Metallurgical and Mechanical Characterization of High-Speed Friction Stir Welded AA 6082-T6 Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

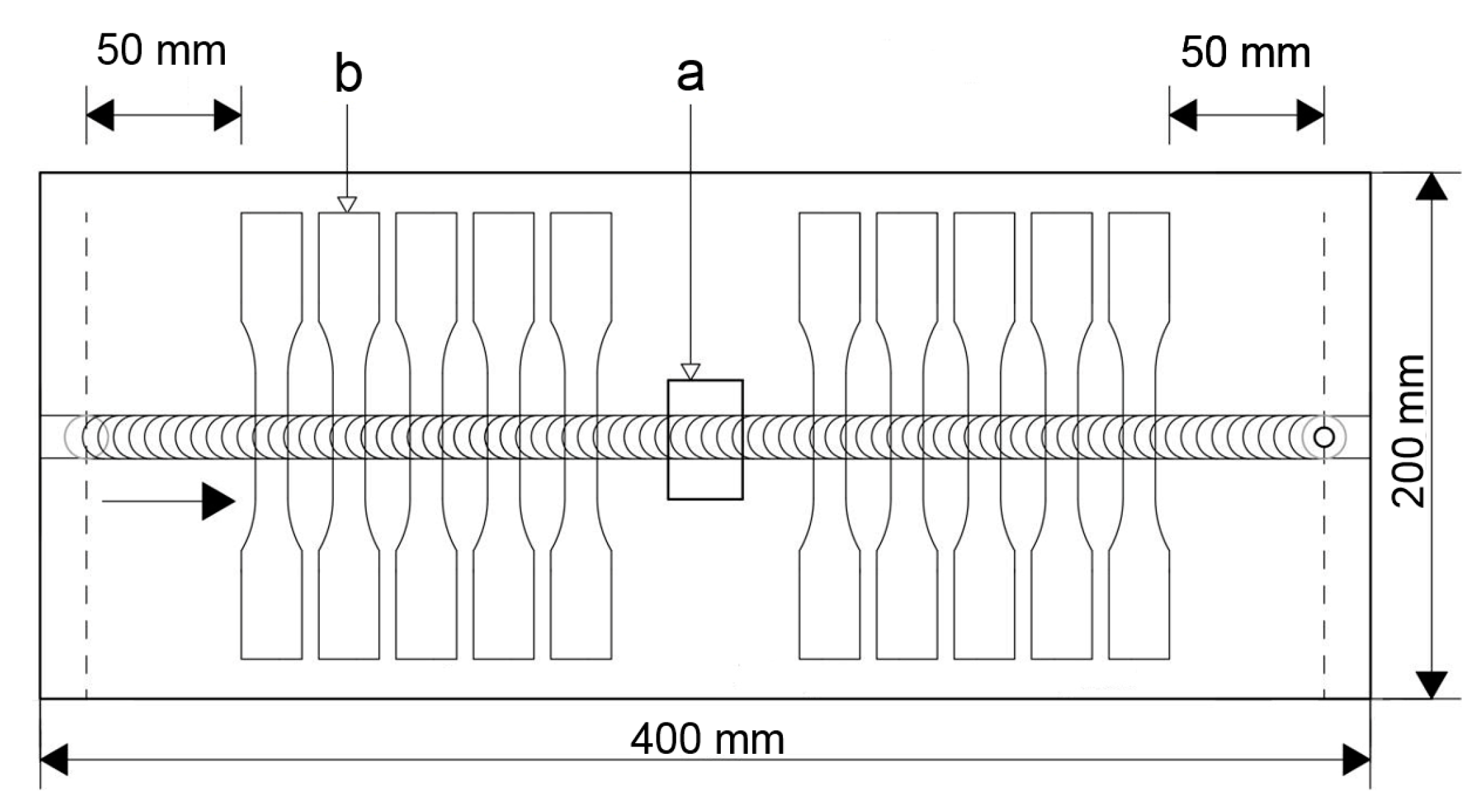

2.1. Friction Stir Welding

2.2. Microstructural and Mechanical Properties Analysis

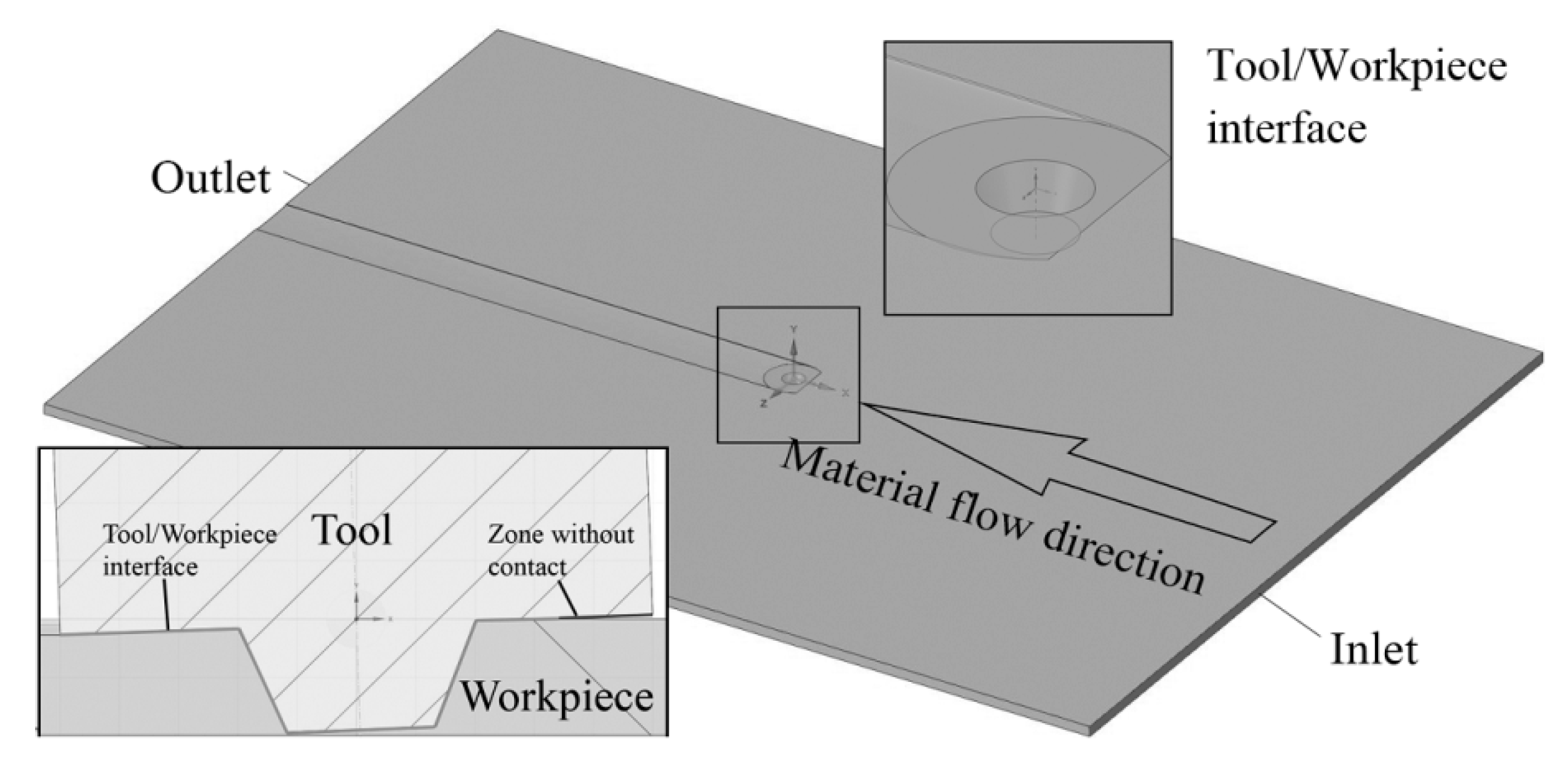

2.3. Numerical Simulation

3. Results

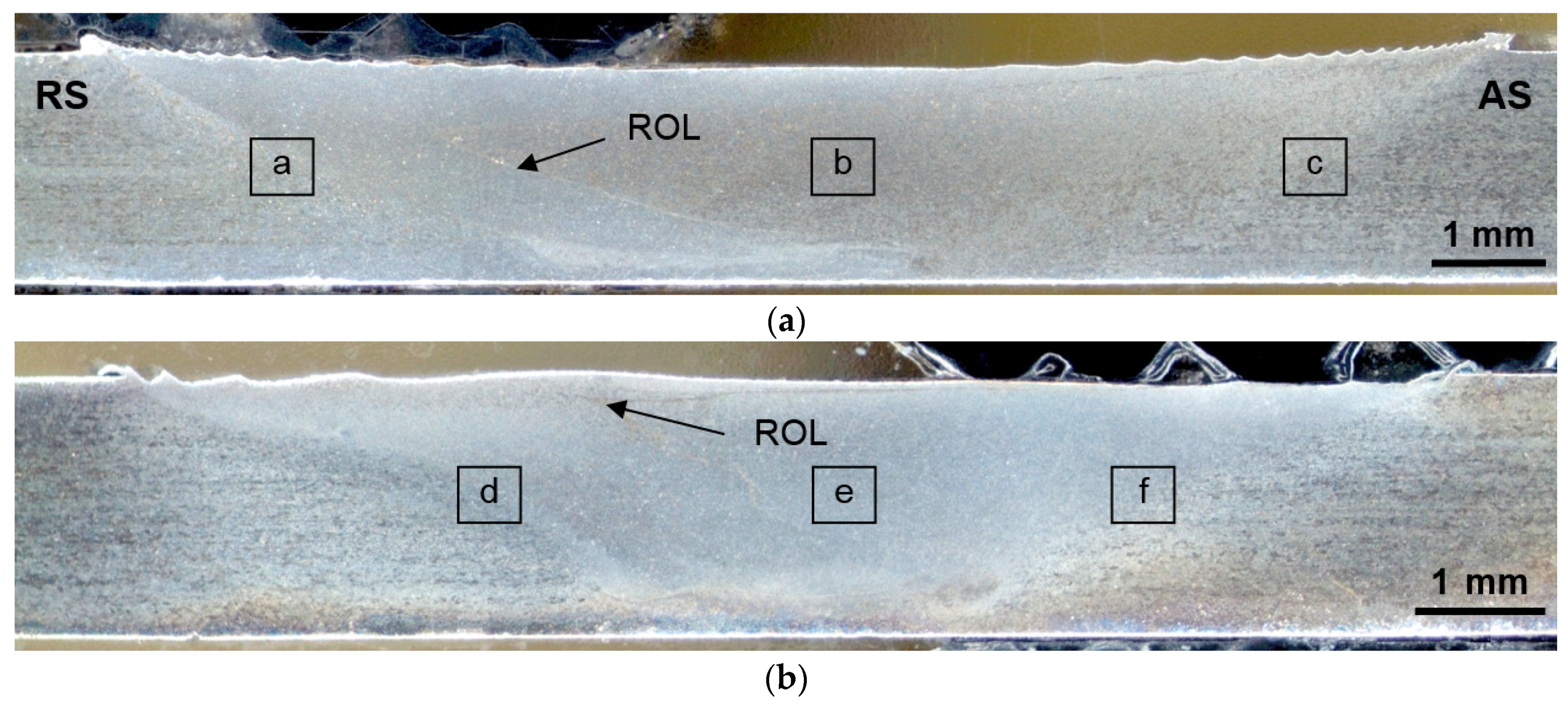

3.1. Macrostructural Characteristics

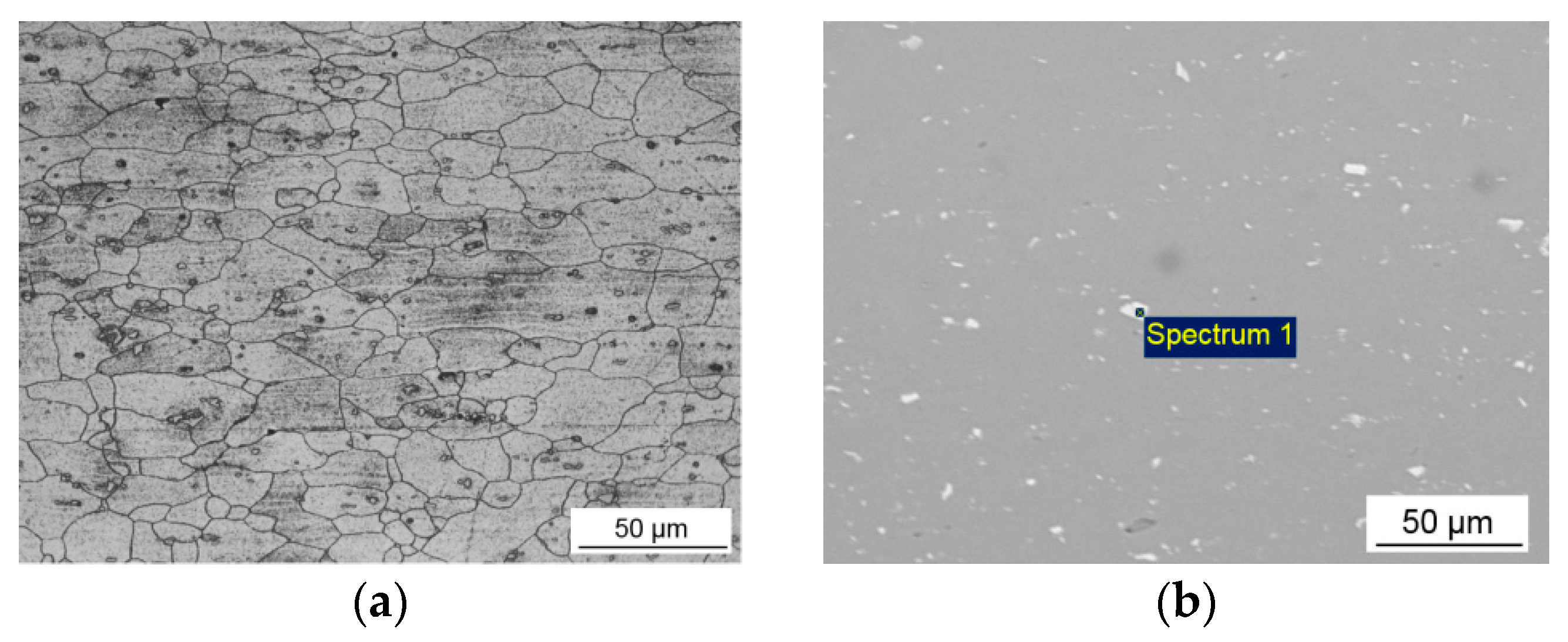

3.2. Microstructural Characteristics

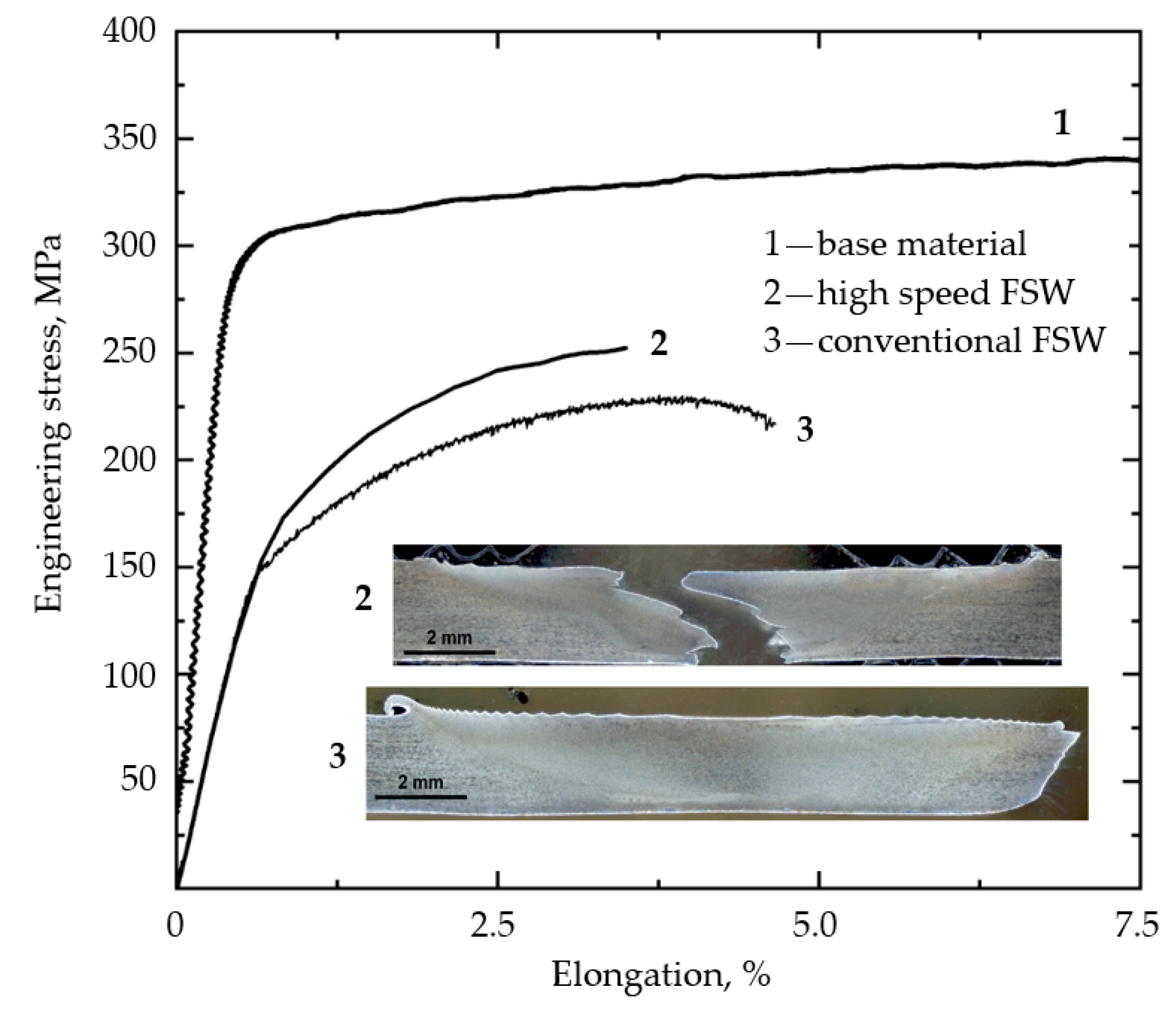

3.3. Microhardness and Tensile Behaviour

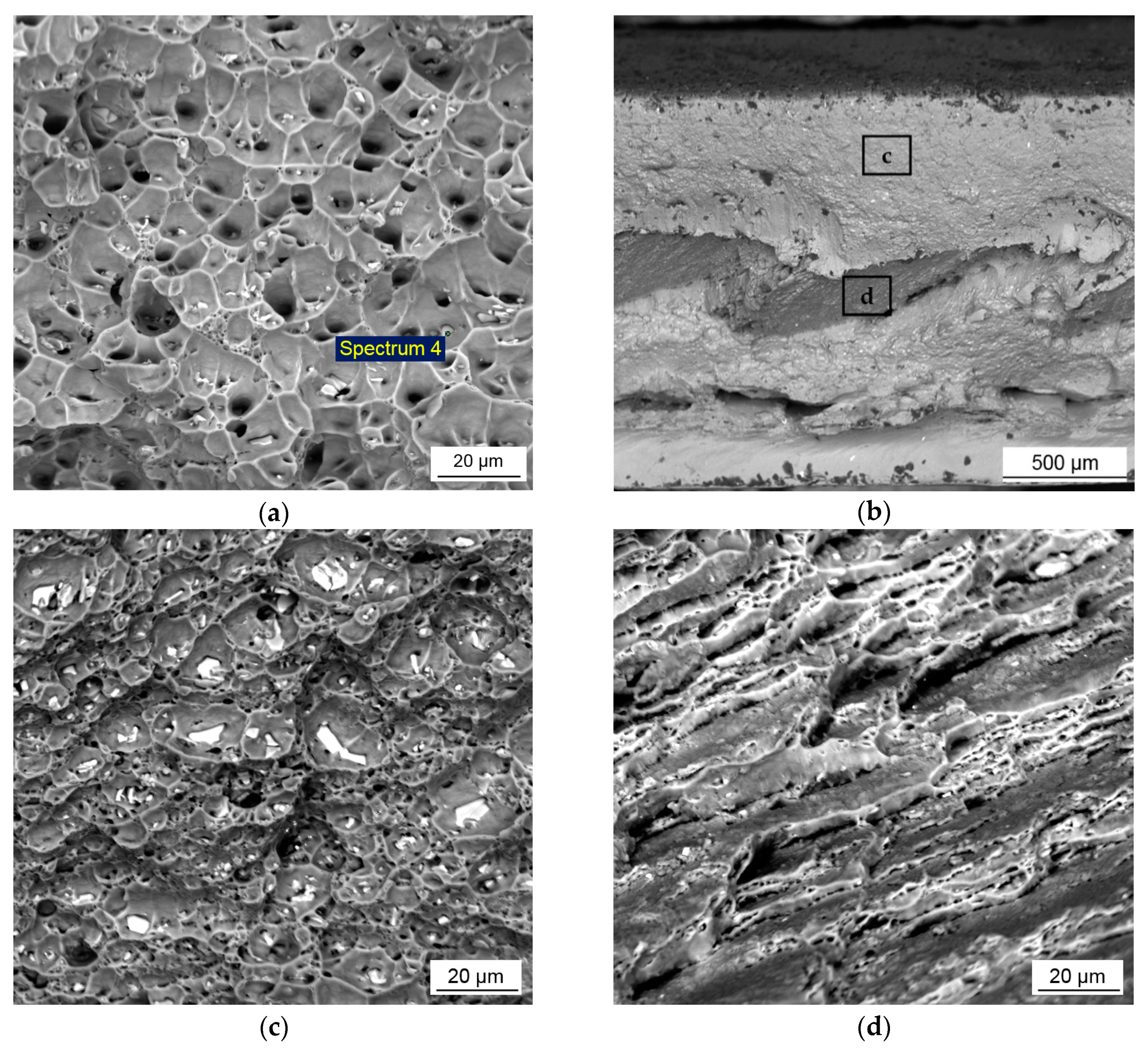

3.4. Fractography

4. Discussion

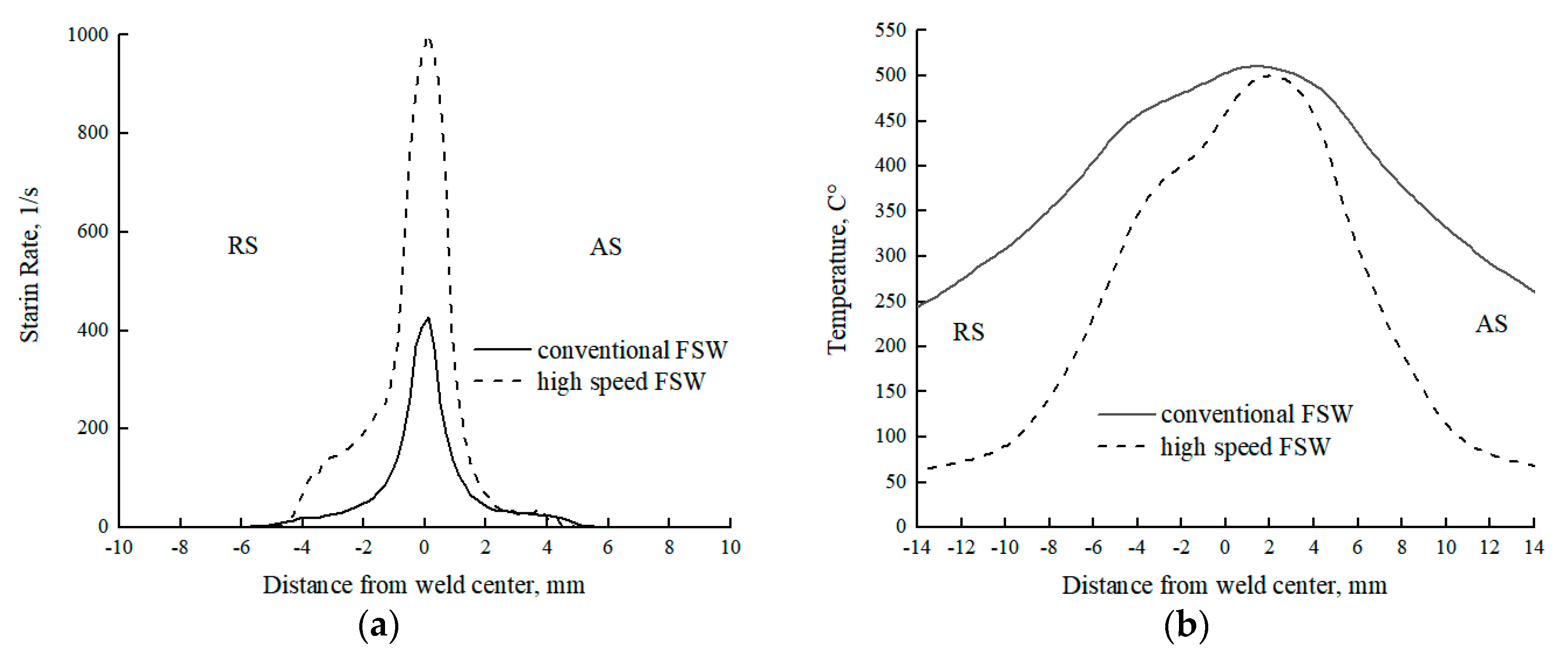

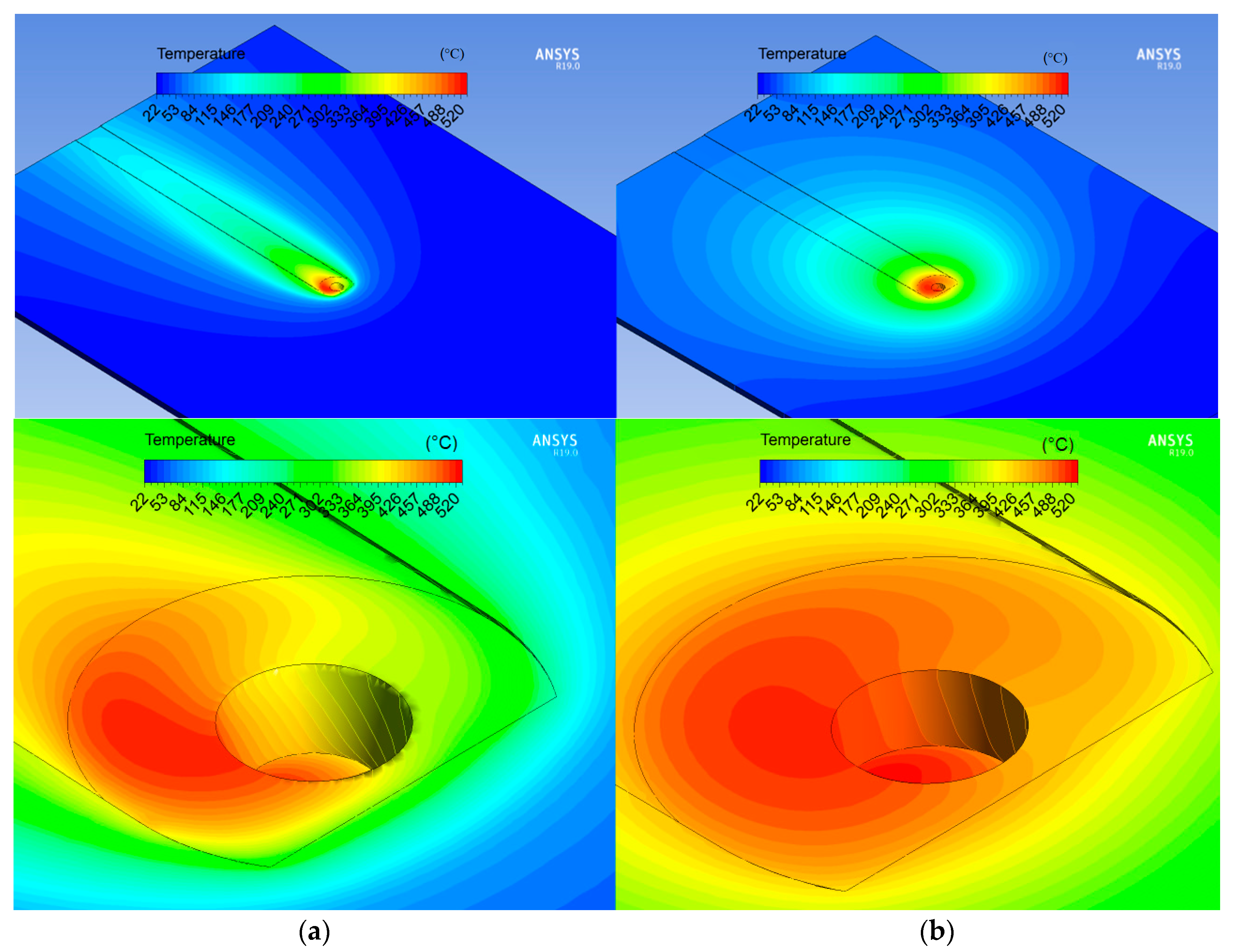

4.1. Microstructure Evolution and Microhardness Distribution

4.2. Influence of Welding Speed on the Tensile Properties

5. Conclusions

- (1)

- Increasing welding speed resulted in the formation of the finer and uniformly distributed grain microstructure in the nugget zone (NZ) as well as severely deformed microstructure in the transition zone;

- (2)

- The high-speed friction stir welding was an effective way to increase an overall hardness level in the softened region of the joint;

- (3)

- The conventional FSW joint fractured in the place where the hardness level was the lowest, while the tensile properties of the high-speed weld were affected by the formation of the thick oxide lines in NZ;

- (4)

- The fracture surface of the conventional FSW joint indicated ductile behavior of the material, while the HSFSW specimens were characterized by mixed ductile and cleavage fracture mode;

- (5)

- The results of the numerical simulation have shown that by high-speed welding the temperature gradient was larger and the temperature fields were shifted to the advancing side. The strain rate calculated using the CFD method in the cross-sections behind the probe in NZ was more than two times higher in the HSFSW joint in comparison with the conventional FSW joint.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Butt Welding. GB Patent Application No. 9125978.8, 6 December 1991. [Google Scholar]

- Dawes, C.J.; Thomas, W.M. Friction Stir Process Welds Aluminum Alloys. Weld. J. 1996, 75, 41–45. [Google Scholar]

- İpekoğlu, G.; Seçil Erim, S.; Çam, G. Investigation into the Influence of Post-Weld Heat Treatment on the Friction Stir Welded AA6061 Al-Alloy Plates with different temper conditions. Metall. Mater. Trans. A 2014, 45, 864–877. [Google Scholar] [CrossRef]

- El-Danaf, E.A.; El-Rayes, M.M. Microstructure and mechanical properties of friction stir welded 6082 AA in as welded and post weld heat treated conditions. Mater. Des. 2013, 46, 561–572. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S.; Shi, L. Local microstructure evolution in Al 6061-T6 friction stir weld nugget enhanced by ultrasonic vibration. Mater. Des. 2016, 92, 710–723. [Google Scholar] [CrossRef]

- Liu, H.J.; Hou, J.C.; Guo, H. Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061-T6 aluminum alloy. Mater. Des. 2013, 50, 872–878. [Google Scholar] [CrossRef]

- Giorgi, M.D.; Scialpi, A.; Panella, F.W.; Filippis, L.A.C.D. Effect of shoulder geometry on residual stress and fatigue properties of AA6082 FSW joints. J. Mech. Sci. Tech. 2009, 23, 26–35. [Google Scholar] [CrossRef]

- Imam, M.; Racherla, V.; Biswas, K. Effect of backing plate material in friction stir butt and lap welding of 6063-T4 aluminium alloy. Int. J. Adv. Manuf. Tech. 2015, 77, 2181–2195. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural Evolution of 6063 Aluminum during Friction-Stir Welding. Metall. Mater. Trans. A 1999, 30A, 2429–2437. [Google Scholar] [CrossRef]

- Hassan, Kh.A.A.; Prangnell, P.B.; Norman, A.F.; Price, D.A.; Williams, S.W. Effect of welding parameters on nugget zone microstructure and properties in high strength aluminium alloy friction stir welds. Sci. Technol. Weld. Join. 2003, 8, 257–268. [Google Scholar] [CrossRef]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. Evaluation of the microstructure and mechanical properties of friction stir welded 6005 aluminum alloy. Mater. Sci. Technol. 2003, 19, 513–518. [Google Scholar] [CrossRef]

- Svensson, L.-E.; Karlsson, L.; Larsson, H.; Karlsson, B.; Fazzini, M.; Karlsson, J. Microstructure and mechanical properties of friction stir welded aluminium alloys with special reference to AA 5083 and AA 6082. Sci. Technol. Weld. Join. 2000, 5, 285–296. [Google Scholar] [CrossRef]

- Olea, C.A.W.; Roldo, L.; dos Santos, J.F.; Strohaecker, T.R. A sub-structural analysis of friction stir welded joints in an AA6056 Al-alloy in T4 and T6 temper conditions. Mater. Sci. Eng. A 2007, 454–455, 52–62. [Google Scholar] [CrossRef]

- Cerri, E.; Leo, P.; Wang, X.; Embury, J.D. Mechanical properties and microstructural evolution of friction-stir-welded thin sheet aluminum alloys. Metall. Mater. Trans. A 2011, 42, 1283–1295. [Google Scholar] [CrossRef]

- Malopheyev, S.; Vysotskiy, I.; Kulitskiy, V.; Mironov, S.; Kaibyshev, R. Optimization of processing-microstructure-properties relationship in friction-stir welded 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2016, 662, 136–143. [Google Scholar] [CrossRef]

- Upadhyay, P.; Reynolds, A.P. Thermal management in friction-stir welding of precipitation-hardened aluminum alloys. JOM 2015, 67, 1022–1031. [Google Scholar] [CrossRef]

- Chen, C.M.; Kovacevic, R. Finite element modeling of friction stir welding-thermal and thermomechanical analysis. Int. J. Mach. Tools Manuf. 2003, 43, 1319–1326. [Google Scholar] [CrossRef]

- Hovanski, Y.; Upadhyay, P.; Carsley, J.; Luzanski, T.; Carlson, B.; Eisenmenger, M.; Soulami, A.; Marshall, D.; Landino, B.; Hartfield-Wunsch, S. High-Speed Friction-Stir Welding to Enable Aluminum Tailor-Welded Blanks. JOM 2015, 67, 1045–1053. [Google Scholar] [CrossRef]

- Zhang, J.; Upadhyay, P.; Hovanski, Y.; Field, D.P. High-Speed Friction Stir Welding of AA7075-T6 Sheet: Microstructure, Mechanical Properties, Micro-texture, and Thermal History. Met. Mater. Trans. A 2018, 49A, 210–222. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Leitão, C.; Louro, R.; Gouveia, H.; Loureiro, H. High speed friction stir welding of aluminium alloys. Sci. Tech. Weld. Join. 2010, 15, 676–681. [Google Scholar] [CrossRef]

- Liu, H.; Liu, X.; Wang, X.; Wang, T.; Yang, S. Mechanical properties and their relations to microstructural characteristics of high-speed friction stir-welded AA6005A-T6 aluminum hollow extrusions. Int. J. Adv. Manuf. Technol. 2017, 88, 3139–3149. [Google Scholar] [CrossRef]

- Liu, F.; Fu, L.; Chen, H. High speed friction stir welding of ultra-thin AA6061-T6 sheets using different backing plates. J. Manuf. Proc. 2018, 33, 219–227. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Loureiro, A.; Leitao, C.; Leal, R.M.; Chaparro, B.M.; Vilaça, P. Influence of friction stir welding parameters on the microstructural and mechanical properties of AA 6016-T4 thin welds. Mater. Des. 2009, 30, 1913–1921. [Google Scholar] [CrossRef]

- Widener, C.A.; Talia, J.E.; Tweedy, B.M.; Burford, D.A. High-rotational speed friction stir welding with a fixed shoulder. In Proceedings of the 6th International Symposium on Friction Stir Welding, Saint Sauveur, QC, Canada, 10–13 October 2006. [Google Scholar]

- Sheikhi, S.; dos Santos, J.F. Effect of process parameter on mechanical properties of friction stir welded tailored blanks from aluminium alloy 6181-T4. Sci. Tech. Weld. Join. 2007, 12, 370–375. [Google Scholar] [CrossRef]

- Rao, D.; Huber, K.; Heerens, J.; dos Santos, J.F.; Huber, N. Asymmetric mechanical properties and tensile behavior prediction of aluminium alloy 5083 friction stir welding joints. Mater. Sci. Eng. A 2013, 565, 44–50. [Google Scholar] [CrossRef]

- Kondrat’ev, S.Y.; Morozova, Y.N.; Golubev, Y.A.; Hantelmann, C.; Naumov, A.A.; Mikhailov, V.G. Microstructure and mechanical properties of welds of Al-Mg-Si alloys after different modes of impulse friction stir welding. Met. Sci. Heat Treat. 2018, 59, 697–702. [Google Scholar] [CrossRef]

- Golubev, I.; Morozova, I.; Naumov, A.; Hantelmann, C.; Doynov, N.; Michailov, V. Numerical simulation and experimental investigation on impulse friction stir welding of 6082-T6 aluminum alloy. In Proceedings of the Materials Science and Technology 2017 (MS&T17), Pittsburgh, PA, USA, 8–12 October 2017; 987–994. [Google Scholar]

- Golubev, I.A.; Chernikov, E.V.; Naumov, A.A.; Michailov, V.G. Temperature distribution and welding distortion measurements after FSW of Al 6082-T6 sheets. In Friction Stir Welding and Processing VIII, TMS; Springer: Cham, Switzerland, 2015; pp. 289–295. [Google Scholar]

- Golubev, I.A.; Naumov, A.A.; Chernikov, E.V.; Michailov, V. Research of temperature distribution during friction stir welding of 2 MM AW 6082 sheets. In Proceedings of the METAL 2015-24th International Conference on Metallurgy and Materials, Brno, Czech Republic, 3–5 June 2015; pp. 1433–1438. [Google Scholar]

- Naumov, A.A.; Morozova, I.; Isupov, F.; Golubev, I.; Michailov, V.G. Temperature Influence on Microstructure and Properties Evolution of Friction Stir Welded Al-Mg-Si Alloy. Key Eng. Mat. 2019, 822, 122–128. [Google Scholar] [CrossRef]

- Bastier, A.; Maitournam, M.H.; Dang Van, K.; Roger, F. Steady state thermomechanical modelling of friction stir welding. Sci. Tech. Weld. Join. 2006, 11, 278–288. [Google Scholar] [CrossRef]

- Chen, G.; Li, H.; Wang, G.; Guo, Z.; Zhang, S.; Dai, Q.; Shi, Q. Effects of pin thread on the in-process material flow behavior during friction stir welding: A computational fluid dynamics study. Int. J. Mach. Tools Manuf. 2018, 124, 12–21. [Google Scholar] [CrossRef]

- Meshram, S.D.; Reddy, G.M. Influence of Tool Tilt Angle on Material Flow and Defect Generation in Friction Stir Welding of AA2219. Def. Sci. J. 2018, 6, 512–518. [Google Scholar] [CrossRef]

- Spittel, T.; Spittel, M. Non-Ferrous Alloys-Light Metals; Springer-Verlag: Berlin/Heidelberg, Germany, 2011; Part 2; p. 234. [Google Scholar]

- Colegrove, P.A.; Shercliff, H.R. CFD modelling of friction stir welding of thick plate 7449 aluminium alloy. Sci. Tech. Weld. Join. 2006, 11, 429–441. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R. Two-dimensional CFD modelling of flow round profiled FSW tooling. Sci. Tech. Weld. Join. 2004, 9, 483–492. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Friction Stir Welding and Processing; ASM International: Materials Park, OH, USA, 2007; p. 360. [Google Scholar]

- Niu, P.; Li, W.; Zhang, Z.; Wang, F.; Feng, Y.; and Fu, M. Significant effect of oxide on mechanical properties of friction-stir-welded AA2024 joints. Sci. Tech. Weld. Join. 2016, 22, 66–70. [Google Scholar] [CrossRef]

- Sato, Y.S.; Takauchi, H.; Park, S.H.C.; Kokawa, H. Characteristics of the kissing-bond in friction stir welded Al alloy 1050. Metall. Mater. Trans. A 2005, 405, 333–338. [Google Scholar] [CrossRef]

- Olea, C.A.W. Influence of Energy Input in Friction Stir Welding on Structure Evolution and Mechanical Behaviour of Precipitation-Hardening in Aluminium Alloys (AA2024-T351, AA6013-T6 and Al-Mg-Sc). Ph.D. Thesis, Ruhr University Bochum, Bochum, Germany, 2008. [Google Scholar]

- Gallais, C.; Simar, A.; Fabregue, D.; Denquin, A.; Lapasset, G.; de Meester, B.; Brechet, Y.; Pardoen, T. Multiscale analysis of the strength and ductility of AA 6056 aluminum friction stir welds. Met. Mater. Trans. A 2007, 38, 964–981. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys. Int. Mater. Rev. 2005, 50, 193–215. [Google Scholar] [CrossRef]

- Zhang, H.; Luo, S.; Xu, W. Influence of Welding Speed on Zigzag Line Feature and Tensile Property of a Friction-Stir-Welded Al-Zn-Mg Aluminum Alloy. J. Mater. Eng. Perform. 2019, 28, 1790–1800. [Google Scholar] [CrossRef]

- Okamura, H.; Aota, K.; Sakamoto, M.; Ezumi, M.; Ikeuchi, K. Behavior of Oxide during Friction Stir Welding of Aluminum Alloy and its Influence on Mechanical Properties. Quart. J. Jpn. Weld. Soc. 2001, 19, 446–456. [Google Scholar] [CrossRef]

- Sato, Y.S.; Yamashita, F.; Sugiura, Y.; Park, S.H.C.; Kokawa, H. FIB-Assisted TEM Study of an Oxide Array in the Root of a Friction Stir Welded Aluminium Alloy. Scr. Mater. 2004, 50, 365–369. [Google Scholar] [CrossRef]

- Zhou, C.Z.; Yang, X.Q.; Luan, G.H. Effect of Oxide Array on the Fatigue Property of Friction Stir Welds. Scr. Mater. 2006, 54, 1515–1520. [Google Scholar] [CrossRef]

- Dai, Q.L.; Wang, X.Y.; Hou, Z.G.; Wu, J.J.; Shi, Q.Y. Microcavities Accompanying a Zigzag Line in Friction Stir Welded A6082-T6 Alloy Joint. Sci. Technol. Weld. Join. 2015, 20, 68–74. [Google Scholar] [CrossRef]

| FSW Type | v, mm/min | N, rpm | Fz, kN | α | WP, mm/rot | Qtotal, Watt | l, J/mm |

|---|---|---|---|---|---|---|---|

| Conventional | 200 | 710 | 4 | 2° | 0.28 | 523 | 157 |

| High-speed | 2500 | 2100 | 6 | 1.2° | 1.19 | 2222 | 53 |

| Zone | Spectrum | Al | Fe | Mn | Si | Cr | Cu | Ni |

|---|---|---|---|---|---|---|---|---|

| BM | 1 | 68.45 | 17.70 | 6.21 | 6.55 | 0.19 | 0.66 | 0.24 |

| NZ-FSW | 2 | 62.59 | 21.62 | 7.19 | 7.74 | 0.17 | 0.69 | - |

| NZ-HSFSW | 3 | 65.39 | 19.97 | 6.68 | 7.06 | 0.19 | 0.58 | 0.12 |

| Fracture-FSW | 4 | 62.09 | 22.36 | 6.85 | 7.82 | 0.19 | 0.69 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naumov, A.; Morozova, I.; Rylkov, E.; Obrosov, A.; Isupov, F.; Michailov, V.; Rudskoy, A. Metallurgical and Mechanical Characterization of High-Speed Friction Stir Welded AA 6082-T6 Aluminum Alloy. Materials 2019, 12, 4211. https://doi.org/10.3390/ma12244211

Naumov A, Morozova I, Rylkov E, Obrosov A, Isupov F, Michailov V, Rudskoy A. Metallurgical and Mechanical Characterization of High-Speed Friction Stir Welded AA 6082-T6 Aluminum Alloy. Materials. 2019; 12(24):4211. https://doi.org/10.3390/ma12244211

Chicago/Turabian StyleNaumov, Anton, Iuliia Morozova, Evgenii Rylkov, Aleksei Obrosov, Fedor Isupov, Vesselin Michailov, and Andrey Rudskoy. 2019. "Metallurgical and Mechanical Characterization of High-Speed Friction Stir Welded AA 6082-T6 Aluminum Alloy" Materials 12, no. 24: 4211. https://doi.org/10.3390/ma12244211

APA StyleNaumov, A., Morozova, I., Rylkov, E., Obrosov, A., Isupov, F., Michailov, V., & Rudskoy, A. (2019). Metallurgical and Mechanical Characterization of High-Speed Friction Stir Welded AA 6082-T6 Aluminum Alloy. Materials, 12(24), 4211. https://doi.org/10.3390/ma12244211