Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works

Abstract

1. Introduction

2. Materials and Methods

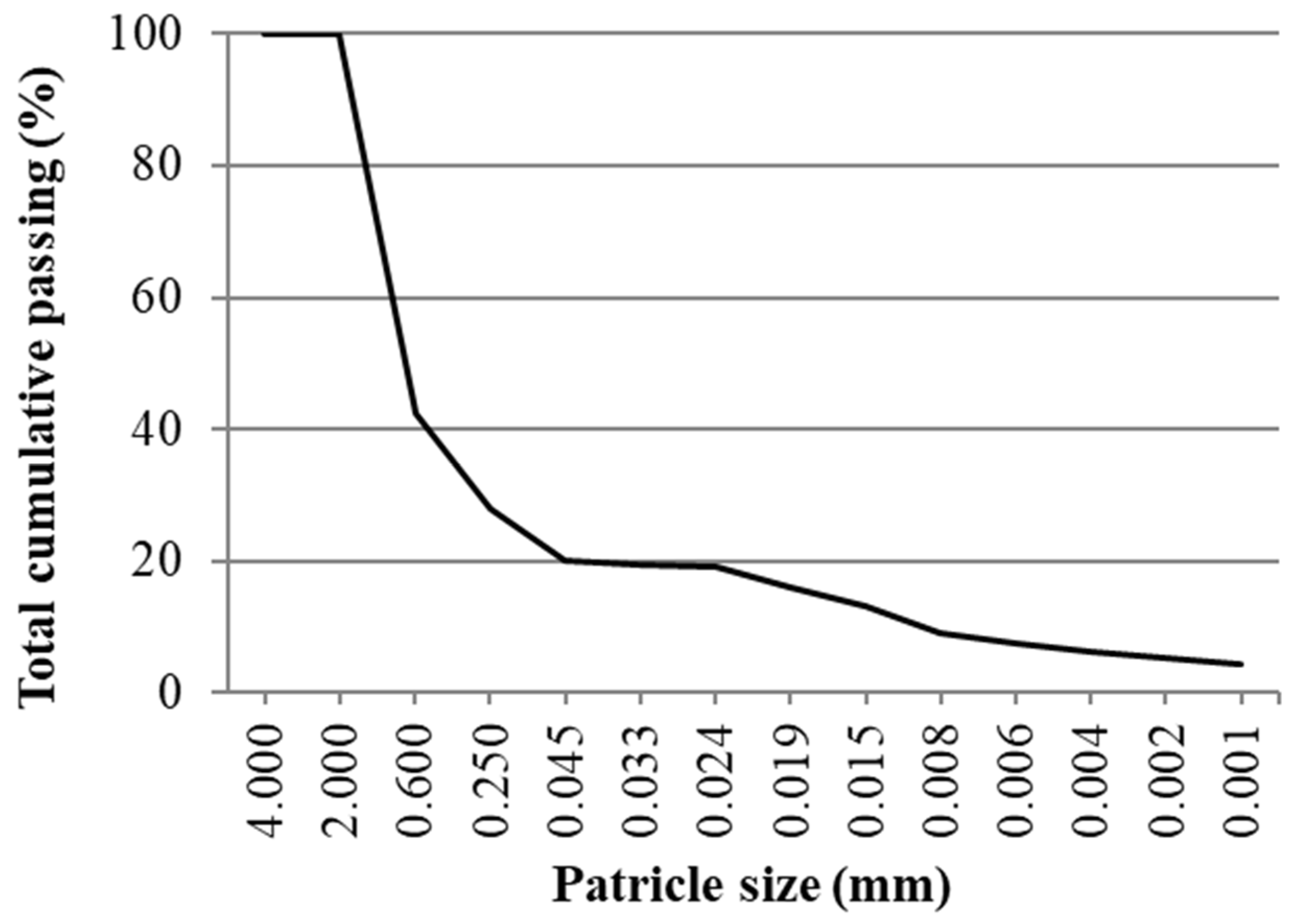

2.1. Raw Materials

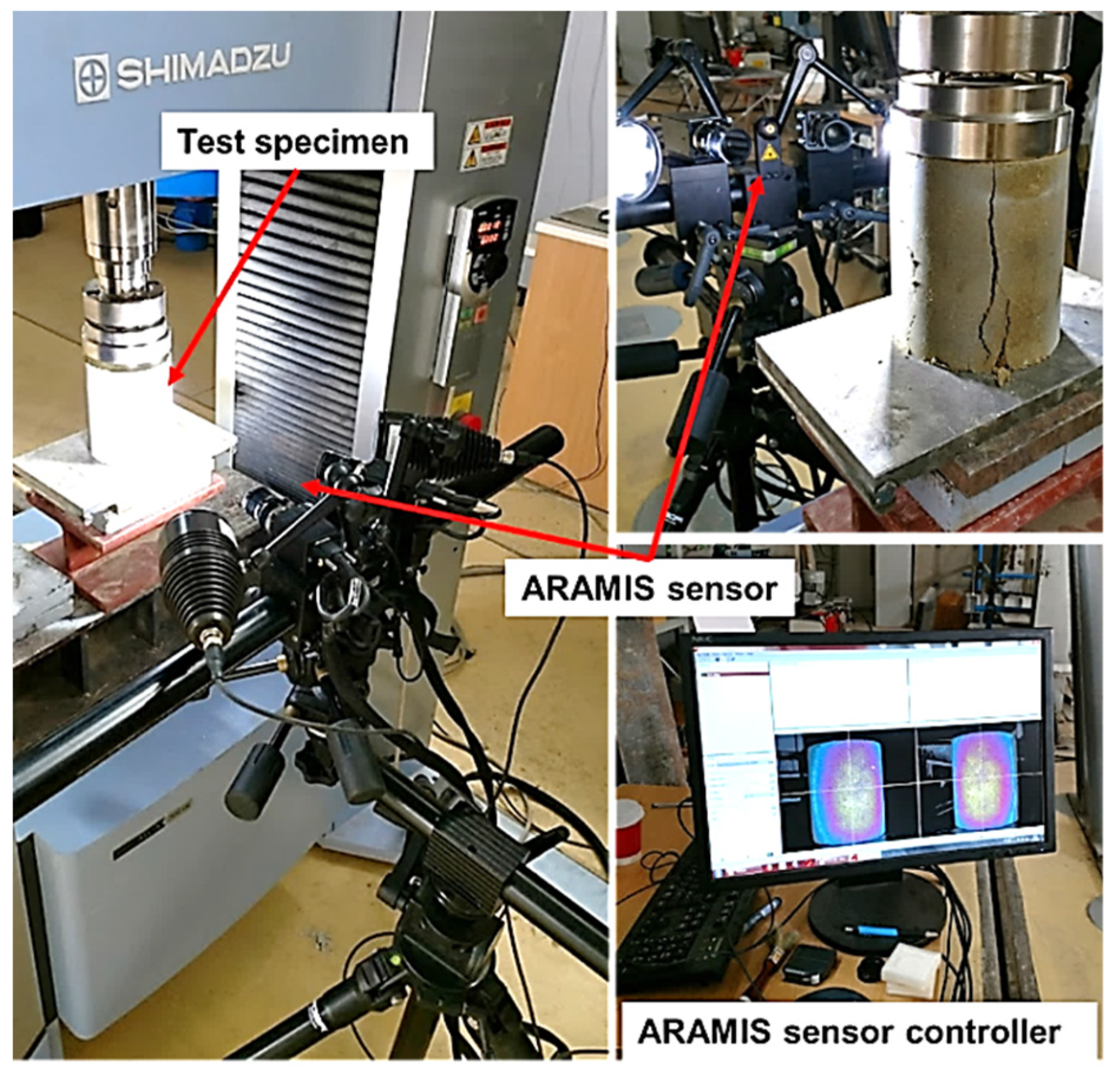

2.2. Sample Preparation and Strength Tests

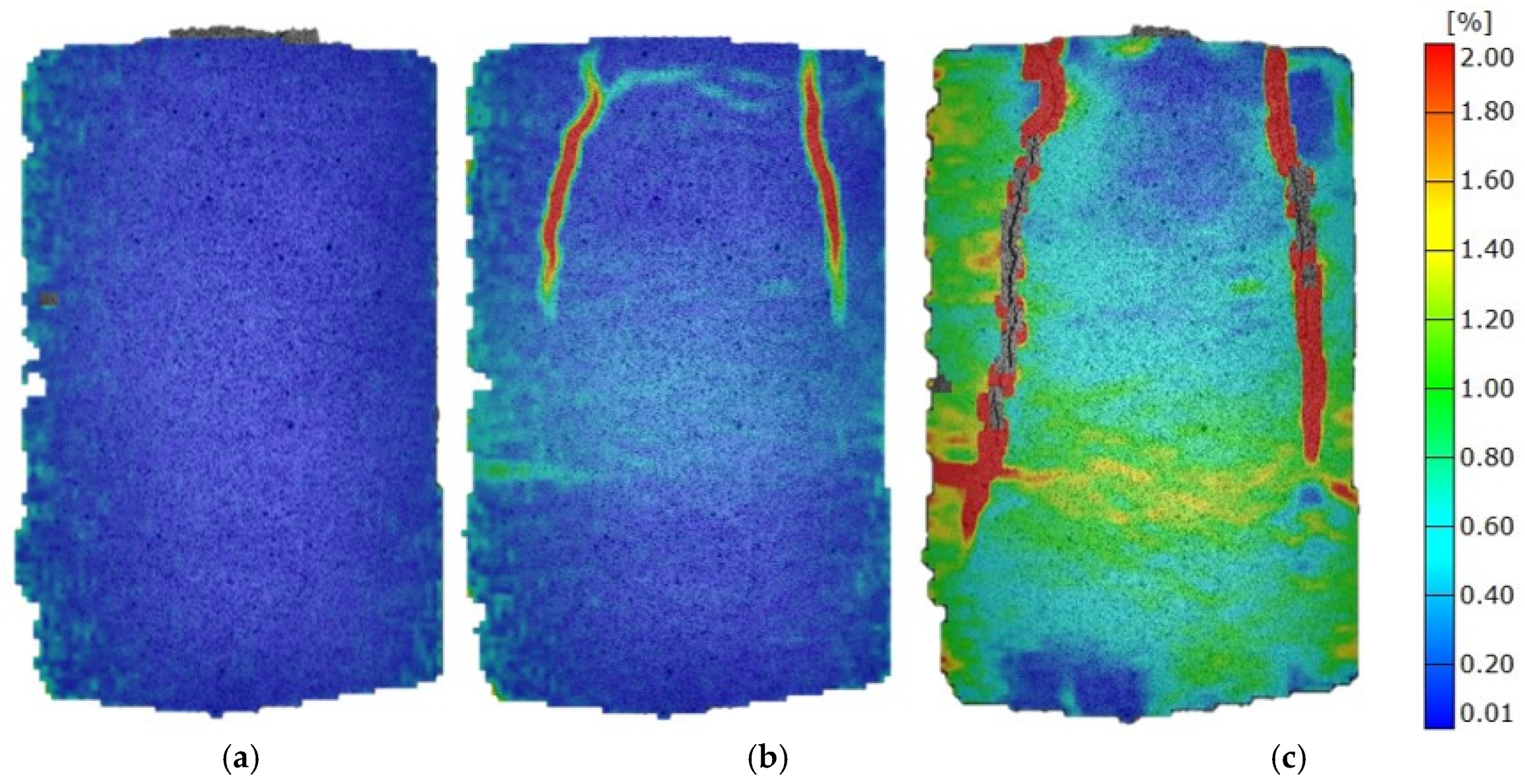

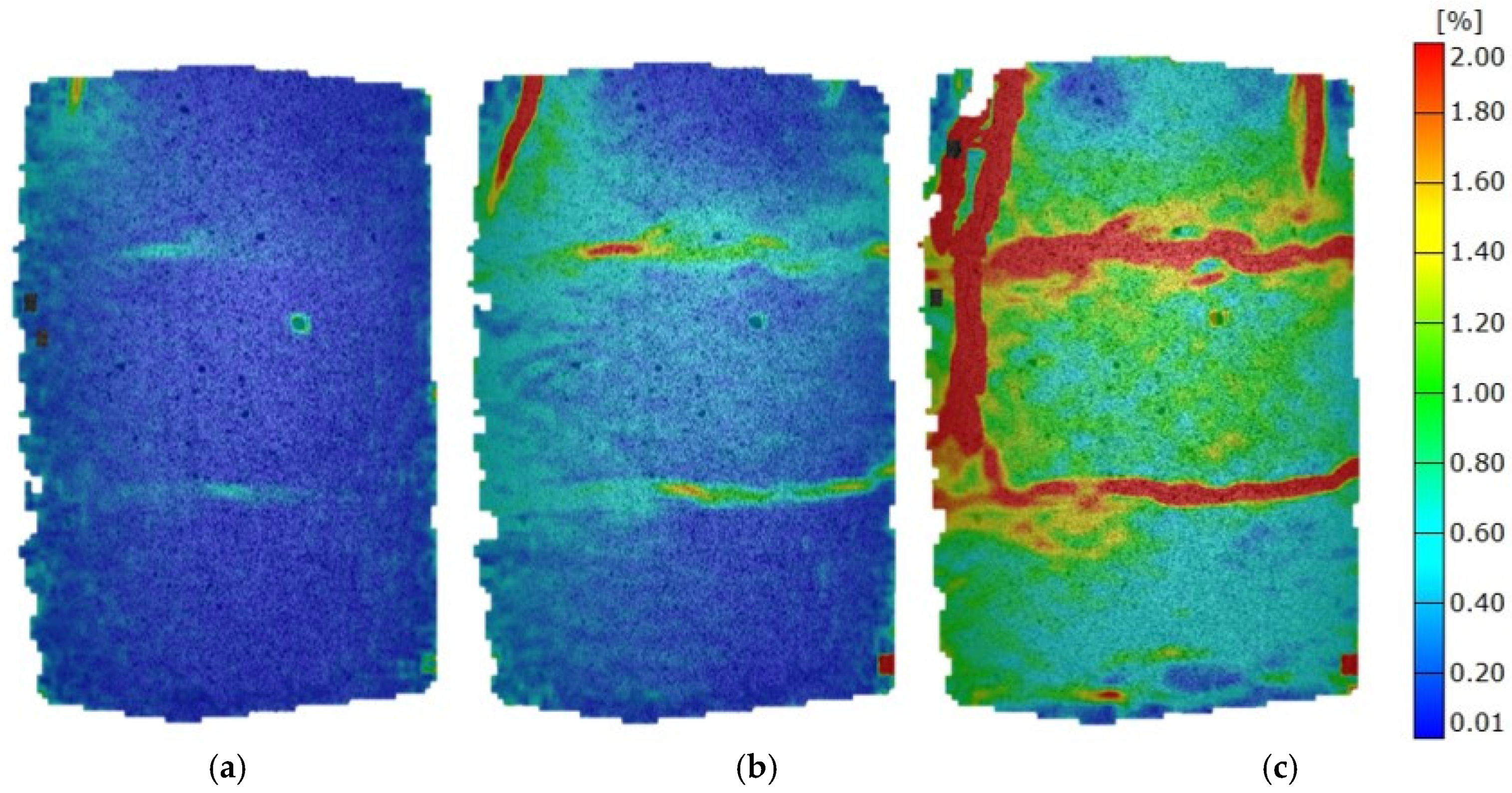

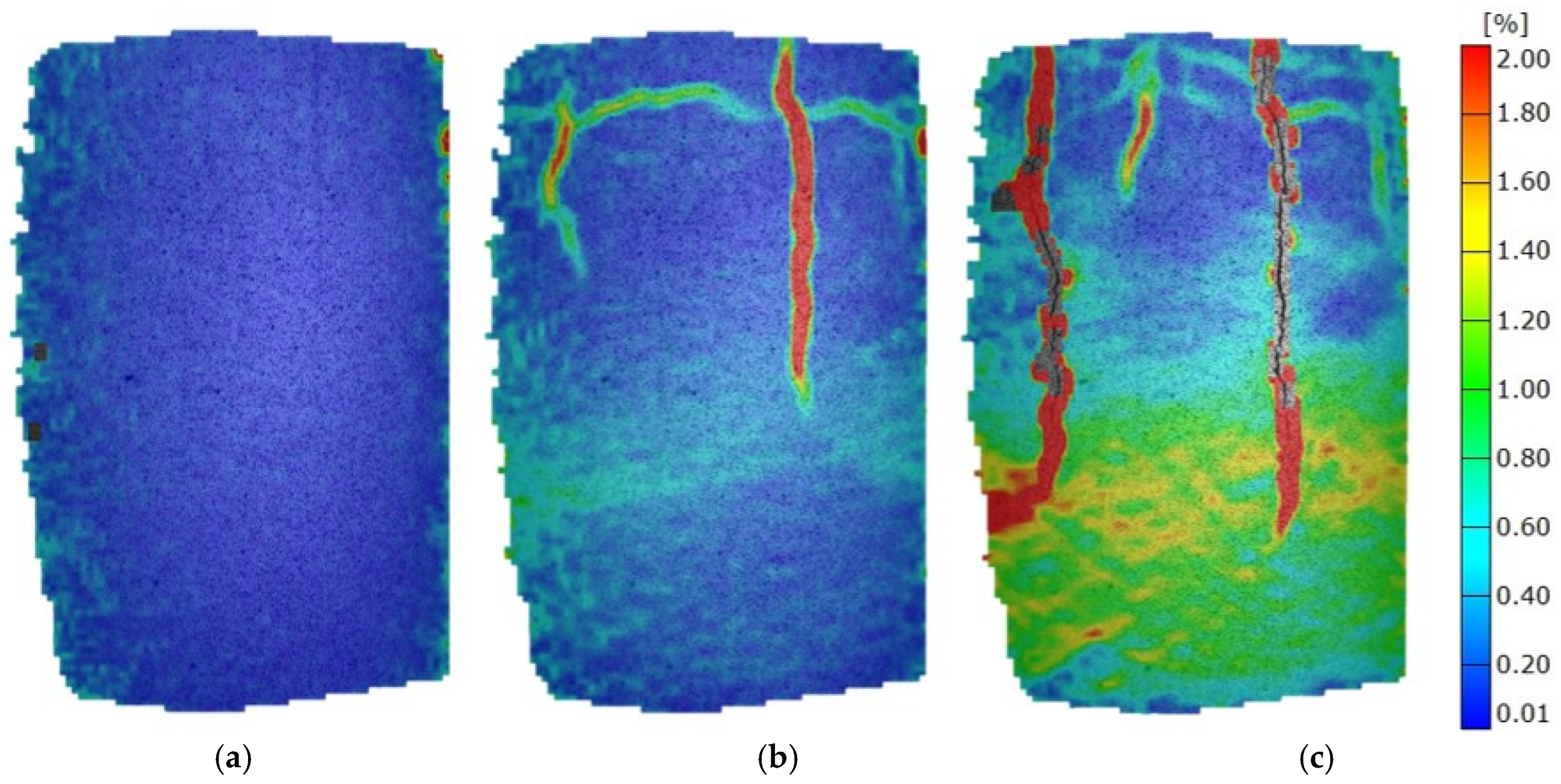

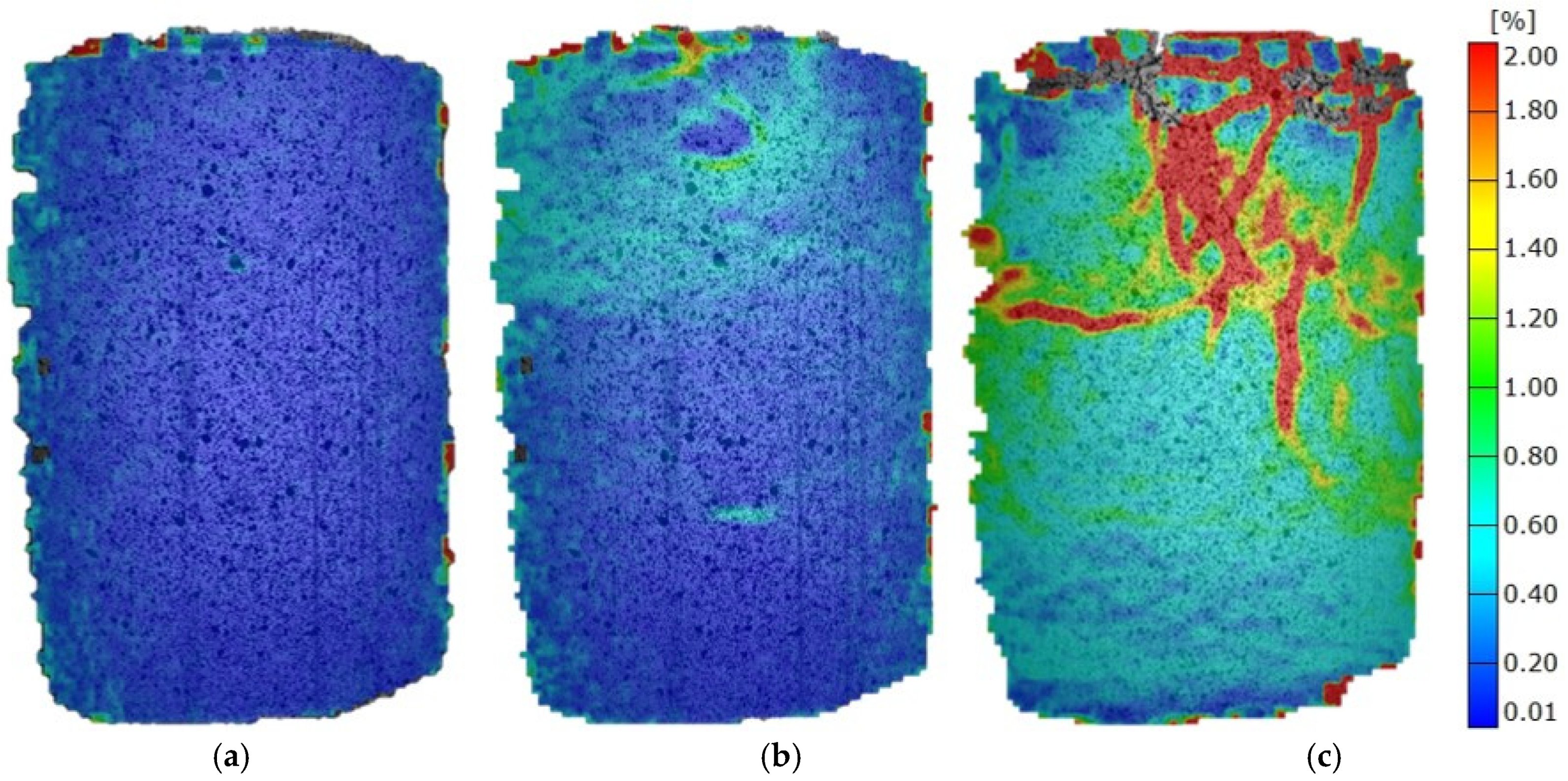

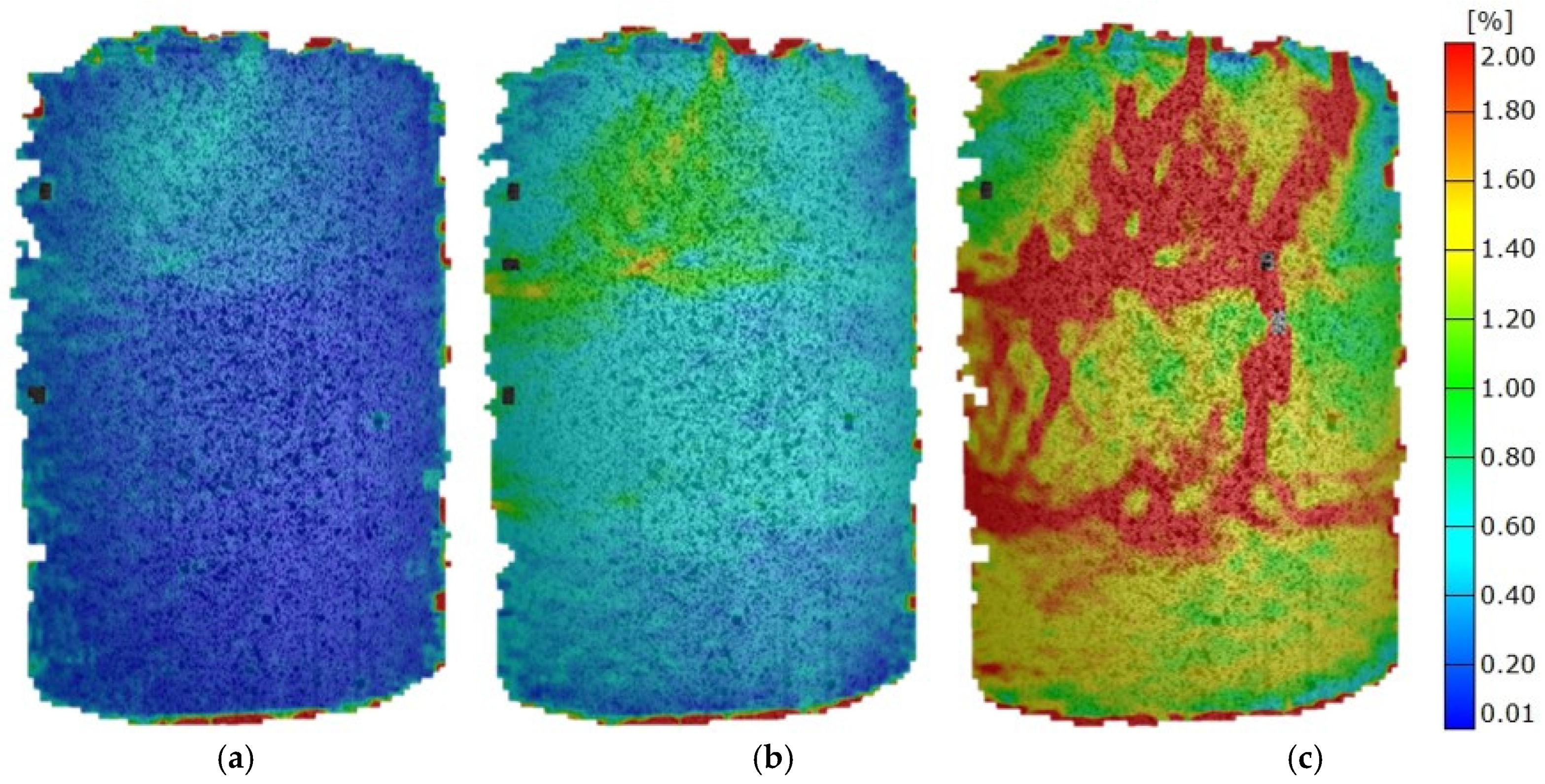

2.3. Elastic Properties-3D Digital Image Correlation

3. Results and Discussion

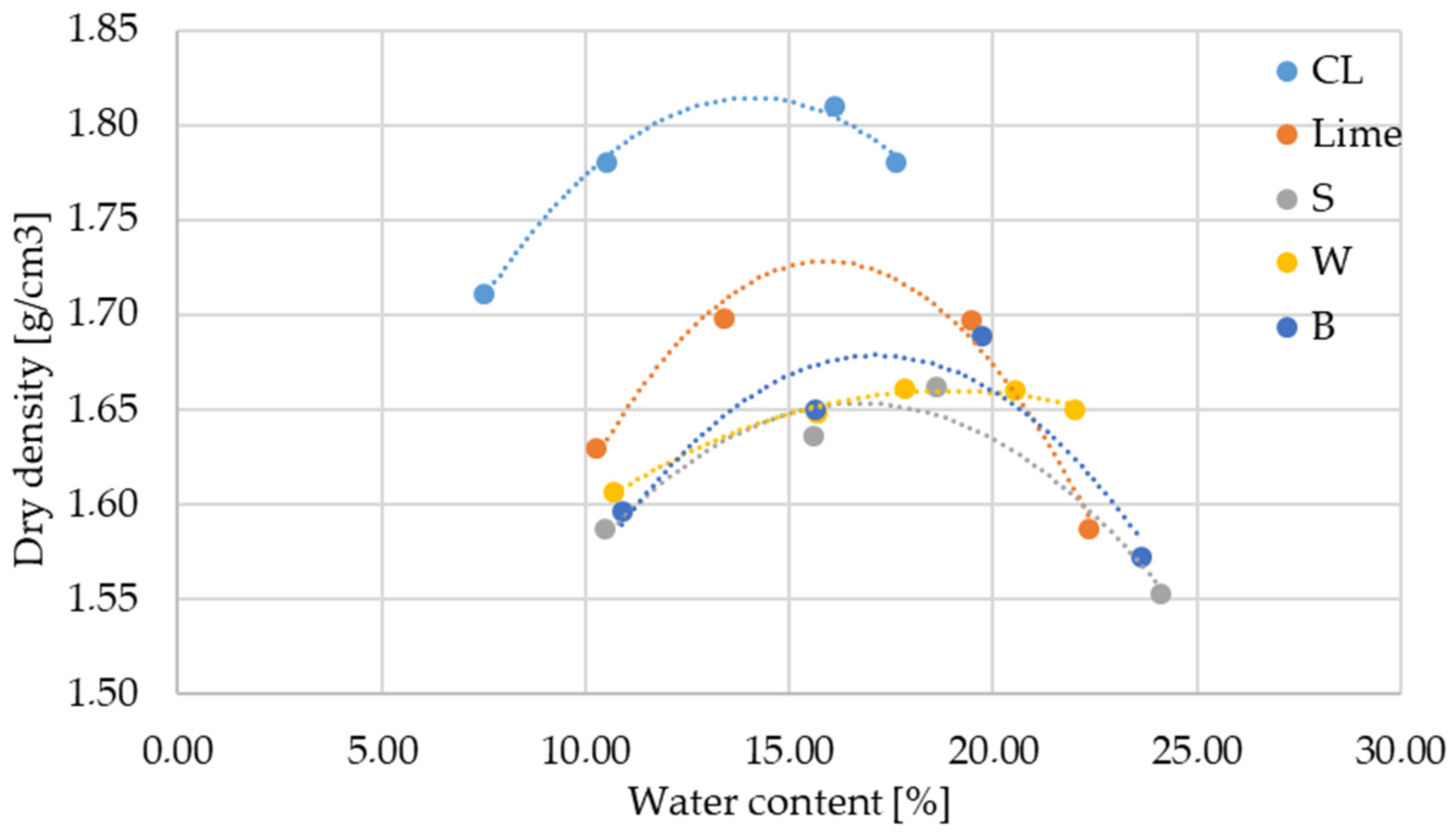

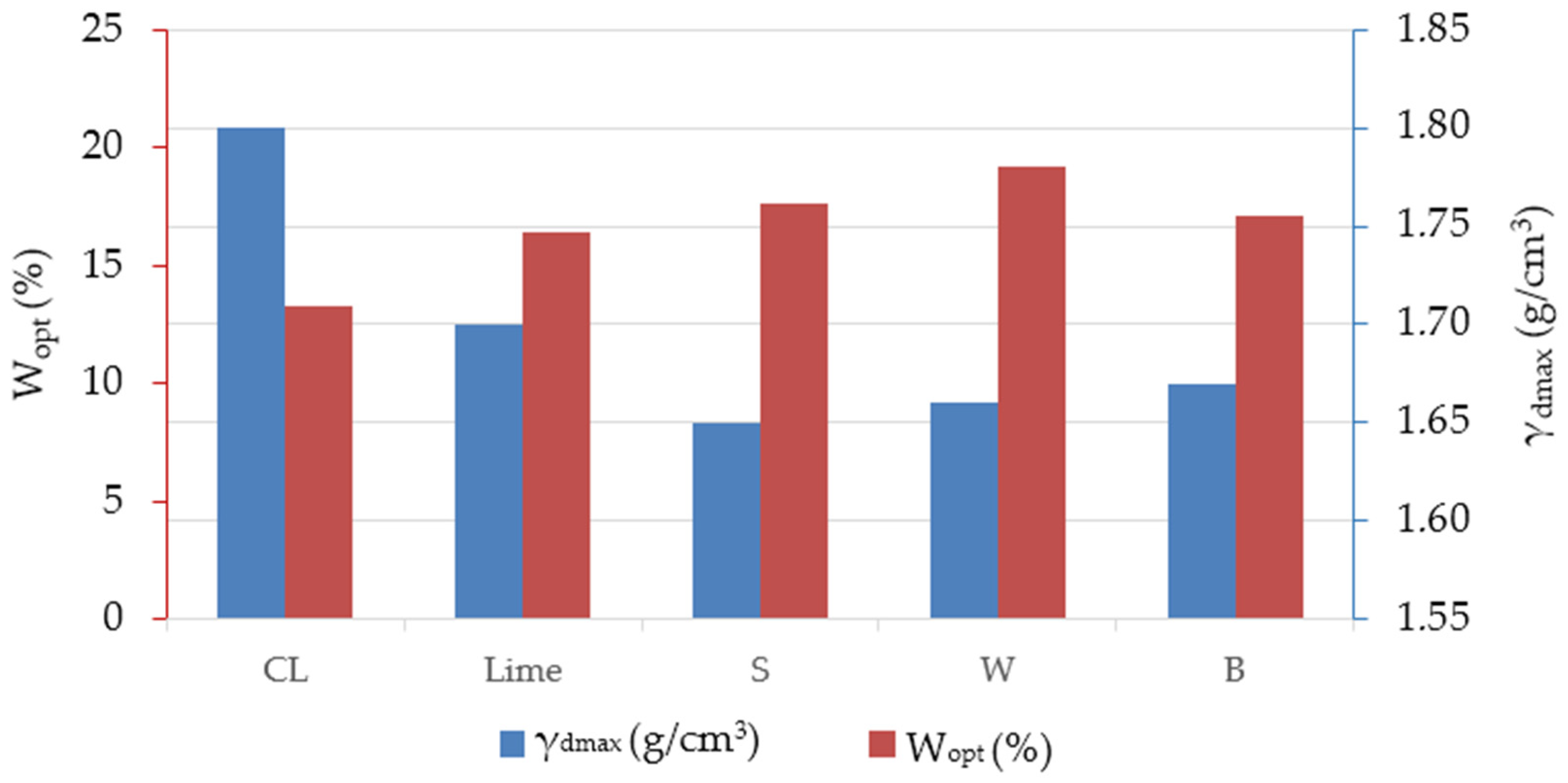

3.1. Geotechnical Characteristics

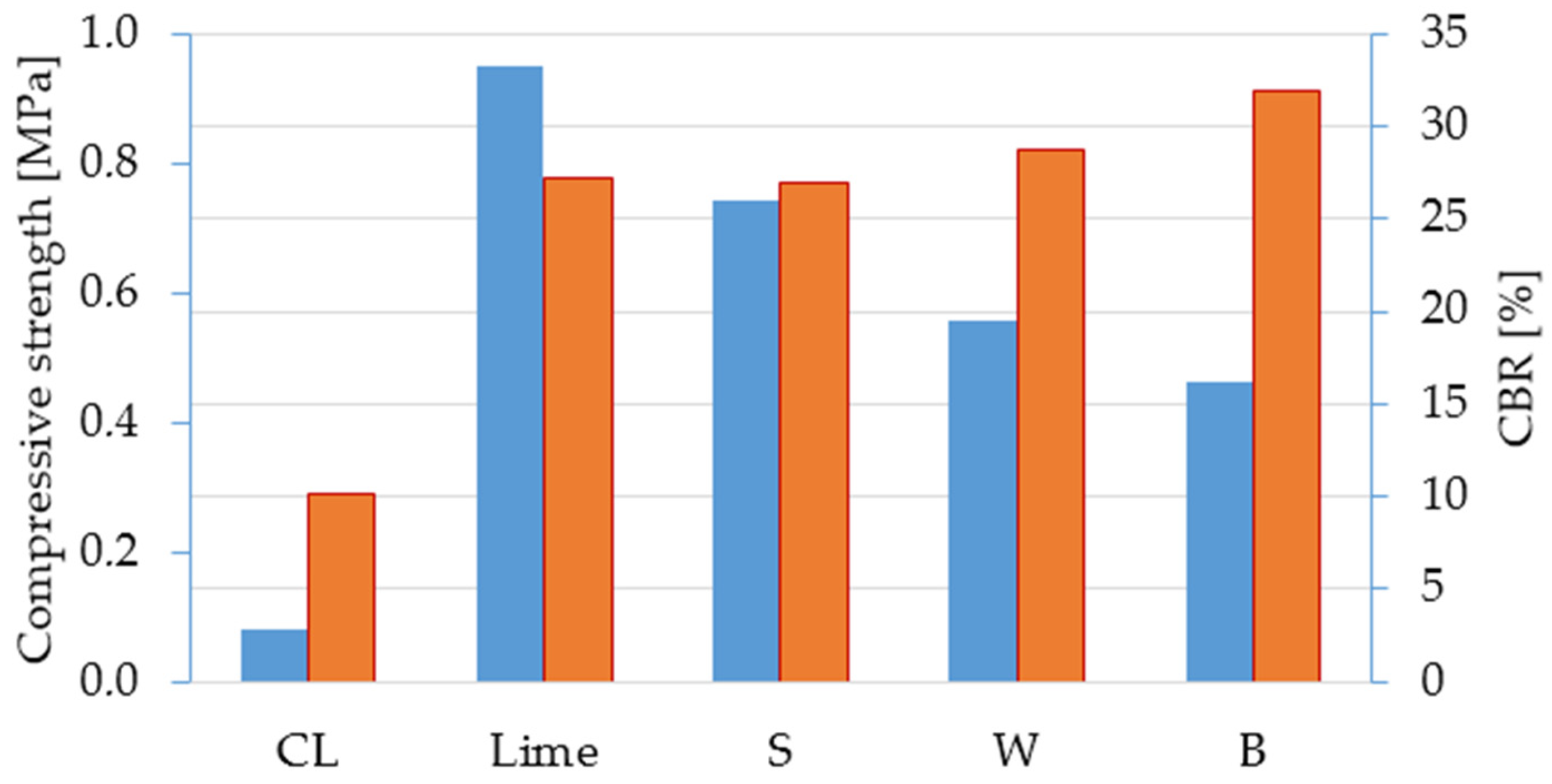

3.2. Strength Characteristics

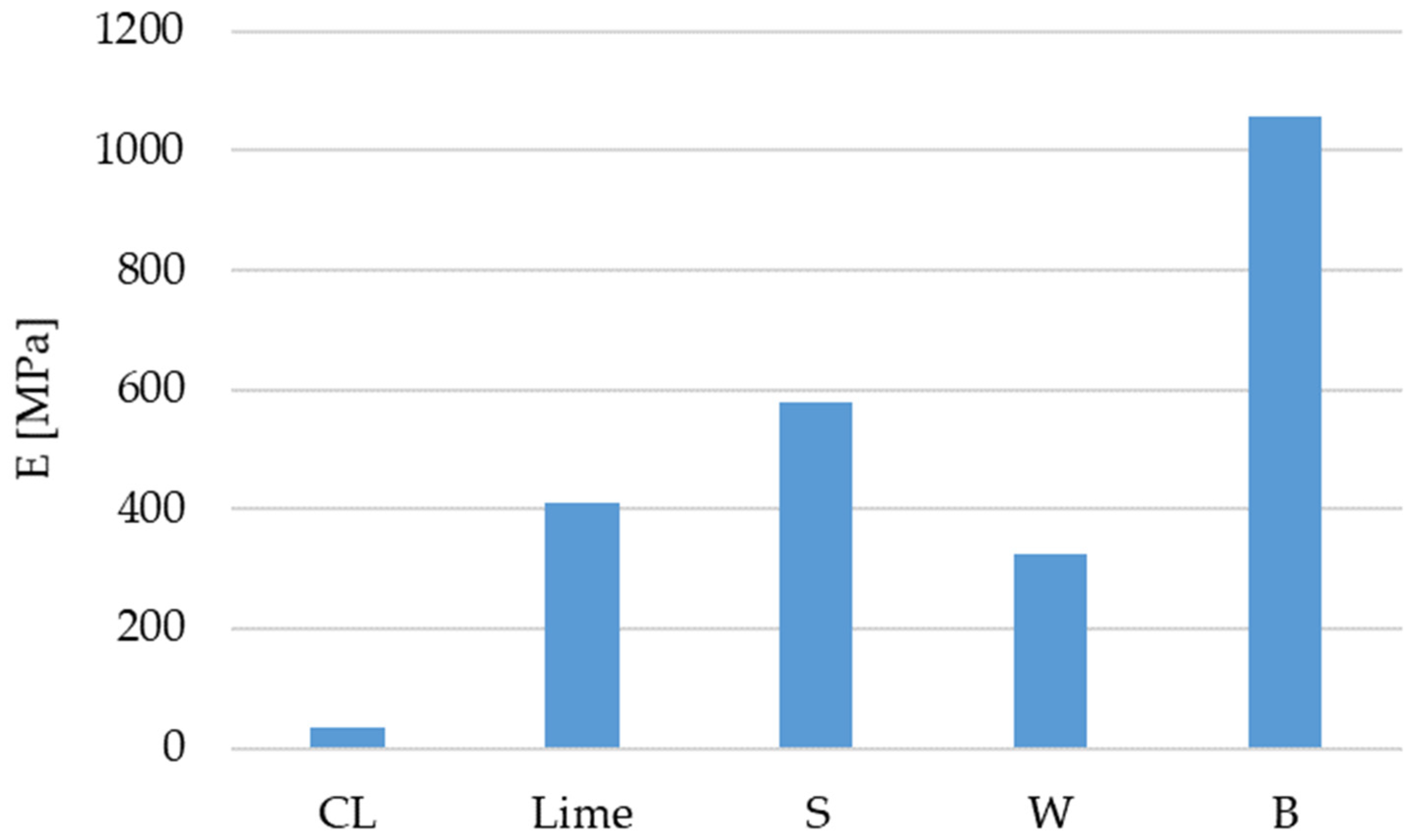

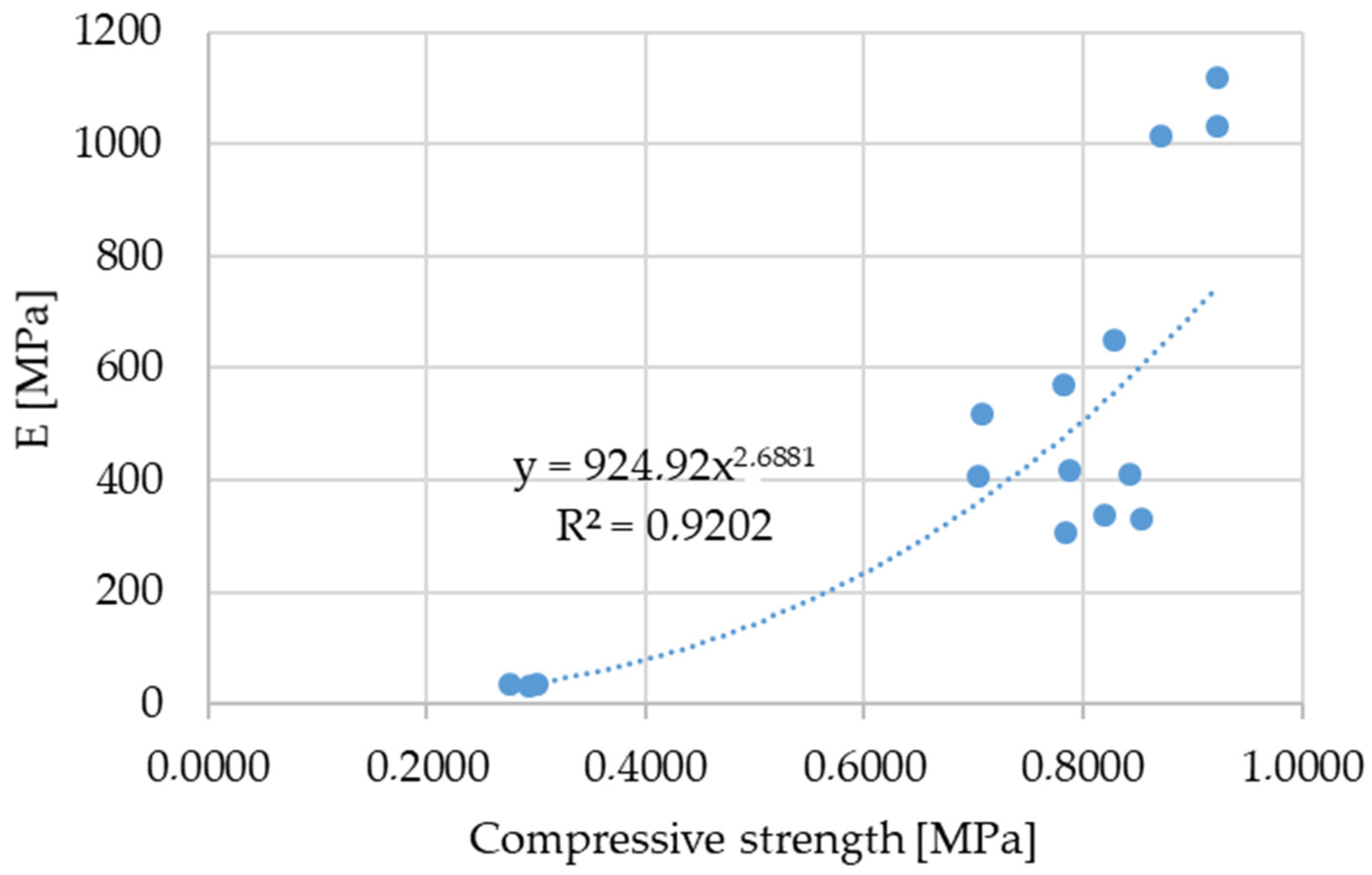

3.3. Elastic Properties and Fracture Mechanism

4. Conclusions

- A lime/biomass fly ash binder improved the geotechnical characteristics of low plasticity clay by reducing the plasticity index and linear swelling and increasing the optimal moisture content.

- When evaluating the potential application of biomass fly ash as a binder substitute, its chemical composition needs to be considered.

- The addition of biomass fly ash results in a soaked CBR value decrease and a compressive strength increase.

- The strength characteristics of stabilised soil incorporating biomass fly ash are highly dependent on its chemical composition.

- The elastic properties of stabilised soil correlate to a fracture mechanism.

- Using a 3D digital image correlation technique as a modern research tool can be efficiently used for fracture mechanism and elastic properties analyses of hydraulically stabilised soil for road works.

- There is a strong correlation between Young’s modulus of elasticity and compressive strength, which can be used for its prediction for pavement design purposes.

Author Contributions

Funding

Conflicts of Interest

References

- Bilandžija, N.; Voća, N.; Jelcic, B.; Jurišić, V.; Matin, A.; Grubor, M.; Krička, T. Evaluation of Croatian agricultural solid biomass energy potential. Renew. Sustain. Energy Rev. 2018, 93, 225–230. [Google Scholar] [CrossRef]

- Carević, I.; Banjad Pečur, I.; Štirmer, N.; Milovanović, B.; Baričević, A. Potencijal biopepela i stanje u Republici Hrvatskoj. In Proceedings of the Sabor hrvatskih graditelja 2016—EU i hrvatsko graditeljstvo, Cavtat, Croatia, 17–18 November 2016. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Melotti, R.; Santagata, E.; Bassani, M.; Salvo, M.; Rizzo, S. A preliminary investigation into the physical and chemical properties of biomass ashes used as aggregate fillers for bituminous mixtures. Waste Manag. 2013, 33, 1906–1917. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Tahami, S.A.; Arabani, M.; Mirhosseini, A.F. Usage of two biomass ashes as filler in hot mix asphalt. Constr. Mater. 2018, 170, 547–556. [Google Scholar] [CrossRef]

- Shrivas, A.; Jain, D.; Joshi, R. Application of Different Waste in Concrete as a Partial Replacement of Cement. Int. J. Sci. Technol. Eng. 2015, 2, 89–107. [Google Scholar]

- Aksogan, O.; Binici, H.; Ortlek, E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Mater. 2016, 106, 253–263. [Google Scholar] [CrossRef]

- Cabrera, M.; Rosales, J.; Ayuso, J.; Estaire, J.; Agrela, F. Feasibility of using olive biomass bottom ash in the sub-bases of roads and rural paths. Constr. Mater. 2018, 181, 266–275. [Google Scholar] [CrossRef]

- Basha, E.; Hashim, R.; Mahmud, H.; Muntohar, A. Stabilization of residual soil with rice husk ash and cement. Constr. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Yadav, A.K.; Gaurav, K.; Kishor, R.; Suman, S. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Anupam, A.K.; Kumar, P.; Ransinchung, G.D. Use of Various Agricultural and Industrial Waste Materials in Road Construction. Procedia -Soc. Behav. Sci. 2013, 104, 264–273. [Google Scholar] [CrossRef]

- Chaunsali, P.; Uvegi, H.; Osmundsen, R.; Laracy, M.; Poinot, T.; Ochsendorf, J.; Olivetti, E. Mineralogical and microstructural characterization of biomass ash binder. Cem. Concr. Compos. 2018, 89, 41–51. [Google Scholar] [CrossRef]

- Kharade, A.S.; Suryavanshi, V.V.; Gujar, B.S.; Deshmukh, R.R. Waste product ‘bagasse ash’ from sugar industry can be used as stabilizing material for expansive soils. Int. J. Res. Eng. Technol. 2014, 3, 506–512. [Google Scholar]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Remediation of Expansive Soils Using Agricultural Waste Bagasse Ash. Procedia Eng. 2016, 143, 1368–1375. [Google Scholar] [CrossRef]

- Amu, O.; Ogunniyi, S.; Oladeji, O. Geotechnical properties of lateritic soil stabilized with sugarcane straw ash. Am. J. Sci. Ind. 2011, 2, 323–331. [Google Scholar] [CrossRef]

- Singh, M.; Sharma, R. Soill stabilization using industrial waste (wheat husk and sugarcane straw ash). Int. J. Res. Eng. Technol. 2017, 4, 589–596. [Google Scholar]

- Anupam, A.K.; Kumar, P.; Ransinchung, R. Effect of Fly Ash and Rice Husk Ash on Permanent Deformation Behaviour of Subgrade Soil under Cyclic Triaxial Loading. Transp. Procedia 2016, 17, 596–606. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Carvajal, M.D.; Ayuso, J. Characterisation and technical feasibility of using biomass bottom ash for civil infrastructures. Constr. Mater. 2014, 58, 234–244. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Castro, J.; Ureña, C.; Azañón, J.M. Stabilisation of clayey and marly soils using industrial wastes: pH and laser granulometry indicators. Eng. Geol. 2016, 200, 10–17. [Google Scholar] [CrossRef]

- Barišić, I.; Dokšanović, T.; Draganić, H. Characterization of hydraulically bound base materials through digital image correlation. Constr. Build. Mater. 2015, 83, 299–307. [Google Scholar] [CrossRef]

- Hossain, K.; Mol, L. Some engineering properties of stabilized clayey soils incorporating natural pozzolans and industrial wastes. Constr. Mater. 2011, 25, 3495–3501. [Google Scholar] [CrossRef]

- Kramar, S.; Ducman, V. Evaluation of Ash Pozzolanic Activity by Means of the Strength Activity Index Test, Frattini Test and DTA/TG Analysis. Teh. -Tech. Gaz. 2018, 25, 1746–1752. [Google Scholar]

- Jaarsveld, J.G.S.; Deventer, J.S.J.; Lukey, G.C. The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Leong, H.Y.; Ong, D.E.L.; Sanjayan, J.G.; Nazari, A. The effect of different Na2O and K2O ratios of alkali activator on compressive strength of fly ash based-geopolymer. Constr. Mater. 2016, 106, 500–511. [Google Scholar] [CrossRef]

- Bose, B. Geo-Engineering Properties of Expansive Soil Stabilized with Fly Ash. Electron. J. Geotech. Eng. 2012, 17, 1339–1353. [Google Scholar]

- Eme, D.B.; Agunwamba, J.C. Prediction of elastic modulus from compessive modulus of lime stabilized lateritic soil for mechanistic design using the split cylinder. Int. J. Eng. Comput. Sci. 2014, 3, 5471–5494. [Google Scholar]

- Ghosh, S.; Datta, T.; Chattapadhyay, B.C. Prediction of Elastic Modulus of Soil Subgrade from Its Various Engineering Properties. In Proceedings of the Indian Geotechnical Conference, Guwahati, India, 14–16 December 2017. [Google Scholar]

- Kaakkurivaara, T.; Kolisoja, P.; Uusitalo, J.; Vuorimies, N. Fly Ash in Forest Road Rehabilitation. Croat. J. For. Eng. 2016, 37, 119–130. [Google Scholar]

- Khatami, H.; Deng, A.; Jaksa, M. An experimental study of the active arching effect in soil using the digital image correlation technique. Comput. Geotech. 2019, 108, 183–196. [Google Scholar] [CrossRef]

| Oxides (mas.%) | S | B | W |

|---|---|---|---|

| P2O5 | 18.71 | 4.40 | 6.70 |

| Na2O | <0.10 | 0.26 | 0.21 |

| K2O | 24.13 | 44.16 | 32.46 |

| CaO | 28.68 | 10.20 | 15.26 |

| MgO | 21.68 | 4.15 | 7.19 |

| Al2O3 | 0.52 | 0.68 | 0.86 |

| TiO2 | 0.01 | 0.03 | 0.05 |

| Fe2O3 | 0.31 | 0.38 | 0.63 |

| SiO2 | 1.96 | 23.38 | 29.49 |

| MnO | 0.08 | 0.03 | 0.05 |

| SO3 | 3.91 | 12.34 | 7.11 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barišić, I.; Netinger Grubeša, I.; Dokšanović, T.; Marković, B. Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials 2019, 12, 1375. https://doi.org/10.3390/ma12091375

Barišić I, Netinger Grubeša I, Dokšanović T, Marković B. Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials. 2019; 12(9):1375. https://doi.org/10.3390/ma12091375

Chicago/Turabian StyleBarišić, Ivana, Ivanka Netinger Grubeša, Tihomir Dokšanović, and Berislav Marković. 2019. "Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works" Materials 12, no. 9: 1375. https://doi.org/10.3390/ma12091375

APA StyleBarišić, I., Netinger Grubeša, I., Dokšanović, T., & Marković, B. (2019). Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials, 12(9), 1375. https://doi.org/10.3390/ma12091375