3.1. Composites Tensile Properties

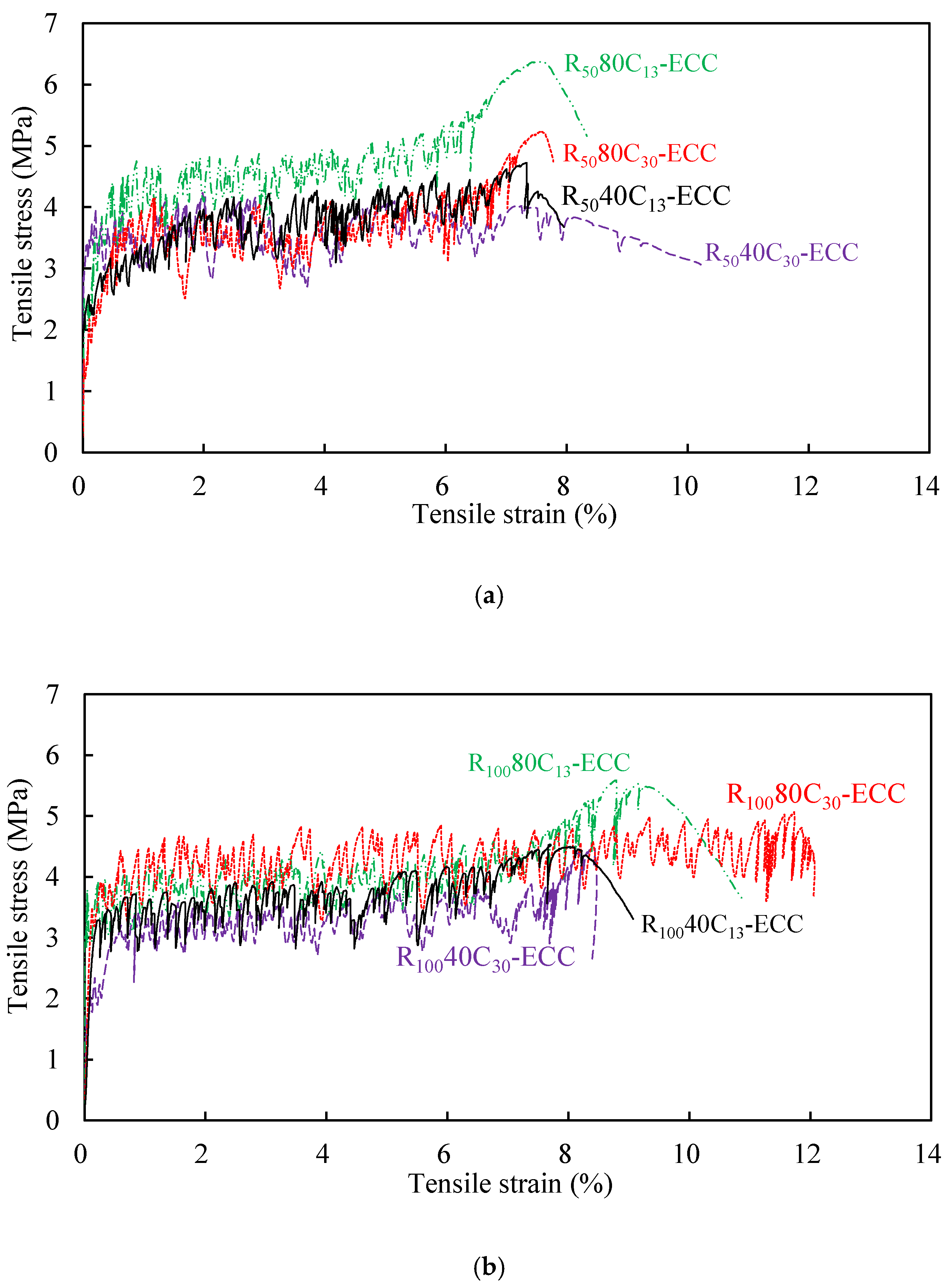

Figure 8 shows the typical tensile stress–strain curves of all the mixtures obtained from uniaxial tension test. It is seen that all mixtures exhibit significant strain-hardening behavior and high ductility with multiple cracks, which is unlike the sudden brittle fracture failure mode for normal concrete. The strain capacity of the mixtures observed in

Figure 8 is obviously higher than 3%, which is normally reported for PVA-ECC in the previous literature [

14]. Three distinct phases can be observed within each sample, which are the elastic stage, the strain-hardening stage, and the failure stage. During the strain-hardening stage, the tensile stress has the larger fluctuation than that observed in PVA-ECC [

30]. This phenomenon is due to the hydrophobic nature of PE fiber used in this study, which leads to a much weaker bond between fiber and matrix, as compared with that from PVA fiber [

36]. However, there is a high chemical bond between PVA fiber and the matrix [

13,

40]. Therefore, it is generally the case that there is a relatively high stress drop when a crack occurs in a composite reinforced by PE fiber.

The tensile test results in terms of initial cracking stress

σtc, peak stress

σtu, tensile strain capacity

εtu (e.g., strain at peak stress), crack number

Nc, crack width

wc and crack spacing

sc are summarized in

Table 4. By counting crack numbers within 80 mm gauge length after tensile tests, the average crack width and crack spacing were calculated. As can be seen in

Table 4, the crack widths of all mixtures were less than 150 μm at peak tensile strength, indicating the excellent crack width control of the developed ECC. The strain capacity of ECC is dependent on the density of multiple cracking and crack width distribution. R

50-ECC and R

100-ECC had the similar crack width, but R100-ECC showed more crack numbers, demonstrating that the increase of RP content not only did not impair on the multi-cracking characteristics of ECC, but it triggered more cracks instead. The tensile strain capacity of all the composites ranged from 7% to 12%, at least ten times higher than that of normal fiber reinforced concrete. Compared with the ECC without RP and CR whose tensile strain capacities are approximately 3–5% [

14,

41], the developed ECC shows significant advantage in tensile ductility. These indicated that the addition of RP and CR did do a positive effect on the improvement of normal ECC’s ductility.

The value of initial cracking stress was determined from the beginning point of the strain hardening branch of the stress–strain curves. It is clearly observed that all the values of the peak tensile stress were about 2–3 times higher than the initial cracking stress, indicating that all the composites satisfied the strength criterion of multiple cracking [

42]. As a result, tensile strain capacity of all the composites could reach over 7%.

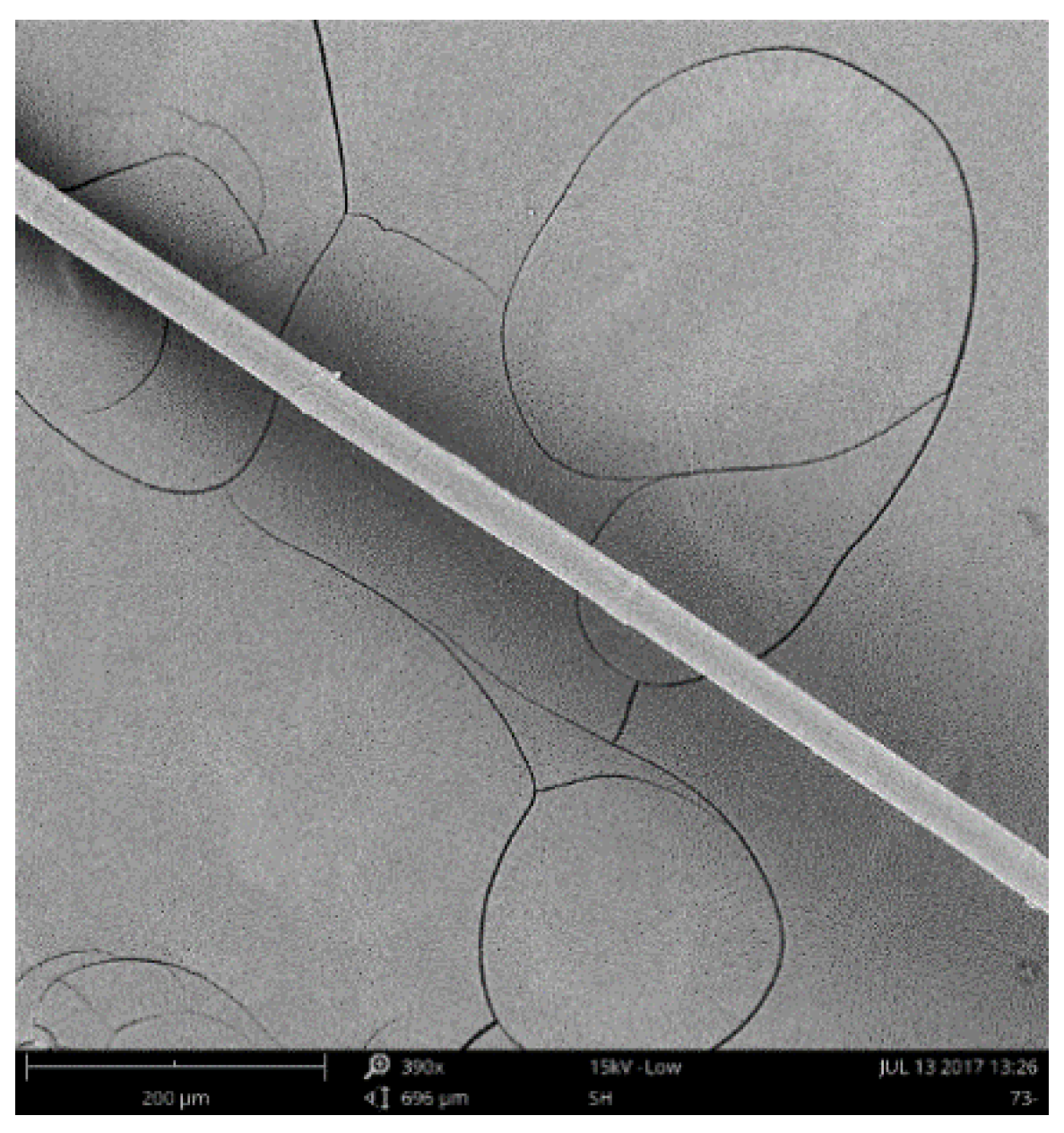

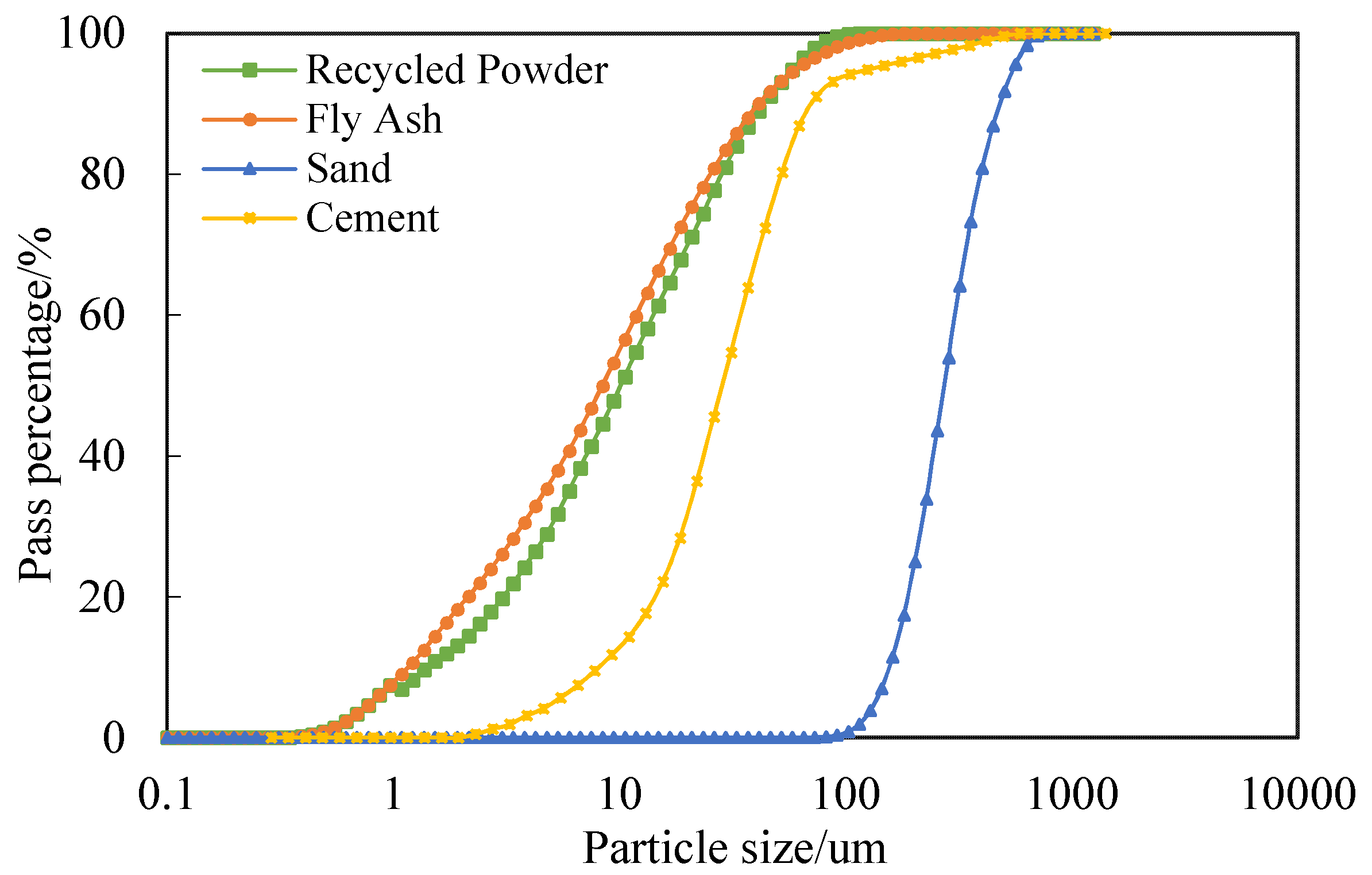

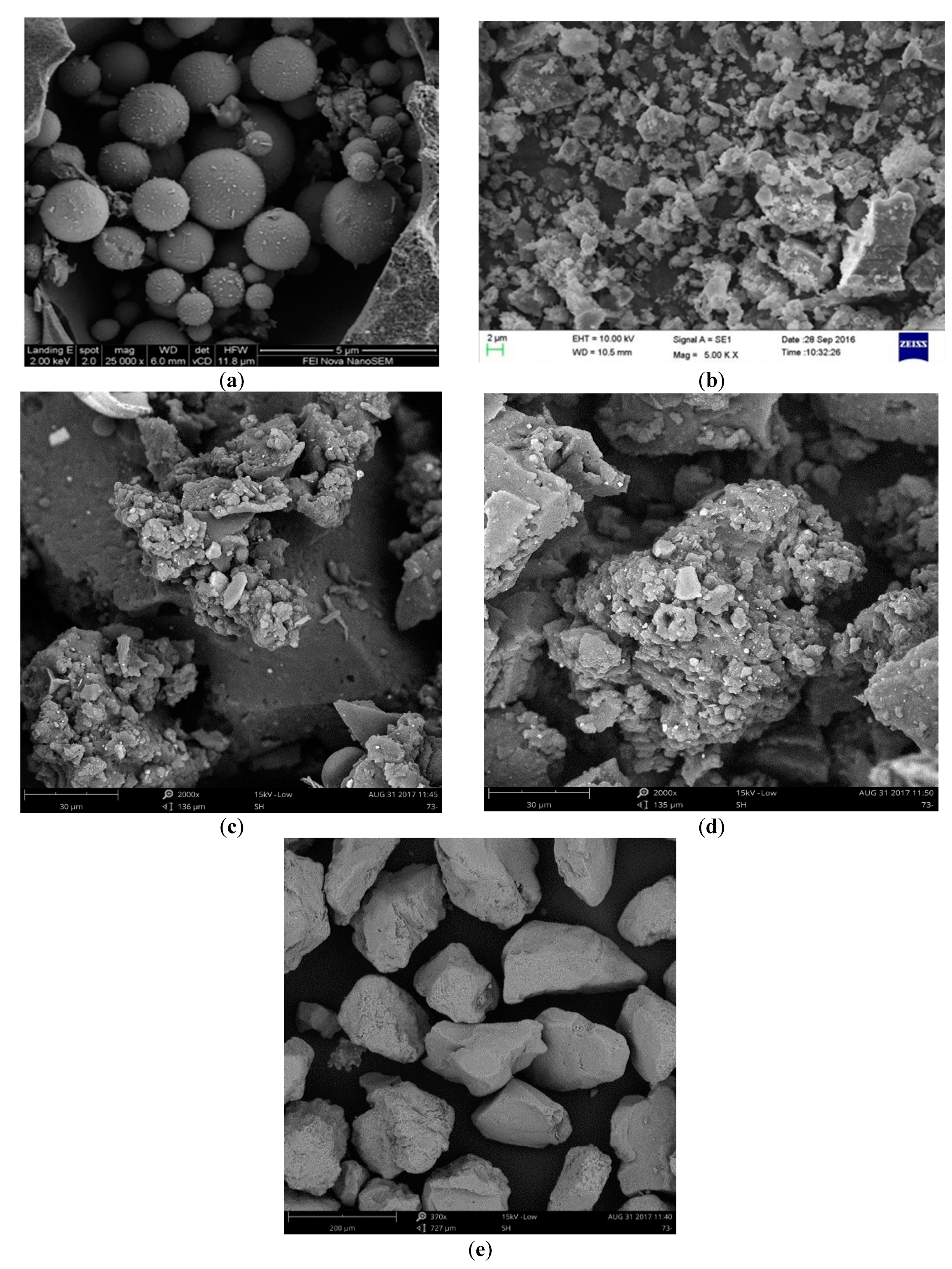

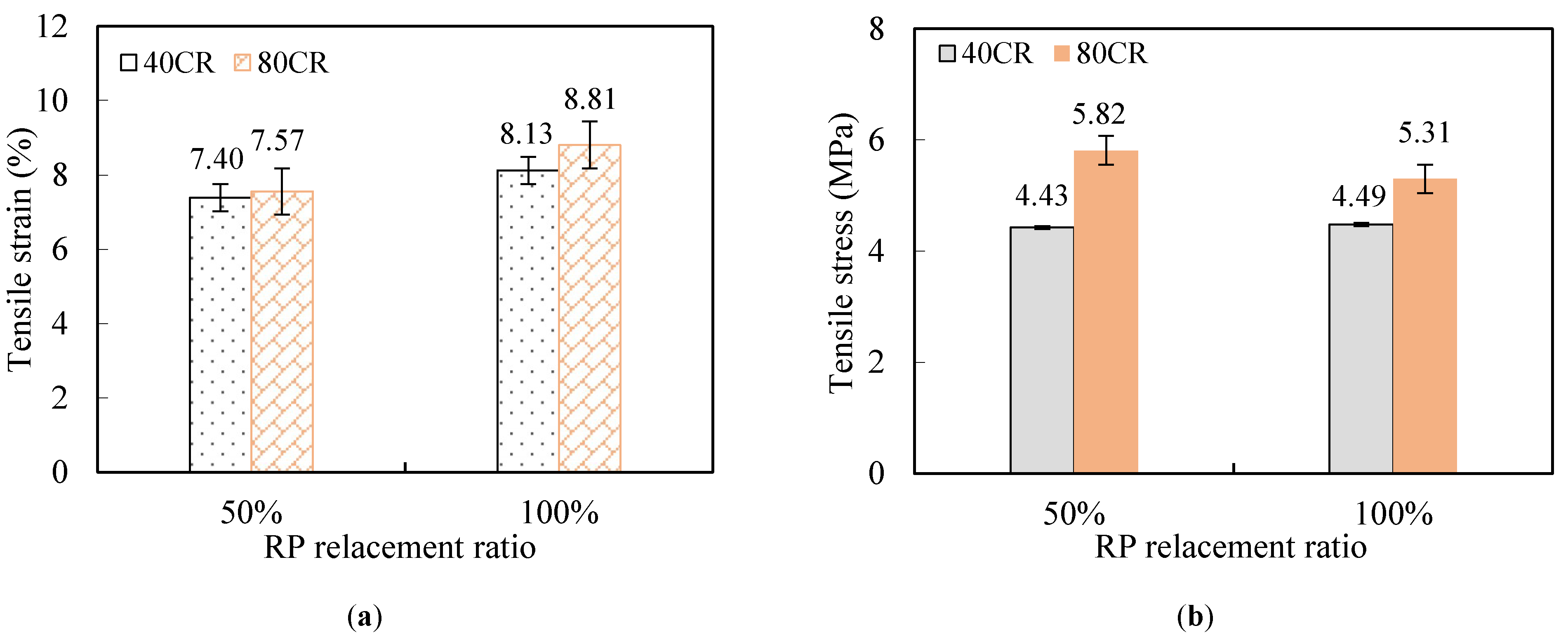

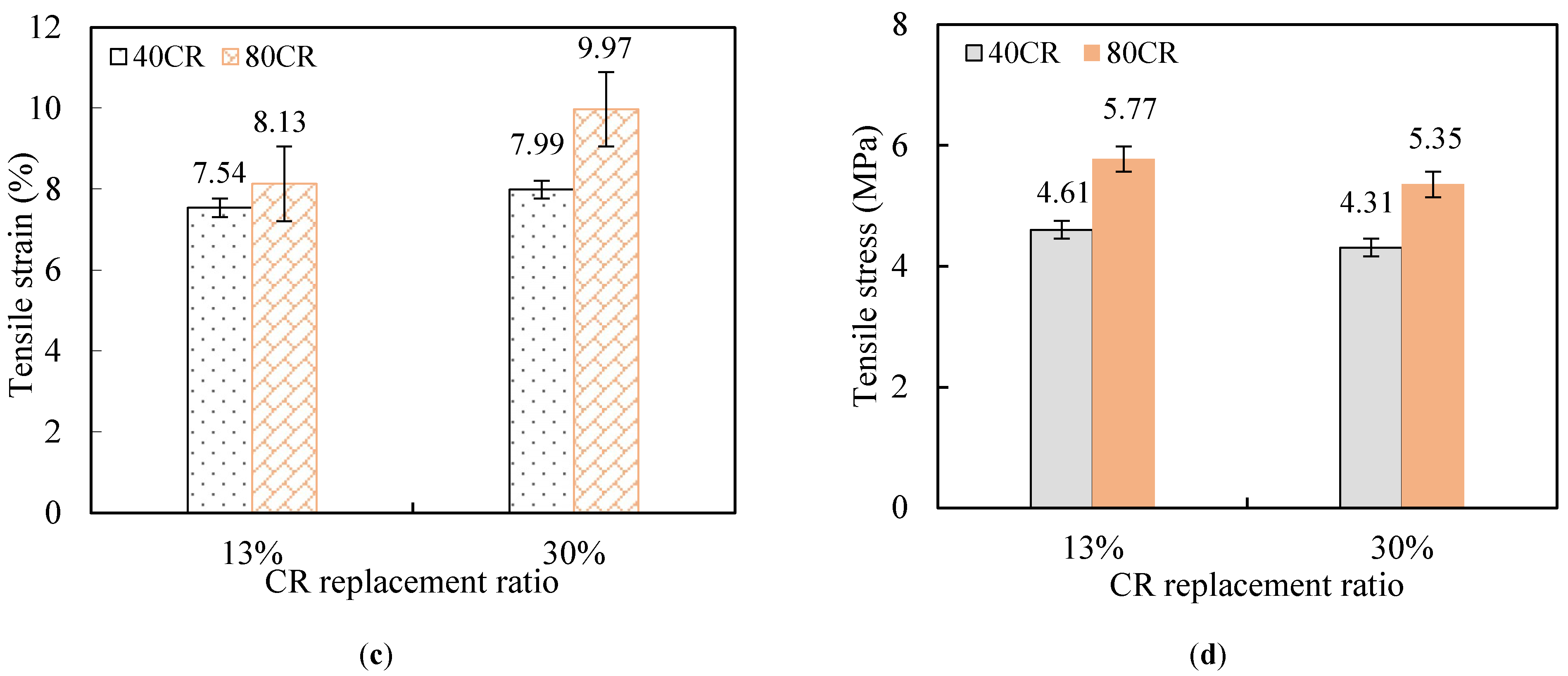

Figure 9 shows the effect of different RP replacement ratio, CR content and CR size on the tensile peak stress and strain capacity of ECC. When fly ash was partially or totally replaced by RP, the strain capacity is significantly improved as increasing the content of RP, denoting that the irregular microstructure of RP enhanced the interface bonding between fiber and matrix, see

Figure 3. Similarly, the strain capacity has a marked increase when the CR content increases, owing to the fact that using rubber powder replacing sand lowers the toughness of matrix. When it comes to the CR particle size, it could be found that the strain capacity is more pronounced when the smaller particle size (80CR) is used. A possible explanation is that finer CR particles entrain more air bubble into ECC since the air bubble is likely to be attached on the surface of CR particle during mixing process [

31], which increase the number of small flaws in ECC matrix. And these would make it easier to initiate crack, leading to benefit the ductility of ECC. The improvement of ductility with the addition of RP and CR can be explained from the micro-mechanics design theory of ECC materials. And a further discussion is presented in

Section 3.3. However, the increase of RP or CR content has no positive effect on the initial cracking stress and peak stress, even a slight decrease.

3.2. Composite Compressive Property

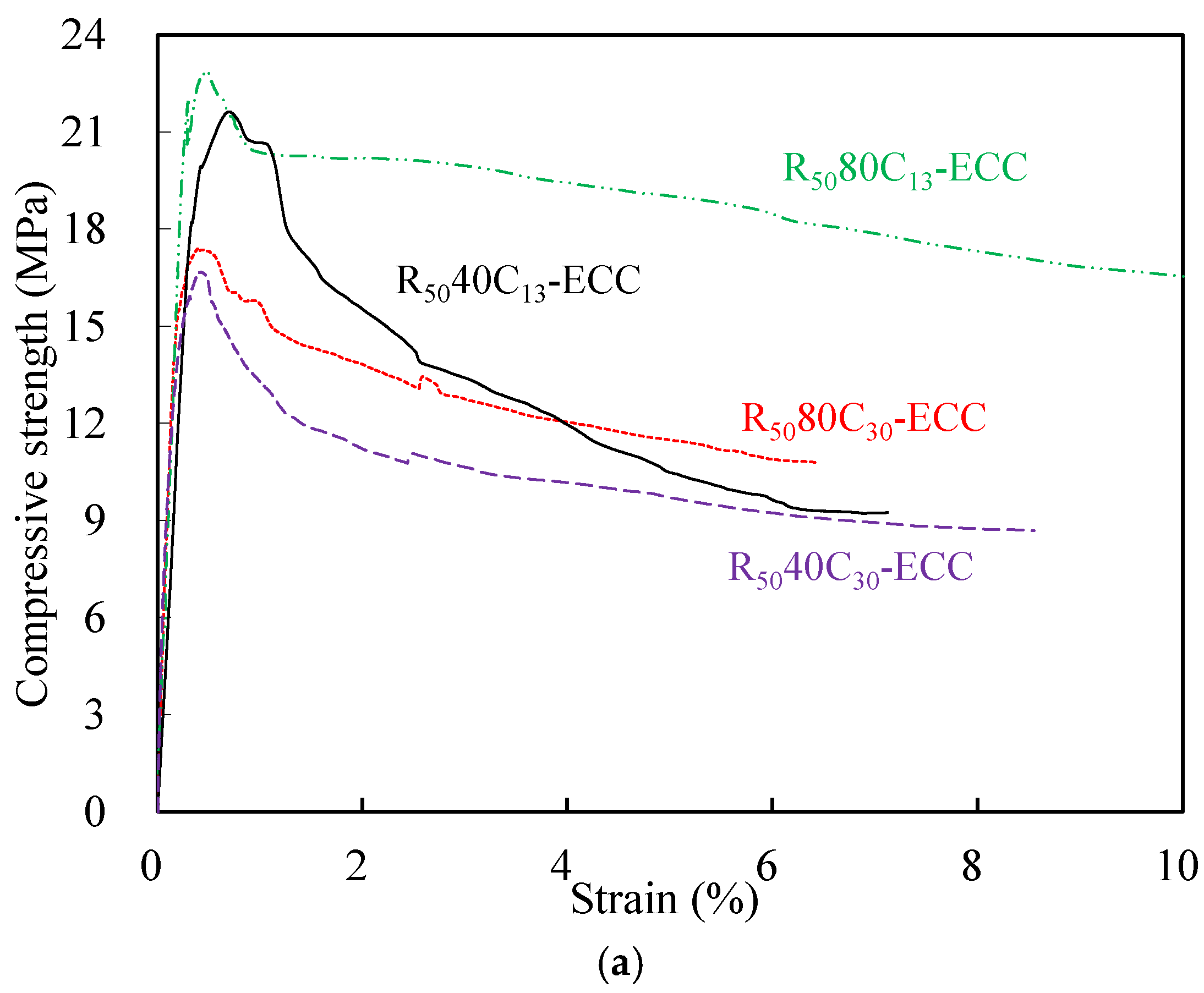

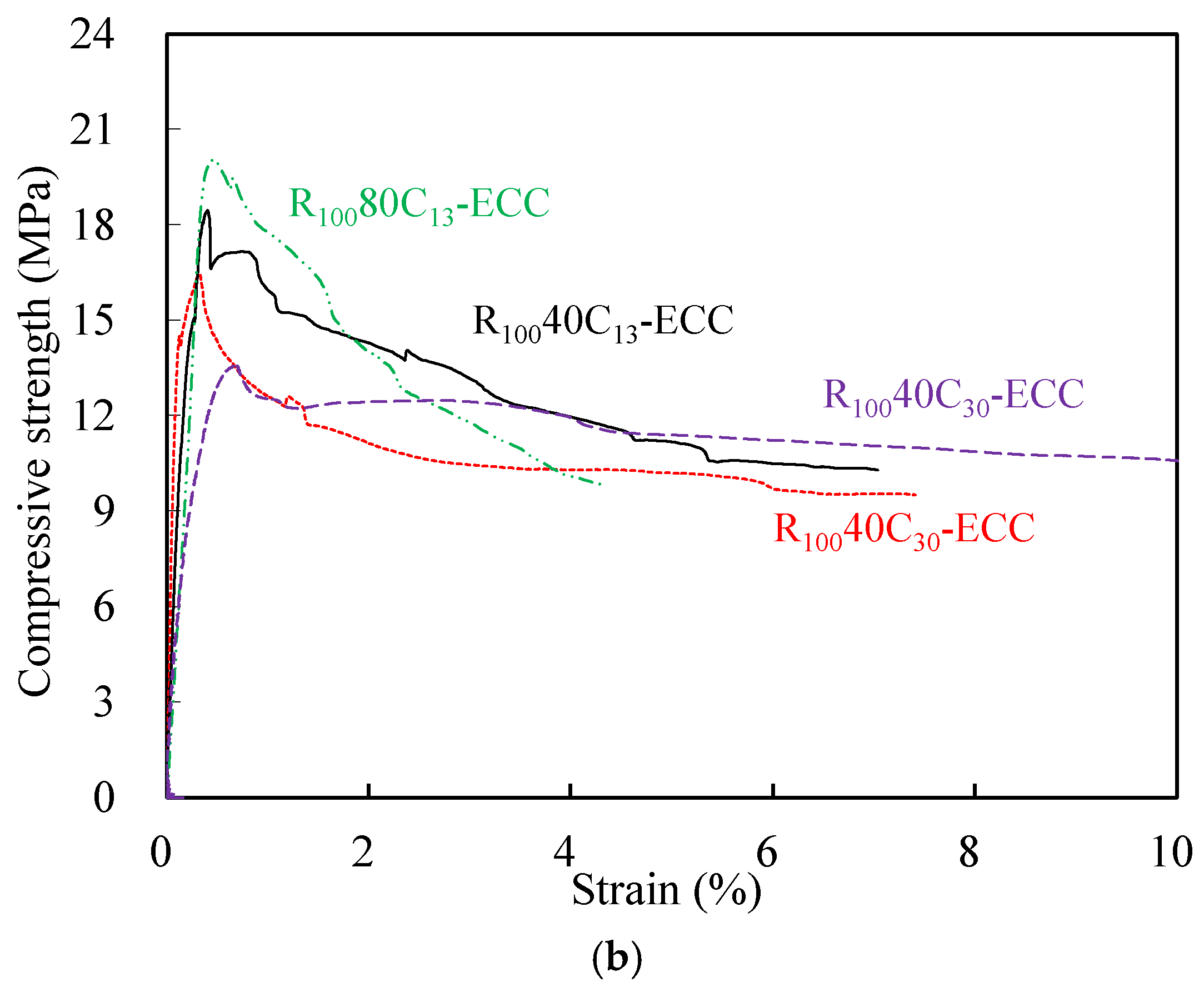

The compressive stress–strain curves of different mixtures are illustrated in

Figure 10. As can be seen, the behaviors of the ECC prior to the peak stress was similar to that of the normal concrete, but the post-peak softening behaviors are quite different. Comparatively, the descending rates of all the mixtures were much gentler, exhibiting their excellent post-peak deformation capacity under compression. According to the data from the compressive stress–strain curves, the strain at peak compressive stress of R

5080C

13-ECC and R

10040C

30-ECC were 0.72% and 0.65% and the strain at 80% peak compressive stress of R

5080C

13-ECC and R

10040C

30-ECC were 6.15% and 4.06%, respectively, about one order of magnitude higher than that of normal concrete. The improvement of compressive deformability of composites can be mainly attributed to the superior crack bridging capacity provided by PE fibers as well as the addition of CR.

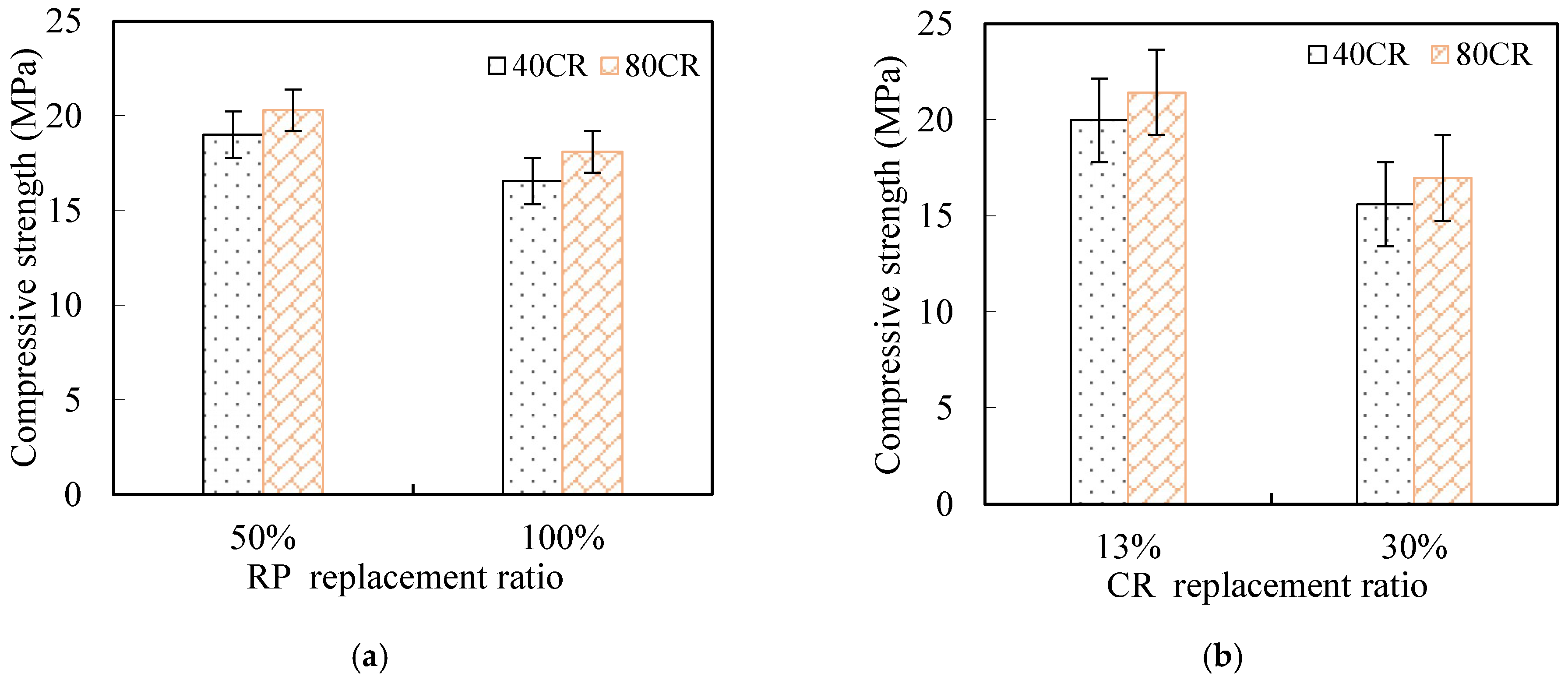

The influence of replacement ratios and CR sizes on the compressive properties of the developed ECC are illustrated in

Figure 11. As shown in

Figure 11, with the RP replacement ratio rising from 50% to 100%, the compressive strength of composites incorporating 40CR and 80CR dipped by 21.9% and 20.8%, respectively. Though the considerable SiO

2 contents in RP, which possess filling and pozzolanic effects, can improve the concrete mechanical properties, the positive effects of RP were taken over by the excessive contents of inactive CaCO

3 when the RP replacement percentage reached 100%. Therefore, identifying the optimal percentage of the RP for a particular mix is of great importance. Similarly, there was a slight decline in the compressive strength of ECC mixtures with the increase of CR replacement ratio. The decrease in compressive strength is due to the increase of porosity caused by the addition of crumb rubber. In terms of the CR particle size, it could be found that the higher compressive strength can be achieved when the finer CR particle size (80CR) partially replaced sand.

It is noted that the ratios of the tensile strength to the compressive strength of the composites ranged from 21% to 32%, which are obviously higher than the usual ratio (about 10%) of normal concrete. This is due to the tensile strength of ECC is mainly dependent on the fiber bridging capacity rather than matrix strength. It is observed that the compressive strain at peak strength is significantly enhanced with the increase of CR content, especially when smaller size CR was used. And these should be due to the much lower elastic modulus and better deformation capacity of CR than silica sand.

3.3. Fiber Bridging Capacity and Fracture Toughness

Unlike the typical trial-and-error material development methodology, ECC is designed based on micromechanics, which links the microstructure at the micro scale with the composite behavior at the macro scale. The tensile strain hardening behavior of ECC can be achieved by satisfying two fundamental criteria, that is, strength criterion and energy criterion [

42]. The strength criterion requires the fiber bridging strength to be higher than the matrix cracking strength, and all the composites proposed in this paper has been shown to meet this condition in

Section 3.1. The energy criterion requires the fiber bridging complementary energy

Jb’ to be far greater than the matrix fracture energy

Jtip to form steady state crack mode. Therefore, the ductility improvement in ECC incorporating RP and CR may be explained by using the two fundamental criteria and the classical PSH index [

43].

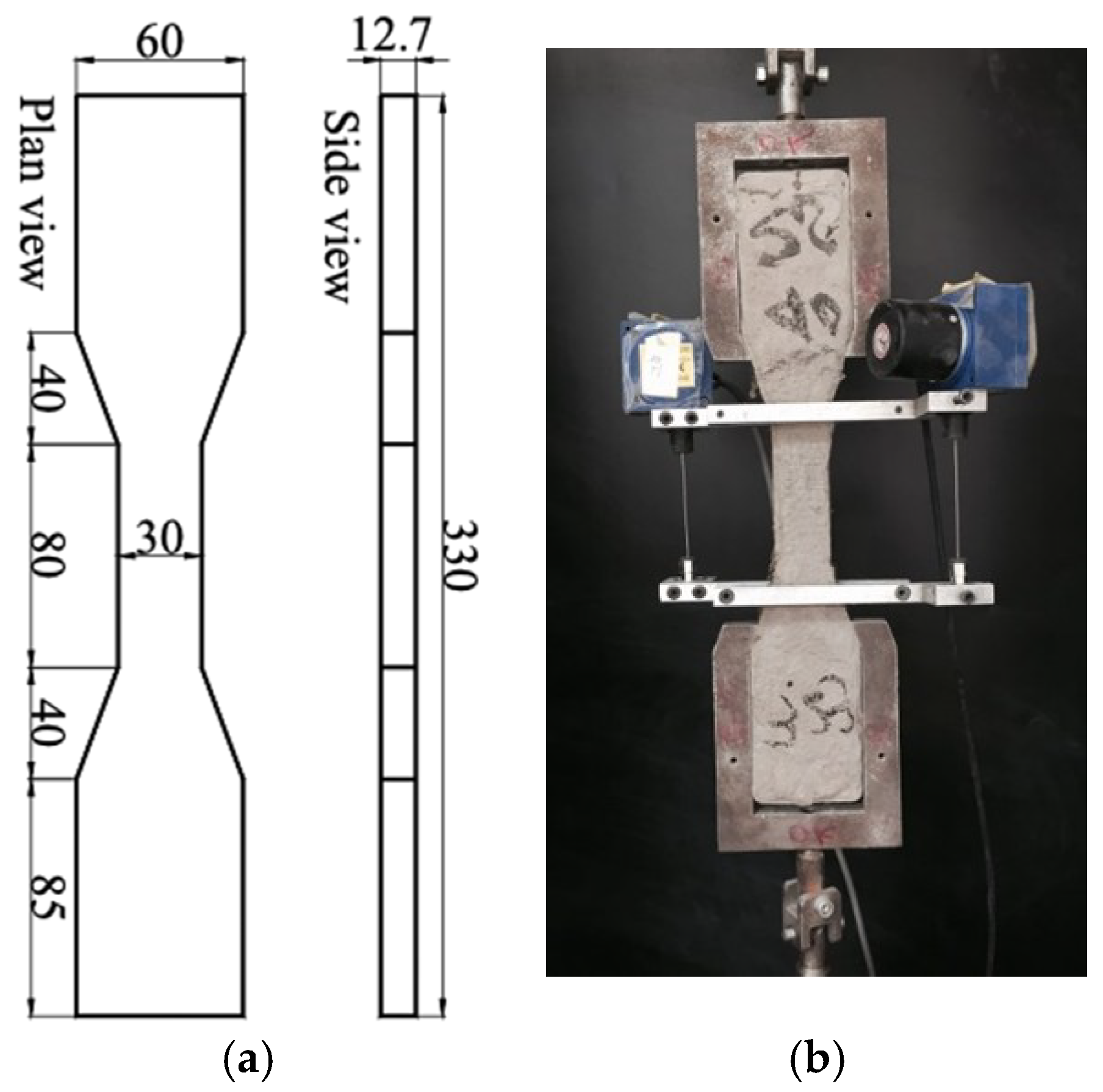

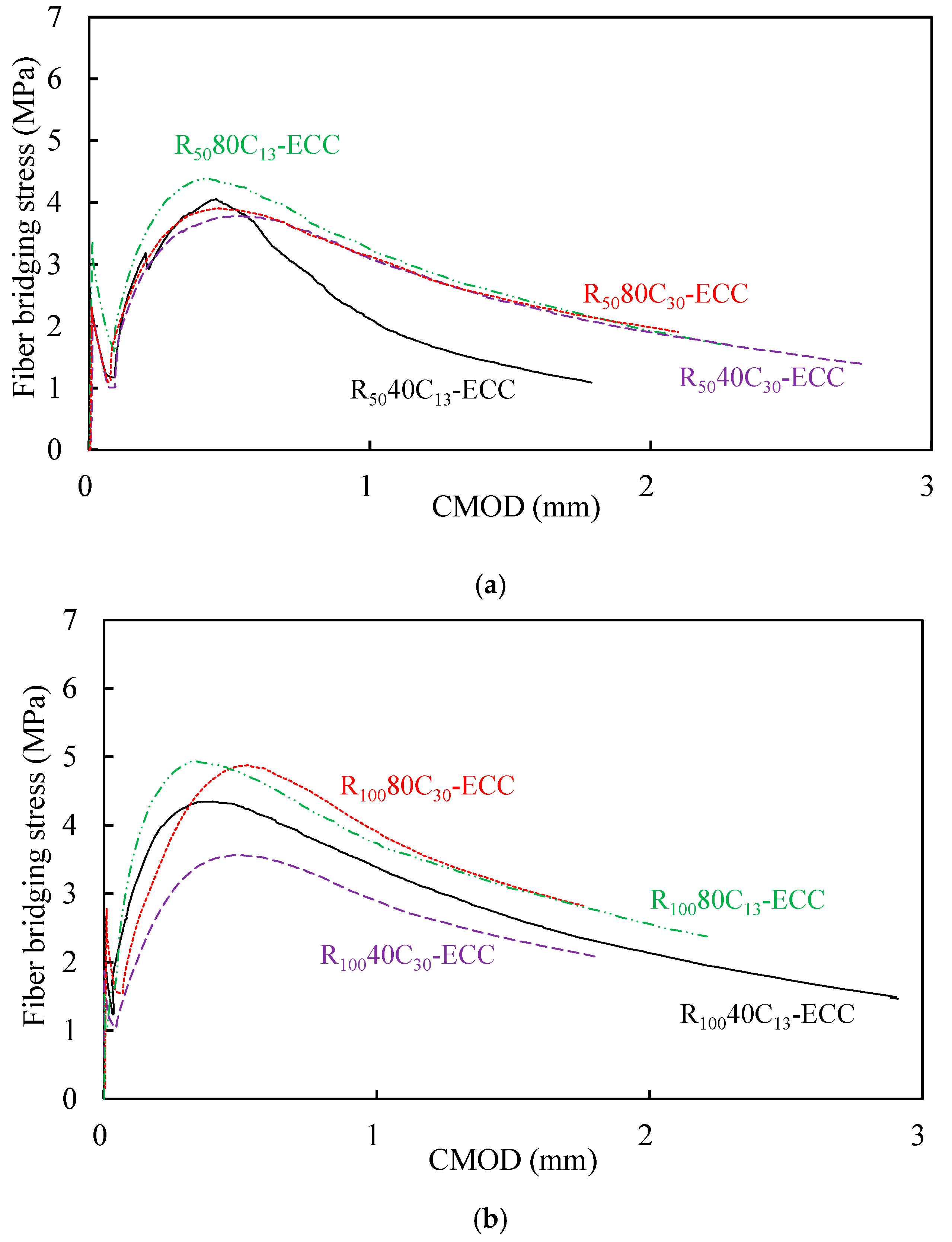

The fiber bridging stress

σOC versus crack mouth opening displacement (CMOD)

δB relation curves illustrated in

Figure 12 were experimentally determined from single-crack tensile test. According to Equation (1),

Jb’, which is the reflection of energy consumed by friction when fibers are pulled out from matrix, can be derived.

Table 5 lists the values of the peak stress

σOC, the corresponding crack opening displacement

δB and

Jb’. As shown in

Table 5, it is clear that the values of

Jb’ are obviously enhanced with the increasing replacement ratio of RP, which demonstrated that RP does have effect of increasing the bond-slip capacity between fiber and matrix, especially in the case that the smooth and spherical-shaped fly ash was replaced by the irregular-shaped RP particles, see

Figure 3. However, there was a slight decrease of fiber bridging stress

σOC when the CR replacement ratio changed from 13% to 30%, indicating that excessive contents of CR would generate negative effect on the interfacial bond between PE fiber and matrix. Despite the reduction of fiber bridging peak stress

σOC as the increase of CR replacement ratio, the value of

Jb’ still had a slight improvement due to the remarkable rise of the

δB value.

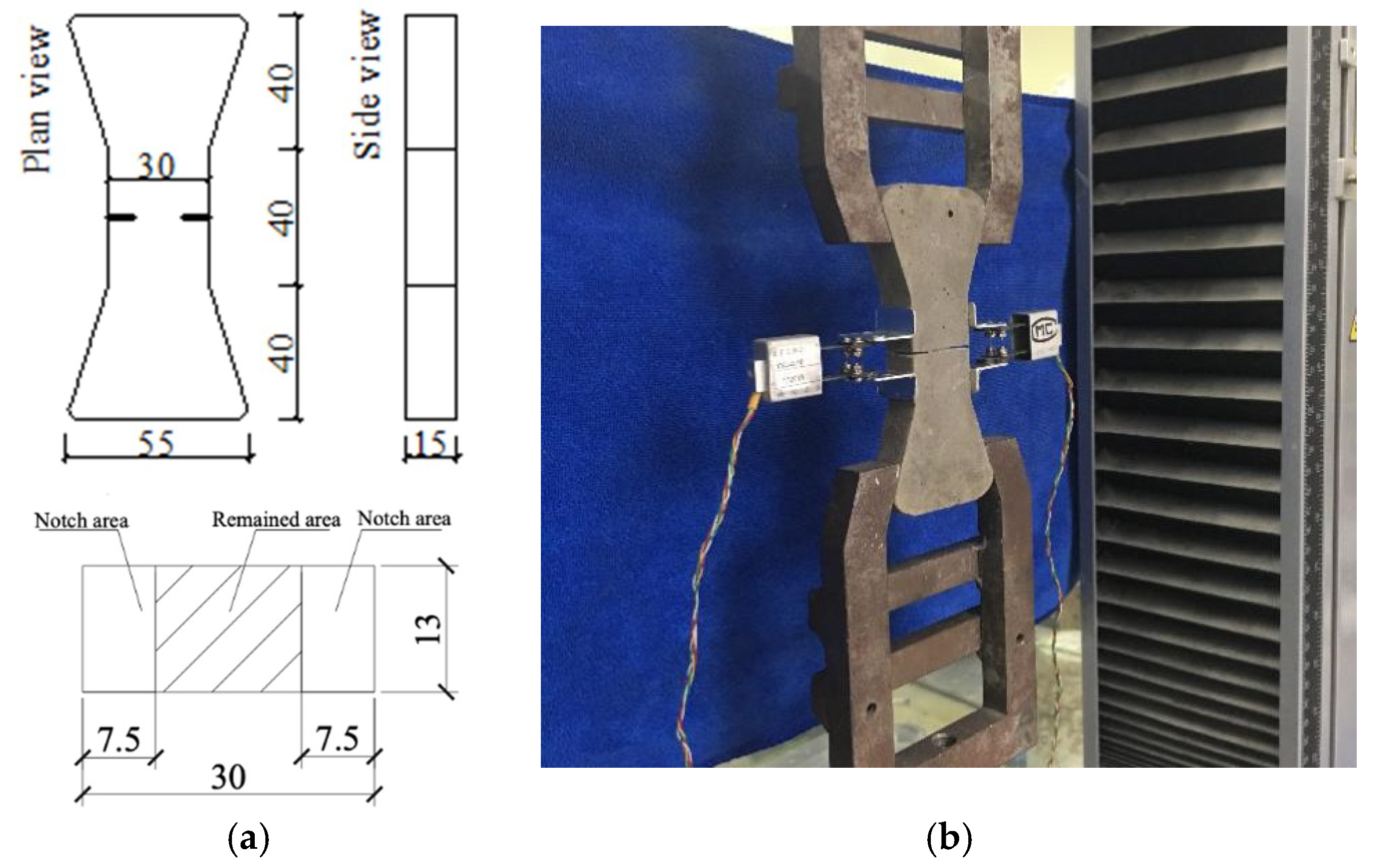

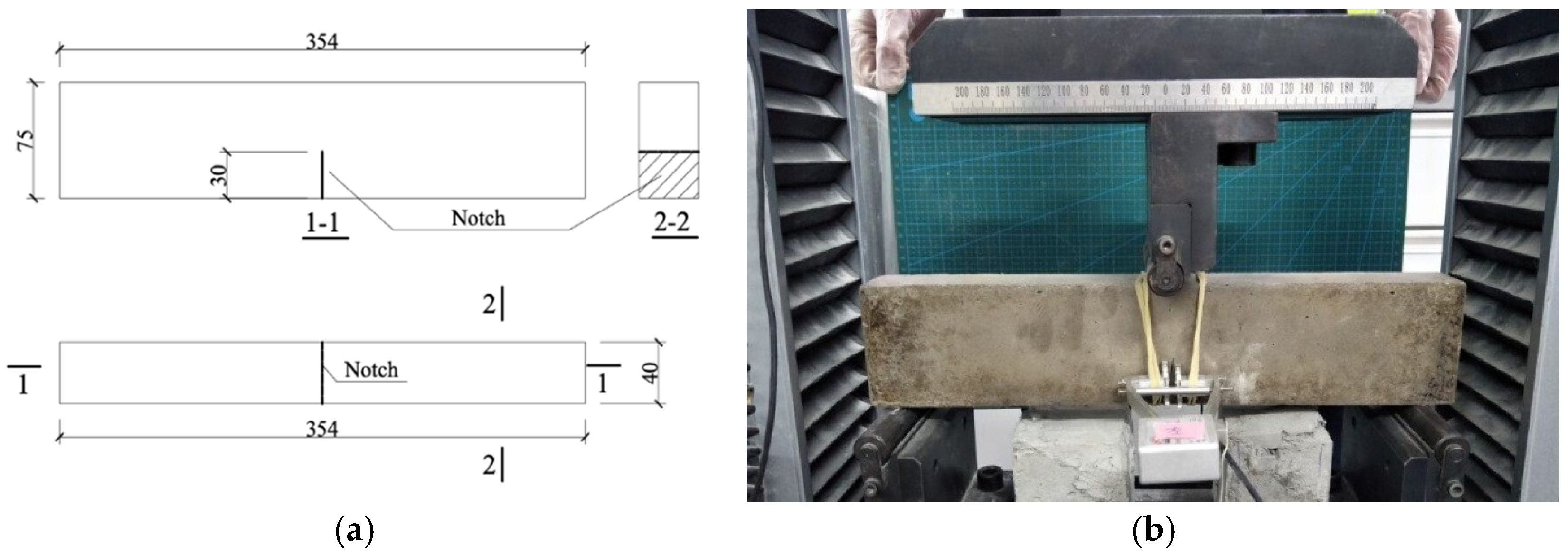

Referring to the three-point bending test in ASTM E399 [

38], the matrix fracture toughness K

Q can be derived according to Equations (2) and (3).

where

PQ is the peak load;

S is the span of the three-point beam;

a is the notch depth;

W is the width of the three-point beam;

B and

BN are the thickness of the three-point beam;

f(

α/W) is the shape parameter of three-point beam.

Based on the maximum load

KQ, the matrix fracture energy

Jtip was computed according to Equation (4), where

Em is the elastic modulus of matrix determined from the initial slope of the tensile stress–strain curve.

The related calculation parameters of the notched beam specimen and the fracture indexes (

KQ and

Jtip) are given in

Table 6. As can be seen, the fracture indexes had a modest decline as the increasing of RP replacement ratio. It can be explained that RP has the close content of SiO

2, but the higher content of CaCO

3 (CaO) in comparison with the fly ash presented in

Table 2. As can be seen, the fracture indexes had a modest decline with the increase of the RP replacement ratio. It can be explained that RP has the close content of SiO

2, but the higher content of CaCO

3 (CaO) in comparison with the fly ash presented in

Table 2. Similarly, the addition of CR diminished the matrix toughness

KQ and the matrix fracture energy

Jtip, which should attribute to the low elastic modulus of CR and weak bonging between CR particle and matrix. To a certain extent, the CR powder can be considered as the artificial flaw and it can make matrix easier to crack.

According to the pseudo-strain hardening (PSH) criterion proposed by Kanda and Li [

43], the tensile strain capacity of cementitious composites is closely related to the ratio

Jb’/

Jtip (PSH index), which indicates the potential of developing multiple cracking. Specifically, a higher

Jb’/

Jtip ratio is favorable for saturated multiple cracking behavior and leads to higher strain capacity.

Jb’,

Jtip, tensile strain capacity

εtu, and the values of

Jb’/

Jtip are listed in

Table 7.

Figure 13 shows the relation between the tensile strain capacity

εtu and the strain hardening index

Jb’/

Jtip. It is observed that

Jb’/

Jtip remains the positive correlation with tensile capacity. The higher

Jb’/

Jtip ratio unsurprisingly leads to higher strain capacity. The ratio of

Jb’/

Jtip/

εtu ranges from 12.4 to 23.8, demonstrating the PSH index still acceptable as a criterion to quantify the tensile ductility of composites.

In summary, the incorporation of RP increases Jb′ and the incorporation of CR decreases Jtip result in enhanced strain-hardening PSH index. Therefore, combining effect of decreasing Jtip and increasing Jb’ leads to a larger Jb’/Jtip, indicating a better chance for saturated multiple cracking and significant improvement ductility.