1. Introduction

In the last decades, Ultra-High Performance Fiber-Reinforced Cementitious Composites (UHP-FRCC) have been developed to meet the requests of the construction industry [

1,

2,

3]. UHP-FRCCs can enhance the resistance of buildings and infrastructures due to the ultra-high strength, high ductility, durability, and energy absorption capacity, when compared with normal strength concrete or traditional FRCC. In fact, UHP-FRCCs show a compressive strength that was larger than 150 MPa, combined with high tensile and flexural strengths. Such performances are achieved with a low water/binder ratio, high content of cementitious materials, and by incorporating a copious amount of fibers (steel, polymeric, glass, etc.) [

4,

5,

6,

7].

One of the most well-known and relevant applications of UHP-FRCC is the retrofitting of existing structures, especially the jacketing of concrete columns and beams, due to these mechanical properties. The aim is to harden those parts of the existing structures that are exposed to high environmental and mechanical actions, especially in the most highly stressed cross-sections and in the structural joints [

8,

9,

10].

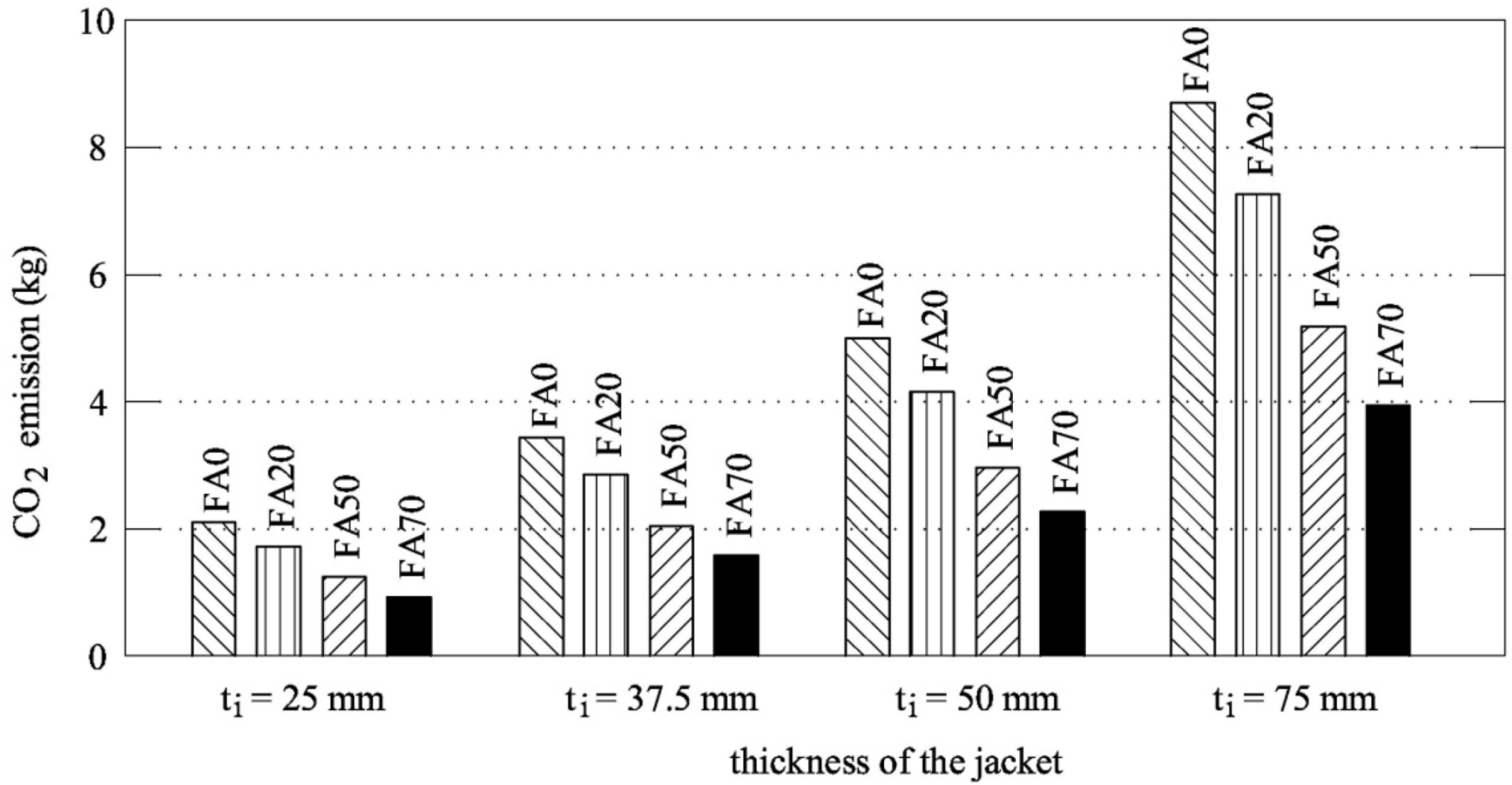

However, this high-performance material has, in parallel, high environmental impact, because of the high content of cement in the mixture [

3,

5,

6,

11,

12]. Indeed, it is unanimously accepted that the compressive strength of concrete is in direct proportion with the power 2 of the cement content and, consequently, this strength is proportional to the power 2 of the CO

2 emission per cubic meter of concrete. Therefore, the “material substitution strategy” that Habert and Roussel introduced [

11] is generally adopted. As the name suggests, it consists of a partial replacement of cement with supplementary cementitious materials, in order to reduce the environmental impact. Specifically, different amounts of cement are substituted by fly ash, a waste by-product that is derived from coal burning. When the mass of fly ash is higher than 50% of the total cementitious materials, the concrete system takes the name of High Volume Fly Ash (HVFA) [

13]. It must be remarked that the substitution of cement with fly ash might not always be beneficial. HVFA significantly reduces the environmental impact, but it also leads to a decrease of concrete strength, especially in the UHP-FRCC [

14,

15].

Some researches, regarding the high strength concrete and UHP-FRC using high quantity of admixtures from by-products, were performed in the last years [

16,

17,

18]. On the other hand, most of these studies only focused on the development of the cement-based material, without focusing on the structural applications. Accordingly, a new experimental campaign has been carried out on normal-strength concrete cylinders that were reinforced with UHP-FRCC jackets, with the aim of simulating the confinement effect in columns. Different jackets are tailored to investigate the relationship between the thickness of the reinforcing layer and the mechanical performances of the reinforced column. In some of them, different percentages of fly ash substitute the cement for achieving the best mechanical and ecological performances [

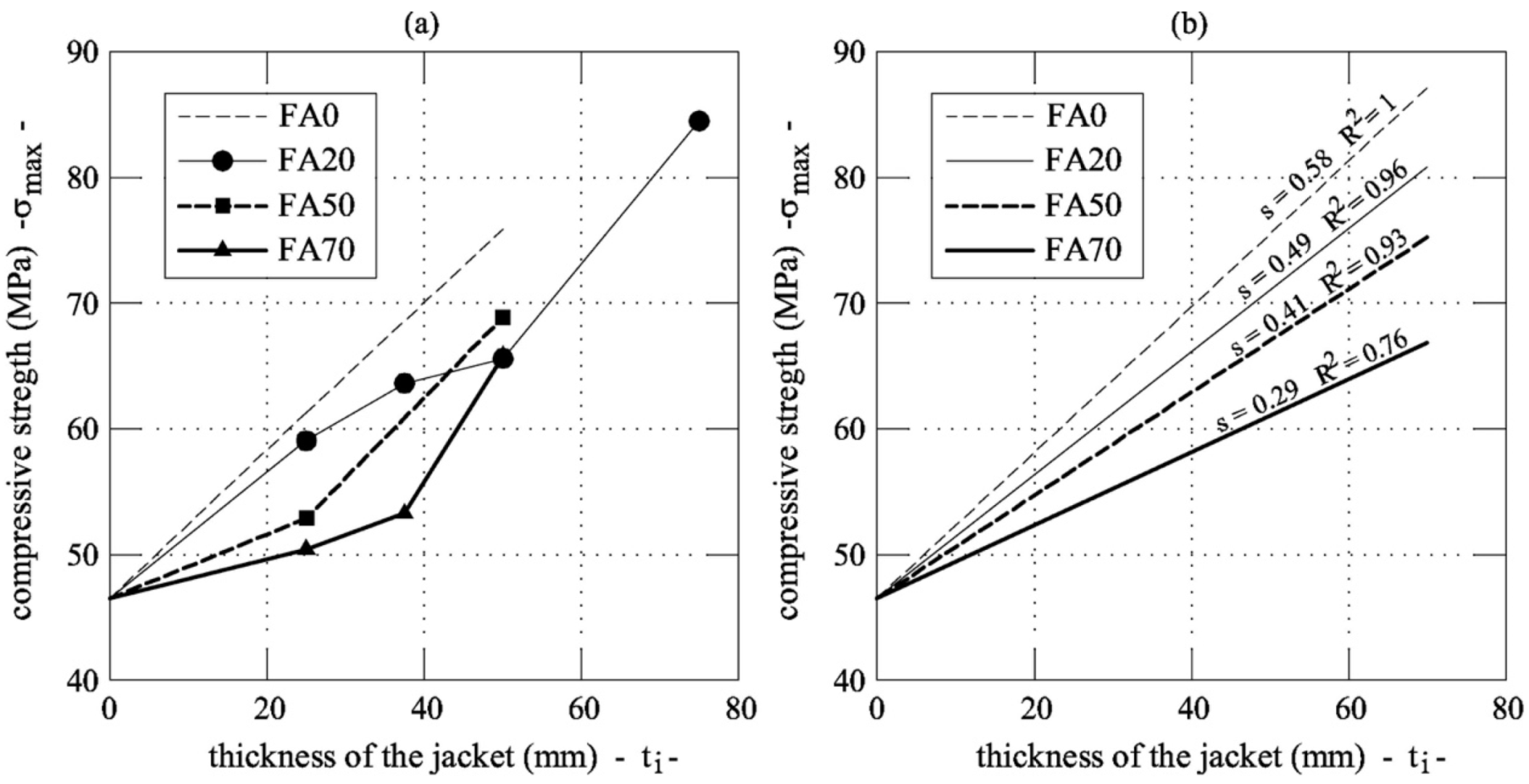

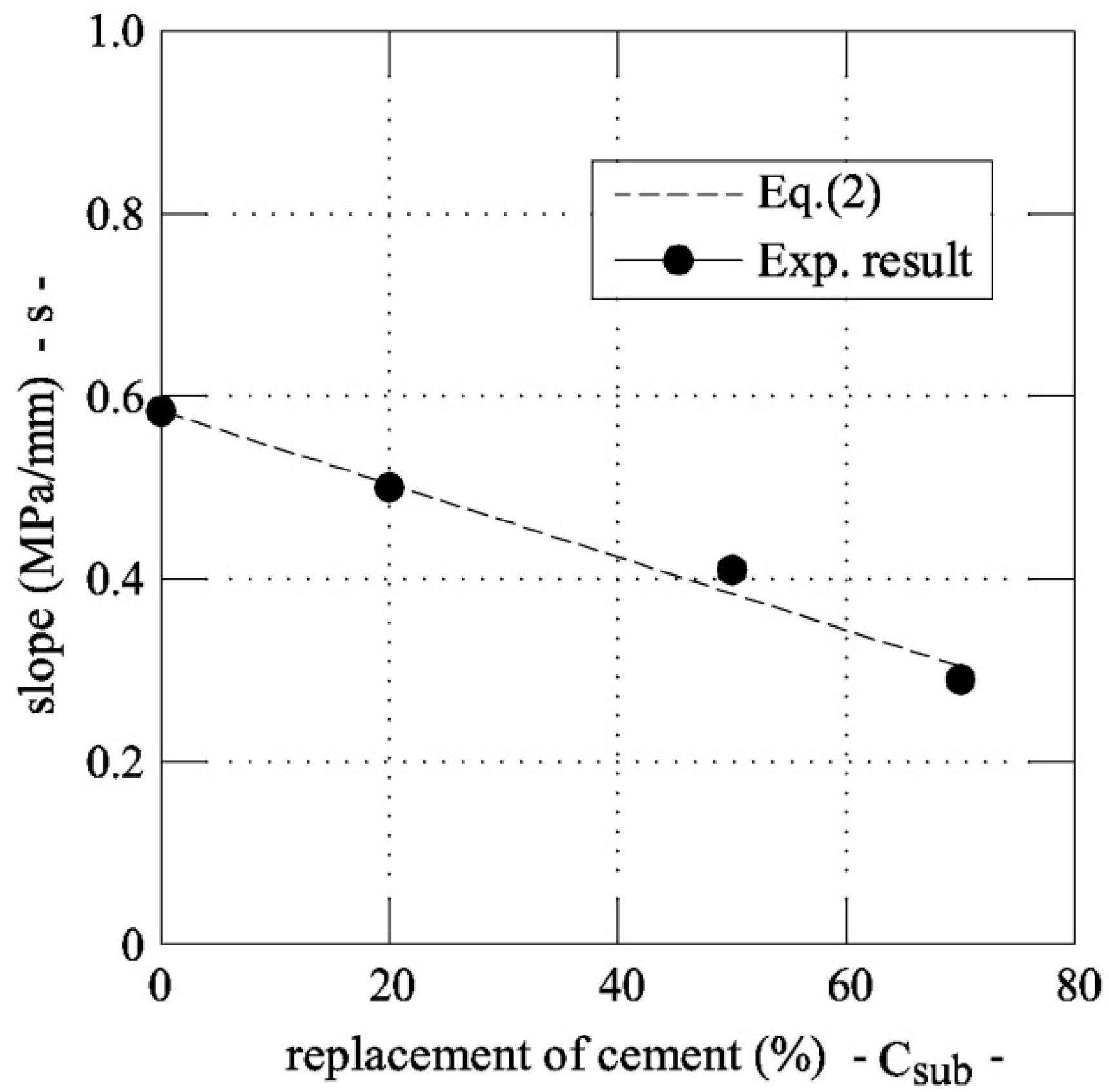

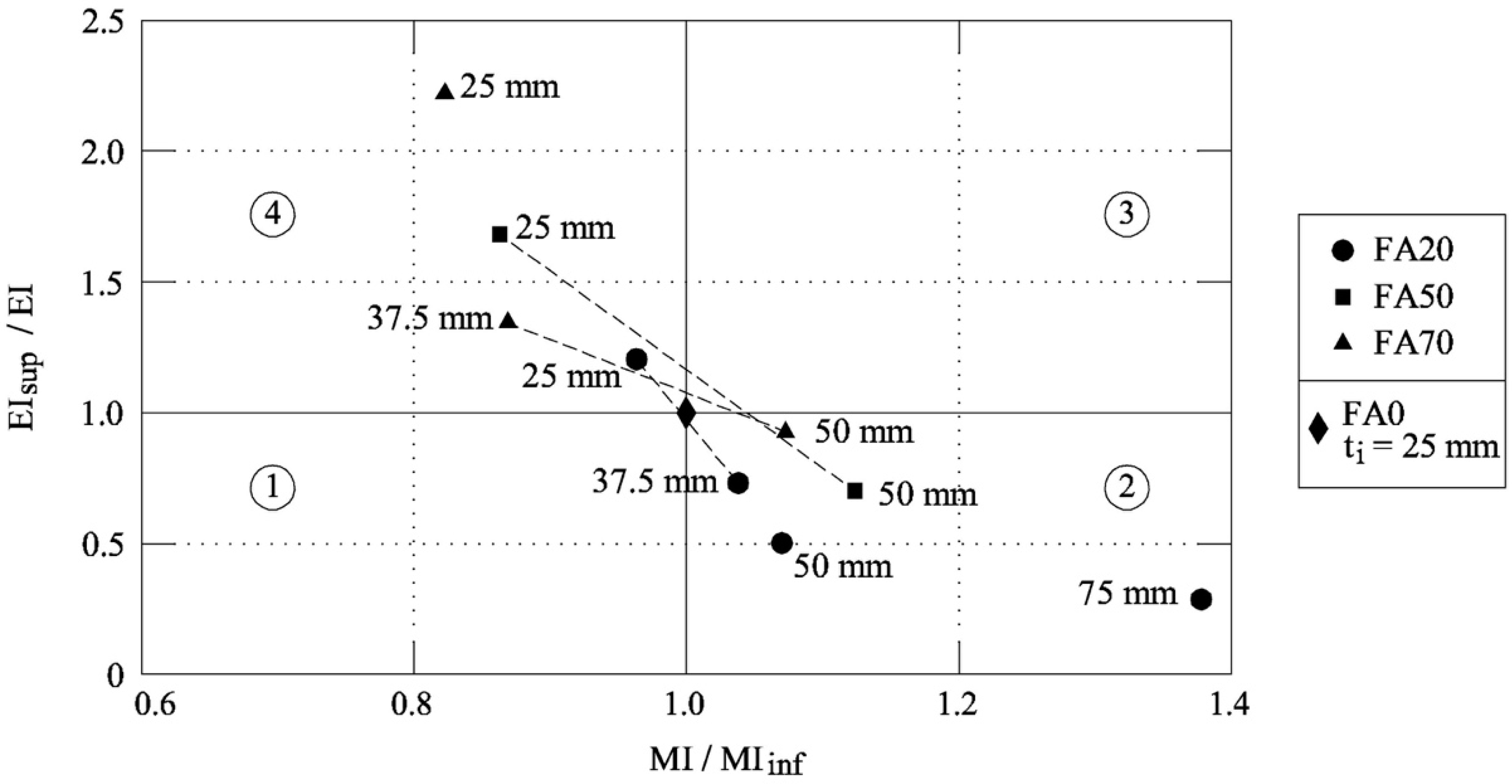

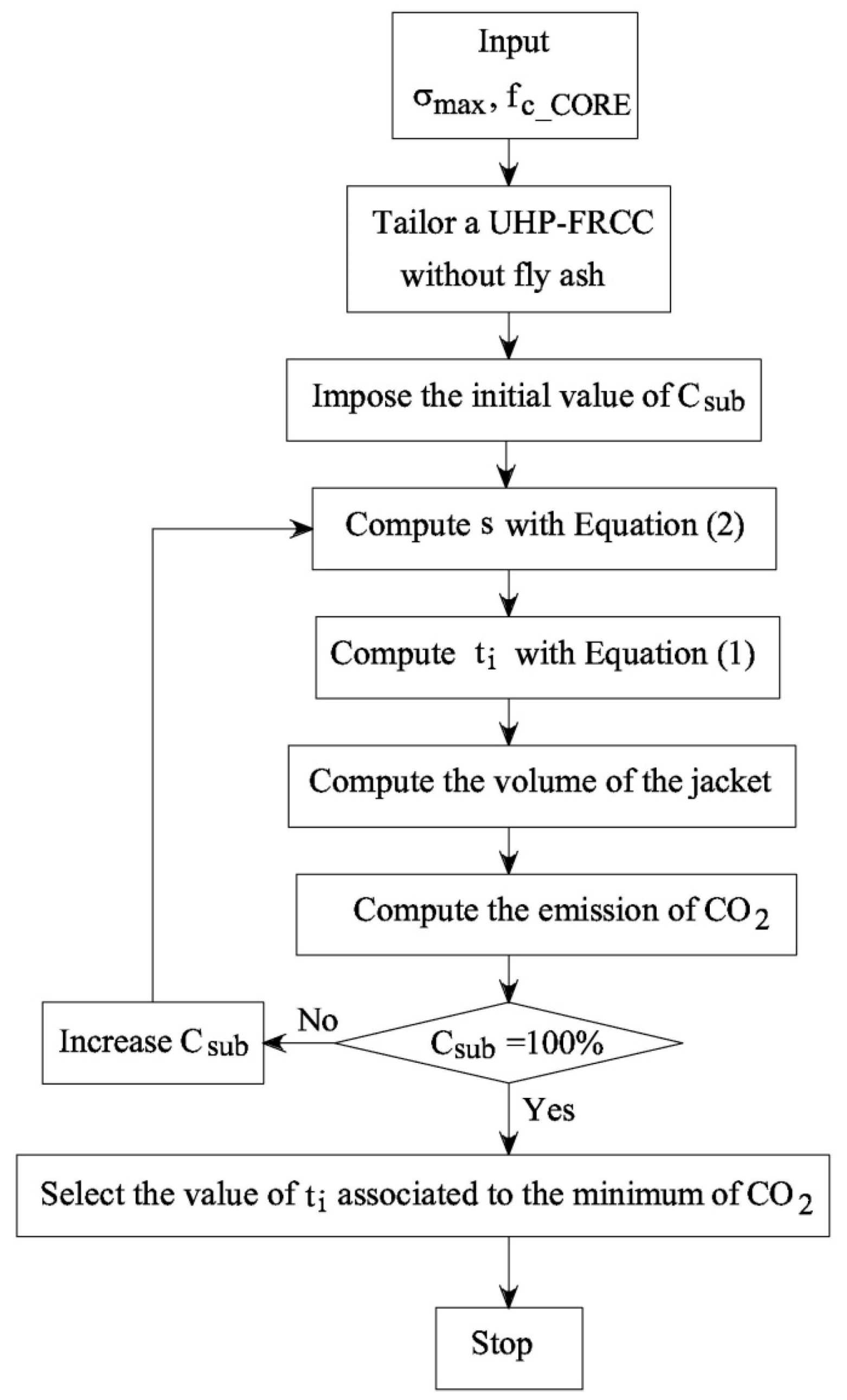

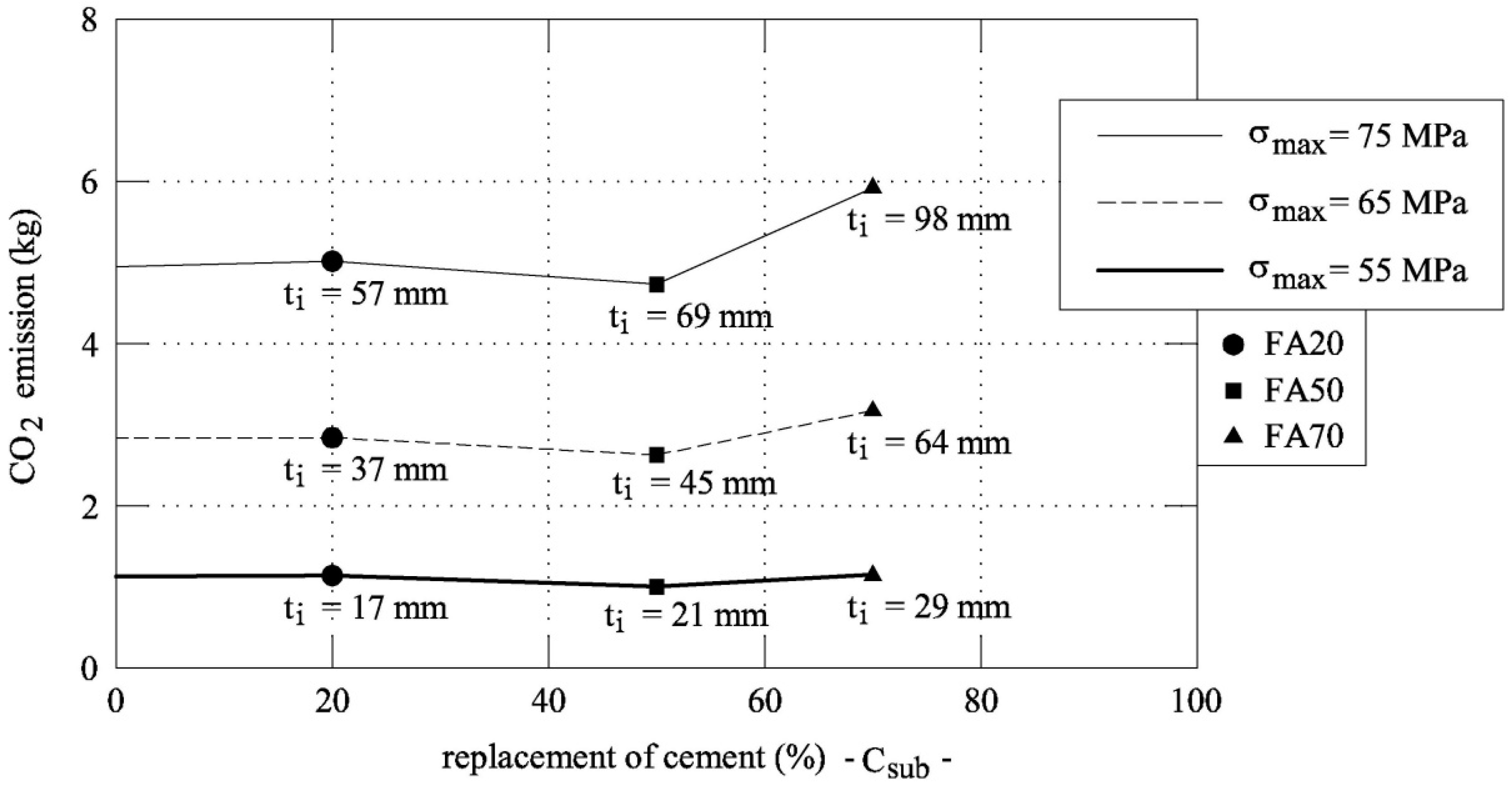

19]. A design procedure is also proposed to select the best solution by defining the optimal replacement rate of cement with fly ash.

2. Experimental Investigation: Materials and Methods

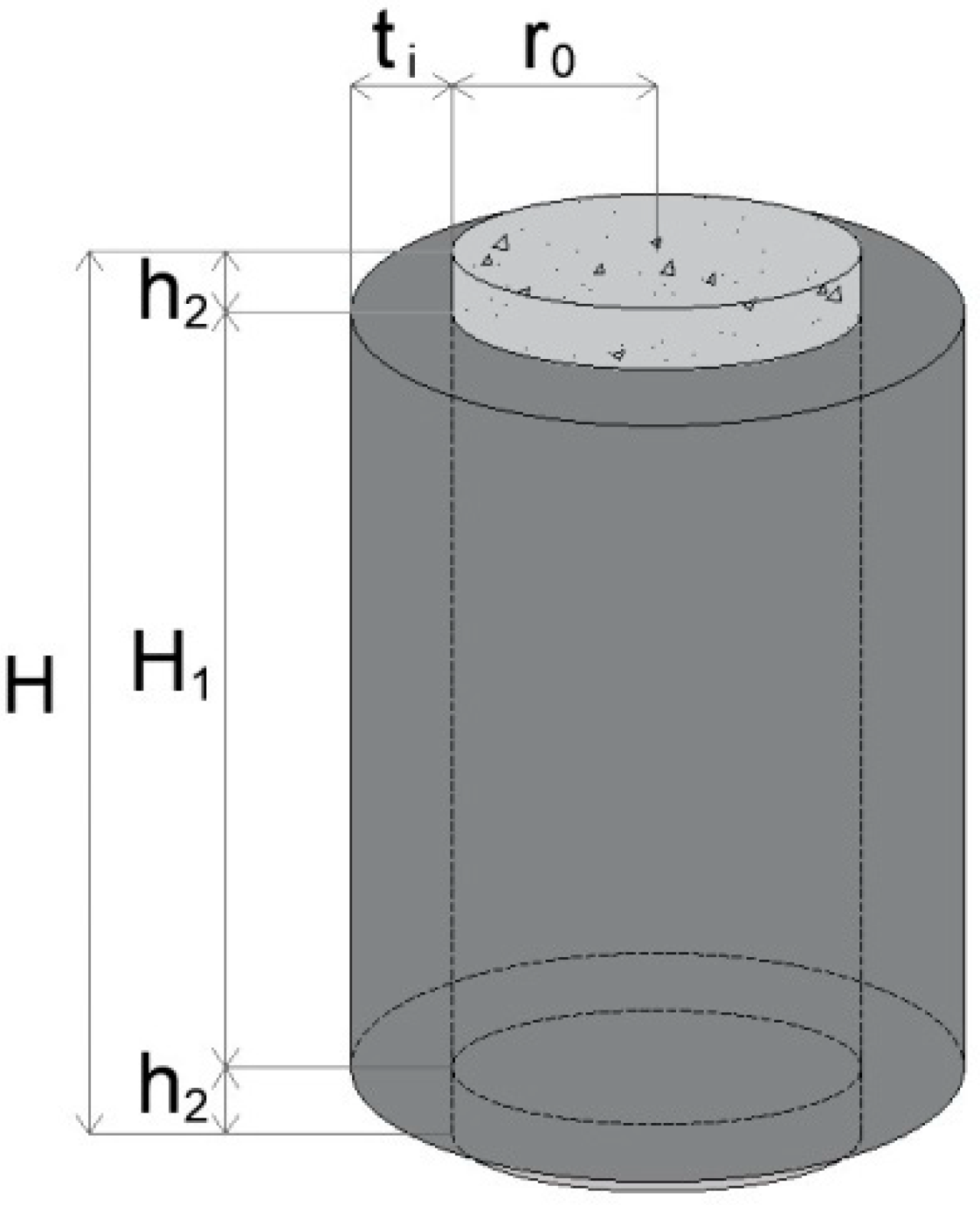

Figure 1 illustrates the cylindrical sample subjected to uniaxial compression. It consists of a normal-strength concrete core, with a radius

r0 = 50 mm and a height

H = 200 mm, confined by a UHP-FRCC jacket of

H1 = 178 mm and different thickness (

ti = 25, 37.5, 50, and 75 mm). As no standard exists to test the confinement effects, the minimum thickness of 25 mm was determined due to the limitation of the casting procedures of the UHP-FRCC layer into a narrow gap.

According to the mix proportion that is shown in

Table 1, the concrete cores have been made with High Early Strength Portland Cement (HESP; Density: 3.14 g/cm

3, Specific surface area: 4490 cm

2/g Ignition loss: 1.08%), the combination of land sand and crushed sand as fine aggregates (S), crushed stone as coarse aggregates (G), tap water (W), and superplasticizer (SP

1; Polycarboxylate-based, Density: 1.03 g/cm

3).

The UHP-FRCCs used herein are made by the following materials [

3,

13,

14]:

Low Heat Portland Cement (LHC; Density: 3.24 g/cm3, Specific surface area: 3640 cm2/g, C2S: 57%, C3A: 3%, MgO: 0.6%, SO3: 2.78%, Ignition loss: 0.72%)

Undensified Silica Fume (SF; Density: 2.20 g/cm3, Bulk density: 0.20–0.35 g/cm3, Coarse particles >45 µm: less than 1.5, SiO2: more than 90%, Ignition loss: less than 3.0%)

Fly Ash (FA; Density: 2.31 g/cm3, Specific surface area: 4050 cm2/g, Coarse particles >45 µm: 5%, SiO2: 54.8%, Ignition loss: 1.2%)

Silica sand (Ss; Density: 2.60 g/cm3, Average particle size: 0.212 mm, SiO2: 98.49%, Al2O3: 0.49%)

Wollastonite mineral fibers (Wo; CaSiO3, Density: 2.60 g/cm3, Length: 50–2000 μm, Aspect ratio: 3–20, SiO2: 49.71%, CaO: 45.87%, Ignition loss: 1.94%)

Specific superplasticizer (SP2; Polycarboxylate-based, Density: 1.05 g/cm3, Solid part: 30%)

De-foaming Agent (DA; Density: 1.05 g/cm3)

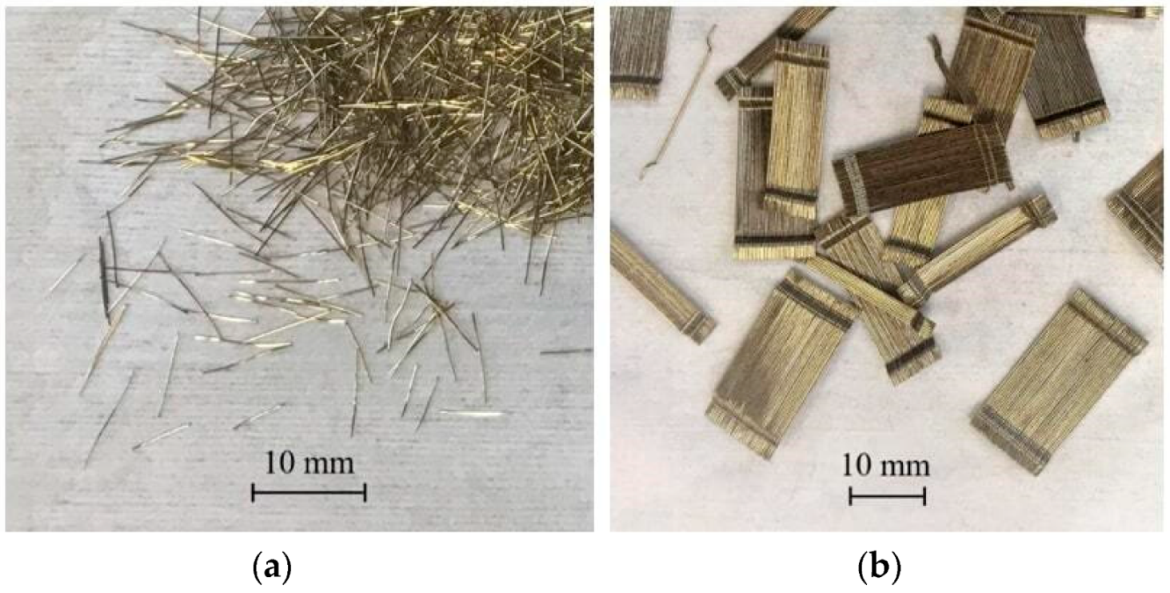

Steel micro-fibers (OL—1% in volume), with a length of 6 mm (see

Figure 2a)

Steel macro-fibers (HDR—1.5% in volume), with a length of 30 mm (see

Figure 2b)

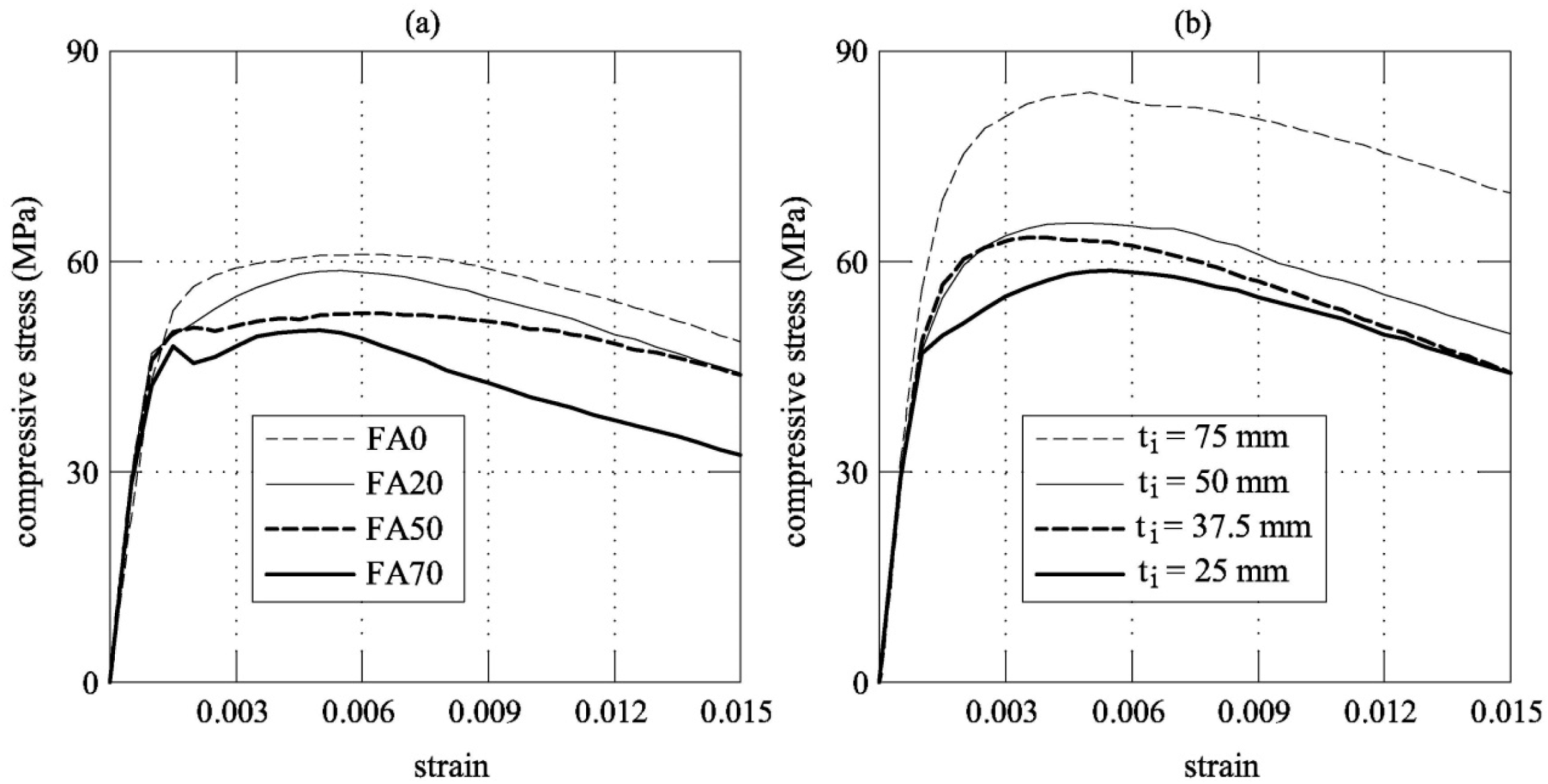

Following the material substitution strategy, four mixtures have been tailored for the UHP-FRCC jackets, modifying only the percentage of cement and fly ash.

Table 2 shows the mix proportion of the four series of UHP-FRCC (FA0, FA20, FA50, and FA70), with, respectively, 0%, 20%, 50%, and 70% of cement replaced by fly ash. In this Table, the components of each series are reported as a percentage with respect to the weight of the binder, whereas

Table 3 shows the mix proportion of UHP-FRCC jackets in kg/m

3. In each series, the water-binder ratio is constant and equal to 0.16, because it guarantees a good balance between the flowability properties and the strength of the hardened concrete, according to the authors’ previous study [

3]. Note that SP

2 contains 30% of the solid part, which is taken into account to calculate the water-binder ratio. The flow table tests were performed in accordance with the Japanese Standard JIS R 5201 [

20], which complies with ASTM C 1437 [

21]. In particular, for FA0, FA20, FA50, and FA70, a diameter of 190 mm, 260 mm, 290 mm, and 250 mm, was, respectively, measured in the tests. Having these consistencies, all of the UHP-FRCs were cast and compacted in the jacket mould without any segregation.

Ten days after casting the concrete cores (which simulate herein an existing column), the UHP-FRCC jackets are cast around using paper cylinders with a height of 178 mm as a disposable formwork, as the proposed jacket has to be applied to existing structures.

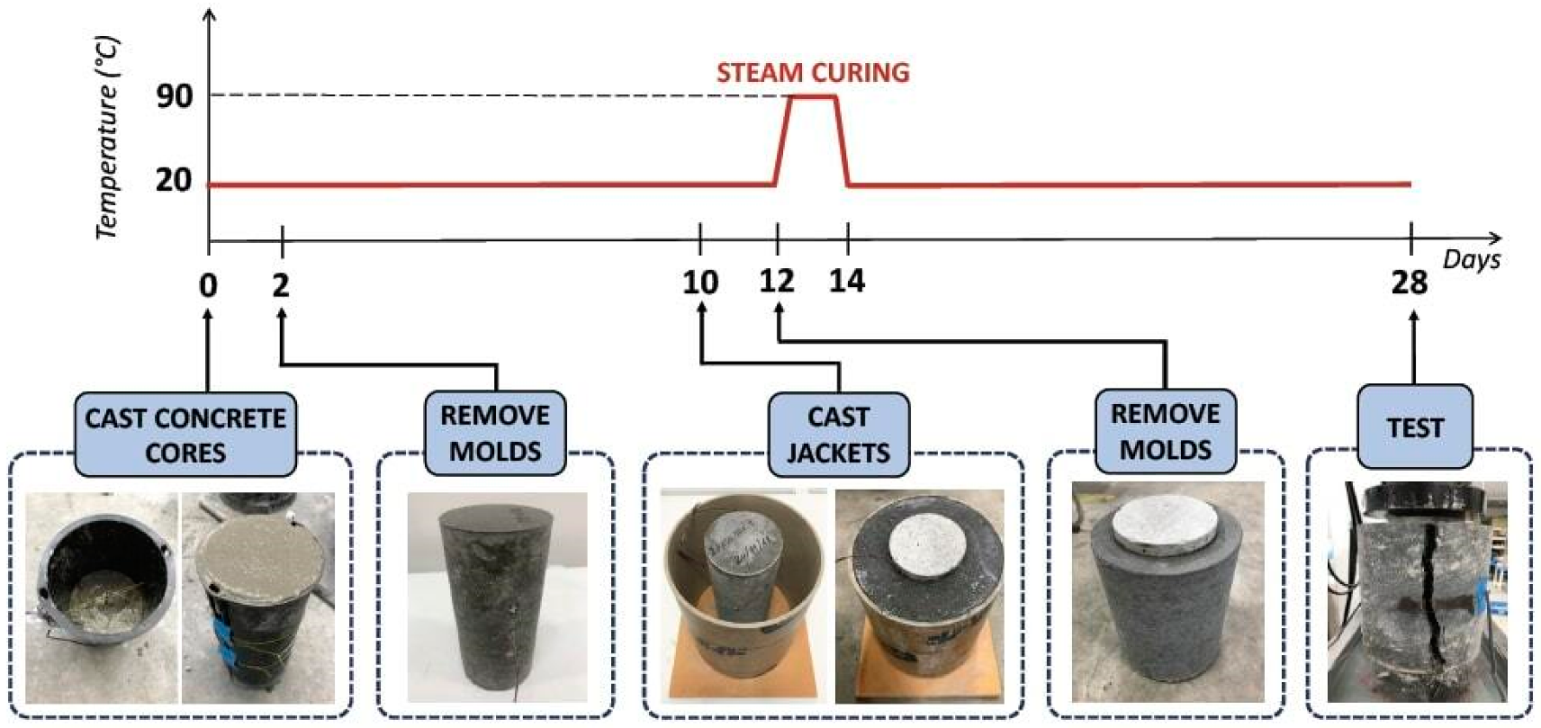

Subsequently, the paper formworks were removed two days later and the specimens were subjected to steam curing for the following 48 h. In this way, the hydration process of the binder was accelerated, especially in the UHP-FRCC jackets containing large amounts of fly ash. As depicted in

Figure 3, the temperature was slowly increased at a rate of 15 °C per hour up to 90 °C to avoid any crack generation produced by the thermal gradient. Uniaxial compression tests are performed after 28 days from the concrete core casting. A universal testing machine (UTM) with a maximum capacity of 1000 kN is used to apply the compressive load by moving the displacement of the stroke (of the loading cell) at a constant velocity of less than 0.3 mm/min. external strain gauges and embedded strain gauges were used to measure the strain during the tests.

Four strain gauges are applied on the jacket’s surface: two in the vertical direction and two in the horizontal direction. The vertical gauges measure the strain along the longitudinal axis, while those horizontally oriented gauges measure the swelling of the specimen. Embedded strain gauges were installed inside in the middle of the moulds before casting the concrete cores to record the vertical strain of the concrete core during the compression test.

As shown in

Table 4, for some of the thickness of the jacket, three samples are tested for each mixture. In addition, for each series, one concrete core with no reinforcement is tested to estimate the mechanical properties without UHP-FRCC jackets.