Constitutive Model and Cutting Simulation of Titanium Alloy Ti6Al4V after Heat Treatment

Abstract

:1. Introduction

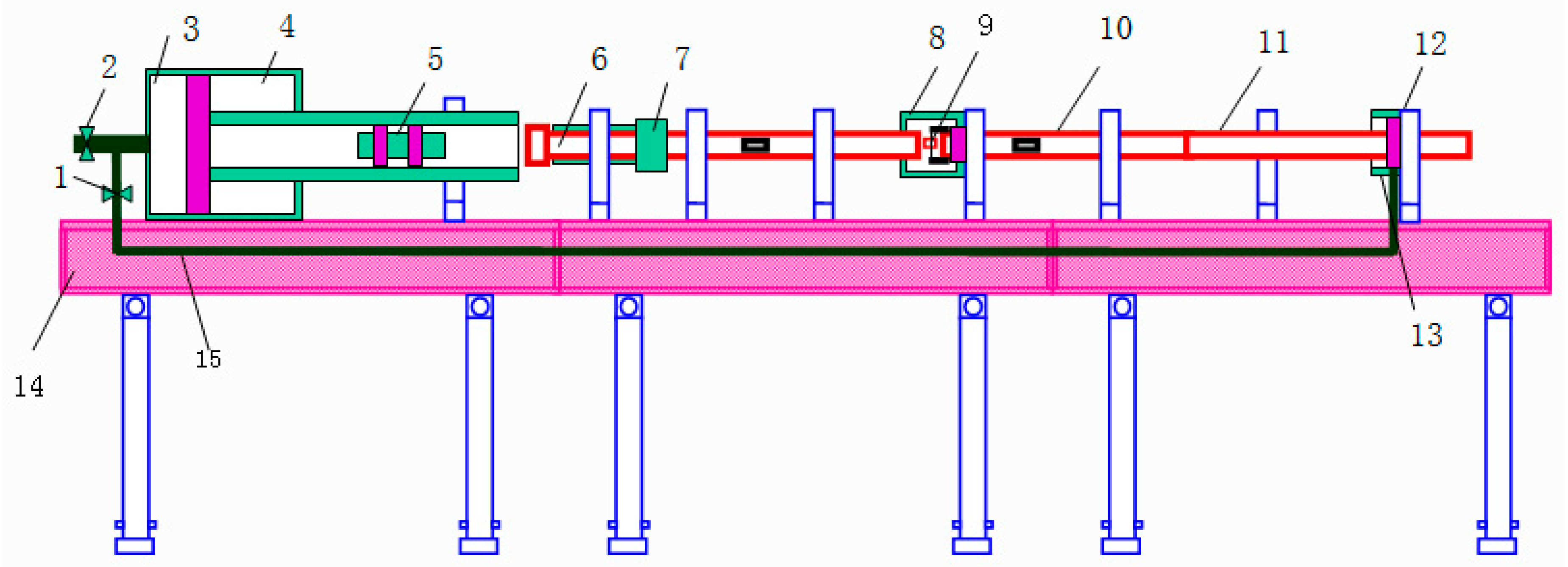

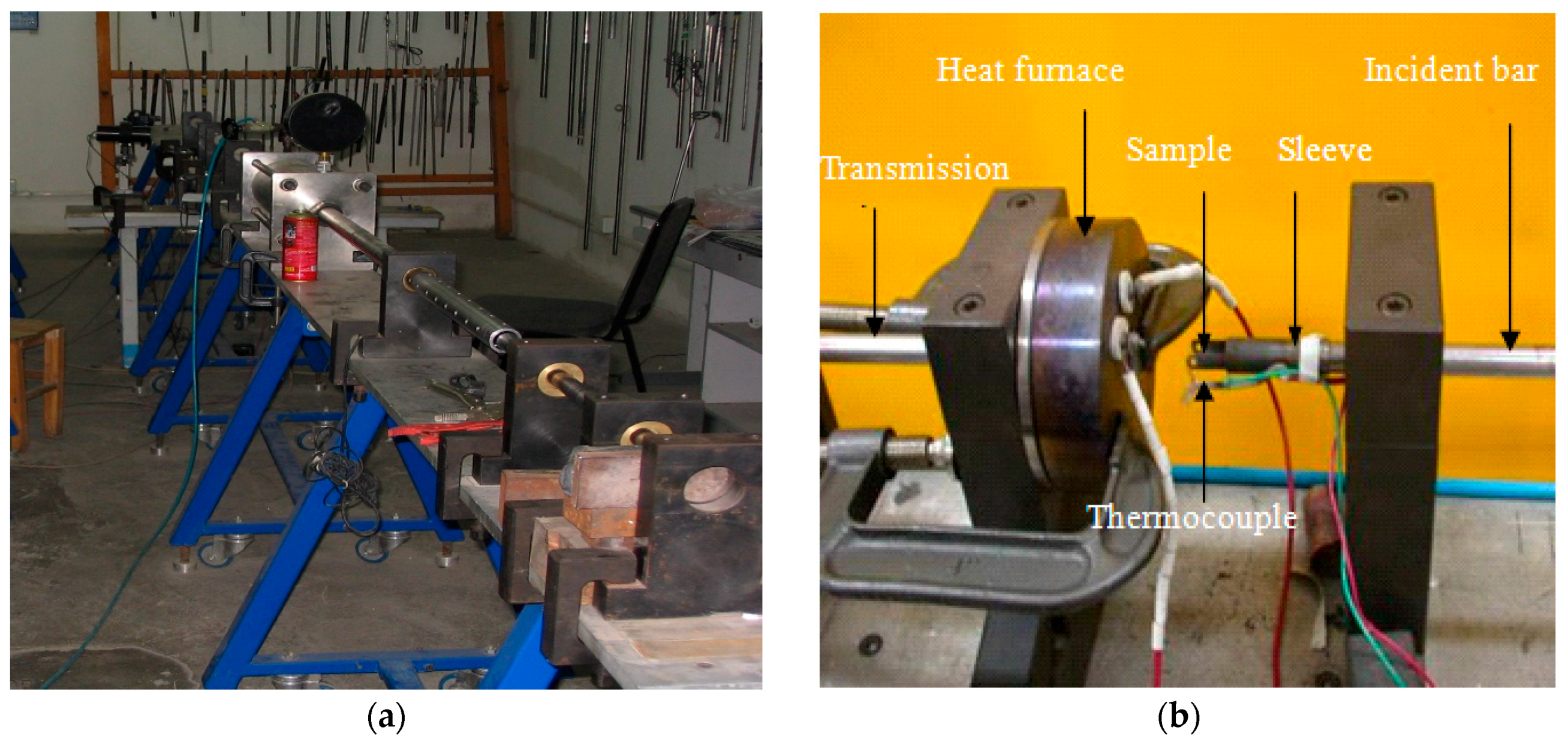

2. Materials and Methods

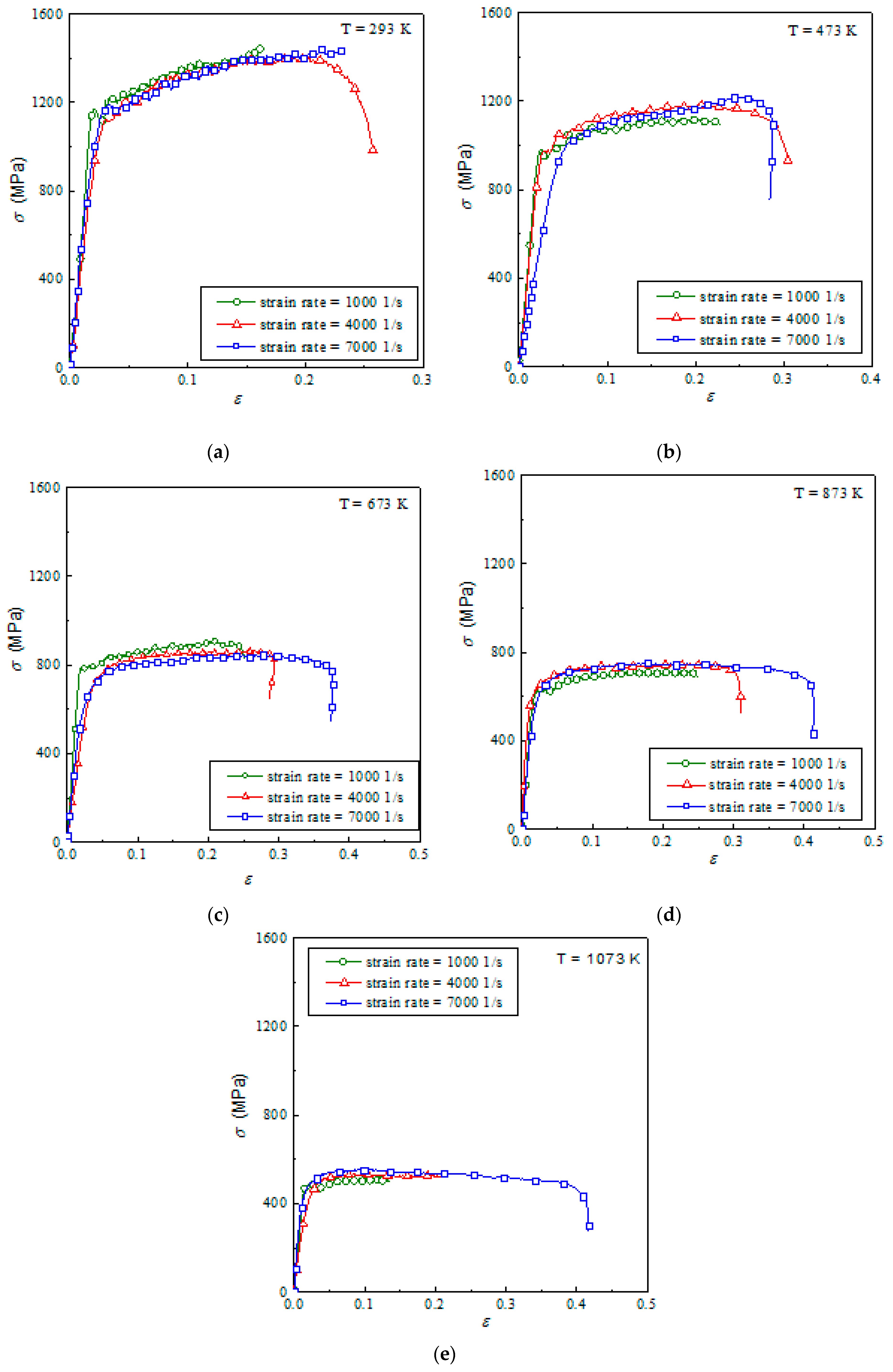

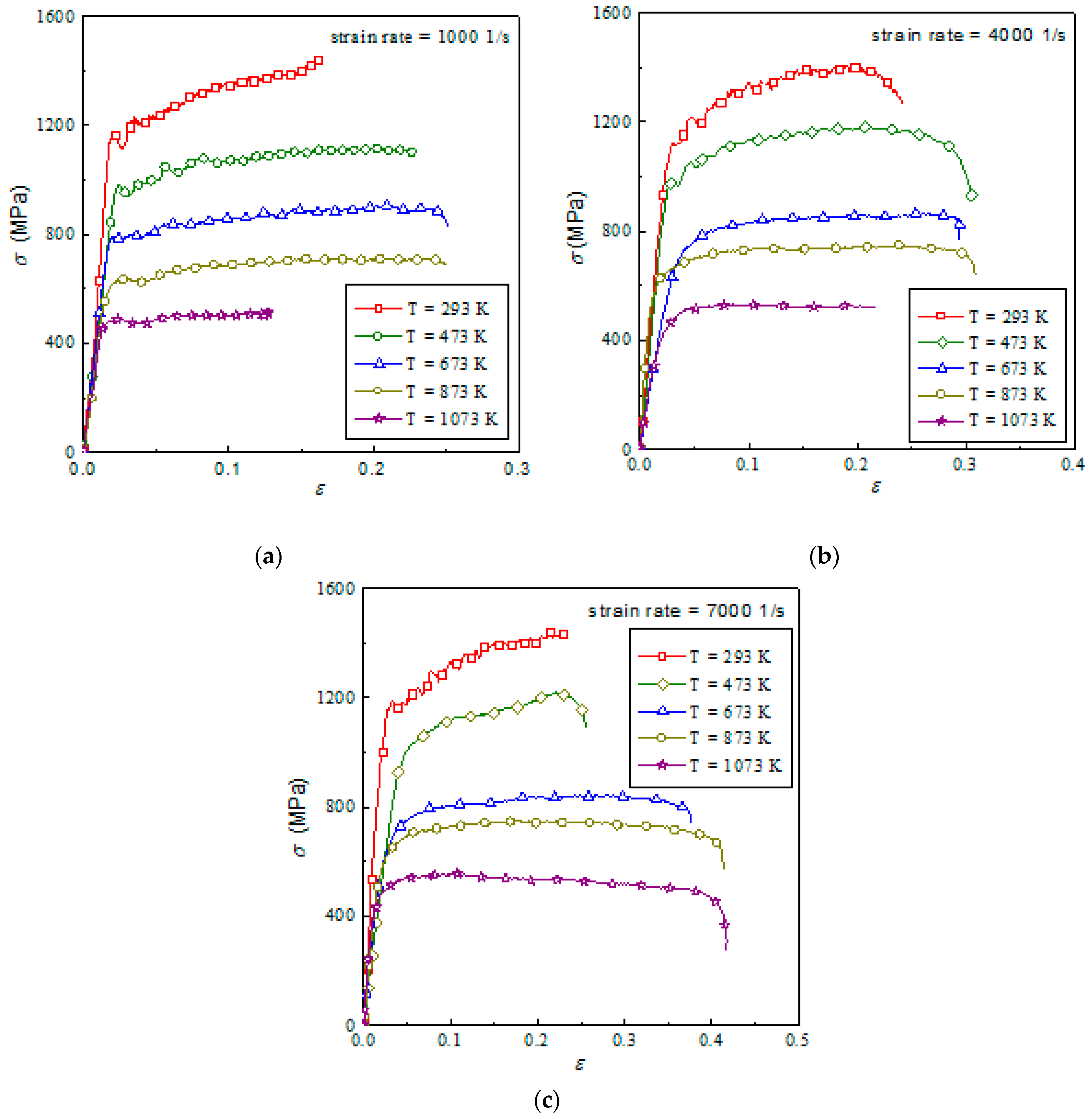

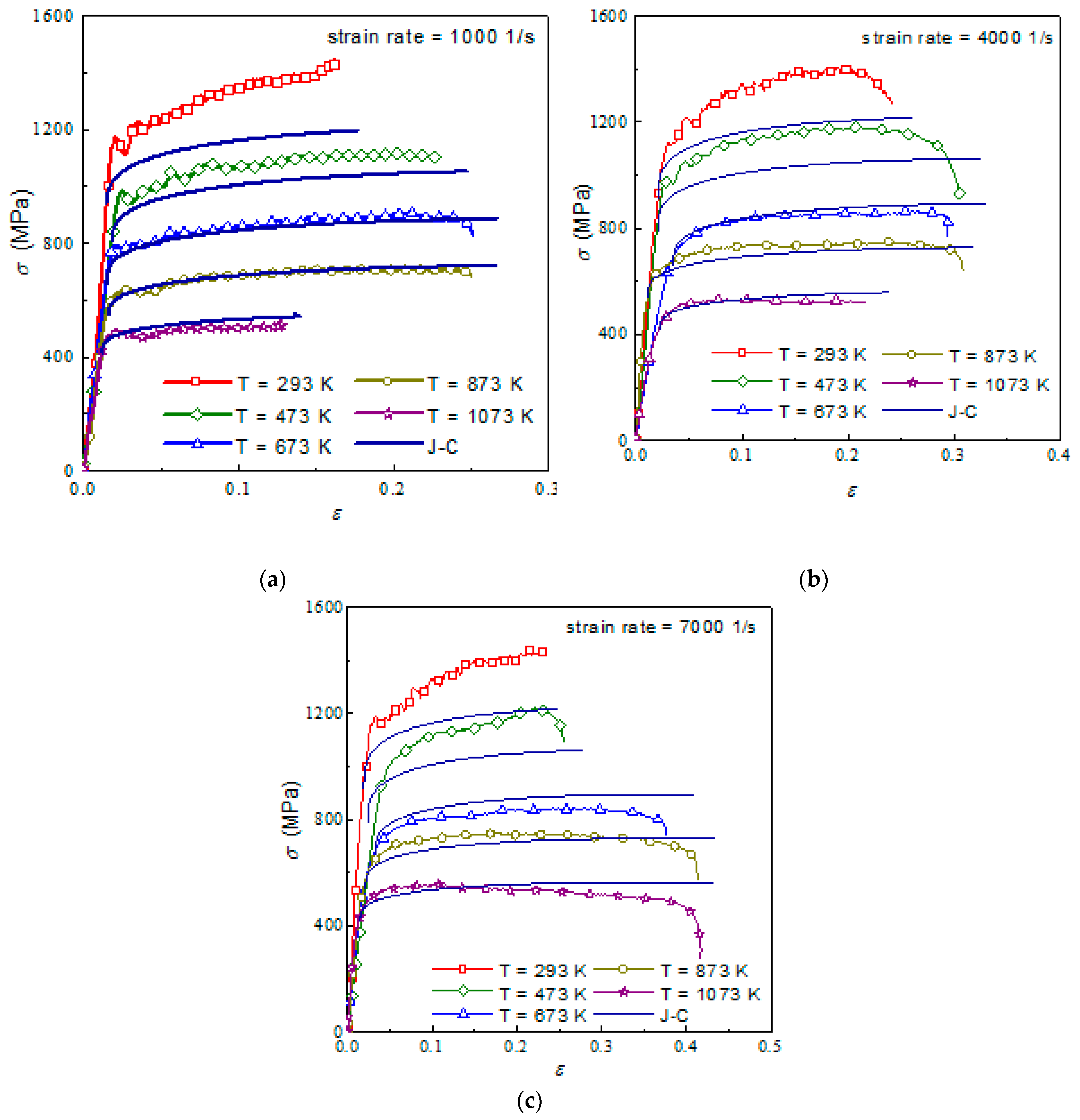

3. Stress–Strain Curves Obtained by Hopkinson Press Bar

4. Material Model

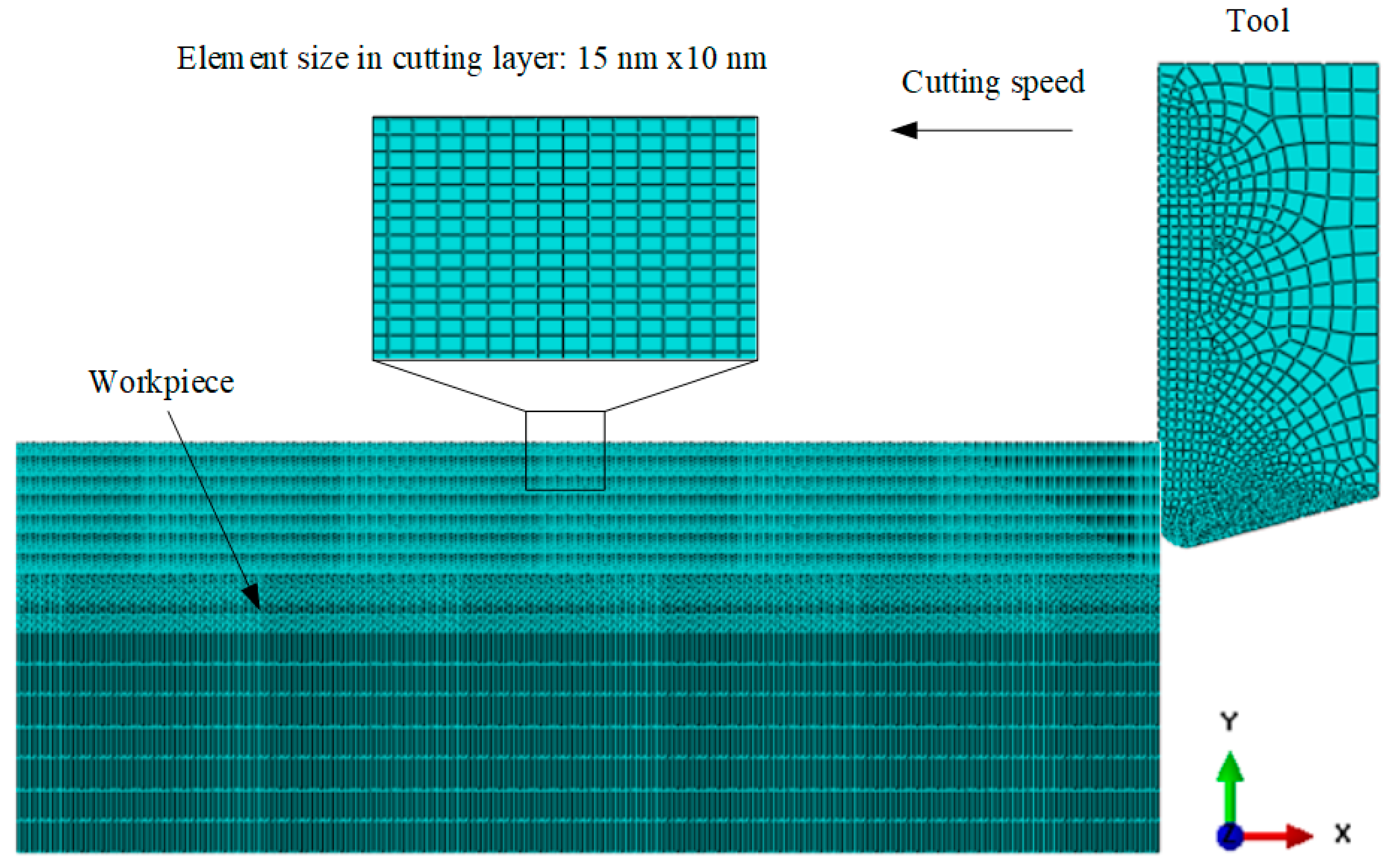

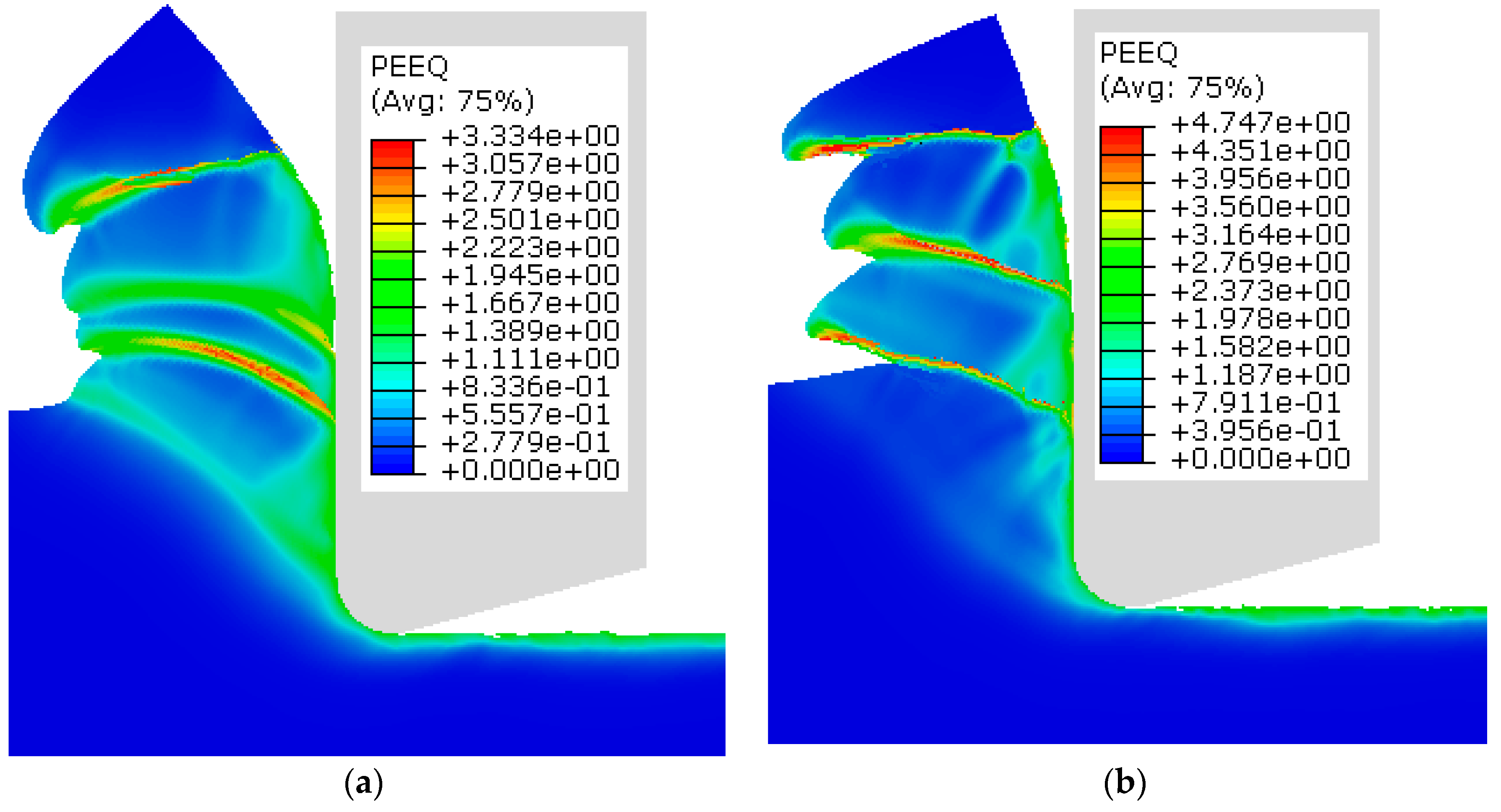

5. Cutting Simulation of Ti6Al4v Alloy

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Brewer, W.D.; Keith, B.R.; Wallace, T.A. Titanium alloys and processing for high speed aircraft. Mater. Sci. Eng. A 1998, 243, 299–304. [Google Scholar] [CrossRef] [Green Version]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, K.; Ziaja, W.; Sieniawski, J. The effect of microstructure on the mechanical properties of two-phase titanium alloys. J. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Matviychuk, Y.V.; Semiatin, S.L.; Ward, C.H.; Fox, S. A comparative study of the mechanical properties of high-strength β-titanium alloys. J. Alloy Compd. 2008, 457, 0–309. [Google Scholar] [CrossRef]

- Guo, P.; Zhao, Y.; Zeng, W.; Hong, Q. The effect of microstructure on the mechanical properties of TC4-DT titanium alloys. Mater. Sci. Eng. A 2013, 563, 106–111. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Mironov, S.; Murzinova, M.A.; Salishchev, S.; Semiatin, S.L. Mechanical behaviour and microstructure evolution of severely deformed two-phase titanium alloys. Mater. Sci. Forum Sci. 2008, 584, 771–776. [Google Scholar] [CrossRef]

- Dehghanmanshadi, A.; Reid, M.H.; Dippenaar, R.J. Effect of microstructural morphology on the mechanical properties of titanium alloys. J. Phys. Conf. Ser. 2010, 240, 012022. [Google Scholar] [CrossRef]

- Laheurte, P.; Prima, F.; Eberhardt, A.; Gloriant, T.; Wary, M.; Patoor, E. Mechanical properties of low modulus beta titanium alloys designed from the electronic approach. J. Mech. Behav. Biomed. Mater. 2010, 3, 565–573. [Google Scholar] [CrossRef]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Lee, W.S.; Lin, C.F. Impact properties and microstructure evolution of 304L stainless steel. Mater. Sci. Eng. A 2001, 308, 124–135. [Google Scholar] [CrossRef]

- Wu, H.B.; To, S. Serrated chip formation and their adiabatic analysis by using the constitutive model of titanium alloy in high speed cutting. J. Alloy Compd. 2015, 629, 368–373. [Google Scholar] [CrossRef]

- Chen, W.; Song, B.; Frew, D.J.; Forrestal, M.J. Dynamic small strain measurements of a metal specimen with a split Hopkinson pressure bar. Exp. Mech. 2003, 43, 20–23. [Google Scholar] [CrossRef]

- Kajberg, J.; Sundin, K.G. Material characterisation using high-temperature Split Hopkinson pressure bar. J. Mater. Process. Technol. 2013, 213, 522–531. [Google Scholar] [CrossRef]

- Hall, I.W.; Guden, M. Split Hopkinson pressure bar compression testing of an aluminum alloy: Effect of lubricant type. J. Mater. Sci. Lett. 2003, 22, 1533–1535. [Google Scholar] [CrossRef] [Green Version]

- Mylonas, G.I.; Labeas, G.N. Mechanical characterisation of aluminium alloy 7449-T7651 at high strain rates and elevated temperatures using Split Hopkinson bar testing. Exp. Tech. 2014, 38, 26–34. [Google Scholar] [CrossRef]

- Taşdemirci, A.; Ergönenç, C.; Güden, M. Split Hopkinson pressure bar multiple reloading and modeling of a 316 L stainless steel metallic hollow sphere structure. Int. J. Impact Eng. 2010, 37, 250–259. [Google Scholar] [CrossRef] [Green Version]

- Zou, D.L.; Luan, B.F.; Liu, Q.; Chai, L.J.; Chen, J.W. Formation and evolution of adiabatic shear bands in zirconium alloy impacted by split Hopkinson pressure bar. J. Nucl. Mater. 2013, 437, 380–388. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Isaacs, J.B. Direct measurement of isothermal flow stress of metals at elevated temperatures and high strain rates with application to Ta and Ta–W alloys. Acta Mater. 1997, 45, 907–919. [Google Scholar] [CrossRef]

- Xu, Y.B.; Zhong, W.L.; Chen, Y.J.; Shen, L.T.; Liu, Q.; Bai, Y.L.; Meyers, M.A. Shear localization and recrystallization in dynamic deformation of 8090 Al–Li alloy. Mater. Sci. Eng. A 2001, 299, 287–295. [Google Scholar] [CrossRef]

- Seo, S.; Min, O.; Yang, H. Constitutive equation for Ti-6Al-4V at high temperatures measured using the SHPB technique. Int. J. Impact Eng. 2005, 31, 735–754. [Google Scholar] [CrossRef]

- Sasso, M.; Newaz, G.; Amodio, D. Material characterization at high strain rate by Hopkinson bar tests and finite element optimization. Mater. Sci. Eng. A 2008, 487, 289–300. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of Constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the Seventh International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; Volume 54, pp. 1–7. [Google Scholar]

- Wu, H.B.; Zhang, S.J. Effects of cutting conditions on the milling process of titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2015, 77, 2235–2240. [Google Scholar] [CrossRef]

- Umbrello, D.; M’Saoubi, R.; Outeiro, J.C. The influence of Johnson–Cook material constants on finite element simulation of machining of AISI 316L steel. Int. J. Mach. Tools Manuf. 2007, 47, 462–470. [Google Scholar] [CrossRef]

- Shrot, A.; BaKer, M. Determination of Johnson—Cook parameters from machining simulations. Comput. Mater. Sci. 2012, 52, 298–304. [Google Scholar] [CrossRef]

- Ducobu, F.; Rivière-Lorphèvre, E.; Filippi, E. On the importance of the choice of the parameters of the Johnson-Cook constitutive model and their influence on the results of a Ti6Al4V orthogonal cutting model. Int. J. Mech. Sci. 2017, 122, 143–155. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Barbero, O.; Urresti, I. Influence of material parameters on serrated chip prediction in finite element modeling of chip formation process. Int. J. Mater. Form. 2010, 3 (Suppl. 1), 519–522. [Google Scholar] [CrossRef]

- Park, K.B.; Cho, Y.T.; Jung, Y.G. Determination of Johnson-Cook constitutive equation for Inconel 601. J. Mech. Sci. Tech. 2018, 32, 1569–1574. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validations in machining of titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Meyer, H.W.J.; Kleponis, D.S. An analysis of parameters for the Johnson-Cook model for 2-inch thick rolled homogeneous armor. In Proceedings of the 1998 Advanced Simulation Technologies Conference on Military, Government and Aerospace Simulation, Simulation Series, Boston, MA, USA, 5–9 April 1998; Volume 30, number 4. pp. 12–17. [Google Scholar]

- Wu, H.B.; Guo, L. Machinability of titanium alloy TC21 under orthogonal turning process. Adv. Manuf. Process. 2014, 29, 1441–1445. [Google Scholar] [CrossRef]

- Bammann, D.J.; Chiesa, M.L.; Johnson, G.C. Modeling large deformation and failure in manufacturing processes. Theor. Appl. Mech. 1996, 9, 359–376. [Google Scholar]

- Schulze, V.; Zanger, F. Numerical Analysis of the influence of Johnson-Cook-material parameters on the surface integrity of Ti-6Al-4V. Procedia Eng. 2011, 19, 306–311. [Google Scholar] [CrossRef] [Green Version]

- Lee, O.S.; Choi, H.B.; Kim, H.M. High-temperature dynamic deformation of aluminum alloys using SHPB. J. Mech. Sci. Tech. 2011, 25, 143–148. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, J.; Li, J.; Yan, Y.; Wang, P. A comparative study on Johnson-Cook and modified Johnson-Cook constitutive material model to predict the dynamic behavior laser additive manufacturing FeCr alloy. J. Alloy Compd. 2017, 723, 179–187. [Google Scholar] [CrossRef]

- Wu, H.B.; Zhang, S.J. 3D FEM simulation of milling process for titanium alloy Ti6Al4V. Inter. J. Adv. Manuf. Technol. 2014, 71, 1319–1326. [Google Scholar] [CrossRef]

- Fowles, R. Plane stress wave propagation in solids. J. Appl. Phys. 1970, 41, 360. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Hardness (HRC) | 30.6 |

| Density (kg/m3) | 4450 |

| Elastic Modulus (GPa) | 112.5 |

| Yield Strength (MPa) | 773.9 |

| Heat Conductivity (W/mk) | 3.85 |

| Linear Thermal Expansion (10−6/°C) | 6.5 |

| Parameters | Values |

|---|---|

| Temperature | 293 K, 473 K, 673 K, 873 K, and 1073 K |

| Strain rate | 1000 1/s, 4000 1/s, and 7000 1/s |

| A (MPa) | B (MPa) | n | C | M |

|---|---|---|---|---|

| 874 | 583 | 0.316 | 0.003 | 0.95 |

| Parameters | Values |

|---|---|

| Depth of cut (mm) | 0.2 |

| Cutting speed (m/min) | 60 |

| Insert material | Carbide |

| Rake angle (o) | 0 |

| Clearance angle (o) | 15 |

| Radius of tool tip | 0.05 mm |

| Cutting environment | Dry cutting |

| Chip Pitch (µm) | Primary Cutting Force (N) | |

|---|---|---|

| T-D | 35 | 187 |

| AD | 26 | 175 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, X.; Duan, X. Constitutive Model and Cutting Simulation of Titanium Alloy Ti6Al4V after Heat Treatment. Materials 2019, 12, 4145. https://doi.org/10.3390/ma12244145

Qian X, Duan X. Constitutive Model and Cutting Simulation of Titanium Alloy Ti6Al4V after Heat Treatment. Materials. 2019; 12(24):4145. https://doi.org/10.3390/ma12244145

Chicago/Turabian StyleQian, Xiaohua, and Xiongying Duan. 2019. "Constitutive Model and Cutting Simulation of Titanium Alloy Ti6Al4V after Heat Treatment" Materials 12, no. 24: 4145. https://doi.org/10.3390/ma12244145

APA StyleQian, X., & Duan, X. (2019). Constitutive Model and Cutting Simulation of Titanium Alloy Ti6Al4V after Heat Treatment. Materials, 12(24), 4145. https://doi.org/10.3390/ma12244145