Influence of Crack Size on Stress Evaluation of Ferromagnetic Low Alloy Steel with Metal Magnetic Memory Technology

Abstract

1. Introduction

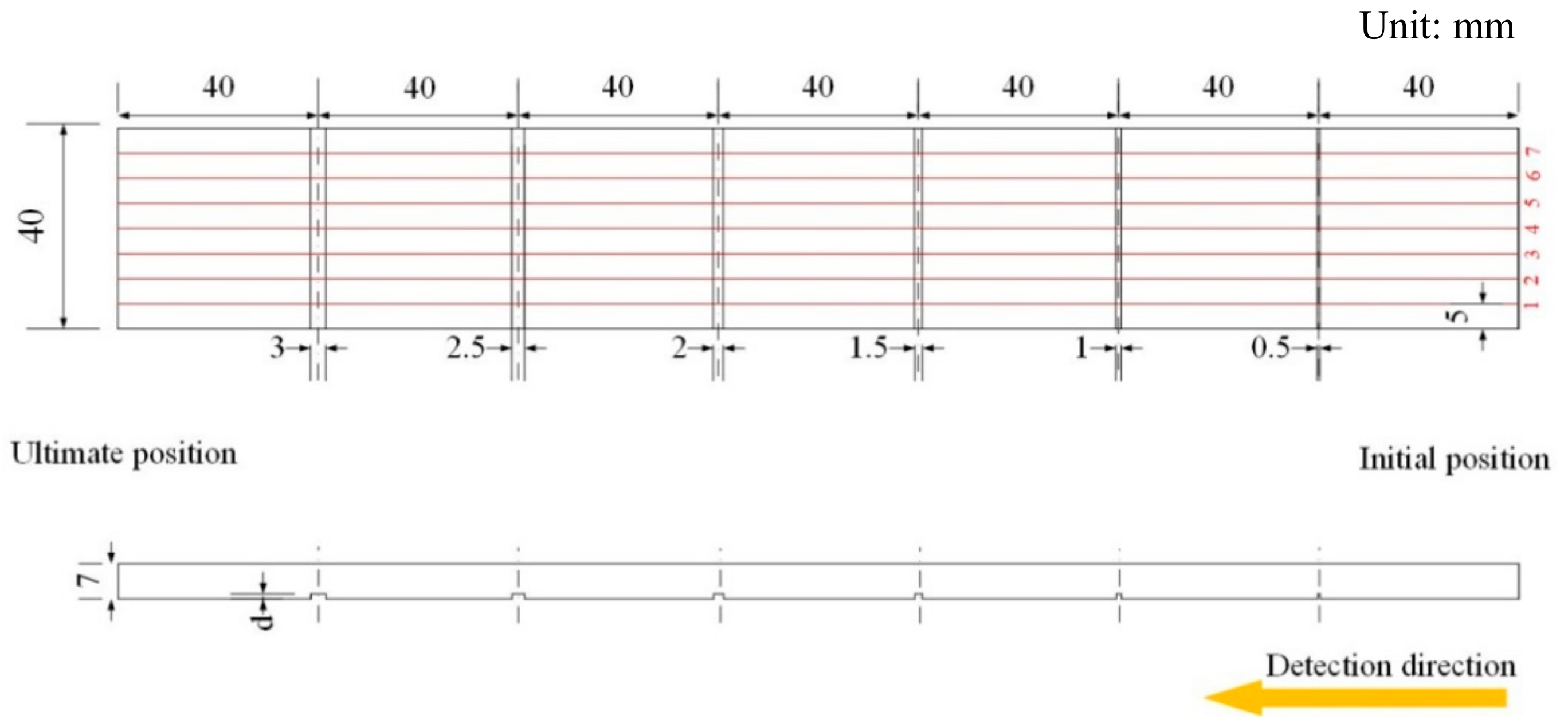

2. Experimental Material and Methods

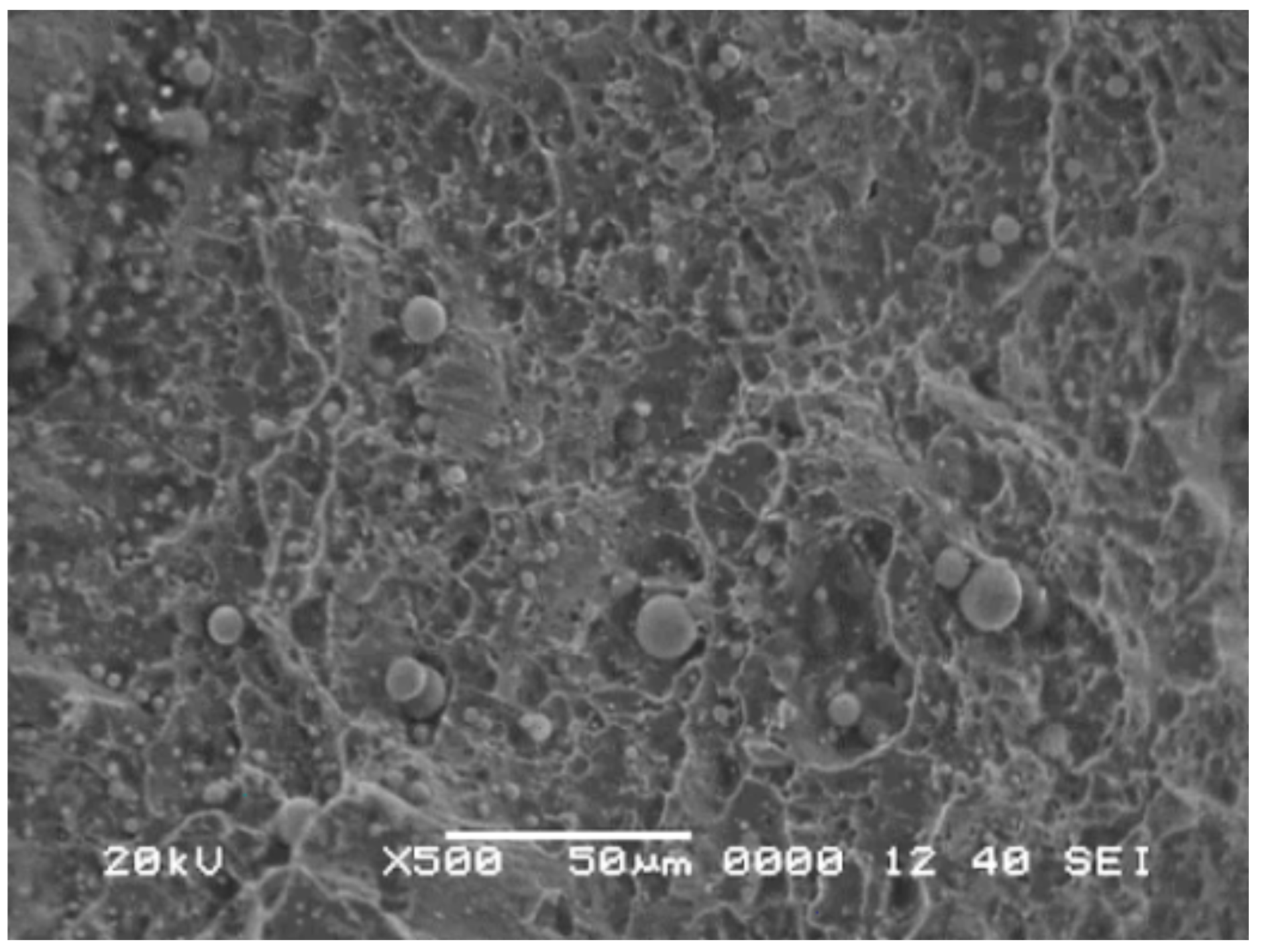

2.1. Experimental Material

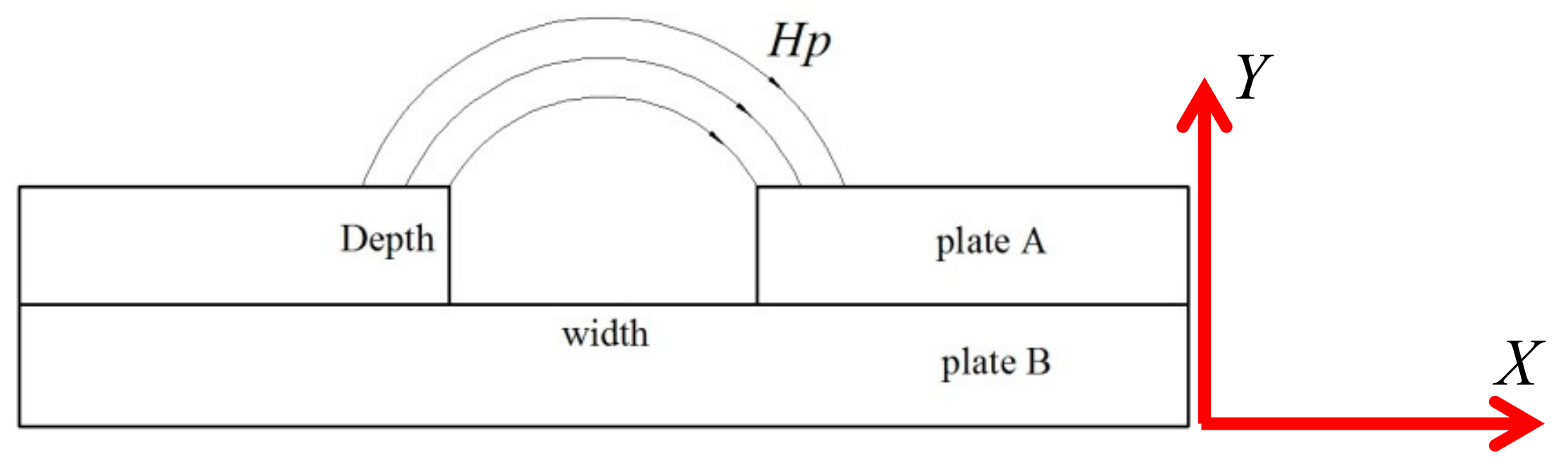

2.2. Experimental System

3. Results and Discussion

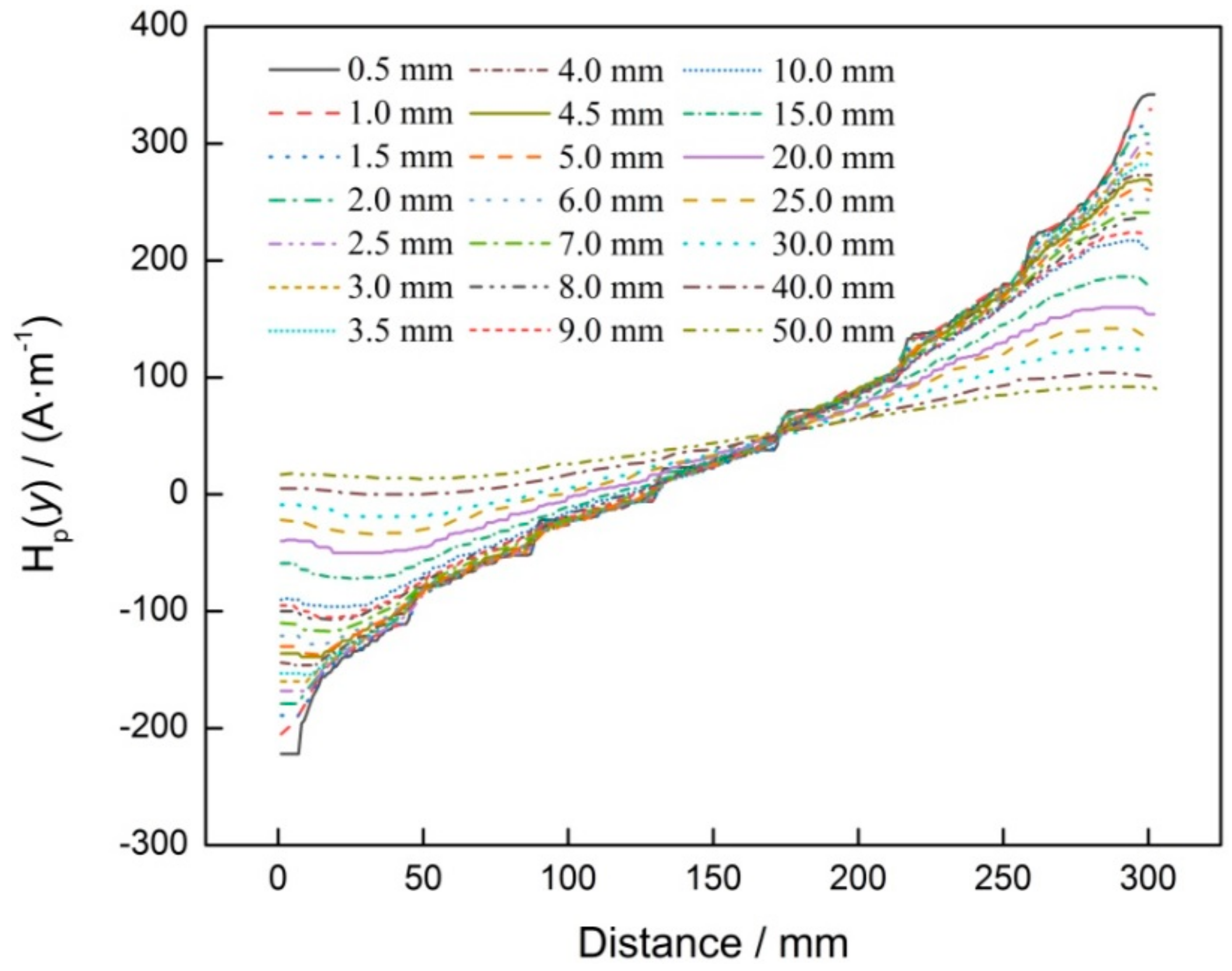

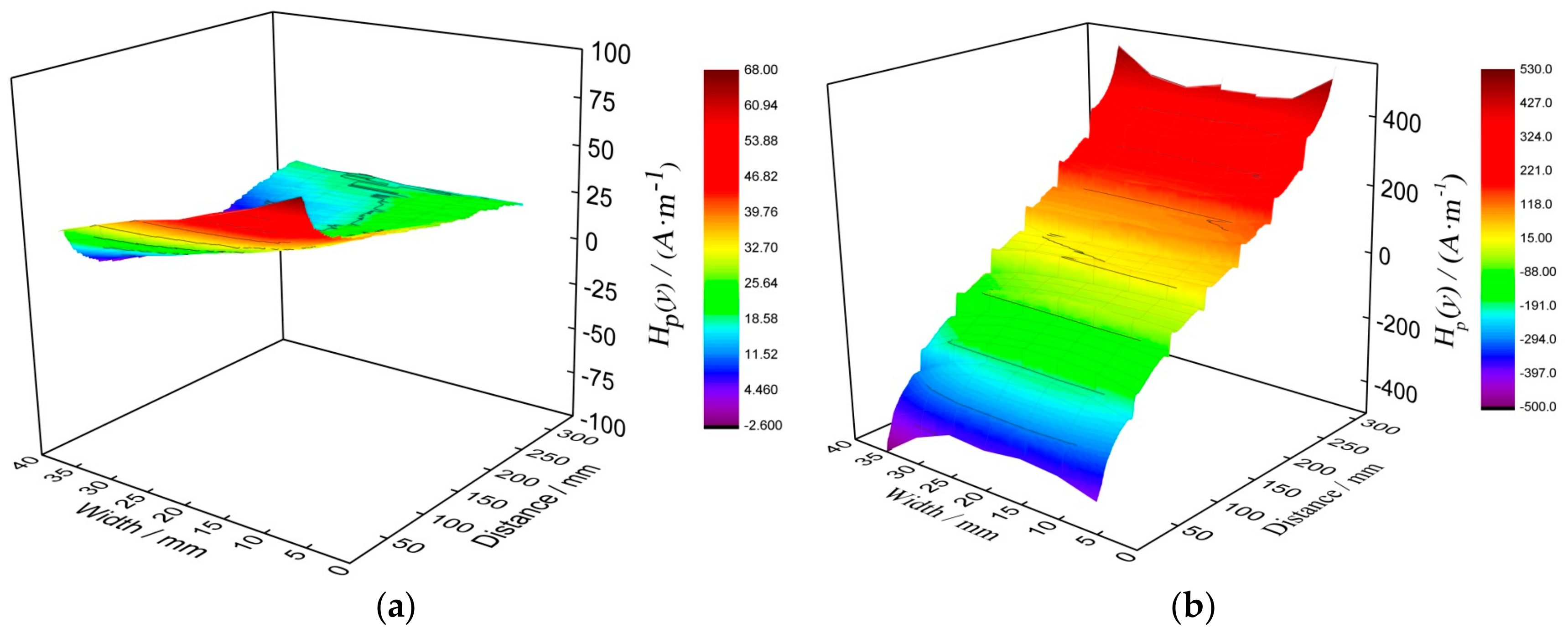

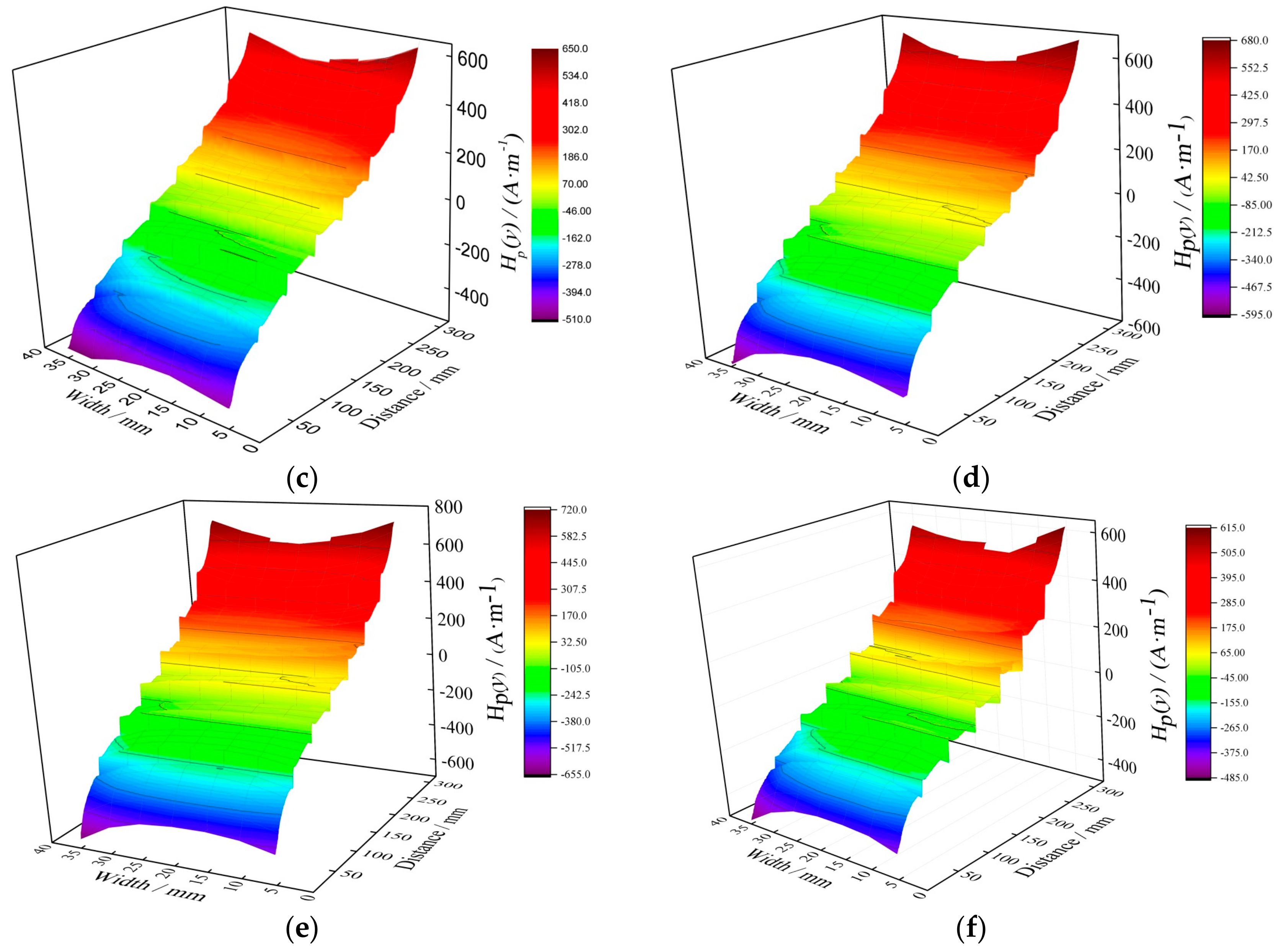

3.1. Experimental Results

3.2. Discussion and Analysis

4. Conclusions

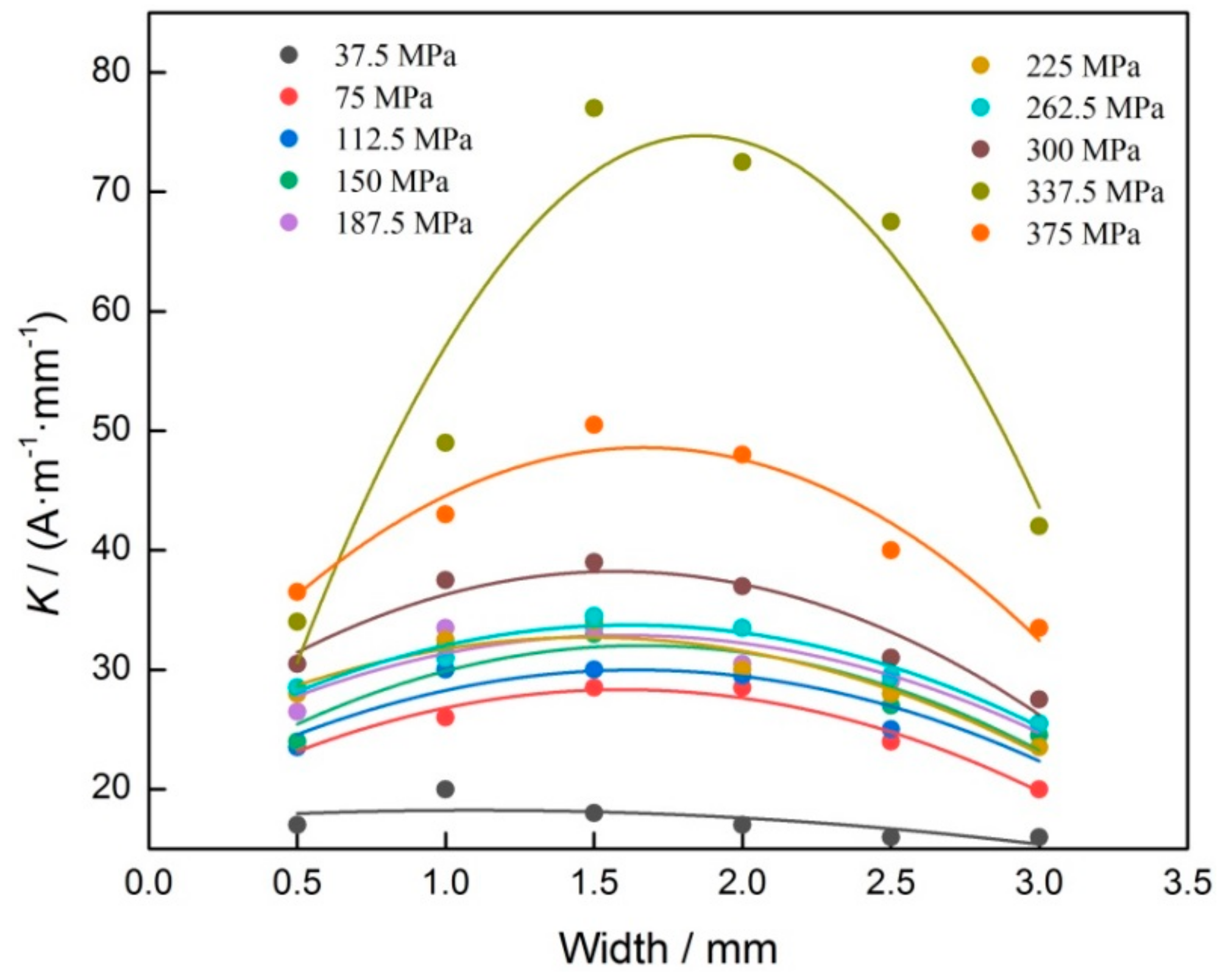

- The K of Hp(y) signal is a quadratic polynomial function of groove width, and the value of K increases gradually as stress increases. When the stress reaches yield strength of the material, the value of K also reaches maximum.

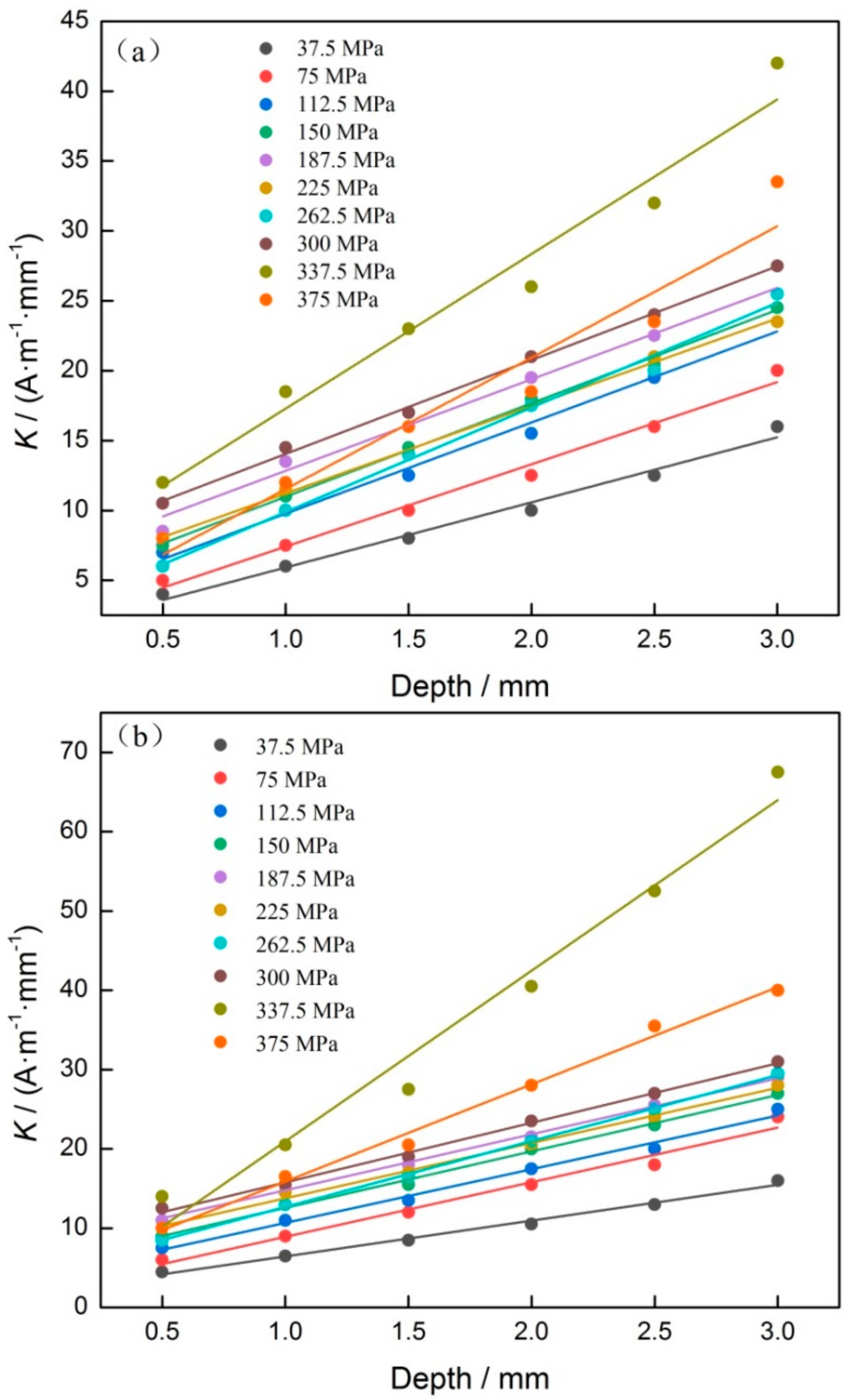

- For different tensile stresses, the K is a linear function of groove depth, and its linear slope increases as stress increases gradually. When the stress reaches yield strength of the material, the linear slope reaches the maximal value.

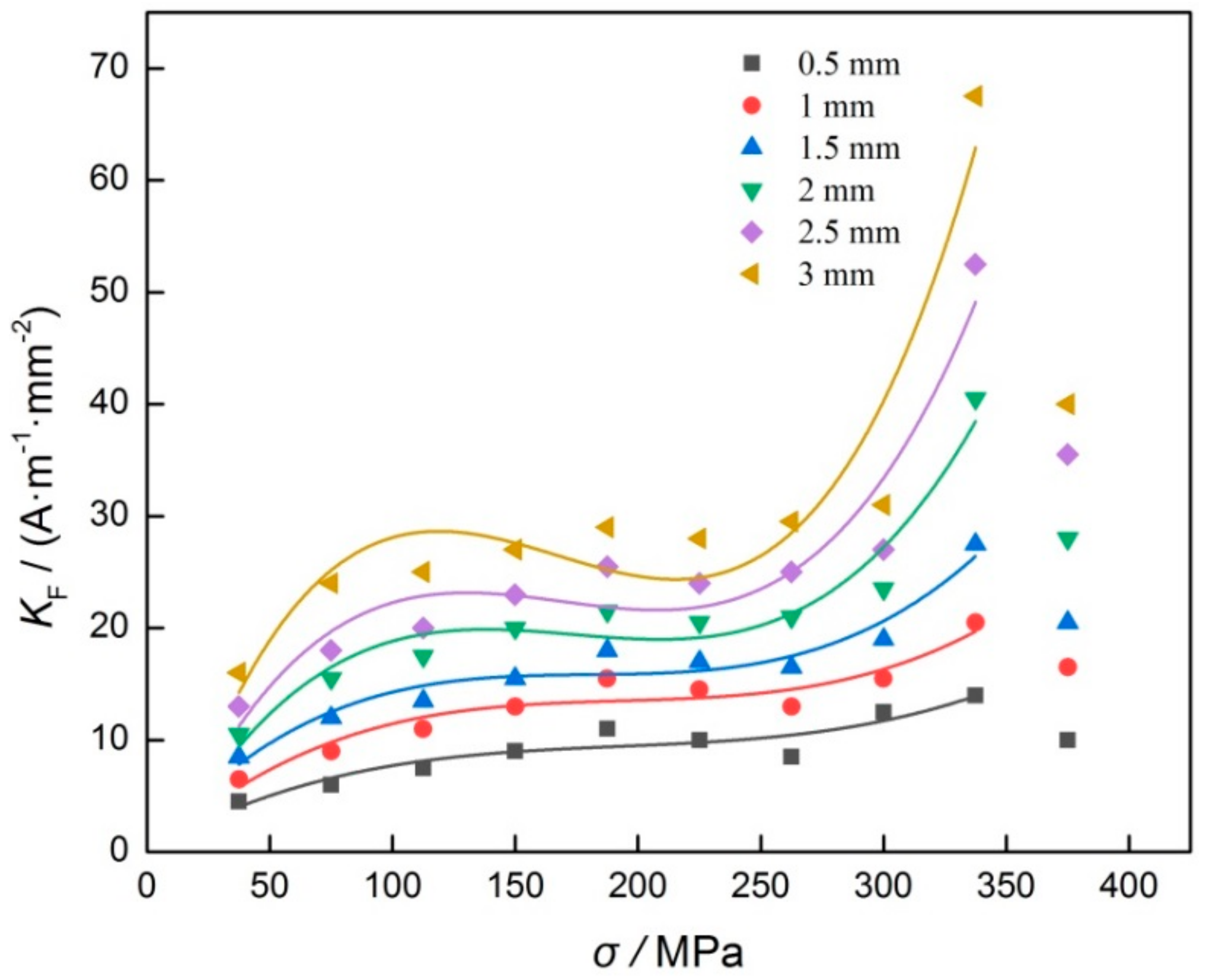

- For different groove widths, the relationship of KF and stress is very similar, and it appears nonlinearly.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, C.; Yang, J.; Shi, Y.; Zhao, Y. Investigation on narrow-gap welding residual stresses in ultra-thick ring-type mockups. Mater. Res. Express 2018, 5, 016526. [Google Scholar] [CrossRef]

- Liu, C.; Yan, Y.; Cheng, X.; Wang, C.; Zhao, Y. Residual stress in a restrained specimen processed by post-weld ultrasonic impact treatment. Sci. Technol. Weld. Join. 2019, 24, 193–199. [Google Scholar] [CrossRef]

- Liu, B.; Dong, S.Y. Anisotropic structure affects thickness measurement of laser cladding coating with surface ultrasonic wave based on cross-correlation function. Mater. Res. Innov. 2015, 19, S5-194–S5-198. [Google Scholar] [CrossRef]

- Liu, B.; Miao, W.; Dong, S.; He, P. Grain size correction of welding residual stress measurement in a carbon steel plate using the critical refraction of longitudinal waves. Res. Nondestruct. Eval. 2019, 30, 112–126. [Google Scholar] [CrossRef]

- Liu, C.; Luo, Y.; Yang, M.; Fu, Q. Three-dimensional finite element simulation of welding residual stress in RPV with two J-groove welds. Weld. World 2017, 61, 151–160. [Google Scholar] [CrossRef]

- Liu, C.; Chen, D.; Hill, M.R.; Tran, M.N.; Zou, J. Effects of ultrasonic impact treatment on weld microstructure, hardness, and residual stress. Mater. Sci. Technol. 2017, 33, 1601–1609. [Google Scholar] [CrossRef]

- Liu, B.; Miao, W.; Dong, S.; He, P. Grain size effect on Lcr elastic wave for surface stress measurement of carbon steel. Nondestruct. Test. Eval. 2018, 33, 139–153. [Google Scholar] [CrossRef]

- Doubov, A.A. A study of metal properties using the method of magnetic memory. Met. Sci. Heat Treat. 1997, 39, 401–402. [Google Scholar] [CrossRef]

- Doubov, A.A. Screening of weld quality using the magnetic metal memory effect. Weld. World 1998, 41, 196–198. [Google Scholar]

- Doubov, A.A. A Technique for monitoring the bends of boiler and steam-line tubes using the magnetic memory of metal. Therm. Eng. 2001, 48, 289–295. [Google Scholar]

- Doubov, A.A. Diagnostics of steam turbine disks using the metal magnetic memory method. Therm. Eng. 2010, 57, 16–21. [Google Scholar] [CrossRef]

- Huang, H.; Yang, C.; Qian, Z.; Han, G.; Liu, Z. Magnetic memory signals variation induced by applied magnetic field and static tensile stress in ferromagnetic steel. J. Magn. Magn. Mater. 2016, 416, 213–219. [Google Scholar] [CrossRef]

- Yin, D.W.; Xu, B.S.; Dong, S.Y.; Yang, S.L.; Dong, L.H. Characteristics of magnetic memory signals for medium carbon steel under static tensile conditions. J. Cent. South Univ. 2005, 12, 106–111. [Google Scholar] [CrossRef]

- Shi, C.L.; Dong, S.Y.; Xu, B.S.; He, P. Metal magnetic memory effect caused by static tension load in a case-hardened steel. J. Magn. Magn. Mater. 2010, 322, 413–416. [Google Scholar] [CrossRef]

- Leng, J.; Liu, Y.; Zhou, G.; Gao, Y. Metal magnetic memory signal response to plastic deformation of low carbon steel. NDT E Int. 2013, 55, 42–46. [Google Scholar] [CrossRef]

- Liu, B.; Xue, X.; Li, J.; Li, R.; Dong, S.; Fang, J. Grain size effect on metal magnetic memory signal for stress damage evaluation of low carbon steel. Nondestruct. Test. Eval. 2019, 34, 267–282. [Google Scholar] [CrossRef]

- Takaya, S.; Nagae, Y. Magnetic property change of type 304 stainless steel due to accumulation of fatigue damage at elevated temperature. Int. J. Appl. Electromagn. Mech. 2007, 25, 211–217. [Google Scholar] [CrossRef]

- Venkatachalapathi, N.; Raju, G.J.; Raghavulu, P. Characterization of fatigued steel states with metal magnetic memory method. Mater. Today Process. 2018, 5, 8645–8654. [Google Scholar] [CrossRef]

- Leng, J.; Xu, M.; Xu, M.; Zhang, J. Magnetic field variation induced by cyclic bending stress. NDT E Int. 2009, 42, 410–414. [Google Scholar] [CrossRef]

- Ni, C.; Hua, L.; Wang, X.K. Crack propagation analysis and fatigue life prediction for structural alloy steel based on metal magnetic memory testing. J. Magn. Magn. Mater. 2018, 462, 144–152. [Google Scholar] [CrossRef]

- Dong, L.H.; Xu, B.S.; Dong, S.Y.; Chen, Q.Z.; Wang, Y.Y.; Zhang, L.; Wang, D.; Yin, D.W. Metal magnetic memory testing for early damage assessment in ferromagnetic materials. J. Cent. South Univ. 2005, 12, 102–106. [Google Scholar] [CrossRef]

- Xu, M.X.; Chen, Z.H.; Xu, M.Q. Micro-mechanism of metal magnetic memory signal variation during fatigue. Int. J. Min. Metall. Mater. 2014, 21, 259–265. [Google Scholar] [CrossRef]

- Lihong, D.; Binshi, X.; Shiyun, D.; Qunzhi, C.; Dan, W. Variation of stress induced magnetic signals during testing of ferromagnetic steels. NDT E Int. 2008, 41, 184–189. [Google Scholar] [CrossRef]

- Udpa, S.S.; Moore, P.O. Nondestructive Testing Handbook: Electromagnetic Testing; The American Society for Nondestructive Testing: Columbus, OH, USA, 2004. [Google Scholar]

| Mechanical Property | σs/MPa | σb/MPa | δ5/% | φ/% |

|---|---|---|---|---|

| 12CrMoV | 337.5 | 547 | 22 | 50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Fu, P.; Li, R.; He, P.; Dong, S. Influence of Crack Size on Stress Evaluation of Ferromagnetic Low Alloy Steel with Metal Magnetic Memory Technology. Materials 2019, 12, 4028. https://doi.org/10.3390/ma12244028

Liu B, Fu P, Li R, He P, Dong S. Influence of Crack Size on Stress Evaluation of Ferromagnetic Low Alloy Steel with Metal Magnetic Memory Technology. Materials. 2019; 12(24):4028. https://doi.org/10.3390/ma12244028

Chicago/Turabian StyleLiu, Bin, Peng Fu, Ruifeng Li, Peng He, and Shiyun Dong. 2019. "Influence of Crack Size on Stress Evaluation of Ferromagnetic Low Alloy Steel with Metal Magnetic Memory Technology" Materials 12, no. 24: 4028. https://doi.org/10.3390/ma12244028

APA StyleLiu, B., Fu, P., Li, R., He, P., & Dong, S. (2019). Influence of Crack Size on Stress Evaluation of Ferromagnetic Low Alloy Steel with Metal Magnetic Memory Technology. Materials, 12(24), 4028. https://doi.org/10.3390/ma12244028