Optimization of Maleinized Linseed Oil Loading as a Biobased Compatibilizer in Poly(Butylene Succinate) Composites with Almond Shell Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of PBS/ASF/MLO Composites

2.3. Mechanical Characterization

2.4. Morphological Characterization

2.5. Thermal Characterization

2.6. Thermomechanical Characterization

3. Results

3.1. Effect of MLO Loading on Mechanical Properties of PBS/ASF Composites

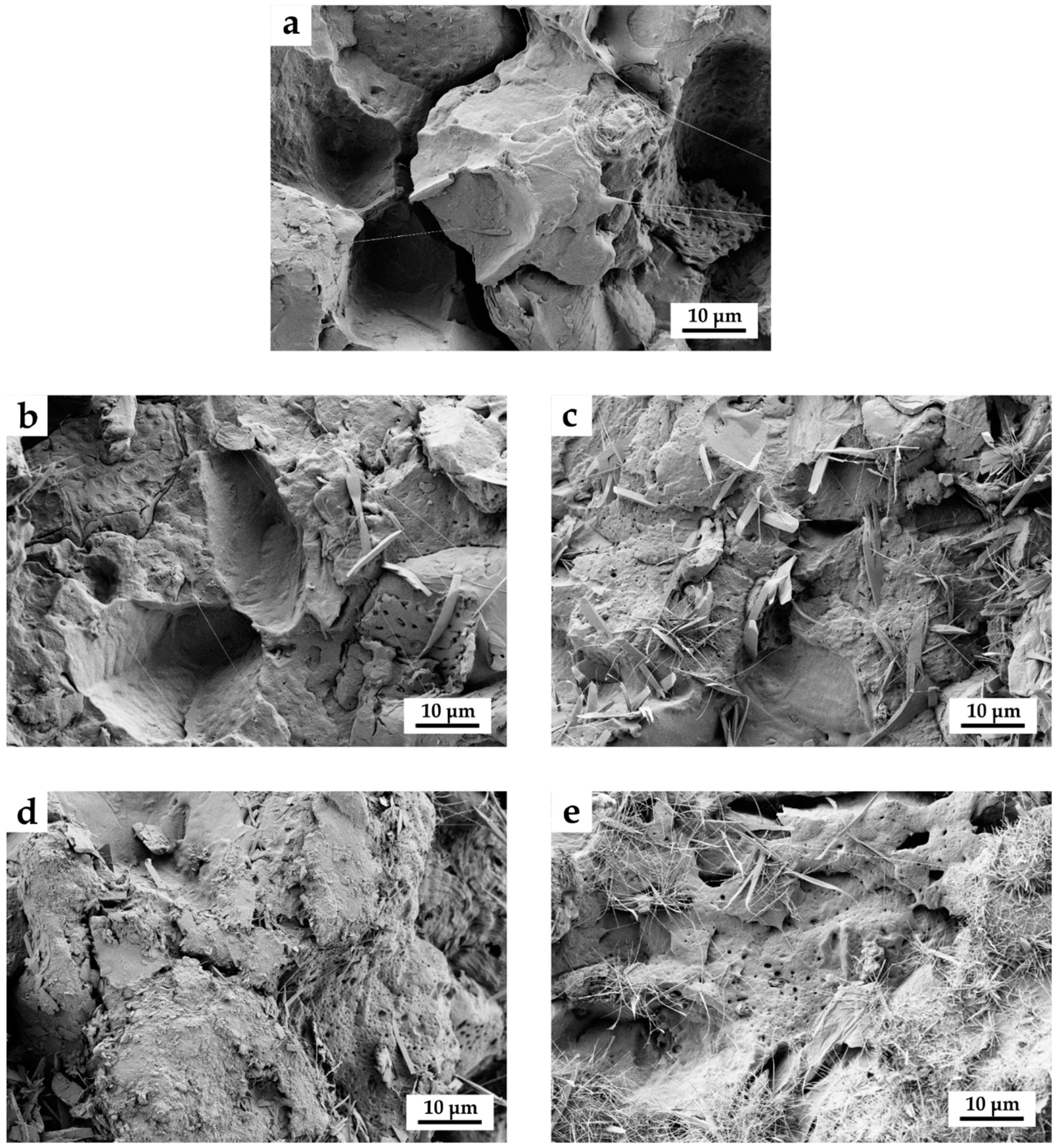

3.2. Effect of MLO Loading on Morphology of PBS/ASF Composites

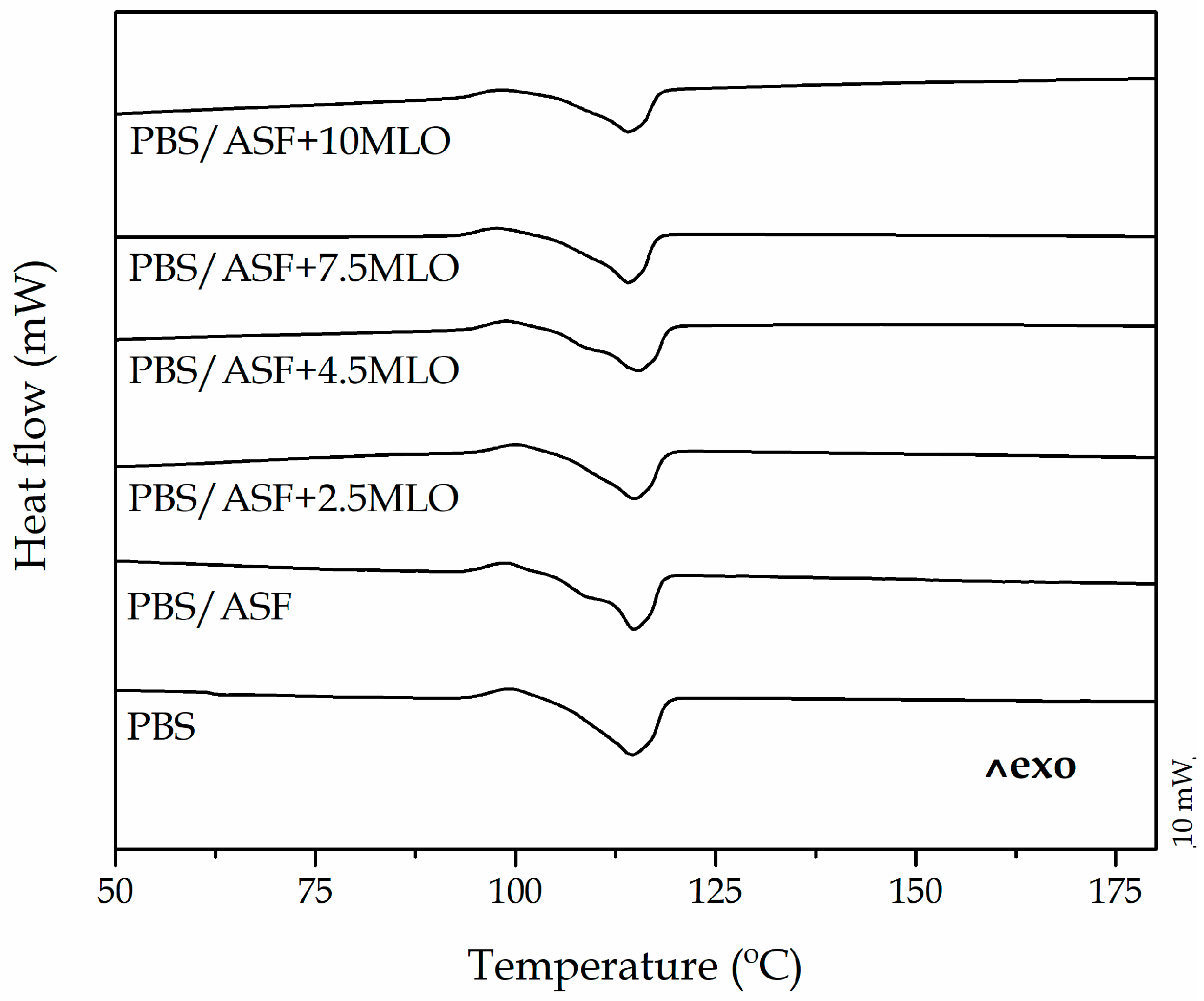

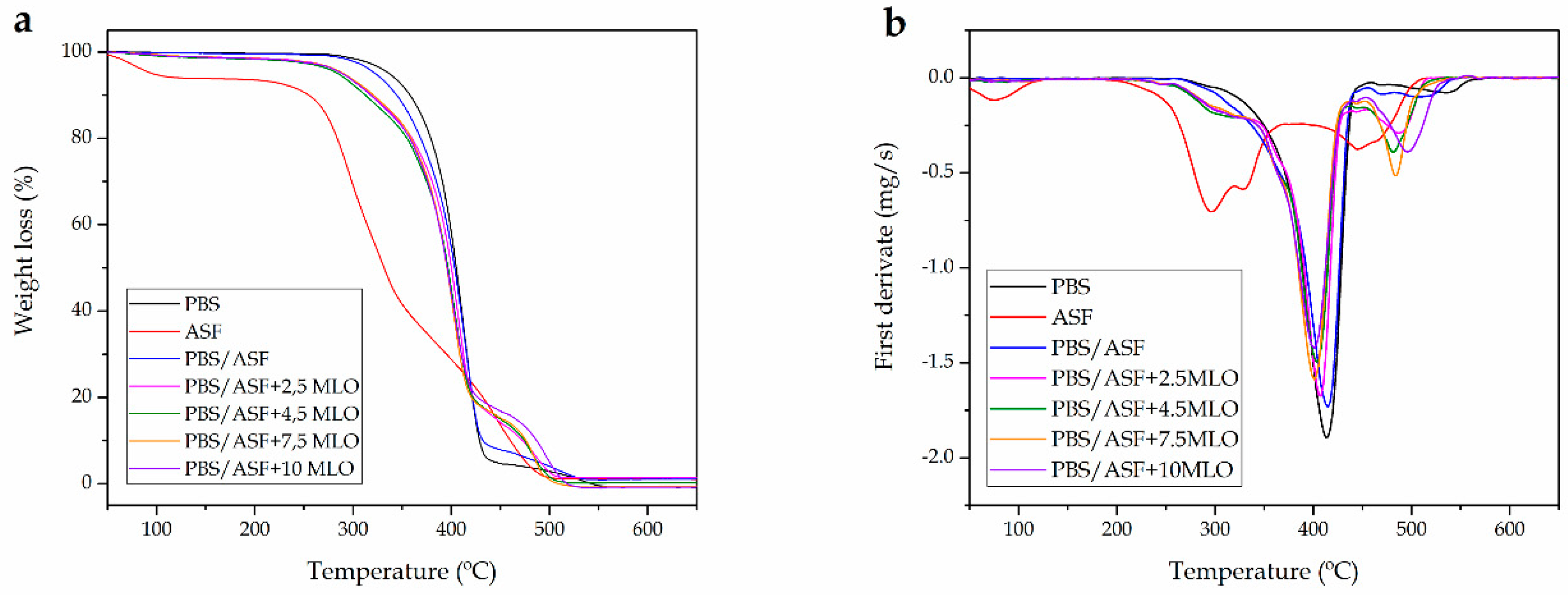

3.3. Effect of MLO Loading on Thermal Properties of PBS/ASF Composites

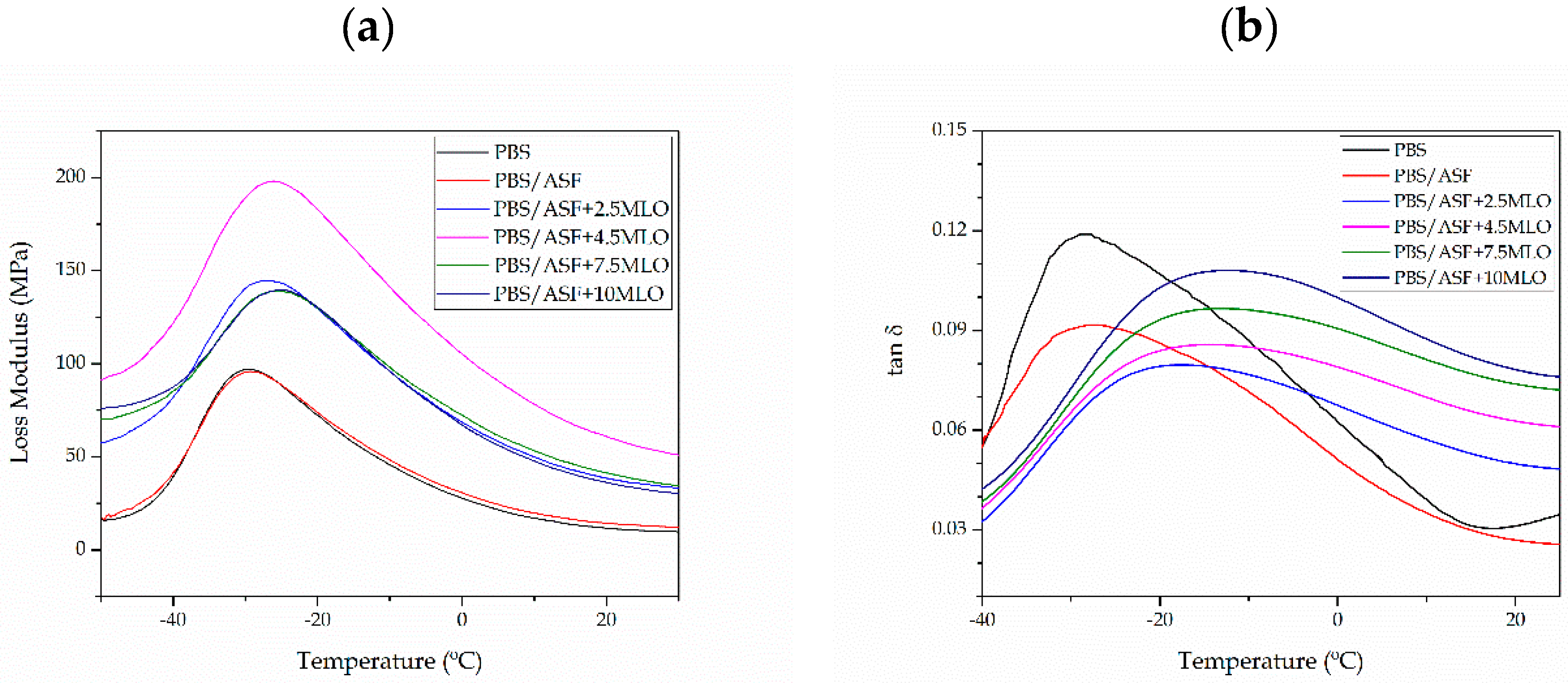

3.4. Effect of MLO Loading on Thermomechanical Properties of PBS/ASF Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly (butylene succinate)(PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Bechthold, I.; Bretz, K.; Kabasci, S.; Kopitzky, R.; Springer, A. Succinic acid: A new platform chemical for biobased polymers from renewable resources. Chem. Eng. Technol. 2008, 31, 647–654. [Google Scholar] [CrossRef]

- McKinlay, J.B.; Vieille, C.; Zeikus, J.G. Prospects for a bio-based succinate industry. Appl. Microbiol. Biotechnol. 2007, 76, 727–740. [Google Scholar] [CrossRef] [PubMed]

- Bozell, J.J.; Petersen, G.R. Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem. 2010, 12, 539–554. [Google Scholar] [CrossRef]

- Kim, H.S.; Yang, H.S.; Kim, H.J. Biodegradability and mechanical properties of agro-flour–filled polybutylene succinate biocomposites. J. Appl. Polym. Sci. 2005, 97, 1513–1521. [Google Scholar] [CrossRef]

- Siracusa, V.; Lotti, N.; Munari, A.; Rosa, M.D. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stabil. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Vytejckova, S.; Vapenka, L.; Hradecky, J.; Dobias, J.; Hajslova, J.; Loriot, C.; Vannini, L.; Poustka, J. Testing of polybutylene succinate based films for poultry meat packaging. Polym. Test 2017, 60, 357–364. [Google Scholar] [CrossRef]

- Hongsriphan, N.; Sanga, S. Antibacterial food packaging sheets prepared by coating chitosan on corona-treated extruded poly(lactic acid)/poly(butylene succinate) blends. J. Plast. Film Sheeting 2018, 34, 160–178. [Google Scholar] [CrossRef]

- Imre, B.; Pukánszky, B. Compatibilization in bio-based and biodegradable polymer blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J.M. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stabil. 2013, 98, 87–95. [Google Scholar] [CrossRef]

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Poly(butylene succinate) reinforced with different lignocellulosic fibers. Ind. Crop. Prod. 2013, 45, 160–169. [Google Scholar] [CrossRef]

- Kurokawa, N.; Kimura, S.; Hotta, A. Mechanical properties of poly(butylene succinate) composites with aligned cellulose-acetate nanofibers. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Reinders, M.; Bikiaris, D.N. Development and Study of Fully Biodegradable Composite Materials Based on Poly(butylene succinate) and Hemp Fibers or Hemp Shives. Polym. Compos. 2016, 37, 407–421. [Google Scholar] [CrossRef]

- Lee, H.Y.; Choi, D. Influence of Waste Fiber Content on the Thermal and Mechanical Properties of Waste Silk/Waste Wool/PBS Hybrid Biocomposites. Polym. Korea 2017, 41, 719–726. [Google Scholar] [CrossRef]

- Flores-Cano, J.V.; Sanchez-Polo, M.; Messoud, J.; Velo-Gala, I.; Ocampo-Perez, R.; Rivera-Utrilla, J. Overall adsorption rate of metronidazole, dimetridazole and diatrizoate on activated carbons prepared from coffee residues and almond shells. J. Environ. Manag. 2016, 169, 116–125. [Google Scholar] [CrossRef] [PubMed]

- Loffredo, E.; Castellana, G.; Senesi, N. Decontamination of a municipal landfill leachate from endocrine disruptors using a combined sorption/bioremoval approach. Environ. Sci. Pollut. Res. 2014, 21, 2654–2662. [Google Scholar] [CrossRef] [PubMed]

- Loffredo, E.; Castellana, G.; Taskin, E. A Two-Step Approach to Eliminate Pesticides and Estrogens from a Wastewater and Reduce Its Phytotoxicity: Adsorption onto Plant-Derived Materials and Fungal Degradation. Water Air Soil Pollut. 2016, 227, 1–12. [Google Scholar] [CrossRef]

- Adanez-Rubio, I.; Perez-Astray, A.; Mendiara, T.; Teresa Izquierdo, M.; Abad, A.; Gayan, P.; de Diego, L.F.; Garcia-Labiano, F.; Adanez, J. Chemical looping combustion of biomass: CLOU experiments with a Cu-Mn mixed oxide. Fuel Process. Technol. 2018, 172, 179–186. [Google Scholar] [CrossRef]

- Cerone, N.; Zimbardi, F. Gasification of Agroresidues for Syngas Production. Energies 2018, 11, 1280. [Google Scholar] [CrossRef]

- Safari, F.; Javani, N.; Yumurtaci, Z. Hydrogen production via supercritical water gasification of almond shell over algal and agricultural hydrochars as catalysts. Int. J. Hydrog. Energy 2018, 43, 1071–1080. [Google Scholar] [CrossRef]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.O.; Arrakhiz, F.Z.; Qaiss, A.; Bouhfid, R. Bio-composites based on polypropylene reinforced with Almond Shells particles: Mechanical and thermal properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- El Mechtali, F.Z.; Essabir, H.; Nekhlaoui, S.; Bensalah, M.; Jawaid, M.; Bouhfid, R.; Qaiss, A. Mechanical and Thermal Properties of Polypropylene Reinforced with Almond Shells Particles: Impact of Chemical Treatments. J. Bionic Eng. 2015, 12, 483–494. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Caballero, J.A.; Conesa, J.A.; Font, R.; Marcilla, A. Pyrolysis kinetics of almond shells and olive stones considering their organic fractions. J. Anal. Appl. Pyrolysis 1997, 42, 159–175. [Google Scholar] [CrossRef]

- Faludi, G.; Dora, G.; Imre, B.; Renner, K.; Moczo, J.; Pukanszky, B. PLA/Lignocellulosic Fiber Composites: Particle Characteristics, Interfacial Adhesion, and Failure Mechanism. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Carbonell, A.; Samper, M.D.; Garcia-Sanoguera, D.; Balart, R. Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos. Part B-Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B-Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Wang, F.; Yang, M.Q.; Zhou, S.J.; Ran, S.Y.; Zhang, J.Q. Effect of fiber volume fraction on the thermal and mechanical behavior of polylactide-based composites incorporating bamboo fibers. J. Appl. Polym. Sci. 2018, 135, 46148. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos. Part B-Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of natural fibre polymer composites. J. Polym. Eng. 2017, 37, 879–895. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sanchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B-Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.S.; Modak, J.M.; Chanda, M. Mechanical properties of wood-fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A-Appl. Sci. Manuf. 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Labidi, S.; Alqahtani, N.; Alejji, M. Effect of Compatibilizer on Mechanical and Physical Properties of Green Composites Based on High Density Polyethylene and Date Palm Fiber; International Conference on Composite Science and Technology: Sorrento, Italy, 2013; pp. 995–997. [Google Scholar]

- Pivsa-Art, W.; Chaiyasat, A.; Pivsa-Art, S.; Yamane, H.; Ohara, H. Preparation of Polymer Blends Between Poly(lactic acid) and Poly(butylene adipate-co-terephthalate) and Biodegradable Polymers as Compatibilizers. In 10th Eco-Energy and Materials Science and Engineering Symposium; Yupapin, P., PivsaArt, S., Ohgaki, H., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2013; Volume 34, pp. 549–554. [Google Scholar]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized Vegetable Oils Plasticized Poly(lactic acid) Biocomposites: Mechanical, Thermal and Morphology Properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, D.; Fenollar, O.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of Mechanical Ductile Properties of Poly(3-hydroxybutyrate) by Using Vegetable Oil Derivatives. Macromol. Mater. Eng. 2017, 302. [Google Scholar] [CrossRef]

- Narute, P.; Rao, G.R.; Misra, S.; Palanisamy, A. Modification of cottonseed oil for amine cured epoxy resin: Studies on thermo-mechanical, physico-chemical, morphological and antimicrobial properties. Prog. Org. Coat. 2015, 88, 316–324. [Google Scholar] [CrossRef]

- Samper, M.D.; Petrucci, R.; Sanchez-Nacher, L.; Balart, R.; Kenny, J.M. Properties of composite laminates based on basalt fibers with epoxidized vegetable oils. Mater. Des. 2015, 72, 9–15. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Qu, J.P.; Feng, Y.H.; Wu, Z.H.; Chen, F.Q.; Tang, H.L. Mechanical and thermal properties of epoxidized soybean oil plasticized polybutylene succinate blends. Polym. Adv. Technol. 2012, 23, 632–638. [Google Scholar] [CrossRef]

- Sarwono, A.; Man, Z.; Bustam, M.A. Blending of Epoxidised Palm Oil with Epoxy Resin: The Effect on Morphology, Thermal and Mechanical Properties. J. Polym. Environ. 2012, 20, 540–549. [Google Scholar] [CrossRef]

- Park, S.J.; Jin, F.L.; Lee, J.R. Effect of biodegradable epoxidized castor oil on physicochemical and mechanical properties of epoxy resins. Macromol. Chem. Phys. 2004, 205, 2048–2054. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, P.; Zhang, J.W.; Li, S.H.; Li, M.; Xia, J.L.; Zhou, Y.H. Preparation of biobased epoxies using tung oil fatty acid-derived C21 diacid and C22 triacid and study of epoxy properties. Green Chem. 2013, 15, 2466–2475. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Campo, M.J.; Quiles-Carrillo, L.; Masia, J.; Reig-Perez, M.J.; Montanes, N.; Balart, R. Environmentally Friendly Compatibilizers from Soybean Oil for Ternary Blends of Poly(lactic acid)-PLA, Poly(epsilon-caprolactone)-PCL and Poly(3-hydroxybutyrate)-PHB. Materials 2017, 10, 1339. [Google Scholar] [CrossRef] [PubMed]

- Carbonell-Verdu, A.; Ferri, J.M.; Dominici, F.; Boronat, T.; Sanchez-Nacher, L.; Balart, R.; Torre, L. Manufacturing and compatibilization of PLA/PBAT binary blends by cottonseed oil-based derivatives. Express Polym. Lett. 2018, 12, 808–823. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Blanes-Martinez, M.M.; Montanes, N.; Fenollar, O.; Torres-Giner, S.; Balart, R. Reactive toughening of injection-molded polylactide pieces using maleinized hemp seed oil. Eur. Polym. J. 2018, 98, 402–410. [Google Scholar] [CrossRef]

- Bayrak, A.; Kiralan, M.; Ipek, A.; Arslan, N.; Cosge, B.; Khawar, K.M. Fatty acid compositions of linseed (Linum usitatissimum l.) genotypes of different origin cultivated in turkey. Biotechnol. Biotechnol. Equip. 2010, 24, 1836–1842. [Google Scholar] [CrossRef]

- Ren, M.; Song, J.; Song, C.; Zhang, H.; Sun, X.; Chen, Q.; Zhang, H.; Mo, Z. Crystallization kinetics and morphology of poly (butylene succinate-co-adipate). J. Polym. Sci. Part B: Polym. Phys. 2005, 43, 3231–3241. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Montanes, N.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil as biobased plasticizer in poly (lactic acid)-based formulations. Polym. Int. 2017, 66, 882–891. [Google Scholar] [CrossRef]

- Ernzen, J.R.; Bondan, F.; Luvison, C.; Wanke, C.H.; Martins, J.D.N.; Fiorio, R.; Bianchi, O. Structure and properties relationship of melt reacted polyamide 6/malenized soybean oil. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Bordbar, M. Biosynthesis of Ag/almond shell nanocomposite as a cost-effective and efficient catalyst for degradation of 4-nitrophenol and organic dyes. RSC Adv. 2017, 7, 180–189. [Google Scholar] [CrossRef]

- Yokohara, T.; Yamaguchi, M. Structure and properties for biomass-based polyester blends of PLA and PBS. Eur. Polym. J. 2008, 44, 677–685. [Google Scholar] [CrossRef]

- Luo, X.; Li, J.; Feng, J.; Yang, T.; Lin, X. Mechanical and thermal performance of distillers grains filled poly (butylene succinate) composites. Mater. Des. 2014, 57, 195–200. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Sautereau, H.; Raihane, M.; Erchiqui, F.; Dufresne, A. Short palm tree fibers polyolefin composites: Effect of filler content and coupling agent on physical properties. Macromol. Mater. Eng. 2008, 293, 140–148. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Lin, X. Preparation and characterization of hollow glass microsphere reinforced poly (butylene succinate) composites. Mater. Des. 2013, 46, 902–909. [Google Scholar] [CrossRef]

- Carrasco, F.; Perez-Maqueda, L.A.; Sanchez-Jimenez, P.E.; Perejon, A.; Santana, O.O.; Maspoch, M.L. Enhanced general analytical equation for the kinetics of the thermal degradation of poly(lactic acid) driven by random scission. Polym. Test 2013, 32, 937–945. [Google Scholar] [CrossRef]

- Shih, Y.-F. Thermal Degradation and Kinetic Analysis of Biodegradable PBS/Multiwalled Carbon Nanotube Nanocomposites. J. Polym. Sci. Part B-Polym. Phys. 2009, 47, 1231–1239. [Google Scholar] [CrossRef]

- Faulstich de Paiva, J.M.; Frollini, E. Unmodified and modified surface sisal fibers as reinforcement of phenolic and lignophenolic matrices composites: Thermal analyses of fibers and composites. Macromol. Mater. Eng. 2006, 291, 405–417. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B: Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Nabinejad, O.; Sujan, D.; Rahman, M.; Davies, I.J. Determination of filler content for natural filler polymer composite by thermogravimetric analysis. J. Therm. Anal. Calorim. 2015, 122, 227–233. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, S.; Kim, H.-J.; Yang, H.-S. Thermal properties of bio-flour-filled polyolefin composites with different compatibilizing agent type and content. Thermochim. Acta 2006, 451, 181–188. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Forte, M.M.; Santana, R.M. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Alemdar, A.; Sain, M. Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Perejón, A.; Criado, J.M. Generalized master plots as a straightforward approach for determining the kinetic model: The case of cellulose pyrolysis. Thermochim. Acta 2013, 552, 54–59. [Google Scholar] [CrossRef]

- Carrasco, F.; Cailloux, J.; Sanchez-Jimenez, P.E.; Maspoch, M.L. Improvement of the thermal stability of branched poly(lactic acid) obtained by reactive extrusion. Polym. Degrad. Stabil. 2014, 104, 40–49. [Google Scholar] [CrossRef]

- Jin, H.-J.; Lee, B.-Y.; Kim, M.-N.; Yoon, J.-S. Properties and biodegradation of poly (ethylene adipate) and poly (butylene succinate) containing styrene glycol units. Eur. Polym. J. 2000, 36, 2693–2698. [Google Scholar] [CrossRef]

- Ciemniecki, S.L.; Glasser, W.G. Polymer Blends with Hydroxypropyl Lignin; ACS Publications: Washington, DC, USA, 1989. [Google Scholar]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Effect of compatibilizer and fillers on the properties of injection molded lignin-based hybrid green composites. J. Appl. Polym. Sci. 2013, 127, 4110–4121. [Google Scholar] [CrossRef]

| Reference | PBS wt % | ASF wt % | MLO wt % |

|---|---|---|---|

| PBS | 100.0 | - | - |

| PBS + ASF | 70.0 | 30.0 | - |

| PBS + ASF + 2.5MLO | 67.5 | 30.0 | 2.5 |

| PBS + ASF + 4.5MLO | 65.5 | 30.0 | 4.5 |

| PBS + ASF + 7.5MLO | 62.5 | 30.0 | 7.5 |

| PBS + ASF + 10MLO | 60.0 | 30.0 | 10.0 |

| Reference | Et (MPa) | σt (MPa) | εb (%) | Shore D Hardness | Impact Strength (kJ m−2) |

|---|---|---|---|---|---|

| PBS | 417.4 ± 21.1 | 31.5 ± 0.9 | 215.6 ± 16.5 | 60.1 ± 0.5 | 16.5 ± 0.8 |

| PBS + ASF | 787.9 ± 55.8 | 14.8 ± 0.5 | 6.3 ± 0.9 | 71.2 ± 0.3 | 1.8 ± 0.3 |

| PBS + ASF + 2.5MLO | 779.8 ± 33.3 | 14.3 ± 0.5 | 17.4 ± 0.3 | 67.8 ± 0.9 | 2.5 ± 0.2 |

| PBS + ASF + 4.5MLO | 534.6 ± 51.3 | 13.8 ± 0.3 | 25.9 ± 1.0 | 67.2 ± 0.2 | 3.8 ± 0.5 |

| PBS + ASF + 7.5MLO | 423.4 ± 13.1 | 12.3 ± 0.1 | 26.1 ± 1.7 | 64.0 ± 0.4 | 3.9 ± 0.3 |

| PBS + ASF + 10MLO | 269.8 ± 30.7 | 11.7 ± 1.1 | 26.6 ± 1.2 | 62.0 ± 0.7 | 4.2 ± 0.2 |

| Code | Melt Enthalpy (J g−1) | Melt Peak Temperature, Tm (°C) | Xc (%) |

|---|---|---|---|

| PBS | 68.9 ± 1.9 | 115.6 ± 2.3 | 60.9 ± 1.8 |

| PBS/ASF | 61.2 ± 1.7 | 115.1 ± 1.9 | 77.4 ± 1.6 |

| PBS/ASF + 2.5MLO | 58.6 ± 2.0 | 114.6 ± 1.7 | 79.6 ± 1.9 |

| PBS/ASF + 4.5MLO | 56.6 ± 2.1 | 115.2 ± 2.1 | 77.1 ± 2.0 |

| PBS/ASF + 7.5MLO | 47.3 ± 1.9 | 113.7 ± 1.7 | 66.9 ± 1.8 |

| PBS/ASF + 10MLO | 43.4 ± 1.5 | 113.9 ± 1.5 | 64.0 ± 1.4 |

| Reference | * T5% (°C) | ** Tmax (°C) | Residual Weight (%) |

|---|---|---|---|

| PBS | 335.9 ± 1.8 | 415.64 ± 1.86 | 0.32 ± 0.12 |

| PBS/ASF | 329.6 ± 2.0 | 414.06 ± 1.98 | 1.23 ± 0.31 |

| PBS/ASF + 2.5MLO | 291.3 ± 2.1 | 407.18 ± 1.67 | 1.29 ± 0.32 |

| PBS/ASF + 4.5MLO | 288.7 ± 2.1 | 405.82 ± 2.08 | 0.68 ± 0.24 |

| PBS/ASF + 7.5MLO | 289.6 ± 1.4 | 400.47 ± 1.87 | 0.46 ± 0.32 |

| PBS/ASF + 10MLO | 289.3 ± 1.8 | 399.93 ± 1.57 | 0.42 ± 0.15 |

| Reference | CLTE below Tg (µm m−1 °C−1) | CLTE above Tg (µm m−1 °C−1) |

|---|---|---|

| PBS/ASF | 59.3 ± 1.6 | 128.1 ± 1.8 |

| PBS/ASF + 2.5MLO | 65.6 ± 1.6 | 132.1 ± 2.1 |

| PBS/ASF + 4.5MLO | 74.2 ± 2.1 | 138.7 ± 2.9 |

| PBS/ASF + 7.5MLO | 78.9 ± 2.3 | 142.9 ± 1.7 |

| PBS/ASF + 10MLO | 84.8 ± 1.9 | 144.1 ± 2.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Optimization of Maleinized Linseed Oil Loading as a Biobased Compatibilizer in Poly(Butylene Succinate) Composites with Almond Shell Flour. Materials 2019, 12, 685. https://doi.org/10.3390/ma12050685

Liminana P, Garcia-Sanoguera D, Quiles-Carrillo L, Balart R, Montanes N. Optimization of Maleinized Linseed Oil Loading as a Biobased Compatibilizer in Poly(Butylene Succinate) Composites with Almond Shell Flour. Materials. 2019; 12(5):685. https://doi.org/10.3390/ma12050685

Chicago/Turabian StyleLiminana, Patricia, David Garcia-Sanoguera, Luis Quiles-Carrillo, Rafael Balart, and Nestor Montanes. 2019. "Optimization of Maleinized Linseed Oil Loading as a Biobased Compatibilizer in Poly(Butylene Succinate) Composites with Almond Shell Flour" Materials 12, no. 5: 685. https://doi.org/10.3390/ma12050685

APA StyleLiminana, P., Garcia-Sanoguera, D., Quiles-Carrillo, L., Balart, R., & Montanes, N. (2019). Optimization of Maleinized Linseed Oil Loading as a Biobased Compatibilizer in Poly(Butylene Succinate) Composites with Almond Shell Flour. Materials, 12(5), 685. https://doi.org/10.3390/ma12050685