1. Introduction

The current explosion of wearable devices has led to increased attention on methods to power them from harvested energy. Implantable Medical Devices (IMDs) might be considered a natural extension of wearable devices especially in the context health related applications. This paper will discuss methods to wirelessly transmit power to IMDs. However, the same methods and devices could easily be applied to wearable devices in order to enhance their usability.

Currently, the most common way to power IMDs is via a direct (wired) external source or a battery implanted along with the IMD. Direct power delivery may cause limitations to patient mobility and creates medical risks associated with passing wires transcutaneously. Batteries help mitigate the problems presented by the direct powering method, however they have finite lifetimes and require periodic replacement. This concern is particularly relevant as the sensing and computation components of IMDs become very small (i.e., 1 mm3 or smaller). In light of these concerns, a Wireless Power Transfer (WPT) system would appear to be a promising solution.

Acoustic WPT systems have recently been investigated largely due to the fact that acoustic power has low attenuation in soft tissue and short wavelengths (compared to electromagnetic wavelengths) which increases the efficiency of very small receivers. However, acoustic power transfer systems are complicated by poor transmission through bone and the need for the transmitter to be in direct contact with the skin [

1]. For a detailed review of acoustic WPT systems applied to IMDs the reader is referred to [

2].

Electromagnetic WPT systems have been widely investigated for use by IMDs. For the purposes of this paper, we classify electromagnetic WPT as either Inductive Power Transfer (IPT) if the coupling is in the near field, or Radio Frequency (RF) if the coupling is in the mid field (i.e., transition region) or far field. Inductive coupling techniques appear to be the most advanced for powering implants. Inductive coupling utilizes a pair of coils that must be physically close and well aligned to allow for the transfer of power. Subsequently, the power transfer is highly dependent on the size, orientation, and distance between the coils [

3]. Ultimately, these dependencies make this form of WPT most viable for IMDs (such as pacemakers [

4]) where the depth of the implant is relatively shallow and the alignment of the coils can be well controlled.

Unlike acoustic and inductively coupled systems, alignment is not as critical for RF WPT systems because receivers do not need to be tightly coupled to the transmitter. However, as the size of receivers decrease, the operating frequency must increase to a level where tissue tends to absorb and attenuate the transmitted signal [

5]. This attenuation is not only inefficient, but it is potentially hazardous because of associated tissue heating. A technology that could make efficient use of low frequency electromagnetic power transfer at a distance could be a significant enabler for very small implantable systems. Magnetoelectric (ME) transducers could be such a technology.

The magnetoelectric effect refers to any type of coupling between electric and magnetic fields found in matter [

6]. The ME effect was first demonstrated experimentally in 1960 when Dzyaloshinskii witnessed it in Cr

2O

3 [

7]. Despite this breakthrough, subsequent research showed that at best the magnetoelectric coefficient for bulk materials such as Cr

2O

3 was very low, on the order of 100 mV/(cm·Oe) [

7]. This, along with other various complications, kept the materials from being used much in practical applications [

6]. Before the ME effect was even observed in bulk materials, Tellegen suggested developing composites that demonstrated a cumulative ME effect [

8]. The implication here is that by coupling two separate physical effects (piezoelectric (PE) and magnetostrictive (MS)) in two separate materials an equivalent ME effect could be obtained. In PE materials, the mechanical strain and electric field are coupled. In MS materials, the mechanical strain and magnetic field are coupled. By linking two such materials mechanically, the resulting pseudo ME effect can be demonstrated simply as [

9]

where the mechanical components in essence cancel out. In 1998 Shin et al. attempted a three-layer laminate composite approach where the MS material was sputtered as a thin film onto a glass substrate which was then bonded onto a PE base. This design has become known in the literature as a unimorph. By applying a voltage to the PE, the bending strain induced into the MS material caused large changes to its magnetic properties [

10].

Building on the ME laminate approach taken by Shin et al., Ryu et al. developed another ME laminate using a sandwich design. This design used silver epoxy to bond a PZT-5A PE disk between two Terfenol-D MS disks. Measuring the magnetoelectric coefficient under various magnetic field strengths yielded values up to 4.68 V/(cm·Oe) [

11]. Not only was this an overwhelming improvement to the magnetoelectric coefficient, it brought the ME effect to a point of usefulness. Following closely on the work done by Ryu et al., Dong et al. published a series of papers which have become seminal works for the design and modeling of sandwich, or extensional bimorph, ME transducer designs and configurations [

12,

13,

14,

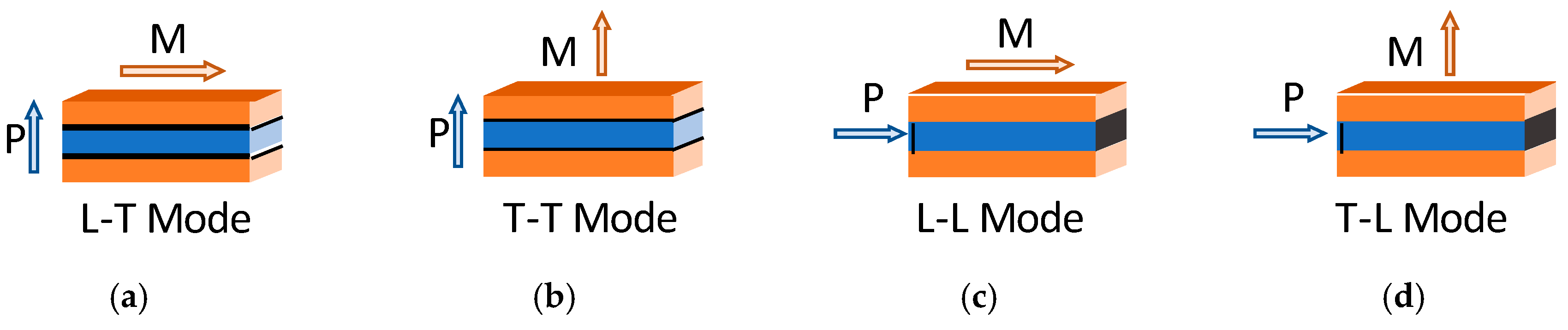

15]. Their work created model subsets for each of the four coupling orientation combinations possible for the PE and MS materials within the laminate structure. These configurations are compiled and shown in

Figure 1 and indicate whether the PE and MS materials are poled longitudinally or transversely to the bimorph structure.

Fundamentally, a magnetoelectric transducer is any device that takes energy from the magnetic domain to the electric domain and vice versa. Recently, another type of ME transducer has been proposed. This transducer operates by coupling the moment induced on a ferromagnet by an external magnetic field with a bending PE beam. This is done by anchoring one end of the beam and by mounting the ferromagnet at the tip of the beam oriented perpendicular to the field [

16]. To this point, most of the research done on such a device has been for the purpose of energy scavenging and the corresponding models are sparse. Nevertheless the design shows significant promise for WPT [

16,

17,

18]. Publications have yet to use a consistent name for this geometry. It will be referred to in this work simply as a Mechano-Magnetoelectric or MME device.

A significant advantage of magnetoelectric transducers for the use in WPT systems for IMDs is that for a given operating frequency, an efficient receiver can be orders of magnitude smaller than for IPT or RF WPT systems. This occurs because the electromagnetic wave is converted to a mechanical acoustic wave before being transduced to electricity. For a given frequency, acoustic wavelengths are much smaller than electromagnetic wavelengths. O’Handley et al. first suggested utilizing a ME bimorph for transcutaneous power transfer in 2008. Their research showed that in air a 0.1 cm

3 receiver could generate 2 mW at a distance of 3 cm from a transmitting solenoid [

19]. Citing O’Handley et al., Paluszek et al. make cases for how wireless endoscopy, brain imaging, and surgical tools might benefit from the use of ME based WPT [

20]. Nonetheless, it would appear that with the exception of some finite element verification work, very little has been done to move the medical research forward [

21].

The purpose of this paper is to critically evaluate ME laminates and MME transducers as candidates for wireless power receivers in a WPT system for IMDs. As such, the evaluation incorporates existing medical safety constraints [

22,

23,

24]. Lumped element models for both types of systems are developed and experimentally validated. Using these models, optimal transducer designs are obtained using numerical optimization techniques. These two optimal designs are compared to one another and to the needs of theoretical WPT powered IMDs.

2. Materials and Methods

The basic approach taken in this work is to develop lumped element models for each type of transducer, fabricate test transducers using off-the-shelf materials, experimentally validate the models using the test transducers, and numerically optimize designs for a micro-fabricated version of the ME transducers using the validated models. This section will cover the modeling, fabrication of test structures, and experimental methods.

2.1. Lumped Element Model for ME Devices

Dong et al. [

14,

15] rank the four ME laminate configurations shown in

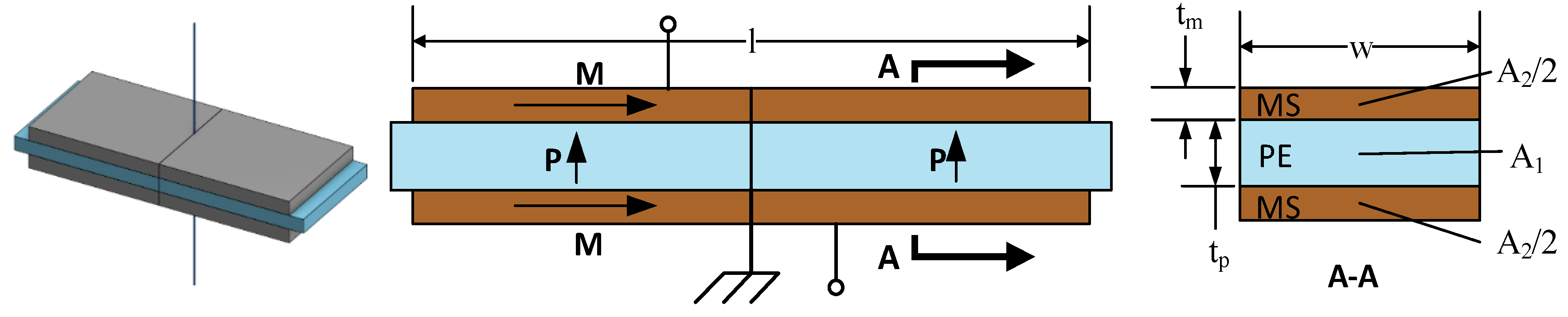

Figure 1 in descending order of the magnetoelectric voltage coefficient as L-L, L-T, T-L, T-T. In practical terms, the L-L and T-L configurations are extremely difficult to fabricate on a small scale. Therefore, the L-T configuration was chosen for further consideration. The laminate is considered to be mounted at the center, as shown in

Figure 2, making a longitudinal mode resonator. This structure can be modeled by the equivalent circuit shown in

Figure 3, which is a slight alteration of the equivalent circuit developed by Dong et al. in [

13]. A load resistor has been added to enable the calculation and optimization of received power.

As shown in

Figure 3, the MS transduction is modeled by the magnetoelectric coupling factor,

φm, which is defined as

where

is the total cross-sectional area of the MS layers,

is the magneto-elastic or piezomagnetic (PM) coefficient in the longitudinal direction, and

is the elastic compliance of the MS material also in the longitudinal direction. When multiplied by the magnetic field level

,

yields the force caused by the MS layer. Similarly, the PE transduction in the model is defined by the elasto-electric or piezoelectric coupling factor,

φp which is defined as

where

and

are the width and length of laminate,

is the thickness of the piezoelectric layer,

is the transverse piezoelectric voltage coefficient,

is the longitudinal compliance, and

is the inverse dielectric constant. The piezoelectric coupling is modeled as a transformer in the Lumped Element Model (LEM) and relates the force caused by the MS layer to the voltage of the PE layer.

The electrical capacitance in the circuit,

, is the clamped capacitance of the piezoelectric material, and is defined as

The value for

, the effective inverse dielectric constant, is calculated by

The mechanical damping coefficient,

, inductance (inertia),

, and capacitance (compliance),

are defined as

where

is the effective mechanical quality factor for the laminate,

is the fundamental frequency of the laminate, and

is the characteristic mechanical impedance of the laminate in the extensional model. These remaining lumped mechanical parameters were derived by Dong et al. [

15] by solving the second order equation of motion for the system. The results of this derivation are summarized in

Table 1.

A frequency domain circuit analysis on the equivalent circuit of

Figure 3 yields the following expression for the effective ME coefficient,

where

is the ME bias factor, which will be discussed in more depth in the following section,

is the operating frequency of the magnetic field

, and

is the impedance of the electrical portion of the circuit of

Figure 3 given by

One will note that the piezoelectric coupling factor,

in Equation (9), is not squared as it is in [

15]. It appears that this is an error in the reporting of the original model in [

15].

The zero-peak load voltage (

) can then be calculated by

where

is the magnitude of the sinusoidal magnetic field. Finally, the RMS power

is calculated as

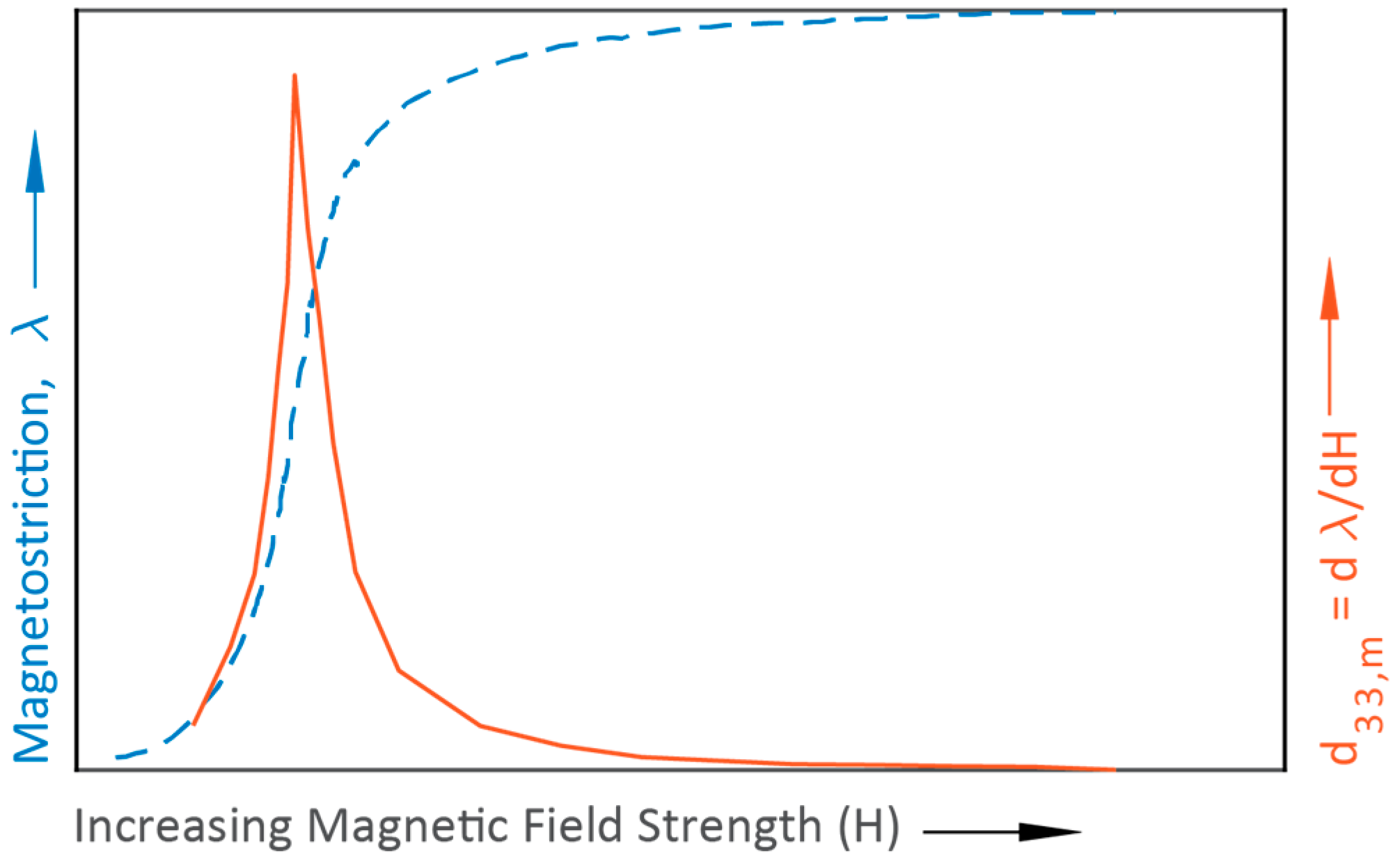

This model makes a few assumptions that need to be made explicit. First, the model assumes complete and uniform strain transfer from the MS layer into the PE layer. This implies that the interface joint between the laminates is infinitely stiff and that there is no strain gradient through the thickness of the laminate. Second, the model assumes that materials operate linearly (i.e., material properties are constant). This is probably a good assumption for the material compliance and piezoelectric voltage coefficients. However, magnetostriction is more complicated. The piezomagnetic coefficient is defined as

where

is the magnetostriction of a given MS material [

25]. Simply put, the PM coefficient is the rate of change of magnetostriction with respect to magnetic field. As indicated by

Figure 4 magnetostriction is nonlinear and furthermore

is quite low at or near zero magnetic field. An effective transducer will operate near a point where

is at a maximum, which requires that the MS material be biased. Biasing is done by applying a direct current (DC) magnetic field (

) to effectively move the ME laminate operating point to the maximum piezomagnetic coefficient value. To account for the DC magnetic field bias, which varies tremendously by material, Dong et al. added the variable

to Equation (9). A value of

means the structure is optimally biased; a value of

means the structure is not biased at all [

15]. This component of the model has to be evaluated experimentally as the optimal bias varies by geometry, material selection, and mechanical preload. Work has been done to build self-biased ME structures that eliminate the need for biasing, however, that research is still premature and beyond the scope of this work [

26].

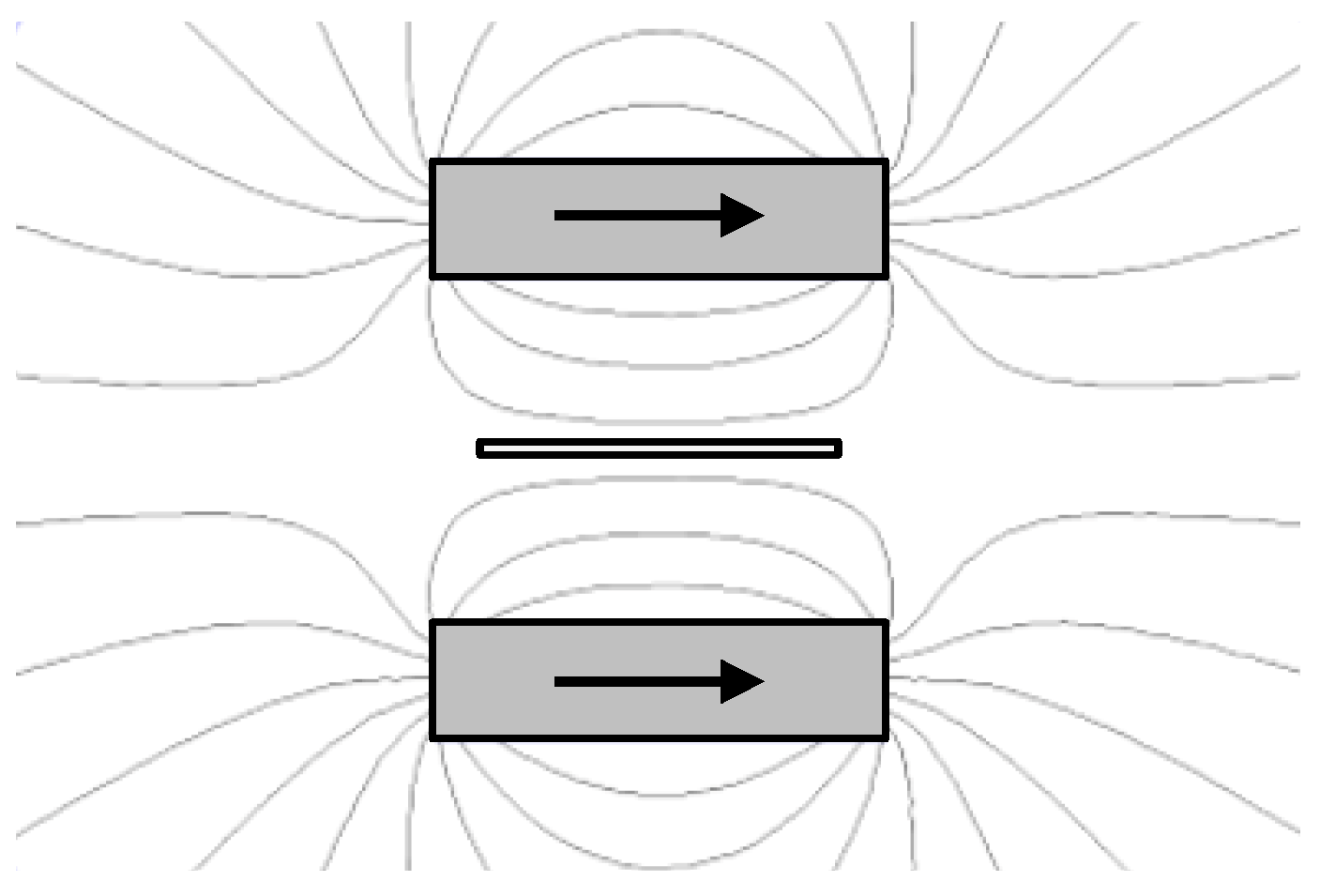

2.2. Lumped Element Model for MME Devices

Figure 5 shows a MME device. The device utilizes a single piezoelectric bending laminate composed of a PE top layer, a structural center layer (S

sub), and another symmetric PE bottom layer. Strain is induced on the structure by anchoring the bending laminate at the center and adding oppositely oriented permanent magnets at its ends. When a magnetic field is applied along the length of the structure, the beam experiences a pure bending moment.

The equivalent circuit model for the structure in

Figure 5 is shown in

Figure 6. By inspection it can be seen that the model is fundamentally similar to the ME laminate model and shares the same parameters for the piezoelectric portion of the circuit.

The power output of the MME structure is calculated as

where

and

At optimal load resistance and open-circuit resonance frequency, the optimal average power is stated as

where

In this case, the optimal load resistance is calculated as

For the sake of simplicity, the variables and constitutive equations that compose Equations (14)–(21) are summarized in

Table 2. One can note that the model for the MME is significantly more convenient than the ME model because there is a closed-form solution for the optimal load and power. A full derivation of Equations (14) though (21) is found in [

18]. (Note that unlike [

18],

Figure 5 neglects the finite length of the center clamp. However, this has no effect on the generality of the model.).

2.3. Fabrication of Test Structures

Two ME transducers were built to validate the model. Two material structure combinations were built: a Galfenol and lead zirconate titanate (PZT) laminate and a Metglas 2605SA1 (Metglas® Inc., Conway, SC, USA) and polyvinylidene fluoride (PVDF) laminate. Terfenol-D was avoided due to the difficulties associated with machining a brittle, pyrophoric material.

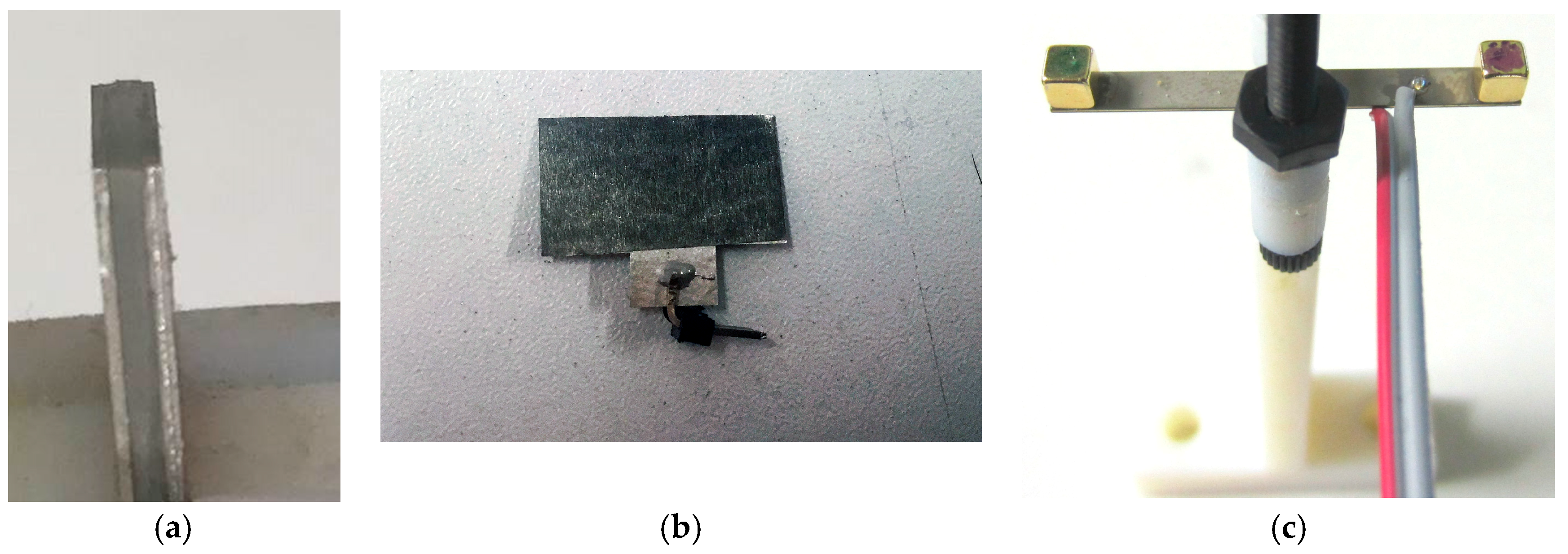

To build the Galfenol-PZT device, 25.4 mm diameter TdVib Galfenol (TdVib LLC, Ames, IA, USA) was cut using electrical discharge machining into two 10 mm × 20 mm × 370 µm sheets poled along the 20 mm length. The PE material used was 1.02 mm thick Piezo Systems PZT-5A (T140-A4E-602, Piezo.com, Division of Mide Technology, Woburn, MA, USA) which was cut using a diamond blade dicing saw to a single 10 mm × 20 mm sheet poled through the thickness. The three layers were then bonded together such that the PE layer was sandwiched between the ME layers. EPO-TEK H20S silver filled (conductive) epoxy was used to adhere the laminate. The epoxy was cured using a heat press, following the epoxy’s minimum cure instructions. Finally, two 0.635 mm right angle header pins were bonded to the top and bottom Galfenol. This bond was done using MG Chemicals silver conductive epoxy given that the joint wasn’t structural. This epoxy was cured overnight at room temperature. The resulting transducer can be seen in

Figure 7a.

The Metglas-PVDF device was built in a fashion similar to that of the Galfenol-PZT device. Raw 23 µm thick 2605SA1 Metglas was cut using scissors into two 10 mm × 20 mm layers. The nature of amorphous Metglas is such that magnetostriction occurs at any orientation in the sheet plane so poling direction was unimportant. To match the very thin Metglas, metalized PVDF (TE 1-1004347-0) was used. These sheets themselves were a sandwich of 28 µm PVDF with 6µm silver ink electrodes on the top and the bottom, poled through the thickness. These sheets were also cut to 10 mm × 20 mm; however, a small tab was left so that electrical leads could be attached to the PE while using a non-conductive epoxy. In particular the nonconductive epoxy EPO-TEK H70E was used for its slightly thinner minimum bond line of less than 20 µm compared to the silver filled alternative which was measured on the Galfenol-PZT device to be about 35 µm. As before, the epoxy was cured in a heat press at the minimum prescribed cure. Similar leads were also bonded as before, however this time on the center flange of the PVDF. The final structure can be seen in

Figure 7b.

The MME device was constructed from an of off-the-shelf PZT4A bimorph from Piezo Systems Inc. with overall dimensions of 32.55 × 3.175 × 0.38 mm. Two Neodymium magnet cubes of 3.175 mm on each edge were bonded to the ends of the PZT beam with cyanoacrylate. The final structure is shown in

Figure 7c.

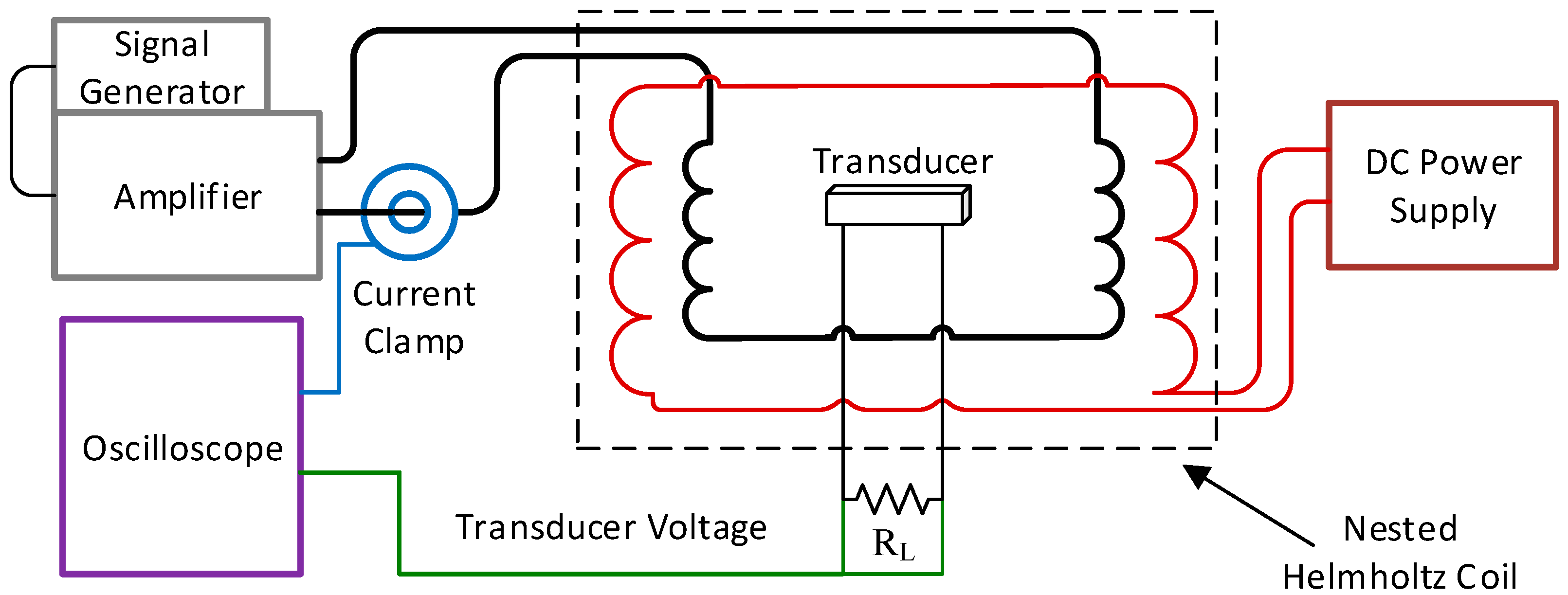

2.4. Experimental Methods

In order to characterize the ME and MME transducers, a nested Helmholtz coil was constructed to create a uniform alternating current (AC) magnetic field superimposed on a DC magnetic field. By superimposing the two fields, ME transducers could be both biased with the DC field and driven with the AC field. (Note that the MME transducer does not need a DC biasing field.). The system diagram for this setup and the nested Helmholtz coil are shown in

Figure 8.

The nested Helmholtz coil can deliver an AC magnetic field () of 2-Oe (2 G in air) at 150 kHz with a 40-watt, 50 Ω amplifier (E&I 240L, Rochester, NY, USA) with no additional circuitry (i.e., tuned resonating capacitors) and a DC magnetic field () of 16-Oe without exceeding the safe wire gauge current. The uniformity of the field was measured using an AlphaLab UHS2 gaussmeter. The AC coil was measured to have 2% field variation over ±1.5 cm at the coil origin (the point co-linear to the coil axis and equidistant from the inner coil faces) along the axial center line. The DC coil had less than 5% variation over the same length. For this and all other work the AC coil was driven by a Tektronix AFG1022 signal generator (Tektronix Inc., Beaverton, OR, USA) and either an E&I 240L (E&I, Rochester, NY, USA) or a Rigol PA1011 amplifier (Rigol Technologies Inc., Beaverton, OR, USA). The DC coils were driven with a B&K Precision 9201 power supply (B&K Precision Corporation, Yorba Linda, CA, USA).

The DC coil is sufficient to optimally bias the Metglas-PVDF ME structure. However, it is not sufficient to bias the Galfenol-PZT ME structure which requires a bias field of 100s of Oe. Therefore, a secondary biasing method was included in the test structure. Two parallel N52 Neodymium magnets were used as shown in

Figure 9. By adjusting the distance between the two magnets with a 3D printed stage, the field seen by the centered transducer can be adjusted such that

for the Galfenol-PZT ME structure.

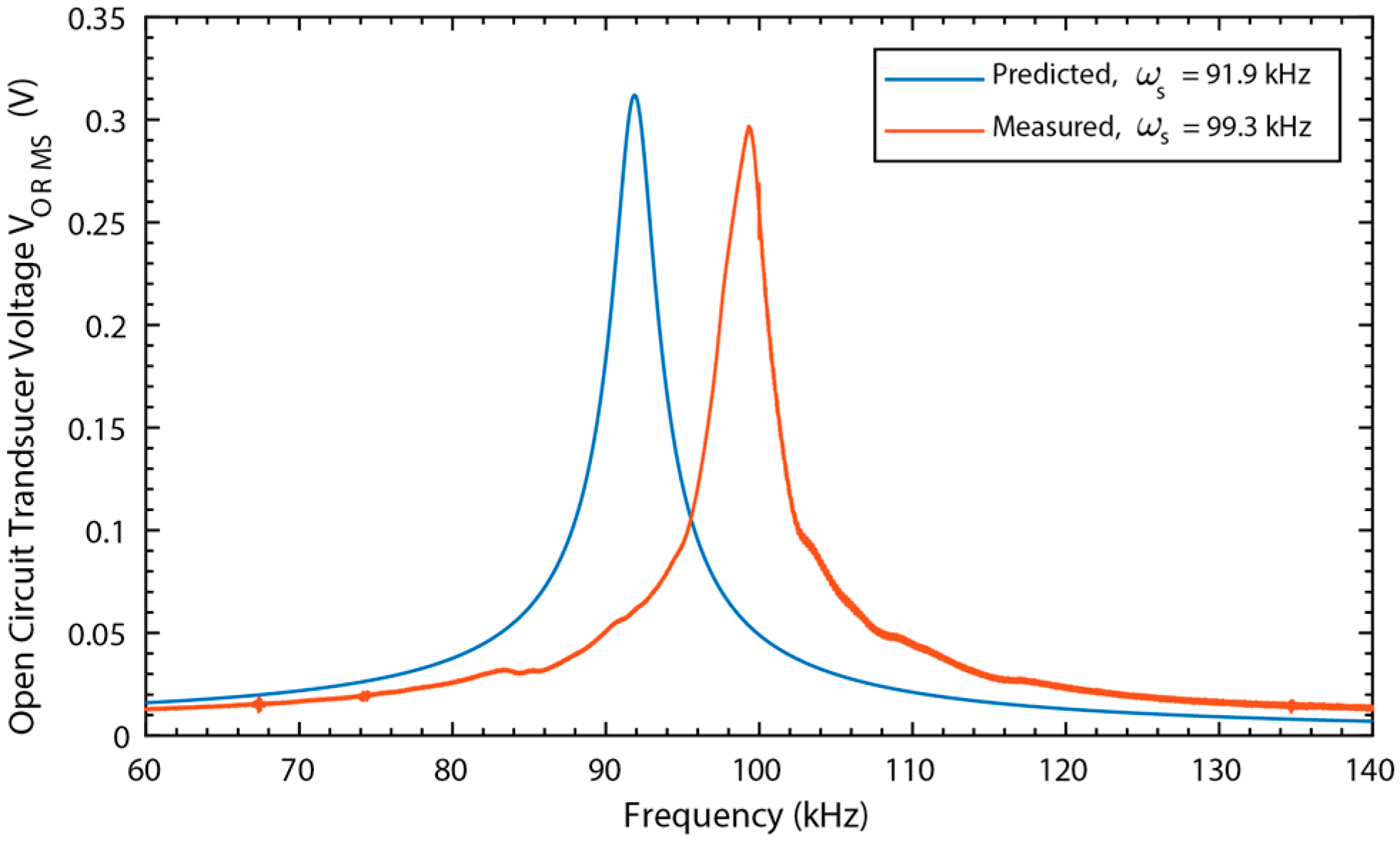

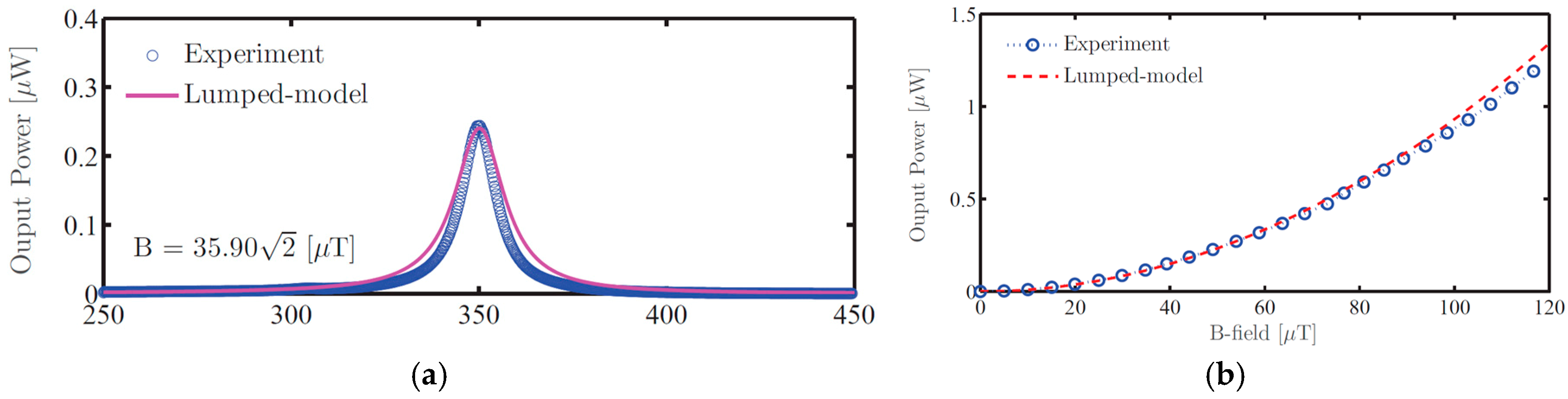

The following three basic steps were performed to characterize the ME and MME devices and validate the lumped element models: optimize magnetic field bias, measure open circuit voltage as a function of frequency and magnetic field, measure power delivered to an optimized resistive load.

To determine the optimal field bias for each ME transducer, a small AC field at a frequency near the device resonance was applied while the DC field was slowly swept. The DC field that maximizes the open circuit AC voltage produced by the ME device was deemed to be the optimal field. The DC field was created by the DC coils for the Metglas-PVDF device and was found to be 22 Oe for the Metglas-PVDF device which is on the same order of magnitude as other reported Metglas transducers [

25]. For the Galfenol-PZT device, the DC field was swept by varying the distance between the two permanent magnets. The DC bias field component parallel to the transducer length was measured along the length of the transducer with an Alphalab GM1-ST DC gauss meter yielding an average strength of 156 Oe with ±20 Oe deviation from average across the length of the device. Literature for bias field levels of Galfenol transducers is sparse, however for stiffer Terfenol-D transducers have reported bias fields of 200–500 Oe, depending on the structure design, so the value of 156 Oe seems reasonable [

13,

27].

Open circuit measurements were performed by sweeping the frequency of the magnetic field from 50 to 150 kHz at a rate of 12.5 kHz/s (10 s total duration). The field amplitude was set at

1 Oe at 50 kHz, however this value attenuated as the sweep progressed due to the increasing coil impedance. To compensate, the magnetic field level and open circuit transducer voltage were measured simultaneously and then normalized for all of the sweeps performed. The normalization was done by performing an FFT on the signals then dividing the resulting transducer voltage amplitude by the field amplitude. The result was then multiplied by

0.707 Oe to find the open circuit RMS voltage,

, across the sweep frequency. It should be noted that this normalization does make the assumption that the transducer performance is linear, as does the model to which it will be compared. This assumption is common for many transducers and was validated experimentally for the ME transducer design by Bian et al. [

28].

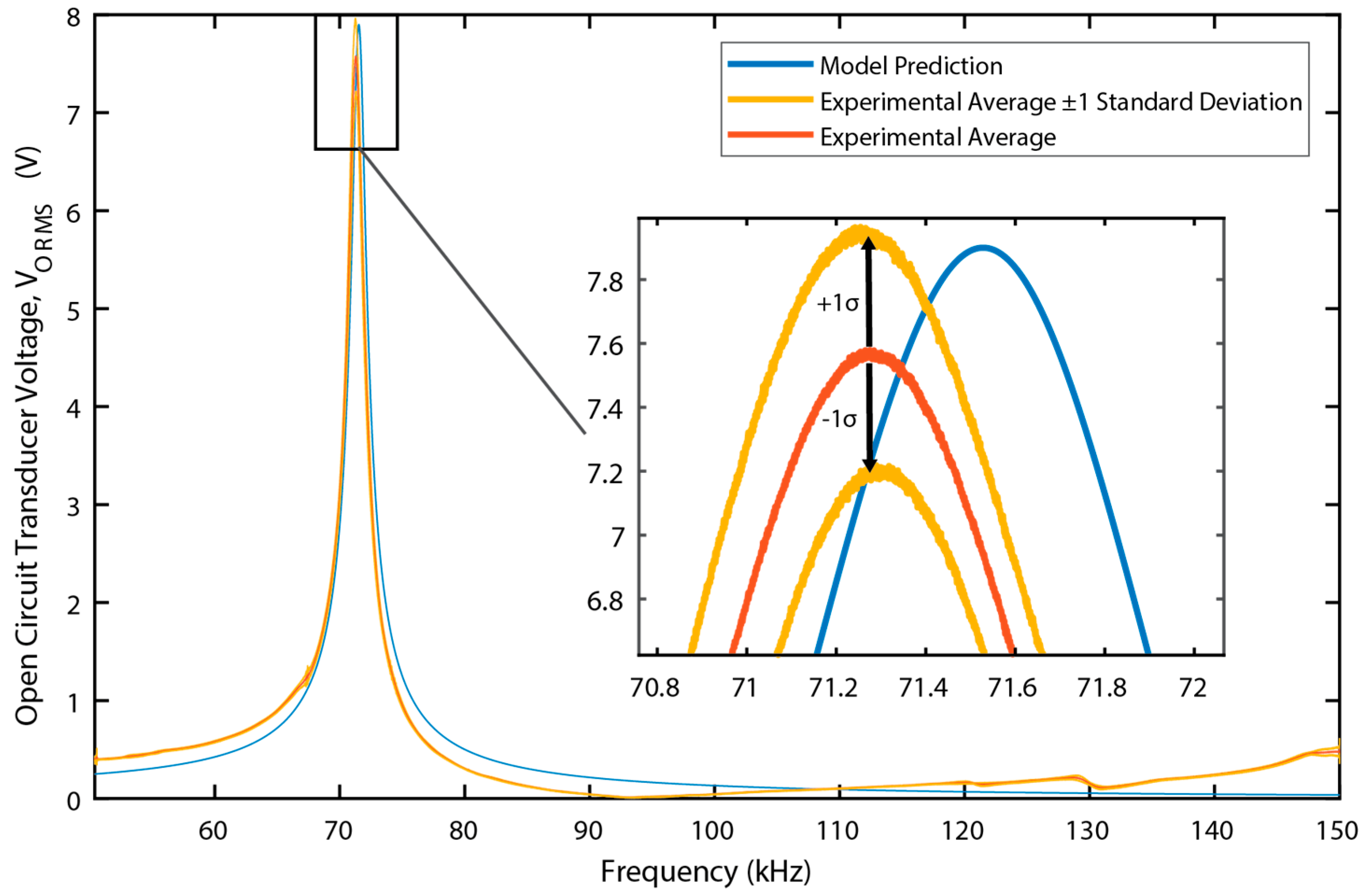

To ensure that test results were consistent, a repeatability test was performed with the Galfenol-PZT device. Nine tests were run. After each sweep, the stage holding the transducer was removed then replaced; after every 3rd sweep, the transducer was also removed from the bias structure entirely then re-clamped. The results of these sweeps can be seen in

Figure 10, which indicate consistent performance.

Once the resonance frequency was determined, the voltage output was measured across a load resistor to determine the power generated. The load resistance was swept to experimentally determine the optimal load. The maximum generated power was taken to be the power dissipated at resonance through an optimal load resistor. This procedure was repeated for each of the three types of devices in order to validate the lumped element models.

4. Discussion

Consider the two material sets used for the ME optimization (see

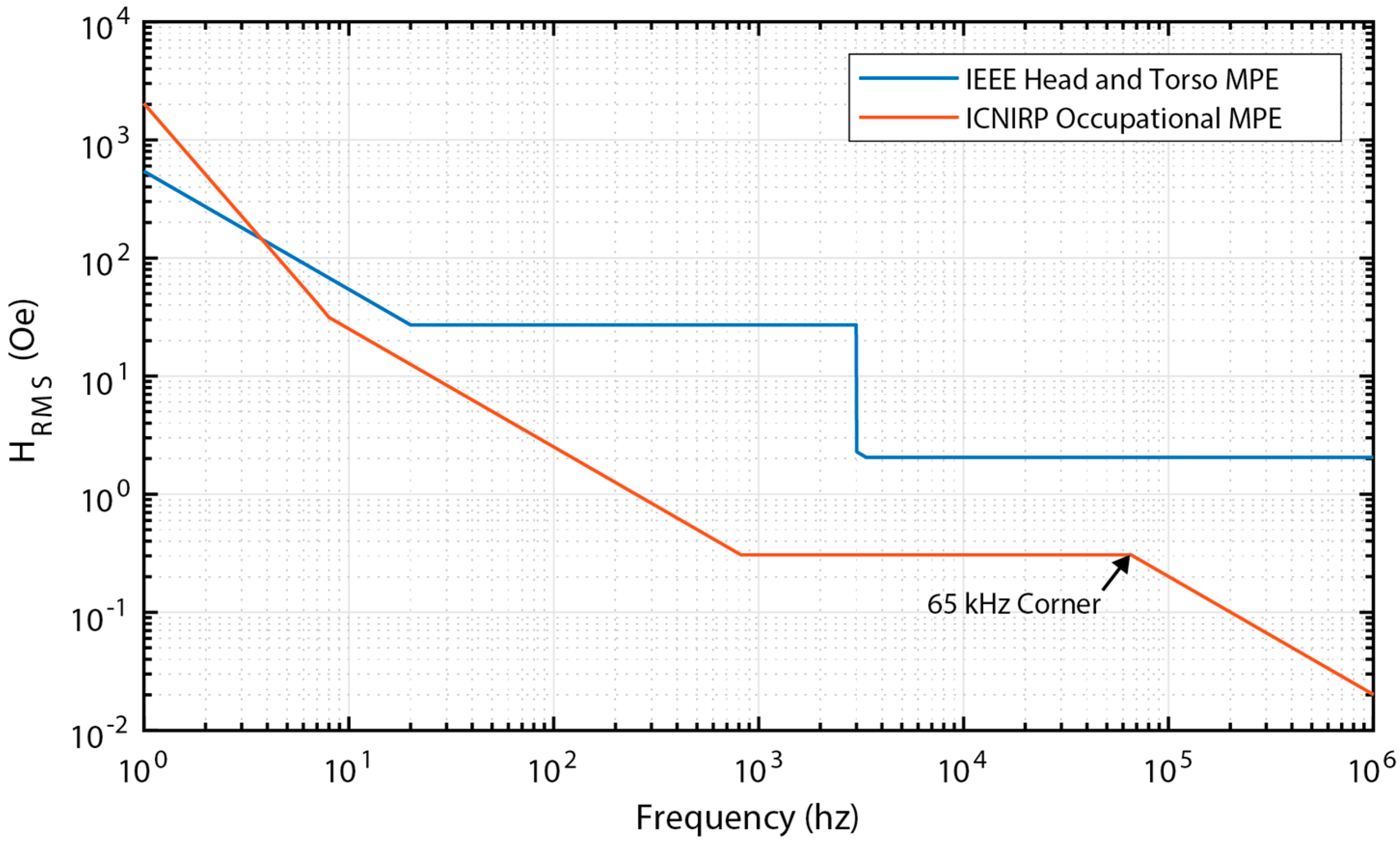

Table 5). For all 3 magnetic field constraint conditions, the Metglas-PZT system outperforms the Galfenol-PZT system. Metglas has a higher magnetostrictive coefficient and is stiffer than Galfenol. This difference allows for greater device extension and a thicker piezoelectric layer thickness relative to the magnetostrictive layer. In addition, Metglas requires a much lower DC bias field, which makes it the clear choice for this application.

The IEEE and ICNIRP standards lead to very different optimal ME beam geometries. The IEEE standard leads to a short, wide, and thick structure ( for Metglas-PZT). From 3.35 kHz to 3 MHz, the magnetic field allowed by the IEEE standard is constant. As power generation will scale with the operational frequency and square of the magnetic field amplitude, the optimization will naturally try to maximize the resonance frequency of the ME structure. The optimization routine also selects a design that maximizes the transducer volume as would be expected. Therefore, as mass is more or less constant, the remaining opportunity for increased power is to increase stiffness within allowable constraints resulting in a short/wide beam. The power output results of this geometry (42.7 mW) are very promising.

As seen in

Figure 14, the allowable magnetic field under the ICNIRP standard is constant from 0.82 to 65 kHz, above which point the allowable field decreases at a rate of approximately 20 dB per decade. Following the same scaling logic, one would expect the optimization routine to select a maximum volume design that operates at the 65 kHz discontinuity in the allowable field. In fact, the optimizer does select a design very close to this operating point (71.9 kHz). In order to maintain maximum volume within allowable geometric constraints, the resulting structure is a long and narrow structure (

for Metglas-PZT) in contrast to the structure constrained by the IEEE standard. The estimated power generated (62.6 μW) is enough for many wireless sensing applications, but certainly not as promising as the estimated power output resulting from the IEEE standard. Finally, the maximum material stresses generated for the ME device designs for each safety constraint were calculated and found to be at least an order of magnitude below the fracture stress (50–70 MPa [

30]).

The MME architecture results in a structure with a far lower resonance frequency given that the transducer is excited in a bending vibration mode rather than in an extensional mode. Therefore, the MME device designs will generally be between 10’s of Hz and 1 kHz. Referring again to

Figure 14, the allowable magnetic field under the IEEE standard for this frequency range is constant while the allowable field under the ICNIRP standard decreases at about 20 dB per decade. Therefore, the same scaling effects are at play with regard to the optimization algorithm. Under the IEEE standard constraint, the optimizer tends to shorten the beam to increase the resonance frequency. Under the ICNIRP standard constraint, the optimizer tends to lengthen the beam to increase the allowable magnetic field by decreasing the resonance frequency. A somewhat arbitrary height limit of 5 mm was placed on the magnet. In all cases, the optimization routine selects the maximum thickness magnet which increases the moment applied to the beam and therefore the stress and generated electric field in the PZT. Given this height constraint, the estimated power under the IEEE standard is about 5 times lower than the ME device (8.7 compared 42.7 mW). However, under the ICNIRP standard, the MME device estimated power actually goes up by about a factor of 2 (120 compared to 62.6 µW). This can be explained by the larger difference in allowable magnetic field as frequency decreases for the ICNIRP standard. However, two complicating factors should be discussed. First, the maximum stress in the PZT material for the MME device is 195 MPa and 37 MPa under the IEEE and ICNIRP standards, respectively. The fracture stress for PZT-5A is approximately 50–70 MPa. So, this MME-IEEE device would certainly fail. The MME-ICNIRP device would also be suspect given fatigue constraints. In order to reduce the stress generated, either the magnet height or the applied magnetic field needs to be reduced. Either of these options results in lower power output. Secondly, as previously discussed, the design that optimizes power output reduces the substrate thickness to zero meaning that bending beam is entirely made of piezoelectric material which is brittle. A thin piezoelectric beam with a large attached proof mass and no substrate between piezoelectric layers will almost certainly fracture in the presence of even a fairly mild shock. Therefore, to achieve a robust design a substrate needs to be added which would further reduce power output. Given these two complicating factors it appears that an ME architecture would almost always make a superior wireless power receiver.