Creep, Hardness, and Elastic Modulus of Lingual Fixed Retainer Adhesives

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

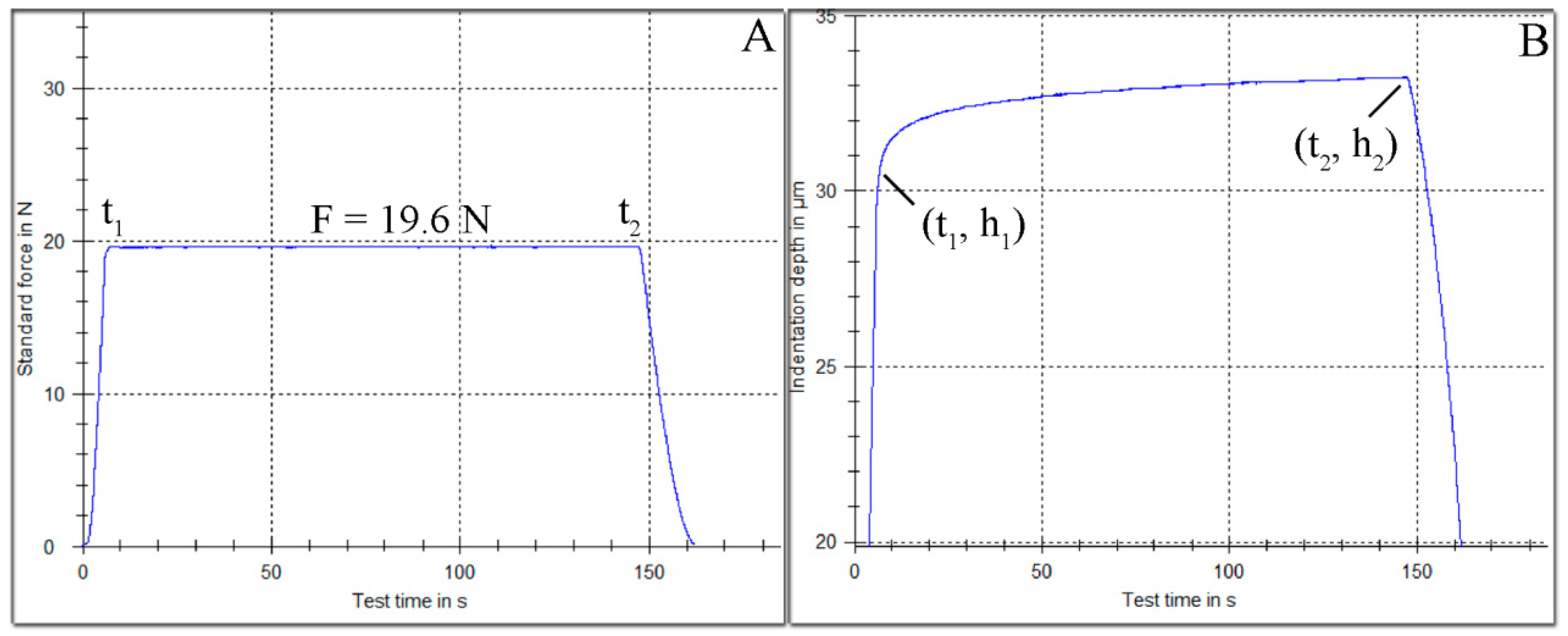

2.3. Mechanical Testing

2.4. Statistical Analysis

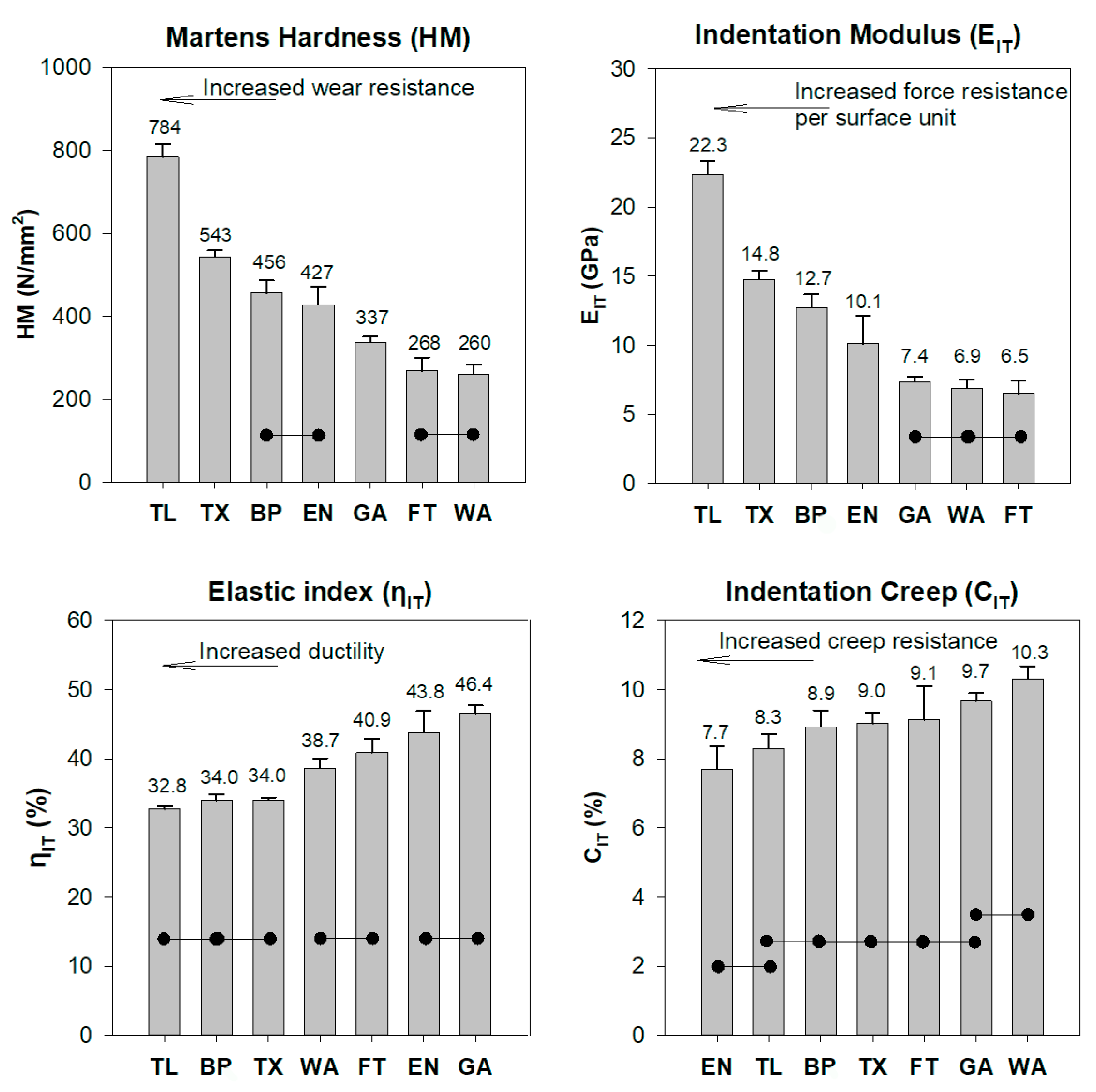

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bearn, D.R. Bonded orthodontic retainers: A review. Am. J. Orthod. Dentofac. Orthop. 1995, 108, 207–213. [Google Scholar] [CrossRef]

- Veli, I.; Akin, M.; Kucukyilmaz, E.; Uysal, T. Shear bond strength of a self-adhering flowable composite when used for lingual retainer bonding. J. Orofac. Orthop. 2014, 75, 374–383. [Google Scholar] [CrossRef] [PubMed]

- Geserick, M.; Wichelhaus, A. A color-reactivated flowable composite for bonding lingual retainers. J. Clin. Orthod. 2004, 38, 165–166. [Google Scholar] [PubMed]

- Elaut, J.; Asscherickx, K.; Vande Vannet, B.; Wehrbein, H. Flowable composites for bonding lingual retainers. J. Clin. Orthod. 2002, 36, 597–598. [Google Scholar] [PubMed]

- Jin, C.; Bennani, F.; Gray, A.; Farella, M.; Mei, L. Survival analysis of orthodontic retainers. Eur. J. Orthod. 2018, 40, 531–536. [Google Scholar] [CrossRef] [PubMed]

- Sifakakis, I.; Zinelis, S.; Patcas, R.; Eliades, T. Mechanical properties of contemporary orthodontic adhesives used for lingual fixed retention. Biomed. Technik. Biomed. Eng. 2017, 62, 289–294. [Google Scholar] [CrossRef] [PubMed]

- Dietrich, P.; Patcas, R.; Pandis, N.; Eliades, T. Long-term follow-up of maxillary fixed retention: Survival rate and periodontal health. Eur. J. Orthod. 2015, 37, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Booth, F.A.; Edelman, J.M.; Proffit, W.R. Twenty-year follow-up of patients with permanently bonded mandibular canine-to-canine retainers. Am. J. Orthod. Dentofac. Orthop. 2008, 133, 70–76. [Google Scholar] [CrossRef]

- Pandis, N.; Vlahopoulos, K.; Madianos, P.; Eliades, T. Long-term periodontal status of patients with mandibular lingual fixed retention. Eur. J. Orthod. 2007, 29, 471–476. [Google Scholar] [CrossRef]

- Bauer, H.; Ilie, N. Effects of aging and irradiation time on the properties of a highly translucent resin-based composite. Dent. Mater. J. 2013, 32, 592–599. [Google Scholar] [CrossRef]

- Iijima, M.; Muguruma, T.; Brantley, W.A.; Yuasa, T.; Uechi, J.; Mizoguchi, I. Effect of mechanical properties of fillers on the grindability of composite resin adhesives. Am. J. Orthod. Dentofac. Orthop. 2010, 138, 420–426. [Google Scholar] [CrossRef] [PubMed]

- Uysal, T.; Ulker, M.; Akdogan, G.; Ramoglu, S.I.; Yilmaz, E. Bond strength of amorphous calcium phosphate-containing orthodontic composite used as a lingual retainer adhesive. Angle Orthod. 2009, 79, 117–121. [Google Scholar] [CrossRef]

- Gugger, J.; Pandis, N.; Zinelis, S.; Patcas, R.; Eliades, G.; Eliades, T. Retrieval analysis of lingual fixed retainer adhesives. Am. J. Orthod. Dentofac. Orthop. 2016, 150, 575–584. [Google Scholar] [CrossRef]

- Atik, E.; Gorucu-Coskuner, H.; Taner, T. Clinical performance of precoated brackets and self-etch bonding technique: A prospective comparative study. Clin. Oral Investig. 2018. [Google Scholar] [CrossRef]

- Grunheid, T.; Larson, B.E. A comparative assessment of bracket survival and adhesive removal time using flash-free or conventional adhesive for orthodontic bracket bonding: A split-mouth randomized controlled clinical trial. Angle Orthod. 2018, 89, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Durgesh, B.H.; Alkheraif, A.A.; Musaibah, A.S.; Asiry, M.A.; Varrela, J.; Vallittu, P.K. Creep Behavior of Resin Composite Interface Between Orthodontic Brackets and Enamel. J. Adhes. Dent. 2018, 20, 417–424. [Google Scholar] [PubMed]

- Papadogiannis, D.; Iliadi, A.; Bradley, T.G.; Silikas, N.; Eliades, G.; Eliades, T. Viscoelastic properties of orthodontic adhesives used for lingual fixed retainer bonding. Dent. Mater. 2017, 33, e22–e27. [Google Scholar] [CrossRef] [PubMed]

- Papadogiannis, D.; Tolidis, K.; Gerasimou, P.; Lakes, R.; Papadogiannis, Y. Viscoelastic properties, creep behavior and degree of conversion of bulk fill composite resins. Dent. Mater. 2015, 31, 1533–1541. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.H.; Park, S.H.; Hwang, I.N. Polymerization Shrinkage and Depth of Cure of Bulk-Fill Resin Composites and Highly Filled Flowable Resin. Oper. Dent. 2015, 40, 172–180. [Google Scholar] [CrossRef]

- Sunbul, H.A.; Silikas, N.; Watts, D.C. Surface and bulk properties of dental resin- composites after solvent storage. Dent. Mater. 2016, 32, 987–997. [Google Scholar] [CrossRef]

- ISO 14577-1. Metallic Materials-Instrumented Indentation Test for Hardness and Materials Parameters; International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar]

- Shahdad, S.A.; McCabe, J.F.; Bull, S.; Rusby, S.; Wassell, R.W. Hardness measured with traditional Vickers and Martens hardness methods. Dent. Mater. 2007, 23, 1079–1085. [Google Scholar] [CrossRef]

- Food and Drug Administration. Available online: https://www.accessdata.fda.gov/cdrh_docs/pdf16/K160782.pdf (accessed on 14 December 2018).

- GC. G-ænial™ Flo & G-ænial™ Universal Flo, 2018. Available online: http://www.gcamerica.com/products/operatory/G-aenialFlowable/GCA_G-aenial_Bro-iPad.pdf (accessed on 14 December 2018).

- Iliadi, A.; Eliades, T.; Silikas, N.; Eliades, G. Development and testing of novel bisphenol A-free adhesives for lingual fixed retainer bonding. Eur J. Orthod. 2017, 39, 1–8. [Google Scholar] [CrossRef]

- ISO 20795-2:2013. Dentistry—Base Polymers—Part 2: Orthodontic Base Polymers; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Mencik, J. Determination of mechanical properties by instrumented indentation. Meccanica 2007, 42, 19–29. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Fok, A.S.; Watts, D.C. Multiple correlations of material parameters of light-cured dental composites. Dent. Mater. 2009, 25, 829–836. [Google Scholar] [CrossRef]

- Thomaidis, S.; Kakaboura, A.; Mueller, W.D.; Zinelis, S. Mechanical properties of contemporary composite resins and their interrelations. Dent. Mater. 2013, 29, e132–e141. [Google Scholar] [CrossRef]

| Brand Name (Code) Manufacturer | Monomer | Filler | wt% Inorganic Fillers |

|---|---|---|---|

| BracePaste (BP) American Ortodontics Sheboygan, WI, USA | BisEMA TD | BisGMA and BisEMA particles are used as resin fillers Silanated Quartz Silanated Silica | 72 |

| Enlight LV (EN) Ormco Corporation, Glendora, CA, USA | BisEMA MAOPTMS | Not available (N/A) | N/A |

| G-aenial Universal Flo (GA) GC Corporation, Tokyo, Japan | UDMA, Bis-MEPP, TEGDMA | 200-nm Sr glass fillers | 69 |

| Flow Tain (FT) Reliance Orthodonics Products, Itasca, IL, USA | Bis-GMA TEGDMA | Glass fillers | 50 |

| Transbond LR (TR) 3M Unitek Monrovia CA | BisGMA TEGDMA | Silanated quartz | 75–85 |

| Transbond XT (TX) (for bracket bonding; used for comparison purposes) 3M | Bis-EMA Bis-GMA | Silanated Quartz Silaneted Silica. | 70–80 |

| Wave (WA) SDI, Victoria, Australia | UDMA BisMEPP TEDMA | Specially treated nano-fillers | 65 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.N.; Zinelis, S.; Hersberger-Zurfluh, M.; Eliades, T. Creep, Hardness, and Elastic Modulus of Lingual Fixed Retainer Adhesives. Materials 2019, 12, 646. https://doi.org/10.3390/ma12040646

Hassan MN, Zinelis S, Hersberger-Zurfluh M, Eliades T. Creep, Hardness, and Elastic Modulus of Lingual Fixed Retainer Adhesives. Materials. 2019; 12(4):646. https://doi.org/10.3390/ma12040646

Chicago/Turabian StyleHassan, Manar N., Spiros Zinelis, Monika Hersberger-Zurfluh, and Theodore Eliades. 2019. "Creep, Hardness, and Elastic Modulus of Lingual Fixed Retainer Adhesives" Materials 12, no. 4: 646. https://doi.org/10.3390/ma12040646

APA StyleHassan, M. N., Zinelis, S., Hersberger-Zurfluh, M., & Eliades, T. (2019). Creep, Hardness, and Elastic Modulus of Lingual Fixed Retainer Adhesives. Materials, 12(4), 646. https://doi.org/10.3390/ma12040646