Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering

Abstract

1. Introduction

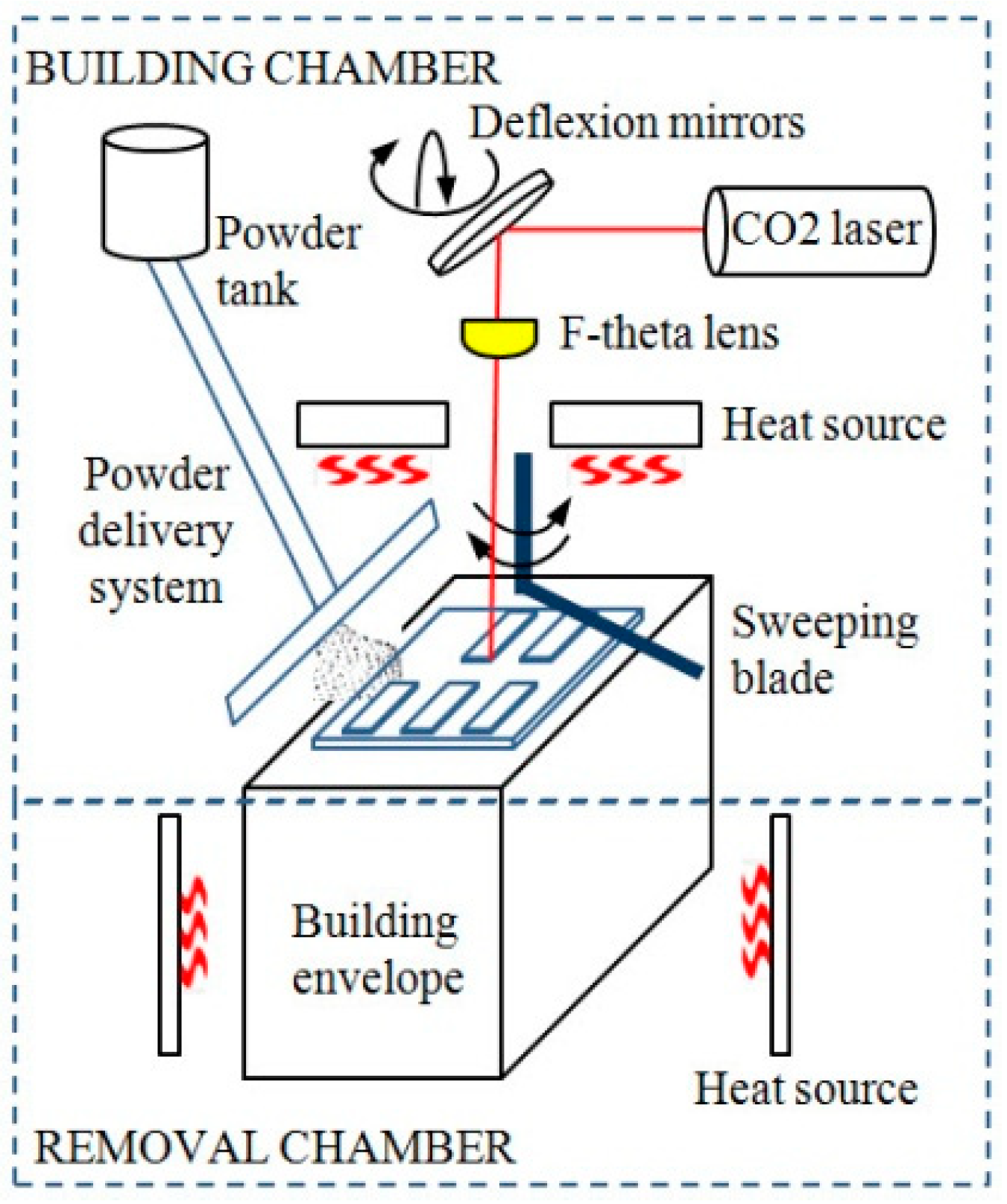

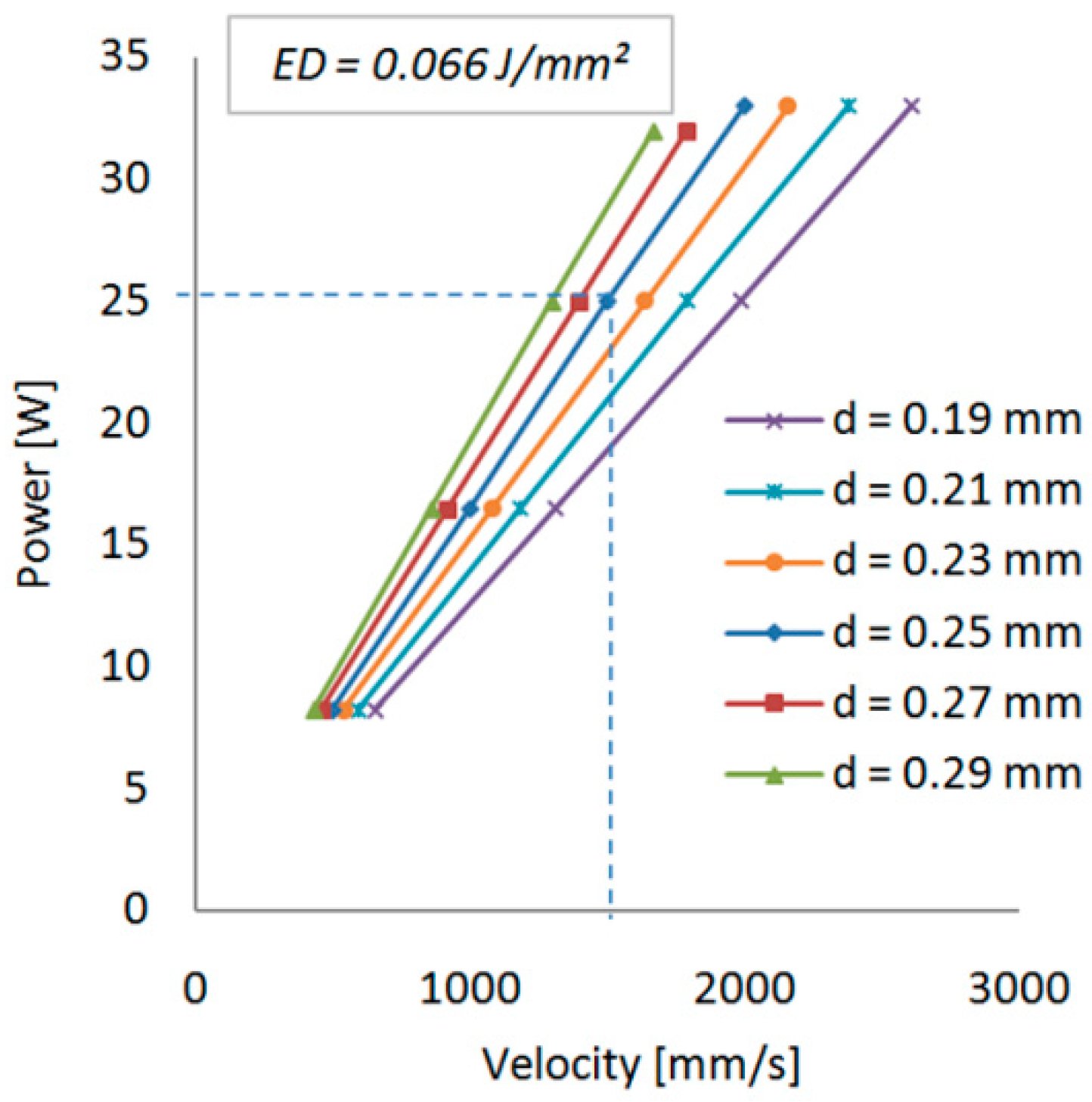

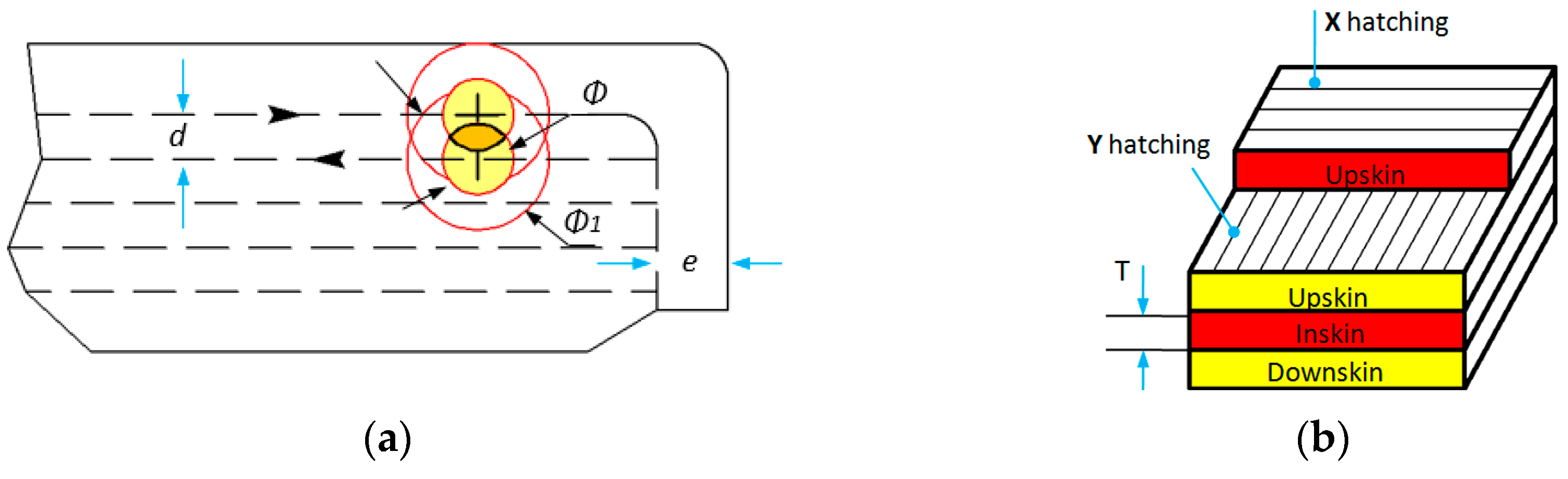

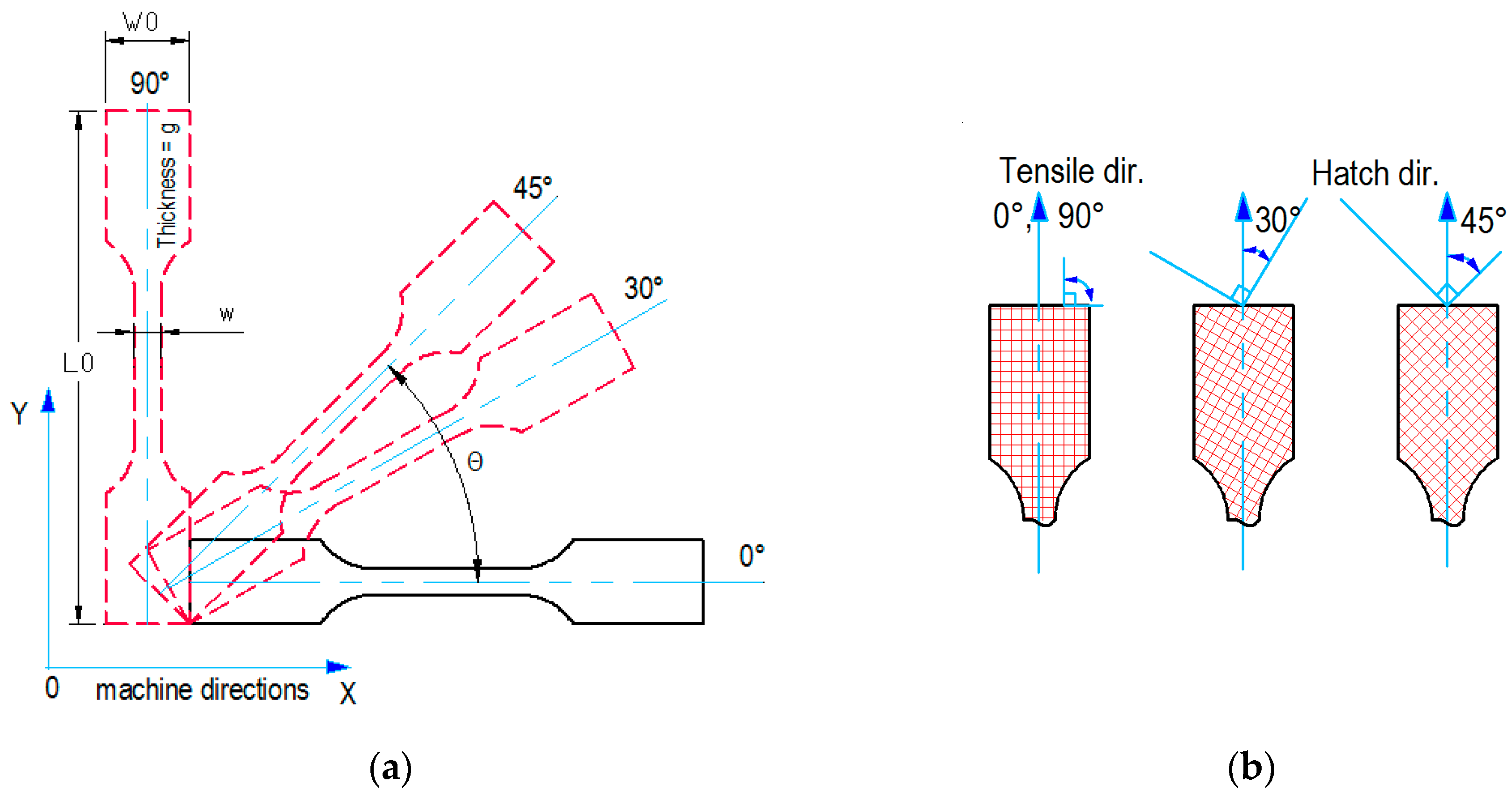

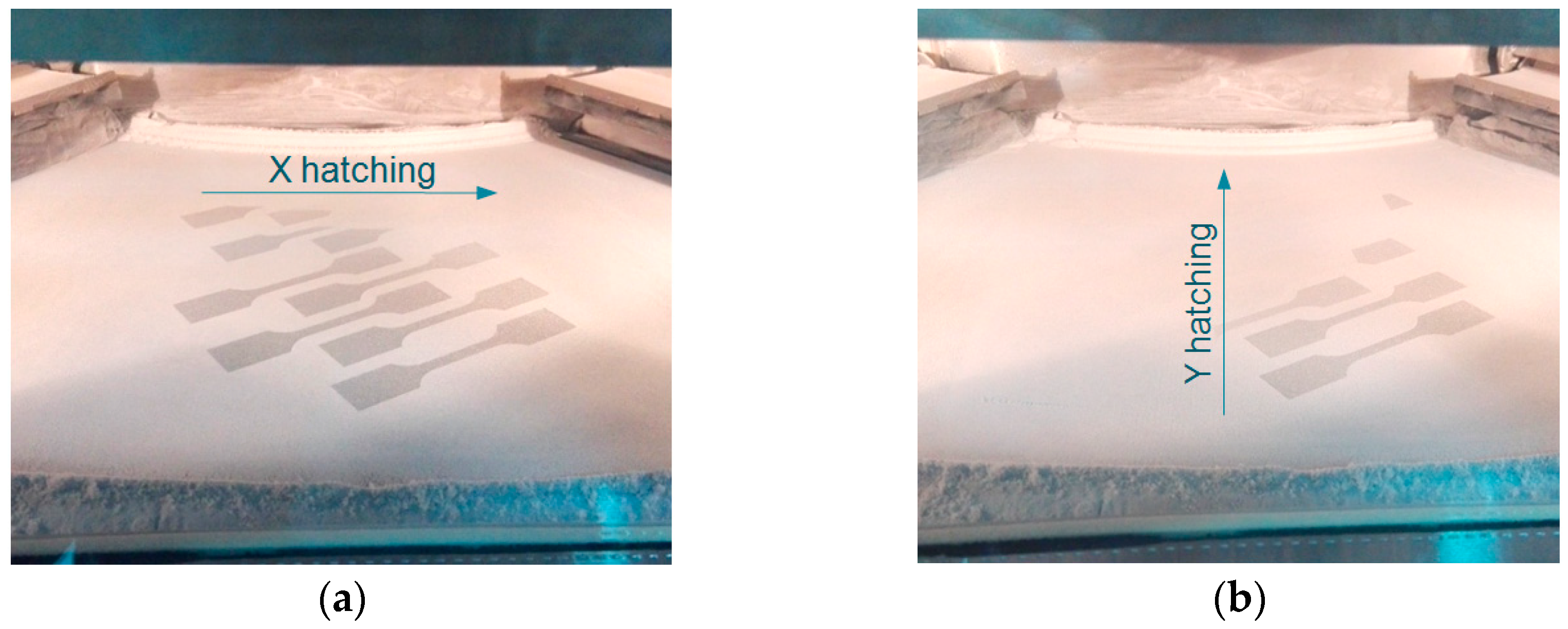

2. Materials and Methods

2.1. Materials

2.2. Methods

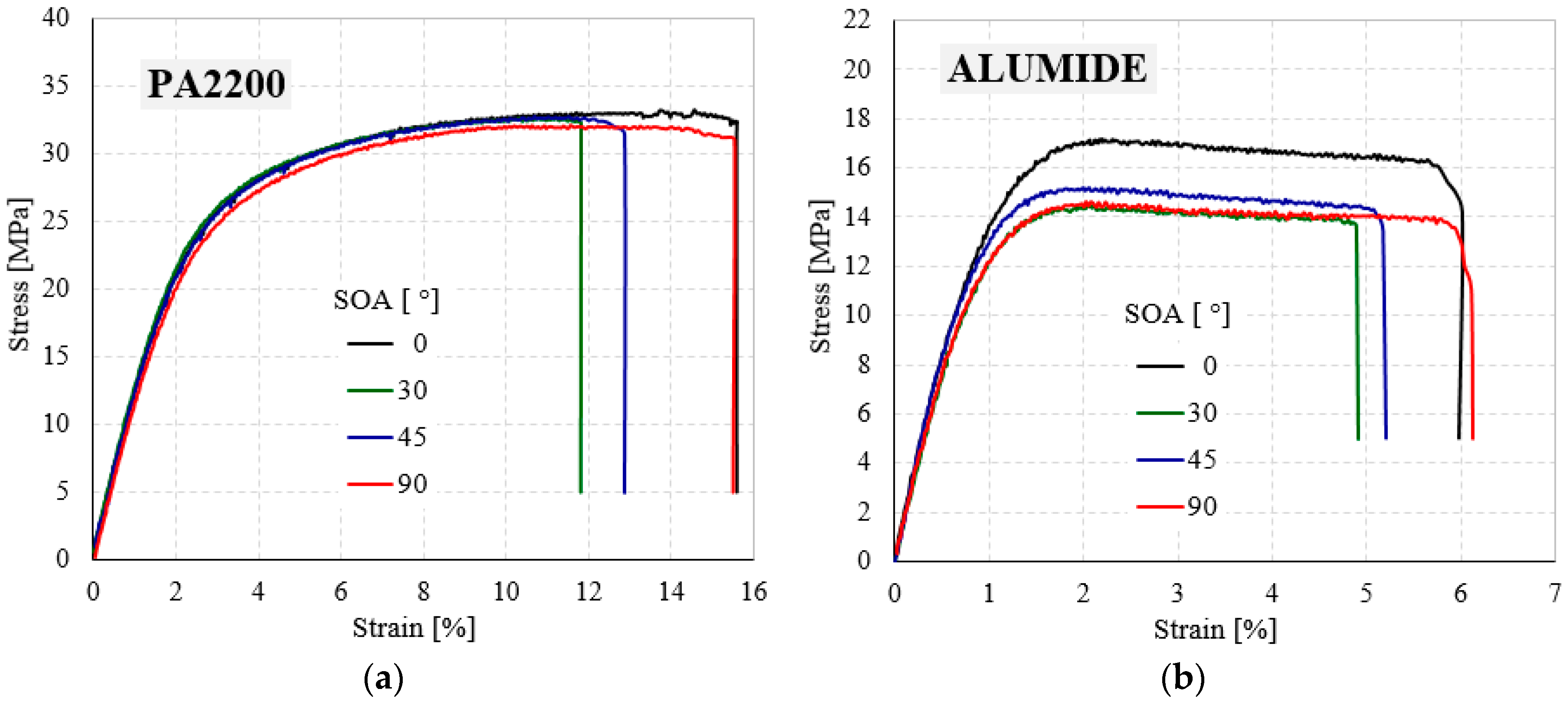

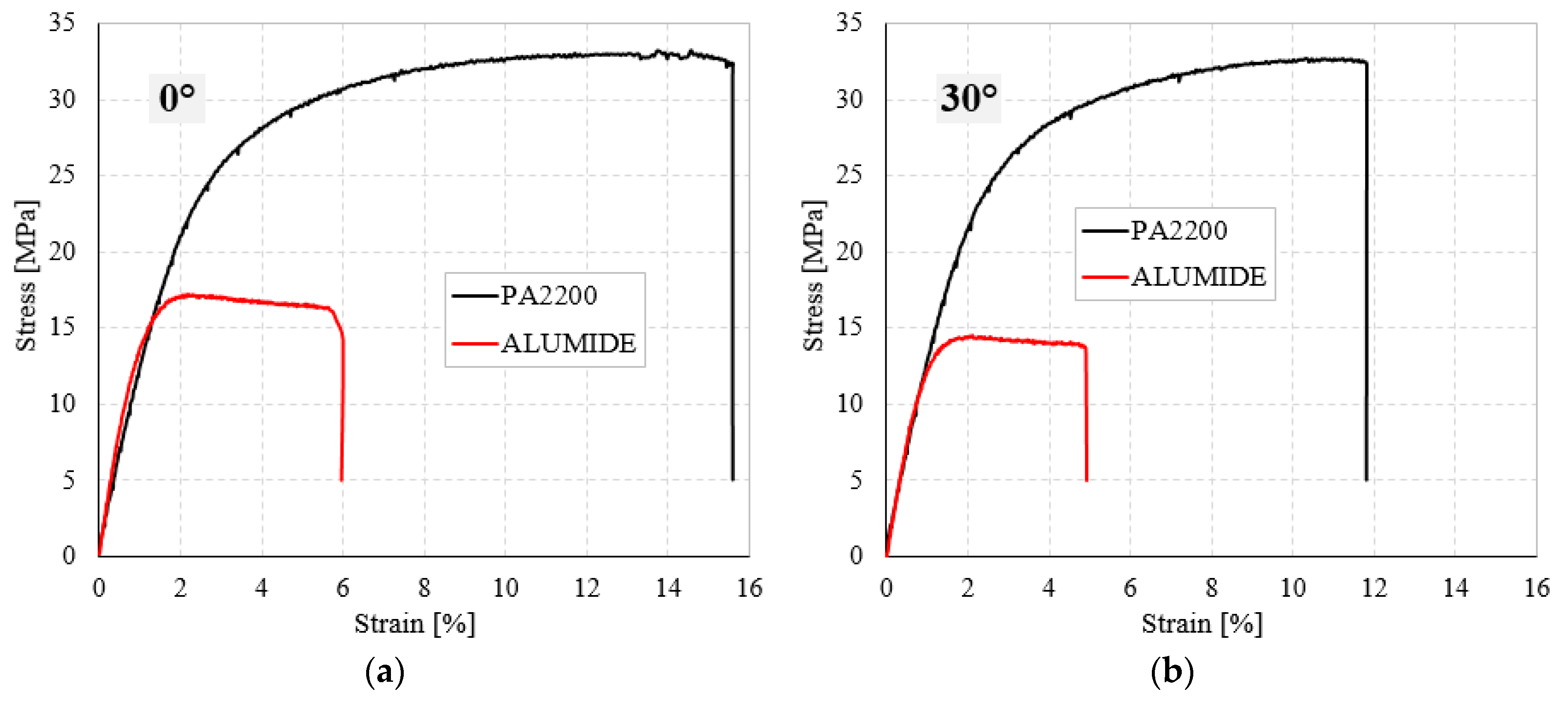

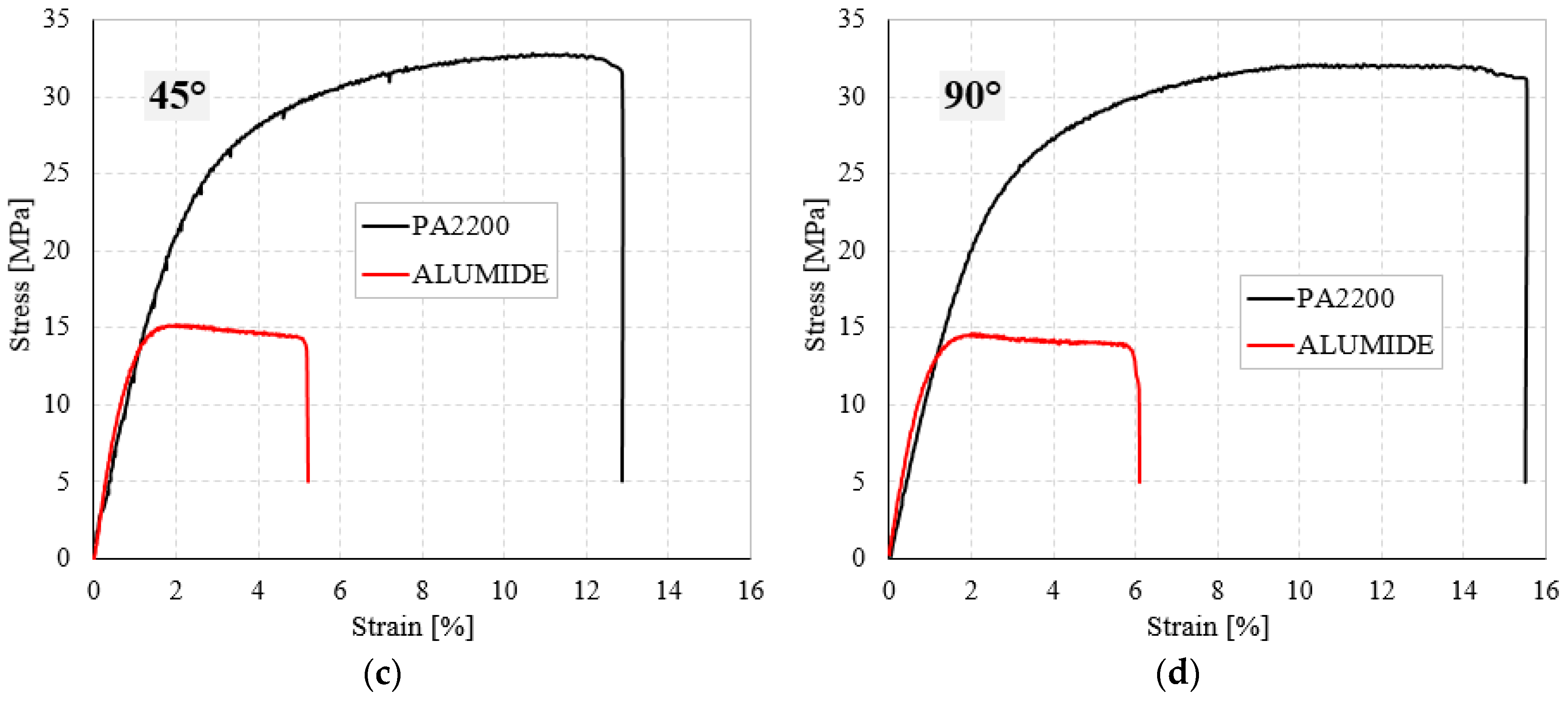

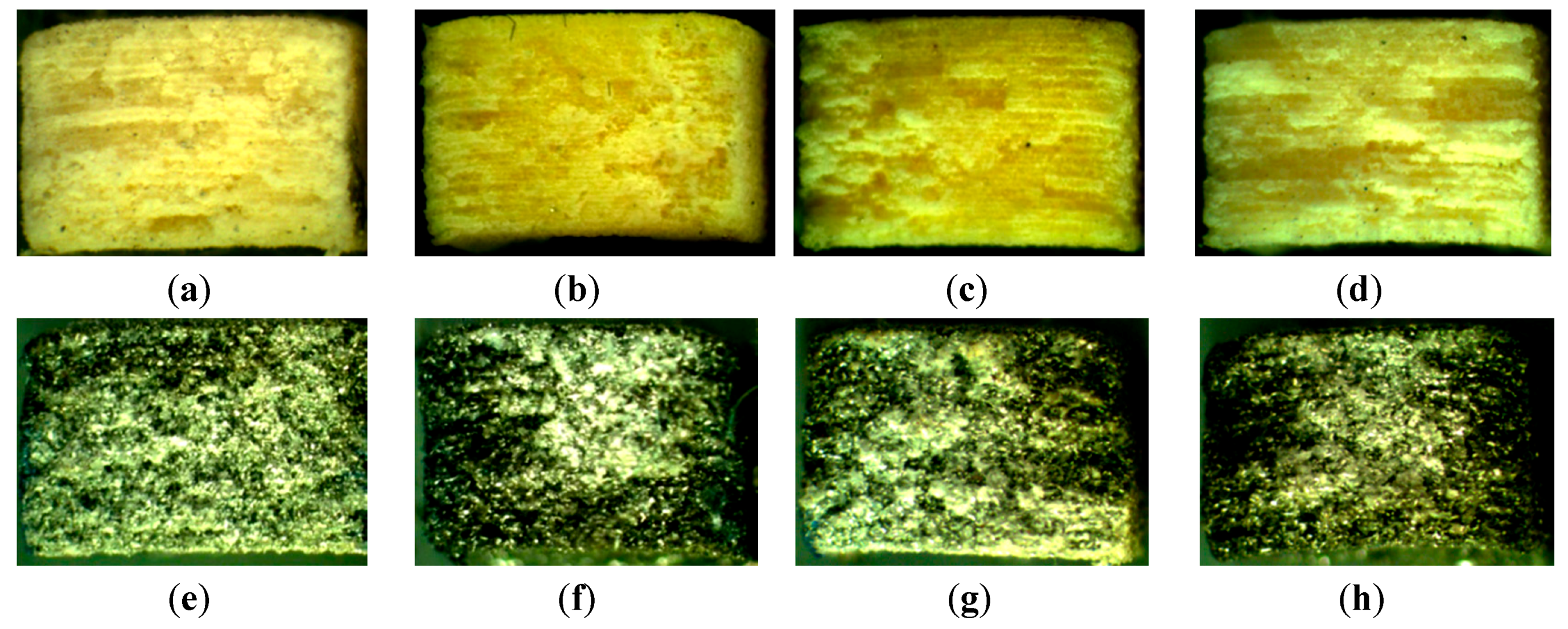

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Linul, E.; Vălean, C.; Linul, P.A. Compressive behavior of aluminum microfibers reinforced semi-rigid polyurethane foams. Polymers 2018, 10, 1298. [Google Scholar] [CrossRef]

- Linul, E.; Şerban, D.A.; Marsavina, L.; Sadowski, T. Assessment of collapse diagrams of rigid polyurethane foams under dynamic loading conditions. Arch. Civ. Mech. Eng. 2017, 17, 457–466. [Google Scholar] [CrossRef]

- Lee, J.J.; Cho, M.Y.; Kim, B.H.; Lee, S. Development of eco-friendly polymer foam using overcoat technology of deodorant. Materials 2018, 11, 1898. [Google Scholar] [CrossRef]

- Rugele, K.; Lehmhus, D.; Hussainova, I.; Peculevica, J.; Lisnanskis, M.; Shishkin, A. Effect of fly-ash cenospheres on properties of clay-ceramic syntactic foams. Materials 2017, 10, 828. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, H.; Rincón Romero, A.; Ferroni, L.; Gardin, C.; Zavan, B.; Bernardo, E. Bioactive glass-ceramic scaffolds from novel ‘inorganic gel casting’ and sinter-crystallization. Materials 2017, 10, 171. [Google Scholar] [CrossRef]

- Elsayed, H.; Rincón Romero, A.; Molino, G.; Vitale-Brovarone, C.; Bernardo, E. Bioactive glass-ceramic foam scaffolds from ‘inorganic gel casting’ and sinter-crystallization. Materials 2018, 11, 349. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. On the lateral compressive behavior of empty and ex-situ aluminum foam-filled tubes at high temperature. Materials 2018, 11, 554. [Google Scholar] [CrossRef] [PubMed]

- Kovacik, J.; Marsavina, L.; Linul, E. Poisson’s ratio of closed-cell aluminium foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef] [PubMed]

- Katona, B.; Szlancsik, A.; Tábi, T.; Orbulov, I.N. Compressive characteristics and low frequency damping of aluminium matrix syntactic foams. Mater. Sci. Eng. A-Struct. 2019, 739, 140–148. [Google Scholar] [CrossRef]

- Linul, E.; Marsavina, L.; Kováčik, J. Collapse mechanisms of metal foam matrix composites under static and dynamic loading conditions. Mater. Sci. Eng. A 2017, 690, 214–224. [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A. Polyurethane foams: past, present, and future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed]

- Marsavina, L.; Constantinescu, D.M.; Linul, E.; Stuparu, F.A.; Apostol, D.A. Experimental and numerical crack paths in PUR foams. Eng. Fract. Mech. 2016, 167, 68–83. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloy Compd. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Ahrens, C.H.; Klauss, P.; Paggi, R.A.; Oliveira, R.G.; Lago, A. Rapid manufacturing of polyethylene parts with controlled pore size gradients using Selective Laser Sintering. Mater. Res. 2007, 10, 211–214. [Google Scholar] [CrossRef]

- Pham, D.T.; Gault, R.S. A comparison of rapid prototyping technologies. Int. J. Mach. Tool Manuf. 1998, 38, 1257–1287. [Google Scholar] [CrossRef]

- Es-Said, O.S.; Foyos, J.; Noorani, R.; Mendelson, M.; Marloth, R.; Pregger, B.A. Effect of layer orientation on mechanical properties of rapid prototyped samples. Mater. Manuf. Process. 2000, 15, 107–122. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. The Effect of Selective Laser Melting Process Parameters on the Microstructure and Mechanical Properties of Al6061 and AlSi10Mg Alloys. Materials 2019, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Hartunian, P.; Eshraghi, M. Effect of Build Orientation on the Microstructure and Mechanical Properties of Selective Laser-Melted Ti-6Al-4V Alloy. J. Manuf. Mater. Process. 2018, 2, 69. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity Measurements and Analysis for Metal Additive Manufacturing Process Control. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 494–528. [Google Scholar] [CrossRef]

- Griessbach, S.; Lach, R.; Grellmann, W. Structure–property correlations of laser sintered nylon 12 for dynamic dye testing of plastic parts. Polym. Test. 2010, 29, 1026–1030. [Google Scholar] [CrossRef]

- Yeong, W.Y.; Chua, C.K. Implementing additive manufacturing for medical devices: A quality perspective. In Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; pp. 115–120. [Google Scholar]

- Lieneke, T.; Denzer, V.; Guido, A.; Adam, O.; Zimmer, D. Dimensional tolerances for additive manufacturing: Experimental investigation for Fused Deposition Modeling. Procedia CIRP 2016, 43, 286–291. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Moroni, G.; Petro, S.; Polini, W. Geometrical product specification and verification in additive manufacturing. CIRP Ann.—Manuf. Technol. 2017, 66, 157–160. [Google Scholar] [CrossRef]

- Borzan, C.Ş.; Dudescu, M.C.; Berce, P. Bending and compression tests for PA 2200 parts obtained using Selective Laser Sintering method. MATEC Web Conf. 2017, 94, 03010. [Google Scholar] [CrossRef]

- Lee, J.-B.; Maeng, W.-Y.; Koh, Y.-H.; Kim, H.-E. Porous Calcium Phosphate Ceramic Scaffolds with Tailored Pore Orientations and Mechanical Properties Using Lithography-Based Ceramic 3D Printing Technique. Materials 2018, 11, 1711. [Google Scholar] [CrossRef] [PubMed]

- Mengqi, Y.; Bourell, D. Orientation effects for laser sintered polyamide optically translucent parts. Rapid Prototyp. J. 2016, 22, 97–103. [Google Scholar]

- Guido, A.O.A.; Detmar, Z. On design for additive manufacturing: evaluating geometrical limitations. Rapid Prototyp. J. 2015, 21, 662–670. [Google Scholar]

- Pilipović, A.; Valentan, B.; Šercer, M. Influence of SLS processing parameters according to the new mathematical model on flexural properties. Rapid Prototyp. J. 2016, 22, 258–268. [Google Scholar] [CrossRef]

- Singh, J.P.; Pandey, P.; Verma, A.K. Fabrication of three dimensional open porous regular structure of PA-2200 for enhanced strength of scaffold using selective laser sintering. Rapid Prototyp. J. 2016, 22, 752–765. [Google Scholar] [CrossRef]

- Mousa, A.A. Experimental investigations of curling phenomenon in selective laser sintering process. Rapid Prototyp. J. 2016, 22, 405–415. [Google Scholar] [CrossRef]

- Berti, G.; D’Angelo, L.; Gatto, A.; Iuliano, L. Mechanical characterisation of PA-Al2O3 composites obtained by selective laser sintering. Rapid Prototyp. J. 2010, 16, 124–129. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Galantucci, M.; Bodi, I.; Kacani, J.; Lavecchi, F. Analysis of dimensional performance for a 3D open-source printer based on fused deposition modeling technique. Procedia CIRP 2015, 28, 82–87. [Google Scholar] [CrossRef]

- Nuñez, P.J.; Rivas, A.; García-Plaza, E.; Beamud, E.; Sanz-Lobera, E. Dimensional and surface texture characterization in Fused Deposition Modelling with ABS plus. Procedia Eng. 2015, 132, 856–863. [Google Scholar] [CrossRef]

- Palumbo, B.; Re, F.; Martorelli, M.; Lanzotti, A.; Corrado, P. Tensile properties characterization of AlSi10Mg parts produced by direct metal laser sintering via nested effects modeling. Materials 2017, 10, 144. [Google Scholar] [CrossRef]

- ISO 10993-1. Biological Evaluation of Medical Devices—Part 1: Evaluation and Testing Within a Risk Management Process; International Organization for Standardization: Vernier/Geneva, Switzerland, 2018; p. 41. [Google Scholar]

- EOS GmbH Product Information. Available online: www.eos.info/material-p (accessed on 9 November 2018).

- Borzan, C.Ş.; Berce, P.; Chezan, H.; Sabău, E.; Radu, S.A.; Ridzon, M. Physico-mechanical properties characterization of the parts from PA2200 manufactured by selective laser sintering technology. Acad. J. Manuf. Eng. 2013, 11, 108–113. [Google Scholar]

- Pilipović, A.; Brajlih, T.; Drstvenšek, I. Influence of Processing Parameters on Tensile Properties of SLS Polymer Product. Polymers 2018, 10, 1208. [Google Scholar] [CrossRef]

- ISO 13320. Particle Size Analysis—Laser Diffraction Methods; International Organization for Standardization: Vernier/Geneva, Switzerland, 2009; p. 51. [Google Scholar]

- ISO 60. Plastics-Determination of Apparent Density of Material That Can Be Poured from a Specified Funnel; International Organization for Standardization: Vernier/Geneva, Switzerland, 1977; p. 2. [Google Scholar]

- ISO 11357-1. Plastics-Differential Scanning Calorimetry (DSC)—Part 1: General Principles; International Organization for Standardization: Vernier/Geneva, Switzerland, 2016; p. 33. [Google Scholar]

- ISO 306. Plastics-Thermoplastic Materials—Determination of Vicat Softening Temperature (VST); International Organization for Standardization: Vernier/Geneva, Switzerland, 2004. [Google Scholar]

- EOS GmbH Product Information. Available online: https://eos.materialdatacenter.com/eo/en (accessed on 9 November 2018).

- Stoia, D.I.; Nicoara, M.; Raduta, A.; Locovei, C. Alumide sinterization aspects according to layer orientation, in Rapid Prototyping Process. Solid State Phenom. 2016, 254, 106–109. [Google Scholar] [CrossRef]

- 3D Printing Material. Alumide. Available online: https://www.sculpteo.com/en/materials/alumidematerial/ (accessed on 3 November 2017).

- Violante, M.G.; Iuliano, L.; Minetola, P. Design and production of fixtures for free-form components using selective laser sintering. Rapid Prototyp. J. 2007, 13, 30–37. [Google Scholar] [CrossRef]

- DIN ISO 171:2000. Plastics - Determination of bulk factor of moulding materials; German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 2000. [Google Scholar]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- Toth-Tascau, M.; Raduta, A.; Stoia, D.I.; Locovei, C. Influence of the energy density on the porosity of Polyamide parts in SLS process. In Proceedings of the 4th International Conference on Advanced Materials and Structures (AMS 2011), Timisoara, Romania, 27–28 October 2011; pp. 400–405. [Google Scholar]

- Ilkgün, Ö. Effects of Production Parameters on Porosity and Hole Properties in Laser Sintering Rapid Prototyping Process. Master’s Thesis, The Graduate School of Natural and Applied Sciences of Middle East Technical University, Ankara, Turkey, 2005. [Google Scholar]

- Osmanlic, F.; Wudy, K.; Laumer, T.; Schmidt, M.; Drummer, D.; Körner, C. Modeling of laser beam absorption in a polymer powder bed. Polymers 2018, 10, 784. [Google Scholar] [CrossRef]

- ISO 527-1. Plastics-Determination of Tensile Properties—Part 1: General Principles; International Organization for Standardization: Vernier/Geneva, Switzerland, 2012; p. 23. [Google Scholar]

- Linul, E.; Serban, D.A.; Voiconi, T.; Marsavina, L.; Sadowski, T. Energy-absorption and efficiency diagrams of rigid PUR foams. Key Eng. Mater. 2014, 601, 246–249. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Linul, E.; Bahmani, A.; Marsavina, L. Experimental and theoretical fracture toughness investigation of PUR foams under mixed mode I+III loading. Polym. Test. 2018, 67, 75–83. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature effect on the axial quasi-static compressive behavior of ex-situ aluminum foam-filled tubes. Compos. Struct. 2017, 180, 709–722. [Google Scholar] [CrossRef]

| Laser Power (W) | Laser Velocity (mm/s) | Scan Spacing (mm) | Energy Density (J/mm2) | Beam Offset (mm) | Building Chamber Temp. (°C) | Removal Chamber Temp. (°C) | Layer Thickness (mm) | Scaling Factors (%) |

|---|---|---|---|---|---|---|---|---|

| 25 | 1500 | 0.25 | 0.066 | 0.15 | 170 | 153 | 0.1 | 2.2 |

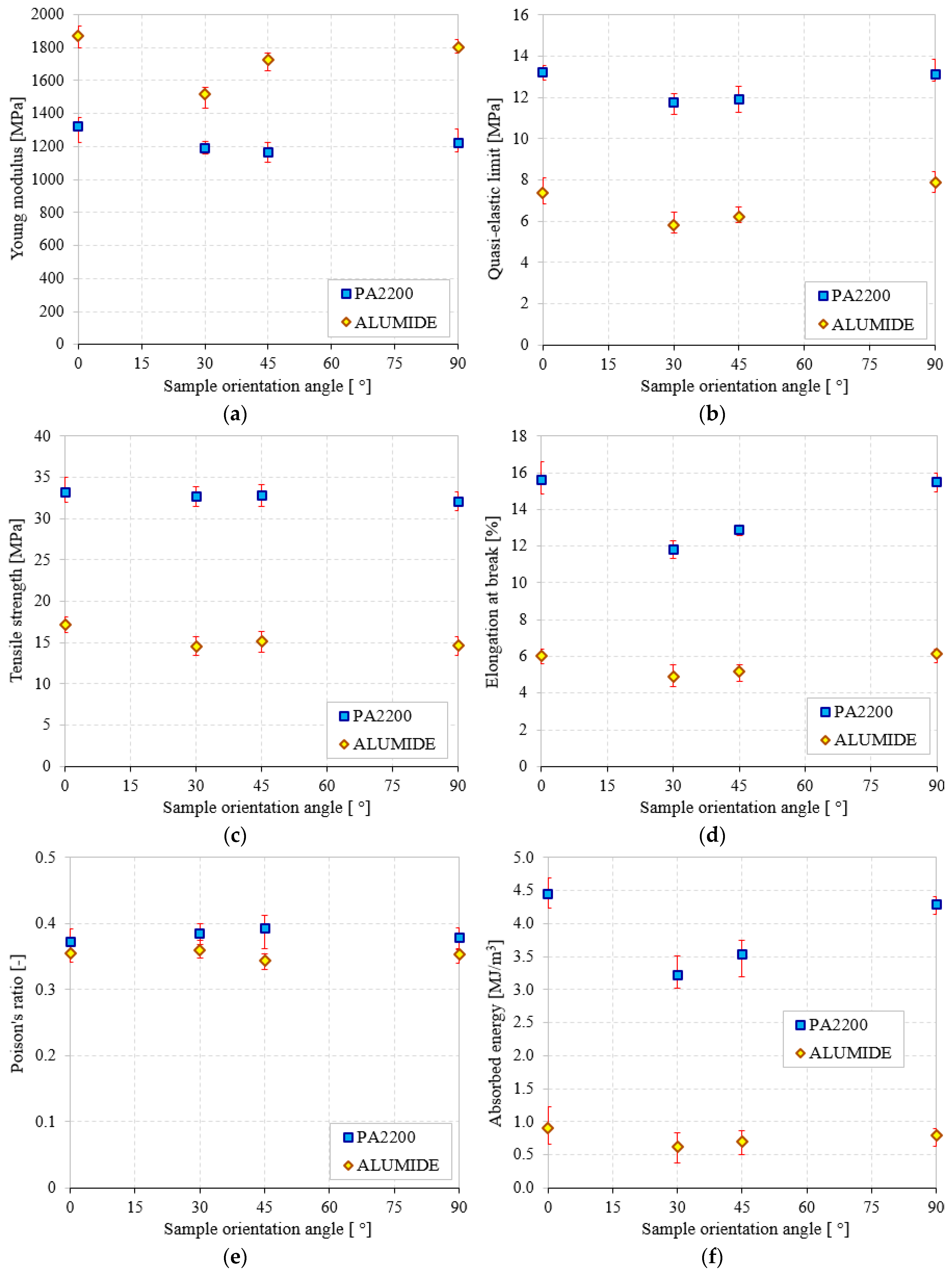

| Material | α (°) | E (MPa) | σe (MPa) | σy (MPa) | σm (MPa) | εb (%) | W1 (MJ/m3) | ν (-) |

|---|---|---|---|---|---|---|---|---|

| PA2200 | 0 | 1321.90 ± 73.1 | 13.21 ± 0.36 | 21.12 ±0.73 | 33.24 ± 1.55 | 15.62 ± 0.91 | 4.45 ± 0.23 | 0.42 ± 0.016 |

| 30 | 1187.00 ± 36.5 | 11.75 ± 0.50 | 20.42 ± 0.68 | 32.69 ± 1.24 | 11.82 ± 0.56 | 3.21 ± 0.25 | 0.39 ± 0.013 | |

| 45 | 1162.50 ± 58.2 | 11.89 ± 0.63 | 20.61 ± 0.56 | 32.81 ± 1.33 | 12.87 ± 0.20 | 3.54 ± 0.28 | 0.42 ± 0.025 | |

| 90 | 1224.10 ± 69.3 | 13.11 ± 0.53 | 20.52 ± 1.02 | 32.08 ± 1.14 | 15.52 ± 0.51 | 4.29 ± 0.14 | 0.40 ± 0.018 | |

| Alumide | 0 | 1871.00 ± 66.4 | 7.39 ± 0.62 | 13.16 ± 0.57 | 17.17 ± 0.99 | 6.01 ± 0.42 | 0.90 ± 0.29 | 0.35 ± 0.012 |

| 30 | 1518.10 ± 63.0 | 5.81 ± 0.50 | 11.78 ± 0.86 | 14.49 ± 1.15 | 4.91 ± 0.60 | 0.62 ± 0.23 | 0.36 ± 0.014 | |

| 45 | 1722.70 ± 53.7 | 6.23 ± 0.39 | 11.82 ± 0.75 | 15.16 ± 1.27 | 5.20 ± 0.48 | 0.69 ± 0.19 | 0.34 ± 0.012 | |

| 90 | 1799.00 ± 41.2 | 7.89 ± 0.52 | 12.35 ± 0.38 | 14.65 ± 1.15 | 6.12 ± 0.35 | 0.79 ± 0.14 | 0.35 ± 0.017 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoia, D.I.; Linul, E.; Marsavina, L. Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering. Materials 2019, 12, 871. https://doi.org/10.3390/ma12060871

Stoia DI, Linul E, Marsavina L. Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering. Materials. 2019; 12(6):871. https://doi.org/10.3390/ma12060871

Chicago/Turabian StyleStoia, Dan Ioan, Emanoil Linul, and Liviu Marsavina. 2019. "Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering" Materials 12, no. 6: 871. https://doi.org/10.3390/ma12060871

APA StyleStoia, D. I., Linul, E., & Marsavina, L. (2019). Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering. Materials, 12(6), 871. https://doi.org/10.3390/ma12060871