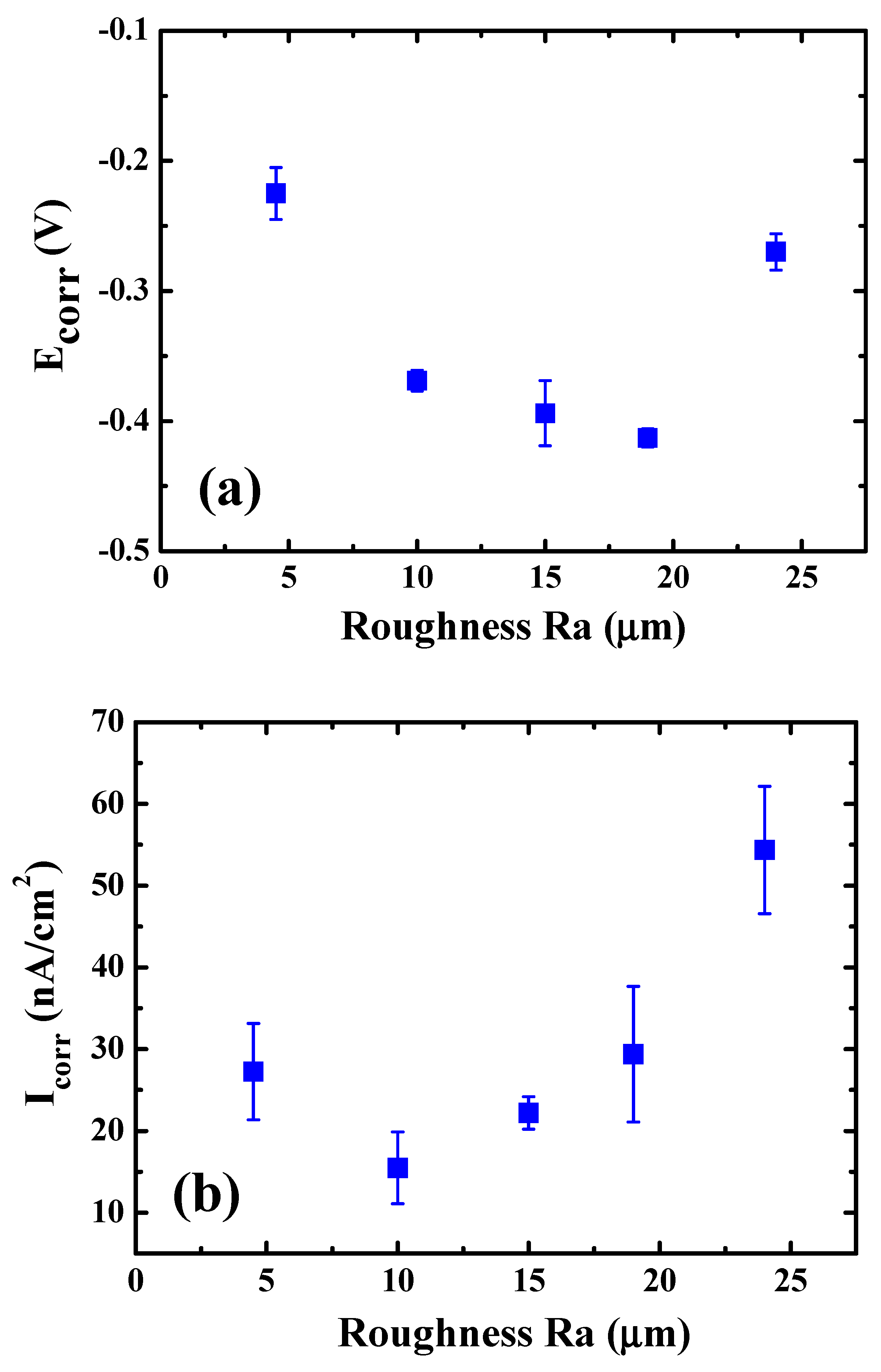

- According to potentiodynamic polarization results, the as-EBMed sample with the highest Ra possesses the higher Ecorr, Icorr and Ipass values. With decreasing Ra, the bio-corrosion rate becomes much lower.

- (5)

- However, when the EP treatment is over-done, the tiny dots induced by EP would impose some negative effects on the bio-corrosion in SBF. Proper EP treatments should result in a flatter surface without tiny EP-induced defects.

Author Contributions

Funding

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Chang, J.; He, J.; Mao, M.; Zhou, W.; Lei, Q.; Li, X.; Li, D.; Chua, C.K.; Zhao, X. Advanced Material Strategies for Next-Generation Additive Manufacturing. Materials 2018, 11, 166. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Terrazas, C.A.; Murr, L.E.; Bermudez, D.; Arrieta, E.; Roberson, D.A.; Wicker, R.B. Microstructure and mechanical properties of Ti-6Al-4V-5% hydroxyapatite composite fabricated using electron beam powder bed fusion. J. Mater. Sci. Technol. 2019, 35, 309–321. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. 2010, 3, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Sochalski-Kolbus, L.M.; Payzant, E.A.; Cornwell, P.A.; Watkins, T.R.; Babu, S.S.; Dehoff, R.R.; Lorenz, M.; Ovchinnikova, O.; Duty, C. Comparison of Residual Stresses in Inconel 718 Simple Parts Made by Electron Beam Melting and Direct Laser Metal Sintering. Metall. Mater. Trans. A 2015, 46, 1419–1432. [Google Scholar] [CrossRef]

- Karlsson, J.; Norell, M.; Ackelid, U.; Engqvist, H.; Lausmaa, J. Surface oxidation behavior of Ti–6Al–4V manufactured by Electron Beam Melting (EBM®). J. Manuf. Process. 2015, 17, 120–126. [Google Scholar] [CrossRef]

- Vandenbroucke, B.; Kruth, J.-P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203. [Google Scholar] [CrossRef]

- Fousová, M.; Vojtěch, D.; Doubrava, K.; Daniel, M.; Lin, C.F. Influence of Inherent Surface and Internal Defects on Mechanical Properties of Additively Manufactured Ti6Al4V Alloy: Comparison between Selective Laser Melting and Electron Beam Melting. Materials 2018, 11, 537. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.J.; Li, S.J.; Wang, H.L.; Hou, W.T.; Hao, Y.L.; Yang, R.; Sercombe, T.B.; Zhang, L.C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar] [CrossRef]

- Shui, X.; Yamanaka, K.; Mori, M.; Nagata, Y.; Kurita, K.; Chiba, A. Effects of post-processing on cyclic fatigue response of a titanium alloy additively manufactured by electron beam melting. Mater. Sci. Eng. A 2017, 680, 239–248. [Google Scholar] [CrossRef]

- Ren, D.; Li, S.; Wang, H.; Hou, W.; Hao, Y.; Jin, W.; Yang, R.; Misra, R.D.K.; Murr, L.E. Fatigue behavior of Ti-6Al-4V cellular structures fabricated by additive manufacturing technique. J. Mater. Sci. Technol. 2019, 35, 285–294. [Google Scholar] [CrossRef]

- Critchlow, G.W.; Brewis, D.M. Review of surface pretreatments for titanium alloys. Int. J. Adhes. Adhes. 1995, 15, 161–172. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and Electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Urlea, V.; Brailovski, V. Electropolishing and electropolishing-related allowances for powder bed selectively laser-melted Ti-6Al-4V alloy components. J. Mater. Process. Technol. 2017, 242, 1–11. [Google Scholar] [CrossRef]

- Han, Y.L.; Mei, J.; Peng, Q.J.; Han, E.H.; Ke, W. Effect of electropolishing on corrosion of nuclear grade 316L stainless steel in deaerated high temperature water. Corros. Sci. 2016, 112, 625–634. [Google Scholar] [CrossRef]

- Babilas, D.; Urbanczyk, E.; Sowa, M.; Maciej, A.; Korotin, D.M.; Zhidkov, I.S.; Basiaga, M.; Krok-Borkowicz, M.; Szyk-Warszynska, L.; Pamula, E.; et al. On the electropolishing and anodic oxidation of Ti-15Mo alloy. Electrochim. Acta 2016, 205, 256–265. [Google Scholar] [CrossRef]

- Perez, N. Electrochemistry and Corrosion Science; Springer: Berlin, Germany, 2004. [Google Scholar]

- Landolt, D. Fundamental aspects of electropolishing. Electrochim. Acta 1987, 32, 1–11. [Google Scholar] [CrossRef]

- Hoar, T.P.; Mears, D.C.; Rothwell, G.P. The relationships between anodic passivity, brightening and pitting. Corros. Sci. 1965, 5, 279–289. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Tsai, C.H.; Hung, C.H.; Kuo, C.N.; Chen, C.Y.; Peng, Y.N.; Shie, M.Y. Improved Bioactivity of 3D Printed Porous Titanium Alloy Scaffold with Chitosan/Magnesium-Calcium Silicate Composite for Orthopaedic Applications. Materials 2019, 12, 203. [Google Scholar] [CrossRef] [PubMed]

- Venkateswarlu, K.; Rameshbadu, N.; Sreekanth, D.; Bose, A.C.; Muthupandi, V.; Babu, N.K.; Subramanian, S. Role of electrolyte additives on in-vitro electrochemical behavior of micro arc oxidized titania films on Cp Ti. Appl. Surf. Sci. 2012, 258, 6853–6863. [Google Scholar]

- Kumar, A.M.; Sudhagar, P.; Ramakrishna, S.; Kang, Y.S.; Kim, H.; Gasem, Z.M.; Rajendran, N. Evaluation of chemically modified Ti–5Mo–3Fe alloy surface: Electrochemical aspects and in vitro bioactivity on MG63 cells. Appl. Surf. Sci. 2014, 307, 52–61. [Google Scholar] [CrossRef]

- Zheng, C.Y.; Nie, F.L.; Zheng, Y.F.; Chene, Y.; Wei, S.C.; Valiev, R.Z. Enhanced in vitro biocompatibility of ultrafine-grained titanium with hierarchical porous surface. Appl. Surf. Sci. 2011, 257, 5634–5640. [Google Scholar] [CrossRef]

- Wu, Y.C.; Kuo, C.N.; Shie, M.Y.; Su, Y.L.; Wei, L.J.; Chen, S.Y.; Huang, J.C. Structural design and mechanical response of gradient porous Ti-6Al-4V fabricated by electron beam additive manufacturing. Mater. Des. 2018, 158, 256–265. [Google Scholar] [CrossRef]

- Weißmann, V.; Drescher, P.; Seitz, H.; Hansmann, H.; Bader, R.; Seyfarth, A.; Klinder, A.; Jonitz-Heincke, A. Effects of Build Orientation on Surface Morphology and Bone Cell Activity of Additively Manufactured Ti6Al4V Specimens. Materials 2018, 11, 915. [Google Scholar] [CrossRef]

- Taniguchi, N.; Fujibayashi, S.; Takemoto, M.; Sasaki, K.; Otsuki, B.; Nakamura, T.; Matsushita, T.; Kokubo, T.; Matsuda, S. Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment. Mater. Sci. Eng. C 2016, 59, 690–701. [Google Scholar] [CrossRef]

- Murr, L.E. Strategies for creating living, additively manufactured, open-cellular metal and alloy implants by promoting osseointegration, osteoinduction and vascularization: An overview. J. Mater. Sci. Technol. 2019, 35, 231–241. [Google Scholar] [CrossRef]

- Shah, F.A.; Snis, A.; Matic, A.; Thomsen, P.; Palmquist, A. 3D printed Ti6Al4V implant surface promotes bone maturation and retains a higher density of less aged osteocytes at the bone-implant interface. Acta Biomater. 2016, 30, 357–367. [Google Scholar] [CrossRef]

- Walter, R.; Kannan, M.B. Influence of surface roughness on the corrosion behaviour of magnesium alloy. Mater. Des. 2011, 32, 2350–2354. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, J.Z.; Che, S.H. Electropolishing mechanism of Ti-6Al-4V alloy fabricated by selective laser melting. Int. J. Electrochem. Sci. 2018, 13, 4792–4807. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, Q.; Cheng, L.; Li, S.; Shi, Y. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting. Mater. Des. 2014, 63, 185–193. [Google Scholar] [CrossRef]

- Ek, R.K.; Rännar, L.-E.; Bäckstöm, M.; Carlsson, P. The effect of EBM process parameters upon surface roughness. Rapid Prototyp. J. 2016, 22, 495–503. [Google Scholar]

- Clerc, C.; Datta, M.; Landolt, D. On the theory of anodic leveling: Model experiments with triangular nickel profiles in chloride solution. Electrochim. Acta 1984, 29, 1477–1486. [Google Scholar] [CrossRef]

- Fu, H.; Yang, X.; An, X.; Fan, W.; Jiang, X.; Yu, A. Experimental and theoretical studies of V2O5@TiO2 core-shell hybrid composites with high gas sensing performance towards ammonia. Sens. Actuat B 2017, 252, 103–115. [Google Scholar] [CrossRef]

- Chávez-Díaz, M.P.; Escudero-Rincón, M.L.; Arce-Estrada, E.M.; Cabrera-Sierra, R. Osteoblast cell response on the Ti6Al4V alloy heat-treated. Materials 2017, 10, 445. [Google Scholar] [CrossRef]

- Huang, C.H.; Lai, J.J.; Huang, J.C.; Lin, C.H.; Jang, J.S.C. Effects of Cu content on electrochemical response in Ti-based metallic glasses under simulated body fluid. Mater. Sci. Eng. C 2016, 62, 368–376. [Google Scholar] [CrossRef]

- Pilkey, W.D.; Pilkey, D.F. Peterson’s Stress Concentration Factors; John Wiley Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Chen, S.Y.; Kuo, C.N.; Su, Y.L.; Huang, J.C.; Wu, Y.C.; Lin, Y.H.; Chung, Y.C.; Ng, C.H. Microstructure and fracture properties of open-cell porous Ti-6Al-4V with high porosity fabricated by electron beam melting. Mater. Charact. 2018, 138, 255–262. [Google Scholar] [CrossRef]

- Dai, N.; Zhang, L.-C.; Zhang, J.; Chen, Q.; Wu, M. Corrosion behavior of selective laser melted Ti-6Al-4V alloy in NaCl solution. Corros. Sci. 2016, 102, 484–489. [Google Scholar] [CrossRef]

- Lai, J.J.; Lin, Y.S.; Chang, C.H.; Wei, T.Y.; Huang, J.C.; Liao, Z.X.; Lin, C.H.; Chen, C.H. Promising Ta-Ti-Zr-Si metallic glass coating without cytotoxic elements for bio-implant applications. Appl. Surf. Sci. 2018, 427, 485–495. [Google Scholar] [CrossRef]

| Ra (µm) | Kt | Young’s Modulus (GPa) | Yield Stress (MPa) | Ultimate Tensile Stress (MPa) | Tensile Elongation (%) | |

|---|---|---|---|---|---|---|

| Unpolished | 24.1 ± 2.6 | 2.8 ± 0.3 | 100 ± 2 | 813 ± 3 | 995 ± 8 | 7.6 ± 0.4 |

| Polished 1 | 15.1 ± 1.2 | 2.4 ± 0.1 | 103 ± 2 | 817 ± 2 | 1012 ± 13 | 8.7 ± 0.5 |

| Polished 2 | 10.2 ± 0.9 | 2.0 ± 0.2 | 100 ± 1 | 809 ± 5 | 1025 ± 7 | 9.3 ± 0.4 |

| Polished 3 | 4.5 ± 0.5 | 1.2 ± 0.1 | 102 ± 3 | 817 ± 2 | 1052 ± 8 | 11.6 ± 0.7 |

| Ra (µm) | OCP E (V) | Ecorr (V) | Epit (V) | ΔE (V) | Icorr (nA/cm2) | Ipass (µA/cm2) |

|---|---|---|---|---|---|---|

| 24.1 ± 2.6 | −0.25 | −0.270 ± 0.014 | 1.850 ± 0.034 | >2 | 54.36 ± 7.80 | 6.71 ± 0.16 |

| 19.0 ± 0.7 | −0.38 | −0.413 ± 0.007 | >2 | >2 | 29.38 ± 8.28 | 2.80 ± 0.08 |

| 15.1 ± 1.2 | −0.45 | −0.394 ± 0.025 | >2 | >2 | 22.19 ± 1.97 | 2.88 ± 0.06 |

| 10.2 ± 1.3 | −0.32 | −0.369 ± 0.008 | >2 | >2 | 15.47 ± 4.40 | 2.68 ± 0.42 |

| 4.5 ± 0.8 | −0.23 | −0.225 ± 0.020 | >2 | >2 | 27.24 ± 5.89 | 2.90 ± 0.32 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.-C.; Kuo, C.-N.; Chung, Y.-C.; Ng, C.-H.; Huang, J.C. Effects of Electropolishing on Mechanical Properties and Bio-Corrosion of Ti6Al4V Fabricated by Electron Beam Melting Additive Manufacturing. Materials 2019, 12, 1466. https://doi.org/10.3390/ma12091466

Wu Y-C, Kuo C-N, Chung Y-C, Ng C-H, Huang JC. Effects of Electropolishing on Mechanical Properties and Bio-Corrosion of Ti6Al4V Fabricated by Electron Beam Melting Additive Manufacturing. Materials. 2019; 12(9):1466. https://doi.org/10.3390/ma12091466

Chicago/Turabian StyleWu, Yao-Cheng, Che-Nan Kuo, Yueh-Chun Chung, Chee-How Ng, and Jacob C. Huang. 2019. "Effects of Electropolishing on Mechanical Properties and Bio-Corrosion of Ti6Al4V Fabricated by Electron Beam Melting Additive Manufacturing" Materials 12, no. 9: 1466. https://doi.org/10.3390/ma12091466

APA StyleWu, Y.-C., Kuo, C.-N., Chung, Y.-C., Ng, C.-H., & Huang, J. C. (2019). Effects of Electropolishing on Mechanical Properties and Bio-Corrosion of Ti6Al4V Fabricated by Electron Beam Melting Additive Manufacturing. Materials, 12(9), 1466. https://doi.org/10.3390/ma12091466