Rheological Property Criteria for Buildable 3D Printing Concrete

Abstract

1. Introduction

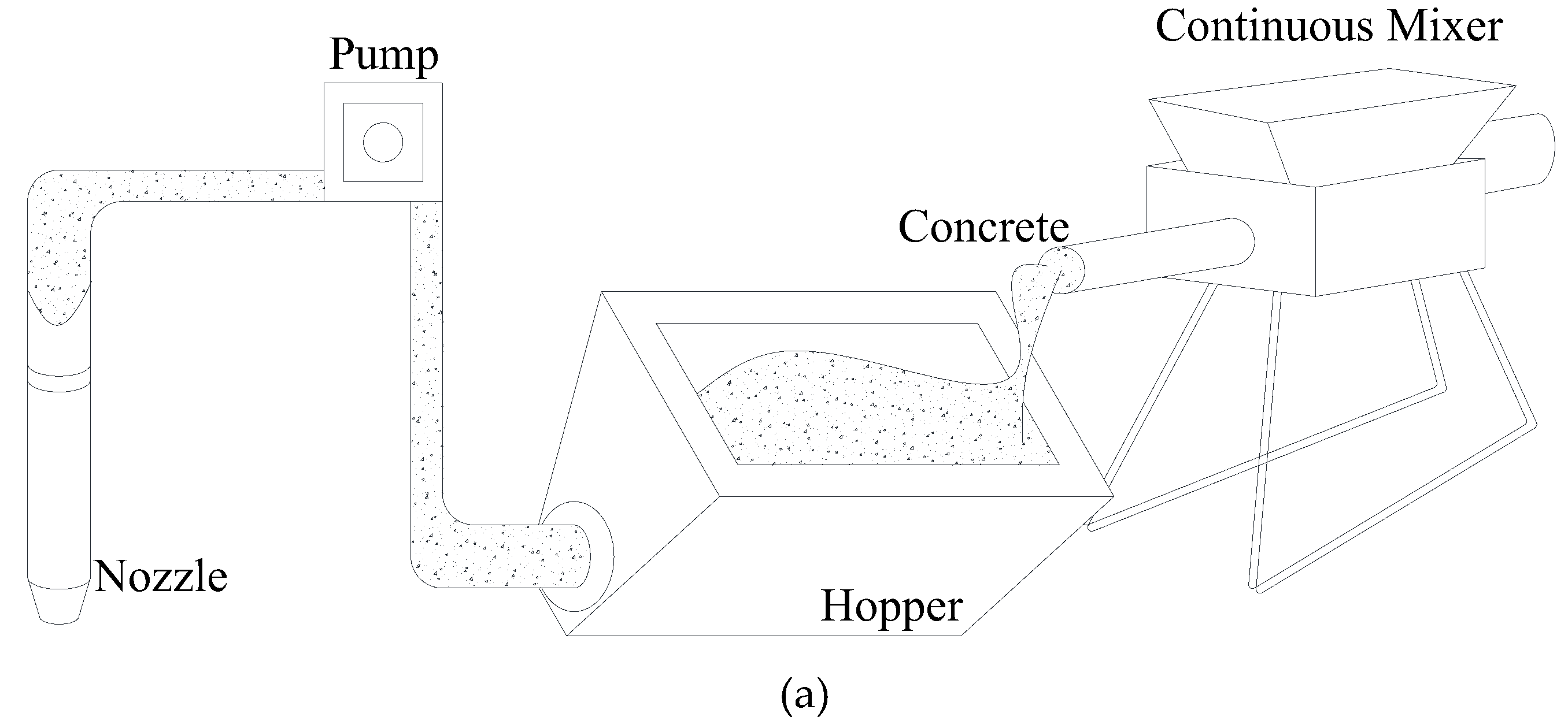

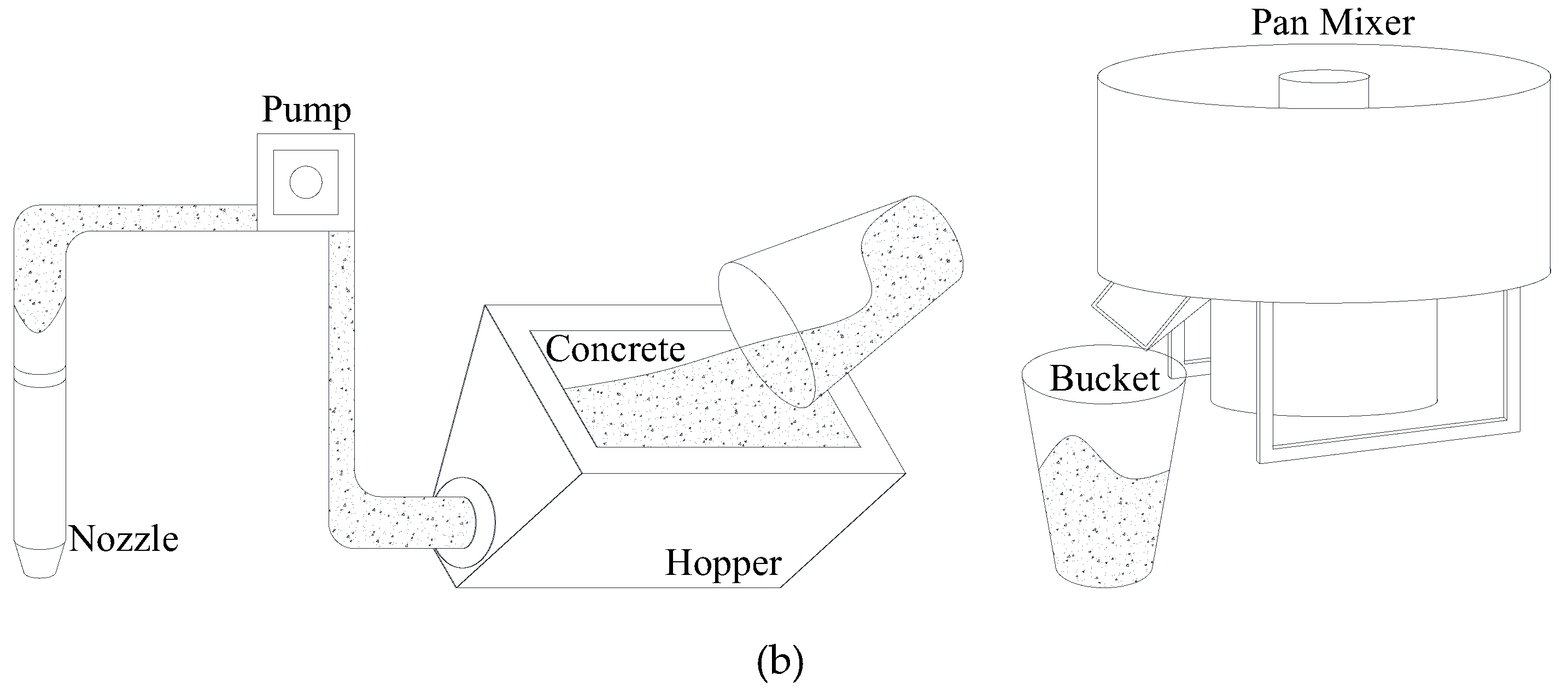

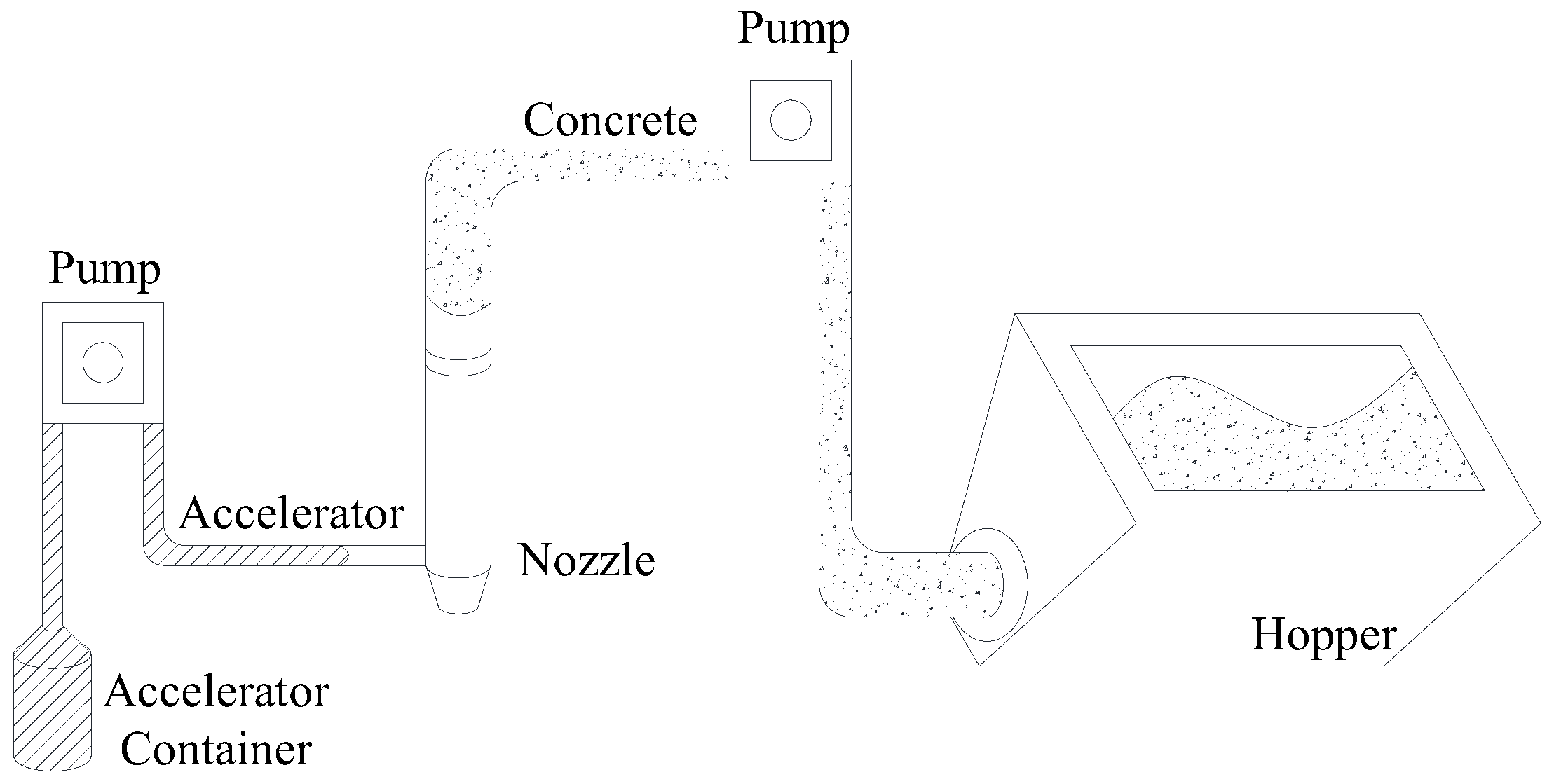

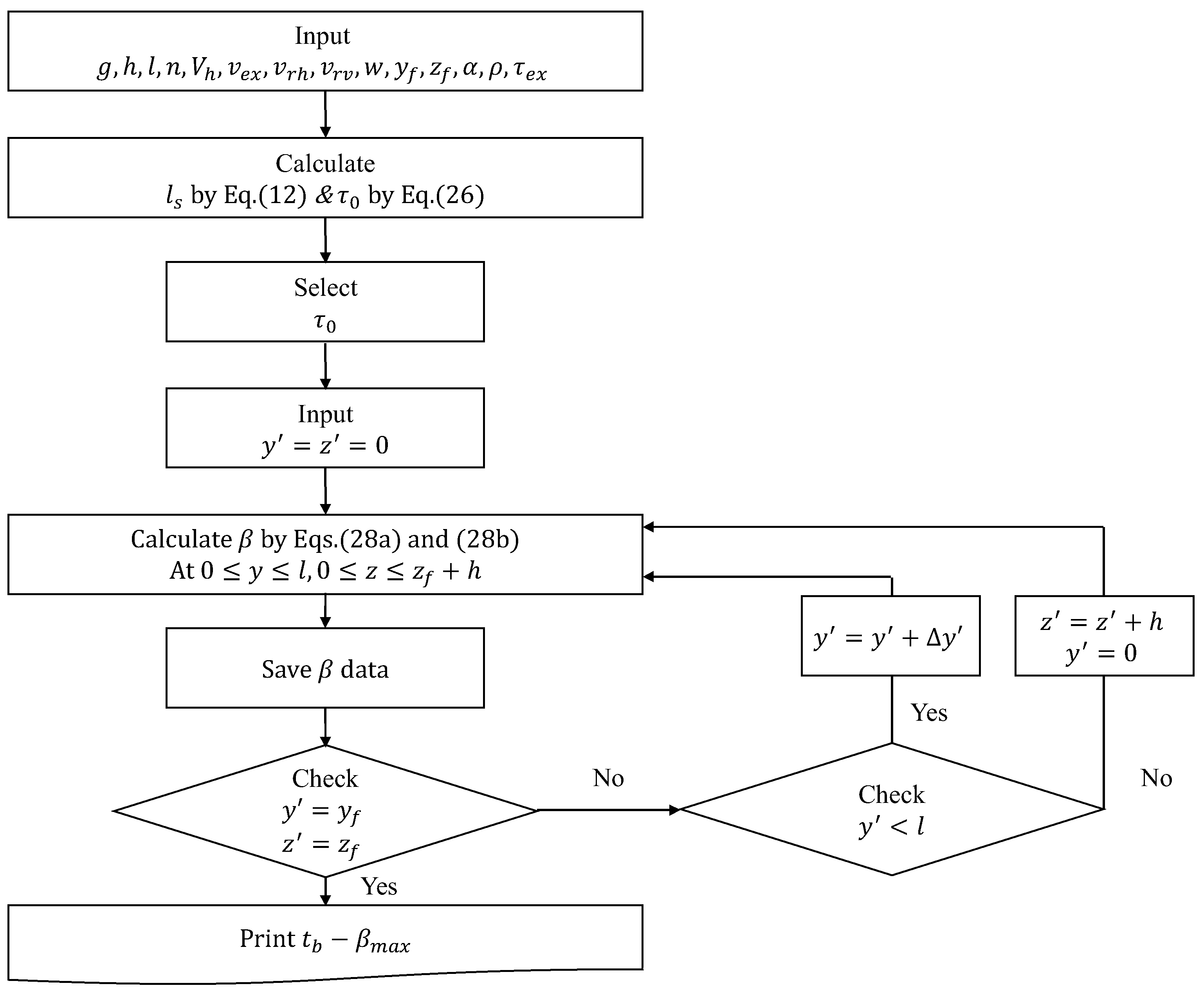

2. Assumptions

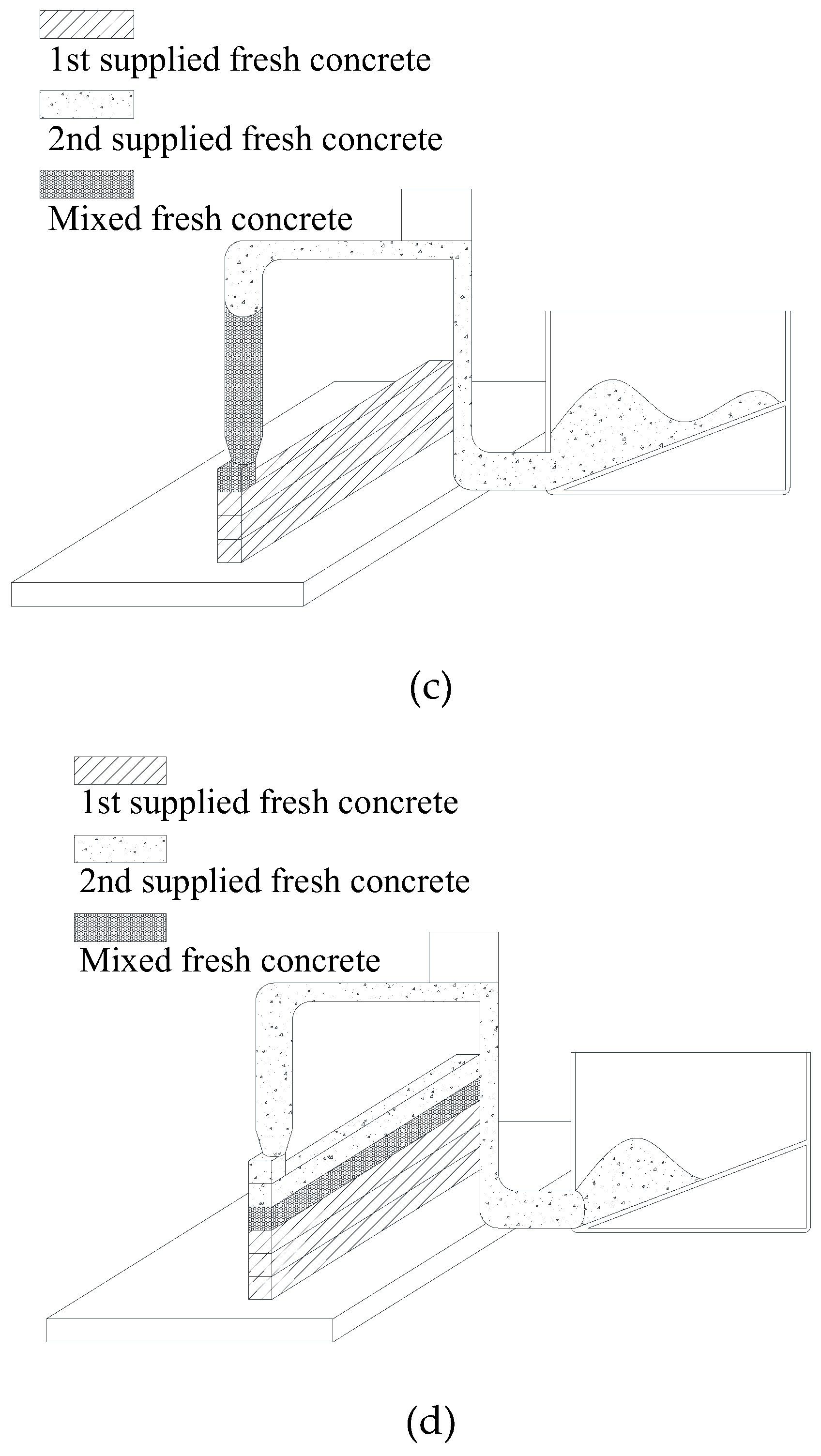

- The accelerator is injected from the nozzle, as shown in Figure 3 and a fixed quantity is injected in proportion to the unit discharge amount.

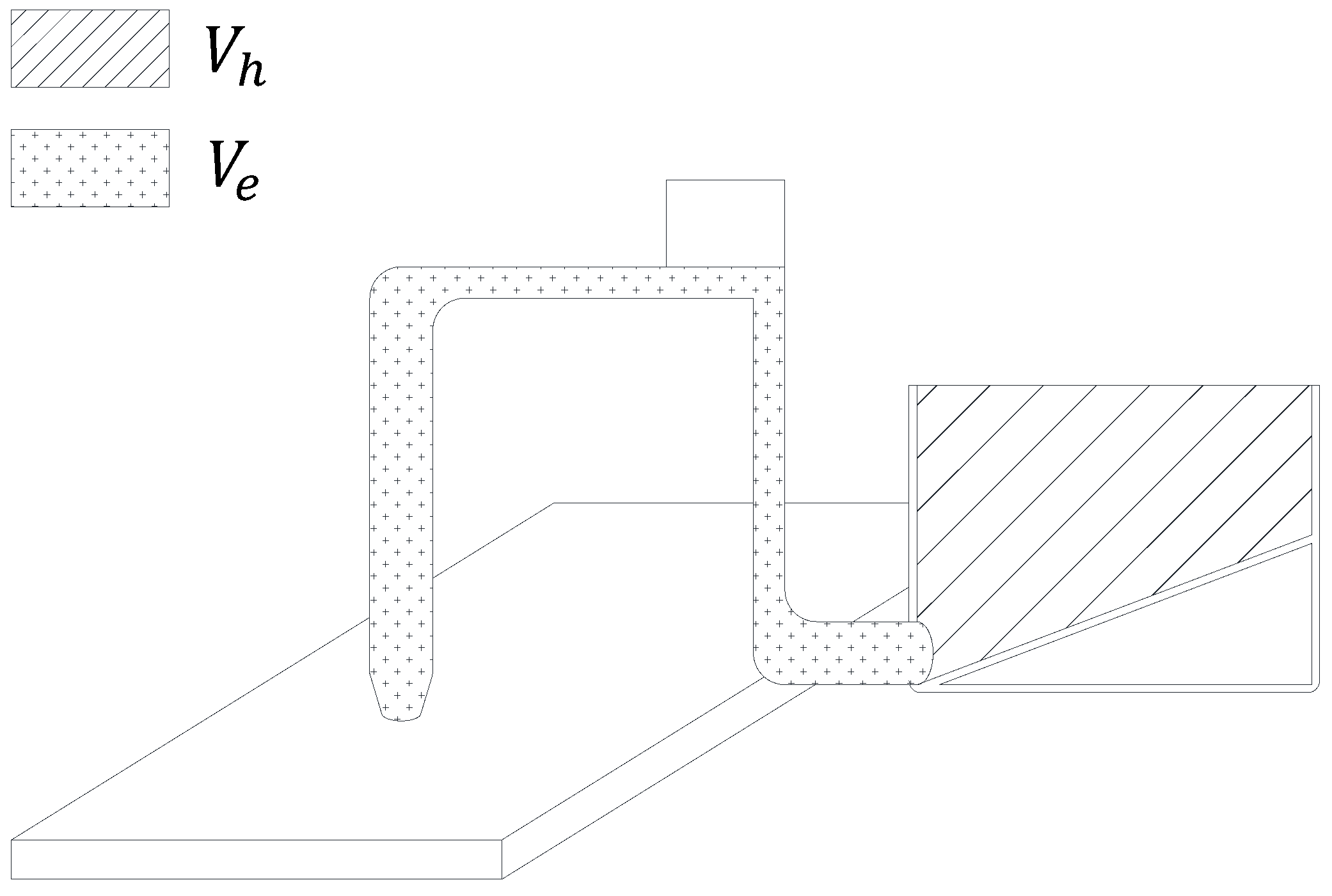

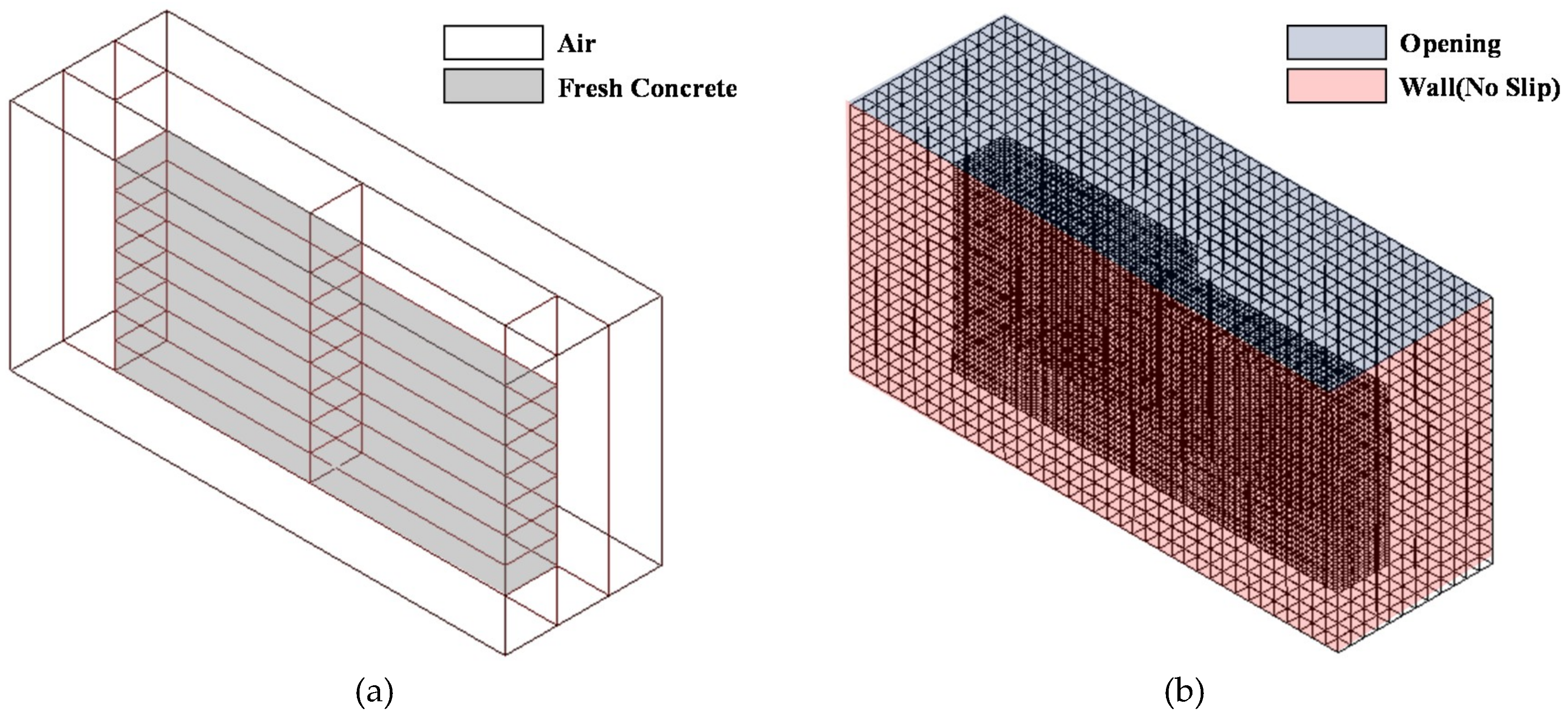

- The cross section of fresh concrete is a perfect rectangle, as shown in Figure 4.

- Fresh concrete is built up vertically and the width (), height () and length () of each layer of printed concrete are the same.

3. Proposed Model

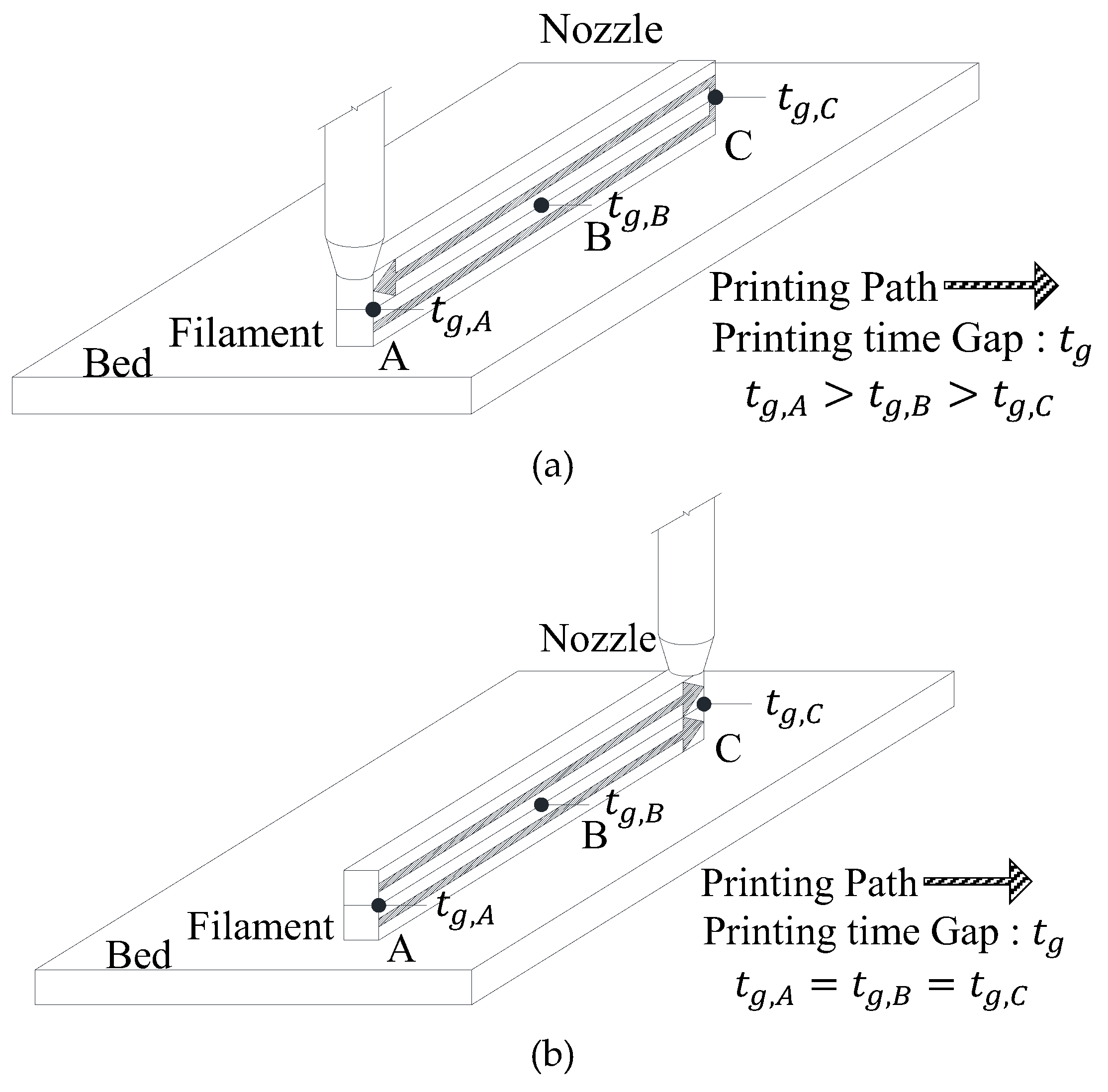

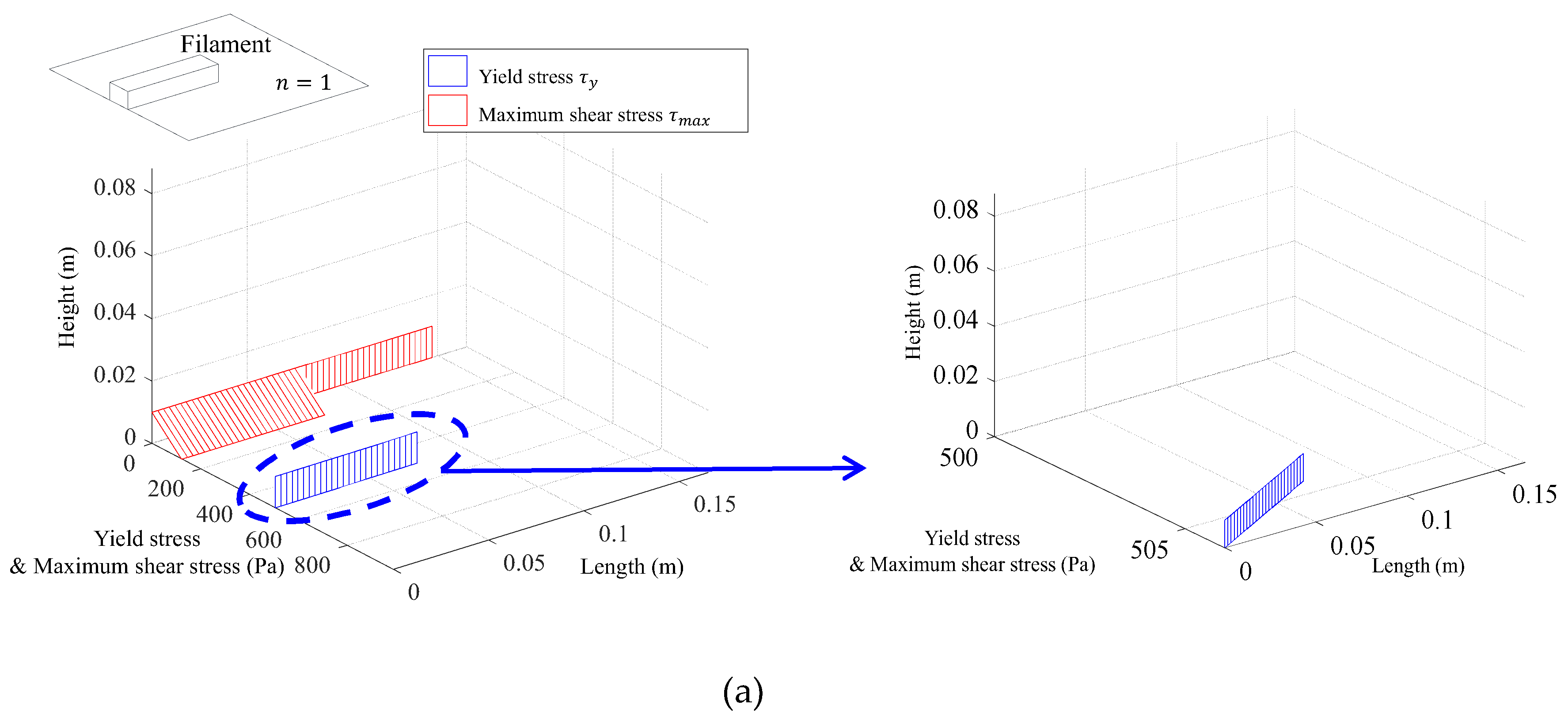

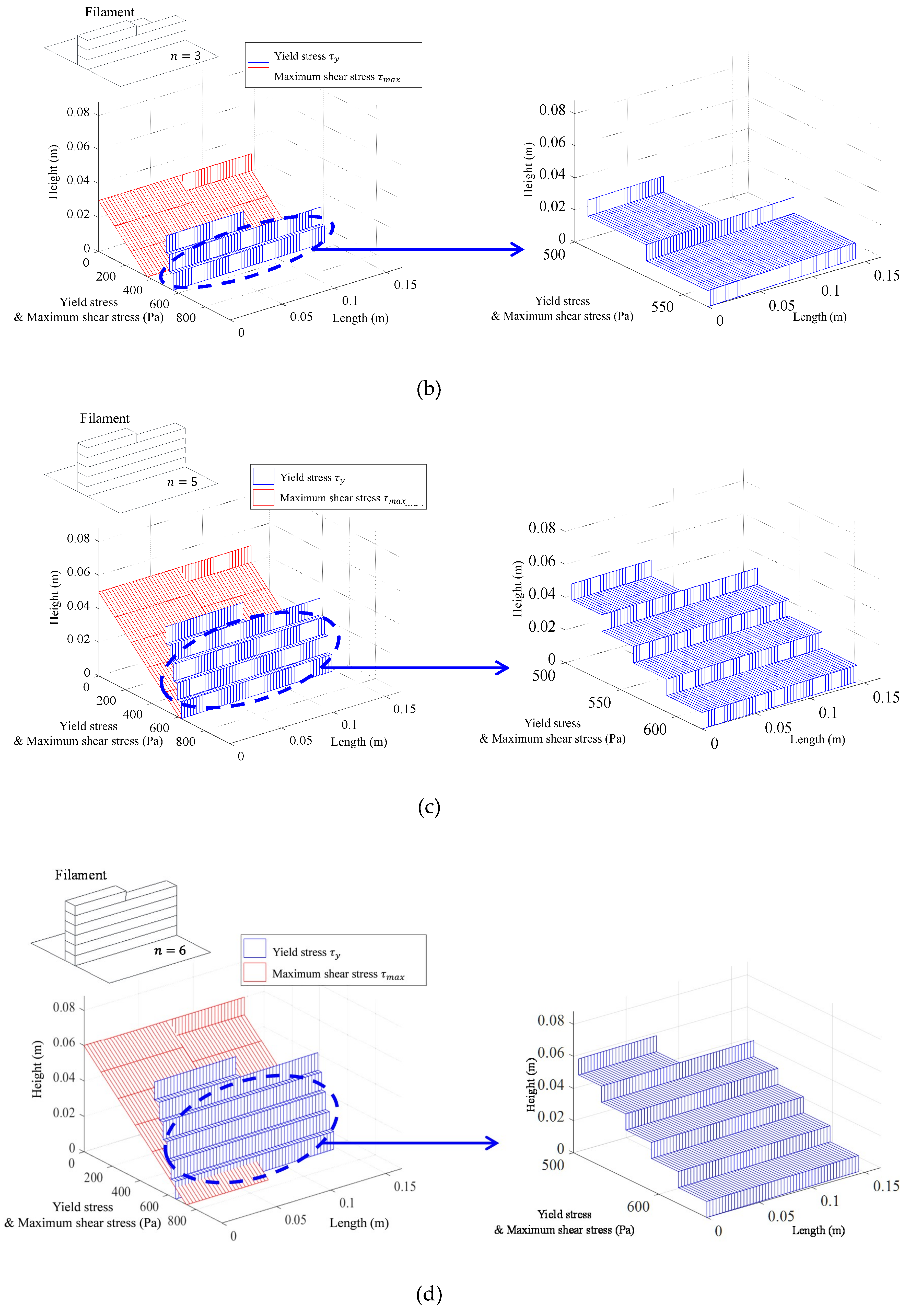

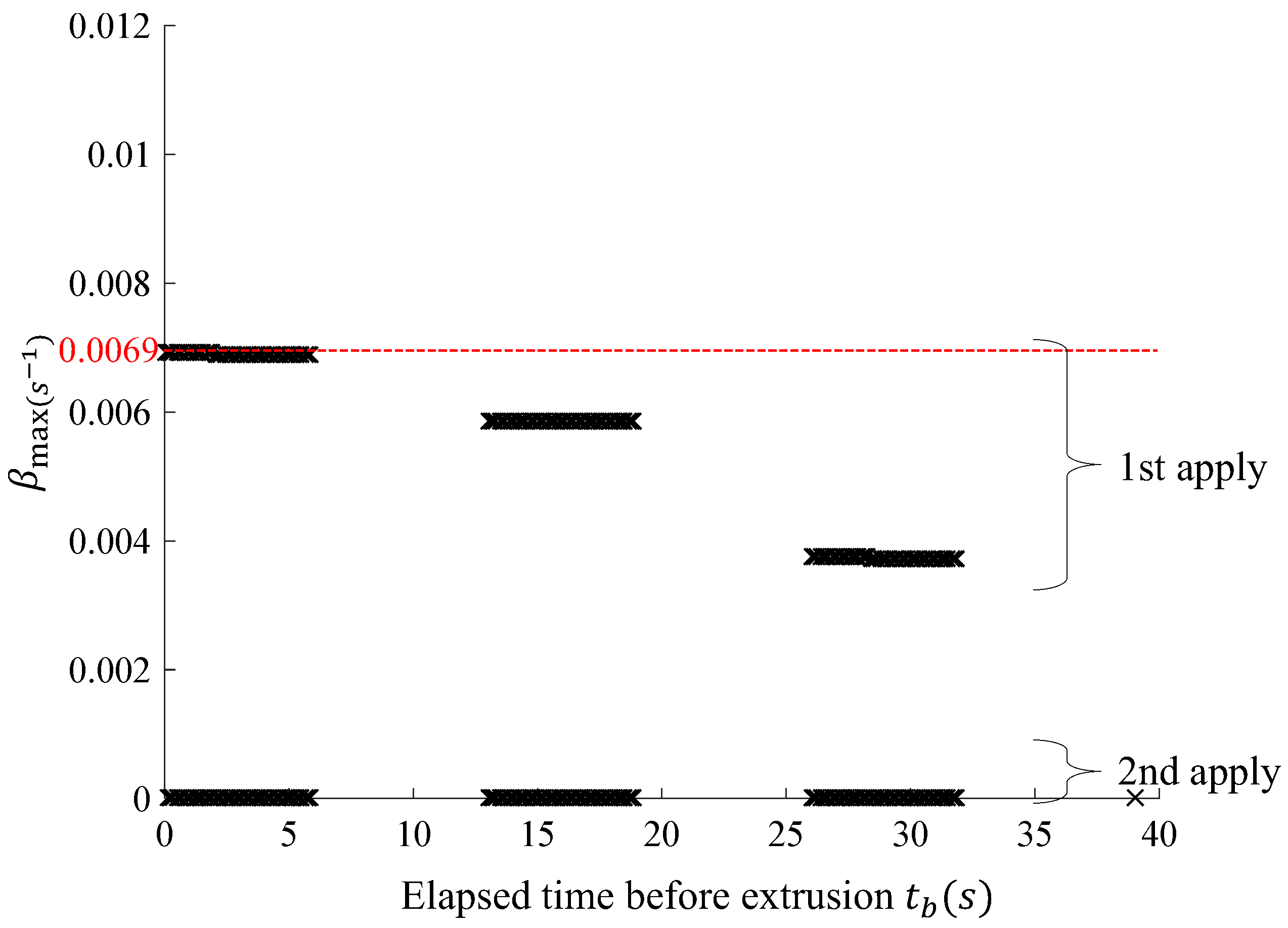

3.1. Maximum Shear Stress Distribution (Demand Curve)

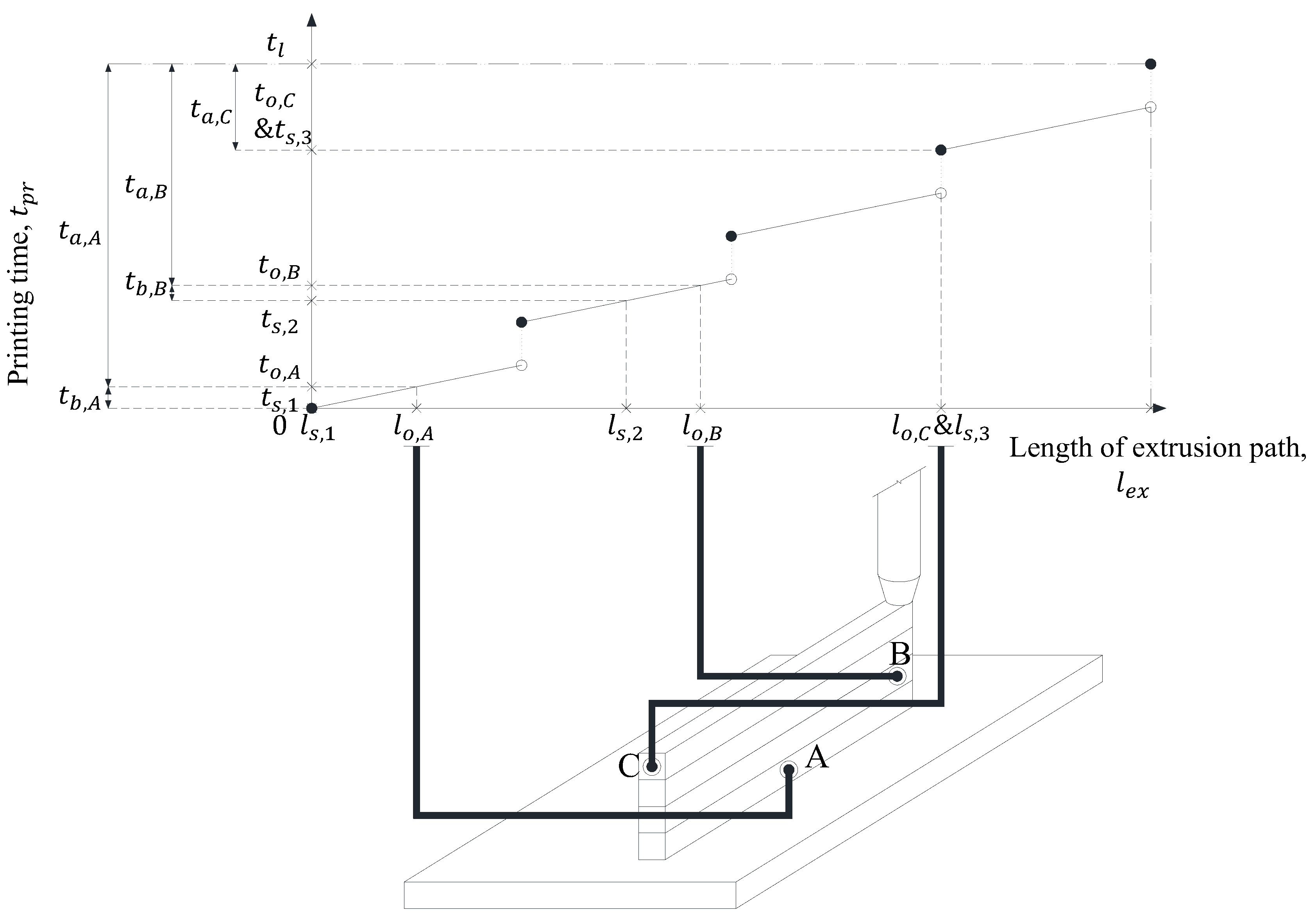

3.2. Elapsed Time

3.3. Relationship between Elapsed Time and Yield Stress

3.4. Yield Stress Distribution (Capacity Curve)

3.5. Demand , and

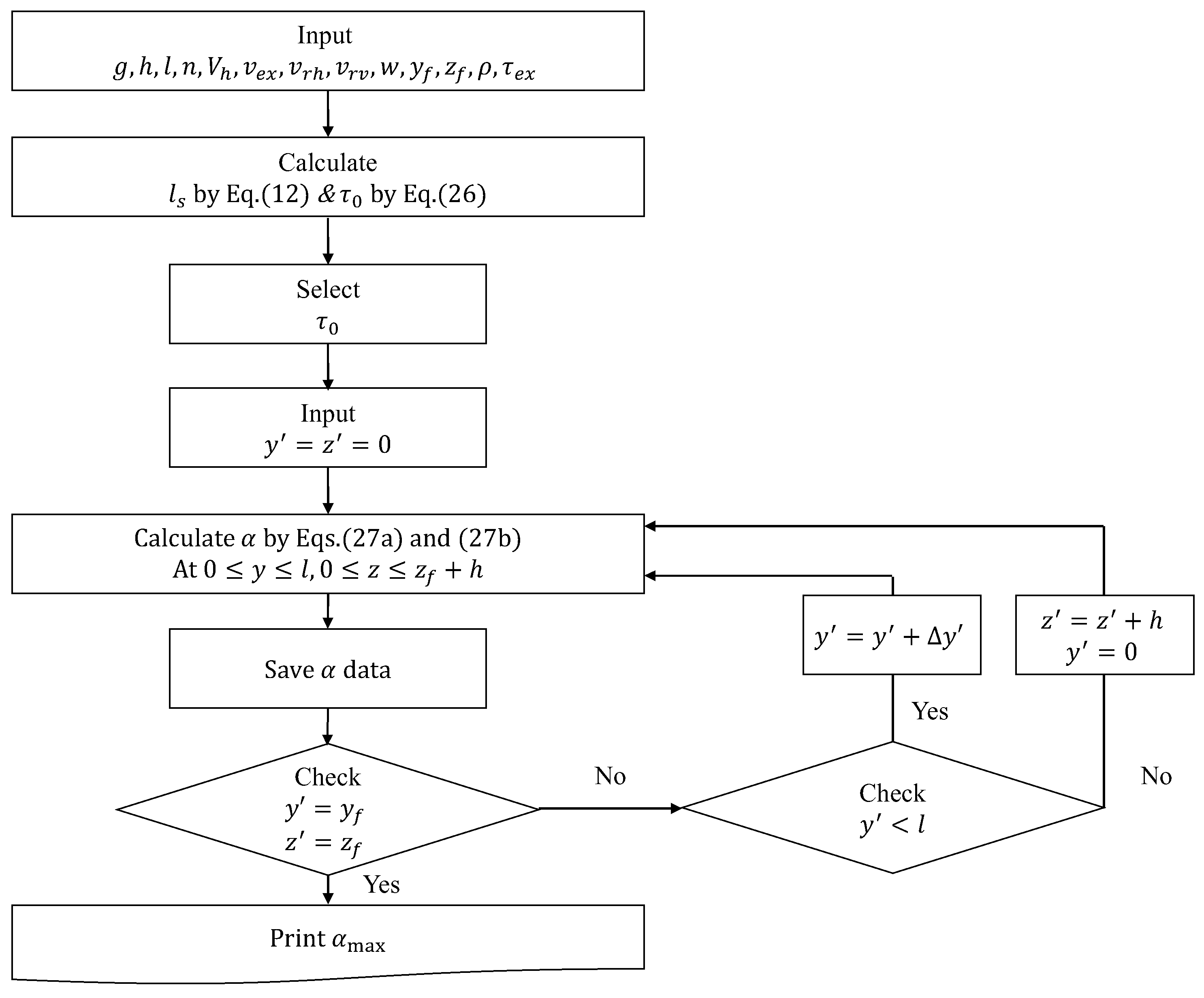

3.6. Determination of Analysis Parameters

3.7. Validation Using Computational Fluid Dynamic Analysis

4. Conclusion

- The proposed model could reflect the increase in the yield stress of the fresh concrete during the 3D concrete printing process by substituting the elapsed time into the yield stress-elapsed time equation.

- Based on the CFD analysis results on the cases examined in this study, it was confirmed that the proposed model can provide very accurate estimations on the occurrence and location of collapse.

- The proposed model would be very helpful to obtain the rheological properties of fresh concrete required for 3D printing, such as hardening coefficient and initial yield stress, without any complex numerical simulations.

- Further researches are still required to check the stability problems of the layered concrete for vertically complicated structures.

Author Contributions

Funding

Conflicts of Interest

References

- Hanna, A.S. Concrete formwork systems; Marcel Dekker: New York, NY, USA, 1999. [Google Scholar]

- Lee, E.Y.; Kim, Y.S. An Analysis and Improvement of Free Form Building’s Construction Productivity Focused on Exposed Concrete Work. Korean J. Constr. Eng. Manag. 2014, 15, 38–46. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—a new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fibre-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Rheology of fresh cement and concr ete. In Rheology reviews; The British Society of Rheology: Edunburgh, UK, 2006; pp. 61–130. [Google Scholar]

- Bingham, E.C. Fluidity and plasticity; McGraw-Hill Book Company, Inc.: New York, NY, USA, 1922. [Google Scholar]

- Murata, J. Flow and deformation of fresh concrete. Matériaux et Construction 1984, 17, 117–129. [Google Scholar] [CrossRef]

- Christensen, G. Modelling the Flow of Fresh Concrete: The Slump Test. Ph.D. Thesis, Princeton University, Princeton, NJ, USA, 1991. [Google Scholar]

- Pashias, N.; Boger, D.V.; Summers, J.; Glenister, D.J. A fifty cent rheometer for yield stress measurement. J. Rheol. 1996, 40, 1179–1189. [Google Scholar] [CrossRef]

- Saak, A.W.; Jennings, H.M.; Shah, S.P. A generalized approach for the determination of yield stress by slump and slump flow. Cem. Concr. Res. 2004, 34, 363–371. [Google Scholar] [CrossRef]

- Petit, J.; Wirquin, E.; Vanhove, Y.; Khayat, K. Yield stress and viscosity equations for mortars and self-consolidating concrete. Cem. Concr. Res. 2007, 37, 655–670. [Google Scholar] [CrossRef]

- Perrot, A.; Pierre, A.; Vitaloni, S.; Picandet, V. Prediction of lateral form pressure exerted by concrete at low casting rates. Mater. Struct. 2015, 48, 2315–2322. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital concrete: opportunities and challenges. RILEM Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Suiker, A.S.J. Mechanical performance of wall structures in 3D printing processes: theory, design tools and experiments. Int. J. Mech. Sci. 2018, 137, 145–170. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Chen, J.F.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef]

- Nerella, V.N.; Krause, M.; Näther, M.; Mechtcherine, V. Studying printability of fresh concrete for formwork free Concrete on-site 3D Printing technology (CONPrint3D). In Proceedings of the 25th conference on rheology of building materials, Regensburg, Germany, 2–3 March 2016. [Google Scholar]

- Roussel, N. Correlation between yield stress and slump: comparison between numerical simulations and concrete rheometers results. Mater. Struct. 2006, 39, 501–509. [Google Scholar] [CrossRef]

| Information | Case 1 | Case 2 |

|---|---|---|

| Injection of accelerator | Applied | |

| curve | Exponential | |

| 9.8 m/s2 | ||

| 0.01 m | ||

| 0.15 m | ||

| 7 | ||

| 0.00003 | ||

| 0.025 m/s | ||

| 0.01 m/s | ||

| 0.02 m | ||

| 0.075 m | ||

| 0.06 m | ||

| 2500 kg/m3 | ||

| 0 | ||

| 500 Pa | ||

| 0.0003/s | ||

| 0.004/s | 0.0069/s | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, H.; Han, S.-J.; Choi, S.-H.; Lee, Y.J.; Yi, S.T.; Kim, K.S. Rheological Property Criteria for Buildable 3D Printing Concrete. Materials 2019, 12, 657. https://doi.org/10.3390/ma12040657

Jeong H, Han S-J, Choi S-H, Lee YJ, Yi ST, Kim KS. Rheological Property Criteria for Buildable 3D Printing Concrete. Materials. 2019; 12(4):657. https://doi.org/10.3390/ma12040657

Chicago/Turabian StyleJeong, Hoseong, Sun-Jin Han, Seung-Ho Choi, Yoon Jung Lee, Seong Tae Yi, and Kang Su Kim. 2019. "Rheological Property Criteria for Buildable 3D Printing Concrete" Materials 12, no. 4: 657. https://doi.org/10.3390/ma12040657

APA StyleJeong, H., Han, S.-J., Choi, S.-H., Lee, Y. J., Yi, S. T., & Kim, K. S. (2019). Rheological Property Criteria for Buildable 3D Printing Concrete. Materials, 12(4), 657. https://doi.org/10.3390/ma12040657