Estimation of Heating Temperature for Fire-Damaged Concrete Structures Using Adaptive Neuro-Fuzzy Inference System

Abstract

:1. Introduction

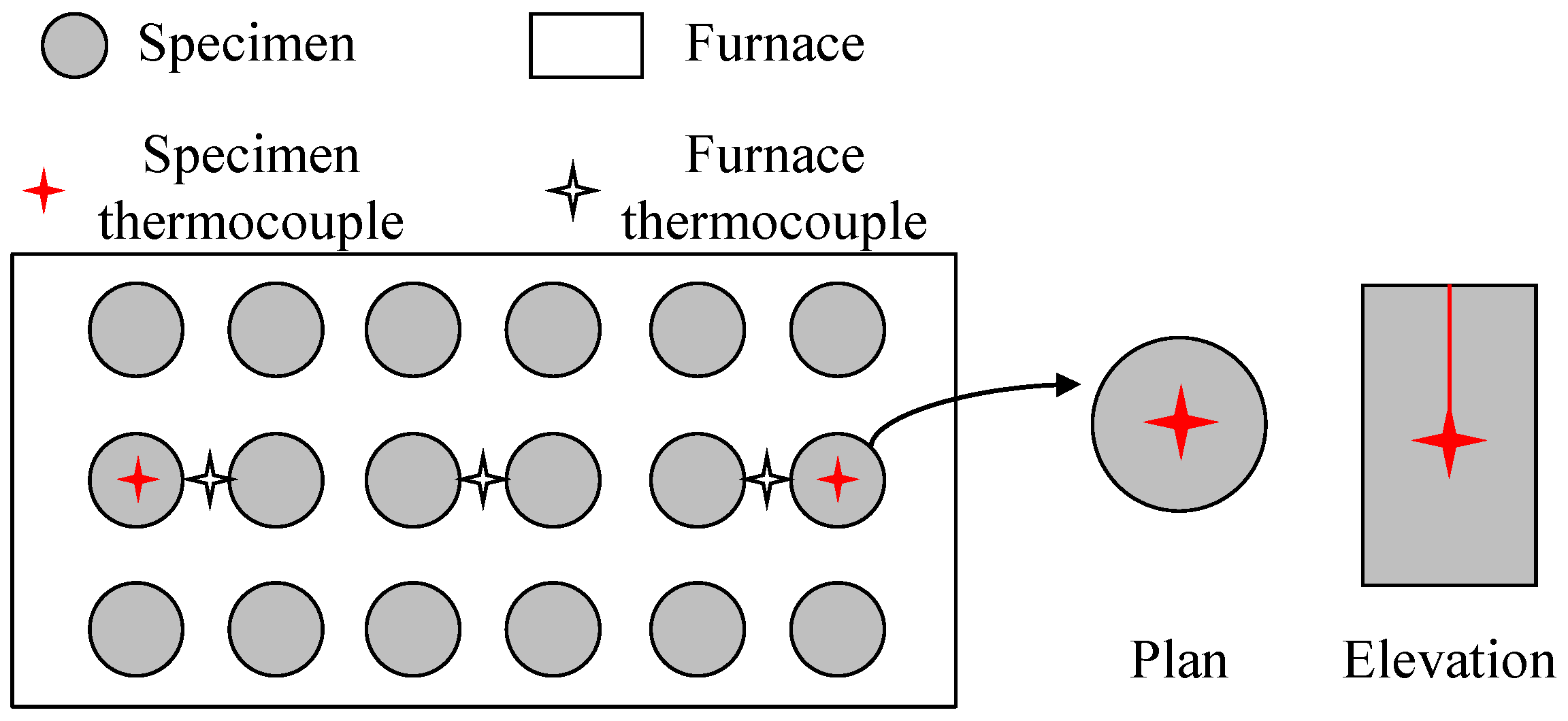

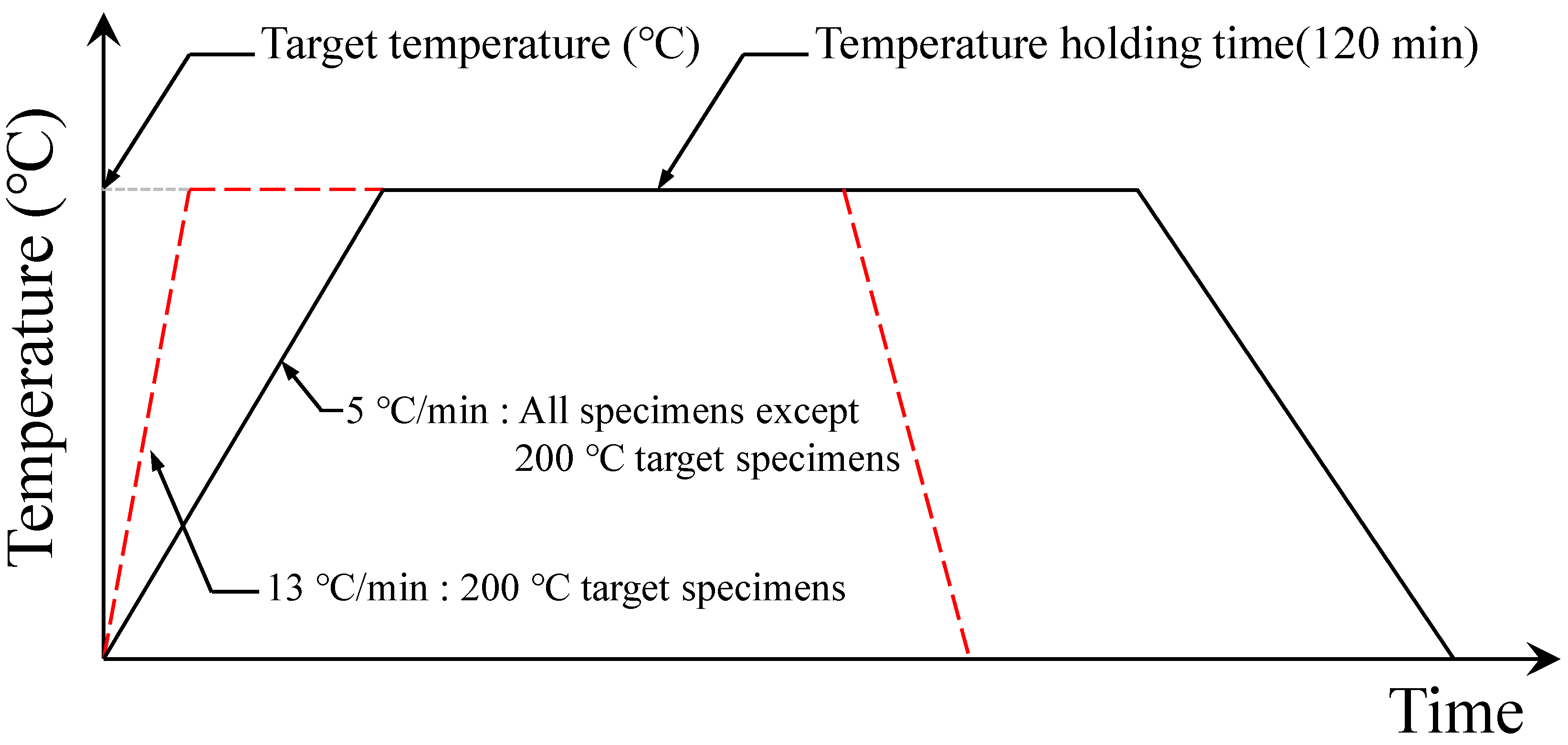

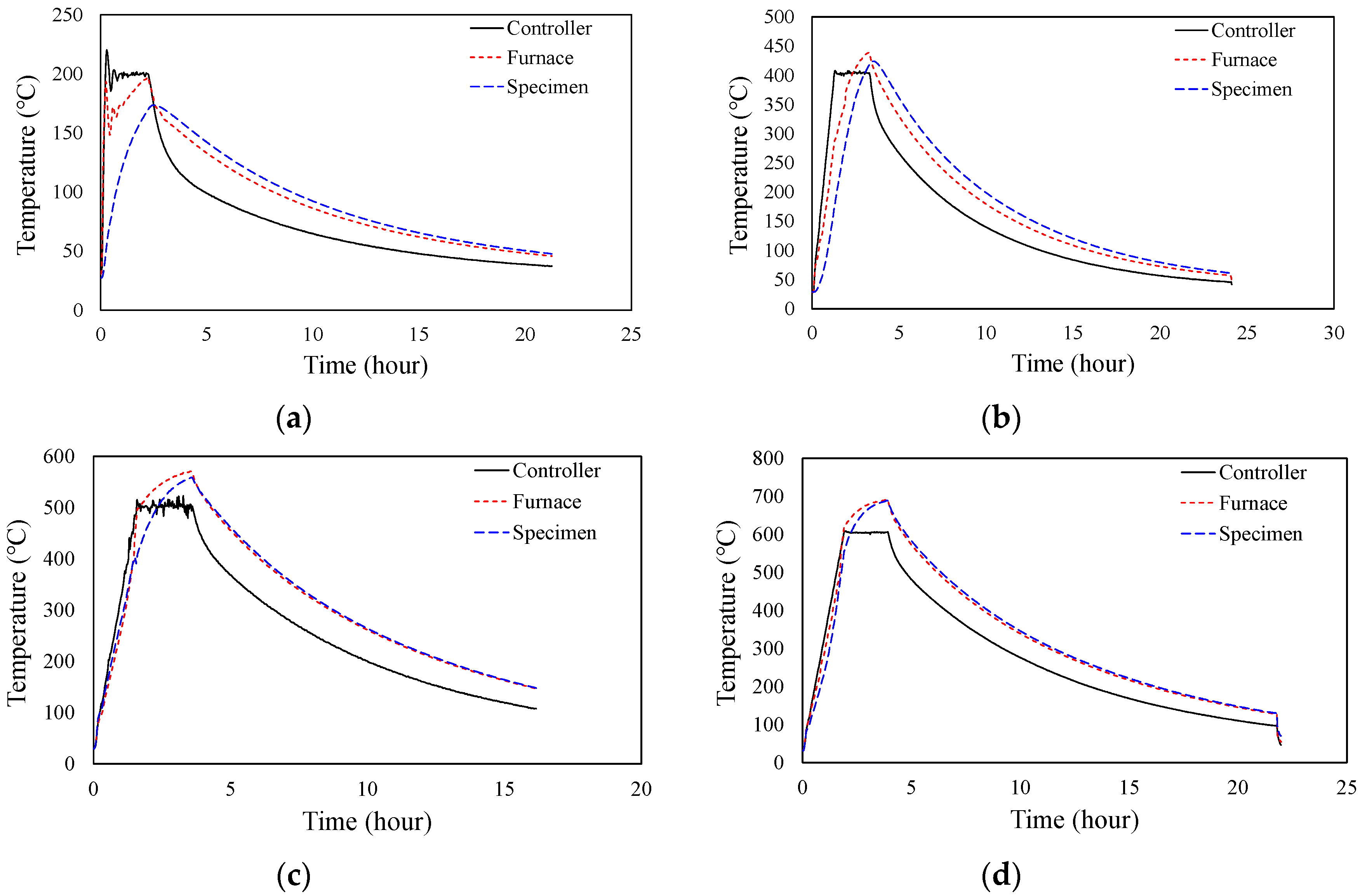

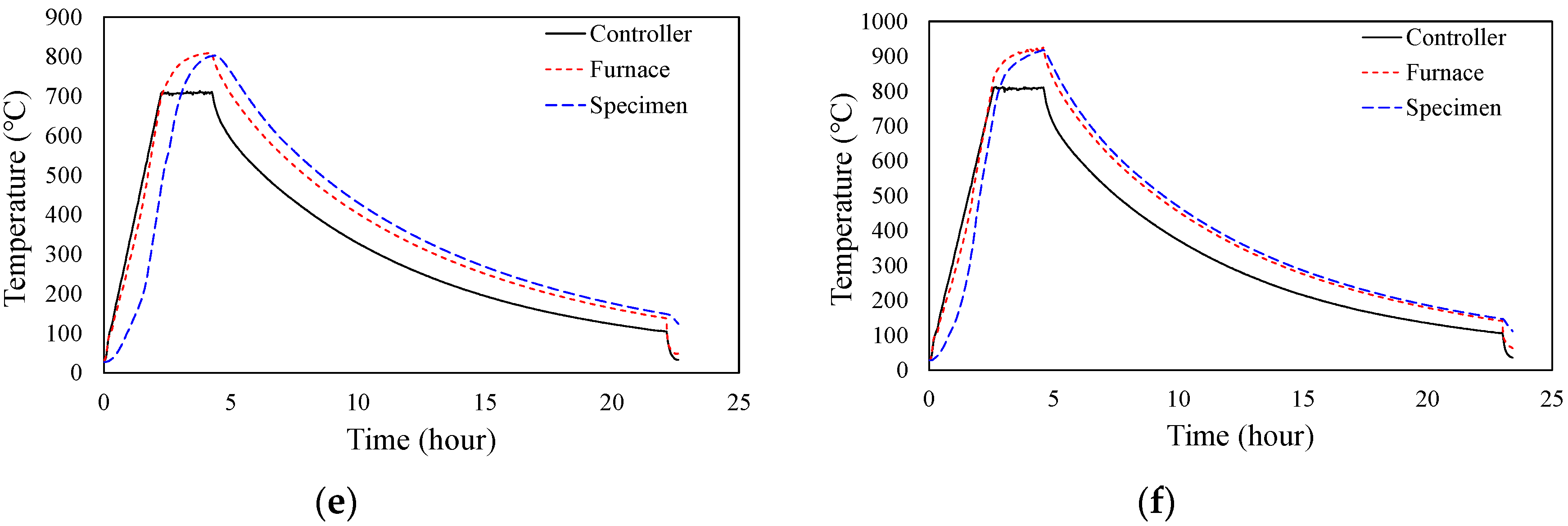

2. Concrete Heating Test

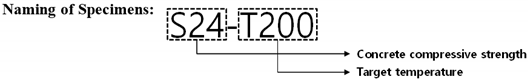

2.1. Test Program

2.2. Heating Test Results

3. Non-Destructive Test

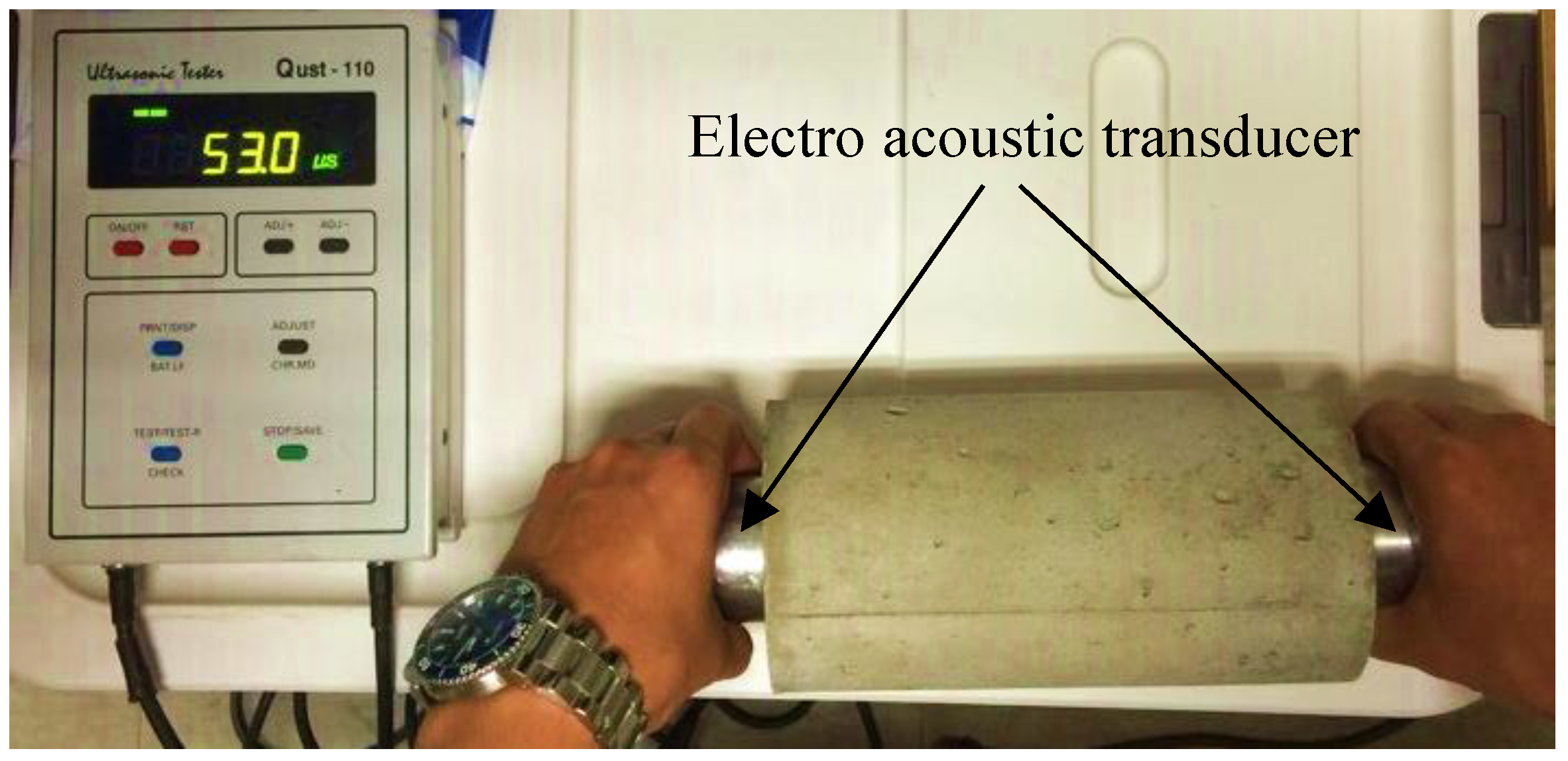

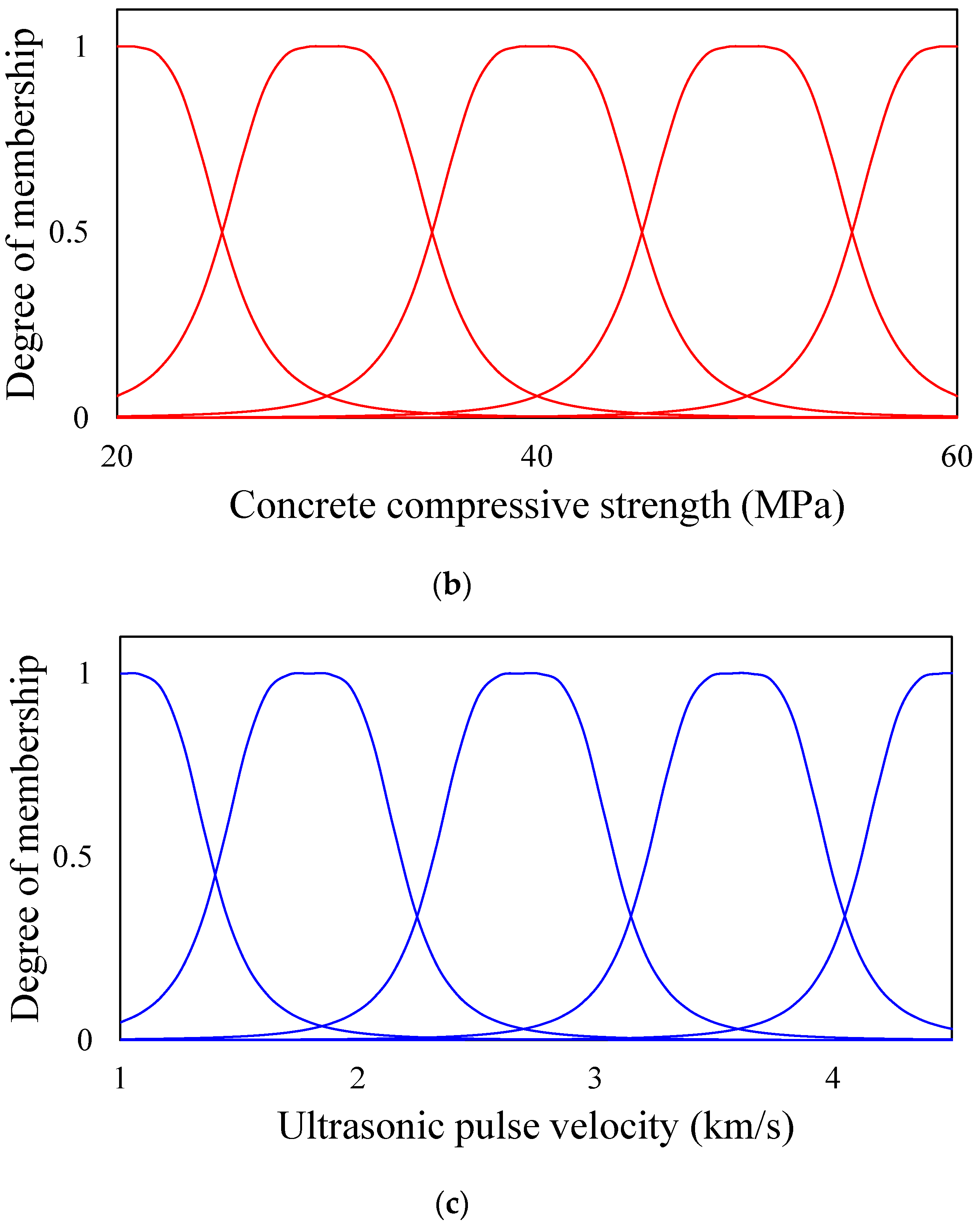

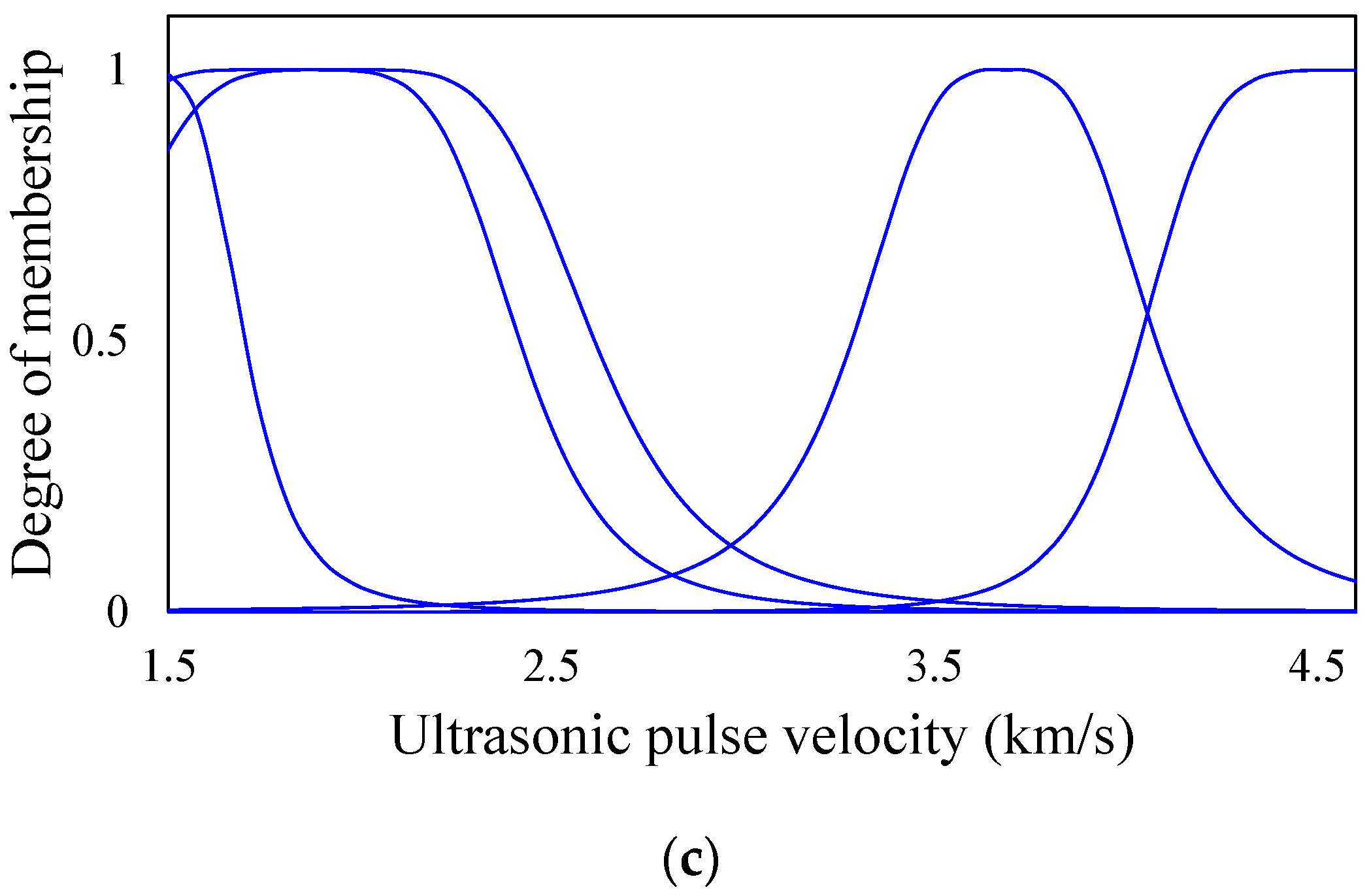

3.1. Ultrasonic Pulse Velocity Test

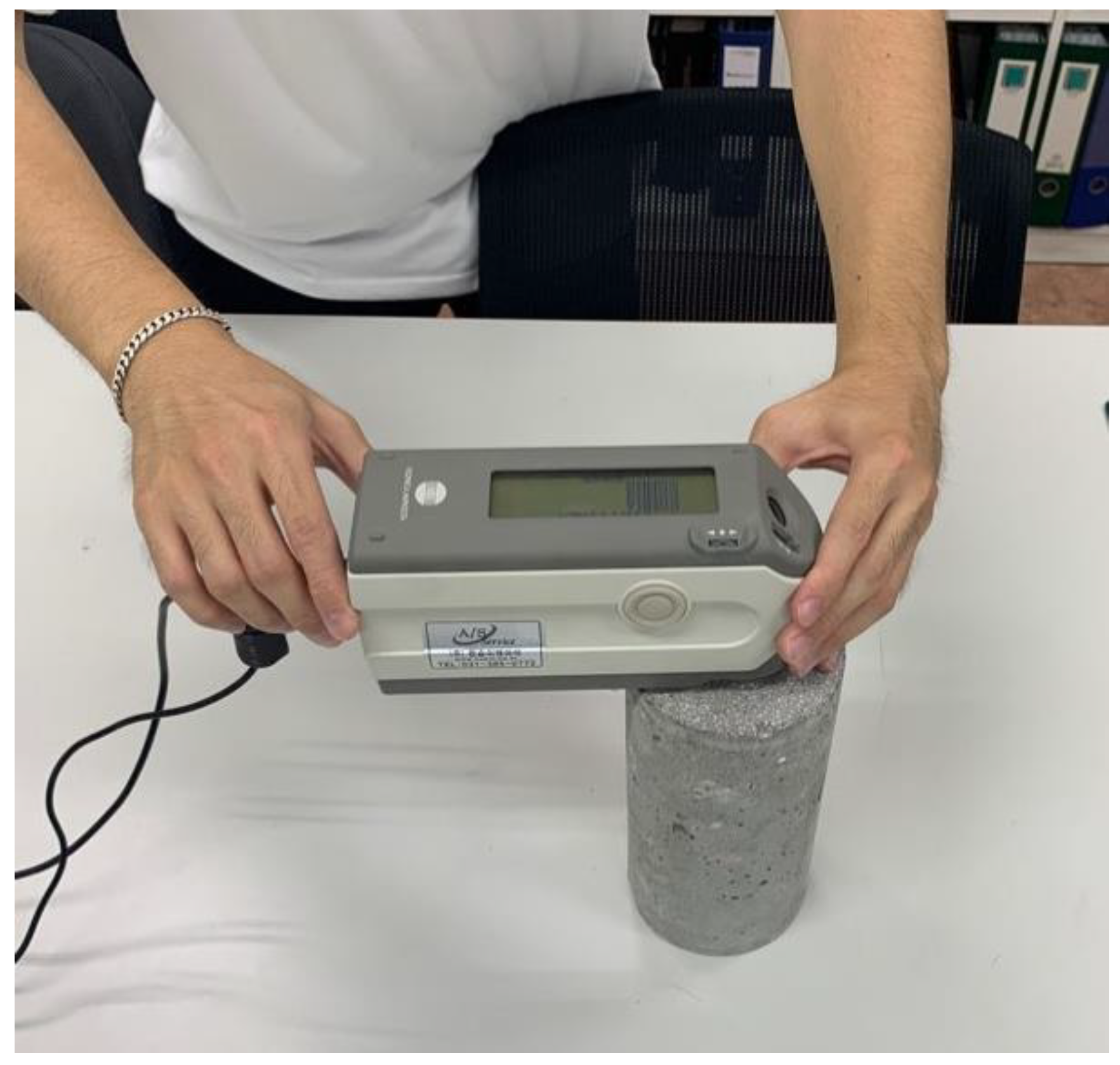

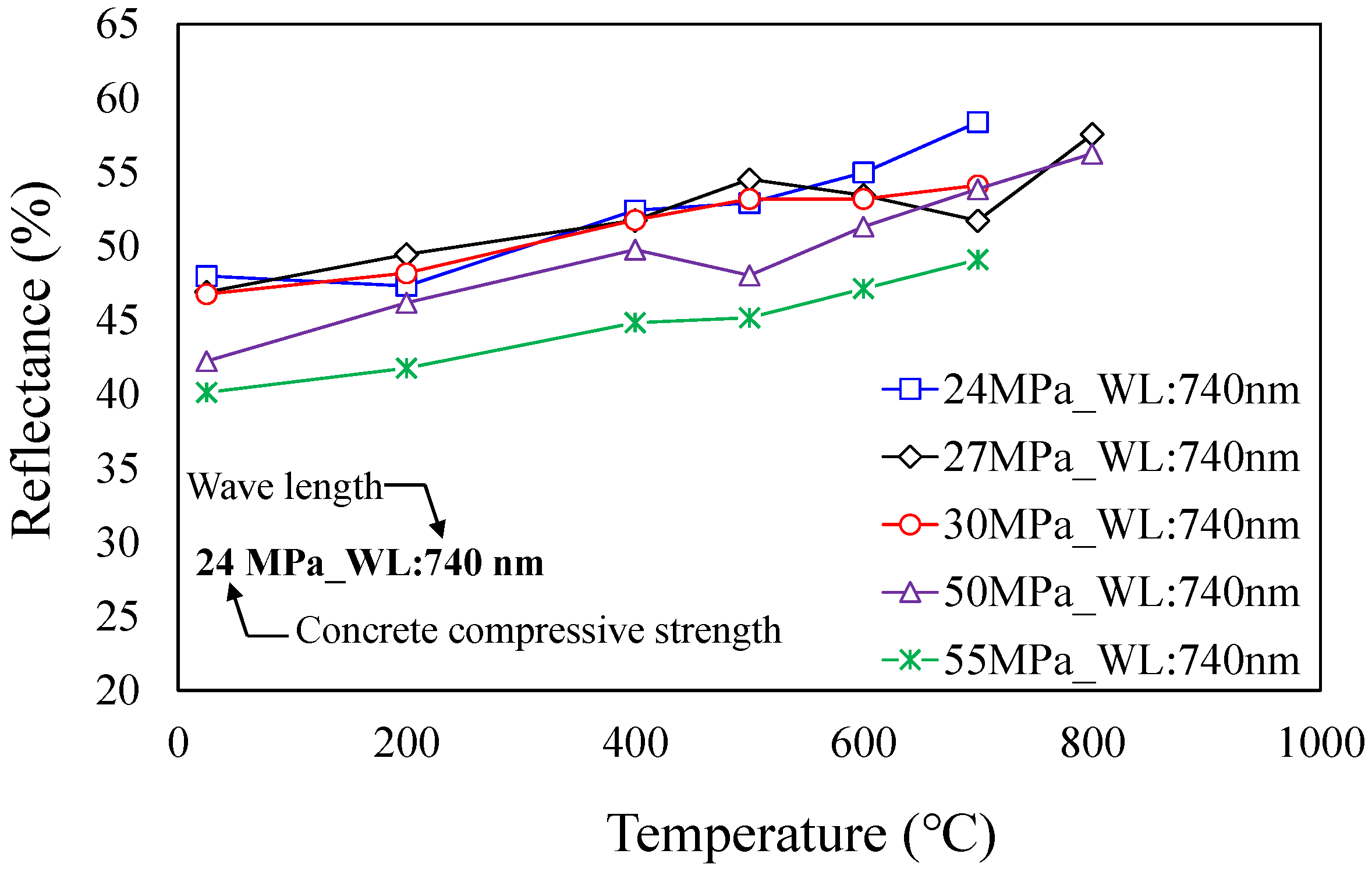

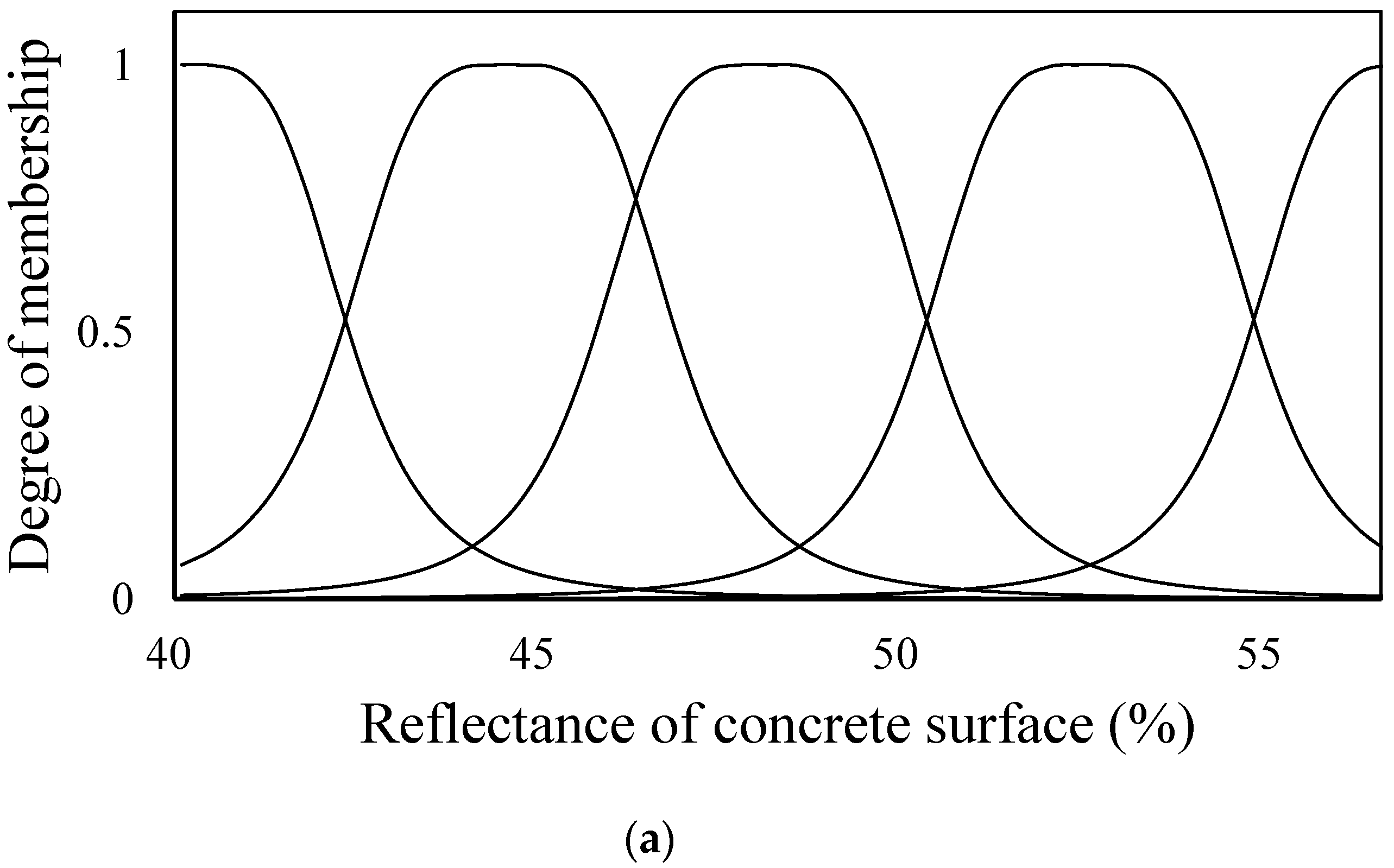

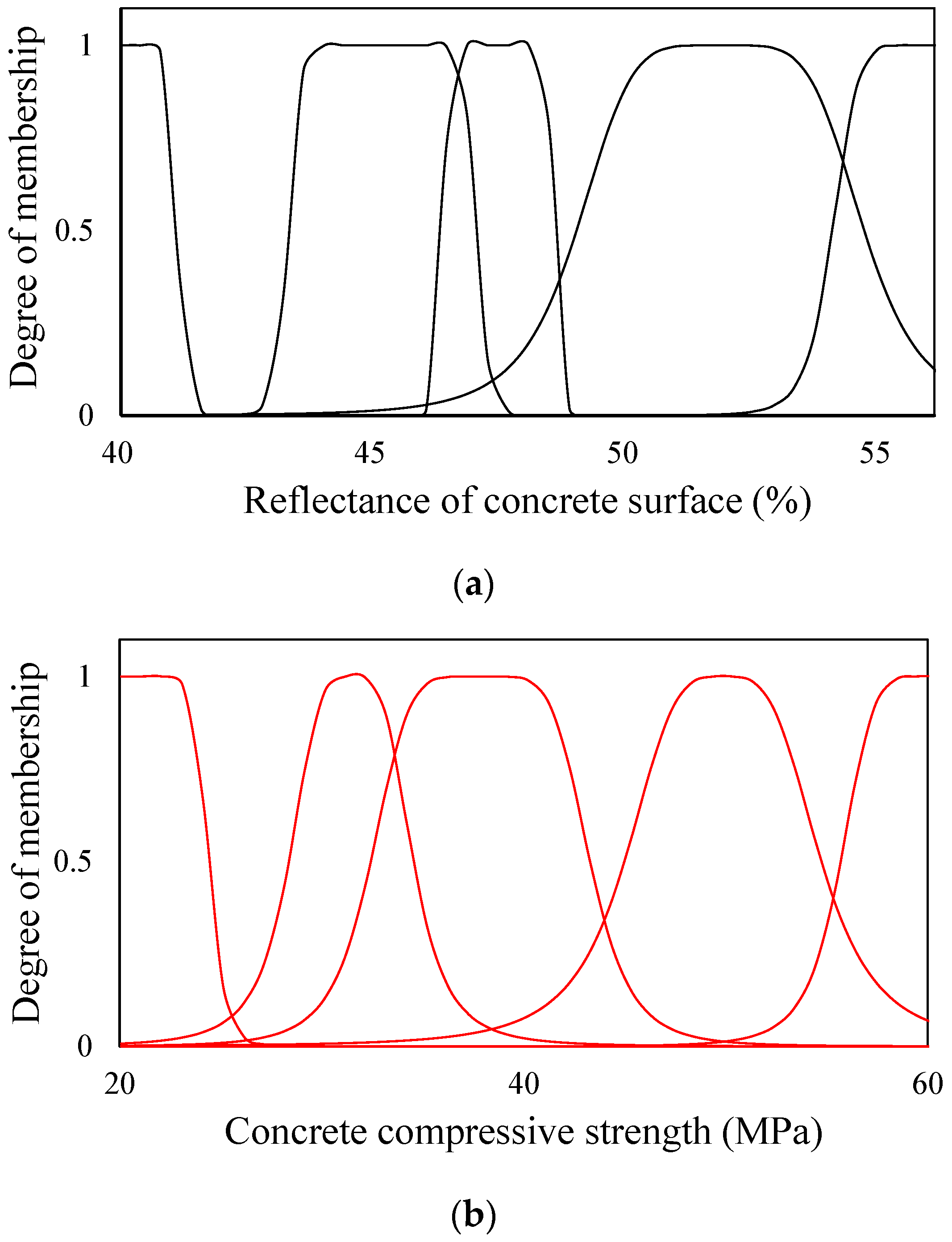

3.2. Colorimetric Analysis

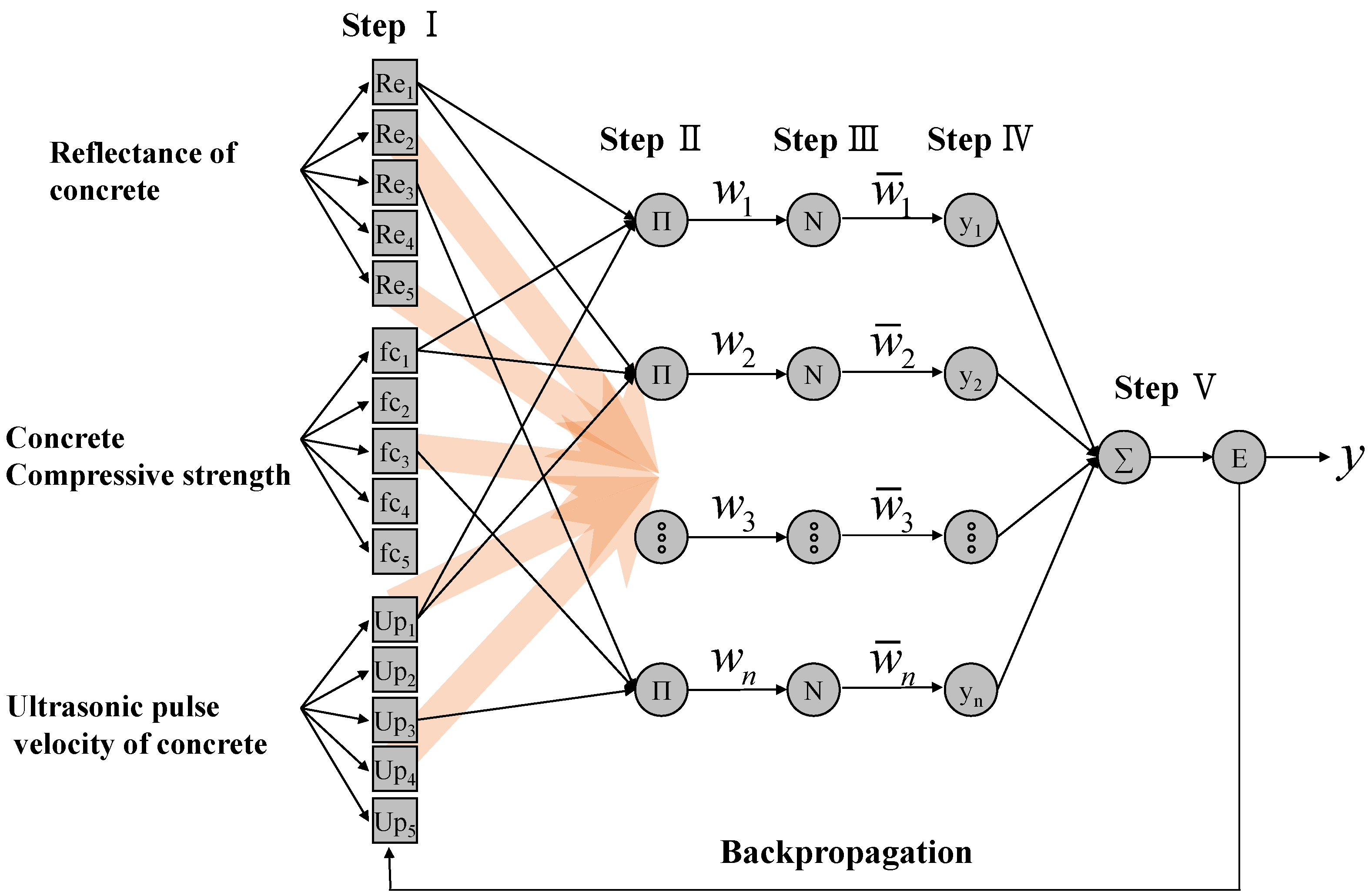

4. Adaptive Neuro-Fuzzy Inference System

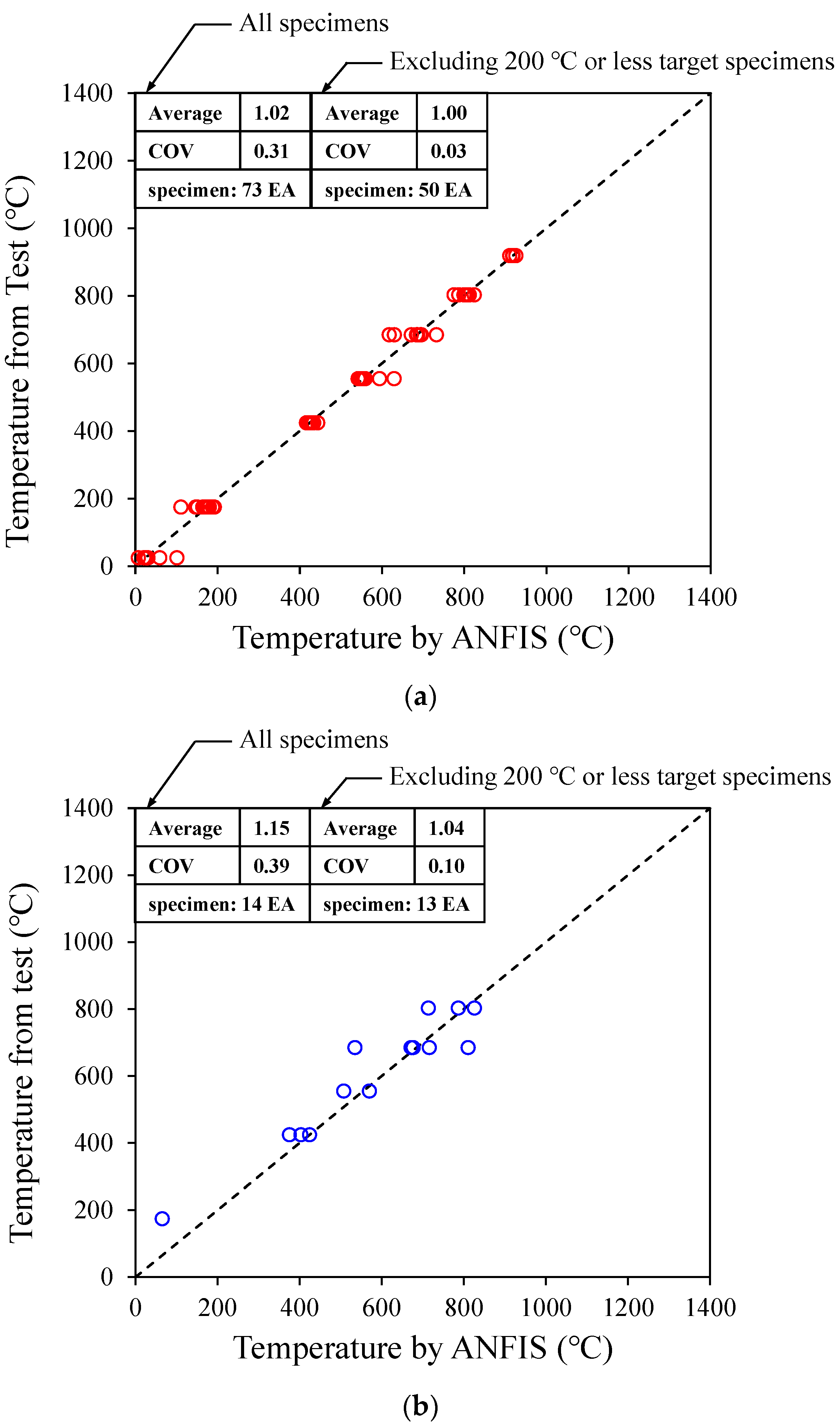

5. Verification

6. Conclusions

- The concrete heating test found that spalling occurred at lower temperatures as the concrete compressive strength increased. It was also found that the ultrasonic pulse velocity tended to decrease because of micro-pores and cracks that occurred inside the concrete as the heating temperature rose.

- The colorimetric analysis revealed that the reflectance of the concrete surface increased as the heating temperature rose and the concrete compressive strength decreased.

- Based on the test results, this study proposed a heating temperature estimation method using the ANFIS algorithm, in which the ultrasonic pulse velocity, reflectance of the concrete surface, and design compressive strength of the concrete were set as the main input parameters.

- The heating temperatures of the specimens were evaluated using the proposed ANFIS algorithm. The results showed that the proposed model estimated the heating temperatures of the specimens, which were not used in training, with a high degree of accuracy.

- In this study, the data training was performed using only the test results of the specimens made of ordinary Portland cement without any admixture. Thus, it is difficult to discuss about the influence of different concrete mixes, for instance, with admixture. Once test data is available, however, the same procedure can be applied to derive the discoloration and heating temperature relationship through the data training process.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, M.; Tang, Y.; Zou, X.; Huang, K.; He, Y. High-accuracy multi-camera reconstruction enhanced by adaptive point cloud correction algorithm. Opt. Lasers Eng. 2019, 122, 170–183. [Google Scholar] [CrossRef]

- Tang, Y.; Li, L.; Wang, C.; Chen, M.; Feng, W.; Zou, X. Real-time detection of surface deformation and strain in recycled aggregate concrete-filled steel tubular columns via four-ocular vision. Robot. Comput. Integr. Manuf. 2019, 59, 36–46. [Google Scholar] [CrossRef]

- Tang, Y.; Li, L.; Feng, W.; Liu, F.; Zou, X.; Chen, M. Binocular vision measurement and its application in full-field convex deformation of concrete-filled steel tubular columns. Measurement 2018, 130, 372–383. [Google Scholar] [CrossRef]

- Kang, H.; Lee, D.H.; Hwang, J.H.; Oh, J.Y.; Kim, K.S.; Kim, H.Y. Structural performances of prestressed composite members with corrugated webs exposed to fire. Fire Technol. 2015, 52, 1957–1981. [Google Scholar] [CrossRef]

- Heo, I.; Kang, H.; Lee, D.H.; Oh, J.Y.; Lee, J.; Kim, K.S. Performance-based fire behaviour analysis for underground parking structures. Int. J. Urban Sci. 2016, 20, 90–100. [Google Scholar] [CrossRef]

- Kang, H.; Cheon, N.R.; Lee, D.H.; Lee, J.; Kim, K.S.; Kim, H.Y. P-M interaction courve for reinforced concrete columns exposed to elevated temperature. Comput. Concr. 2017, 19, 537–544. [Google Scholar] [CrossRef]

- Dwaikat, M.B.; Kodur, V.K.R. A numerical approach for modeling the fire induced restraint effects in reinforced concrete beams. Fire Saf. J. 2008, 43, 291–307. [Google Scholar] [CrossRef]

- Architectural Institute of Japan. Diagnosis and Repair Methods of Fire-Damaged Buildings; Architectural Institute of Japan: Tokyo, Japan, 2004; pp. 40–63. [Google Scholar]

- Korea Concrete Institute. Fire Resistance Characteristics of Reinforced Concrete Structures; Korea Concrete Institute: Seoul, Korea, 2005. [Google Scholar]

- Fire Diagnosis. Repair and Reinforcement Method of Buildings; Architectural Institute of Japan: Tokyo, Japan, 2009. [Google Scholar]

- ACI. Concrete Repair Manual, 3rd ed.; ACI: Farmington Hills, MI, USA, 2008; Volume 2. [Google Scholar]

- Hager, I. Behaviour of cement concrete at high temperature. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 1–10. Available online: https://webcache.googleusercontent.com/search?q=cache:DYKMTJdl_YgJ:https://suw.biblos.pk.edu.pl/downloadResource%26mId%3D914477+&cd=13&hl=ko&ct=clnk&gl=kr (accessed on 1 March 2013). [CrossRef]

- Felicetti, R. Digital Camera Colorimetry for the Assessment of Fire Damaged Concrete. In Proceedings of the Fib Task Group 4.3 Workshop Fire Design of Concrete Structures: What Now? What Next? Milan, Italy, 2–4 December 2004. [Google Scholar]

- Yoshida, M.; Okamura, Y.; Tasaka, S.; Shimode, T. A study on temperature estimation in concrete members after fire. In Proceedings of the Fire Safety Science-Proceedings of the Fourth International Symposium, Munich, Germany, 13–17 July 1994; pp. 1183–1194. [Google Scholar]

- Park, S.J.; Yim, H.J.; Kwan, H.G. Experimental relationship between nonlinear ultrasonic method and compressive strength of thermally damaged concrete. In Proceedings of the The Twenty-Fifth KKCNN Symposium on Civil Engineering, Dajeon, Korea, 28 September 2012. [Google Scholar]

- Alqassim, M.A.; Jones, M.R.; Berlouis, L.E.A.; Nic Daeid, N. A thermoanalytical, X-ray diffraction and petrographic approach to the forensic assessment of fire affected concrete in the United Arab Emirates. Forensic Sci. Int. 2016, 264, 82–88. [Google Scholar] [CrossRef]

- Heo, Y.; Lee, G.; Lee, G. Effect of elevated temperatures on chemical properties, microstructure and carbonation of cement paste. J. Ceram. Process. Res. 2016, 17, 648–652. Available online: http://jcpr.kbs-lab.co.kr/file/JCPR_vol.17_2016/JCPR17-6/24.2016-052_648-652.pdf (accessed on 1 January 2016).

- Chen, B.T.; Chang, T.P.; Shih, J.Y.; Wang, J.J. Estimation of exposed temperature for fire-damaged concrete using support vector machine. Comput. Mater. Sci. 2009, 44, 913–920. [Google Scholar] [CrossRef]

- Cho, H.C.; Ju, H.; Lee, K.J.; Hahm, K.W.; Kim, K.S. Estimation of concrete carbonation depth considering multiple influencing factors on the deterioration of durability for reinforced concrete structures. Adv. Mater. Sci. Eng. 2016, 2016, 1–18. [Google Scholar] [CrossRef]

- Jang, J.S.R.; Sun, C.T.; Mizutani, E. Neuro-Fuzzy and Soft Computing; Prentice Hall: Upper Saddle river, NJ, USA, 1997. [Google Scholar]

- Jang, J.S.R.; Sun, C.T. Neuro-fuzzy modeling and control. Proc. IEEE 1995, 83, 378–406. [Google Scholar] [CrossRef]

- Purkiss, J.A. Fire Safety Engineering: Design of Structures, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Dwaikat, M.B.; Kodur, V.K.R. Hydrothermal model for predicting fire-induced spalling in concrete structural systems. Fire Saf. J. 2009, 44, 425–434. [Google Scholar] [CrossRef]

- Kodur, V.K.R. Spalling in high strength concrete exposed to fire—Concerns, causes, critical parameters and cures. In Proceedings of the ASCE Structures Congress, Philadelphia, PA, USA, 8–10 May 2000; pp. 1–9. [Google Scholar] [CrossRef]

- Kang, H. Structural Behavior of Reinforced Concrete Flexural Members under Fire. Master’s Thesis, University of Seoul, Seoul, Korea, 2012. [Google Scholar]

- Shih, Y.F.; Wang, Y.R.; Lin, K.L.; Chen, C.W. Improving non-destructive concrete strength tests using support vector machines. Materials 2015, 8, 7169–7178. [Google Scholar] [CrossRef]

- Hager, I. Colour change in heated concrete. Fire Technol. 2014, 50, 945–958. [Google Scholar] [CrossRef]

- Dilek, U. Assessment of fire damage to a reinforced concrete structure during construction. J. Perform. Constr. Facil. 2007, 41, 257–263. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 33–353. [Google Scholar] [CrossRef]

- Zimmermann, H.J. Fuzzy Set Theory and its Applications; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Cho, H.C.; Lee, D.H.; Ju, H.; Park, H.C.; Kim, H.Y.; Kim, K.S. Fire damage assessment of reinforced concrete structures using fuzzy theory. Appl. Sci. 2017, 7, 518. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man Cybern. 1985, 15, 116–132. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man Mach. Stud. 1975, 7, 1–13. [Google Scholar] [CrossRef]

- Hung, W.L.; Wu, J.W. Correlation of intuitionistic fuzzy sets by centroid method. Inf. Sci. 2002, 144, 219–225. [Google Scholar] [CrossRef]

- Eurocode 2 EN. Basis of Design and Design Actions on Structures Part1-2: Actions on Structures Exposed to Fire; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

| Korea and Japan | US | |

|---|---|---|

| Grade | Condition | Condition |

| A | Unaffected | Unaffected |

| B | Damage to finishing materials.

|

|

| C | No damage to the rebar

|

|

| D | Affected on bond performance of main rebar

|

|

| E | Great damage such as main rebar buckling

|

|

| No. | Concrete Compressive | Number of Specimens | Target Temperature (°C) | |

|---|---|---|---|---|

| Strength (MPa) | ||||

| Design Strength | Measured Strength | |||

| 1 | 24 | 25.5 | 21/each test | 25 |

| 200 | ||||

| 2 | 27 | 28.8 | 400 | |

| 3 | 30 | 35 | 500 | |

| 4 | 50 | 50.9 | 600 | |

| 5 | 55 | 56.9 | 700 | |

| 6 | 80 | 77.1 | 800 | |

| Concrete Compressive Strength (MPa) | Target Temperature (°C) | Temperature (°C) | |

|---|---|---|---|

| Furnace | Specimen | ||

| 77.1 | 400 | 344 | 268 |

| 77.1 | 500 | 400 | 226 |

| 419 | 239 | ||

| 420 | 255 | ||

| 56.9 | 600 | 498 | 310 |

| 35.0 | 700 | 453 | 228 |

| 56.9 | 800 | 453 | 303 |

| 475 | 337 | ||

| Average temperature | 433 | 270 | |

| Target Temperature (°C) | Ultrasonic Pulse Velocity (km/s) | ||||

|---|---|---|---|---|---|

| 24 MPa * Concrete Specimens | 27 MPa * Concrete Specimens | 30 MPa * Concrete Specimens | 50 MPa * Concrete Specimens | 55 MPa * Concrete Specimens | |

| 25 | 5.13 | 4.17 | 5.00 | 4.56 | 4.92 |

| 4.65 | 4.15 | 4.62 | 4.57 | 4.65 | |

| 4.78 | 4.21 | 4.89 | 4.81 | 4.72 | |

| 200 | 4.41 | 3.90 | 4.72 | 3.96 | 4.49 |

| 4.21 | 3.71 | 4.51 | 3.98 | 4.13 | |

| 4.45 | 3.90 | 4.42 | 4.07 | - ** | |

| 400 | 3.08 | 2.73 | 3.58 | 2.56 | 3.48 |

| 2.82 | 2.77 | 3.21 | 3.10 | 3.51 | |

| 2.96 | 2.75 | 3.12 | 3.01 | - ** | |

| 500 | 2.41 | 1.87 | 2.42 | 2.21 | 2.59 |

| 2.12 | 1.54 | 2.42 | 2.06 | 2.62 | |

| 2.42 | 1.50 | 2.66 | 2.10 | - ** | |

| 600 | 2.14 | 1.29 | 2.34 | 1.39 | 2.57 |

| 2.10 | 1.29 | 2.40 | 1.43 | 2.42 | |

| 2.10 | 1.30 | 2.42 | 1.31 | - ** | |

| 1.98 | - ** | 2.36 | - ** | - ** | |

| 700 | 1.55 | 1.01 | 1.88 | 1.05 | 1.68 |

| 1.52 | 0.99 | 1.85 | 1.12 | 1.66 | |

| 1.51 | 0.96 | 1.79 | 1.04 | - ** | |

| 1.63 | - ** | - ** | - ** | - ** | |

| 800 | - ** | 0.46 | - ** | 0.92 | - ** |

| - ** | - ** | - ** | 0.94 | - ** | |

| - ** | - ** | - ** | 0.96 | - ** | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.; Cho, H.-C.; Choi, S.-H.; Heo, I.; Kim, H.-Y.; Kim, K.S. Estimation of Heating Temperature for Fire-Damaged Concrete Structures Using Adaptive Neuro-Fuzzy Inference System. Materials 2019, 12, 3964. https://doi.org/10.3390/ma12233964

Kang H, Cho H-C, Choi S-H, Heo I, Kim H-Y, Kim KS. Estimation of Heating Temperature for Fire-Damaged Concrete Structures Using Adaptive Neuro-Fuzzy Inference System. Materials. 2019; 12(23):3964. https://doi.org/10.3390/ma12233964

Chicago/Turabian StyleKang, Hyun, Hae-Chang Cho, Seung-Ho Choi, Inwook Heo, Heung-Youl Kim, and Kang Su Kim. 2019. "Estimation of Heating Temperature for Fire-Damaged Concrete Structures Using Adaptive Neuro-Fuzzy Inference System" Materials 12, no. 23: 3964. https://doi.org/10.3390/ma12233964