Old Timber Reinforcement with FRPs

Abstract

1. Introduction

- structural protection and reinforcement by introducing extra components (independent structural reinforcement, suspended structural reinforcement system or reinforcement cooperating with the existing structural system), and

- structural operations (increasing the technical and operational values of damaged components).

- Usually, reinforcements working with an existing structural system include [1]:

- timber beams reinforcement along their entire length by joining the side surfaces with reinforcing components such as planks or log tops, steel sections and the introduction of reinforcement into the beam tension zone;

- reinforcement on a beam section, including the replacement of the damaged beam section with a supplementary element, the removal of the damaged beam end and the floor beam suspension by steel stirrups;

- reinforcement based on the floor beam-reinforced concrete slab composition, and

- beam reinforcement with tie rods.

2. Testing on Small Samples

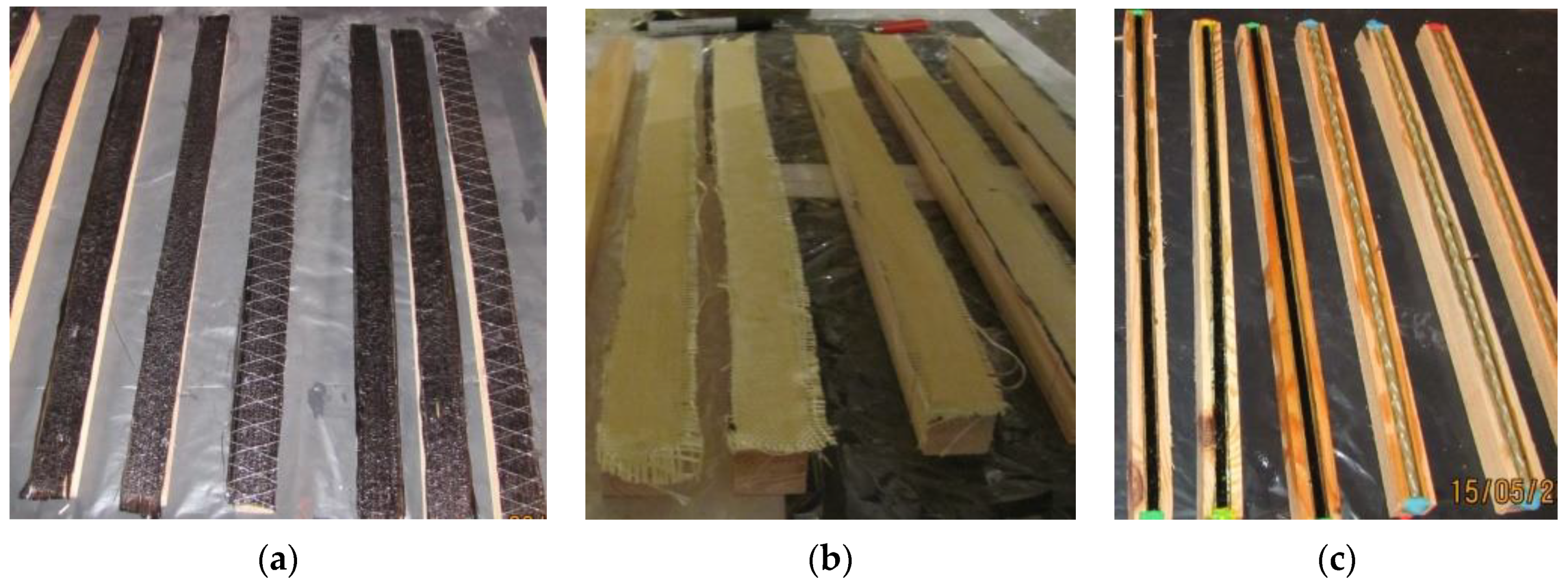

2.1. Research Materials

2.2. Research Methodology

2.3. Test Results on Small Samples

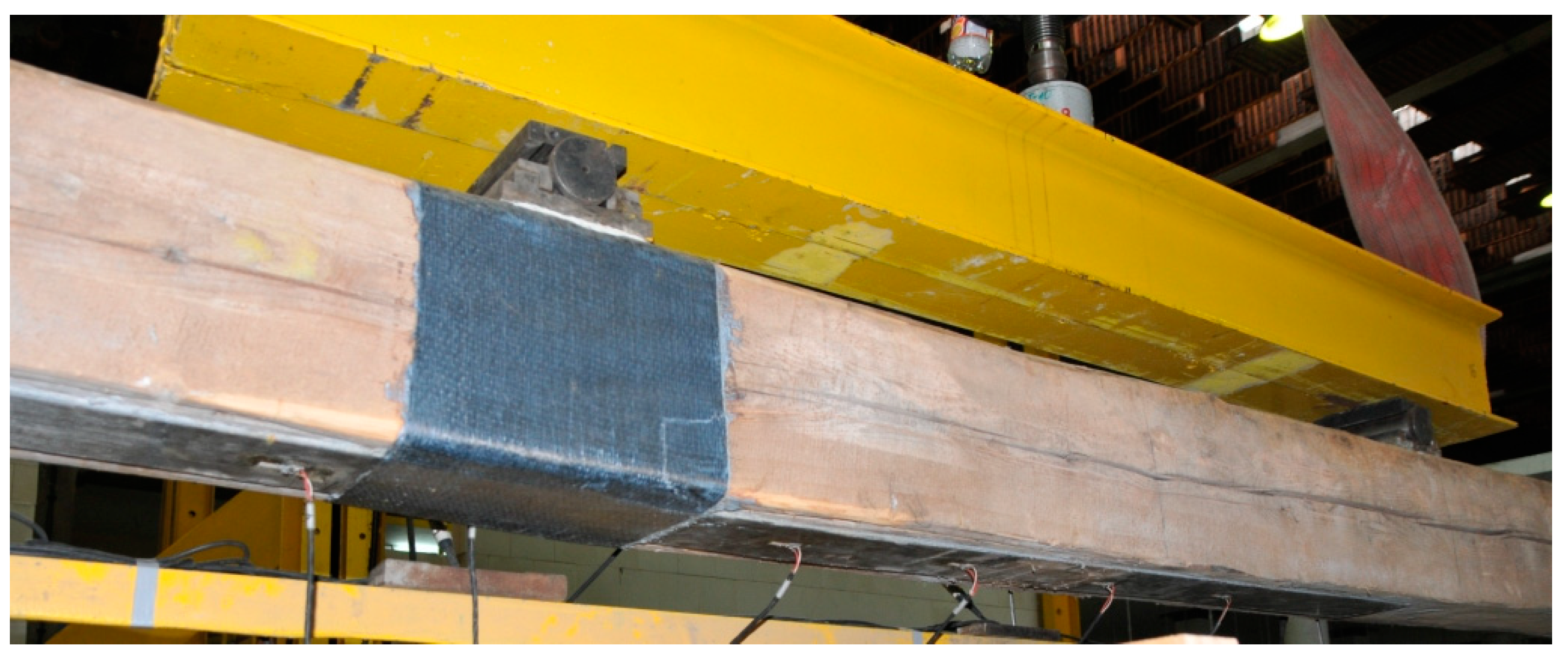

3. Real-Size Scale Tests on Beams

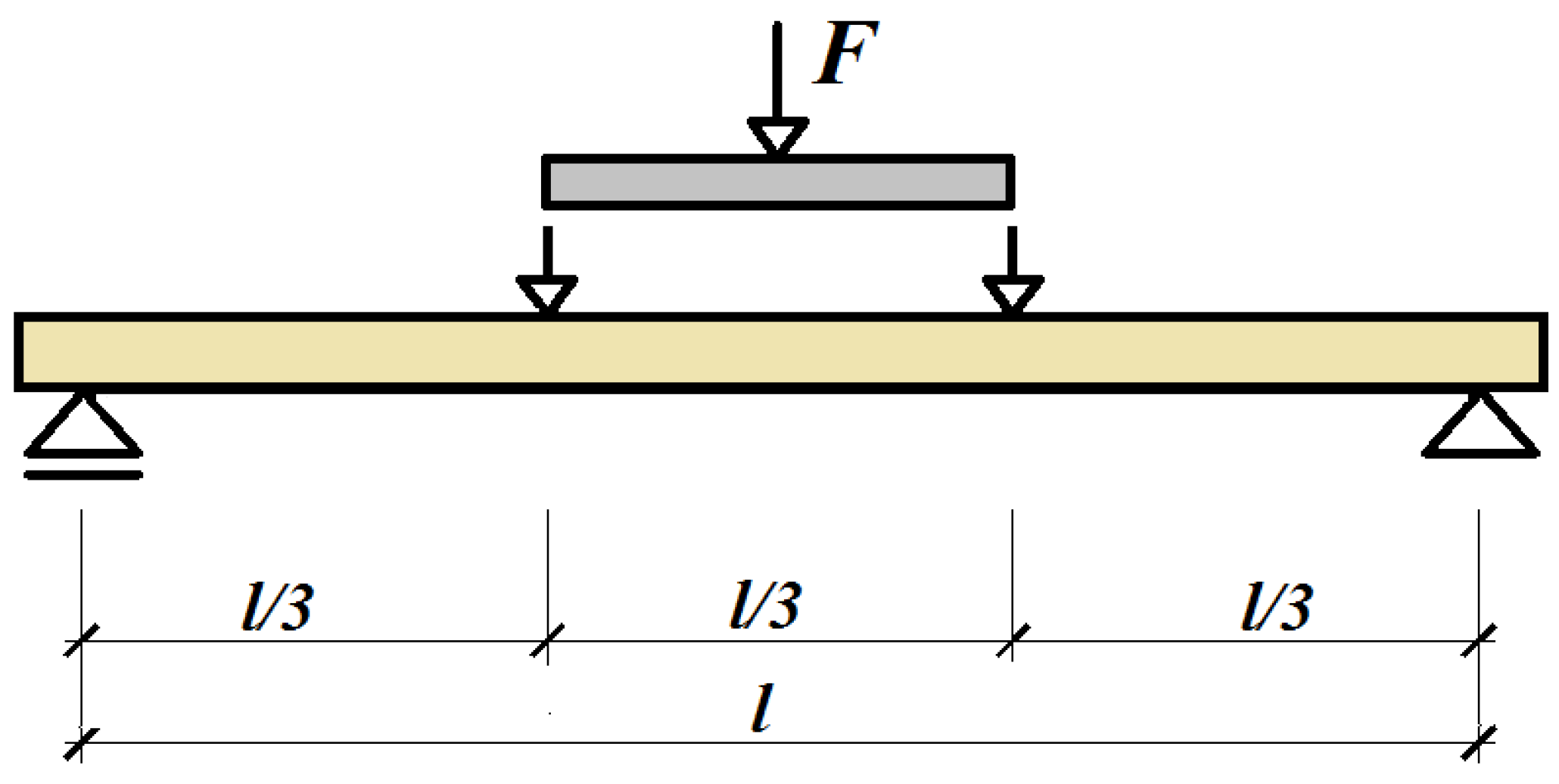

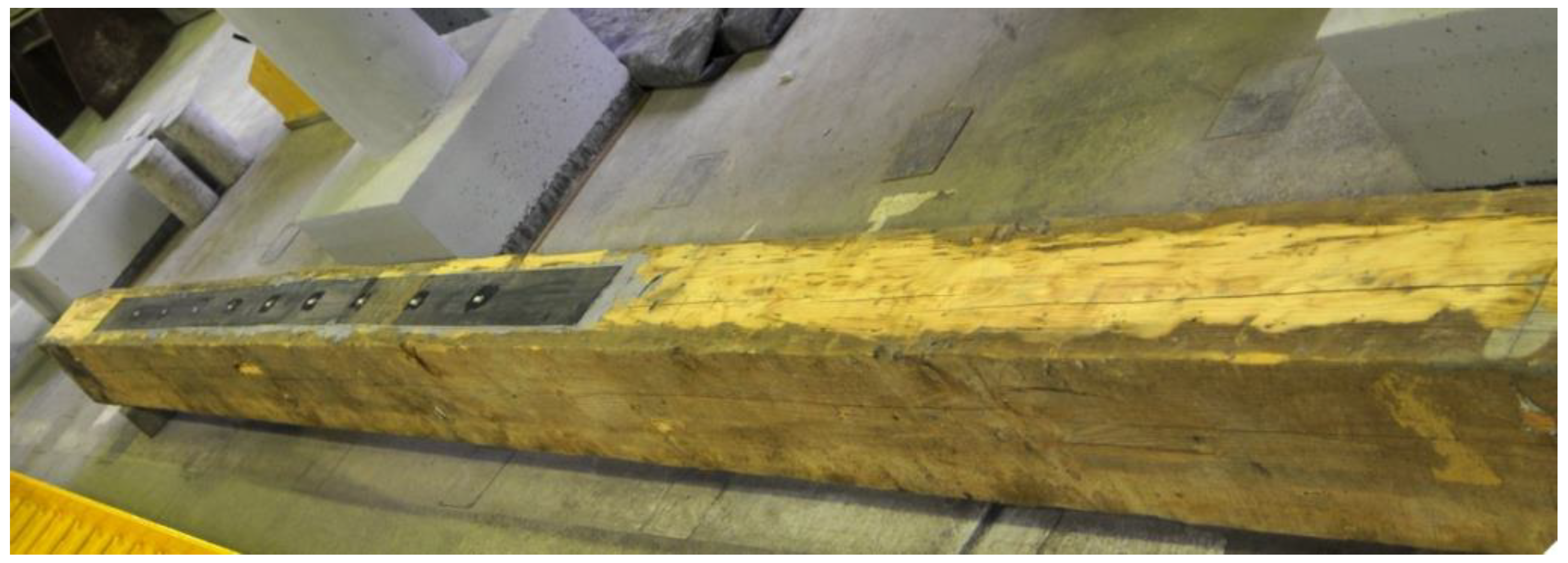

3.1. Research Materials and Research Methodology

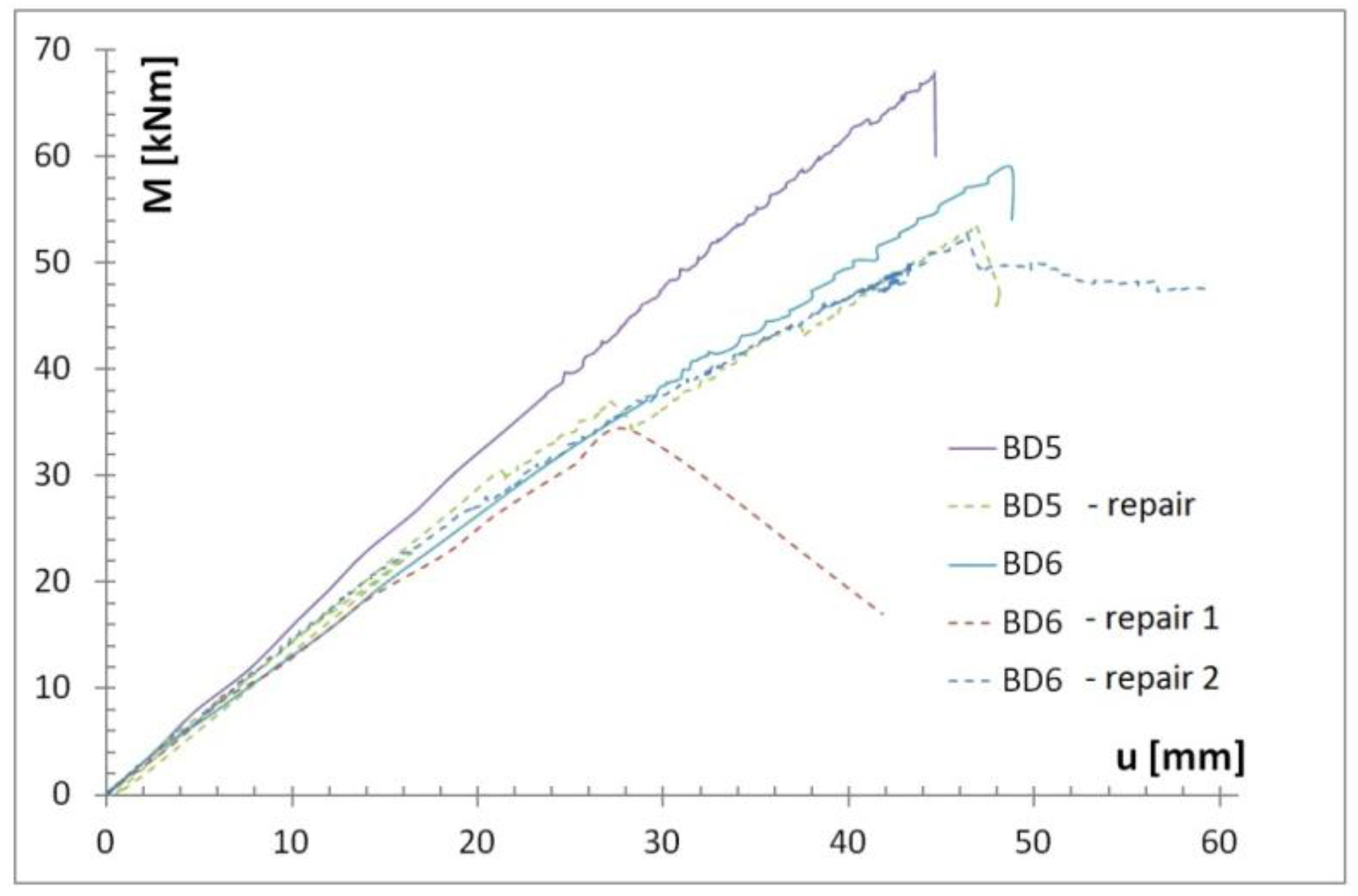

3.2. Test Results for Wooden Beams

4. Conclusions

- Reinforcement of timber structures with the use of fibrous composites is relatively easy to perform, effective and resistant to external factors, which was also shown in [26,27]. These solutions should especially be used where traditional reinforcement is impossible or inappropriate for some reason.

- The reinforcement effectiveness depends on the fibrous composites used, and their quantitative content. Based on [26] and other research conducted by the authors [6,27], it was found that the reinforcement effect is also related to the timber species. The authors’ investigations demonstrated that the effectiveness of larch timber reinforcement is higher than that of pine timber.

- It should be added that reinforcement with carbon-fibre strips or mats does not practically increase the size of the cross-section, and it is easily possible to cover the reinforcing pieces or place them in the cross-section in the case of historic buildings. The use of CFRP to reinforce timber structures, especially along the fibres, also has the advantage of having a comparable coefficient of thermal expansion as timber.

- Some structural and geometric features reduced the bending strength of non-reinforced pieces, especially occurring grain slopes, cracks, decay, etc.

- The knots had a negative impact on the bending strength of the timber. Sapstain did not affect the mechanical properties of non-reinforced and reinforced pieces.

- Static bending strength increased with increasing timber density and parallel fibre system. The highest strength was observed in the case of timber with a fibre course as close as possible to the direction of the sample axis.

- Higher strength values were obtained for pieces with higher shares of heartwood and summer wood present.

- The applied reinforcement positively affected the work of pieces with timber defects, making it possible to obtain higher reinforcement effects, especially in the case of sawn timber of lower classes—KS, KG.

- The damage of pieces during the bending test was mainly due to the folding of the compressed plane and the tearing of the tension plane. In the reinforced pieces, composite mats were torn off during bending strength tests.

- In solid timber pieces of European larch (Larix decidua Mill.) originating from a building built in 1860, the highest average bending load capacity occurred when samples were reinforced with carbon-fibre mats (an increase of about 61% compared to non-reinforced pieces), and the lowest when samples were reinforced with 10-mm GFRP (an increase of 19%).

- Comparing the reinforcement effectiveness of solid timber pieces of the European larch (Larix decidua Mill.) from a building built in 1860, the increase in bending strength of a carbon-fibre mat was 60.66%, that of an aramid-fibre mat was 31.23%, BFRP (10 mm in diameter) was 20.43% and GFRP (10 mm in diameter) was 19.04%.

- Tests performed for the repair of damaged timber beams show that it is possible to restore their original load-bearing capacity using fibrous materials (FRP); however, it should be remembered that timber is a heterogeneous material with defects, and in the case of damage, the damage occurs irregularly. This results in uneven displacements at the adjacent edges of the crack at the next load after the reinforcement, which leads to delamination at the timber/FRP material contact (as observed in the BD6 test—repair 1). It is, therefore, necessary to perform additional anti-laminating ties (as shown in BD6 test—repair 2).

Author Contributions

Funding

Conflicts of Interest

References

- Rudziński, L. Konstrukcje Drewniane. Naprawy, Wzmocnienia, Przykłady Obliczeń; Politechnika Świętokrzyska: Kielce, Poland, 2010. [Google Scholar]

- Brol, J.; Wdowiak, A. The Use of Glass and Aramid Fibres for the Strengthening of Timber Structures; Annals of Warsaw University of Life Sciences, Forestry and Wood Technology: Warsaw, Poland, 2017; pp. 128–138. [Google Scholar]

- Brol, J.; Nowak, T.; Wdowiak, A. Numerical Analysis and Modelling of Timber Elements Strengthened with FRP Materials; Annals of Warsaw University of Life Sciences, Forestry and Wood Technology: Warsaw, Poland, 2018; pp. 274–282. [Google Scholar]

- Wdowiak, A. Assessment of technical condition of wooden structures. Proc. Transcom 2015, 7, 326–332. [Google Scholar]

- Wdowiak, A. Analysis of bent timber beam reinforcement with the application of composite materials. Struct. Environ. 2016, 8, 10–16. [Google Scholar]

- Wdowiak, A. Właściwości Strukturalno-Wytrzymałościowe Zginanych Belek Drewnianych Wzmocnionych Kompozytami Włóknistymi. Ph.D. Thesis, Kielce University of Technology, Kielce, Poland, 2018. [Google Scholar]

- Wdowiak, A.; Brol, J. Effectiveness of Reinforcing Bent Non-Uniform Pre-Stressed Glulam Beams with Basalt Fibre Reinforced Polymers Rods. Materials 2019, 12, 3141. [Google Scholar] [CrossRef] [PubMed]

- Wdowiak, A.; Kroner, A. Wpływ niejednorodności struktury zginanych belek z drewna klejonego na efekt ich wzmocnienia. Mater. Bud. 2017, 1, 87–89. [Google Scholar] [CrossRef]

- Jasieńko, J. Naprawa i wzmacnianie zginanych belek drewnianych. Mater. Bud. 2000, 5, 19–24. [Google Scholar]

- Rajczyk, M.; Jończyk, D. Przegląd metod wzmacniania konstrukcji drewnianych. Zesz. Nauk. Politech. Częstochowskiej Bud. 2011, 17, 146–160. [Google Scholar]

- Triantafillou, T.C. Shear reinforcement of wood using FRP materials. J. Mater. Civ. Eng. ASCE 1997, 9, 65–69. [Google Scholar] [CrossRef]

- Triantafillou, T.C. A new possibility for the shear strengthening of concrete, masonry and wood. Compos. Sci. Technol. 1998, 58, 1285–1295. [Google Scholar] [CrossRef]

- Derkowski, W.; Zych, T. Nowoczesne materiały kompozytowe do wzmacniania konstrukcji budowlanych. Czas. Tech. 2004, 101, 15–25. [Google Scholar]

- Barnes, R.A.; Mays, G.C. Fatigue performance of concrete beams strengthened with CFRP plates. J. Compos. Constr. 1999, 5, 63–72. [Google Scholar] [CrossRef]

- Wilczyński, A.P. Polimerowe Kompozyty Włókniste; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 1996. [Google Scholar]

- Ajdukiewicz, A.; Brol, J.; Malczyk, A.; Właszczuk, M. Rehabilitation of the highest wooden telecommunication tower. In Structures for the Future-the Search for Quality, IABSE Symposium; International Association for Bridge and Structural Engineering: Zurich, Switzerland; Rio de Janeiro, Brazil, 1999; pp. 262–263. [Google Scholar]

- PN-EN 408+A1:2012 Wooden Structures—Structural Solid and Glulam Wood—Designation of Certain Physical and Mechanical Properties; Polish Standards Committee: Warsaw, Poland, 2012.

- PN-D-94021:2013-10 Coniferous Structural Sawn Timber Sorted Using Strength-Based Methods; Polish Standards Committee: Warsaw, Poland, 2013.

- Rudziński, L.; Wdowiak, A. Strength and structural properties of structural timber. Struct. Environ. 2016, 8, 103–108. [Google Scholar]

- Wdowiak, A. Using the visual method to sort Polish pine structural sawn timber with respect to strength. Czas. Tech. 2016, 2-B, 219–224. [Google Scholar]

- Wdowiak, A. Defects in structural timber. Struct. Environ. 2017, 9, 112–122. [Google Scholar]

- Wdowiak, A. Badanie cech strukturalnych i geometrycznych podczas sortowania wytrzymałościowego tarcicy konstrukcyjnej metodą wizualną. Przegląd Bud. 2017, 88, 42–46. [Google Scholar]

- Wdowiak, A. Struktura drewna konstrukcyjnego. J. Civil. Eng. Environ. Archit. 2017, 34, 365–380. [Google Scholar] [CrossRef][Green Version]

- Brol, J.; Dawczyński, S.; Malczyk, A.; Adamczyk, K. Testing timber beams after 130 years of utilization. Structural analysis of historical constructions. In Proceedings of the International Conference on Structural Analysis of Historical Constructions. SAHC 2012, Wrocław, Poland, 15–17 October 2012. [Google Scholar]

- Rapp, P.; Lis, Z. Wzdłużne połączenia belek drewnianych wzmocnione prętami stalowymi. Inżynieria Bud. 2001, 57, 171–173. [Google Scholar]

- Nowak, T. Analiza Pracy Statycznej Zginanych Belek Drewnianych Wzmacnianych Przy Użyciu CFRP. Ph.D. Thesis, Politechnika Wrocławska, Wrocław, Poland, 2007. [Google Scholar]

- Brol, J. Analiza Doświadczalno-Teoretyczna Wzmacniania Konstrukcji Drewnianych Kompozytami Polimerowo-Węglowymi. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 2005. [Google Scholar]

| Symbol | GFRP | BFRP |

|---|---|---|

| E, (GPa) | 55 | 78 |

| εu, (%) | 28 | 39 |

| Symbol | Dimension (mm × mm × mm) | Moisture Content (%) | Sample Details | Density (kg/m3) | Grain (mm) |

|---|---|---|---|---|---|

| SZL1 | 31 × 32 × 597 | 10.2 | KW, deep sapstain, brown discolouration, sound longitudinal through knot (USM = 9/40, USC = 1/10), considerable hardwood, sapwood, early and late wood share | 712.6 | 2.7 |

| WSZLw1, coal-fibre mat, the European larch Larix decidua Mill. originating from a building from 1860. | 33 × 32 × 598 | 9.2 | KW, grain slope (0,3%), hardwood, sapwood, early and late wood share | 704.7 | 3.6 |

| WSZLa8, aramid-fibre mat, the European larch Larix decidua Mill. originating from a building from 1860. | 32 × 33 × 599 | 9.9 | KW, decaying oval knot on the plane, sound oval knot on the plane (USM = 1/5, USC = 1/10), grain slope (0,3%), burls, hardwood, sapwood, early and late wood share | 673.5 | 2.6 |

| SWZLPb13 BFRP 10 mm in diameter, epoxy adhesive (LG385 + HG385), the European larch Larix decidua Mill., originating from a building erected in 1860. | 33 × 33 × 597 | 9.8 | KW, lengthwise decayed through knot—(USM = 1/4, USC = 1/8), grain slope (0,2%), burls, hardwood, sapwood, early and late wood share | 836.8 | 3.5 |

| SWZLPsz16 GFRP 10 mm in diameter, epoxy adhesive (LG385 + HG385), the European larch Larix decidua Mill., originating from a building erected in 1860. | 32 × 31 × 597 | 9.7 | KG, sound lengthwise knot on the reinforced edge, sound oval knot on the plane—(USM = 1/3, USC = 1/4), grain slope (0.3%), heartwood, sapwood, spring early and late summer wood share | 797.0 | 3.7 |

| Sample Symbol | Support Spacing, (m) | Destructive Force, (kN) | The Moment of Destruction, (kNm) | Deflection (mm) |

|---|---|---|---|---|

| SZL1 | 0.54 | 3.94 | 0.71 | 18.3 |

| SZL2 | 0.54 | 3.51 | 0.63 | 21.2 |

| SZL3 | 0.54 | 4.21 | 0.76 | 26.1 |

| SZL4 | 0.54 | 2.26 | 0.41 | 13.2 |

| SZL5 | 0.54 | 3.01 | 0.54 | 15.8 |

| SZL6 | 0.54 | 3.93 | 0.71 | 16.8 |

| SZL7 | 0.54 | 3.92 | 0.71 | 19.2 |

| SZL8 | 0.54 | 2.96 | 0.53 | 18.7 |

| SZL9 | 0.54 | 1.83 | 0.33 | 9.3 |

| SZL10 | 0.54 | 2.18 | 0.39 | 13.4 |

| SZL11 | 0.54 | 3.39 | 0.61 | 20.2 |

| SZL12 | 0.54 | 3.84 | 0.69 | 21.6 |

| SZL13 | 0.54 | 3.59 | 0.65 | 20.8 |

| SZL14 | 0.54 | 3.29 | 0.59 | 18.1 |

| SZL15 | 0.54 | 2.11 | 0.38 | 10.9 |

| Sample Symbol | Support Spacing, (m) | Destructive Force, (kN) | The Moment of Destruction, (kNm) | Deflection (mm) |

|---|---|---|---|---|

| WSZLw1 | 0.54 | 5.47 | 0.99 | 28.8 |

| WSZLw2 | 0.54 | 4.20 | 0.76 | 29.6 |

| WSZLw3 | 0.54 | 6.46 | 1.16 | 28.5 |

| WSZLa7 | 0.54 | 3.87 | 0.70 | 25.9 |

| WSZLa8 | 0.54 | 4.08 | 0.73 | 28.1 |

| WSZLa9 | 0.54 | 4.27 | 0.77 | 26.7 |

| SWZLPb13 | 0.54 | 4.12 | 0.74 | 30.8 |

| SWZLPb14 | 0.54 | 4.66 | 0.84 | 21.7 |

| SWZLPb15 | 0.54 | 3.31 | 0.60 | 42.0 |

| SWZLPsz16 | 0.54 | 3.14 | 0.57 | 23.3 |

| SWZLPsz17 | 0.54 | 3.48 | 0.63 | 20.6 |

| SWZLPsz18 | 0.54 | 4.17 | 0.75 | 19.7 |

| Beam Designation | Average Cross-Sectional Dimension of Beams, (m) | Support Spacing, (m) | Destructive Force, (kN) | The Moment of Destruction, (kNm) | Bending Stress at Damage, (MPa) | Deflection (mm) | |

|---|---|---|---|---|---|---|---|

| Width | Height | ||||||

| BD5 | 0.208 | 0.256 | 4.5 | 89.62 | 67.215 | 29.585 | 44.43 |

| Repair BD5 | 0.208 | 0.256 | 4.5 | 71.40 | 53.55 | 23.570 | 46.75 |

| BD6 | 0.212 | 0.245 | 4.5 | 78.49 | 58.871 | 27.758 | 48.36 |

| BD6 Repair 1 | 0.212 | 0.245 | 4.5 | 45.47 | 34.10 | 16.079 | 28.45 |

| Repair 2 | 0.212 | 0.245 | 4.5 | 71.43 | 53.57 | 25.260 | 48.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brol, J.; Wdowiak-Postulak, A. Old Timber Reinforcement with FRPs. Materials 2019, 12, 4197. https://doi.org/10.3390/ma12244197

Brol J, Wdowiak-Postulak A. Old Timber Reinforcement with FRPs. Materials. 2019; 12(24):4197. https://doi.org/10.3390/ma12244197

Chicago/Turabian StyleBrol, Janusz, and Agnieszka Wdowiak-Postulak. 2019. "Old Timber Reinforcement with FRPs" Materials 12, no. 24: 4197. https://doi.org/10.3390/ma12244197

APA StyleBrol, J., & Wdowiak-Postulak, A. (2019). Old Timber Reinforcement with FRPs. Materials, 12(24), 4197. https://doi.org/10.3390/ma12244197