Dynamic Characteristics and Failure Mechanism of Vegetated Revetment under Cyclic Loading

Abstract

1. Introduction

2. Test Schemes

2.1. Vegetated Bituminous Mixture

2.1.1. Raw Materials

- Adopting an appropriate proportion of nutrient solution, ferrous sulfate particles and water to form a mixed solution;

- Properly mixing vermiculite powder, perlite, nutritive soil, compound fertilizer and seeds to prepare the cultivation environment for vegetation;

- Adding CMC-Na thickener into the cultivation solution until it reached a uniform state;

- Finally, infiltrating the viscous cultivation solution from the last step into the porous bituminous mixture; an alternative approach would be to immerse the porous bituminous mixture into the cultivation solution for half an hour (see Figure 1). The cultivation solution should be abundant to immerse the asphalt samples. Theoretically, the porous asphalt has a porosity rate of around 20% and could be fully filled with cultivation solution. In practice, however, volumes between 10% and 15% of asphalt samples were filled by cultivation solution.

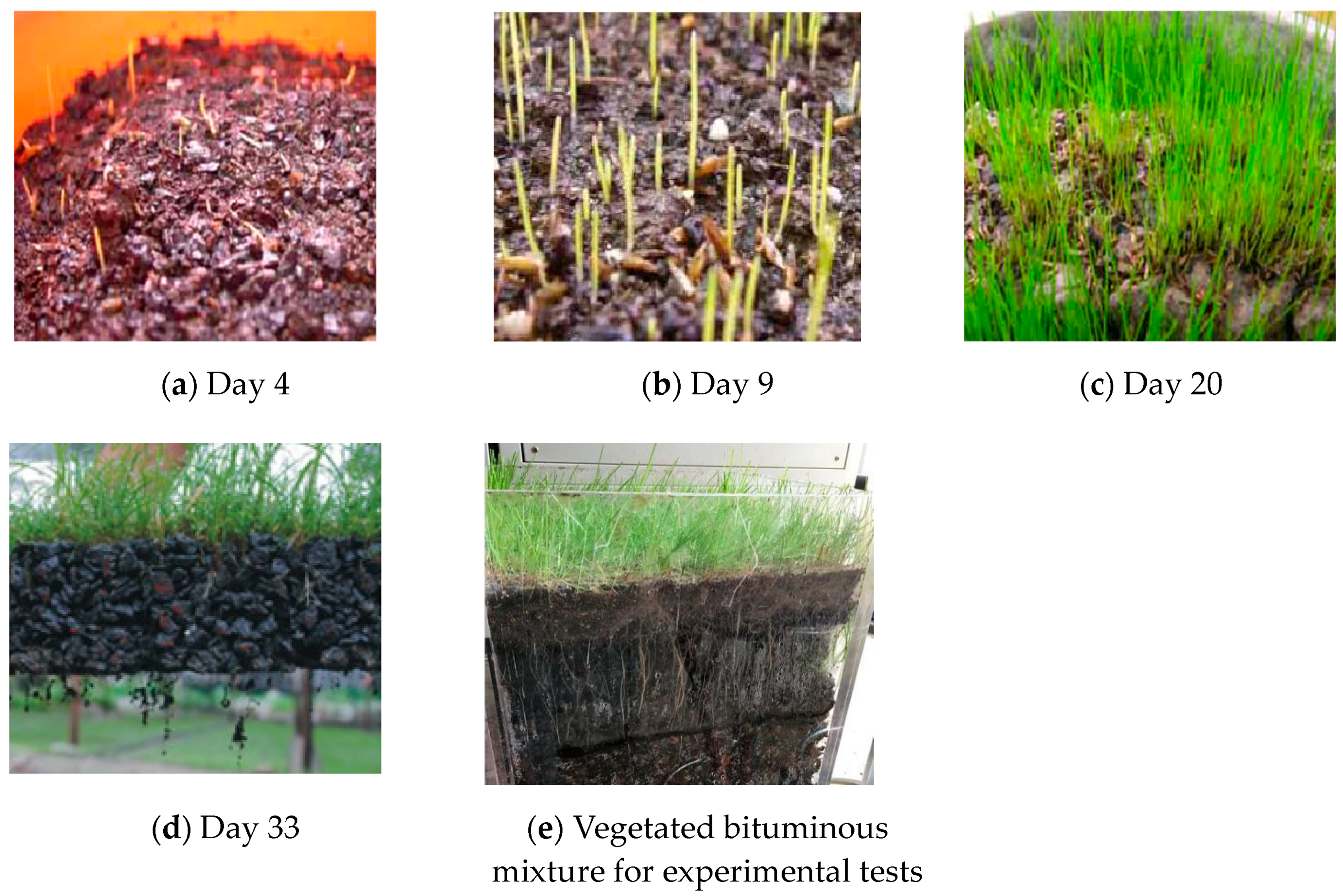

2.1.2. Vegetation Preparation and Growth

2.2. Physical and Mechanical Properties of Foundation Soil

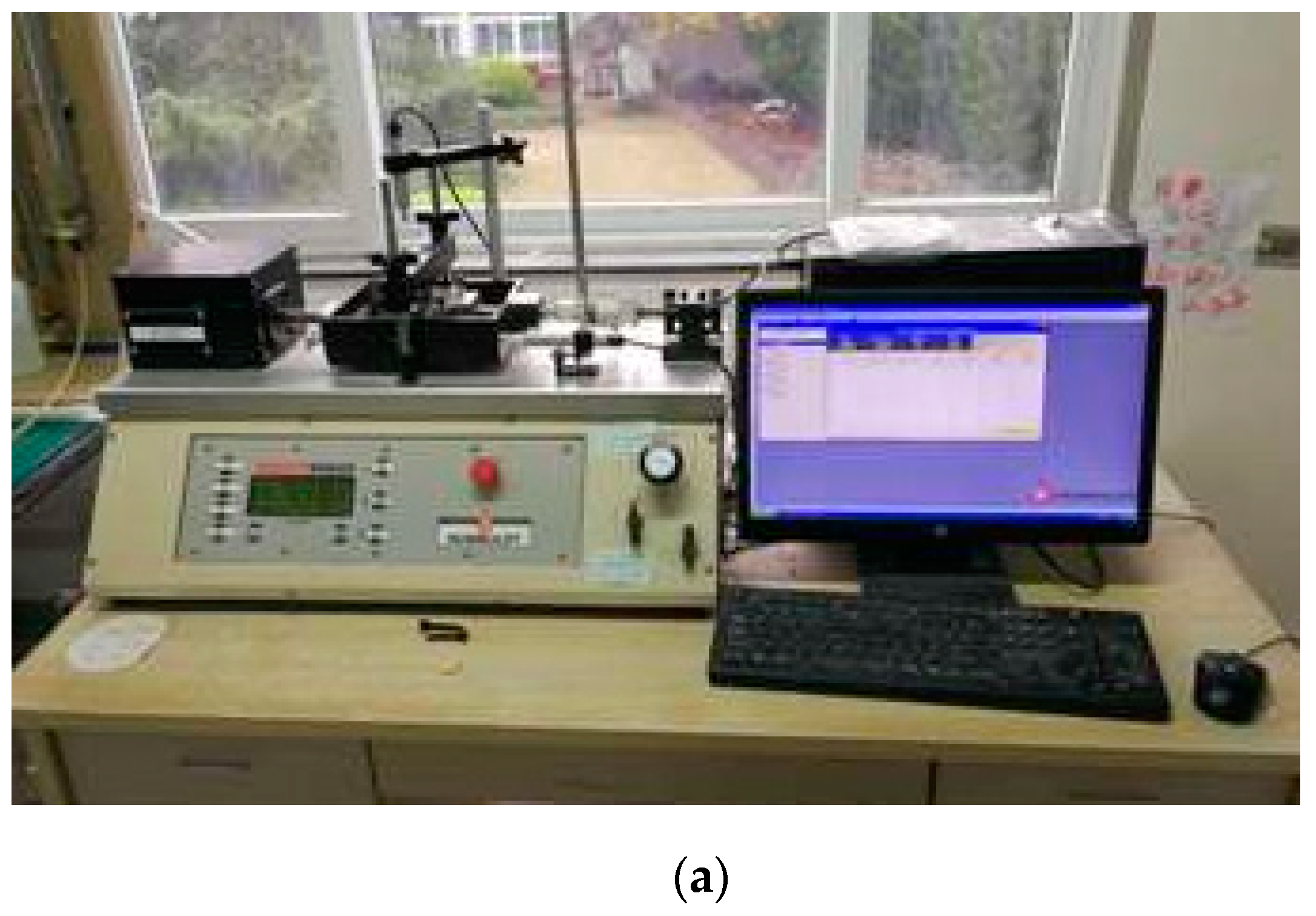

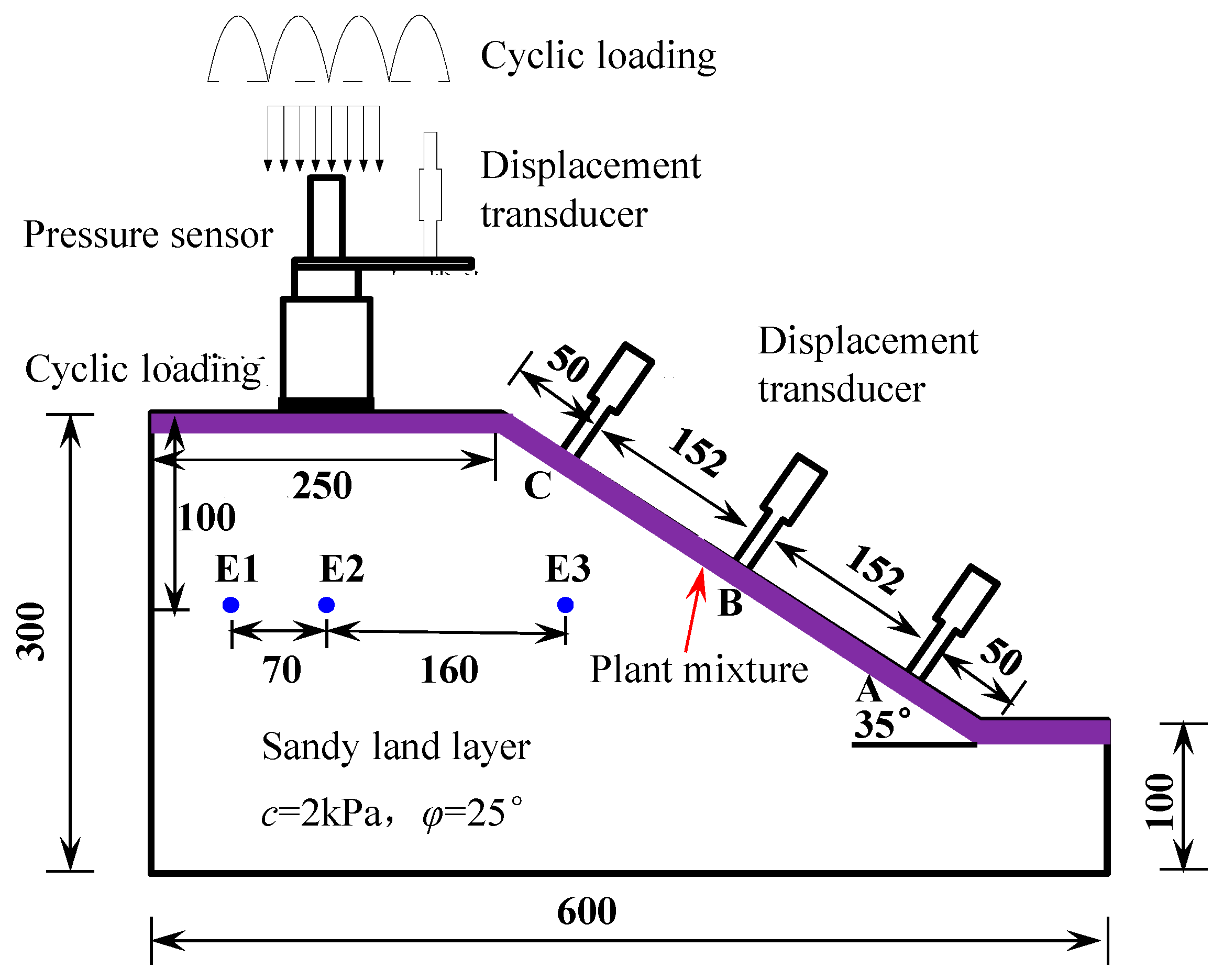

2.3. Loading Device and the Monitoring Scheme

3. Analysis of Test Results

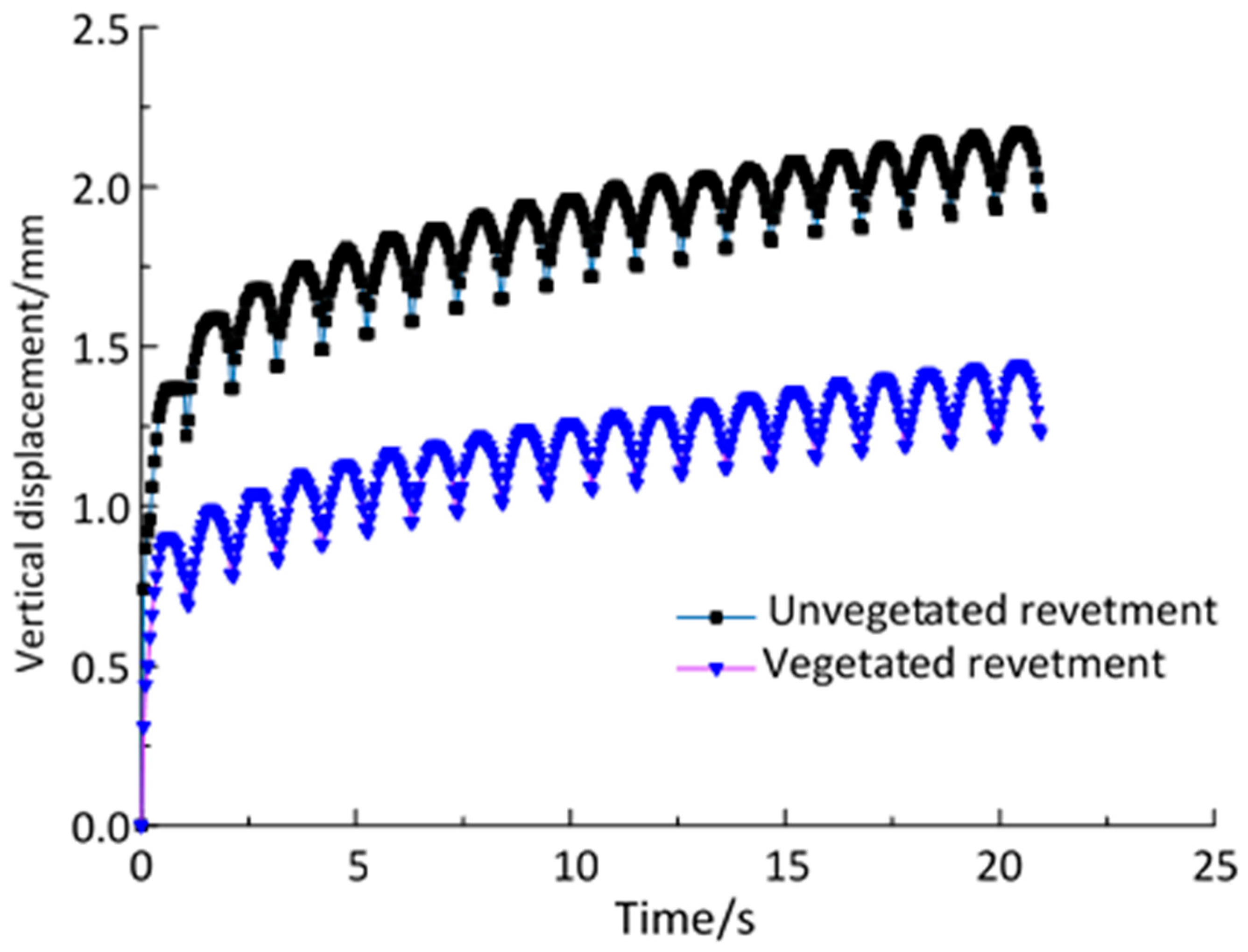

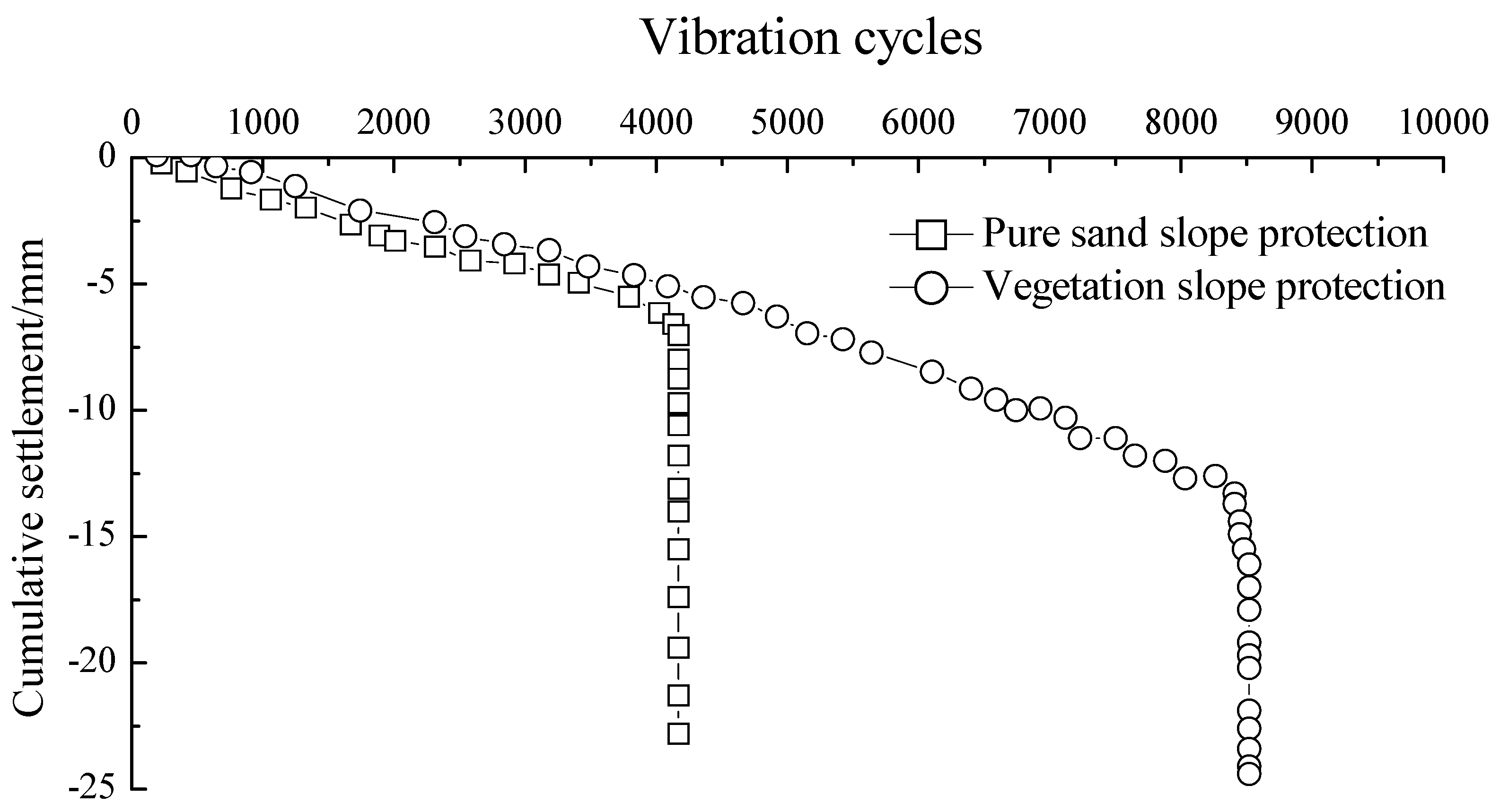

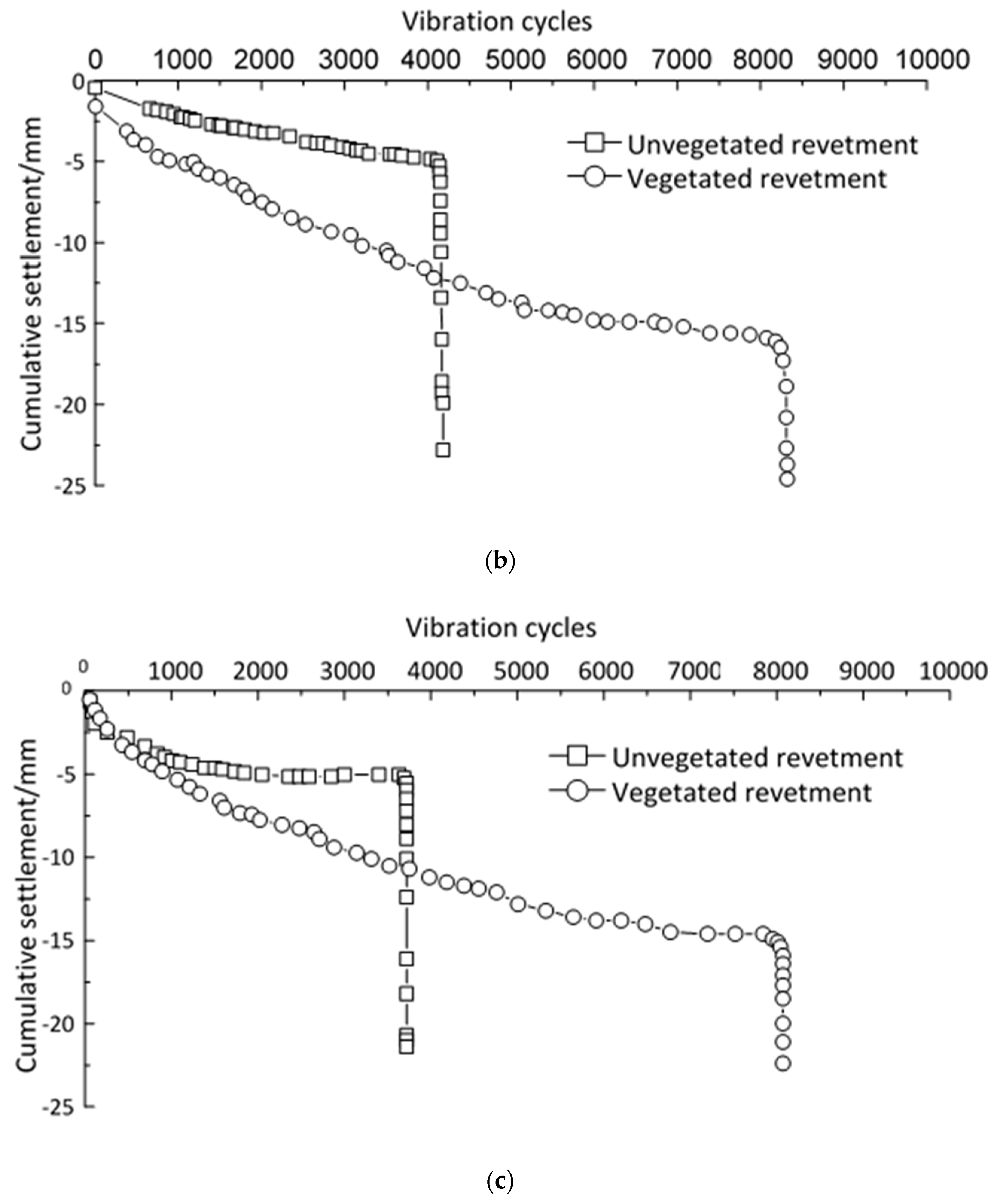

3.1. Displacement of Revetment

3.2. Lateral Cumulative Deformation of Revetment

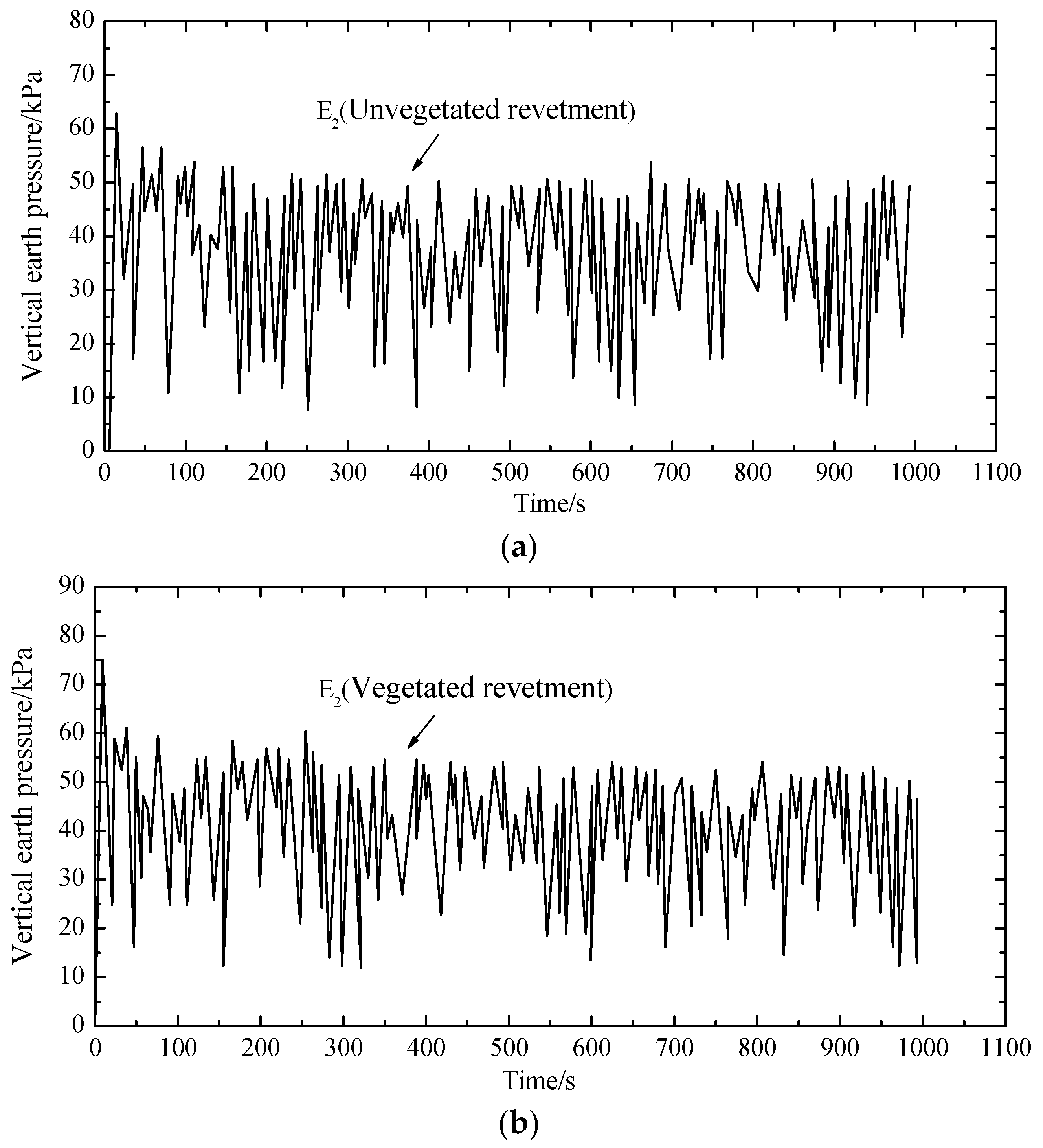

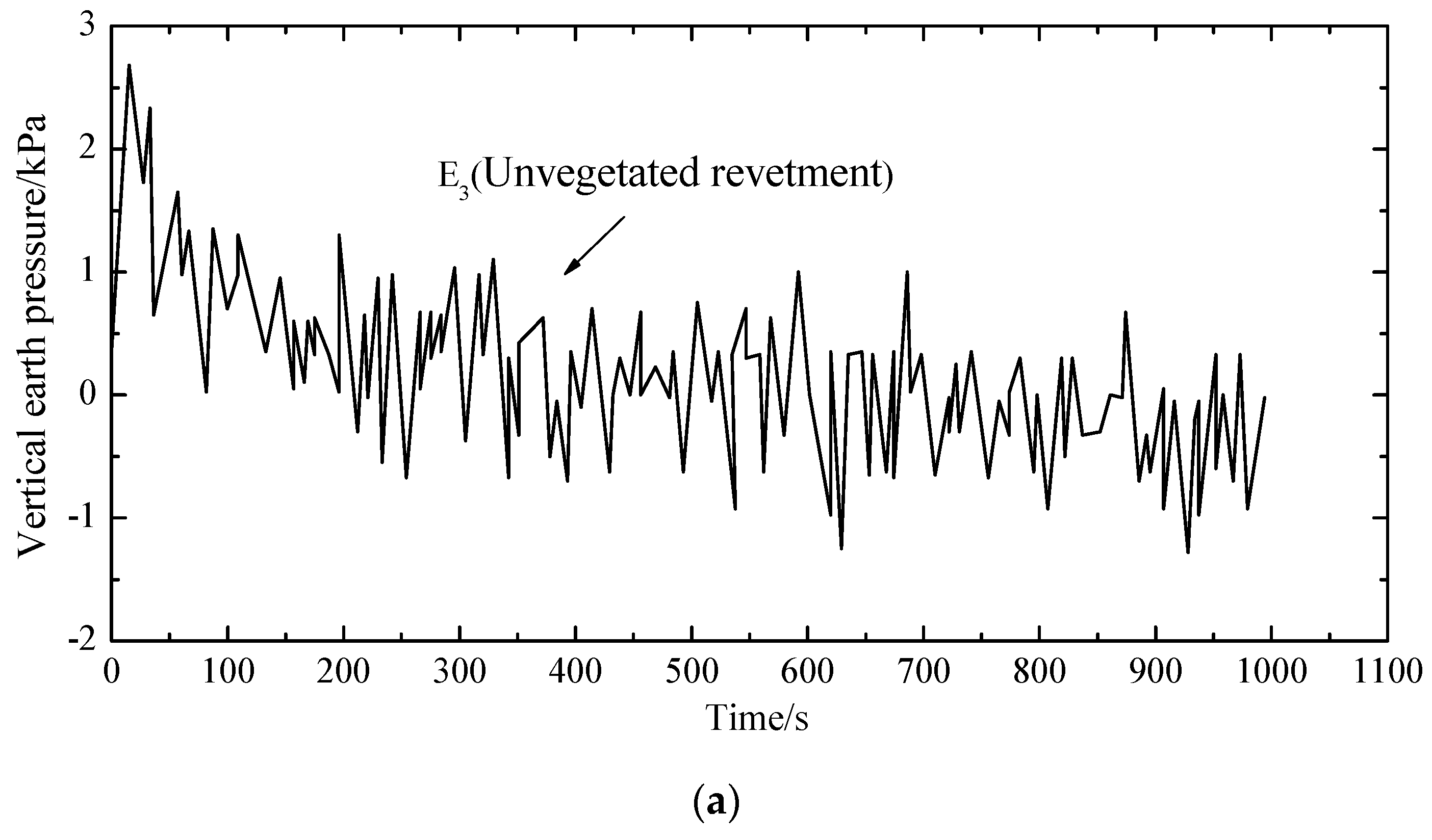

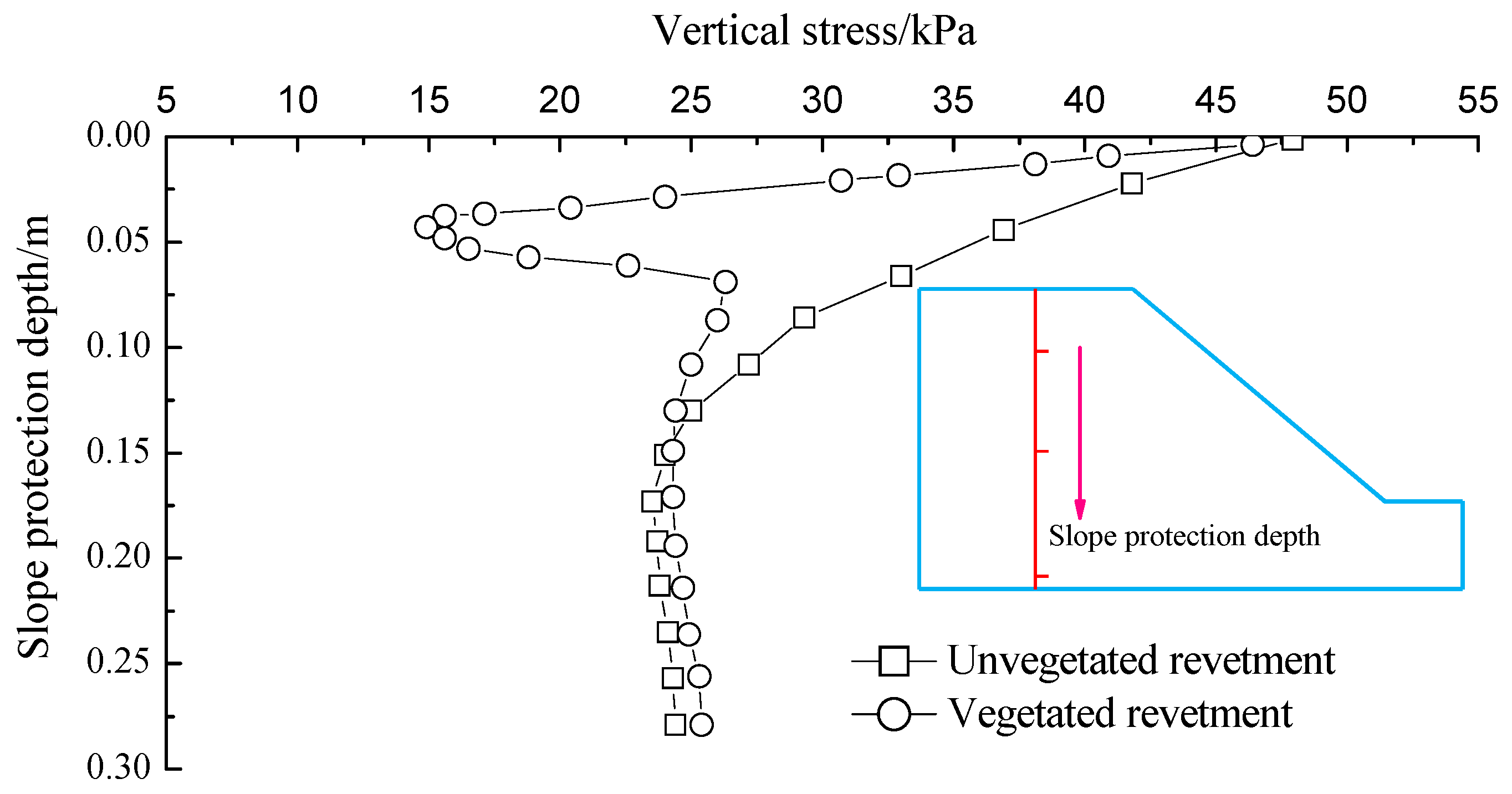

3.3. Soil Pressure in Revetments under Dynamic Cyclic Loading

4. FEM Analysis of the Stability of Vegetated Revetments

4.1. Method of Applying Cyclic Loading

4.2. Establishment of the Three-Dimensional Finite Element Model

4.3. Analysis of Numerical Simulation

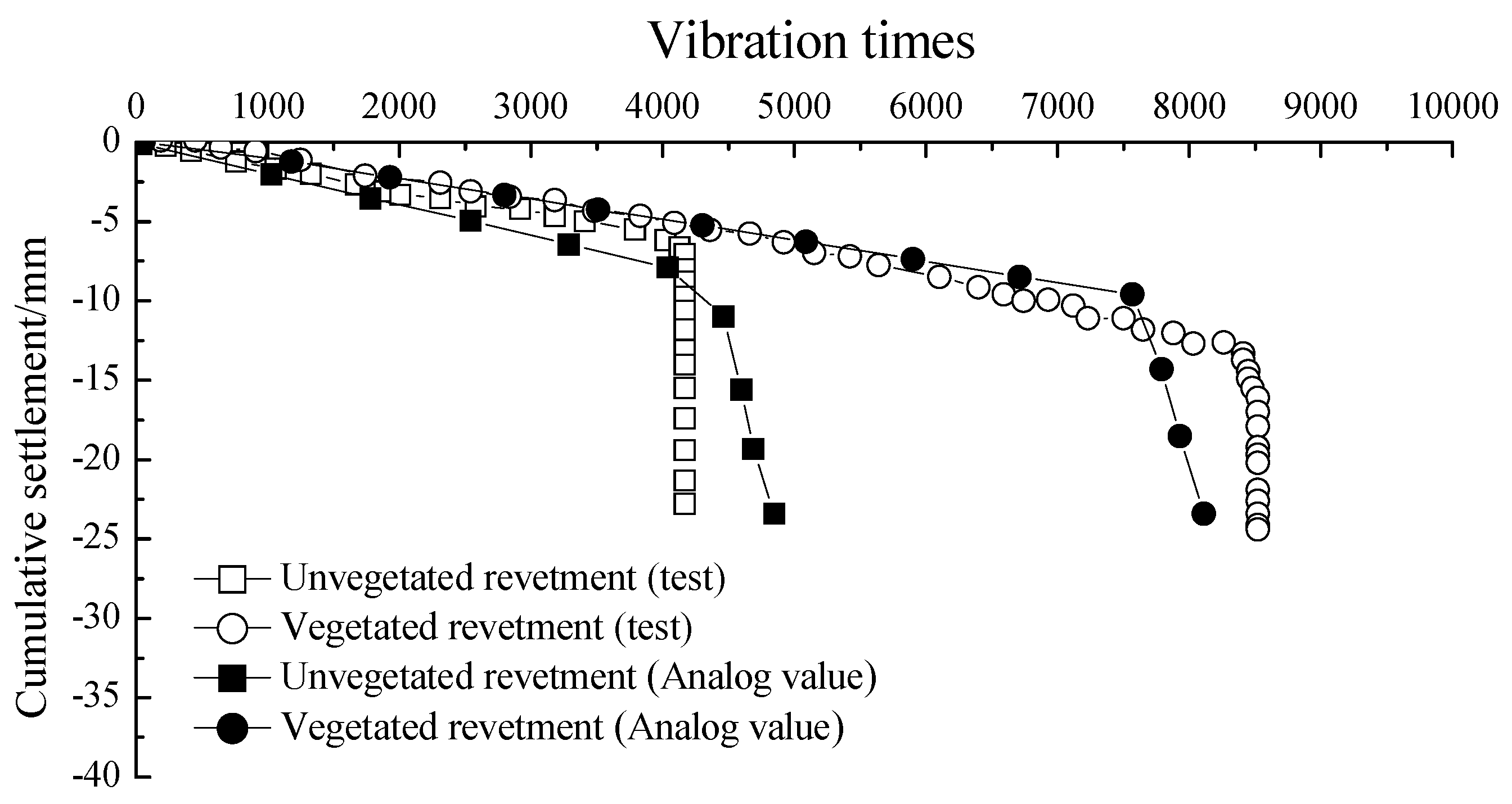

4.3.1. Comparison between Test and Numerical Calculation

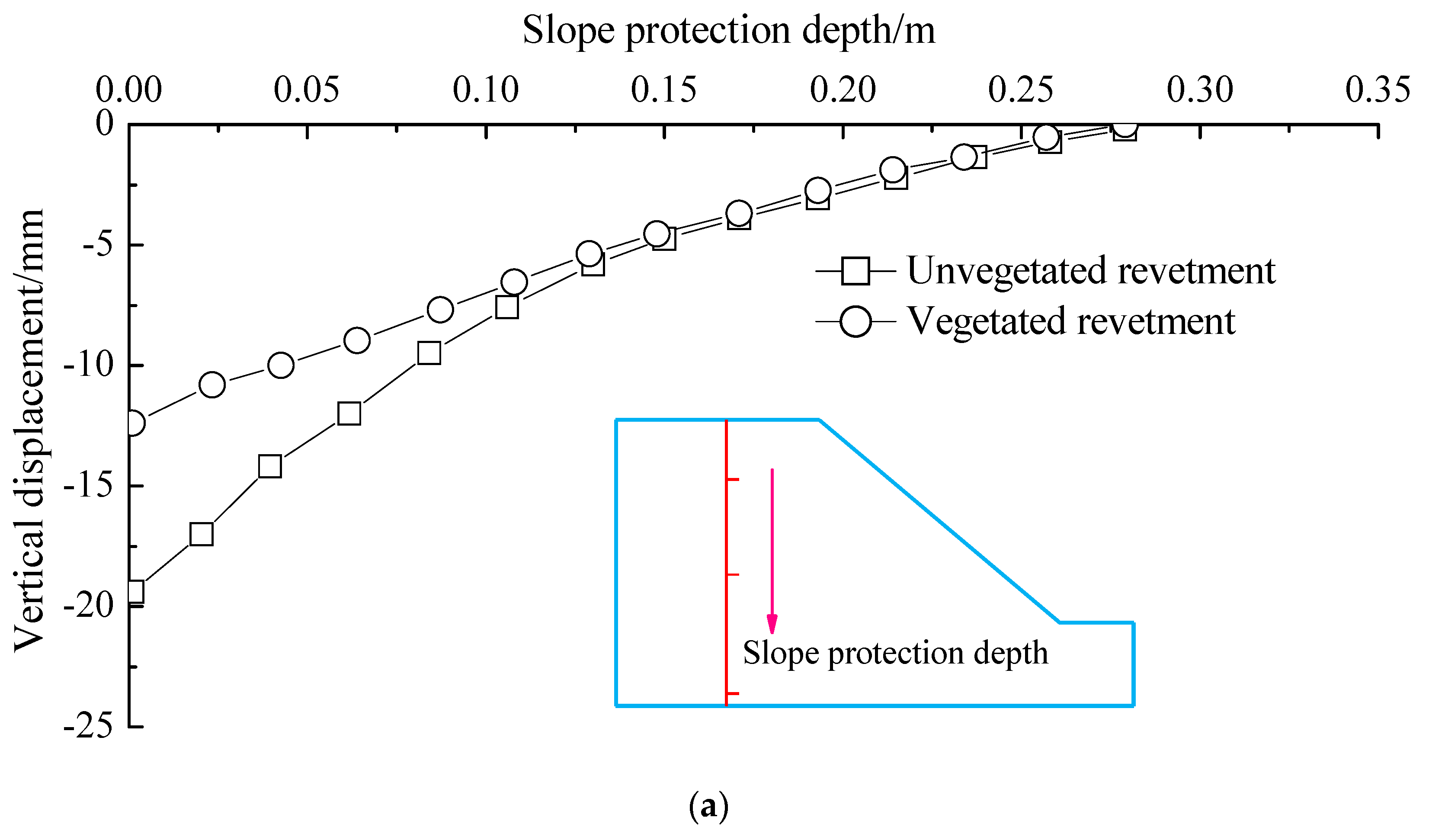

4.3.2. Displacements along the Depth of Revetments

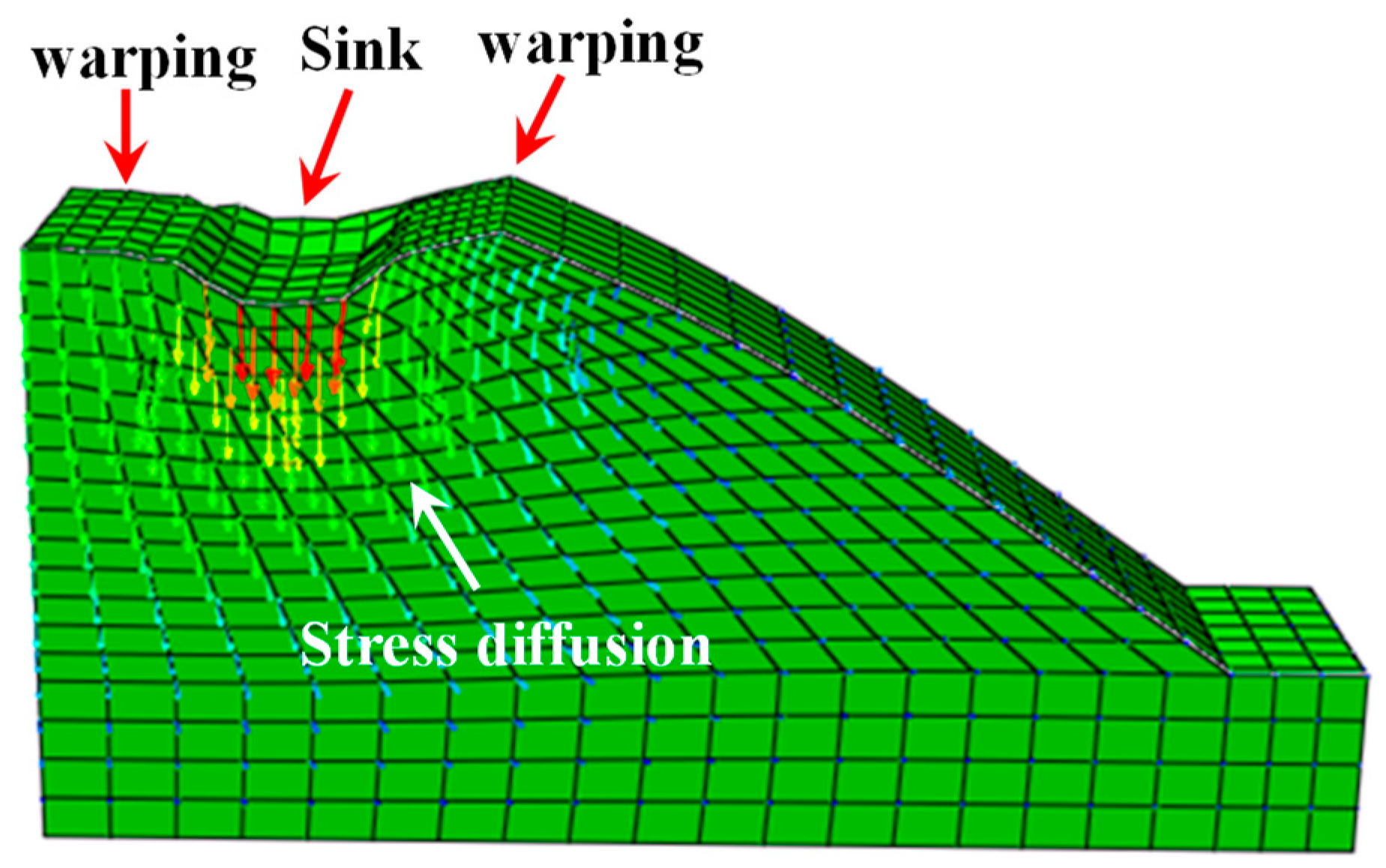

4.3.3. Sliding Trend of Vegetated Revetment

4.3.4. Internal Stress Distribution in Revetments

5. Conclusions

- As the loading cycle increased, accumulative settlement reached a critical point. Afterwards, the cumulative settlement increased sharply as a result of the revetment slope failure;

- The top of the revetment slope, which was closer to the loading center, there was a higher lateral deformation compared to the points at the middle and bottom of the slope;

- The vegetation in bituminous mixture had a significant influence on the lateral displacement of a revetment by increasing its overall stability;

- Within the same horizontal layer, the peak and mean values of soil pressure at the test point right below the loading center were significantly larger than the points on two sides;

- The maximum and mean values of soil pressure within the vegetated revetment were generally higher than those in the unvegetated models, indicating that the vegetated bituminous mixture increased the soil stiffness;

- The numerical simulation adopting a three-dimensional finite element model showed generally consistent vertical settlement values as the experimental tests did for both vegetated and unvegetated revetments. The potential causes of the differences between the numerical simulation and experimental tests were identified, such as the mesh partitioning in the finite element model;

- The vegetation had a reinforcement effect in restricting the vertical movement along the depth of the revetment under the loading plate. However, the reinforcement effect was more significant in the shallow soil layers.

Author Contributions

Funding

Conflicts of Interest

References

- Akbar, A.T.A.; Ha, S.R. Landslide hazard zoning along Himalayan Kaghan Valley of Pakistan-by integration of GPS, GIS, and remote sensing technology. Landslides 2011, 8, 527–540. [Google Scholar] [CrossRef]

- Lee, S. Application of logistic regression model and its validation for landslide susceptibility mapping using GIS and remote sensing data. Int. J. Remote Sens. 2005, 26, 1477–1491. [Google Scholar] [CrossRef]

- Korup, O. Geomorphometric characteristics of New Zealand landslide dams. Eng. Geol. 2004, 73, 13–35. [Google Scholar] [CrossRef]

- Del Ventisette, C.; Gigli, G.; Bonini, M. Insights from analogue modelling into the deformation mechanism of the Vaiont landslide. Geomorphology 2015, 228, 52–59. [Google Scholar] [CrossRef]

- Jian, W.; Wang, Z.; Yin, K. Mechanism of the Anlesi landslide in the Three Gorges Reservoir. Eng. Geol. 2009, 108, 86–95. [Google Scholar] [CrossRef]

- Miao, H.; Wang, G.; Yin, K. Mechanism of the slow-moving landslides in Jurassic red-strata in the Three Gorges Reservoir. Eng. Geol. 2014, 171, 59–69. [Google Scholar] [CrossRef]

- Bao, X.; Liao, W.; Dong, Z.; Wang, S.; Tang, W. Development of Vegetation-Pervious Concrete in Grid Beam System for Soil Slope Protection. Materials 2017, 10, 96. [Google Scholar] [CrossRef] [PubMed]

- Dutto, P.; Stickle, M.M.; Pastor, M.; Manzanal, D.; Yague, A.; Moussavi Tayyebi, S.; Lin, C.; Elizalde, M.D. Modelling of Fluidised Geomaterials: The Case of the Aberfan and the Gypsum Tailings Impoundment Flowslides. Materials 2017, 10, 562. [Google Scholar] [CrossRef] [PubMed]

- Meyer, C. The greening of the industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Sumanasooriya, M.S.; Neithalath, N. Pore structure features of pervious concretes proportioned for desired porosities and their performance prediction. Cem. Concr. Compos. 2011, 33, 778–787. [Google Scholar] [CrossRef]

- Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar]

- Deo, O.; Neithalath, N. Comrressive response of pervious concrete proportioned for desired porosities. Constr. Build. Mater. 2011, 25, 4181–4189. [Google Scholar] [CrossRef]

- LP, H.; Beek, V.; Bogaard, T.A. Assessing the relative importance of root reinforcement and hydrology with respect to slope stabilization by eco-engineering. Geophys. Res. Abstr. 2004, 6, 68–79. [Google Scholar]

- Osman, N.; Barakbah, S.S. Parameters to Predict Slope Stability-Soil Wate and Root Profiles. Int. J. Civ. Eng. 2006, 28, 621–629. [Google Scholar]

- Zhou, X.J.; Zhao, X.F. Reinforcement Action of Slope Protection with Herbage at Shallow Layer. J. North. Jiaotong Univ. 1995, 19, 143–146. [Google Scholar]

- Zhang, Y.W.; Liu, Y.M.; Zhou, Y. Study for the Destroy Principle and Model of the Yunnan Pine’s Lateral Root-soil Friction Bond. Shandi Xuebao (China) 2002, 20, 628–631. [Google Scholar]

- Zhang, F.; Chen, J.X.; Chen, X.B. The Study on Shear Strength of Facial Soil-in-Root of Biotechnological Protection on Side Slope. Soil Mech. Found. Eng. 2005, 19, 25–27. (In Chinese) [Google Scholar]

- Ahmed, A.E.; EI-Kourd, A.A. Properties of Concrete incorporating Natural and Crushed Stone Very Fine Sand. ACI Mater. J. 1989, 86, 417–424. [Google Scholar]

- Malhotra, V.M.; Carette, G.G. Performance of Concrete Incorporating Limestone Dust as Partial Replacement for Sand. ACI Mater. J. 2007, 82, 363–371. [Google Scholar]

- Zhou, J.; Chen, X.; Fu, Q.; Xu, G.; Cai, D. Dynamic Responses of Asphalt Concrete Waterproofing Layer in Ballastless Track. Appl. Sci. 2019, 9, 375. [Google Scholar] [CrossRef]

- Si, C.; Cao, H.; Chen, E.; You, Z.; Tian, R.; Zhang, R.; Gao, J. Dynamic Response Analysis of Rutting Resistance Performance of High Modulus Asphalt Concrete Pavement. Appl. Sci. 2018, 8, 2701. [Google Scholar] [CrossRef]

- Bazzaz, M.; Darabi, M.K.; Little, D.N.; Garg, N. A Straightforward Procedure to Characterize Nonlinear Viscoelastic Response of Asphalt Concrete at High Temperatures. Transport. Res. Rec.: J. Transp. Res. Board 2018, 2672, 481–492. [Google Scholar] [CrossRef]

- Dapportp, S.; Rinaldi, M.; Casagli, N. Failure mechanisms and pore water pressure conditions: Analysis of a riverbank along the Arno River (Central Italy). Eng. Geol. 2001, 61, 221–242. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Fatigue performance of bituminous mixtures made with recycled concrete aggregates and waste tire rubber. Constr. Build. Mater. 2017, 157, 26–33. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Structural analysis of polymer modified bituminous materials in the rehabilitation of light-medium traffic volume roads. Constr. Build. Mater. 2017, 156, 621–631. [Google Scholar] [CrossRef]

- Botella, R.; Pérez-Jiménez, F.E.; Miró, R.; Martínez, A.H. New methodology to estimate the fatigue behavior of bituminous mixtures using a strain sweep test. Constr. Build. Mater. 2017, 135, 233–240. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T.; Grenfell, J.R.A. Influence of fibres on rheological properties and toughness of bituminous binder. Constr. Build. Mater. 2018, 163, 901–911. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Rubio-Gámez, M.C. A review of fatigue damage in bituminous mixtures: Understanding the phenomenon from a new perspective. Constr. Build. Mater. 2016, 113, 927–938. [Google Scholar] [CrossRef]

- Botella, R.; Pérez-Jiménez, F.E.; Riahi, E.; López-Montero, T.; Miró, R.; Martínez, A.H. Self-heating and other reversible phenomena in cyclic testing of bituminous materials. Constr. Build. Mater. 2017, 156, 809–818. [Google Scholar] [CrossRef]

- Topini, D.; Toraldo, E.; Andena, L.; Mariani, E. Use of recycled fillers in bituminous mixtures for road pavements. Constr. Build. Mater. 2018, 159, 189–197. [Google Scholar] [CrossRef]

- Nosetti, A.; Pérez-Madrigal, D.; Pérez-Jiménez, F.; Martínez, A.H. Effect of the recycling process and binder type on bituminous mixtures with 100% reclaimed asphalt pavement. Constr. Build. Mater. 2018, 167, 440–448. [Google Scholar] [CrossRef]

- Hernández, M.I.G. Life time prediction for low energy and ecological effects bituminous mixtures. Constr. Build. Mater. 2018, 158, 108–113. [Google Scholar] [CrossRef]

- Ramalingam, S.; Murugasan, R.; Nagabhushana, M.N. Laboratory performance evaluation of environmentally sustainable sisal fibre reinforced bituminous mixes. Constr. Build. Mater. 2017, 148, 22–29. [Google Scholar] [CrossRef]

- El-Naggar, M.E.; Kennedy, J.B. New design method for reinforced sloped embankments. Eng. Struct. 1997, 19, 28–36. [Google Scholar] [CrossRef]

- Chen, W.; Gen, J.; Xu, Y.D. A Study on Planting Property Test of Environmental Ecotype Asphalt Mixture. Shanghai Environ. Sci. 2015, 34, 127–131. [Google Scholar]

- Liu, H.S.; Nian, T.K.; Wan, S.S. Effect of Boundary Constraint Condition on the Stability Analysis of 3D Slope. J. Jilin Univ.: Earth Sci. Ed. 2010, 40, 638–644. (in Chinese). [Google Scholar]

- Forrest, J.A.; Hunt, H.E.M. A three-dimensional tunnel model for calculation of train-induced ground vibration. J. Sound. Vib. 2006, 294, 678–705. [Google Scholar] [CrossRef]

- Dobran, S.; Zagury, G.J. Arsenic speciation and mobilization in CCA-contaminated soils: Influence of organic matter content. Sci. Total Environ. 2006, 364, 239–250. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.J.; Chen, X.P.; Yang, J. Effect of microbial mediated iron plaque reduction on arsenic mobility in paddy soil. J. Environ. Sci. 2009, 21, 1562–1568. [Google Scholar] [CrossRef]

- Kirk, M.F.; Roden, E.E.; Crossey, L.J. Experimental analysisof arsenic precipitation during microbial sulfate and iron reduction in model aquifer sediment reactors. Geochim. Cosmochim. Acta 2010, 74, 2538–2555. [Google Scholar] [CrossRef]

| Porosity (%) | Compressive Strength Under 15 °C (MPa) | Compressive Modulus Under 15 °C (MPa) | Dynamic Stability Under 60 °C (Number/mm) | Total Deformation (mm) | Three-Day Flying Loss (%) | Permeability Coefficient (cm/s) |

|---|---|---|---|---|---|---|

| 23 | 2.19 | 412.12 | 2875 | 2.90 | 12.7 | 0.039 |

| Raw Material | µ | E/MPa | c/kPa | φ/(°) | ρ/g.cm−3 | Moisture (%) |

|---|---|---|---|---|---|---|

| Foundation soil | 0.32 | 10.82 | 2.2 | 25 | 1.91 | 35.7 |

| Asphalt mixture | 0.27 | 395 | — | — | 1.92 | 23.52 |

| Measurement Point | Un- Vegetated E1 | Vegetated E1 | Un- Vegetated E2 | Vegetated E2 | Un- Vegetated E3 | Vegetated E3 |

|---|---|---|---|---|---|---|

| Mean value/kPa | 9.57 | 9.49 | 34.02 | 37.68 | 0.23 | 0.30 |

| Maximum value/kPa | 15.79 | 18.65 | 57.45 | 67.43 | 3.32 | 0.95 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Jin, R.; Zhu, H.; Xu, Y.; Wanatowski, D.; He, L.; Guo, Q. Dynamic Characteristics and Failure Mechanism of Vegetated Revetment under Cyclic Loading. Materials 2019, 12, 716. https://doi.org/10.3390/ma12050716

Chen W, Jin R, Zhu H, Xu Y, Wanatowski D, He L, Guo Q. Dynamic Characteristics and Failure Mechanism of Vegetated Revetment under Cyclic Loading. Materials. 2019; 12(5):716. https://doi.org/10.3390/ma12050716

Chicago/Turabian StyleChen, Wei, Ruoyu Jin, Han Zhu, Yidong Xu, Dariusz Wanatowski, Lili He, and Qinglin Guo. 2019. "Dynamic Characteristics and Failure Mechanism of Vegetated Revetment under Cyclic Loading" Materials 12, no. 5: 716. https://doi.org/10.3390/ma12050716

APA StyleChen, W., Jin, R., Zhu, H., Xu, Y., Wanatowski, D., He, L., & Guo, Q. (2019). Dynamic Characteristics and Failure Mechanism of Vegetated Revetment under Cyclic Loading. Materials, 12(5), 716. https://doi.org/10.3390/ma12050716