Investigation of AlGaN/GaN Heterostructures Grown on Sputtered AlN Templates with Different Nucleation Layers

Abstract

1. Introduction

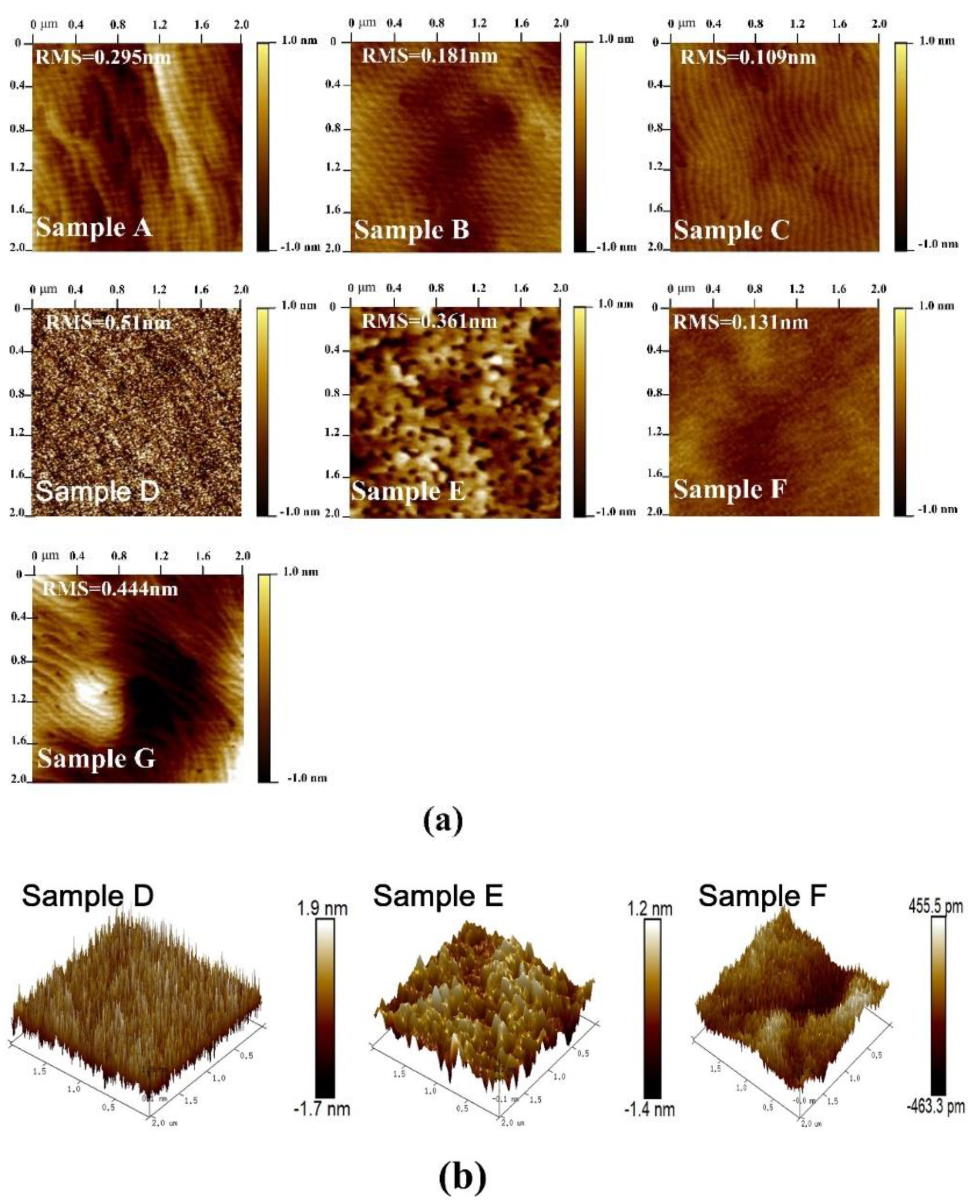

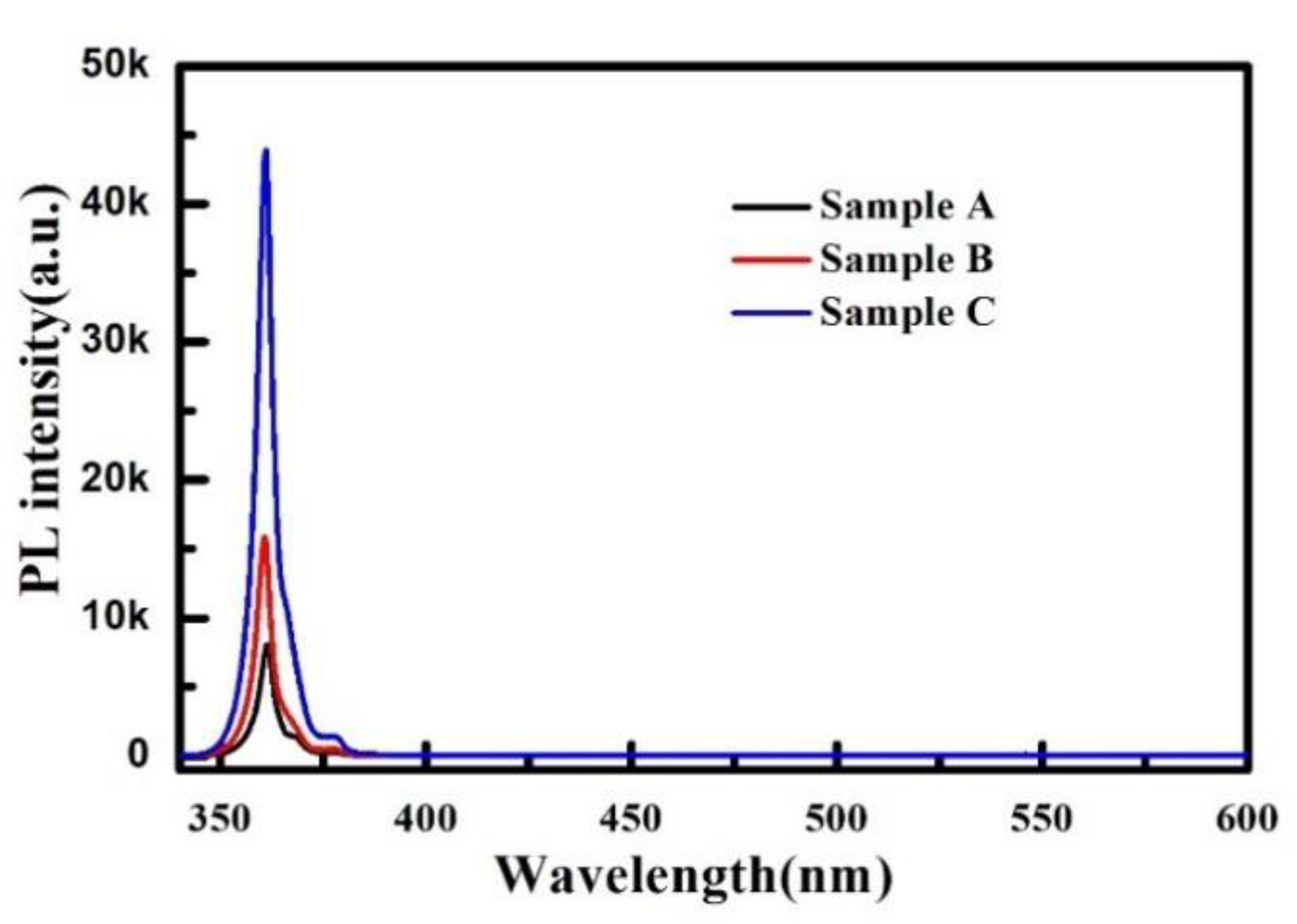

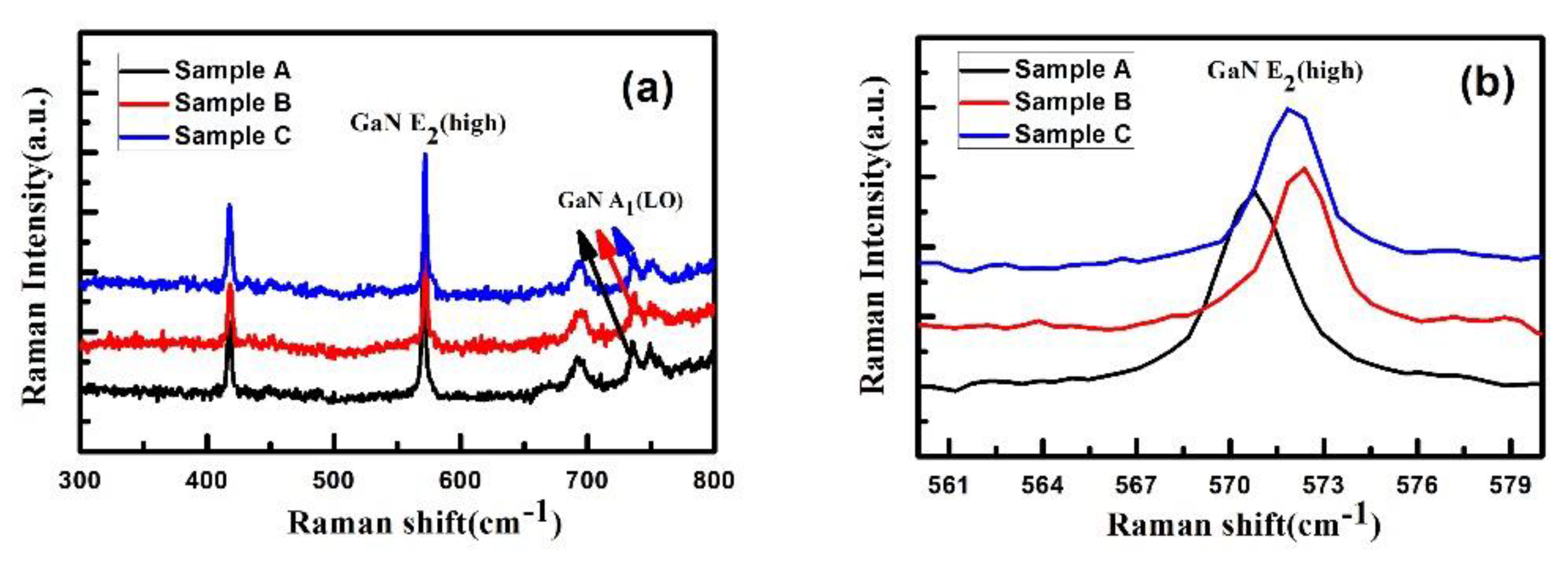

2. Experimental Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barletta, P.T.; Berkman, E.A.; Moody, B.F.; El-Masry, N.A.; Emara, A.M.; Reed, M.J.; Bedair, S.M. Development of green, yellow, and amber light emitting diodes using InGaN multiple quantum well structures. Appl. Phys. Lett. 2007, 90, 151109. [Google Scholar] [CrossRef]

- Cai, Y.F.; Zhu, C.Q.; Jiu, L.; Gong, Y.P.; Yu, X.; Bai, J.; Esendag, V.; Wang, T. Strain Analysis of GaN HEMTs on (111) Silicon Two Transitional AlxGa1-xN Layers. Materials 2018, 11, 1968. [Google Scholar] [CrossRef] [PubMed]

- Kashima, Y.; Maeda, N.; Matsuura, E.; Jo, M.; Iwai, T.; Morita, T.; Kokubo, M.; Tashiro, T.; Kamimura, R.; Osada, Y.; et al. High external quantum efficiency (10%) AlGaN-based deep-ultraviolet light-emitting diodes achieved by using highly reflective photonic crystal on p-AlGaN contact layer. Appl. Phys. Express 2018, 11, 012101. [Google Scholar] [CrossRef]

- Martínez, P.J.; Maset, E.; Martín-Holgado, P.; Morilla, Y.; Gilabert, D.; Sanchis-Kilders, E. Impact of Gamma Radiation on Dynamic RDSON Characteristics in AlGaN/GaN Power HEMTs. Materials 2019, 12, 2760. [Google Scholar] [CrossRef]

- Roccaforte, F.; Greco, G.; Fiorenza, P.; Iucolano, F. An Overview of Normally-Off GaN-Based High Electron Mobility Transistors. Materials 2019, 12, 1599. [Google Scholar] [CrossRef]

- Tao, H.C.; Xu, S.R.; Zhang, J.C.; Li, P.X.; Lin, Z.Y.; Hao, Y. Numerical Investigation on the Enhanced Performance of N-Polar AlGaN-Based Ultraviolet Light-Emitting Diodes with Superlattice p-Type Doping. IEEE Trans. Electron Devices 2019, 66, 478–484. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Schaff, W.J.; Eastman, L.F.; Dimitrov, R.; Wittmer, L.; et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N- and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Guo, R.; Xu, S.R.; Zhang, J.C.; Zhao, S.L.; Wang, H.Y.; Hu, Q.; Zhang, C.F.; Hao, Y. High-performance high electron mobility transistors with GaN/InGaN composite channel and superlattice back barrier. Appl. Phys. Lett. 2019, 115, 072105. [Google Scholar] [CrossRef]

- Chung, J.W.; Hoke, W.E.; Chumbes, E.M.; Palacios, T. AlGaN/GaN HEMT with 300-GHz fmax. IEEE Electron Device Lett. 2010, 31, 195–197. [Google Scholar] [CrossRef]

- Wu, Y.F.; Saxler, A.; Moore, M.; Smith, R.P.; Sheppard, S.; Chavarkar, P.M.; Wisleder, T.; Mishra, U.K.; Parikh, P. 30-W/mm GaN HEMTs by Field Plate Optimization. IEEE Electron Device Lett. 2004, 25, 117–119. [Google Scholar] [CrossRef]

- Chen, Z.B.; Zhang, J.C.; Xu, S.R.; Xue, J.S.; Jiang, T.; Hao, Y. Influence of stacking faults on the quality of GaN films grown on sapphire substrate using a sputtered AlN nucleation layer. Mater. Res. Bull. 2017, 89, 193–196. [Google Scholar] [CrossRef]

- Chen, Y.A.; Kuo, C.H.; Wu, J.P.; Chang, C.W. Interruption-free growth of 10 μ m-thick GaN film prepared on sputtered AlN/PSS template by hydride vapor phase epitaxy. J. Cryst. Growth 2015, 426, 180–185. [Google Scholar] [CrossRef]

- He, C.G.; Zhao, W.; Zhang, K.; He, L.F.; Wu, H.L.; Liu, N.Y.; Zhang, S.; Liu, X.Y.; Chen, Z.T. High-Quality GaN Epilayers Achieved by Facet-Controlled Epitaxial Lateral Overgrowth on Sputtered AlN/PSS Templates. ACS Appl. Mater. Interfaces 2017, 9, 43386–43392. [Google Scholar] [CrossRef] [PubMed]

- Yen, C.H.; Lai, W.C.; Yang, Y.Y.; Wang, C.K.; Ko, T.K.; Hon, S.J.; Chang, S.J. GaN Based Light-Emitting Diode With Sputtered AlN Nucleation Layer. IEEE Photonics Technol. Lett. 2012, 24, 294–296. [Google Scholar] [CrossRef]

- Lai, W.C.; Yen, C.H.; Yang, Y.Y.; Wang, C.K.; Chang, S.J. GaN-Based Ultraviolet Light Emitting Diodes With Ex Situ Sputtered AlN Nucleation Layer. J. Display Technol. 2013, 9, 895. [Google Scholar] [CrossRef]

- Pan, L.; Dong, X.; Li, Z.H.; Luo, W.K.; Ni, J.Y. Influence of the AlN nucleation layer on the properties of AlGaN/GaN heterostructure on Si (111) substrates. Appl. Surf. Sci. 2018, 447, 512–517. [Google Scholar] [CrossRef]

- Hu, H.P.; Zhou, S.J.; Liu, X.T.; Gao, Y.L.; Gui, C.Q.; Liu, S. Effects of GaN/AlGaN/Sputtered AlN nucleation layers on performance of GaN-based ultraviolet light-emitting diodes. Sci. Rep. 2017, 7, 44627. [Google Scholar] [CrossRef]

- Yu, H.P.; Caliskan, D.; Ozbay, E. Growth of high crystalline quality semi-insulating GaN layers for high electron mobility transistor applications. J. Appl. Phys. 2006, 100, 033501. [Google Scholar] [CrossRef]

- Lee, S.R.; West, A.M.; Allerman, A.A.; Waldrip, K.E.; Follstaedt, D.M.; Provencio, P.P.; Koleske, D.D.; Abernathy, C.R. Effect of threading dislocations on the Bragg peakwidths of GaN, AlGaN, and AlN heterolayers. Appl. Phys. Lett. 2005, 86, 241904. [Google Scholar] [CrossRef]

- Heinke, H.; Kirchner, V.; Einfeldt, S.; Hommel, D. X-ray diffraction analysis of the defect structure in epitaxial GaN. Appl. Phys. Lett. 2000, 77, 2145–2147. [Google Scholar] [CrossRef]

- Simpkins, B.S.; Yu, E.T.; Waltereit, P.; Speck, J.S. Correlated scanning Kelvin probe and conductive atomic force microscopy studies of dislocations in gallium nitride. J. Appl. Phys. 2003, 94, 1448–1453. [Google Scholar] [CrossRef]

- Zhao, D.G.; Yang, H.; Zhu, J.J.; Jiang, D.S.; Liu, Z.S.; Zhang, S.M.; Wang, Y.T.; Liang, J.W. Effects of edge dislocations and intentional Si doping on the electron mobility of n-type GaN films. Appl. Phys. Lett. 2006, 89, 112106. [Google Scholar] [CrossRef]

- Rosner, S.J.; Carr, E.C.; Ludowise, M.J.; Girolami, G.; Erikson, H.I. Correlation of cathodoluminescence inhomogeneity with microstructural defects in epitaxial GaN grown by metalorganic chemical-vapor deposition. Appl. Phys. Lett. 1997, 70, 420. [Google Scholar] [CrossRef]

- Fischer, A.; Kiihne, H.; Richter, H. New Approach in Equilibrium Theory for Strained Layer Relaxation. Phys. Rev. Lett. 1994, 73, 2172–2175. [Google Scholar] [CrossRef] [PubMed]

- Kisielowski, C.; Kruger, J.; Ruvimov, S.; Suski, T.; Ager, J.W., III; Jones, E.; Liliental-Weber, Z.; Rubin, M.; Weber, E.R. Strain-related phenomena in GaN thin films. Phys. Rev. B 1996, 54, 17745. [Google Scholar] [CrossRef] [PubMed]

- Tripathy, S.; Chua, S.J.; Chen, P.; Miao, Z.L. Micro-Raman investigation of strain in GaN and AlxGa1-xN/GaN heterostructures grown on Si (111). J. Appl. Phys. 2002, 92, 3503–3510. [Google Scholar] [CrossRef]

- Nakamura, S. GaN Growth Using GaN Buffer Layer. Jpn. J. Appl. Phys. 1991, 30, L1705–L1707. [Google Scholar] [CrossRef]

- Amano, H.; Sawaki, N.; Akasaki, I.; Toyoda, Y. Metalorganic vapor phase epitaxial growth of a high quality GaN film using an AlN buffer layer. Appl. Phys. Lett. 1986, 48, 353–355. [Google Scholar] [CrossRef]

| Sample | Sputtered AlN | LT AlN | HT AlN | GaN Buffer | AlN Interlayer | AlGaN Barrier | GaN Cap |

|---|---|---|---|---|---|---|---|

| #A | 25 nm | × | × | 1.6 μm | 1 nm | 25 nm | 1 nm |

| 650 °C | 1080 °C | 1080 °C | 1080 °C | 1080 °C | |||

| #B | 25 nm | × | 160 nm | 1.6 μm | 1 nm | 25 nm | 1 nm |

| 650 °C | 1200 °C | 1080 °C | 1080 °C | 1080 °C | 1080 °C | ||

| #C | 25 nm | 40 nm | 160 nm | 1.6 μm | 1 nm | 25 nm | 1 nm |

| 650 °C | 900 °C | 1200 °C | 1080 °C | 1080 °C | 1080 °C | 1080 °C | |

| #D | 25 nm | × | × | × | × | × | × |

| 650 °C | |||||||

| #E | 25 nm | × | 160 nm | × | × | × | × |

| 650 °C | 1200 °C | ||||||

| #F | 25 nm | 40 nm | 160 nm | × | × | × | × |

| 650 °C | 900 °C | 1200 °C | |||||

| #G | × | 40 nm | 160 nm | 1.6 μm | 1 nm | 25 nm | 1 nm |

| 900 °C | 1200 °C | 1080 °C | 1080 °C | 1080 °C | 1080 °C |

| Sample | A | B | C |

|---|---|---|---|

| MOCVD AlN NL | without | HT | LT and HT |

| 1.97 × 107 | 4.69 × 107 | 3.13 × 107 | |

| 2.42 × 109 | 7.14 × 108 | 6.02 × 108 | |

| 2.44 × 109 | 7.61 × 108 | 6.33 × 108 |

| Sample | A | B | C | G |

|---|---|---|---|---|

| MOCVD AlN NL | without | HT | LT and HT | LT and HT without sputtered AlN |

| Sheet resistance (Ω/sq) | 383.27 | 330.95 | 329.67 | 450.40 |

| 2DEG Mobility (cm2/V·s) | 1901.97 | 1987.44 | 2050.70 | 1775.97 |

| 2DEG density (cm−2) | 8.56 × 1012 | 9.49 × 1012 | 9.23 × 1012 | 7.80 × 1012 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.-Y.; Zhang, Y.-C.; Xu, S.-R.; Jiang, L.; Zhang, J.-C.; Hao, Y. Investigation of AlGaN/GaN Heterostructures Grown on Sputtered AlN Templates with Different Nucleation Layers. Materials 2019, 12, 4050. https://doi.org/10.3390/ma12244050

Liu C-Y, Zhang Y-C, Xu S-R, Jiang L, Zhang J-C, Hao Y. Investigation of AlGaN/GaN Heterostructures Grown on Sputtered AlN Templates with Different Nucleation Layers. Materials. 2019; 12(24):4050. https://doi.org/10.3390/ma12244050

Chicago/Turabian StyleLiu, Chuan-Yang, Ya-Chao Zhang, Sheng-Rui Xu, Li Jiang, Jin-Cheng Zhang, and Yue Hao. 2019. "Investigation of AlGaN/GaN Heterostructures Grown on Sputtered AlN Templates with Different Nucleation Layers" Materials 12, no. 24: 4050. https://doi.org/10.3390/ma12244050

APA StyleLiu, C.-Y., Zhang, Y.-C., Xu, S.-R., Jiang, L., Zhang, J.-C., & Hao, Y. (2019). Investigation of AlGaN/GaN Heterostructures Grown on Sputtered AlN Templates with Different Nucleation Layers. Materials, 12(24), 4050. https://doi.org/10.3390/ma12244050