Nanocomposite Film Based on Cellulose Acetate and Lignin-Rich Rice Straw Nanofibers

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Rice Straw Pulp

2.3. Xylanases Pretreatment of Unbleached Rice Straw Pulp

2.4. Isolation of Rice Straw Nanofibers (RSNF)

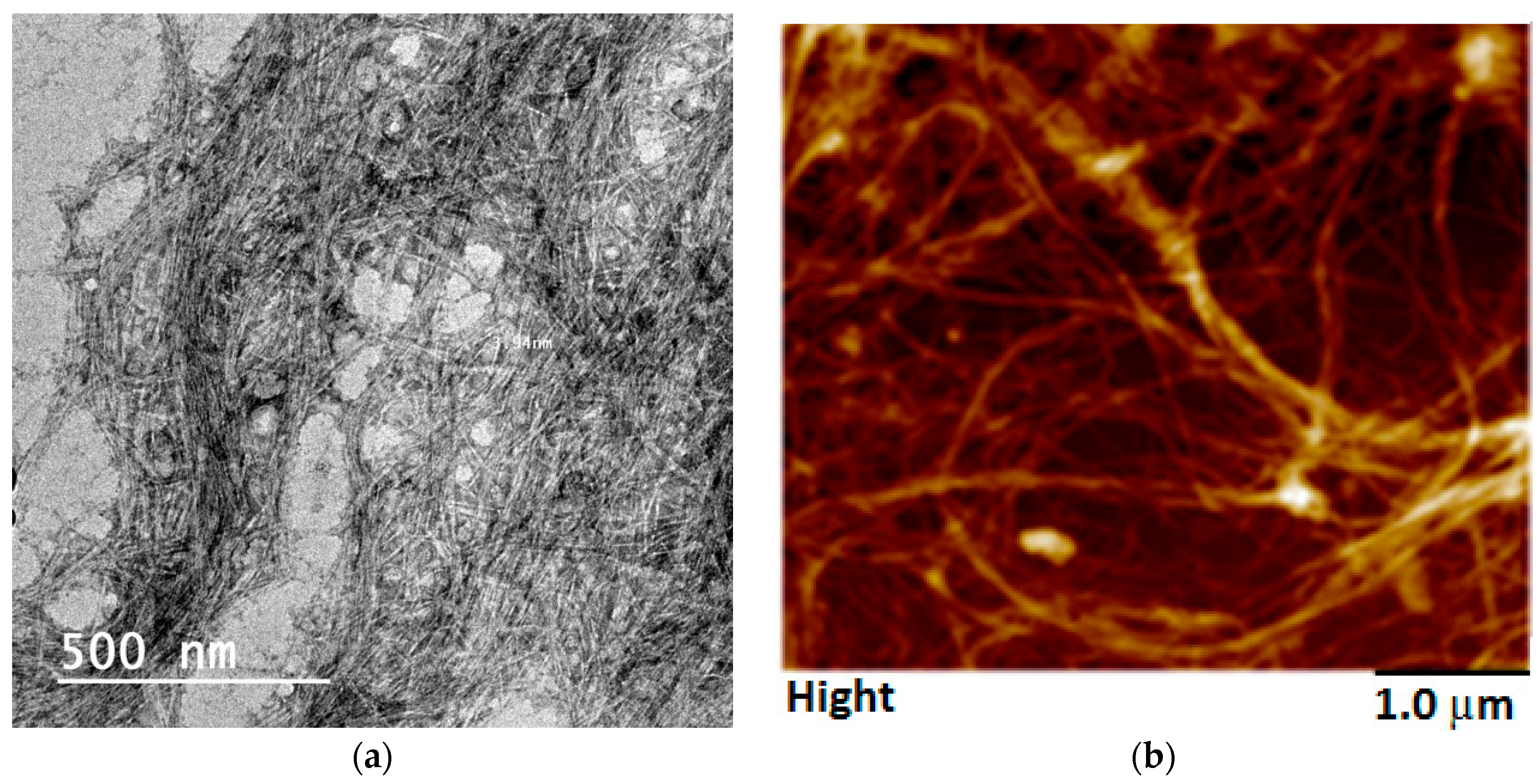

2.5. Characterization of RSNF

2.6. Film Casting

2.7. Characterization

3. Results and Discussion

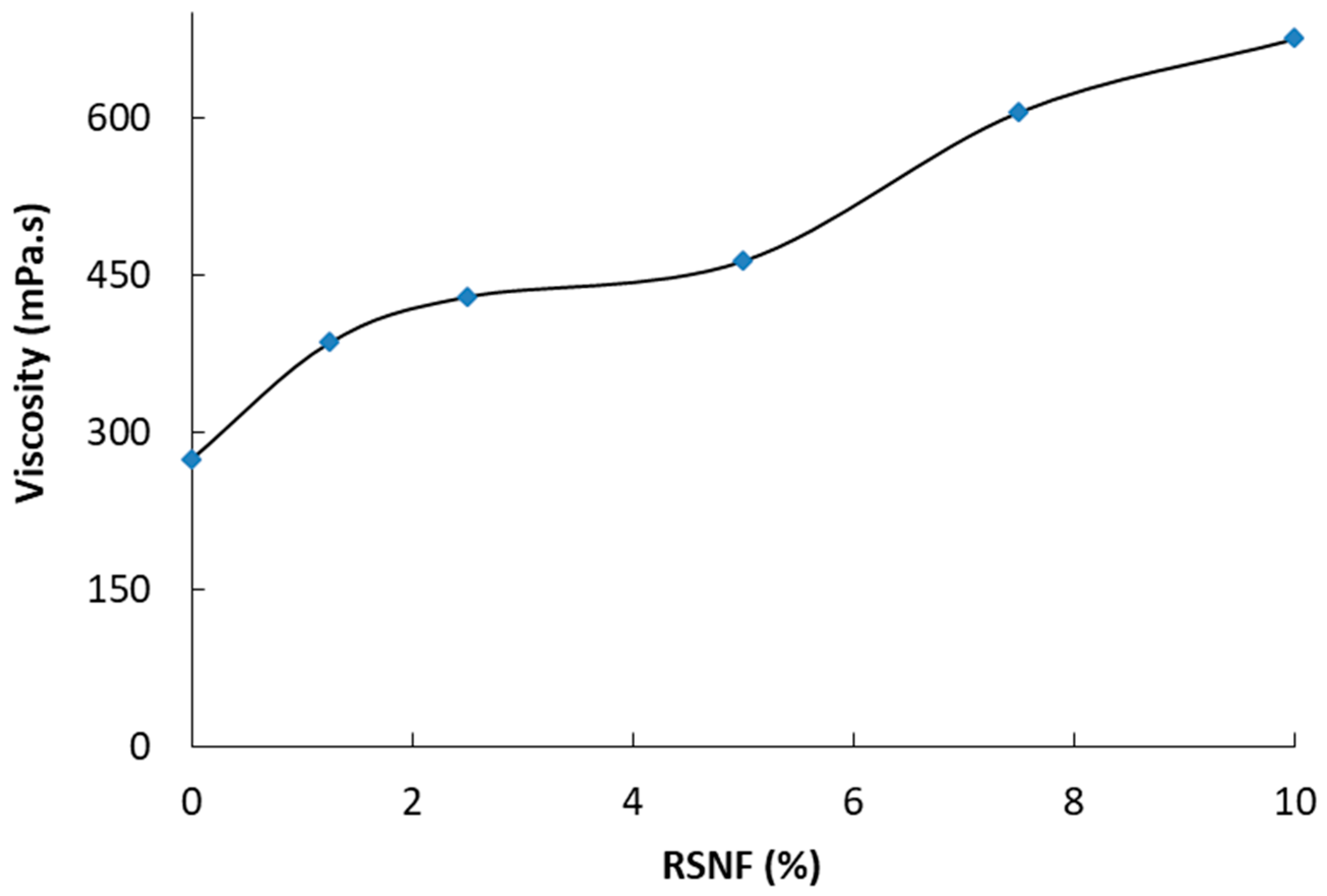

3.1. Viscosity of the CA/RSNF Suspension

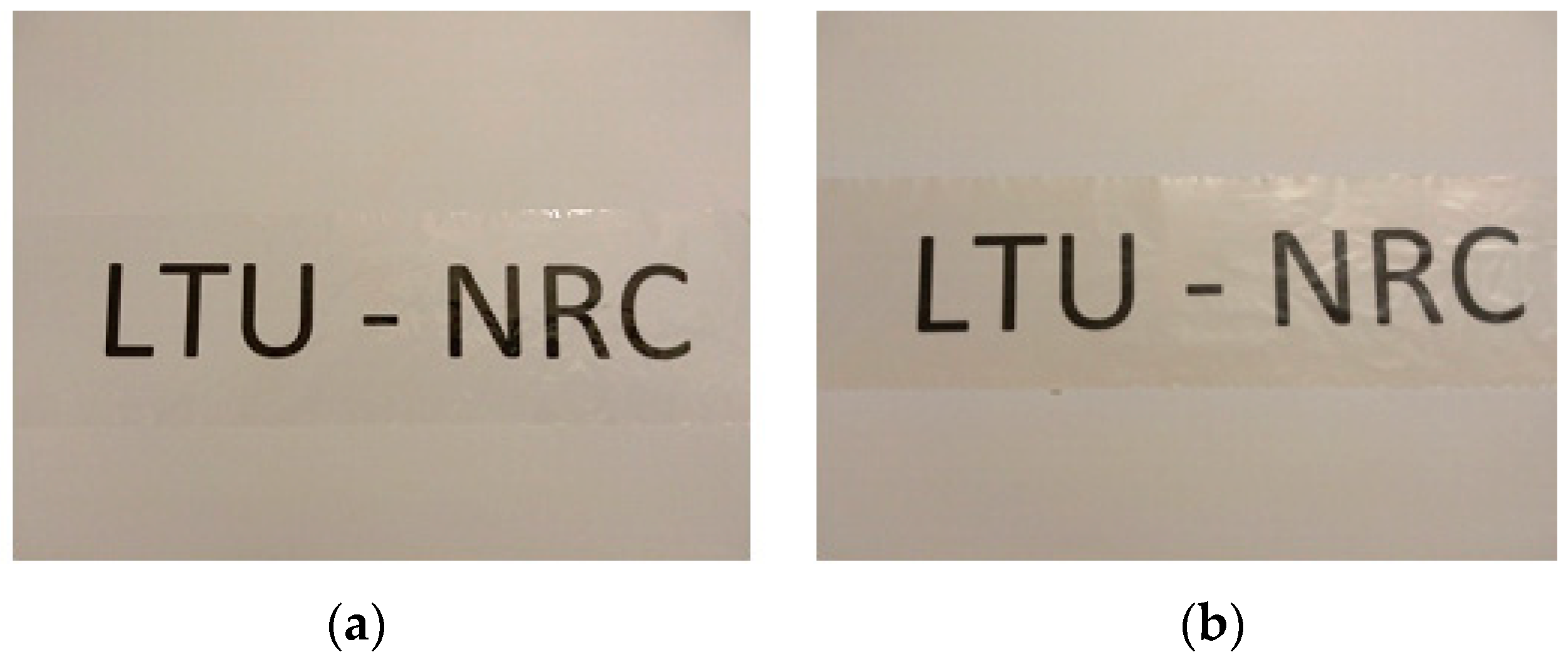

3.2. Mirco-Structure of CA and CA/RSNF Films

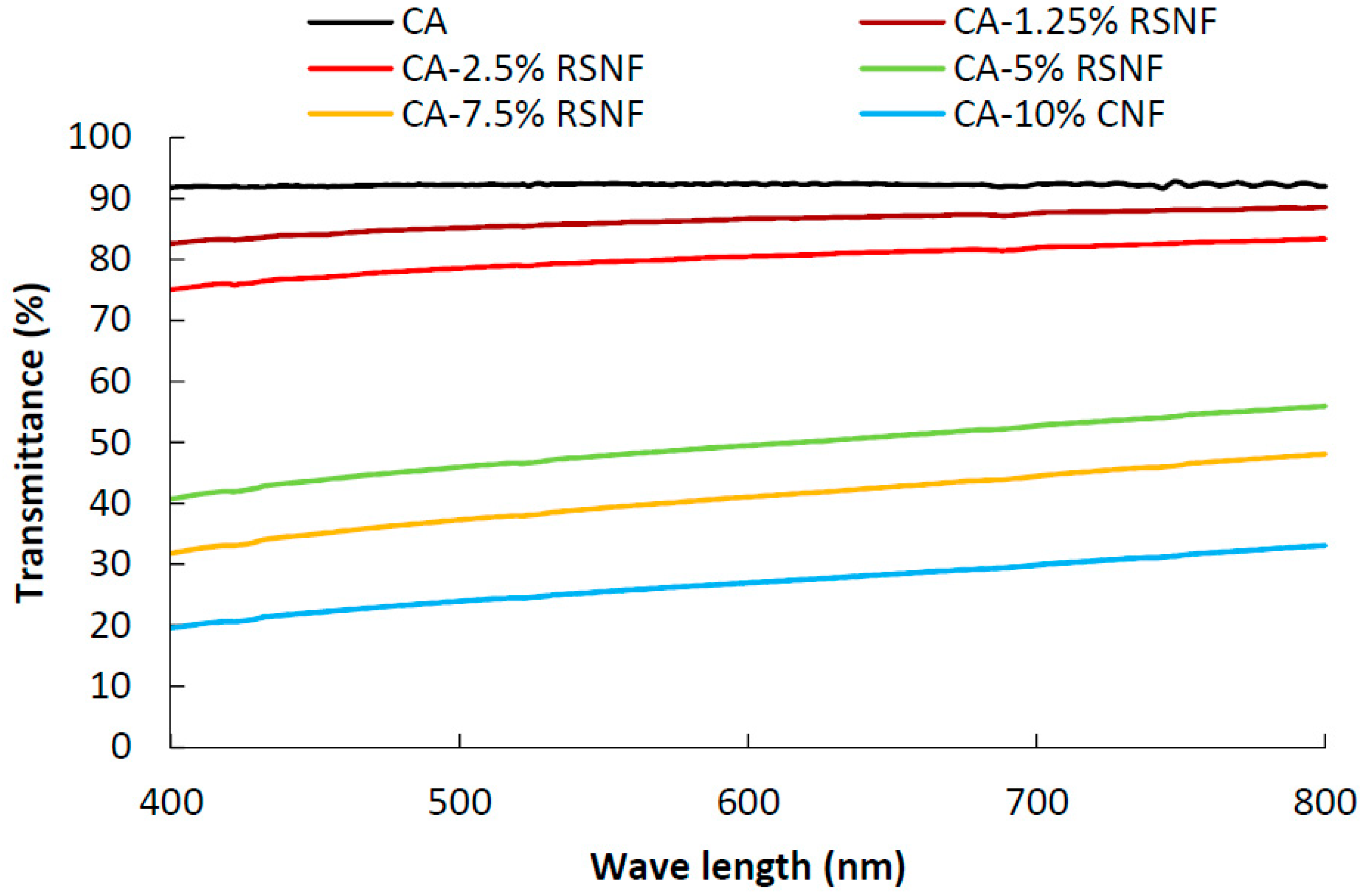

3.3. Transparency and Light Transmittance

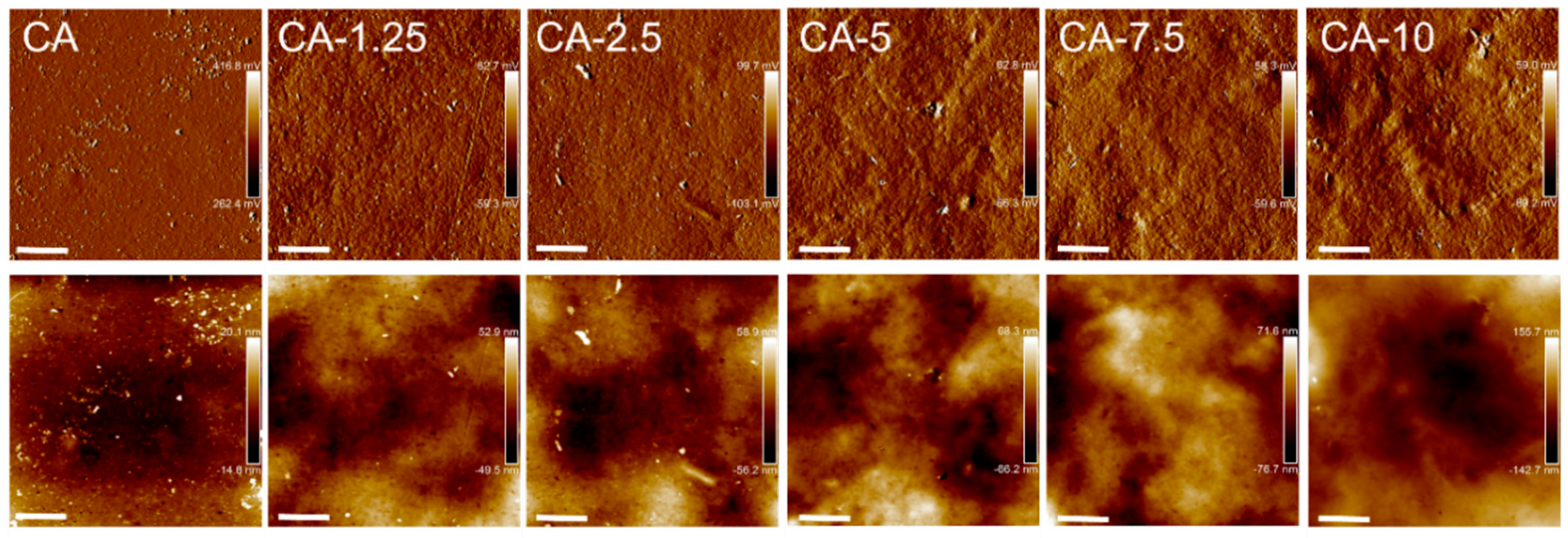

3.4. Surface Characteristics: Wettability and Topography

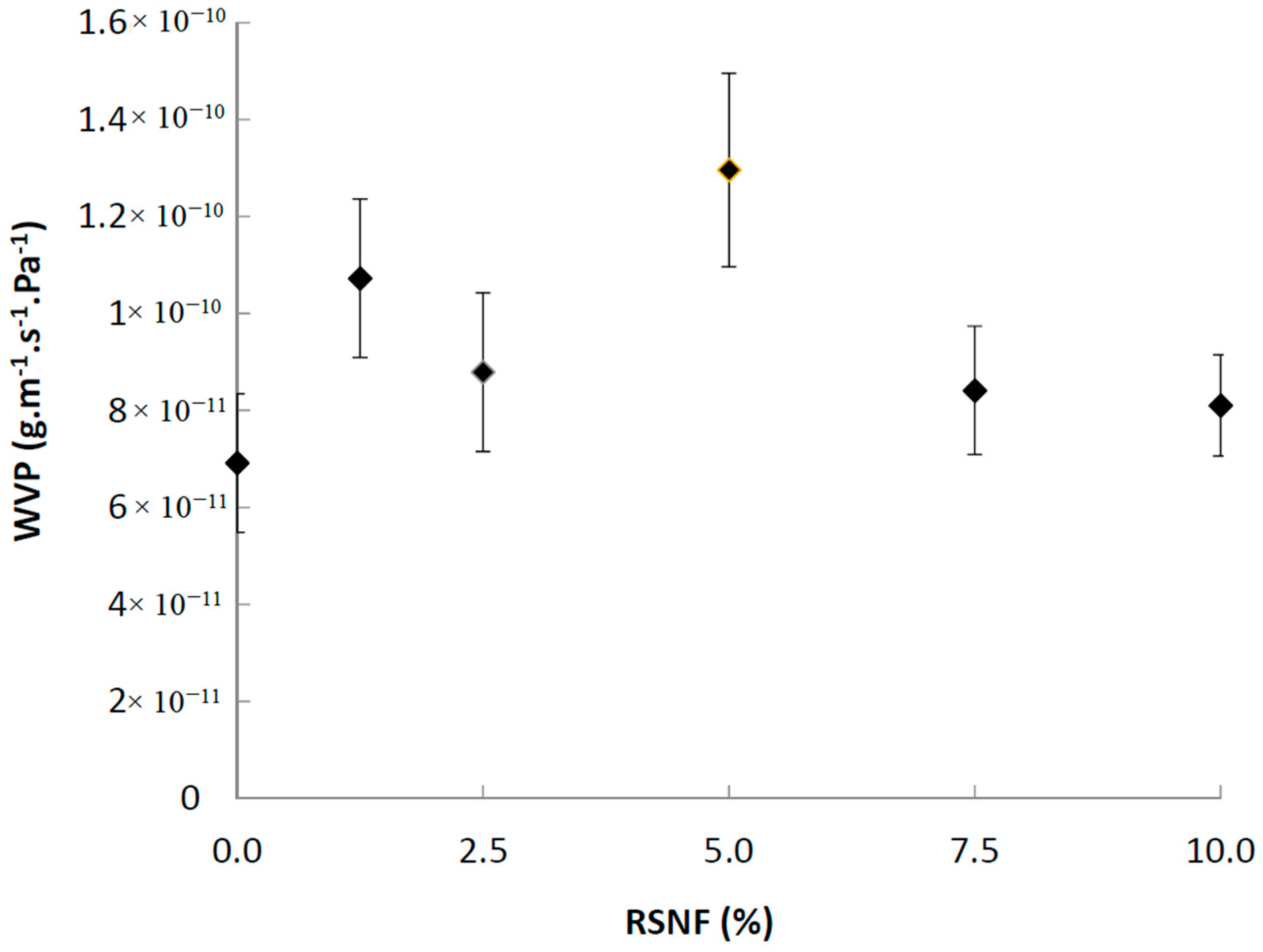

3.5. Water Vapor Permeability (WVP)

3.6. Porosity and Surface Area Characteristics of CA/RSNF Films

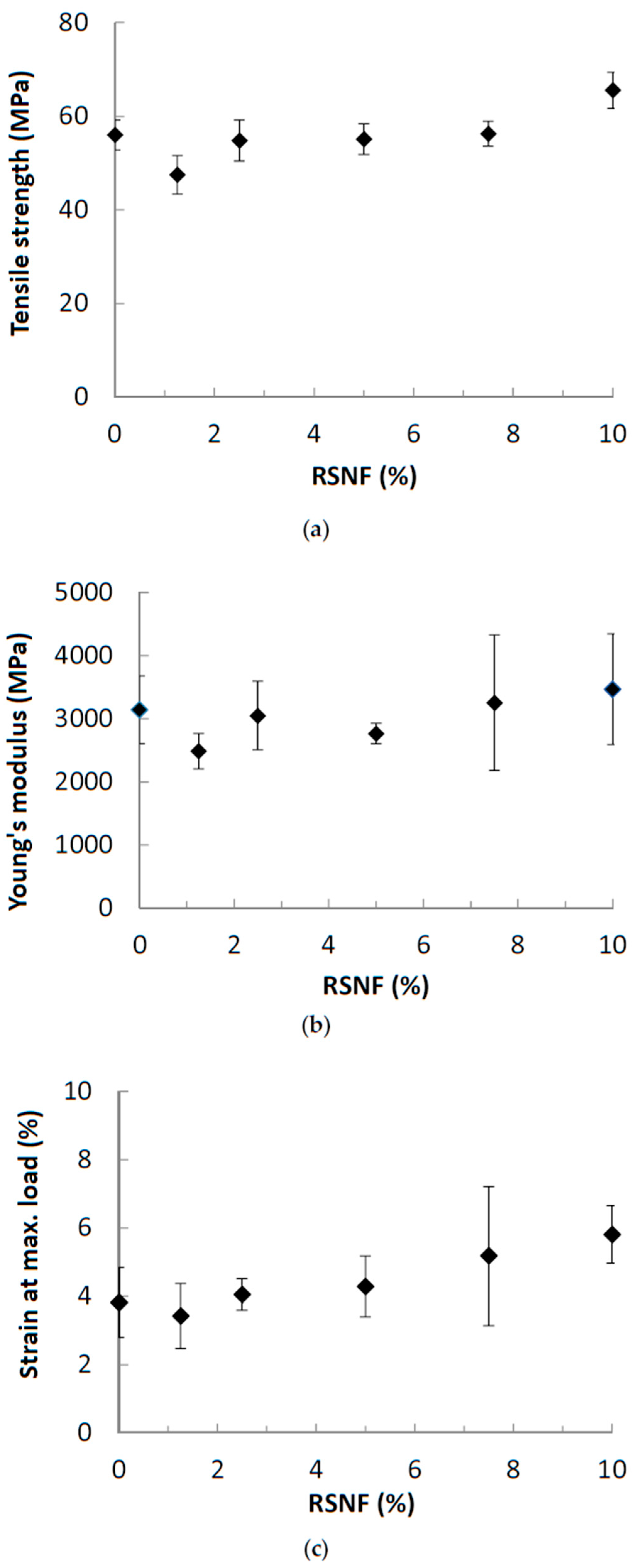

3.7. Mechanical Properties of CA/RSNF Films

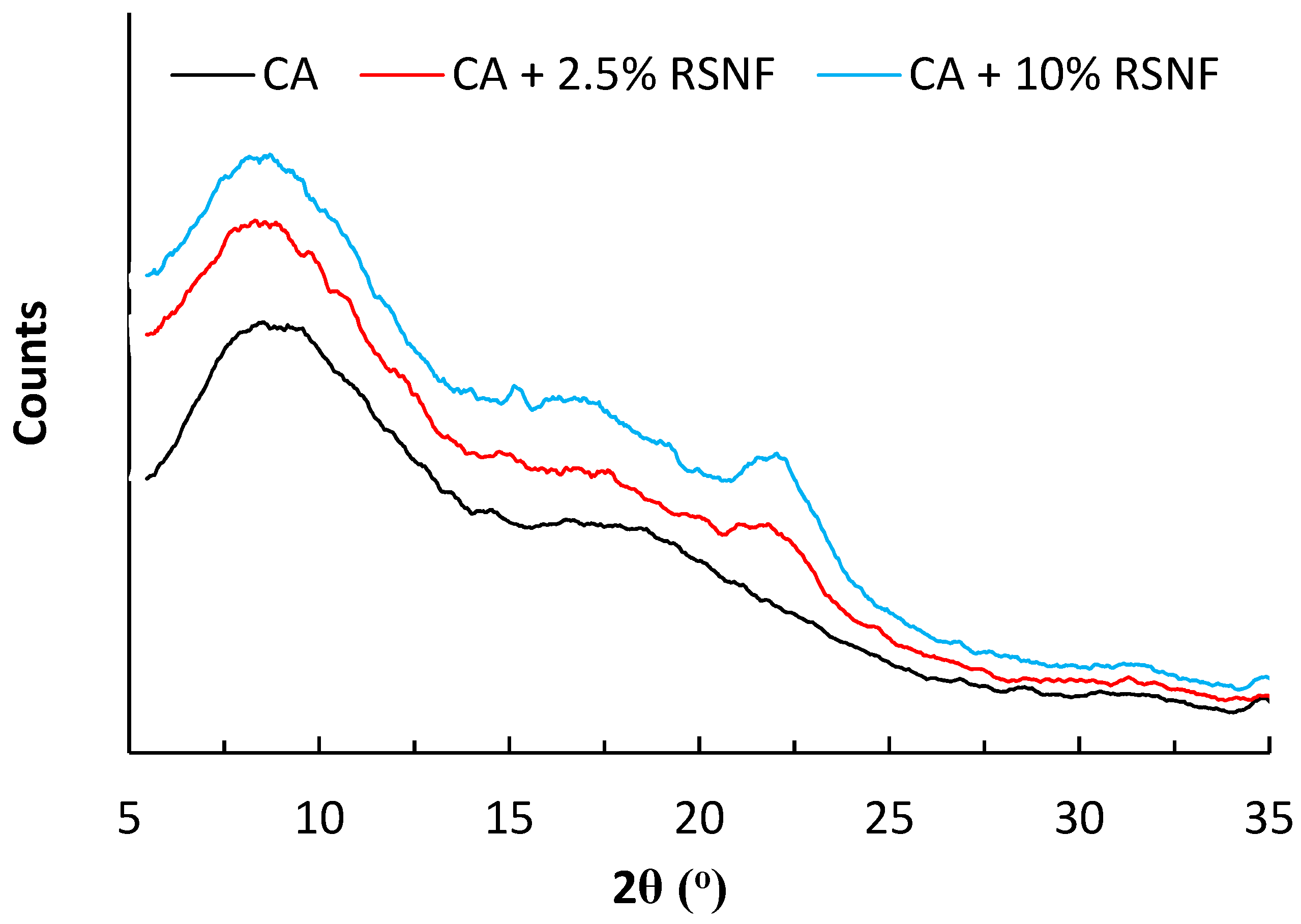

3.8. Crystallinity

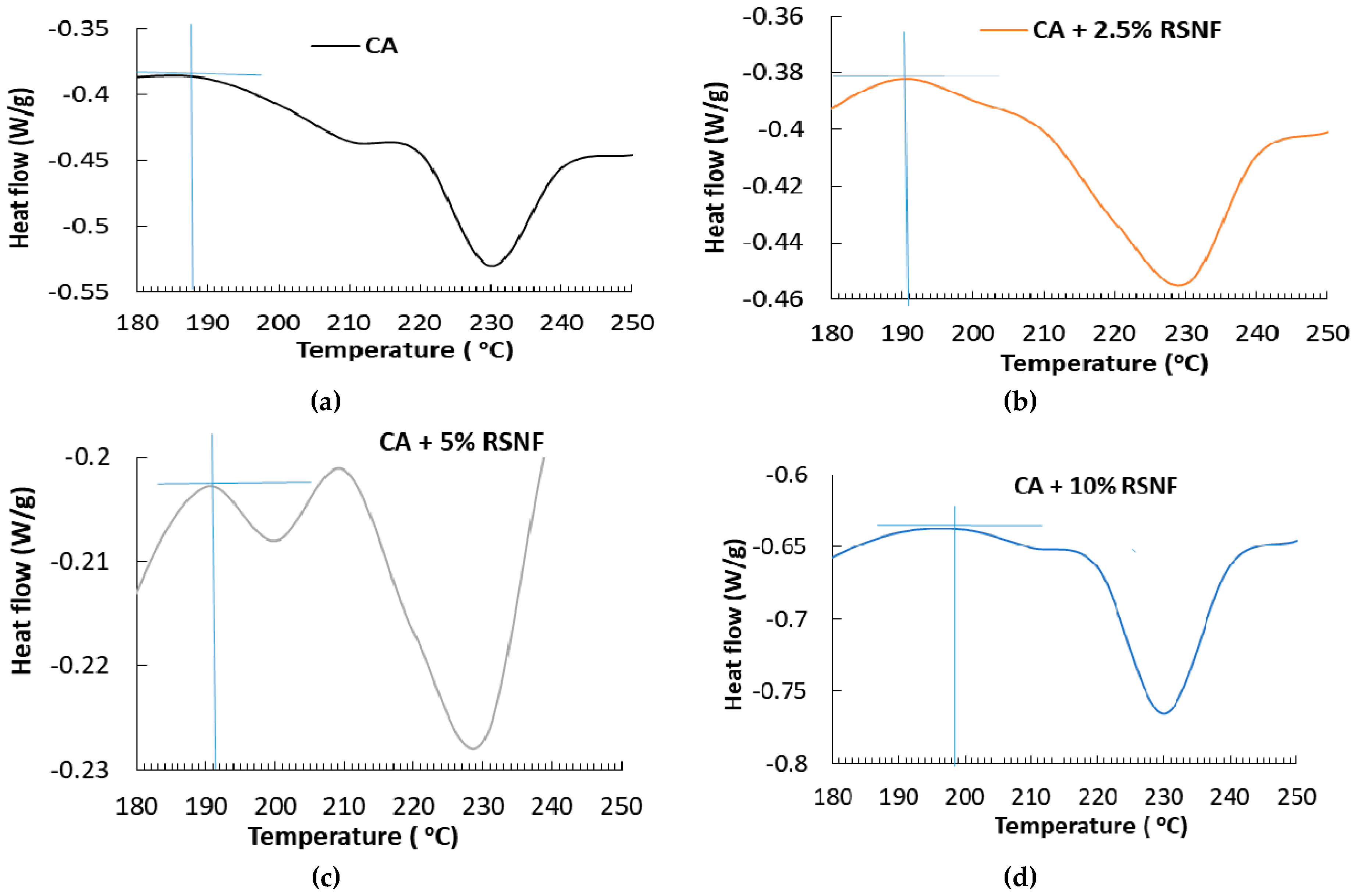

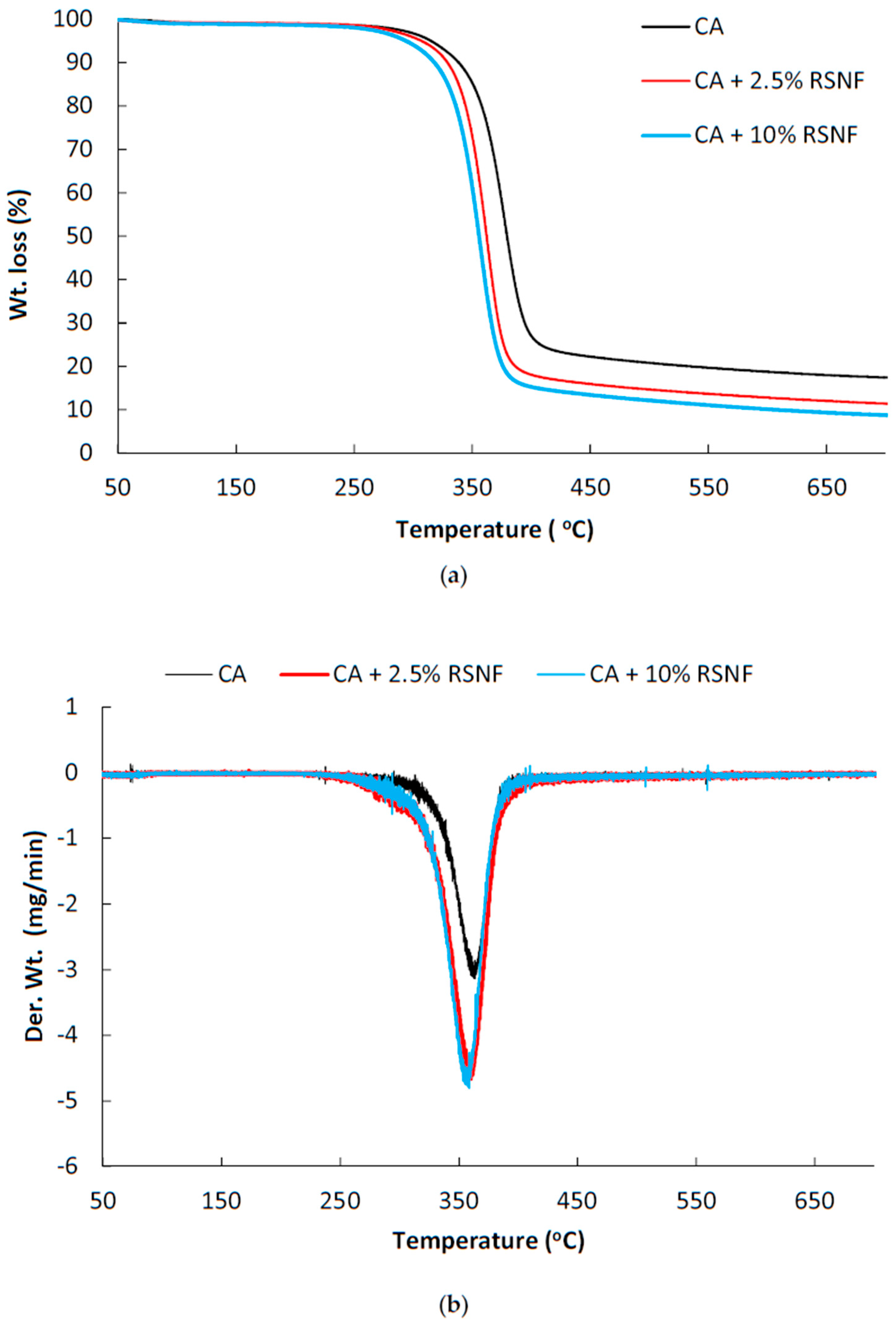

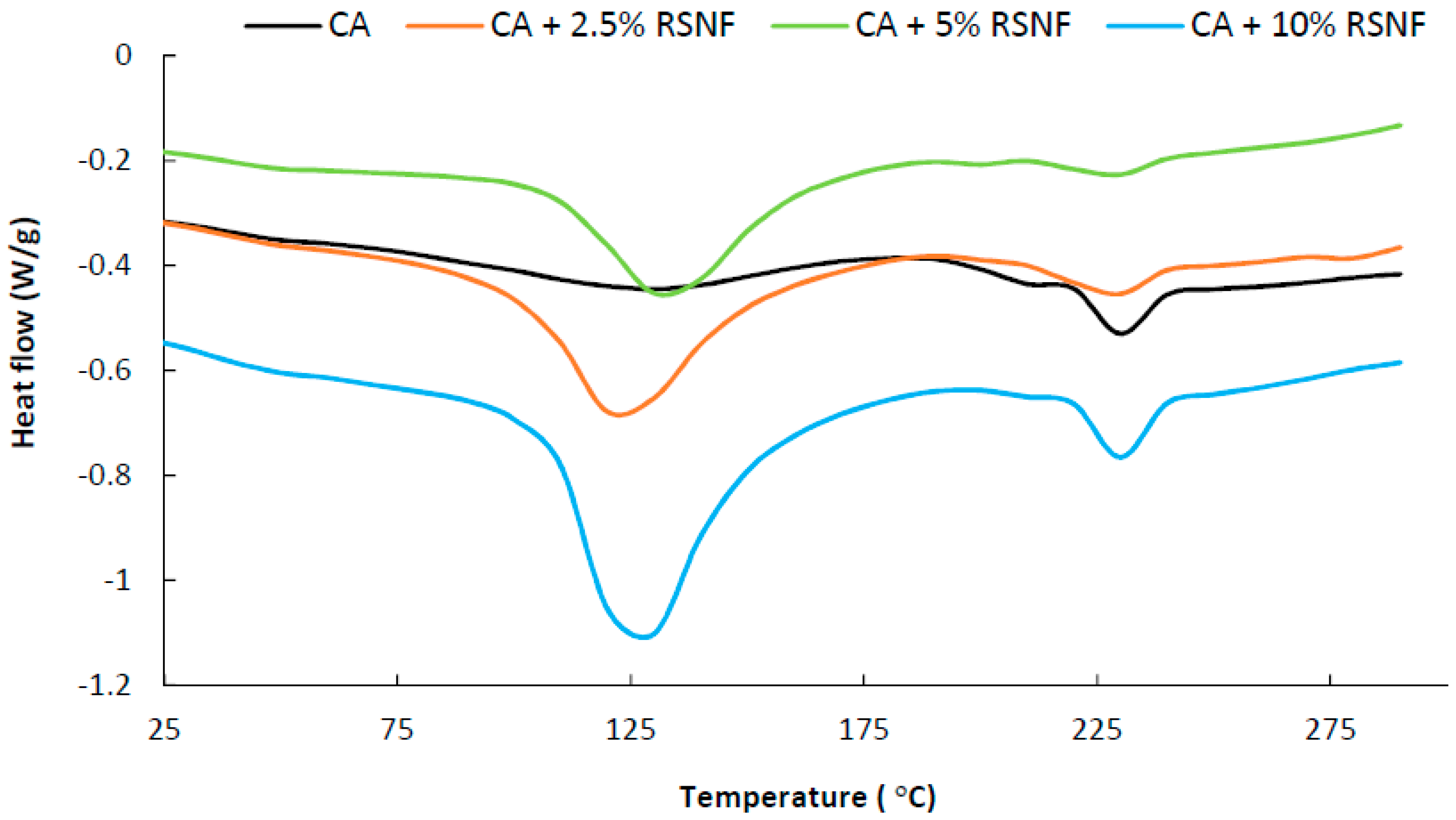

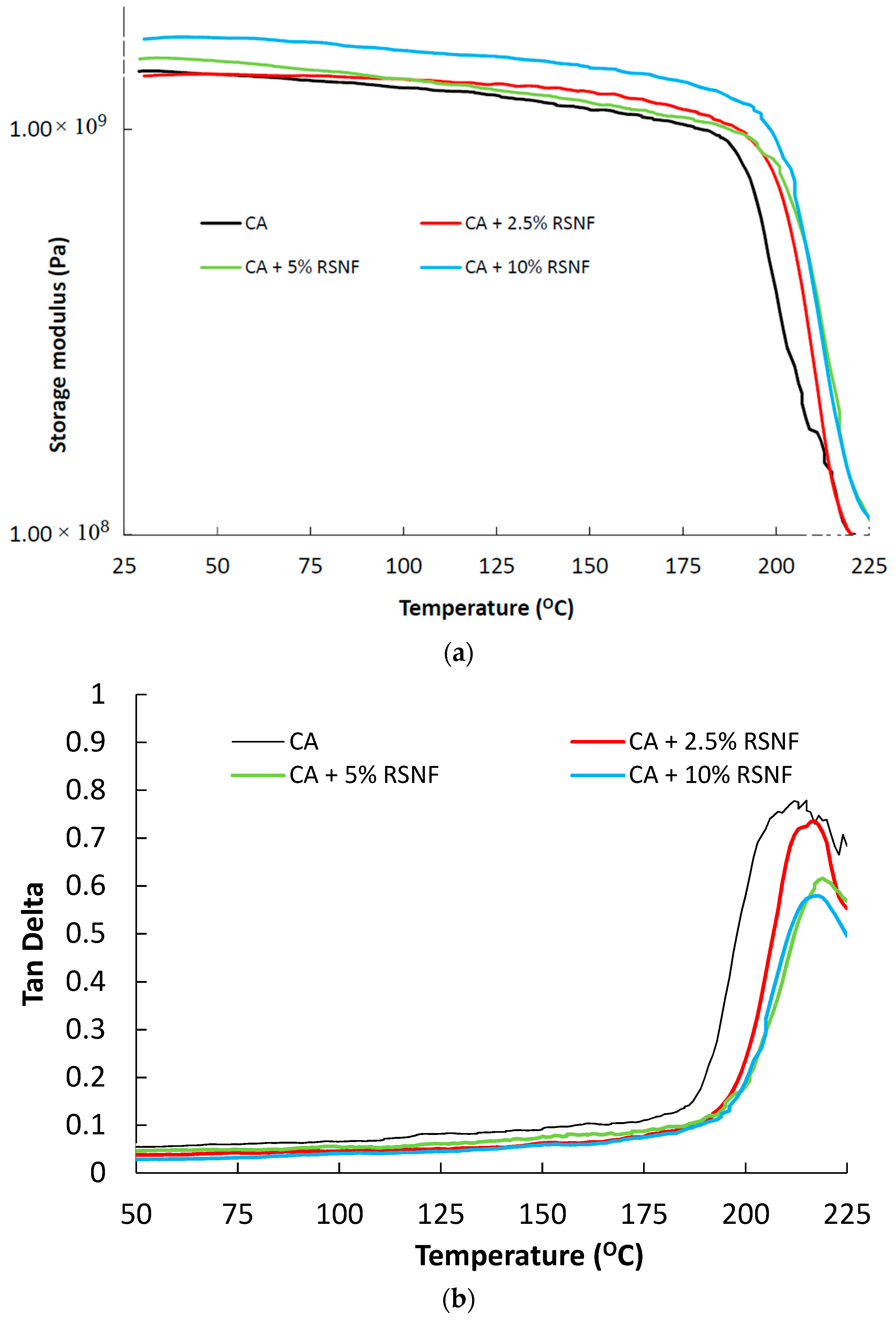

3.9. Thermal Properties of CA/RSNF Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Mu, K.; Zhang, D.; Shao, Z.; Qin, D.; Wang, Y.; Wang, S. Enhanced permeability and antifouling performance of cellulose acetate ultrafiltration membrane assisted by L-DOPA functionalized halloysite nanotubes. Carbohydr. Polym. 2017, 174, 688–696. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, J.; Hou, D.; Bai, Y.; Liu, H. Fabrication and performance of PET mesh enhanced cellulose acetate membranes for forward osmosis. J. Environ. Sci. 2015, 45, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Su, Y.; Zhang, L.; Shi, Q.; Peng, J.; Jiang, Z. In situ generated silica nanoparticles as pore-forming agent for enhanced permeability of cellulose acetate membranes. J. Memb. Sci. 2010, 348, 75–83. [Google Scholar] [CrossRef]

- Lee, W.G.; Kim, D.Y.; Kang, S.W. Porous Cellulose Acetate by Specific Solvents with Water Pressure Treatment for Applications to Separator and Membranes. Macromol. Res. 2018, 26, 630–633. [Google Scholar] [CrossRef]

- Kusworo, T.D.; Soetrisnanto, D.; Santoso, C.; Payanti, T.D.; Utomo, D.P. Hydrophylicity Enhancement of Modified Cellulose Acetate Membrane to Improve the Membrane Performance in Produced Water Treatment. MATEC Web Conf. 2018. [Google Scholar] [CrossRef]

- Najafi, M.; Sadeghi, M.; Bolverdi, A.; Pourafshari Chenar, M.; Pakizeh, M. Gas permeation properties of cellulose acetate/silica nanocomposite membrane. Adv. Polym. Technol. 2018, 37, 2043–2052. [Google Scholar] [CrossRef]

- Nakai, Y.; Yoshimizu, H.; Tsujita, Y. Enhanced gas permeability of cellulose acetate membranes under microwave irradiation. J. Memb. Sci. 2005, 256, 72–77. [Google Scholar] [CrossRef]

- Gemili, S.; Yemenicioǧlu, A.; Altinkaya, S.A. Development of cellulose acetate based antimicrobial food packaging materials for controlled release of lysozyme. J. Food Eng. 2009, 90, 453–462. [Google Scholar] [CrossRef]

- Rodríguez, F.J.; Torres, A.; Peñaloza, Á.; Sepúlveda, H.; Galotto, M.J.; Guarda, A.; Bruna, J. Development of an antimicrobial material based on a nanocomposite cellulose acetate film for active food packaging. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2014, 31, 342–353. [Google Scholar] [CrossRef]

- Saha, N.R.; Sarkar, G.; Roy, I.; Bhattacharyya, A.; Rana, D.; Dhanarajan, G.; Banerjee, R.; Sen, R.; Mishra, R.; Chattopadhyay, D. Nanocomposite films based on cellulose acetate/polyethylene glycol/modified montmorillonite as nontoxic active packaging material. RSC Adv. 2016, 6, 92569–92578. [Google Scholar] [CrossRef]

- Law, R.C. 5. Applications of cellulose acetate 5.1 Cellulose acetate in textile application. Macromol. Symp. 2004, 208, 255–266. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agarwal, S.; Tyagi, I.; Pathania, D.; Rathore, B.S.; Sharma, G. Synthesis, characterization and analytical application of cellulose acetate-tin (IV) molybdate nanocomposite ion exchanger: binary separation of heavy metal ions and antimicrobial activity. Ionics 2015, 21, 2069–2078. [Google Scholar] [CrossRef]

- Samadian, H.; Salehi, M.; Farzamfar, S.; Vaez, A.; Ehterami, A.; Sahrapeyma, H.; Goodarzi, A.; Ghorbani, S. In vitro and in vivo evaluation of electrospun cellulose acetate/gelatin/hydroxyapatite nanocomposite mats for wound dressing applications. Artif. Cells Nanomed. Biotechnol. 2018, 46, 964–974. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.K.; Saleh, T.A.; Pathania, D.; Rathore, B.S.; Sharma, G. A cellulose acetate based nanocomposite for photocatalytic degradation of methylene blue dye under solar light. Ionics 2015, 21, 1787–1793. [Google Scholar] [CrossRef]

- Sacarescu, L.; Simionescu, M.; Sacarescu, G.; Coseri, S. Transparent and fluorescent thin films of polysilane–SiQD nanocomposite: cellulose acetate. Cellulose 2016, 23, 3847–3860. [Google Scholar] [CrossRef]

- Luthfiyah, S.Z.; Krisnandi, Y.K.; Andhika, K.; Sihombing, R.; Fisli, A. Modification of cellulose acetate nanocomposite with TiO2-organoclay as nanofiller and its self-photodegradation study. AIP Conf. Proc. 2016, 1729, 020054. [Google Scholar]

- Jahan, N.; Khan, W.; Azam, A.; Naqvi, A.H. Fabrication of transparent cellulose acetate/graphene oxide nanocomposite film for UV shielding. AIP Conf. Proc. 2016, 1731, 050061. [Google Scholar]

- Ghanbari, D.; Salavati-Niasari, M. Hydrothermal synthesis of different morphologies of MgFe2O4 and magnetic cellulose acetate nanocomposite. Korean J. Chem. Eng. 2015, 32, 903–910. [Google Scholar] [CrossRef]

- Khan, F.U.; Asimullah; Khan, S.B.; Kamal, T.; Asiri, A.M.; Khan, I.U.; Akhtar, K. Novel combination of zero-valent Cu and Ag nanoparticles @ cellulose acetate nanocomposite for the reduction of 4-nitro phenol. Int. J. Biol. Macromol. 2017, 102, 868–877. [Google Scholar] [CrossRef]

- Ghanbari, D.; Salavati-Niasari, M. Synthesis of urchin-like CdS-Fe3O4 nanocomposite and its application in flame retardancy of magnetic cellulose acetate. J. Ind. Eng. Chem. 2015, 24, 284–292. [Google Scholar] [CrossRef]

- Jamshidi, P.; Ghanbari, D.; Salavati-Niasari, M. Sonochemical synthesis of La(OH)3 nanoparticle and its influence on the flame retardancy of cellulose acetate nanocomposite. J. Ind. Eng. Chem. 2014, 20, 3507–3512. [Google Scholar] [CrossRef]

- César, N.R.; de Menezes, A.J.; Botaro, V.R. Nanocomposite of cellulose acetate reinforced with nanocrystals modified chemically: Modification with bifunctional reagent. Polym. Compos. 2018. [Google Scholar] [CrossRef]

- Okita, Y.; Fujisawa, S.; Saito, T.; Isogai, A. TEMPO-oxidized cellulose nanofibrils dispersed in organic solvents. Biomacromolecules 2011, 12, 518–522. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Chen, J.; He, M.; Yao, J. Cellulose acetate ultrafiltration membranes reinforced by cellulose nanocrystals: Preparation and characterization. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Peresin, M.S.; Rojas, O.J. All-Cellulose Composite Fibers Obtained by Electrospinning Dispersions of Cellulose Acetate and Cellulose Nanocrystals. J. Polym. Environ. 2012, 20, 1075–1083. [Google Scholar] [CrossRef]

- Sun, C.; Boluk, Y.; Ayranci, C. Investigation of nanofiber nonwoven meshes produced by electrospinning of cellulose nanocrystal suspensions in cellulose acetate solutions. Cellulose 2015, 22, 2457–2470. [Google Scholar] [CrossRef]

- Leite, L.S.F.; Battirola, L.C.; da Silva, L.C.E.; Gonçalves, M.C. Morphological investigation of cellulose acetate/cellulose nanocrystal composites obtained by melt extrusion. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Nair, S.S.; Mathew, A.P. Porous composite membranes based on cellulose acetate and cellulose nanocrystals via electrospinning and electrospraying. Carbohydr. Polym. 2017, 175, 149–157. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, G.; Zhang, H.; Yang, F. Exploration of permeability and antifouling performance on modified cellulose acetate ultrafiltration membrane with cellulose nanocrystals. Carbohydr. Polym. 2017, 174, 190–199. [Google Scholar] [CrossRef]

- Battirola, L.C.; Andrade, P.F.; Marson, G.V.; Hubinger, M.D.; do Carmo Gonçalves, M. Cellulose acetate/cellulose nanofiber membranes for whey and fruit juice microfiltration. Cellulose 2017, 24, 5593–5604. [Google Scholar] [CrossRef]

- Qin, D.; Zhang, D.; Shao, Z.; Wang, J.; Mu, K.; Liu, Y.; Zhao, L. Short-chain amino acids functionalized cellulose nanofibers composite ultrafiltration membrane with enhanced properties. RSC Adv. 2016, 6, 76336–76343. [Google Scholar] [CrossRef]

- Kong, L.; Zhang, D.; Shao, Z.; Han, B.; Lv, Y.; Gao, K.; Peng, X. Superior effect of TEMPO-oxidized cellulose nanofibrils (TOCNs) on the performance of cellulose triacetate (CTA) ultrafiltration membrane. Desalination 2014, 332, 117–125. [Google Scholar] [CrossRef]

- Lu, J.; Drzal, L.T. Microfibrillated cellulose/cellulose acetate composites: Effect of surface treatment. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 153–161. [Google Scholar] [CrossRef]

- Hassan, M.; Berglund, L.; Hassan, E.; Abou-Zeid, R.; Oksman, K. Effect of xylanase pretreatment of rice straw unbleached soda and neutral sulfite pulps on isolation of nanofibers and their properties. Cellulose 2018, 25, 2939–2953. [Google Scholar] [CrossRef]

- Browning, B.L. Methods of wood chemistry; Wiley: New York, NY, USA, 1967; Volume 2, p. 498. [Google Scholar]

- Cerqueira, D.A.; Rodrigues Filho, G.; Assunção, R.M.N. A new value for the heat of fusion of a perfect crystal of cellulose acetate. Polym. Bull. 2006, 56, 475–484. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Liu, J.; Zhang, H.; Wang, K. Preparation and antibacterial property of polyethersulfone ultrafiltration hybrid membrane containing halloysite nanotubes loaded with copper ions. Chem. Eng. J. 2012, 210, 298–308. [Google Scholar] [CrossRef]

- Song, J.; Rojas, O.J. Song Approaching super-hydrophobicity from cellulosic materials: A Review. Nord. Pulp Pap. Res. J. 2013, 28, 216–238. [Google Scholar] [CrossRef]

- Candido, R.G.; Godoy, G.G.; Gonçalves, A. Characterization and application of cellulose acetate synthesized from sugarcane bagasse. Carbohydr. Polym. 2017, 167, 280–289. [Google Scholar] [CrossRef]

- Werner, O.; Wågberg, L.; Lindström, T. Wetting of structured hydrophobic surfaces by water droplets. Langmuir 2005, 21, 12235–12243. [Google Scholar] [CrossRef]

- Wan Daud, W.R.; Djuned, F.M. Cellulose acetate from oil palm empty fruit bunch via a one step heterogeneous acetylation. Carbohydr. Polym. 2015, 132, 252–260. [Google Scholar] [CrossRef]

- Humbert, S.; Lame, O.; Séguéla, R.; Vigier, G. A re-examination of the elastic modulus dependence on crystallinity in semi-crystalline polymers. Polymer 2011, 52, 4899–4909. [Google Scholar] [CrossRef]

- Borsoi, C.; Zimmernnam, M.V.G.; Zattera, A.J.; Santana, R.M.C.; Ferreira, C.A. Thermal degradation behavior of cellulose nanofibers and nanowhiskers. J. Therm. Anal. Calorim. 2016, 126, 1867–1878. [Google Scholar] [CrossRef]

- Ruangudomsakul, W.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Preparation and characterization of cellulose nanofibers from cassava pulp. Macromol. Symp. 2015, 354, 170–176. [Google Scholar] [CrossRef]

- Kamide, K.; Saito, M. Thermal Analysis of Cellulose Acetate Solids with Total Degrees of Substitution of 0.49, 1.75, 2.46, and 2.92. Polym. J. 1985, 17, 919–928. [Google Scholar] [CrossRef]

| RSNF Content (wt.%) | CA | CA-1.25 | CA-2.5 | CA-5 | CA-7.5 | CA-10 |

|---|---|---|---|---|---|---|

| Contact Angle (°) | 71.0 ± 2.0 | 66.1 ± 0.8 | 66.4 ± 1 | 65.0 ± 2.2 | 63.1 ± 2.0 | 60.7 ± 2.2 |

| Roughness (nm) | 5.9 ± 1.9 | 14.2 ± 2.0 | 18.0 ± 2.2 | 20.1 ± 4.0 | 28.7 ± 5.1 | 45.9 ± 6.0 |

| Property | CA | CA-1.25% RSNF | CA-2.5% RSNF | CA-5% RSNF | CA-7.5% RSNF | CA-10% RSNF |

|---|---|---|---|---|---|---|

| Porosity (%) | 15.1 ± 0.72 | 14.8 ± 0.55 | 14.6 ± 1.38 | 14.3 ± 1.1 | 16.6 ± 0.58 | 15.1 ± 0.87 |

| Surface Area (m2/g) | 7.68 | - | 7.46 | 6.43 | - | 8.24 |

| Pore Volume (cc/g) | 0.01 | - | 0.01 | 0.01 | - | 0.01 |

| Average Pore Radius (nm) | 1.92 | - | 1.93 | 1.93 | - | 1.92 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.; Berglund, L.; Abou-Zeid, R.; Hassan, E.; Abou-Elseoud, W.; Oksman, K. Nanocomposite Film Based on Cellulose Acetate and Lignin-Rich Rice Straw Nanofibers. Materials 2019, 12, 595. https://doi.org/10.3390/ma12040595

Hassan M, Berglund L, Abou-Zeid R, Hassan E, Abou-Elseoud W, Oksman K. Nanocomposite Film Based on Cellulose Acetate and Lignin-Rich Rice Straw Nanofibers. Materials. 2019; 12(4):595. https://doi.org/10.3390/ma12040595

Chicago/Turabian StyleHassan, Mohammad, Linn Berglund, Ragab Abou-Zeid, Enas Hassan, Wafaa Abou-Elseoud, and Kristiina Oksman. 2019. "Nanocomposite Film Based on Cellulose Acetate and Lignin-Rich Rice Straw Nanofibers" Materials 12, no. 4: 595. https://doi.org/10.3390/ma12040595

APA StyleHassan, M., Berglund, L., Abou-Zeid, R., Hassan, E., Abou-Elseoud, W., & Oksman, K. (2019). Nanocomposite Film Based on Cellulose Acetate and Lignin-Rich Rice Straw Nanofibers. Materials, 12(4), 595. https://doi.org/10.3390/ma12040595