Morphological Development of Sub-Grain Cellular/Bands Microstructures in Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experiment Arrangement and Procedures

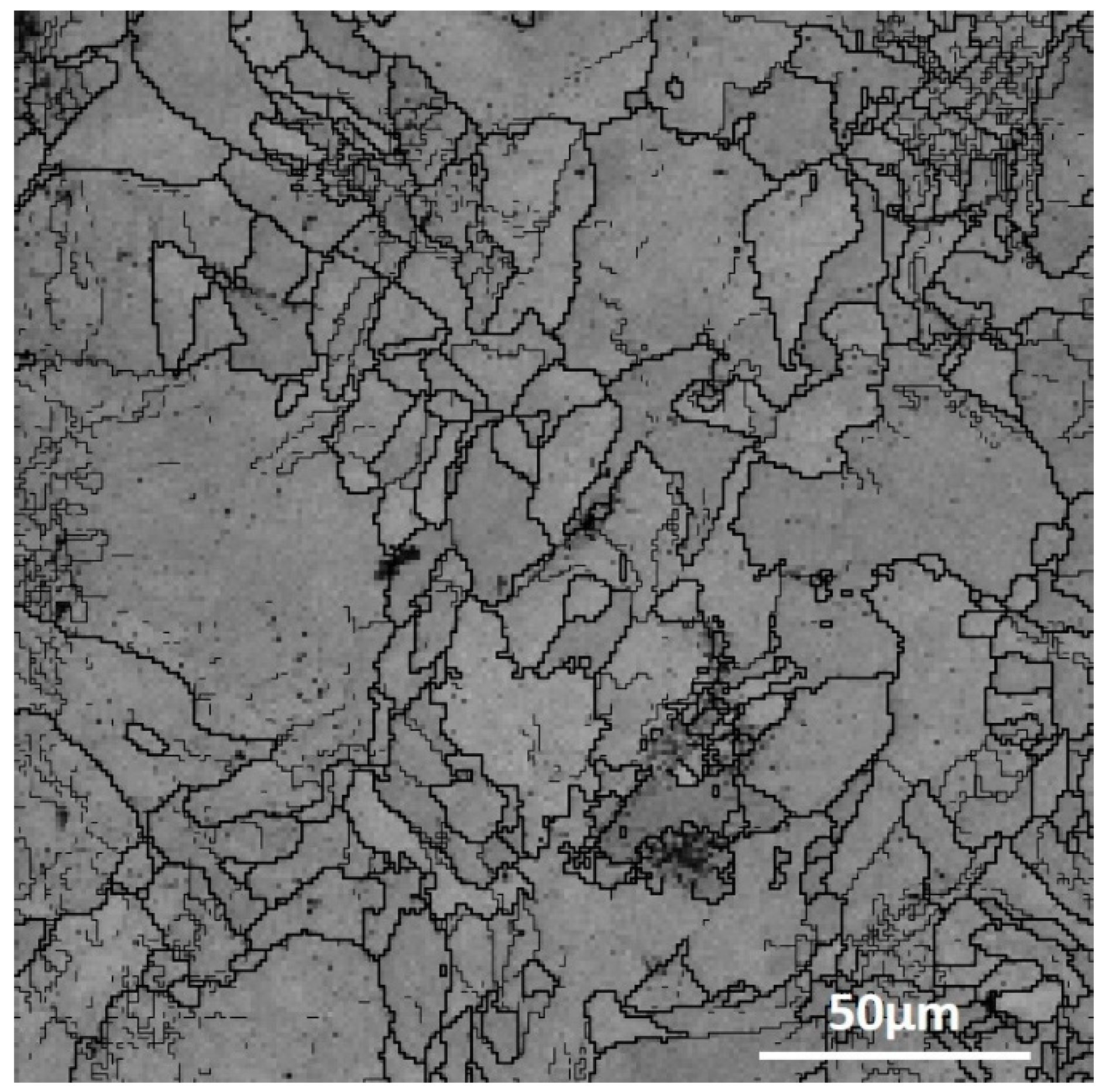

2.3. Microstructural Characterization

3. Results

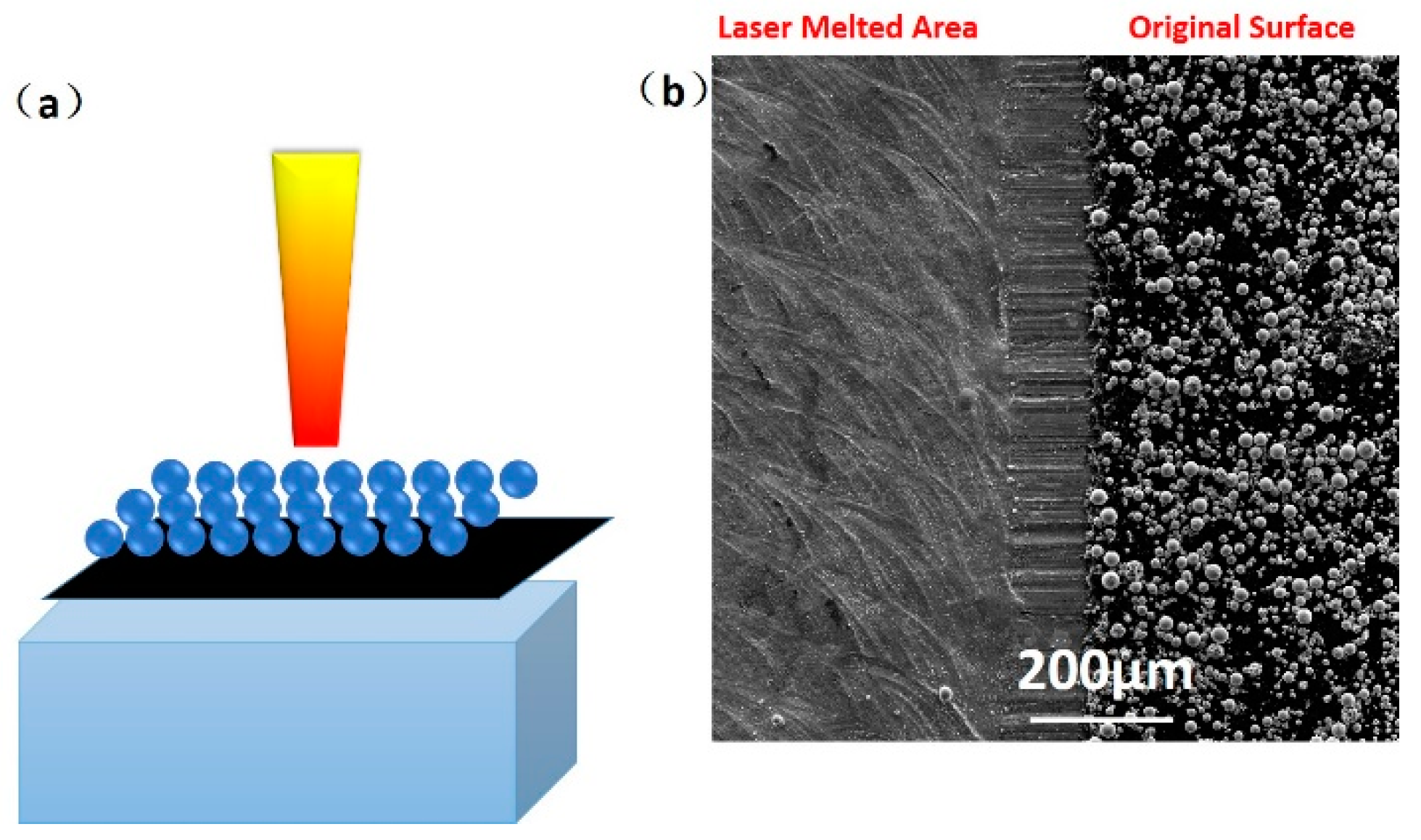

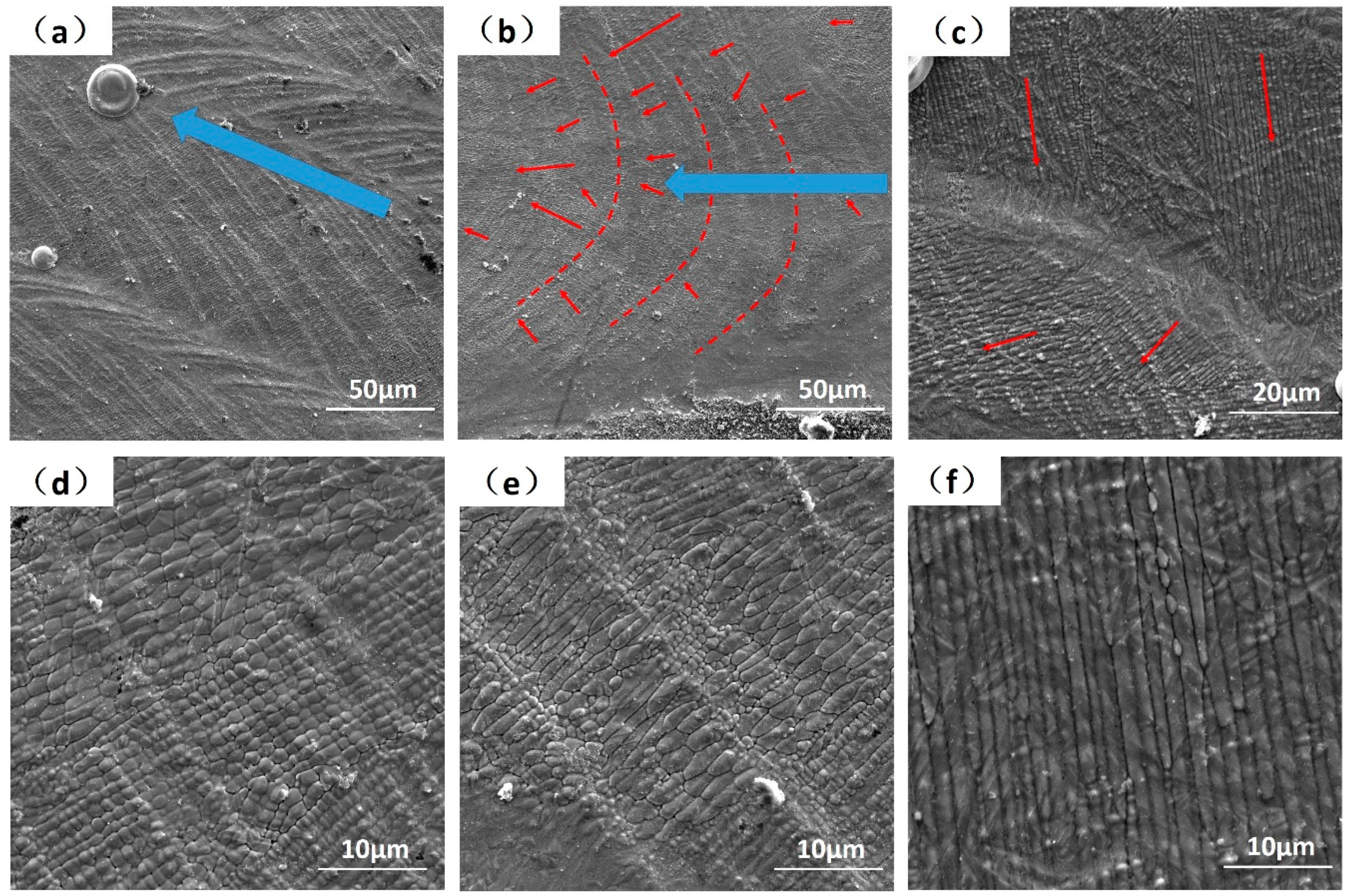

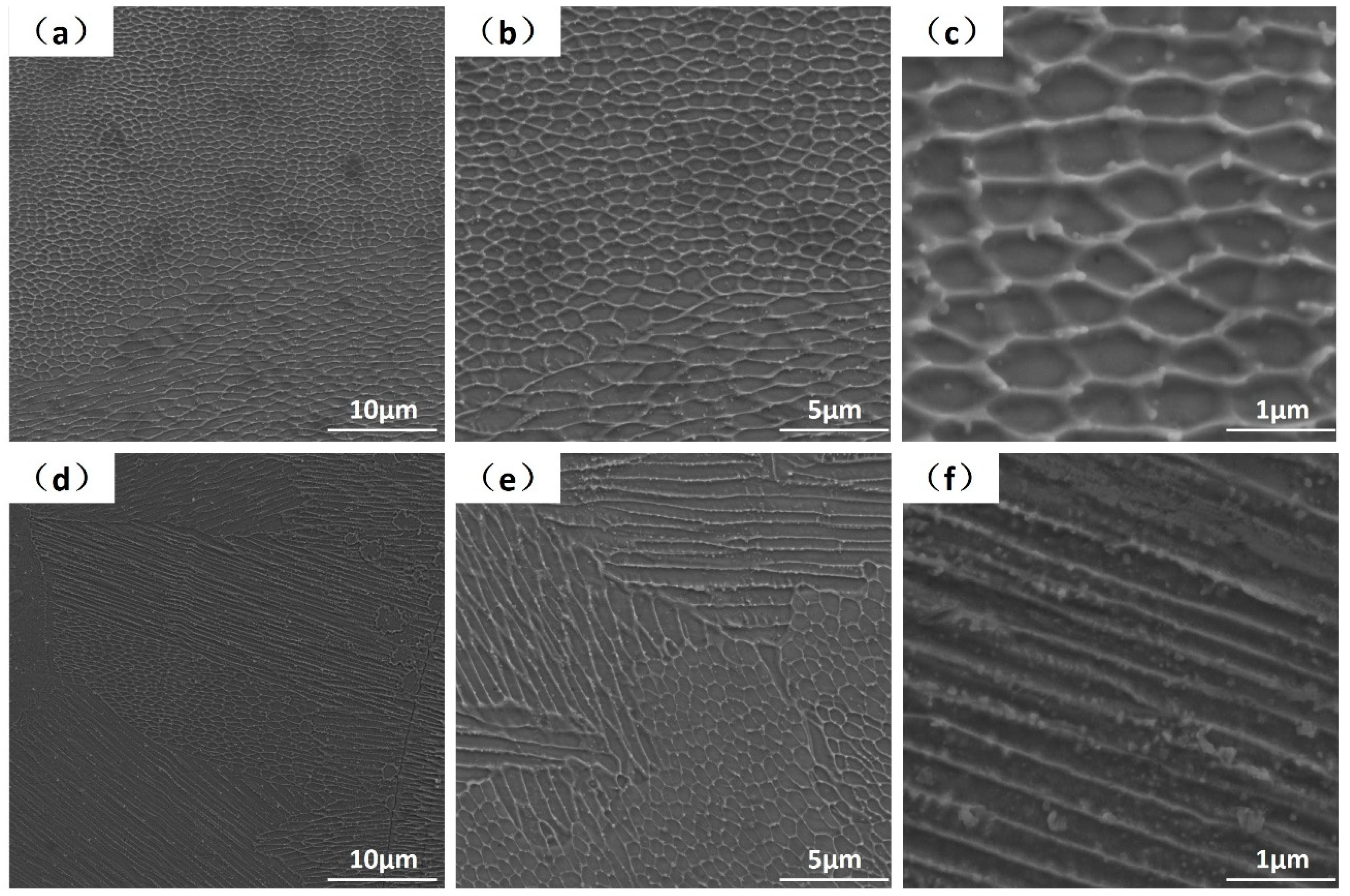

3.1. The Top Surface Morphologies of Single-Layer Laser Melting

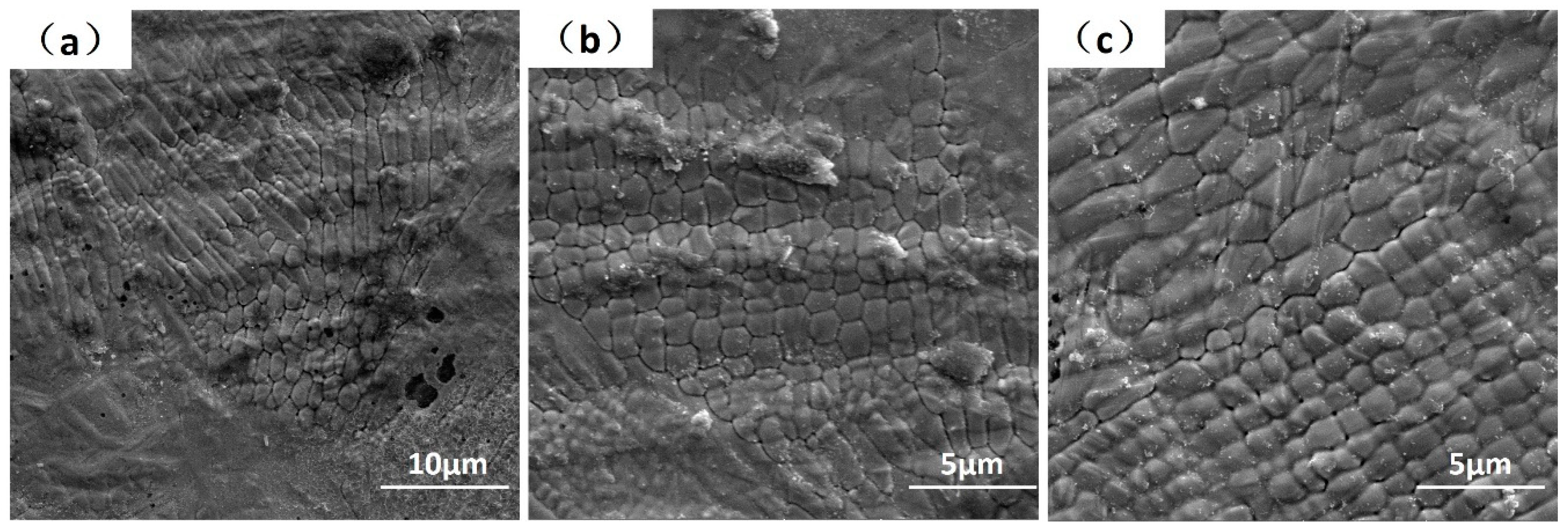

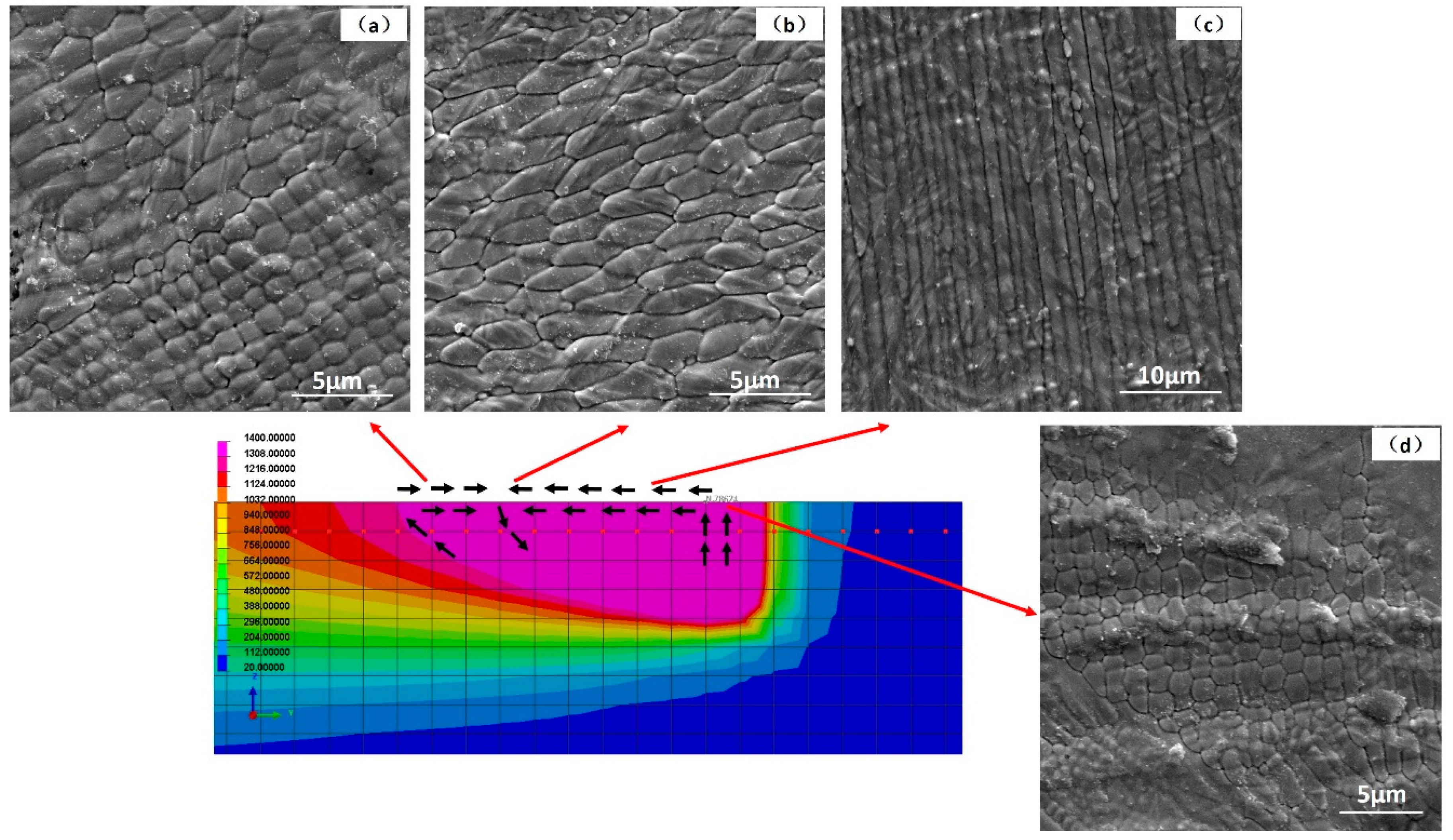

3.2. The Sub-Grain Cellular/Bands Microstructures

3.3. The TEM Observation

4. Discussion

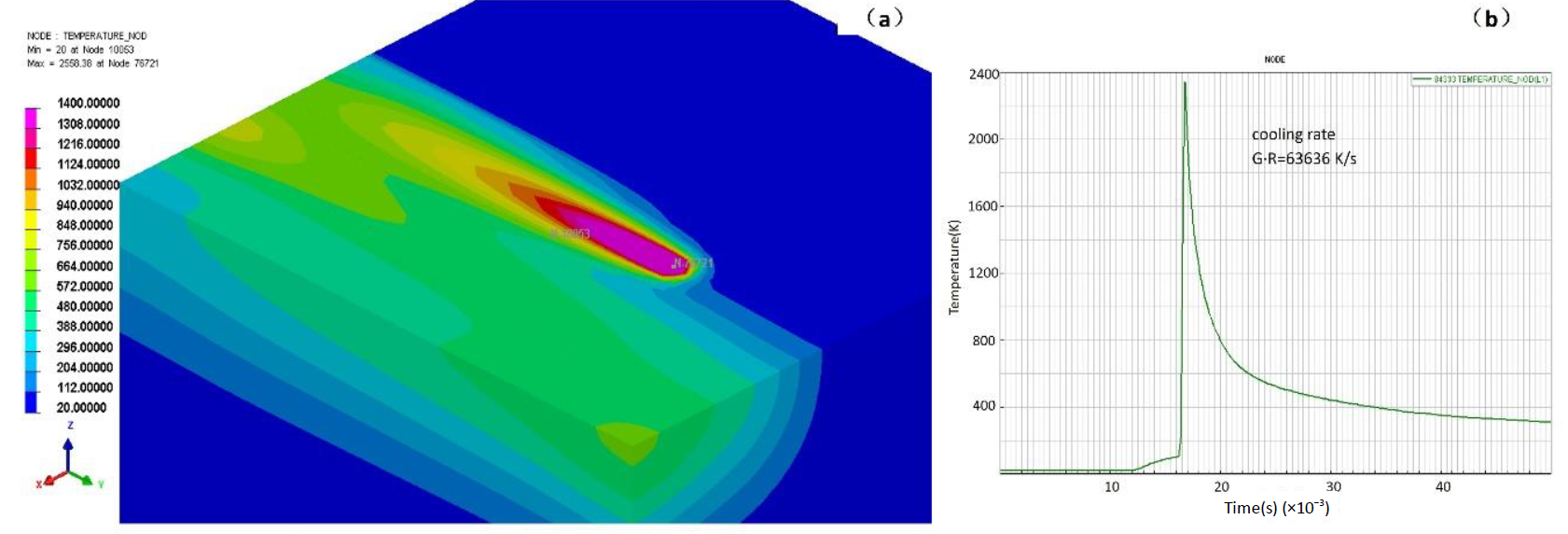

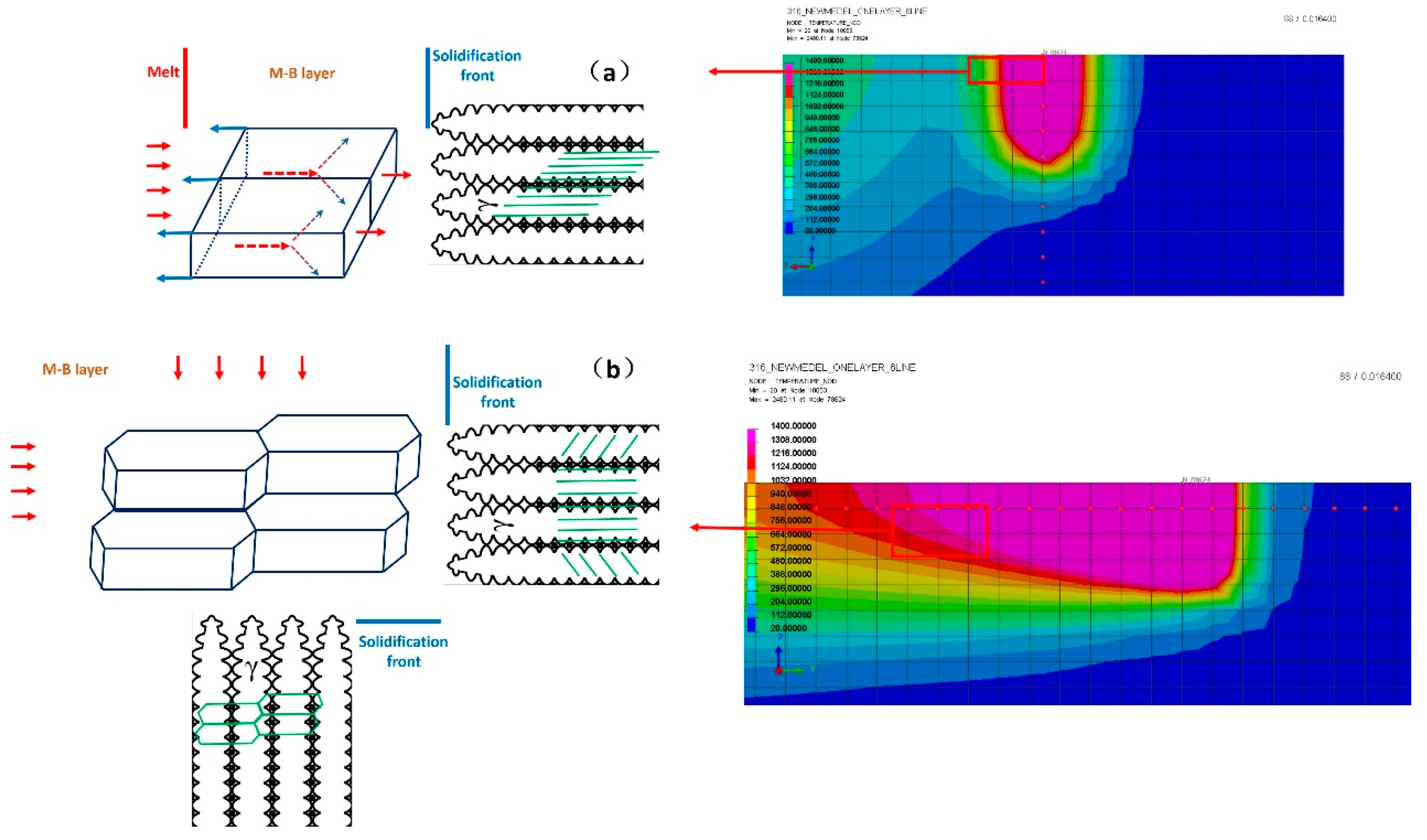

4.1. The Complex Thermocapillary and Solutocapillary Convections in the Melt Pool

4.2. Bénard Instabilities and Cellular Microstructures in Front of the S/L Interface

4.3. The Micro-Segregations of Sub-Grain Cellular Structures

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Zhou, X.; Li, K.; Zhang, D.; Liu, X.; Ma, J.; Liu, W.; Shen, Z.; Li, K.; Zhang, D.; Liu, X.; et al. Textures formed in a CoCrMo alloy by selective laser melting. J. Alloy. Compd. 2015, 631, 153–164. [Google Scholar] [CrossRef]

- Oliveira, J.; Cavaleiro, A.; Schell, N.; Stark, A.; Miranda, R.; Ocana, J.; Fernandes, F.B. Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing. Scr. Mater. 2018, 152, 122–126. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of Metal and Alloy Components by Additive Manufacturing: Examples of 3D Materials Science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and proper ties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Hierarchical design principles of selective laser melting for high quality metallic objects. Addit. Manuf. 2015, 7, 45–56. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Gao, M.; Zeng, X. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.; Contuzzi, N.; Ludovico, A. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Lofaj, F.; Kvetková, L.; Shen, Z. Transformation of austenite to duplex austenite-ferrite assembly in annealed stainless steel 316L consolidated by laser melting. J. Alloy. Compd. 2015, 633, 463–469. [Google Scholar] [CrossRef]

- Bartkowiak, K.; Ullrich, S.; Frick, T.; Schmidt, M. New Developments of Laser Processing Aluminium Alloys via Additive Manufacturing Technique. Phys. Procedia 2011, 12, 393–401. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Bhattacharya, S.; Natu, H.; Dutta, B.; Mazumder, J. Microstructural characterization of laser-deposited Al 4047 alloy. Metall. Mater. Trans. A 2013, 44, 2233–2242. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Materialia 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Prashanth, K.; Scudino, S.; Klauss, H.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.; Kühn, U.; Eckert, J.; Gokuldoss, P.K. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Influence of process-induced microstructure and imperfections on mechanical properties of AlSi12 processed by selective laser melting. J. Mater. Process. Technol. 2015, 221, 205–213. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloy. Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Hedberg, Y.S.; Qian, B.; Shen, Z.; Virtanen, S.; Wallinder, I.O. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dent. Mater. 2014, 30, 525–534. [Google Scholar] [CrossRef]

- Takaichi, A.; Suyalatu; Nakamoto, T.; Joko, N.; Nomura, N.; Tsutsumi, Y.; Migita, S.; Doi, H.; Kurosu, S.; Chiba, A.; et al. Microstructures and mechanical properties of Co–29Cr–6Mo alloy fabricated by selective laser melting process for dental applications. J. Mech. Behav. Biomed. Mater. 2013, 21, 67–76. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Li, J.; Zhao, C.; Zhuo, D.; Lin, J. Investigation on the microstructure, mechanical property and corrosion behavior of the selective laser melted CoCrW alloy for dental application. Mater. Sci. Eng. C 2015, 49, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Song, B.; Dong, S.; Coddet, P.; Liao, H.; Coddet, C. Fabrication of NiCr alloy parts by selective laser melting: Columnar microstructure and anisotropic mechanical behavior. Mater. Des. 2014, 53, 1–7. [Google Scholar] [CrossRef]

- Qian, B.; Saeidi, K.; Kvetková, L.; Lofaj, F.; Xiao, C.; Shen, Z. Defects-tolerant Co-Cr-Mo dental alloys prepared by selective laser melting. Dent. Mater. 2015, 31, 1435–1444. [Google Scholar] [CrossRef]

- España, F.A.; Balla, V.K.; Bandyopadhyay, A. Laser processing of bulk Al–12Si alloy: Influence of microstructure on thermal properties. Philos. Mag. 2011, 91, 574–588. [Google Scholar] [CrossRef]

- Mohanty, P.S.; Mazumder, J. Solidification behavior and microstructural evolution during laser beam—material interaction. Met. Mater. Trans. A 1998, 29, 1269–1279. [Google Scholar] [CrossRef]

- Phanikumar, G.; Dutta, P.; Chattopadhyay, K. Continuous welding of Cu–Ni dissimilar couple using CO2 laser. Sci. Technol. Weld. Join. 2005, 10, 158–166. [Google Scholar] [CrossRef]

- Kianersi, D.; Mostafaei, A.; Mohammadi, J. Effect of Welding Current and Time on the Microstructure, Mechanical Characterizations, and Fracture Studies of Resistance Spot Welding Joints of AISI 316 L Austenitic Stainless Steel. Met. Mater. Trans. A 2014, 45, 4423–4442. [Google Scholar] [CrossRef]

- Fukumoto, S.; Kurz, W. Solidification Phase and Microstructure Selection Maps for Fe-Cr-Ni Alloys. ISIJ Int. 1999, 39, 1270–1279. [Google Scholar] [CrossRef]

- Pinto, M.A.; Cheung, N.; Ierardi, M.C.F.; Garcia, A. Microstructural and hardness investigation of an aluminum–copper alloy processed by laser surface melting. Mater. Charact. 2003, 50, 249–253. [Google Scholar] [CrossRef]

- Guan, Y.; Zhou, W.; Zheng, H.; Hong, M.; Zhu, Y.; Qi, B. Effect of pulse duration on heat transfer and solidification development in laser-melt magnesium alloy. Appl. Phys. A 2015, 119, 437–442. [Google Scholar] [CrossRef]

- Zhong, R.; Kulovits, A.; Wiezorek, J.; Leonard, J. Four-zone solidification microstructure formed by laser melting of copper thin films. Appl. Surf. Sci. 2009, 256, 105–111. [Google Scholar] [CrossRef]

- Jamgotchian, H.; Bergeon, N.; Benielli, D.; Voge, P.; Billia, B.; Guerin, R. Localized Microstructures Induced by Fluid Flow in Directional Solidification. Phys. Rev. Lett. 2001, 87, 166105. [Google Scholar] [CrossRef] [PubMed]

- Bergeon, N.; Mota, F.L.; Chen, L.; Tourret, D.; Debierre, J.M.; Guerin, R.; Karma, A.; Billia, B.; Trivedi, R. Dynamical microstructure formation in 3D directional solidification of transparent model alloys: in situ characterization in DECLIC Directional Solidification Insert under diffusion transport in microgravity. IOP Conf. Series: Mater. Sci. Eng. 2015, 84, 012077. [Google Scholar] [CrossRef]

- Lewis, G.K.; Schlienger, E. Practical considerations and capabilities for laser assisted direct metal deposition. Mater. Des. 2000, 21, 417–423. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. The effect of laser pulse width on multiple-layer 316L steel clad microstructure and surface finish. Appl. Surf. Sci. 2003, 208, 411–416. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Pinkerton, A.; Liu, Z.; Manna, I.; Li, L. Microstructure characterisation and process optimization of laser assisted rapid fabrication of 316L stainless steel. Appl. Surf. Sci. 2005, 247, 320–327. [Google Scholar] [CrossRef]

- El Cheikh, H.; Courant, B.; Branchu, S.; Huang, X.; Hascoet, J.; Guillen, R. Direct Laser Fabrication process with coaxial powder projection of 316L steel. Geometrical characteristics and microstructure characterization of wall structures. Opt. Laser Eng. 2012, 50, 1779–1784. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; Hosson, J.T.M.; De Hosson, J.T.M. Microstructural characterization of AISI 431 martensitic stainless steel laser-deposited coatings. J. Mater. Sci. 2011, 46, 3405–3414. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Microstructure and mechanical properties of a novel beta titanium metallic composite by selective laser melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; John Wiley and Sons, Incorporated: Hoboken, NJ, USA, 2003. [Google Scholar]

- Lin, X.; Yang, H.; Chen, J.; Huang, W. Mcriostructures evolution of 316L stainless steel during laser rapid forming. Acta Metall. Sin. 2006, 42, 361–368. [Google Scholar]

- Carrard, M.; Gremaud, M.; Zimmermann, M.; Kurz, W. About the banded structure in rapidly solidified dendritic and eutectic alloys. Acta Mater. 1992, 40, 983–996. [Google Scholar] [CrossRef]

- Kurz, W.; Trivedi, R. Rapid solidification processing and microstructure formation. Mater. Sci. Eng. A 1994, 179, 46–51. [Google Scholar] [CrossRef]

- McKeown, J.T.; Kulovits, A.K.; Liu, C.; Zweiacker, K.; Reed, B.W.; Lagrange, T.; Wiezorek, J.M.; Campbell, G.H. In situ transmission electron microscopy of crystal growth-mode transitions during rapid solidification of a hypoeutectic Al–Cu alloy. Acta Materialia 2014, 65, 56–68. [Google Scholar] [CrossRef]

- Qu, M.; Liu, L.; Cui, Y.; Liu, F.-B. Interfacial morphology evolution in directionally solidified Al-1.5%Cu alloy. Trans. Nonferrous Met. Soc. 2015, 25, 405–411. [Google Scholar] [CrossRef]

- Fukumoto, S.; Kurz, W. The δ to γ transition in Fe-Cr-Ni Alloys during laser treatment. ISIJ Int. 1997, 37, 677–684. [Google Scholar] [CrossRef]

- Fukumoto, S.; Kurz, W. Prediction of the δ to γ transition in austenitic stainless steels during laser treatment. ISIJ Int. 1998, 38, 71–77. [Google Scholar] [CrossRef]

- Rozas, R.E.; Korzhenevskii, A.L.; Bausch, R.; Schmitz, R. Periodic layer formation in the growth of dilute binary alloys. Phys. A Stat. Mech. Appl. 2014, 413, 394–399. [Google Scholar] [CrossRef]

- Asta, M.; Beckermann, C.; Karma, A.; Kurz, W.; Napolitano, R.; Plapp, M.; Purdy, G.; Rappaz, M.; Trivedi, R. Solidification microstructures and solid-state parallels: Recent developments, future directions. Acta Mater. 2009, 57, 941–971. [Google Scholar] [CrossRef]

- Boettinger, W.; Coriell, S.; Greer, A.; Karma, A.; Kurz, W.; Rappaz, M.; Trivedi, R. Solidification microstructures: recent developments, future directions. Acta Mater. 2000, 48, 43–70. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, D.; Liu, X.; Zhang, D.; Qu, S.; Ma, J.; London, G.; Shen, Z.; Liu, W. 3D-imaging of selective laser melting defects in a Co–Cr–Mo alloy by synchrotron radiation micro-CT. Acta Mater. 2015, 98, 1–16. [Google Scholar] [CrossRef]

- Zhou, X.; Tian, Y. The Simulation of 316L Selective Laser Melting: Thermoanalysis, Melt Flow and Residual Stresses; Tsinghua University: Beijing, China, 2015; p. 218. (In Chinese) [Google Scholar]

- Zhao, Y. Simulation of Fluid Dynamics Behavior and Solidified Structure in Welding Pool. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2004. (In Chinese). [Google Scholar]

- Yuan, Z.; Ke, J.; Li, J. The Surface Tension of Metal and Alloys; Science Press: Beijing, China, 2006. (In Chinese) [Google Scholar]

- Chakraborty, N. The effects of turbulence on molten pool transport during melting and solidification processes in continuous conduction mode laser welding of copper–nickel dissimilar couple. Appl. Therm. Eng. 2009, 29, 3618–3631. [Google Scholar] [CrossRef]

- Koschmieder, E.L. Bénard Cells and Taylor Vortices; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Schwabe, D. Convective instabilities in complex systems with partly free surface. J. Physics Conf. Ser. 2007, 64, 012001. [Google Scholar] [CrossRef]

- Phanikumar, G.; Chattopadhyay, K.; Dutta, P. Modelling of transport phenomena in laser welding of dissimilar metals. Int. J. Numer. Methods Heat Flow 2001, 11, 156–174. [Google Scholar] [CrossRef]

- Mizev, A.I.; Schwabe, D. Convective instabilities in liquid layers with free upper surface under the action of an inclined temperature gradient. Phys. Fluids 2009, 21, 112102. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.; Zhang, D.; Shen, Z.; Liu, W. Balling phenomena in selective laser melted tungsten. J. Mater. Process. Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Ueno, I.; Kurosawa, T.; Kawamura, H. Thermocapillary convection in thin liquid layer with temperature gradient inclined to free surface. In Proceedings of the 12th International Heat and Mass Transfer Conference, Grenoble, France, 18–23 August 2002. [Google Scholar]

- Shklyaev, O.E.; Nepomnyashchy, A.A. Thermocapillary flows under an inclined temperature gradient. J. Mech. 2004, 504, 99–132. [Google Scholar] [CrossRef]

- Egolf, D.A.; Melnikov, I.V.; Pesch, W.; Ecke, R.E. Mechanisms of extensive spatiotemporal chaos in Rayleigh-Bernard convection. Nature 2000, 404, 733–736. [Google Scholar] [CrossRef]

- Schwabe, D.; Mizev, A.I.; Udhayasankar, M.; Tanaka, S. Formation of dynamic particle accumulation structures in oscillatory thermocapillary flow in liquid bridges. Phys. Fluids 2007, 19, 072102. [Google Scholar] [CrossRef]

- Schatz, M.F.; VanHook, S.J.; McCormick, W.D.; Swift, J.B.; Swinney, H.L. Time-independent square patterns in surface-tension-driven Bénard convection. Phys. Fluids 1999, 11, 2577–2582. [Google Scholar] [CrossRef]

- Kotecki, D.J.; Lippold, J.C. Welding Metallurgy and Weldability of Stainless Steels; John Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Schwabe, D.; Mizev, A.; Tanaka, S.; Kawamura, H. Particle accumulation structures in time-dependent thermocapillary flow in a liquid bridge under microgravity. Sci. Technol. 2006, 18, 117–127. [Google Scholar] [CrossRef]

- Schwabe, D.; Frank, S. Particle accumulation structures (PAS) in the toroidal thermocapillary vortex of a floating zone—Model for a step in planet-formation? Adv. Res. 1999, 23, 1191–1196. [Google Scholar] [CrossRef]

- Schwabe, D. Particle accumulation structures (PAS) in thermocapillary flow in floating zones. In proceeding of the 2nd European Symposium on the Utilisation of the International Space Station, Noordwijk, The Netherlands, 24–26 November 1998. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhou, X.; Xu, B.; Ma, J.; Zhao, C.; Shen, Z.; Liu, W. Morphological Development of Sub-Grain Cellular/Bands Microstructures in Selective Laser Melting. Materials 2019, 12, 1204. https://doi.org/10.3390/ma12081204

Liu X, Zhou X, Xu B, Ma J, Zhao C, Shen Z, Liu W. Morphological Development of Sub-Grain Cellular/Bands Microstructures in Selective Laser Melting. Materials. 2019; 12(8):1204. https://doi.org/10.3390/ma12081204

Chicago/Turabian StyleLiu, Xihe, Xin Zhou, Ben Xu, Jing Ma, Congcong Zhao, Zhijian Shen, and Wei Liu. 2019. "Morphological Development of Sub-Grain Cellular/Bands Microstructures in Selective Laser Melting" Materials 12, no. 8: 1204. https://doi.org/10.3390/ma12081204

APA StyleLiu, X., Zhou, X., Xu, B., Ma, J., Zhao, C., Shen, Z., & Liu, W. (2019). Morphological Development of Sub-Grain Cellular/Bands Microstructures in Selective Laser Melting. Materials, 12(8), 1204. https://doi.org/10.3390/ma12081204