Fatigue and Corrosion Fatigue Behaviour of Brazed Stainless Steel Joints AISI 304L/BAu-4 in Synthetic Exhaust Gas Condensate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

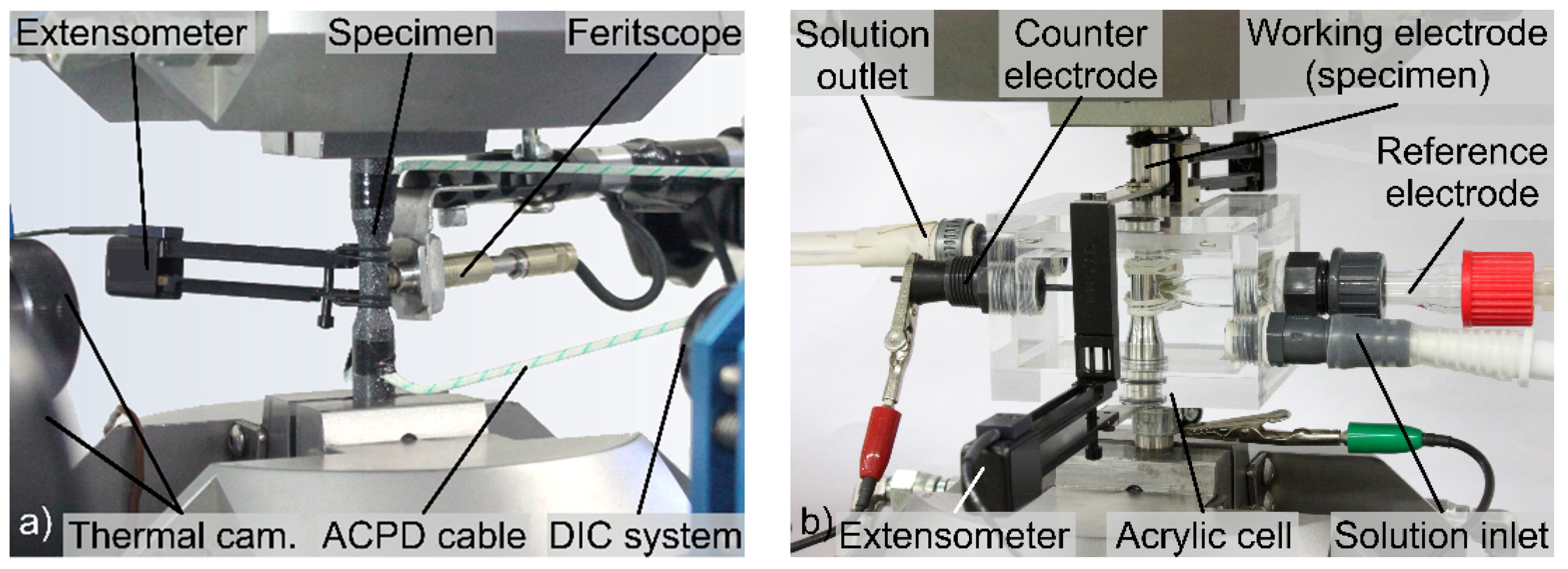

2.2. Experimental Setup and Procedure

3. Results and Discussion

3.1. Fatigue Behaviour in Air

3.2. Corrosion Fatigue Behaviour in a Synthetic Exhaust Gas Condensate

3.3. Fractographic Analysis

4. Conclusions

- For the as-received brazed specimens, a fatigue strength of 397 MPa at 2 × 106 cycles was determined. The S-N curve and the cyclic deformation behaviour of the brazed joints were characteristic for the metastable austenitic base material.

- Corrosion fatigue loading in a synthetic condensate led to a significant degradation of the fatigue properties, with a reduction of the fatigue strength at 2 × 106 cycles down to 51% (202 MPa). Since corrosion mechanisms are known to be time-dependent, test frequencies that are representative of service conditions have to be investigated.

- Strain, electrical, magnetic, temperature and electrochemical measurement techniques within fatigue and corrosion fatigue tests are well applicable to characterise the cyclic deformation and damage behaviour of the brazed joints.

- In the synthetic condensate, a single fatigue crack initiation was environmentally assisted. After six weeks of pre-corrosion, the corroded diffusion zones facilitated several fatigue crack initiations. As different microstructure-related damage mechanisms were identified, it is recommended to consider both fatigue tests after pre-corrosions and corrosion fatigue tests for the design of brazed components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holländer, U.; Weber, F.; Möhwald, K.; Maier, H.J. Determination of failure criteria of mechanically and corrosively loaded brazed joints of sheets made of stainless chromium-nickel steel. Weld Cut 2015, 5, 280–288. [Google Scholar]

- Bobzin, K.; Tillmann, W. Systematic Investigation of the Properties of Brazed Joints with Application-Relevant Testing Procedures II; Final Report IGF 16.558N; Forschungsvereinigung Schweißen und verwandte Verfahren e.V.: Düsseldorf, Germany, 2012. [Google Scholar]

- Koster, M.; Kenel, C.; Stutz, A.; Lee, W.J. Fatigue and cyclic deformation behaviour of brazed steel joints. Mater. Sci. Eng. A 2013, 581, 90–97. [Google Scholar] [CrossRef]

- Schmiedt, A.; Manka, M.; Tillmann, W.; Walther, F. Characterisation of the corrosion fatigue behaviour of brazed AISI 304L/BNi-2 joints in synthetic exhaust gas condensate. Weld World 2018, 62, 617–627. [Google Scholar] [CrossRef]

- Schmiedt, A.; Manka, M.; Tillmann, W.; Walther, F. Influence of condensate corrosion on tensile and fatigue properties of brazed stainless steel joints AISI 304L/BNi-2 for automotive exhaust systems. Mater. Werkst. 2018, 49, 249–263. [Google Scholar] [CrossRef]

- Fernández, I.; Rosa, E.; Ibarra, Á. Progress on the design of a brazing connector for DEMO in-vessel components. Fusion Eng. Des. 2015, 98, 1483–1487. [Google Scholar] [CrossRef]

- Lugscheider, E.; Klöhn, K.; Lison, R. Strength of high temperature brazed joints—Influence of brazing parameters. In Proceedings of the 10th International AWS-WRC Brazing Conference, Detroit, MI, USA, 3–5 April 1979; pp. 296–300. [Google Scholar]

- Schmiedt, A.; Jaquet, S.; Manka, M.; Tillmann, W.; Walther, F. Tensile and fatigue assessments of brazed stainless steel joints using digital image correlation. MATEC Web Conf. 2018, 165, 06003. Available online: https://www.matec-conferences.org/articles/matecconf/pdf/2018/24/matecconf_fatigue2018_06003.pdf (accessed on 21 February 2019). [CrossRef]

- Nebel, T.; Eifler, D. Cyclic deformation behaviour of austenitic steels at ambient and elevated temperatures. Sadhana 2003, 28, 187–208. [Google Scholar] [CrossRef]

- Hahnenberger, F.; Smaga, M.; Eifler, D. Microstructural investigation of the fatigue behavior and phase transformation in metastable austenitic steels at ambient and lower temperatures. Int. J. Fatigue 2014, 69, 36–48. [Google Scholar] [CrossRef]

- Smaga, M.; Walther, F.; Eifler, D. Deformation-induced martensitic transformation in metastable austenitic steels. Mater. Sci. Eng. A 2008, 483, 394–397. [Google Scholar] [CrossRef]

- Sarkar, A.; De, P.S.; Mahato, J.K.; Kundu, A. Effect of mean stress and solution annealing temperature on ratcheting behaviour of AISI 304 stainless steel. Procedia Eng. 2014, 74, 376–383. [Google Scholar] [CrossRef]

- Kamaya, M.; Kawakubo, M. Mean stress effect on fatigue strength of stainless steel. Int. J. Fatigue 2015, 4, 20–29. [Google Scholar] [CrossRef]

- Dutta, K.; Sivaprasad, S.; Tarafder, S. Influence of asymmetric cyclic loading on substructure formation and ratcheting fatigue behaviour of AISI 304LN stainless steel. Mater. Sci. Eng. A 2010, 527, 7571–7579. [Google Scholar] [CrossRef]

- Krupp, U.; West, C.; Christ, H.J. Deformation-induced martensite formation during cyclic deformation of metastable austenitic steel: Influence of temperature and carbon content. Mater. Sci. Eng. A 2008, 481, 713–717. [Google Scholar] [CrossRef]

- Nikitin, I.; Besel, M. Effect of low-frequency on fatigue behaviour of austenitic steel AISI 304 at room temperature and 25 C. Int. J. Fatigue 2008, 30, 2044–2049. [Google Scholar] [CrossRef]

- Colin, J.; Fatemi, A.; Taheri, S. Cyclic hardening and fatigue behavior of stainless steel 304L. J. Mater. Sci. 2011, 46, 145–154. [Google Scholar] [CrossRef]

- Müller-Bollenhagen, C. Verformungsinduziere Martensitbildung bei Mehrstufiger Umformung und Deren Nutzung zur Optimierung der HCF- und VHCF-Eigenschaften von Austenitischen Edelstahlblech. Ph.D. Thesis, University Siegen, Siegen, Germany, April 2011. [Google Scholar]

- Colbus, J.; Zimmermann, K.F. Properties of gold-nickel alloy brazed joints in high temperature materials. Gold Bull. 1974, 7, 42–49. [Google Scholar] [CrossRef]

- Hurley, M.J.; Knori, K.; Jaques, B. Corrosion and High Temperature Oxidation Behavior of 316L Stainless Steel Joined with Cu-Ag Based Braze Alloys. In Proceedings of the 5th International Brazing and Soldering Conference, Las Vegas, NV, USA, 22–25 April 2012; pp. 139–143. [Google Scholar]

- Davis, J.R. Corrosion of Weldments; ASM International: Materials Park, OH, USA, 2006. [Google Scholar]

- Wang, X.; Li, S.; Peng, J. Corrosion behaviors of 316LN stainless steel joints brazed with Sn-plated silver filler metals. Int. J. Mod. Phys. B 2018, 32, 1850198. [Google Scholar] [CrossRef]

- VDA Test Sheet 230-214 Resistance of Metallic Materials to Condensate Corrosion in Exhaust Gas-Carrying Components; Verband der Automobilindustrie: Berlin, Germany, 2010.

- Schmiedt, A.; Lingnau, L.; Manka, M.; Tillmann, W.; Walther, F. Effect of condensate corrosion on tensile and fatigue properties of brazed AISI 304L stainless steel joints using gold-base filler metal. Proc. Struct. Integr. 2018, 13, 22–27. [Google Scholar] [CrossRef]

- Schmiedt, A.; Manka, M.; Tillmann, W.; Walther, F. Local Quasi-Static and Cyclic Deformation Behaviour of Brazed AISI 304L/BAu-4 Joints Characterised by Digital Image Correlation. 2019. Available online: https://link.springer.com/content/pdf/10.1007%2Fs40194-018-00693-x.pdf (accessed on 21 February 2019).

- Weil, K.S.; Rice, J.P. Substrate effects on the high-temperature oxidation behavior of a gold-based braze filler metal. Scr. Mater. 2005, 52, 1081–1085. [Google Scholar] [CrossRef]

- Smaga, M.; Boemke, A.; Daniel, T.; Klein, M.W. Metastability and fatigue behavior of austenitic stainless steels. MATEC Web Conf. 2018, 165, 04010. Available online: https://www.matec-conferences.org/articles/matecconf/pdf/2018/24/matecconf_fatigue2018_04010.pdf (accessed on 21 February 2019). [CrossRef]

- Krupp, U.; Christ, H.J.; Lezuo, P.; Maier, H.J. Influence of carbon concentration on martensitic transformation in metastable austenitic steels under cyclic loading conditions. Mater. Sci. Eng. A 2001, 319–321, 527–530. [Google Scholar] [CrossRef]

- Straka, L.; Yagodzinskyy, Y.; Kawakami, H. Open-circuit potential as an indicator of damage of atomic layer deposited TiO2 on AISI 304 stainless steel. Thin Solid Films 2008, 517, 641–647. [Google Scholar] [CrossRef]

- Sun, Y.; Rana, V. Tribocorrosion behaviour of AISI 304 stainless steel in 0.5 M NaCl solution. Mater. Chem. Phys. 2011, 129, 138–147. [Google Scholar] [CrossRef]

- Von der Ohe, C.B.; Johnsen, R.; Espallargas, N. A multi-degradation test rig for studying the synergy effects of tribocorrosion interacting with 4-point static and cyclic bending. Wear 2011, 271, 2978–2990. [Google Scholar] [CrossRef]

- Adedipe, O.; Brennan, F.; Kolios, A. Corrosion fatigue load frequency sensitivity analysis. Mar. Struct. 2015, 42, 115–136. [Google Scholar] [CrossRef]

- Zavieh, A.H.; Espallargas, N. The role of surfacechemistry and fatigue on tribocorrosion of austenitic stainless steel. Tribol. Int. 2016, 103, 368–378. [Google Scholar] [CrossRef]

- Schmiedt, A.; Lücker, L.; Manka, M.; Tillmann, W.; Walther, F. Frequency-dependent fatigue and corrosion fatigue assessment of brazed AISI 304L/BNi-2 joints in air and synthetic exhaust gas condensate. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2338–2349. [Google Scholar] [CrossRef]

- Huang, Y.H.; Tu, S.T.; Xuan, F.Z.; Itoh, T. Corrosion fatigue behaviour of 304 stainless steel under proportional and non-proportional multiaxial loading condition. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 436–445. [Google Scholar] [CrossRef]

- Spähn, R. Electrochemical investigation of crack initiation during corrosion fatigue of stainless steels in the passive state. Werkst. Korros. 1991, 42, 109–117. [Google Scholar] [CrossRef]

| C | Cr | Ni | Mn | Si | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.018 | 18.23 | 8.06 | 1.05 | 0.42 | 0.035 | 0.027 | 0.074 | bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmiedt-Kalenborn, A.; Lingnau, L.A.; Manka, M.; Tillmann, W.; Walther, F. Fatigue and Corrosion Fatigue Behaviour of Brazed Stainless Steel Joints AISI 304L/BAu-4 in Synthetic Exhaust Gas Condensate. Materials 2019, 12, 1040. https://doi.org/10.3390/ma12071040

Schmiedt-Kalenborn A, Lingnau LA, Manka M, Tillmann W, Walther F. Fatigue and Corrosion Fatigue Behaviour of Brazed Stainless Steel Joints AISI 304L/BAu-4 in Synthetic Exhaust Gas Condensate. Materials. 2019; 12(7):1040. https://doi.org/10.3390/ma12071040

Chicago/Turabian StyleSchmiedt-Kalenborn, Anke, Lars Andree Lingnau, Matthias Manka, Wolfgang Tillmann, and Frank Walther. 2019. "Fatigue and Corrosion Fatigue Behaviour of Brazed Stainless Steel Joints AISI 304L/BAu-4 in Synthetic Exhaust Gas Condensate" Materials 12, no. 7: 1040. https://doi.org/10.3390/ma12071040

APA StyleSchmiedt-Kalenborn, A., Lingnau, L. A., Manka, M., Tillmann, W., & Walther, F. (2019). Fatigue and Corrosion Fatigue Behaviour of Brazed Stainless Steel Joints AISI 304L/BAu-4 in Synthetic Exhaust Gas Condensate. Materials, 12(7), 1040. https://doi.org/10.3390/ma12071040