Investigation on Cf/PyC Interfacial Properties of C/C Composites by the Molecular Dynamics Simulation Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microstructure of the Cf/PyC Interphase Manufactured by the CVI Process

2.2. Establishment of the MD Simulation Model

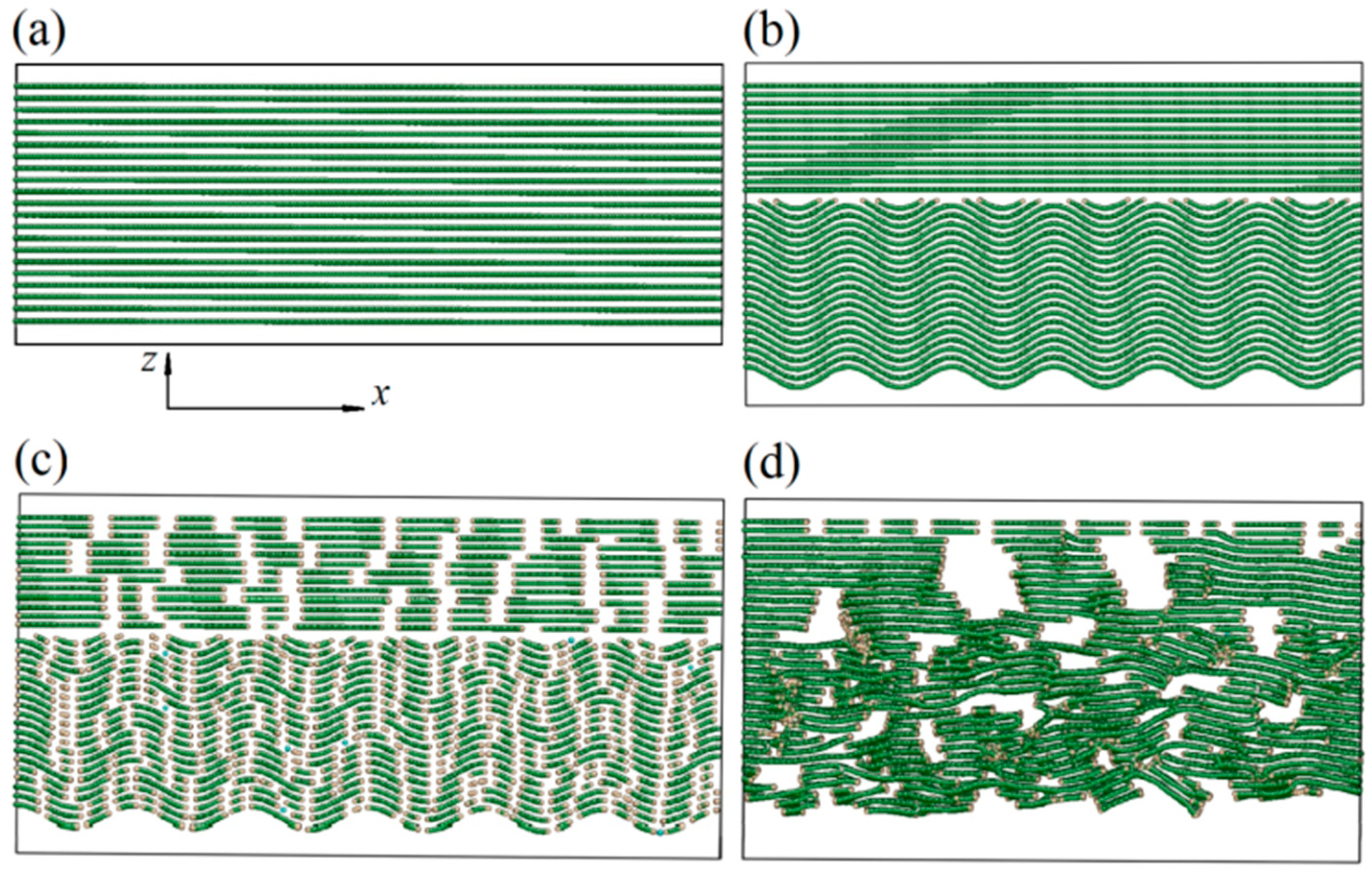

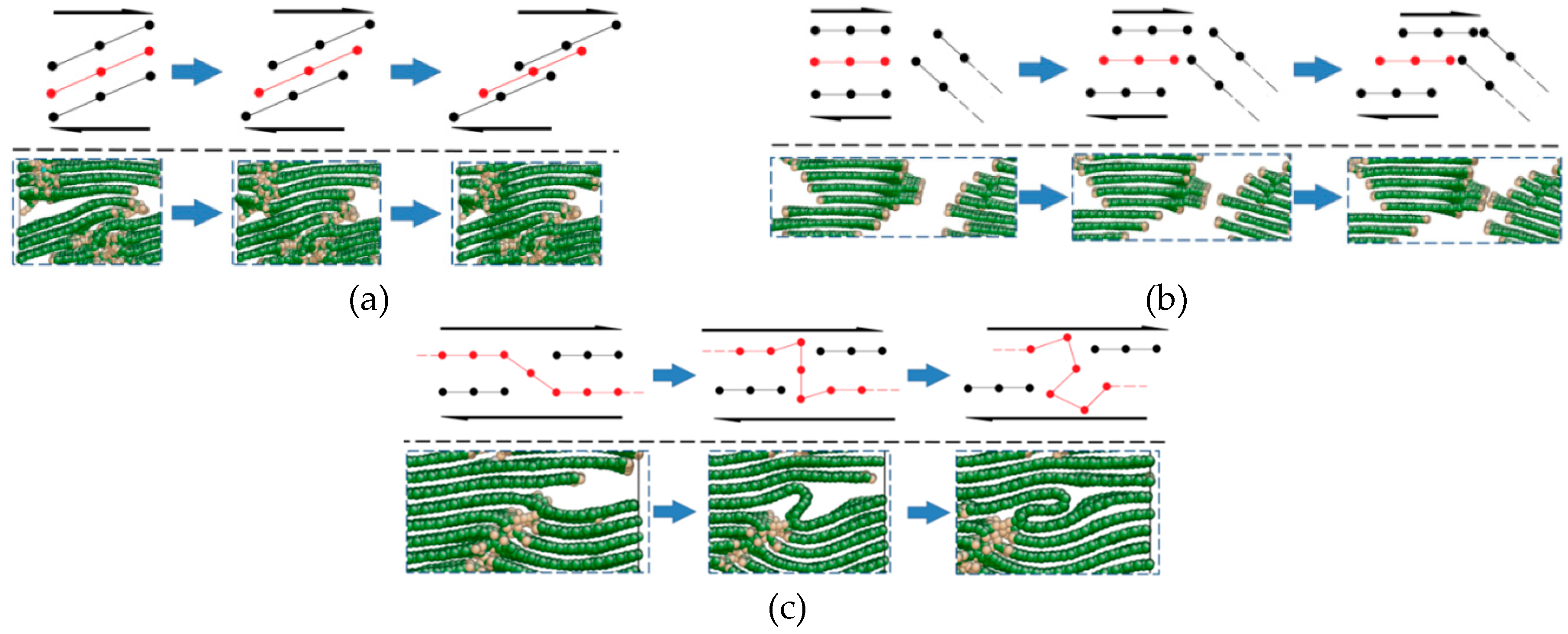

2.2.1. MD Simulation Model for the Cf/PyC Interphase

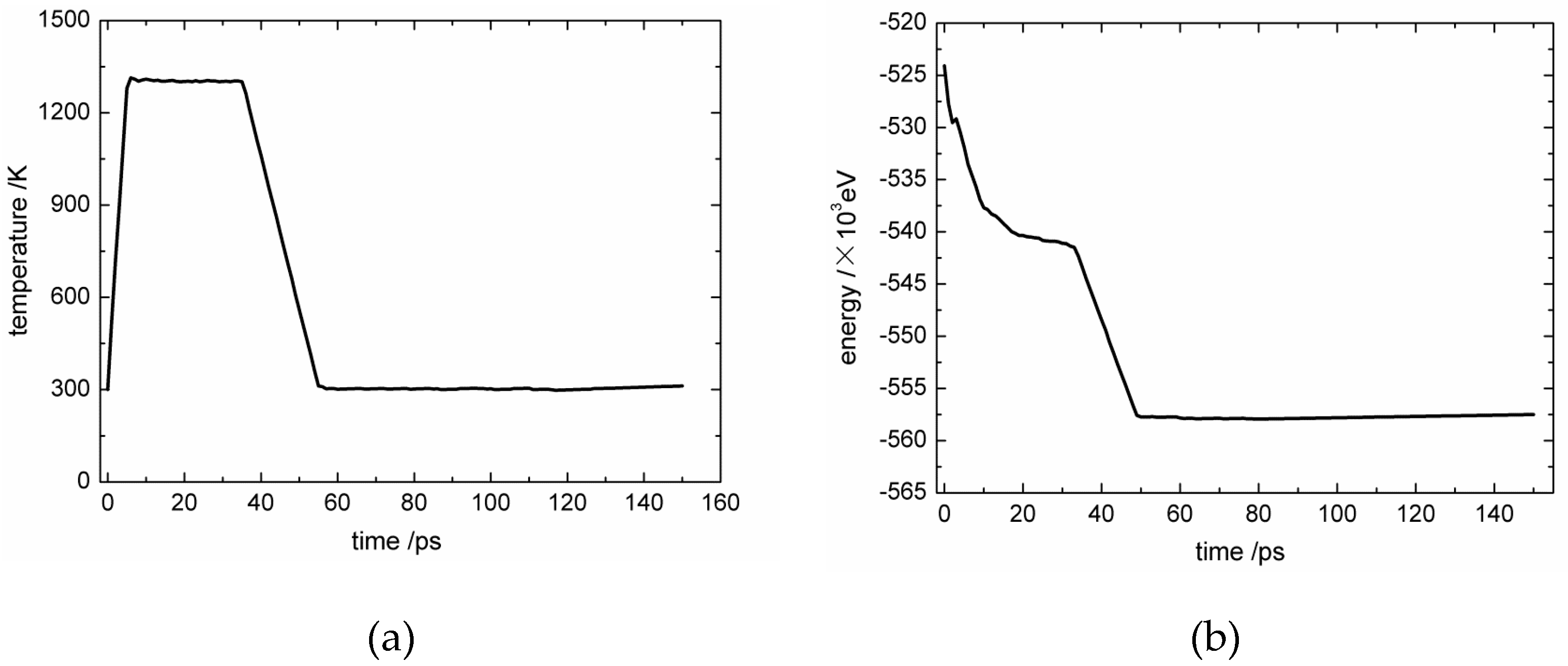

2.2.2. MD Simulation Model for the IPyC Matrix

3. Results

3.1. MD Simulation Results of the Cf/PyC Interphase under Normal Tensile Conditions

3.1.1. Interfacial Normal Tensile Property with Different

3.1.2. Failure Mechanism of the Cf/PyC Interphase under a Normal Tensile Load

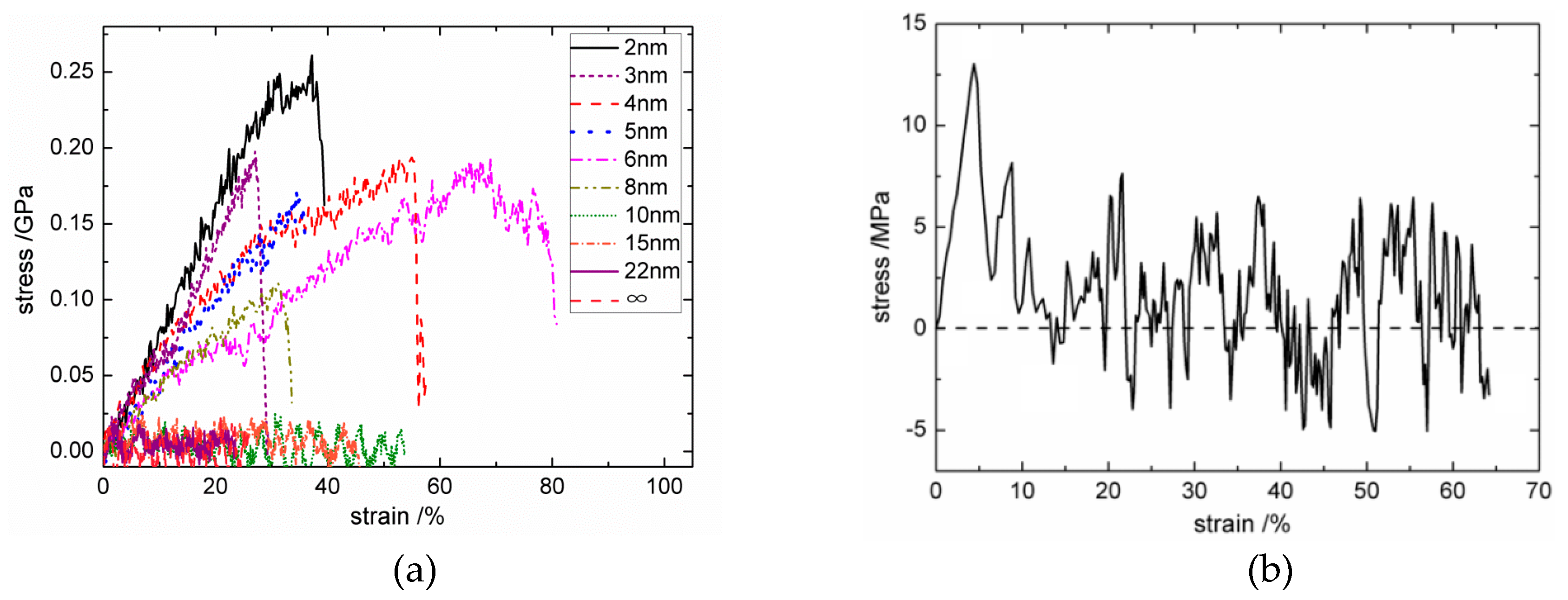

3.2. MD Simulation Results of the Cf/PyC Interphase under Tangential Shear

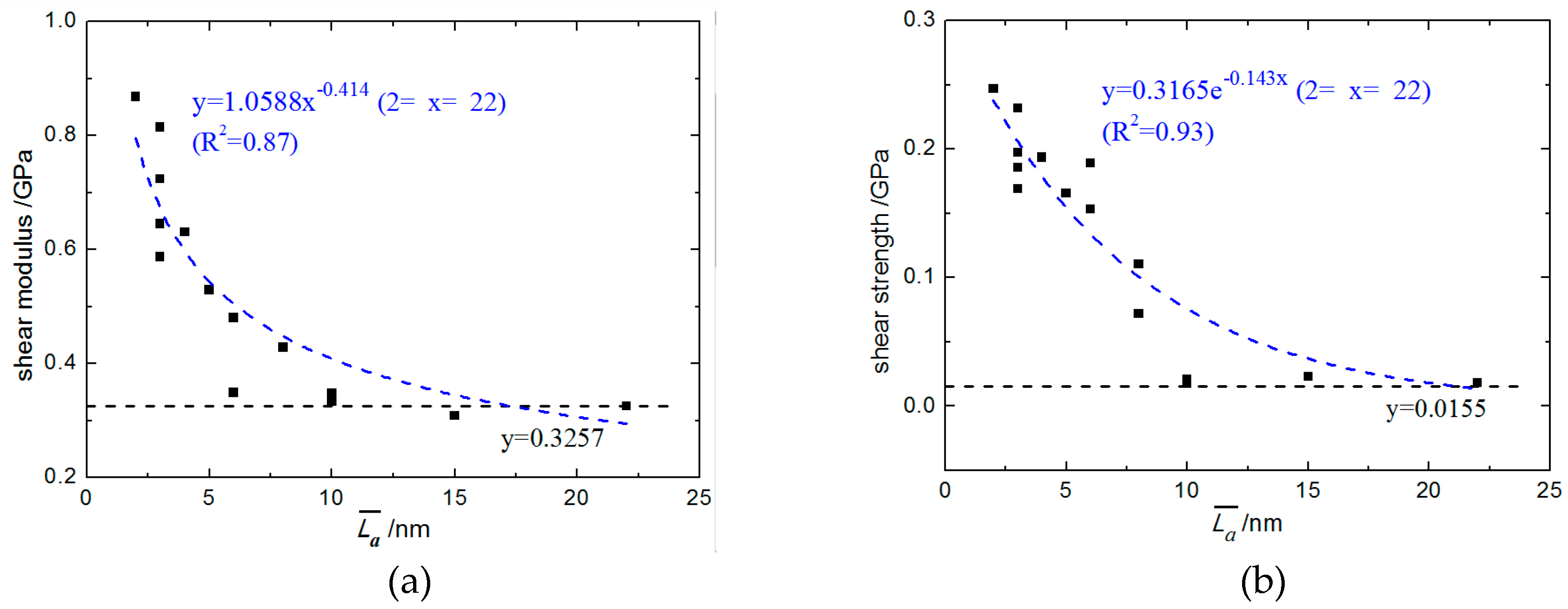

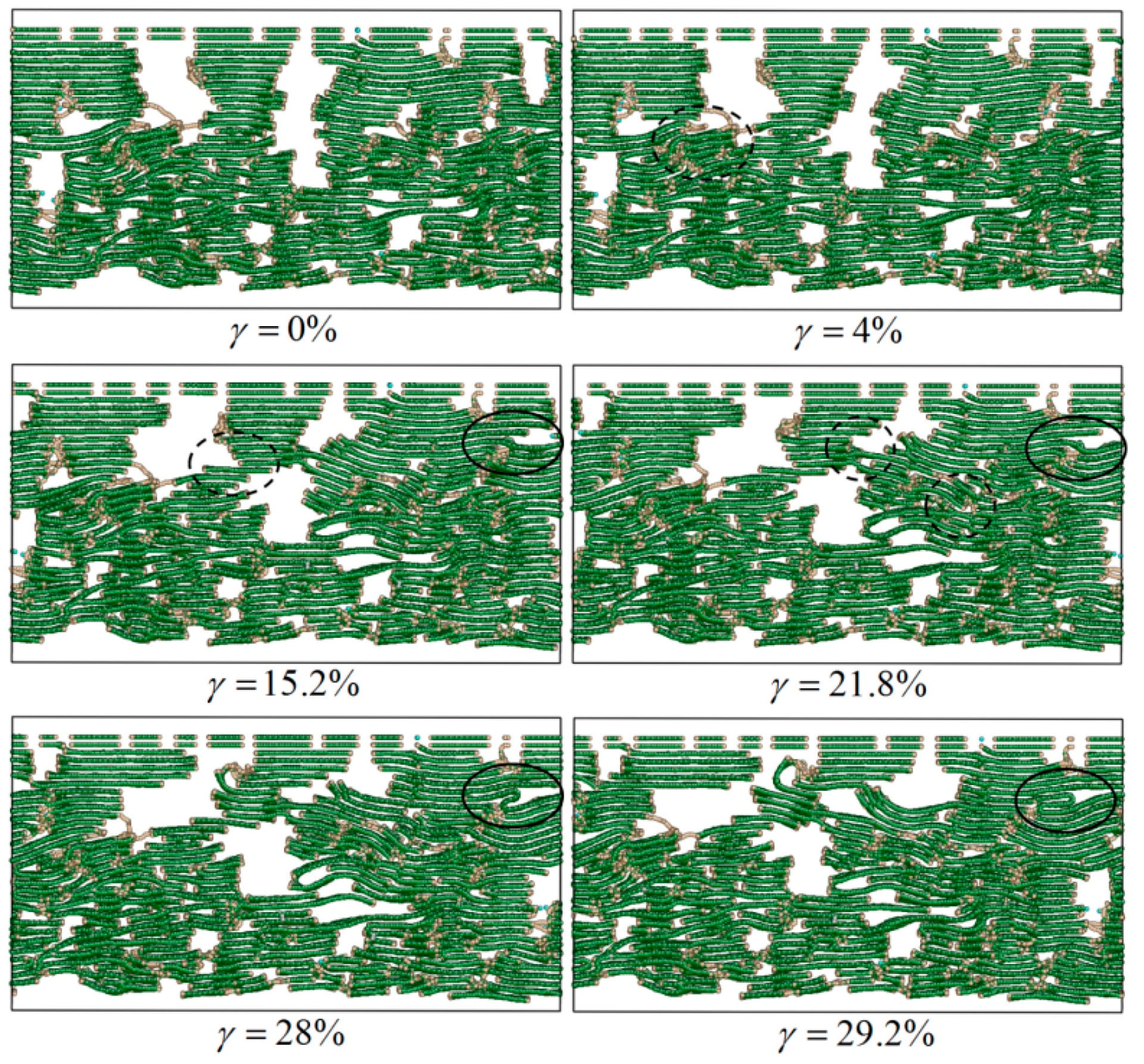

3.2.1. Interfacial Tangential Shear Property with Different

3.2.2. Failure Mechanism of the Cf/PyC Interphase under Tangential Shear

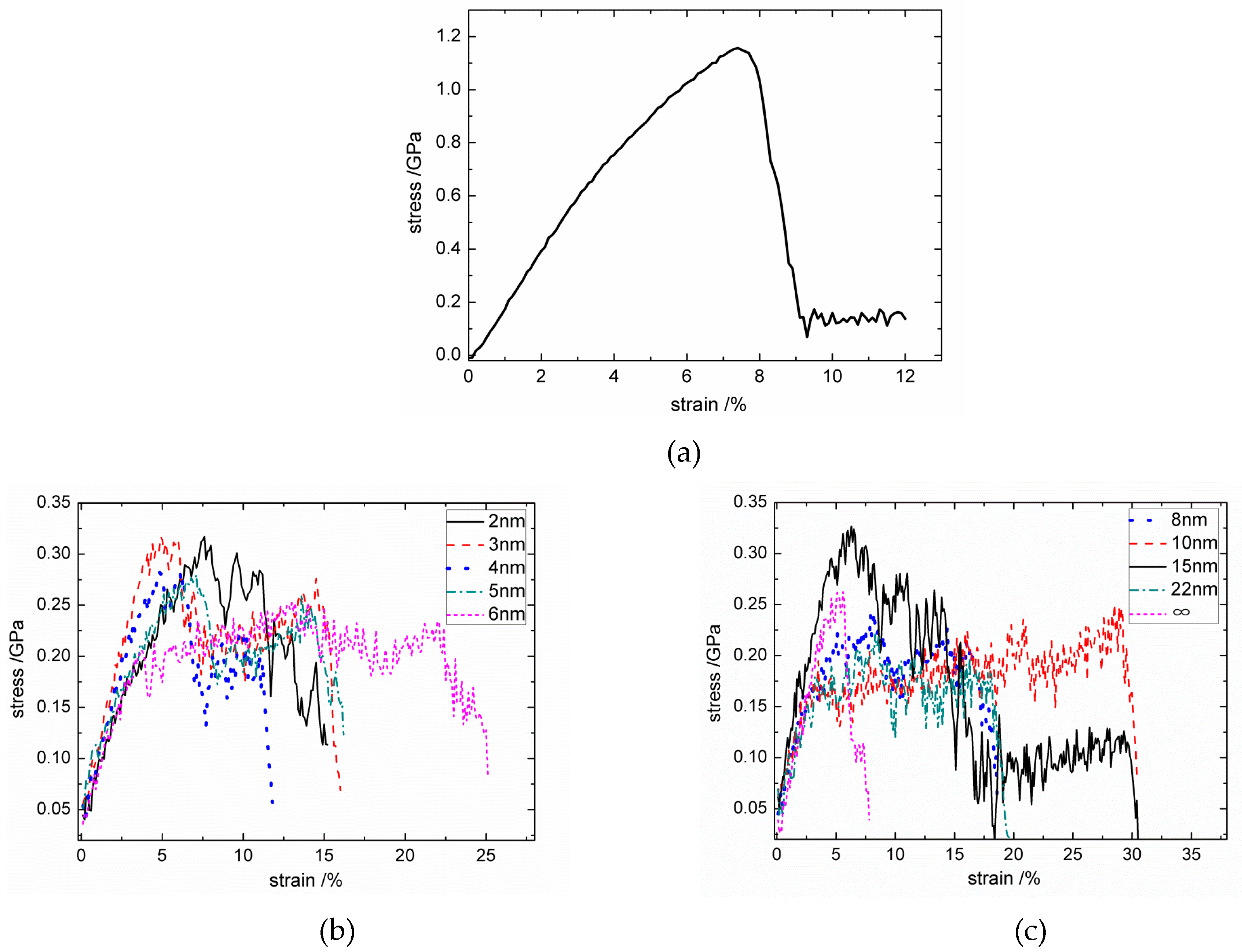

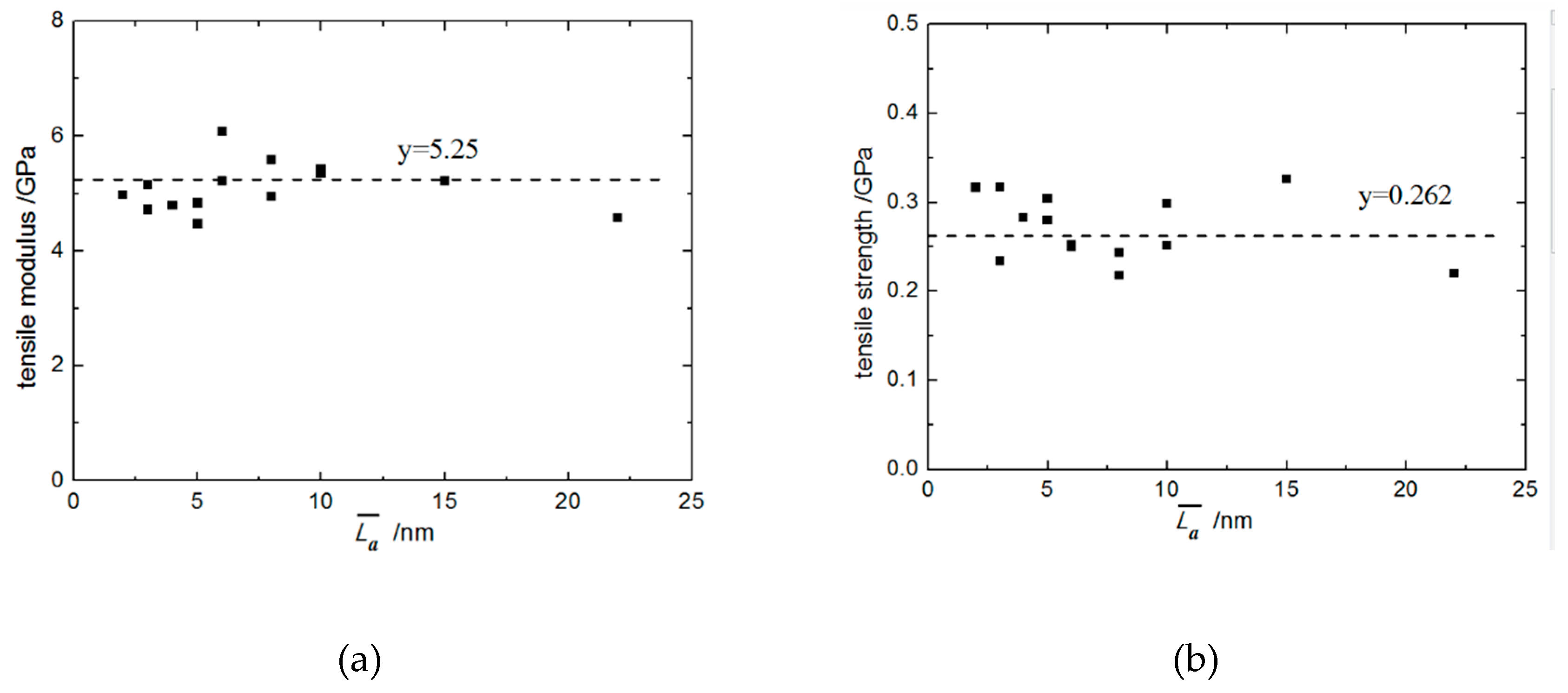

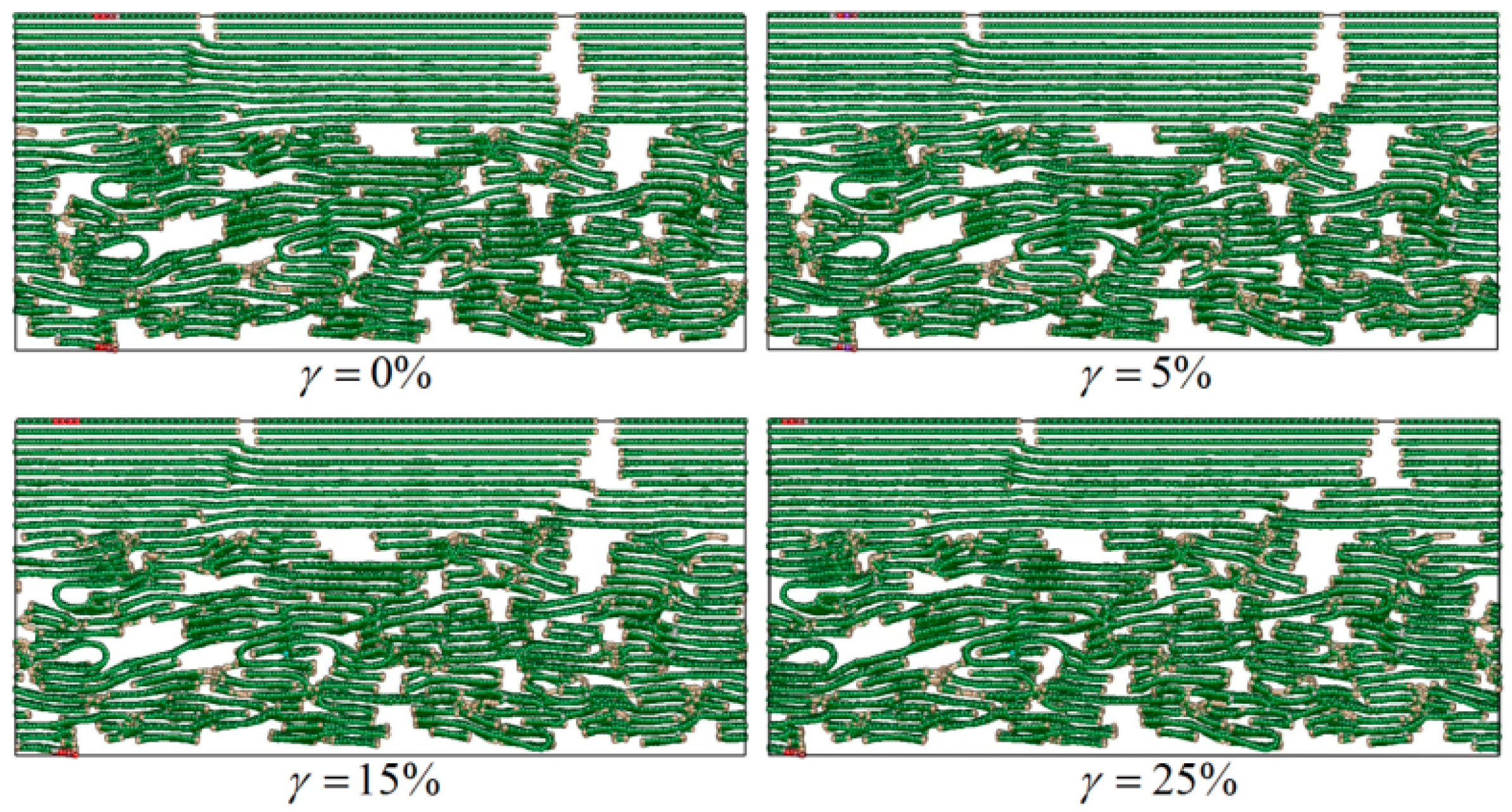

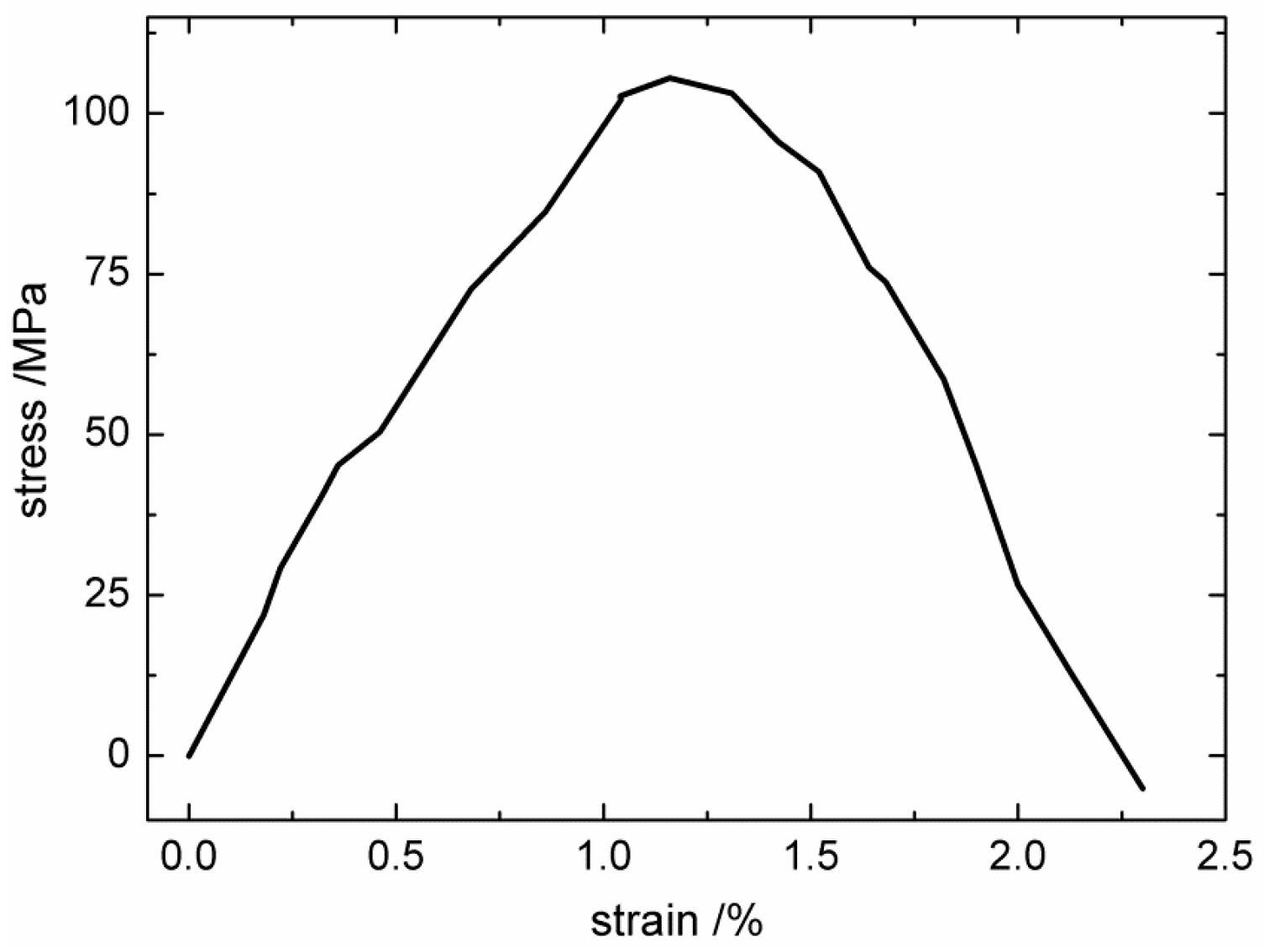

3.3. MD Simulation Results of the IPyC Matrix under Tangential Shear

3.4. Verification of MD Simulation Results

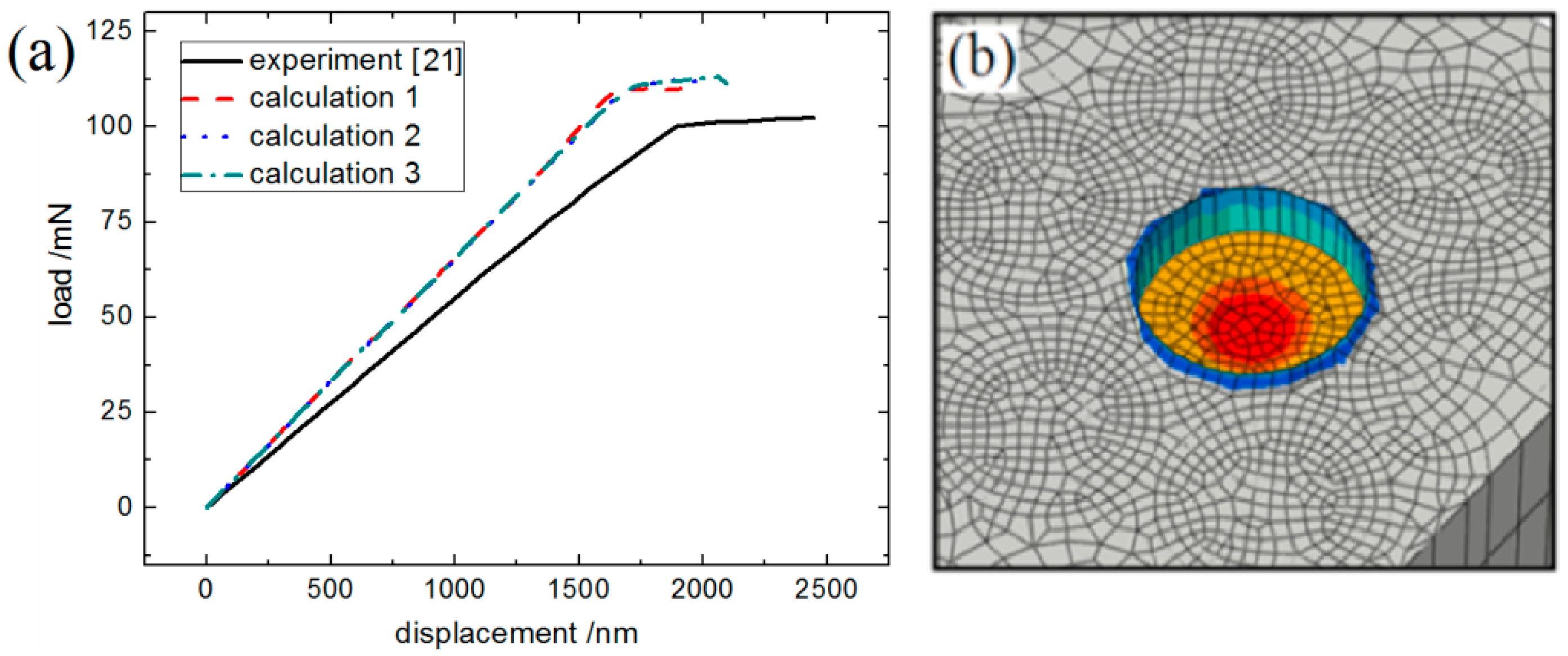

3.4.1. Establishment of the FEA Model

3.4.2. FEA Results of the Fiber Ejection Test Simulation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mikociak, D.; Rudawski, A.; Blazewicz, S. Mechanical and thermal properties of C/C composites modified with SiC nanofiller. Mater. Sci. Eng. A 2018, 716, 220–227. [Google Scholar] [CrossRef]

- Hwang, D.G.; Chung, G.Y. Studies on the effects of the concentration in the preparation of C/C composites by the CVI process of propane. J. Ind. Eng. Chem. 2012, 3, 1136–1140. [Google Scholar] [CrossRef]

- Ren, J.C.; Zhang, Y.L.; Li, J.H.; Tian, S.; Fei, T.; Li, H. Effects of deposition temperature and time on HfC nanowires synthesized by CVD on SiC-coated C/C composites. Ceram. Int. 2016, 5, 5623–5628. [Google Scholar] [CrossRef]

- Tzeng, S.S.; Lin, W.C. Mechanical behavior of two-dimensional carbon/carbon composites with interfacial carbon layers. Carbon 1999, 37, 2011–2019. [Google Scholar] [CrossRef]

- Shi, B.; Hu, G.X.; Li, H.J.; Kang, M.K. Interfacial microstructures of intrabundle inas-received carbon/carbon composites prepared by CVI. Carbon 1998, 36, 1331–1335. [Google Scholar] [CrossRef]

- Dupel, P.; Bourrat, X.; Pailler, R. Structure of pyrocarbon infiltrated by pulse-CVI. Carbon 1995, 33, 1193–1204. [Google Scholar] [CrossRef]

- Pishehvarz, G.; Erfan-Niya, H.; Zaminpayma, E. The role of hydrogen bonding in interaction energy at the interface of conductive polymers and modified graphene-based nanosheets: A reactive molecular dynamics study. Comput. Mater. Sci. 2018, 155, 499–523. [Google Scholar] [CrossRef]

- Alian, A.R.; Meguid, S.A. Molecular dynamics simulations of the effect of waviness and agglomeration of CNTs on interface strength of thermoset nanocomposites. Phys. Chem. Chem. Phys. 2017, 19, 4426–4434. [Google Scholar] [CrossRef] [PubMed]

- Elkhateeb, M.G.; Shin, Y.C. Molecular dynamics-based cohesive zone representation of Ti6Al4V/TiC composite interface. Mater. Des. 2018, 155, 161–169. [Google Scholar] [CrossRef]

- Nouranian, S.; Jang, C.G.; Lacy, T.E.; Gwaltney, S.R.; Toghiani, H.; Pittman, C.U., Jr. Molecular dynamics simulations of vinyl ester resin monomer interactions with a pristine vapor-grown carbon nanofiber and their implications for composite interphase formation. Carbon 2011, 49, 3219–3232. [Google Scholar] [CrossRef]

- Jang, C.W.; Nouranian, S.; Lacy, T.E.; Gwaltney, S.R.; Toghiani, H.; Pittman, C.U., Jr. Molecular dynamics simulations of oxidized vapor-grown carbon nanofiber surface interactions with vinyl ester resin monomers. Carbon 2012, 50, 748–760. [Google Scholar] [CrossRef]

- Chawla, R.; Sharma, S. A molecular dynamics study on Young’s modulus and tribology of carbon nanotube reinforced styrene-butadiene rubber. J. Mol. Model. 2018, 24, 96. [Google Scholar] [CrossRef] [PubMed]

- Shi, G.; He, Y.L.; Zhang, J.W.; Jiang, D.Z. Tensile properties of carbon nanoring linked graphene sheets: A molecular dynamics investigation. Mater. Sci. Forum 2018, 913, 607–613. [Google Scholar] [CrossRef]

- Eshkalak, K.E.; Sadeghzadeh, S.; Jalaly, M. Mechanical properties of defective hybrid graphene-boron nitride nanosheets: A molecular dynamics study. Comput. Mater. Sci. 2018, 149, 170–181. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, S.Y.; Liu, H.; Zhang, J.W.; Yang, X.N. Correction: Molecular dynamics simulation of the mechanical properties of multilayer graphene oxide nanosheets. RSC Adv. 2018, 8, 22785. [Google Scholar] [CrossRef]

- Boitier, G.; Vicens, J.; Chermant, J.L. Understanding the creep behavior of a 2.5 D Cf–SiC composite-I. Morphology and microstructure of the as-received material. Mater. Sci. Eng. A 2000, 279, 73–80. [Google Scholar] [CrossRef]

- Guigon, M.; Oberlin, A.; Desarmot, G. Microtexture and structure of some high tensile strength, PAN-base carbon fibres. Fibre Sci. Technol. 1984, 20, 55–72. [Google Scholar] [CrossRef]

- Després, J.; Monthioux, M. Mechanical properties of C/SiC composites as explained from their interfacial features. J. Eur. Ceram. Soc. 1995, 15, 209–224. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Frauenheim, T.; Porezag, D.; Köhler, T.; Weich, F. Molecular-dynamic simulations of structure formation in complex materials. Comput. Phys. 1996, 294–328. [Google Scholar] [CrossRef]

- Long, Y.; Javed, A.; Zhao, Y.; Chen, Z.K.; Xiong, X.; Xiao, P. Fiber/matrix interfacial shear strength of C/C composites with PyC–TaC–PyC and PyC–SiC–TaC–PyC multi-interlayers. Ceram. Int. 2013, 39, 6489–6496. [Google Scholar] [CrossRef]

- Lu, Z.; Xia, B.; Yang, Z. Investigation on the tensile properties of three-dimensional full five-directional braided composites. Comput. Mater. Sci. 2013, 77, 445–455. [Google Scholar] [CrossRef]

- Abaqus 6.10 User’s Manual; Abaqus Inc. Dassault Systemes Simulia Corp.: Pawtucket, RI, USA, 2010.

- Oya, N.; Johnson, D.J. Longitudinal compressive behaviour and microstructure of PAN-based carbon fibres. Carbon 2001, 39, 635–645. [Google Scholar] [CrossRef]

- Bobet, J.; Lamon, J. Thermal residual stresses in ceramic matrix composites—I. Axisymmetrical model and finite element analysis. Acta Metal. Mater. 1995, 43, 2241–2253. [Google Scholar] [CrossRef]

- Nozawa, T.; Katoh, Y.; Snead, L.L. The effects of neutron irradiation on shear properties of monolayered PyC and multilayered PyC/SiC interfaces of SiC/SiC composites. J. Nucl. Mater. 2007, 367, 685–691. [Google Scholar] [CrossRef]

- Furukawa, Y.; Hatta, H.; Kogo, Y. Interfacial shear strength of C/C composites. Carbon 2003, 41, 1819–1826. [Google Scholar] [CrossRef]

| Cf/PyC Interphase | KT/GPa | GS/GPa | ST/GPa | SS/GPa | ||

|---|---|---|---|---|---|---|

| 4.94 | 0.67 | 0.55 | 0.2 | |||

| IPyC matrix | G/GPa | ν | S/MPa | |||

| 9.8 | 0.23 [26] | 105 | ||||

| T300 Fiber | E11/GPa | E22 = E33/GPa | G12 = G13/GPa | G23/GPa | ||

|---|---|---|---|---|---|---|

| 220 | 22 | 4.8 | 7.7 | 0.12 | 0.42 | |

| aluminum base | G/GPa | ν | ||||

| 70 | 0.33 | |||||

| P/mN | IFSS/MPa | ||

|---|---|---|---|

| Experiment [21] | 84 | 97 ± 7 | 53 ± 4 |

| simulation | 84 | 111.7 | 60.5 |

| Error (%) | - | 7%–23% | 7%–23% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Ye, T.; Ma, L.; Lu, Z.; Yang, Z.; Liu, S. Investigation on Cf/PyC Interfacial Properties of C/C Composites by the Molecular Dynamics Simulation Method. Materials 2019, 12, 679. https://doi.org/10.3390/ma12040679

Zhou Y, Ye T, Ma L, Lu Z, Yang Z, Liu S. Investigation on Cf/PyC Interfacial Properties of C/C Composites by the Molecular Dynamics Simulation Method. Materials. 2019; 12(4):679. https://doi.org/10.3390/ma12040679

Chicago/Turabian StyleZhou, Yuan, Tianyuan Ye, Long Ma, Zixing Lu, Zhenyu Yang, and Shouwen Liu. 2019. "Investigation on Cf/PyC Interfacial Properties of C/C Composites by the Molecular Dynamics Simulation Method" Materials 12, no. 4: 679. https://doi.org/10.3390/ma12040679

APA StyleZhou, Y., Ye, T., Ma, L., Lu, Z., Yang, Z., & Liu, S. (2019). Investigation on Cf/PyC Interfacial Properties of C/C Composites by the Molecular Dynamics Simulation Method. Materials, 12(4), 679. https://doi.org/10.3390/ma12040679