Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties

Abstract

1. Introduction

2. Scope and Objectives

3. Materials and Methods

3.1. Binders

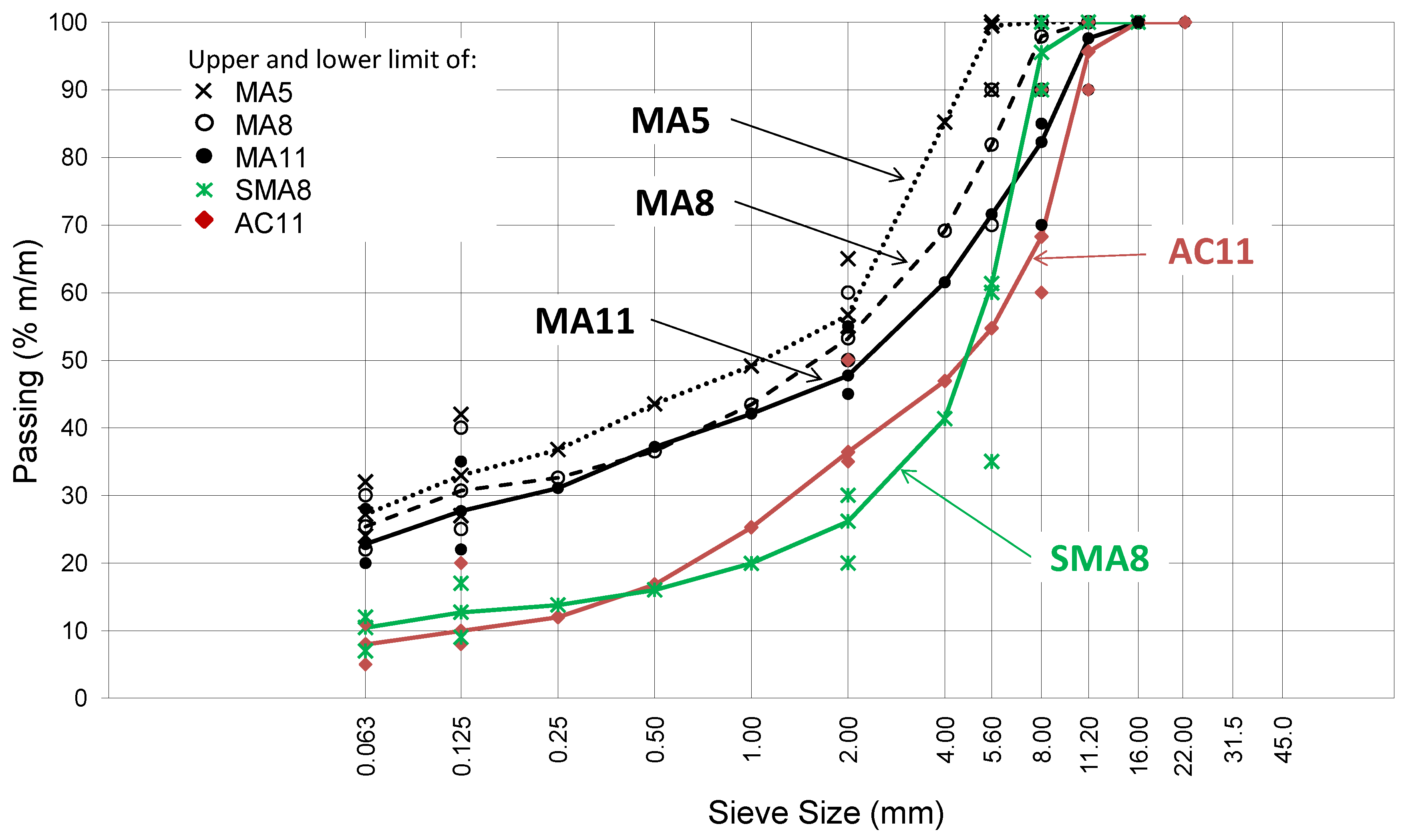

3.2. Asphalt Mixtures

3.3. Conventional Testing of Binders

3.4. Conventional Testing of Asphalt Mixtures

4. Overheating

4.1. Overheating Method

4.2. Overheating Assessment

5. Results

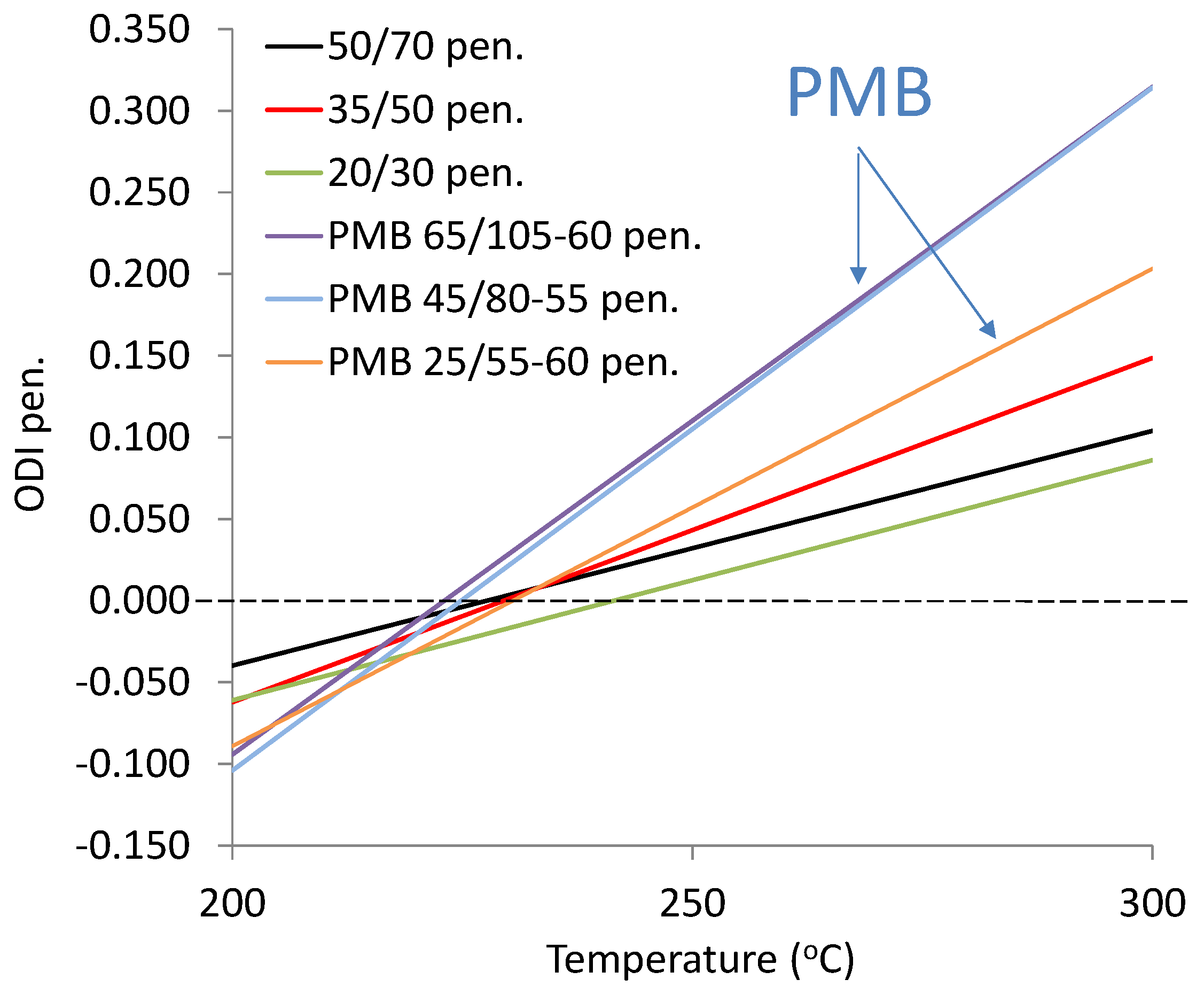

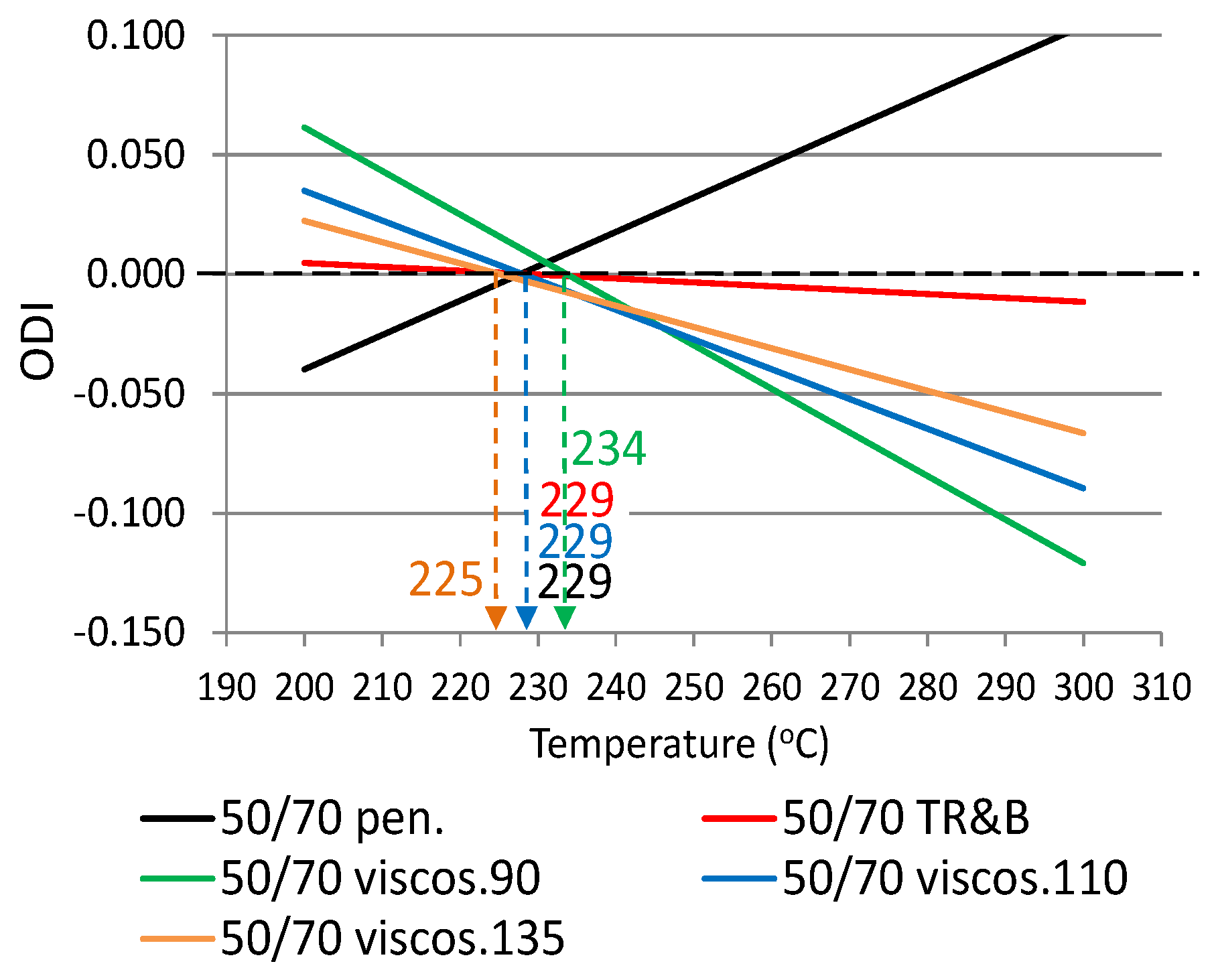

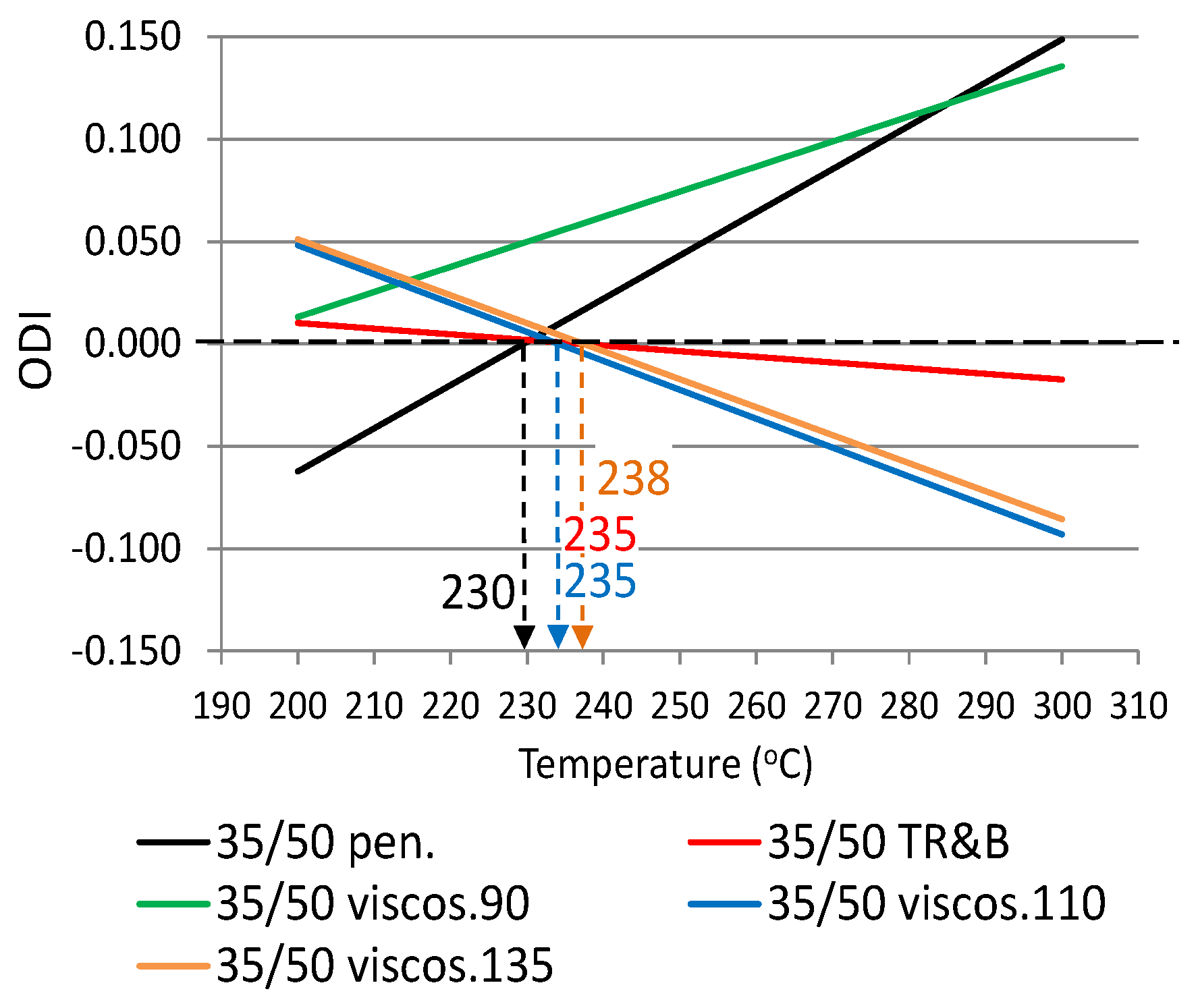

5.1. Binder Overheating

5.2. Asphalt Mixture Overheating

6. Discussion and Conclusions

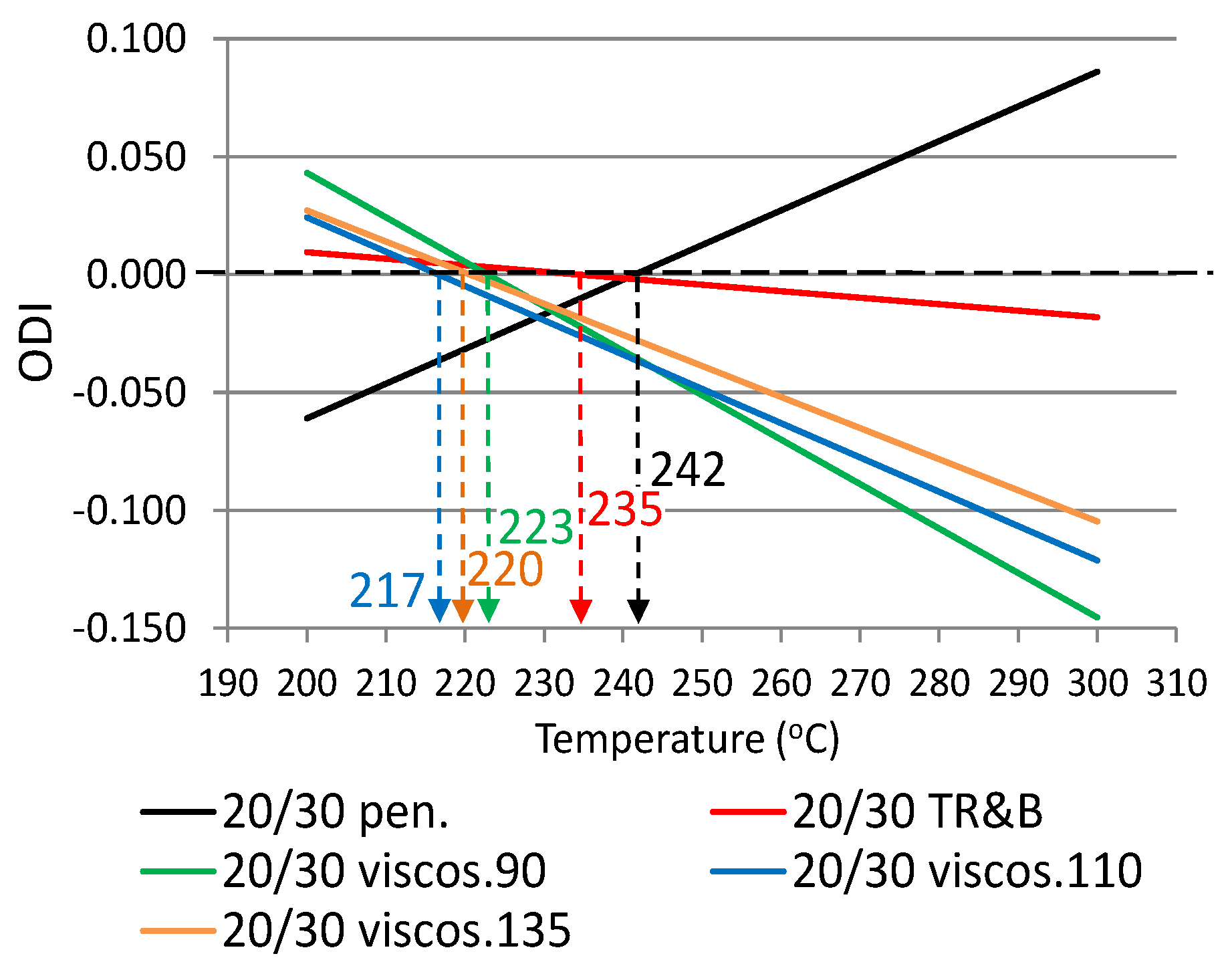

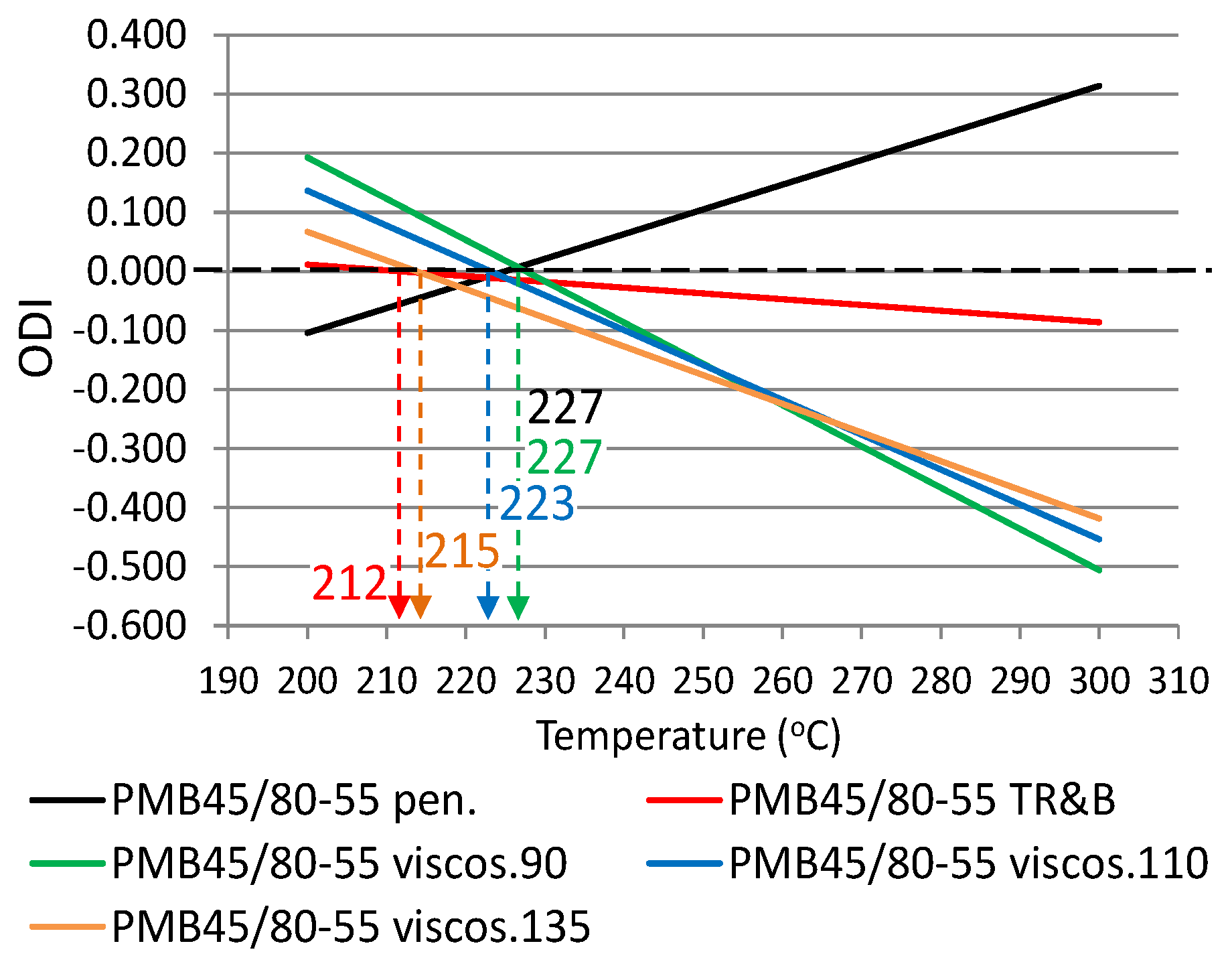

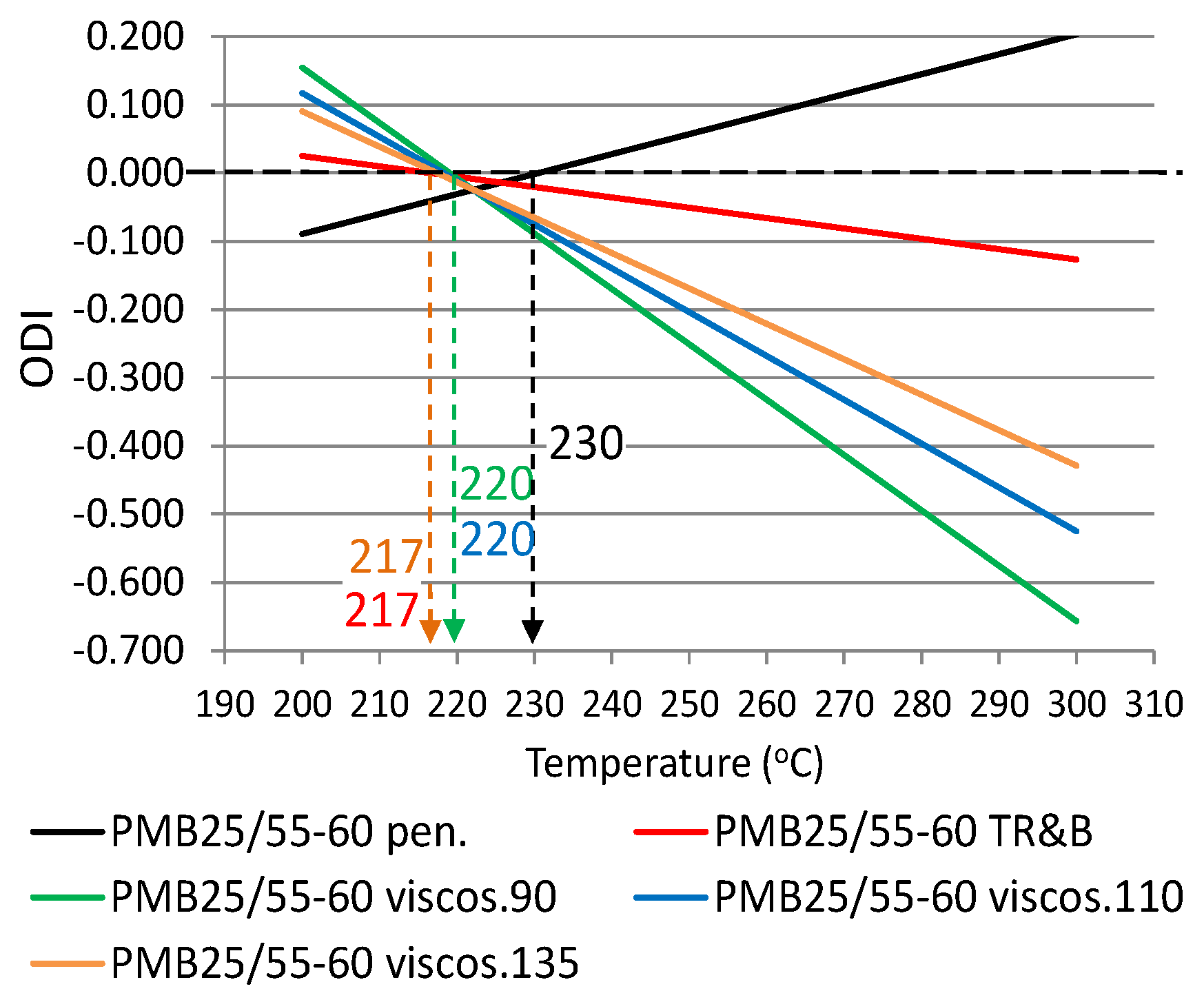

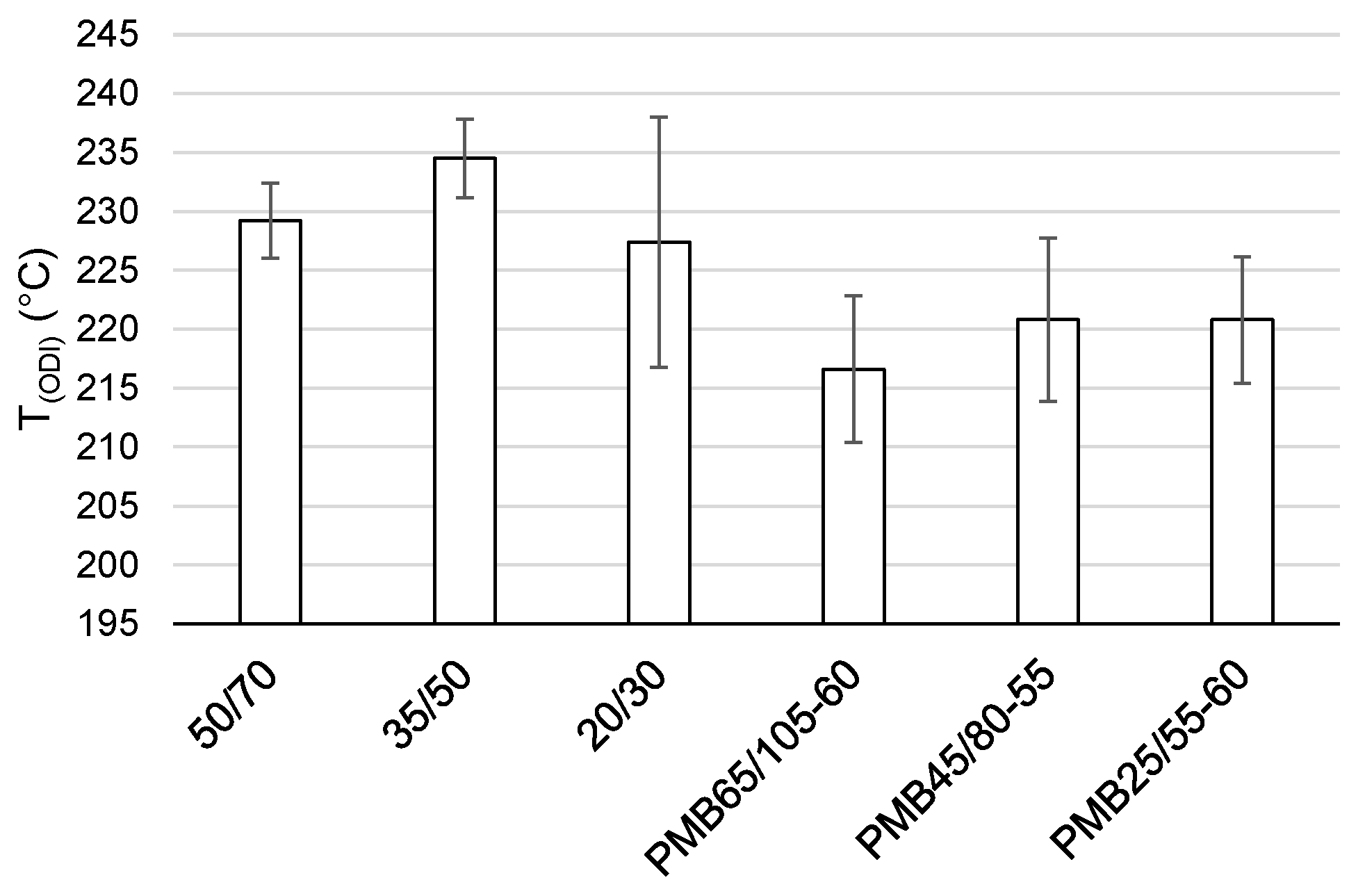

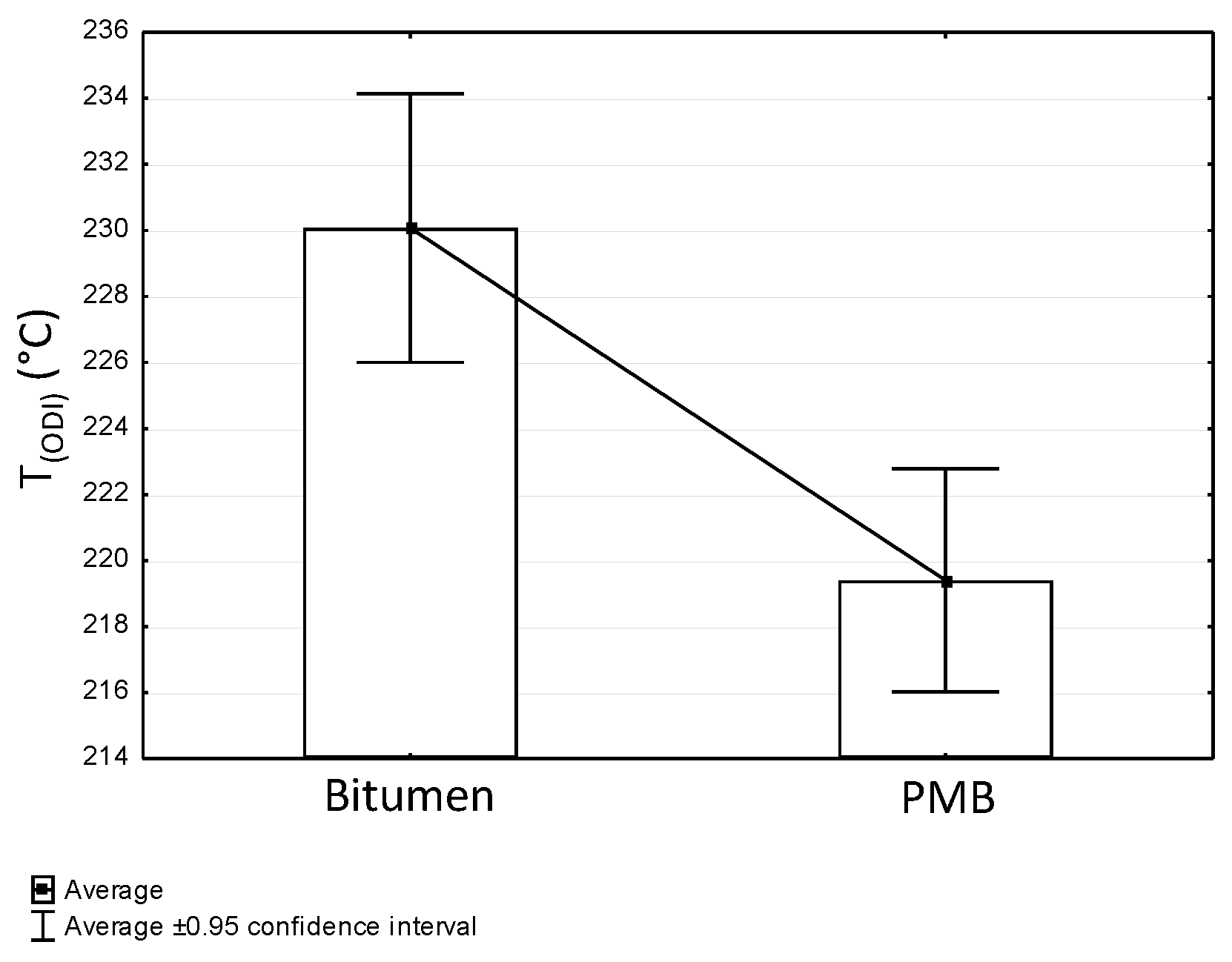

- Based on the calculated temperature T(ODI) for different European bituminous binders used for road and bridge pavements, it was concluded that non-modified bitumens are more resistant to overheating than polymer-modified bitumens. Variance analysis showed that the difference between these two binder groups was statistically significant (p < 0.05). Bitumen 35/50 is characterized by temperature T(ODI) higher by 18 °C than the polymer-modified bitumen PMB 65/105-60. Lower temperature sensitivity of a binder A(ODI) does not always mean a higher limit temperature T(ODI). However, it does shows the rate of change of the studied property, along with increasing heating temperature.

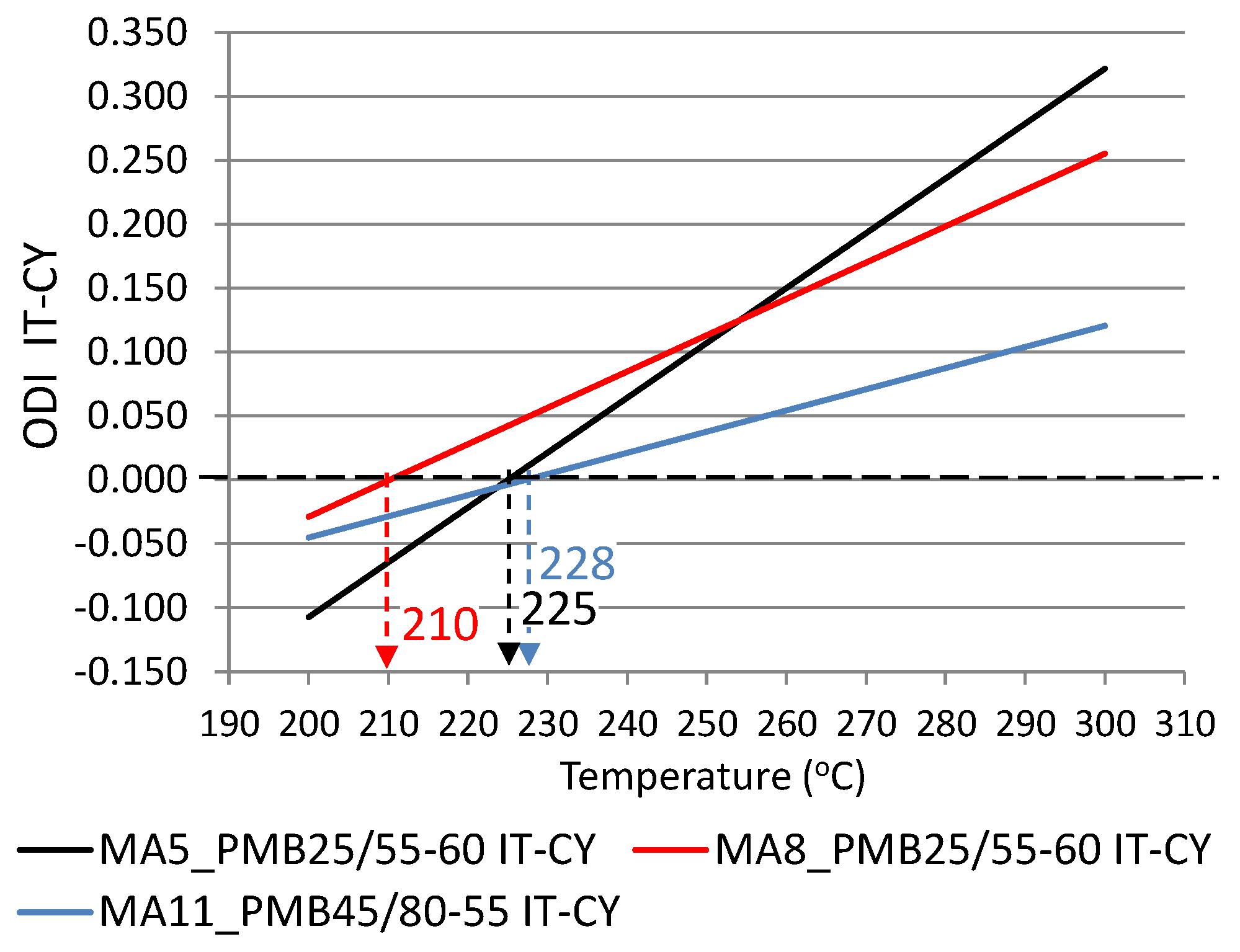

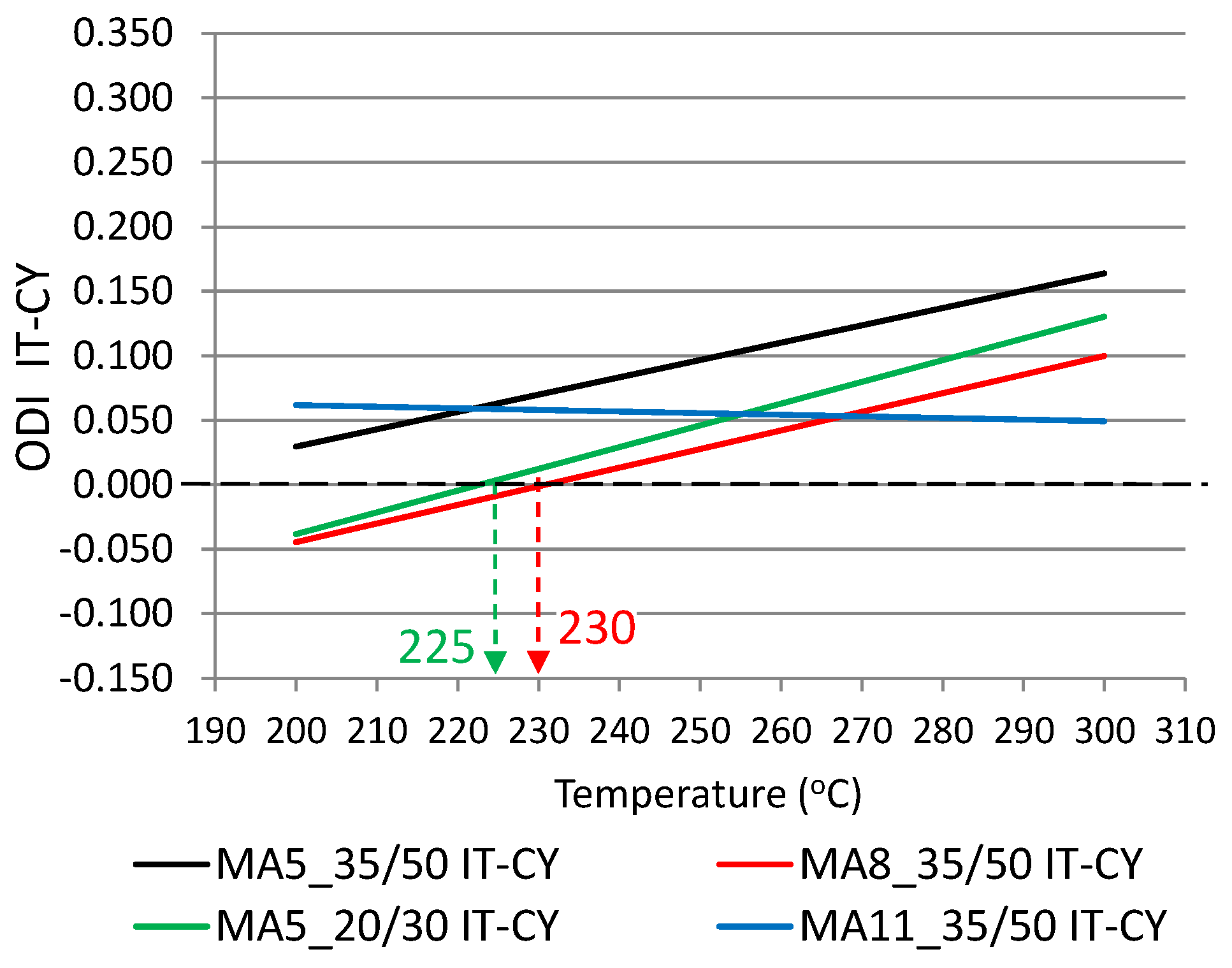

- Based on the analysis of the stiffness modulus IT-CY tests regarding the mastic asphalt with polymer-modified bitumen PMB25/55-60, it was concluded that the limit temperature T(ODI) for the MA5 mixture was 225 °C, and for MA8 T(ODI) = 210 °C. Comparing these temperatures with the temperature determined for PMB25/55-60 (T(ODI) = 221 °C) it can be stated that there is no direct correlation of the limit temperature determined for a binder and the temperature determined for a asphalt mixture. However, these are similar temperatures. In the case of mastic asphalt MA11 with polymer-modified binder PMB45/80-55, the mixture limit temperature T(ODI) = 228 °C. This temperature is 7 °C higher than the limit temperature for polymer-modified bitumen PMB45/80-55, calculated on the basis of penetration, softening point and viscosity tests (T(ODI) = 221 °C). The limit temperature for a MA8 mixture with bitumen 35/50 was approximately 230 °C, which is a value close to the temperature T(ODI) = 235 °C read for bitumen 35/50. The limit temperature for mastic asphalt MA5 with bitumen 20/30 corresponds to the temperature determined for this bitumen based on penetration, softening point and viscosity tests (T(ODI) = 227 °C).

- The sensitivity to overheating A(ODI) of asphalt mixtures of the same type but with different binders can be evaluated by comparing the inclination of ODI lines shown in Figure 11 and Figure 12. Sensitivity A(ODI) of both MA5 and MA8 mastic asphalts is higher in the case of mixtures with polymer-modified bitumens, compared to mixtures with non-modified bitumens. Meanwhile the temperature sensitivity of mastic asphalt MA11 with polymer-modified bitumen PMB45/80-55 is the same as of mastic asphalt MA5 with bitumen 20/30. It should be noted that the sensitivity of this polymer-modified bitumen, determined based on penetration at 25 °C, is the highest among the analyzed binders, and the one for bitumen 20/30 is the lowest (Figure 2). This means that the ultimate resistance to overheating of a asphalt mixture is impacted by its grading, composition and volumetric properties, and bitumen temperature sensitivity is only one of the components.

- As indicated by the conducted tests, the overheating temperature of a mixture with a given binder can differ by ±10 °C from the limit temperature of such a binder. In the case of mixtures with a more closed structure and with a more developed grit matrix, the impact of the overheating phenomenon on the properties of a mixture is largely reduced, despite the application of polymer-modified bitumen. MA11 and SMA8 mixtures are characterized by such resistance.

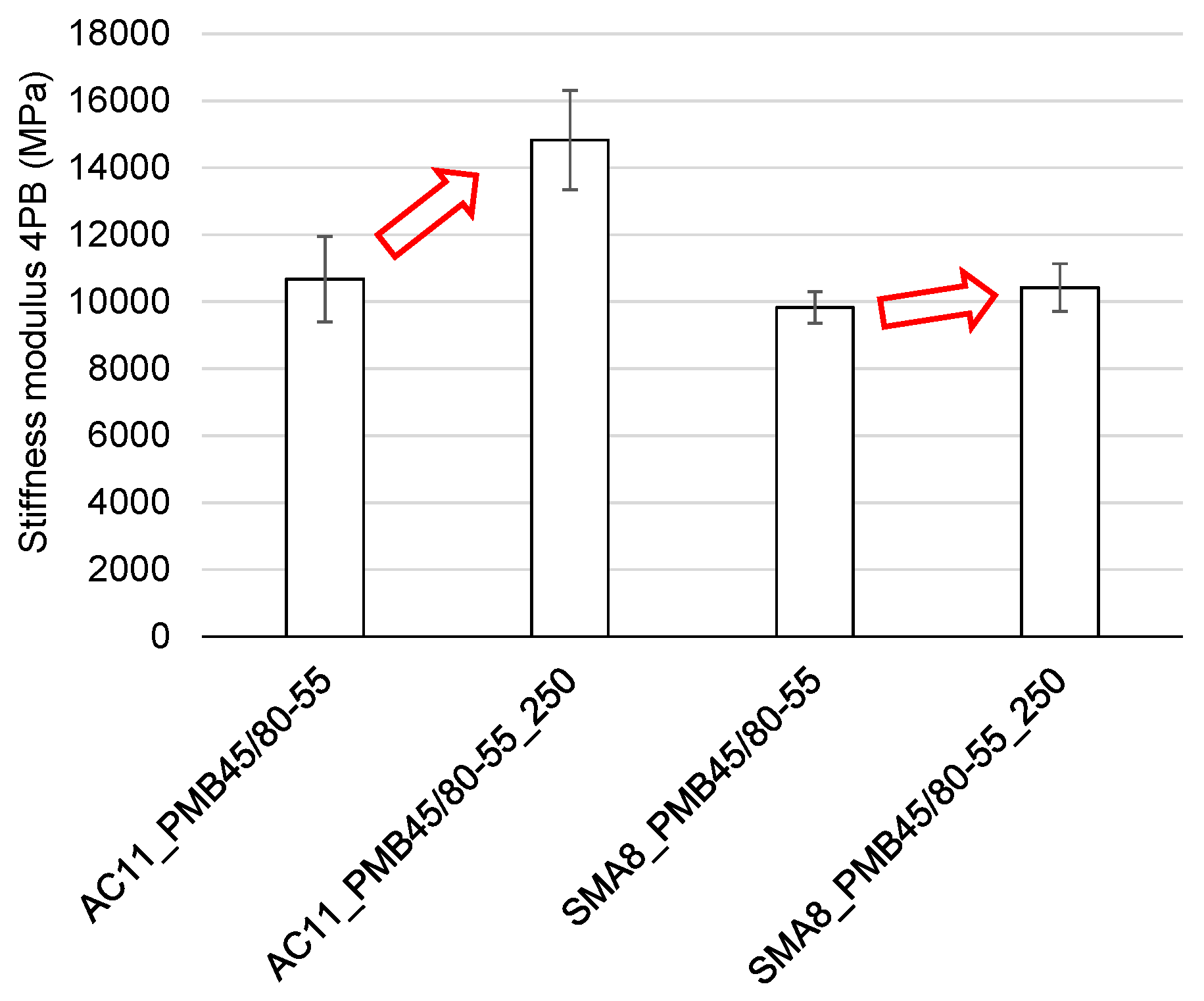

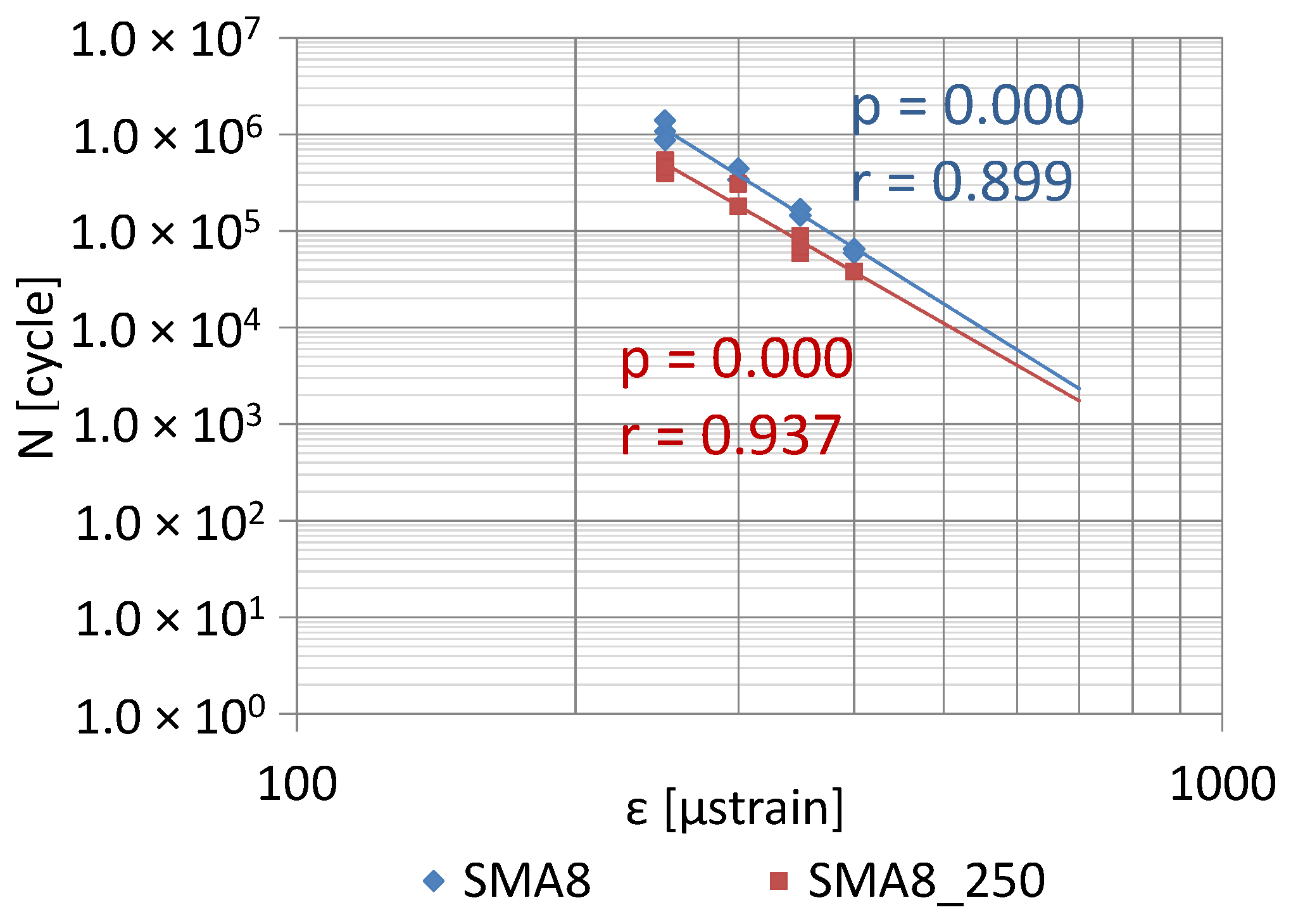

- The research paper involved analyzing the impact of heating on changes to the stiffness modulus and fatigue life according to the 4PB method, utilizing asphalt concrete and SMA with polymer-modified bitumen PMB45/80-55, with the temperature T(ODI) = 221 °C. Overheating these mixtures by 30 °C in relation to T(ODI) of the polymer-modified bitumen, resulted in an increase of their stiffness modulus and a significant decrease of their fatigue life. Asphalt concrete turned out to be more sensitive to overheating, and suffered greater adverse changes, leading to the loss of viscous properties in favor of brittle fracture. In the case of unheated mixtures, with the same strain amplitude, e.g., ε = 300 µm/m, the fatigue life of an SMA mixture was about four times higher than that of asphalt concrete. Even greater differences in the resistance to fatigue cracking were observed in the case of mixtures subjected to heating at a temperature of 250 °C. For a strain amplitude ε = 300 µm/m, the fatigue life of an SMA mixture was about ten times higher than that of asphalt concrete. The significance of identified relationships was confirmed using the statistical methods.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- General Directorate for National Roads and Motorways (GDDKiA). WT-2 “Asphalt Pavement for National Roads. Asphalt Mixtures. Technical Requirement”. 2014. Available online: https://www.gddkia.gov.pl/userfiles/articles/z/zarzadzenia-generalnego-dyrektor_13901/zalacznik%20do%20zarz%2047.pdf (accessed on 3 December 2018).

- Iwański, M.; Mazurek, G. Wpływ dodatku wosku syntetycznego Fischera-Tropscha na właściwości funkcjonalne asfaltu. Polimery 2015, 60, 272–278. (In Polish) [Google Scholar]

- Król, J.; Kowalski, K.J.; Radziszewski, P.; Sarnowski, M. Rheological behaviour of n-alkane modified bitumen in aspect of Warm Mix Asphalt technology. Constr. Build. Mater. 2015, 93, 703–710. [Google Scholar] [CrossRef]

- Radziszewski, P.; Ziółkowski, R.; Čygas, D. Technological Ageing Influence On Viscosity Of Selected Bitumens. J. Civil Eng. Manag. 2003, 9, 20–24. [Google Scholar] [CrossRef]

- O’Connell, J.; Steyn, W.J.V.D.M. An overview of the ageing of bituminous binders. In Proceedings of the Southern African Transportation Conference 2017, Pretoria, South Africa, 10–13 July 2017. [Google Scholar]

- Iwanski, M.; Mazurek, G. Hydrated lime as the Anti-aging Bitumen Agent. Procedia Eng. 2013, 57, 424–432. [Google Scholar] [CrossRef]

- Byzyka, J.; Rahman, M.; Chamberlain, D.A. An innovative asphalt patch repair pre–heating method using dynamic heating. Constr. Build. Mater. 2018, 188, 178–197. [Google Scholar] [CrossRef]

- Urquhart, R.; Woodall, E.; Malone, S.; Lourensz, S. Effects of hot storage on polymer modified binder properties and field performance. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. Paper No. EE.2016.064. [Google Scholar]

- Tang, N.; Yang, Y.-L.; Yu, M.-L.; Wang, W.-L.; Cao, S.-Y.; Wang, Q.; Pan, W.-H. Investigation of Ageing in Bitumen Using Fluorescence Spectrum. Materials 2018, 11, 1325. [Google Scholar] [CrossRef] [PubMed]

- Pan, P.; Kuang, Y.; Hu, X.; Zhang, X. A Comprehensive Evaluation of Rejuvenator on Mechanical Properties, Durability, and Dynamic Characteristics of Artificially Aged Asphalt Mixture. Materials 2018, 11, 1554. [Google Scholar] [CrossRef]

- He, R.; Wu, S.; Wang, X.; Wang, Z.; Chen, H. Temperature Sensitivity Characteristics of SBS/CRP-Modified Bitumen after Different Aging Processes. Materials 2018, 11, 2136. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Tao, G.; Xiao, Y. Initial Self-Healing Temperatures of Asphalt Mastics Based on Flow Behavior Index. Materials 2018, 11, 917. [Google Scholar] [CrossRef]

- Vila-Cortavitarte, M.; Jato-Espino, D.; Castro-Fresno, D.; Calzada-Pérez, M.Á. Self-Healing Capacity of Asphalt Mixtures Including By-Products Both as Aggregates and Heating Inductors. Materials 2018, 11, 800. [Google Scholar] [CrossRef]

- Dessouky, S.; Reyes, C.; Ilias, M.; Contreras, D.; Papagiannakis, A.T. Effect of pre-heating duration and temperature conditioning on the rheological properties of bitumen. Constr. Build. Mater. 2011, 25, 2785–2792. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2018. [Google Scholar] [CrossRef]

- Kowalski, K.J.; McDaniel, R.S.; Olek, J.; Shah, A. Modified Ignition Oven Test Procedure for Determination of Binder Content in Hot Mix Asphalt Containing Dolomite Aggregate. J. Test. Eval. 2011, 39, 1060–1069. [Google Scholar]

- Radziszewski, P.; Piłat, J.; Sarnowski, M.; Król, J.; Kowalski, K.J. Asphalt Pavements on Bridge Structures; Warsaw University of Technology (OWPW): Warsaw, Poland, 2016. (In Polish) [Google Scholar]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SBS- and SBS/sulfur-modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Li, M.; Pang, L.; Chen, M.; Xie, J.; Liu, Q. Effects of Aluminum Hydroxide and Layered Double Hydroxide on Asphalt Fire Resistance. Materials 2018, 11, 1939. [Google Scholar] [CrossRef] [PubMed]

- Cortizo, M.S.; Larsen, D.O.; Bianchetto, H.; Alessandrini, J.L. Effect of the thermal degradation of SBS copolymers during the ageing of modified asphalts. Polym. Degrad. Stab. 2004, 86, 275–282. [Google Scholar] [CrossRef]

- Bartos, P.J.M.; Hughes, J.J.; Trtik, P.; Zhu, W. Nanotechnology in Construction. In Advancing the Chemical Sciences; The Royal Society of Chemistry: London, UK, 2004; ISBN 0-85404-623-2. [Google Scholar]

- Nurfazilah, B.M.S. Effects of overheating bitumen on hot mix asphalt properties. J. Online Jar. Pengaj. Seni Bina (JOJAPS) 2012, 5, 48–58. [Google Scholar]

- Gueit, C.; Robert, M. Durability of a bitumen in a hot mix asphalt: Consequences of over-heating at the mixing plant. In Proceedings of the 5th Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012. Paper No. A5EE-337. [Google Scholar]

- Lolly, R.; Zeiada, W.; Souliman, M.; Kaloush, K. Effects of Short-Term Aging on Asphalt Binders and Hot Mix Asphalt at Elevated Temperatures and Extended Aging Time. MATEC Web Conf. 2017, 120, 07010. [Google Scholar] [CrossRef]

- Singh, S.K.; Kumar, Y.; Ravindranath, S.S. Thermal degradation of SBS in bitumen during storage: Influence of temperature, SBS concentration, polymer type and base bitumen. Polym. Degrad. Stab. 2018, 147, 64–75. [Google Scholar] [CrossRef]

- EN 12591. Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumens; British Standards Institution (BSI): London, UK, 2009. [Google Scholar]

- EN 14023. Bitumen and Bituminous Binders—Specification Rramework for Polymer Modified Bitumens; British Standards Institution (BSI): London, UK, 2010. [Google Scholar]

- EN 1426. Bitumen and Bituminous Binders. Determination of Needle Penetration; British Standards Institution (BSI): London, UK, 2015. [Google Scholar]

- EN 1427. Bitumen and Bituminous Binders. Determination of the Softening Point. Ring and Ball Method; British Standards Institution (BSI): London, UK, 2015. [Google Scholar]

- EN 13302. Bitumen and Bituminous Binders. Determination of the Dynamic Viscosity of a Bituminous Binder using a Rotating Spindle Apparatus; British Standards Institution (BSI): London, UK, 2018. [Google Scholar]

- EN 12697-26. Bituminous Mixtures. Test Methods. Stiffness; British Standards Institution (BSI): London, UK, 2018. [Google Scholar]

- EN 12697-33. Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Specimen Prepared by Roller Compactor; British Standards Institution (BSI): London, UK, 2013. [Google Scholar]

- EN 12697-24. Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Resistance to Fatigue; British Standards Institution (BSI): London, UK, 2012. [Google Scholar]

- Androjić, I. Ageing of hot mix asphalt. Građevinar 2016, 68, 477–483. [Google Scholar]

- Liu, X.; Wu, S.; Liu, G.; Li, L. Effect of Ultraviolet Aging on Rheology and Chemistry of LDH-Modified Bitumen. Materials 2015, 8, 5238–5249. [Google Scholar] [CrossRef] [PubMed]

- Radziszewski, P.; Piłat, J.; Sarnowski, M.; Kowalski, K.J.; Król, J.B. Influence of high temperature on properties of materials used in bridge asphalt pavement structures. Roads Bridges—Drogi i Mosty 2015, 14, 175–191. [Google Scholar]

- Wang, H.; Yang, J.; Lu, G.; Liu, X. Accelerated healing in asphalt concrete via laboratory microwave heating. J. Test. Eval. 2018, 48. [Google Scholar] [CrossRef]

- Liu, Q.T.; Li, B.; Schlangen, E.; Sun, Y.H.; Wu, S.P. Research on the mechanical, thermal, induction heating and healing properties of steel slag/steel fibers composite asphalt mixture. Appl. Sci. 2017, 7, 1088. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Zhang, Y.; Feng, S.; Lu, G.; Cao, L. Laboratory and Numerical Investigation of Microwave Heating Properties of Asphalt Mixture. Materials 2019, 12, 146. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, S.; Schlangen, E. Induction heating of asphalt mastic for crack control. Constr. Build. Mater. 2013, 41, 345–351. [Google Scholar] [CrossRef]

| Properties | Units | MA 5 | MA 8 | MA 11 | SMA 8 | AC 11 |

|---|---|---|---|---|---|---|

| Lime filler content | % | 29.4 | 27.6 | 25.0 | 11.2 | 8.5 |

| Fine aggregate content | % | 20.2 | 22.1 | 18.6 | 12.1 | 28.4 |

| Coarse aggregate content (gabbro) | % | 42.4 | 42.3 | 48.9 | 69.7 | 57.7 |

| Binder content | % | 8.0 | 8.0 | 7.5 | 7.0 | 5.4 |

| Air voids content Va (blows: 2 × 75–AC; 2 × 50–SMA) | % | 0.4 | 0.1 | 0.2 | 2.6 | 2.1 |

| Voids in mineral aggregate VMA | % | 17.6 | 18.5 | 18.6 | 19.8 | 15.6 |

| Voids filled with bitumen VFB | % | 97.8 | 99.4 | 99.1 | 86.9 | 86.6 |

| Type of Bitumen | Properties | Units | Heating Temperature (°C) | |||

|---|---|---|---|---|---|---|

| - | 200 | 250 | 300 | |||

| 50/70 | Penetration, 25 °C | (0.1 mm) | 57.1 | 56.7 | 54.8 | 62.3 |

| Softening point | (°C) | 48.9 | 48.9 | 49.2 | 48.4 | |

| Viscosity, 90 °C | (Pa·s) | 9.06 | 9.72 | 9.21 | 8.20 | |

| Viscosity, 110 °C | (Pa·s) | 1.92 | 1.99 | 1.93 | 1.76 | |

| Viscosity, 135 °C | (Pa·s) | 0.45 | 0.46 | 0.45 | 0.42 | |

| 35/50 | Penetration, 25 °C | (0.1 mm) | 37.3 | 36.7 | 34.9 | 41.7 |

| Softening point | (°C) | 54.3 | 54.7 | 54.8 | 53.7 | |

| Viscosity, 90 °C | (Pa·s) | 18.60 | 19.21 | 19.88 | 22.97 | |

| Viscosity, 110 °C | (Pa·s) | 3.38 | 3.51 | 3.50 | 3.14 | |

| Viscosity, 135 °C | (Pa·s) | 0.70 | 0.72 | 0.74 | 0.66 | |

| 20/30 | Penetration, 25 °C | (0.1 mm) | 24.5 | 23.0 | 23.3 | 25.3 |

| Softening point | (°C) | 61.4 | 61.7 | 62.0 | 60.6 | |

| Viscosity, 90 °C | (Pa·s) | 49.44 | 51.11 | 49.45 | 41.8 | |

| Viscosity, 110 °C | (Pa·s) | 7.48 | 7.46 | 7.5 | 6.39 | |

| Viscosity, 135 °C | (Pa·s) | 1.29 | 1.31 | 1.29 | 1.14 | |

| PMB65/105-60 | Penetration, 25 °C | (0.1 mm) | 64.7 | 61.1 | 63.1 | 85.4 |

| Softening point | (°C) | 60.6 | 59.8 | 60.5 | 47.3 | |

| Viscosity, 90 °C | (Pa·s) | 55.56 | 64.50 | 58.00 | 9.29 | |

| Viscosity, 110 °C | (Pa·s) | 6.98 | 6.96 | 6.58 | 2.09 | |

| Viscosity, 135 °C | (Pa·s) | 1.25 | 1.23 | 1.13 | 0.52 | |

| PMB45/80-55 | Penetration, 25 °C | (0.1 mm) | 46.2 | 41.3 | 45.8 | 60.1 |

| Softening point | (°C) | 56.6 | 56.0 | 56.4 | 50.3 | |

| Viscosity, 90 °C | (Pa·s) | 28.78 | 30.36 | 33.96 | 12.09 | |

| Viscosity, 110 °C | (Pa·s) | 5.06 | 5.33 | 5.37 | 2.49 | |

| Viscosity, 135 °C | (Pa·s) | 1.14 | 1.16 | 1.07 | 0.57 | |

| PMB25/55-60 | Penetration, 25 °C | (0.1 mm) | 32.2 | 29.2 | 31.1 | 37.3 |

| Softening point | (°C) | 67.0 | 67.2 | 66.7 | 56.8 | |

| Viscosity, 90 °C | (Pa·s) | 110.13 | 115.0 | 111.63 | 25.97 | |

| Viscosity, 110 °C | (Pa·s) | 12.20 | 12.40 | 12.38 | 4.63 | |

| Viscosity, 135 °C | (Pa·s) | 1.86 | 1.89 | 1.85 | 0.92 | |

| Type of Bitumen | Fitting Formula of ODI ODIY property = A(ODI)x + B | T(ODI) (°C) | Average T(ODI) (°C) | Sd (°C) |

|---|---|---|---|---|

| 50/70 | ODIpen = 0.0014x − 0.3276 | 229 | 229 | 3.19 |

| ODIR&B = −0.0002x + 0.0373 | 229 | |||

| ODIviscos (90) = −0.0018x + 0.4265 | 234 | |||

| ODIviscos (110) = −0.0012x + 0.2841 | 229 | |||

| ODIviscos (135) = −0.0009x + 0.2002 | 225 | |||

| 35/50 | ODIpen = 0.0021x − 0.4841 | 230 | 235 | 3.32 |

| ODIR&B = −0.0003x + 0.0650 | 235 | |||

| ODIviscos (110) = −0.0014x + 0.3309 | 235 | |||

| ODIviscos (135) = −0.0014x + 0.3244 | 238 | |||

| 20/30 | ODIpen = 0.0015x − 0.3551 | 242 | 227 | 10.64 |

| ODIR&B = −0.0003x + 0.0644 | 235 | |||

| ODIviscos (90) = −0.0019x + 0.4201 | 223 | |||

| ODIviscos (110) = −0.0015x + 0.3149 | 217 | |||

| ODIviscos (135) = −0.0013x + 0.2908 | 220 | |||

| PMB65/105-60 | ODIpen = 0.0041x - 0.9125 | 223 | 217 | 6.23 |

| ODIR&B = −0.002x + 0.4392 | 215 | |||

| ODIviscos (90) = −0.01x + 2.2419 | 223 | |||

| ODIviscos (110) = −0.0068x + 1.4522 | 213 | |||

| ODIviscos (135) = −0.0052x + 1.0972 | 209 | |||

| PMB45/80-55 | ODIpen = 0.0042x − 0.9407 | 227 | 221 | 6.94 |

| ODIR&B = −0.001x + 0.2067 | 212 | |||

| ODIviscos (90) = −0.007x + 1.5904 | 227 | |||

| ODIviscos (110) = −0.0059x + 1.3157 | 223 | |||

| ODIviscos (135) = −0.0048x + 1.0363 | 215 | |||

| PMB25/55-60 | ODIpen = 0.0029x − 0.6742 | 230 | 221 | 5.36 |

| ODIR&B = −0.0015x + 0.3276 | 217 | |||

| ODIviscos (90) = −0.0081x + 1.7781 | 220 | |||

| ODIviscos (110) = −0.0064x + 1.4023 | 220 | |||

| ODIviscos (135) = −0.0052x + 1.1278 | 217 |

| Asphalt Mixture | Type of Binder | Stiffness Modulus IT-CY (MPa) | Fitting Formula of ODIIT-CY (ODIY property = A(ODI)x + B) | T(ODI) (°C) | |||

|---|---|---|---|---|---|---|---|

| Heating Temperature (°C) | |||||||

| - | 200 | 250 | 300 | ||||

| MA5 | 35/50 | 5603 | 5640 | 6443 | 7352 | ODIIT-CY = 0.0013x − 0.2395 | - * |

| 20/30 | 8399 | 7520 | 8867 | 9434 | ODIIT-CY = 0.0017x − 0.3754 | 225 | |

| PMB25/55-60 | 5408 | 4842 | 5333 | 7064 | ODIIT-CY = 0.0043x − 0.9660 | 225 | |

| MA8 | 35/50 | 6168 | 5774 | 6158 | 6653 | ODIIT-CY = 0.0014x − 0.3330 | 230 |

| PMB25/55-60 | 5945 | 5771 | 6429 | 8067 | ODIIT-CY = 0.0028x − 0.5970 | 210 | |

| MA11 | 35/50 | 6478 | 7076 | 7040 | 7601 | ODIIT-CY = -0.0001x + 0.0872 | - * |

| PMB45/80-55 | 4958 | 4490 | 5103 | 5466 | ODIIT-CY = 0.0017x − 0.3761 | 228 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarnowski, M.; Kowalski, K.J.; Król, J.B.; Radziszewski, P. Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties. Materials 2019, 12, 610. https://doi.org/10.3390/ma12040610

Sarnowski M, Kowalski KJ, Król JB, Radziszewski P. Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties. Materials. 2019; 12(4):610. https://doi.org/10.3390/ma12040610

Chicago/Turabian StyleSarnowski, Michał, Karol J. Kowalski, Jan B. Król, and Piotr Radziszewski. 2019. "Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties" Materials 12, no. 4: 610. https://doi.org/10.3390/ma12040610

APA StyleSarnowski, M., Kowalski, K. J., Król, J. B., & Radziszewski, P. (2019). Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties. Materials, 12(4), 610. https://doi.org/10.3390/ma12040610