Tool Life Performance of Injection Mould Tooling Fabricated by Selective Laser Melting for High-Volume Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Overall Framework

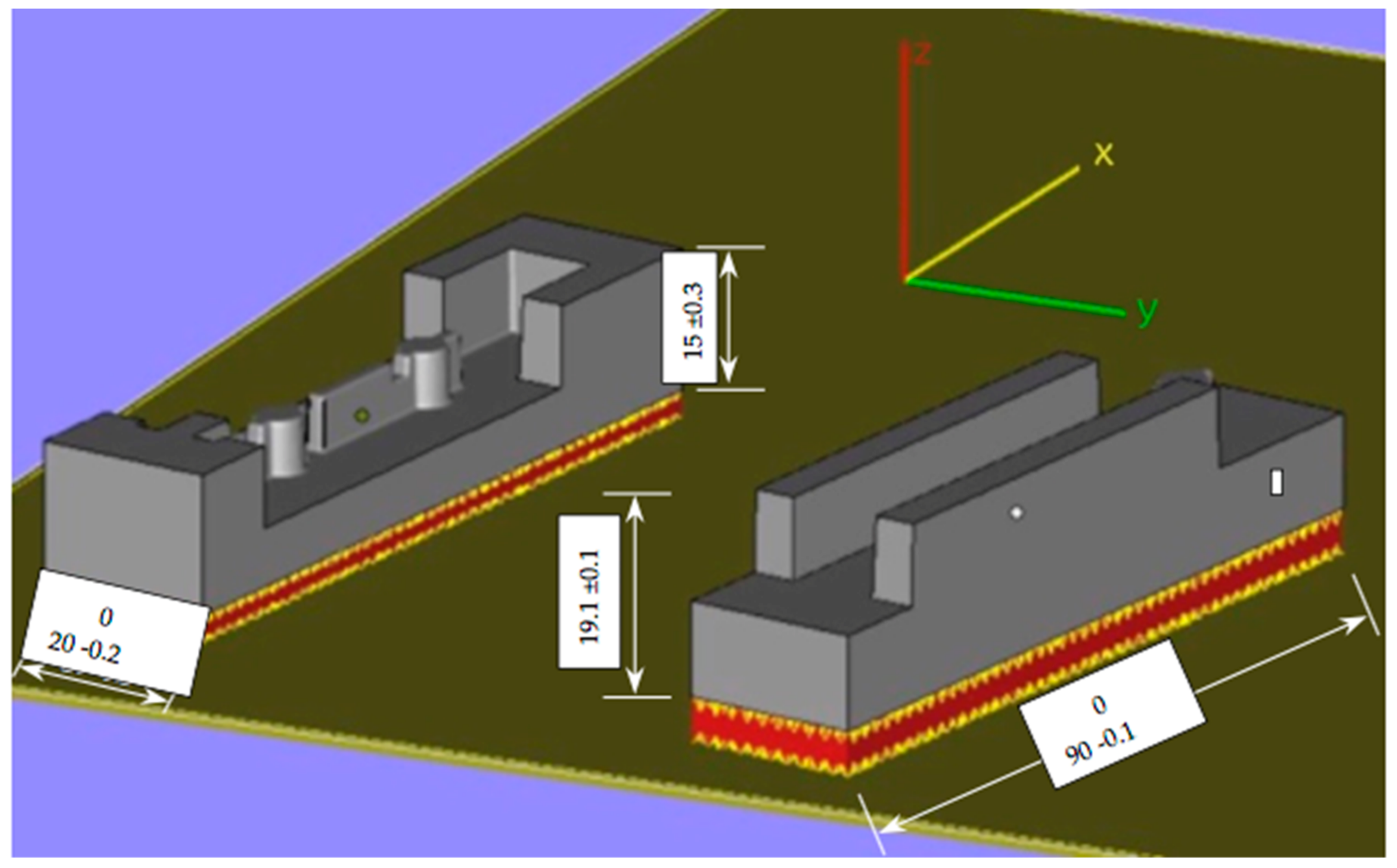

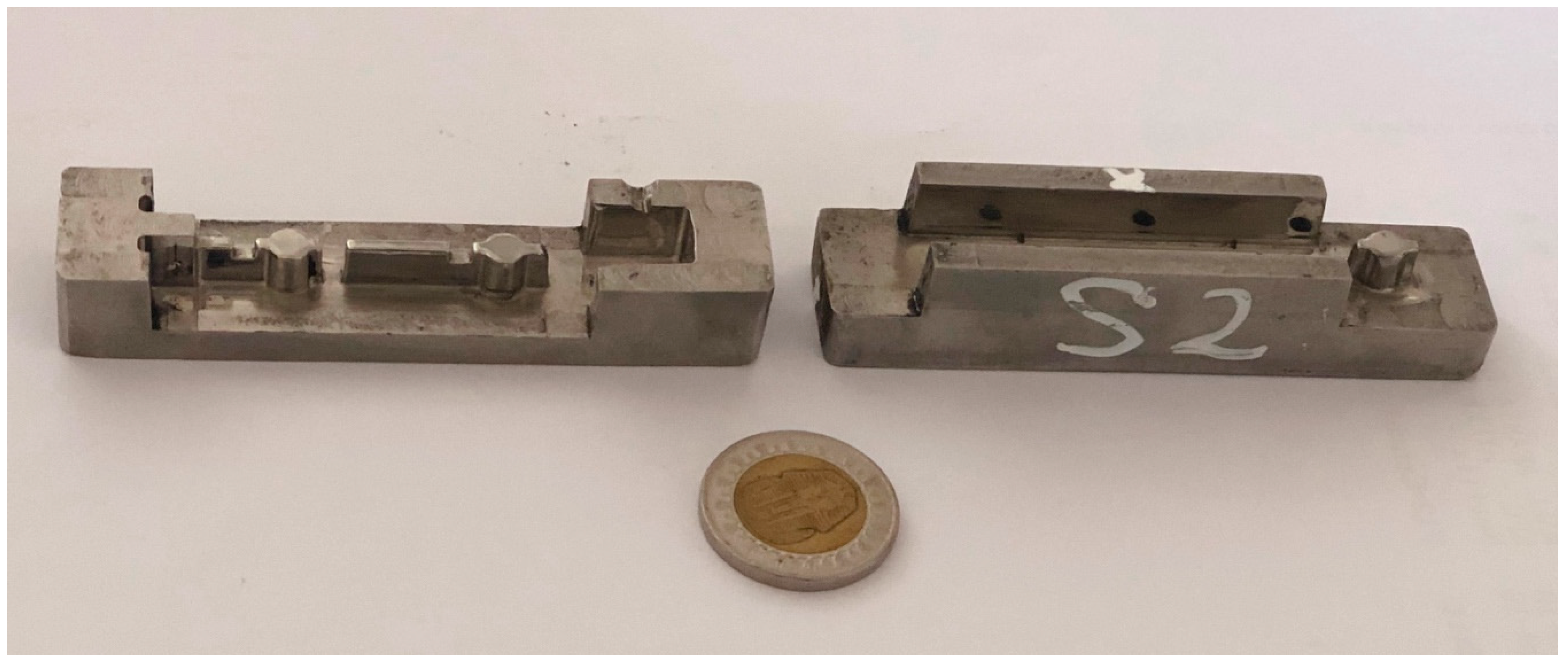

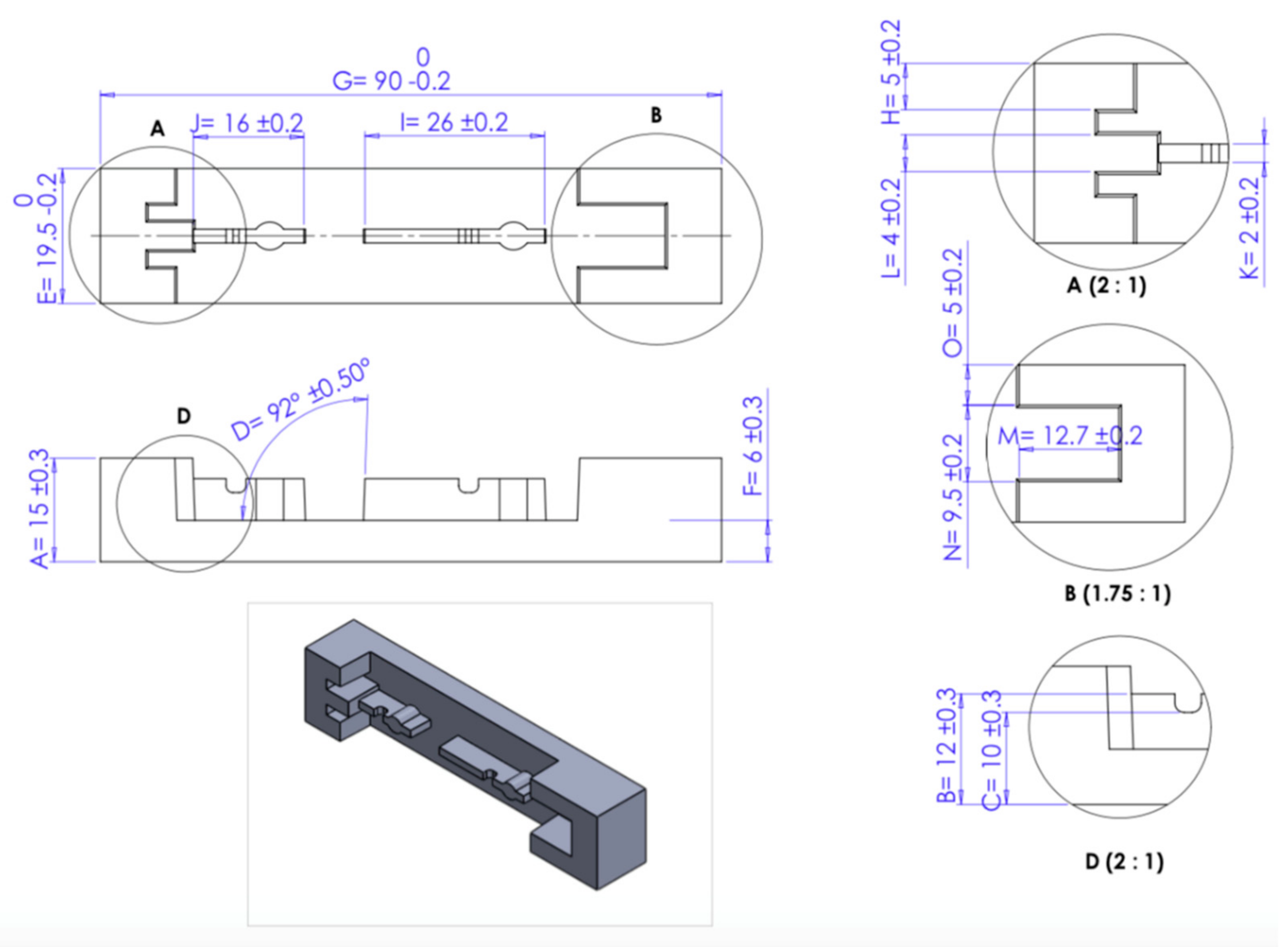

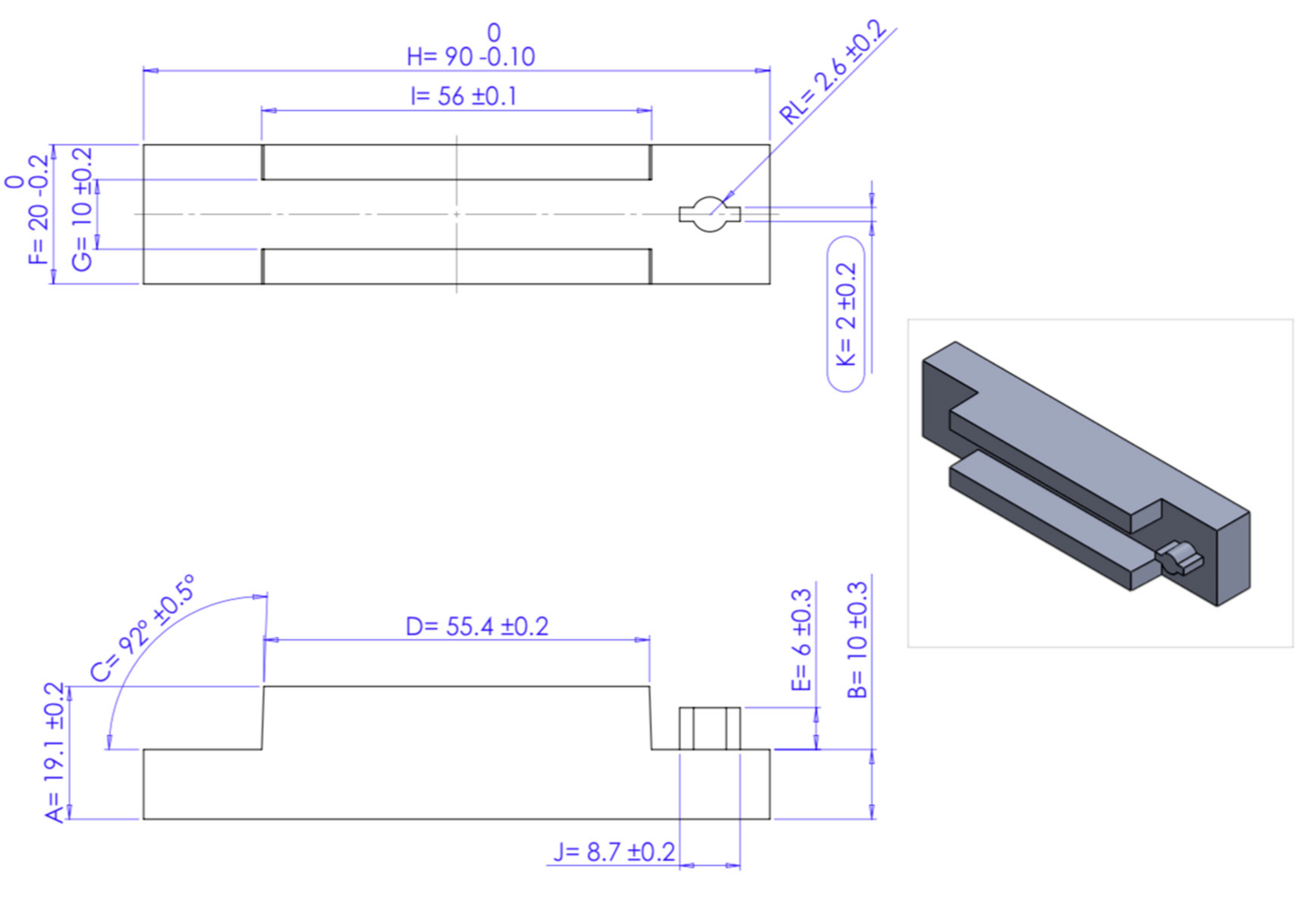

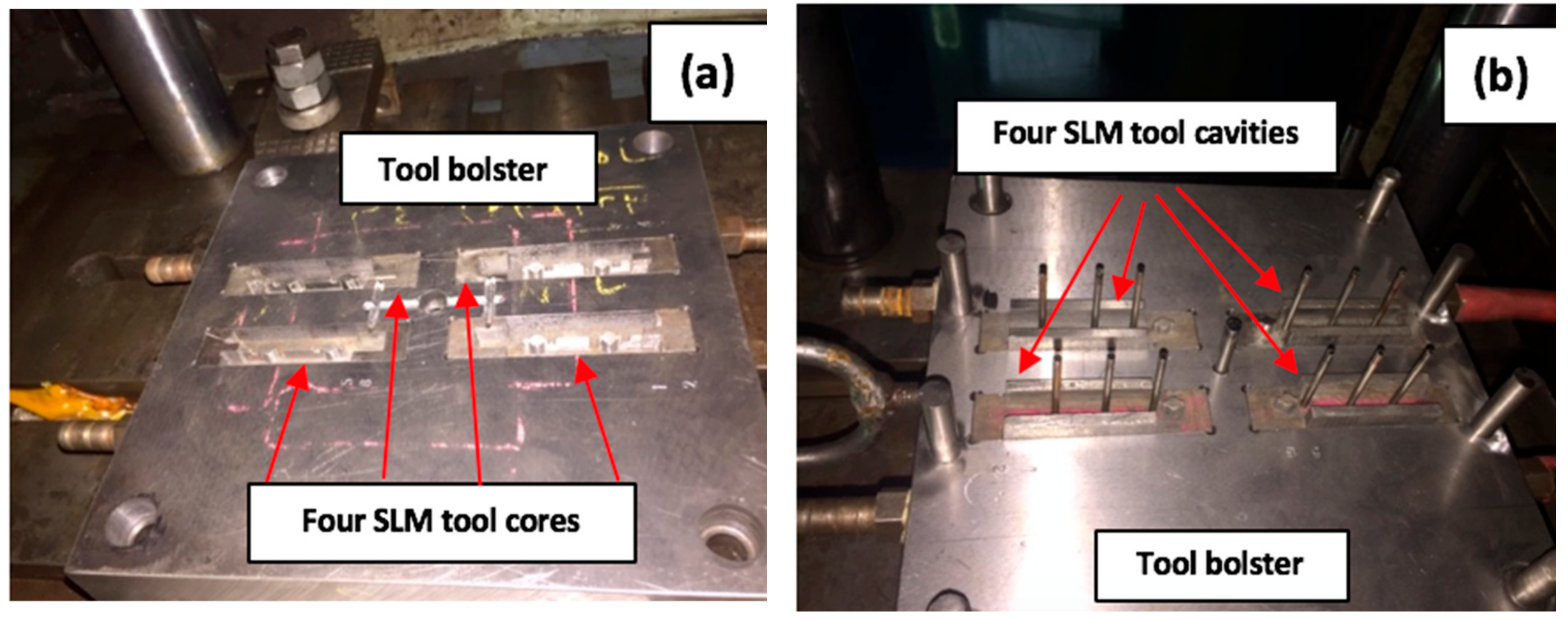

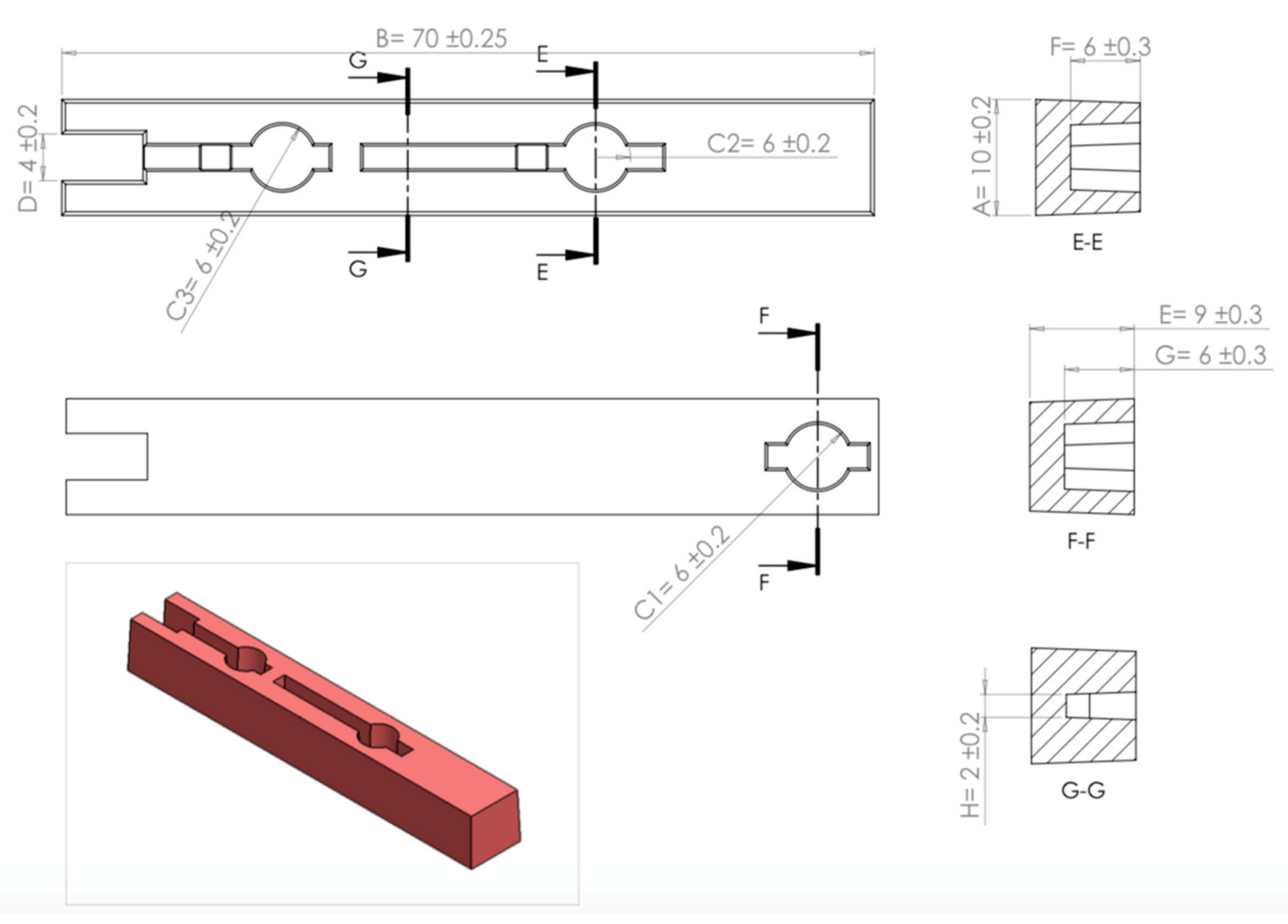

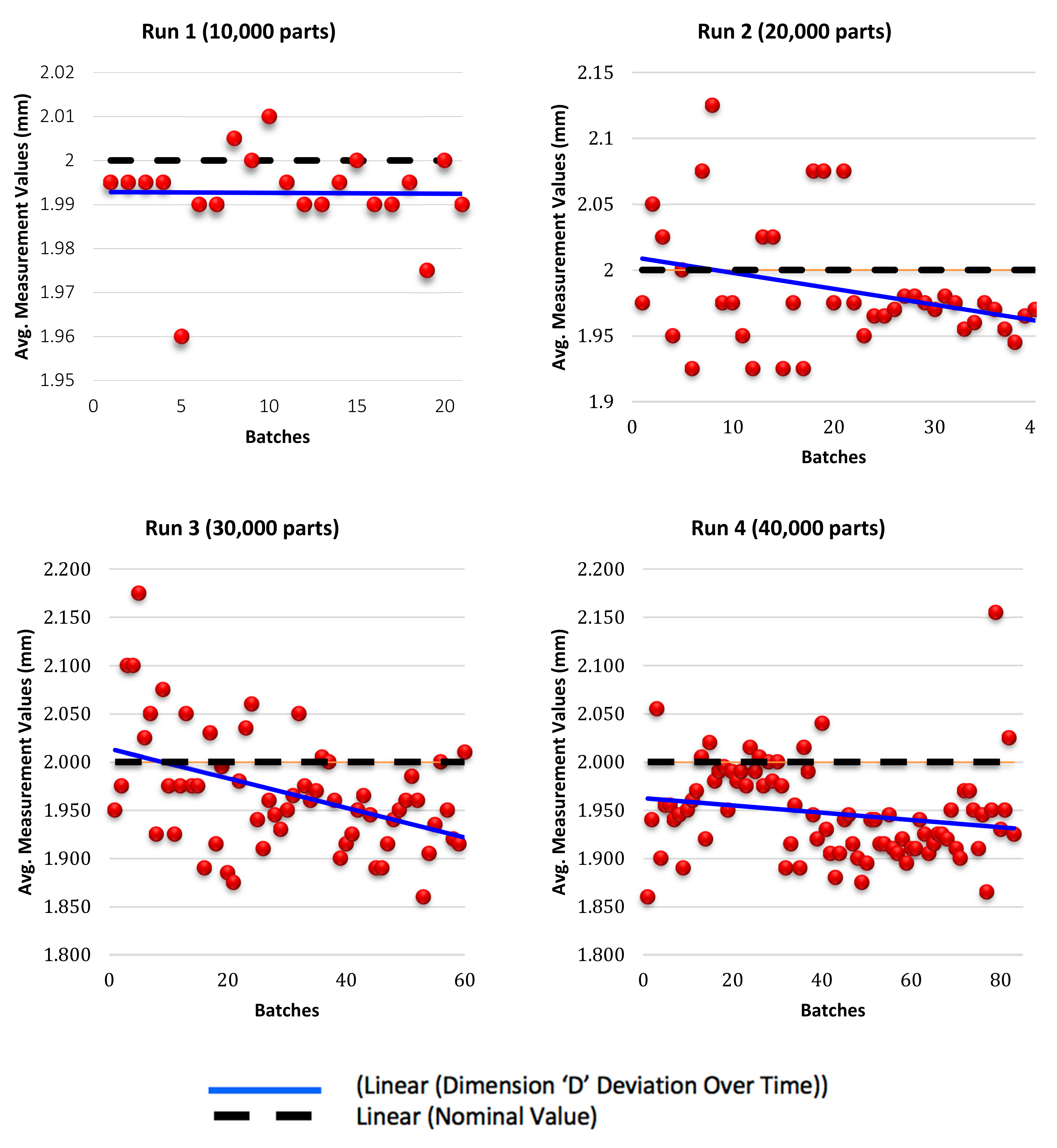

2.2. Tool Insert Fabrication

3. Tool Experimentation, Results and Discussion

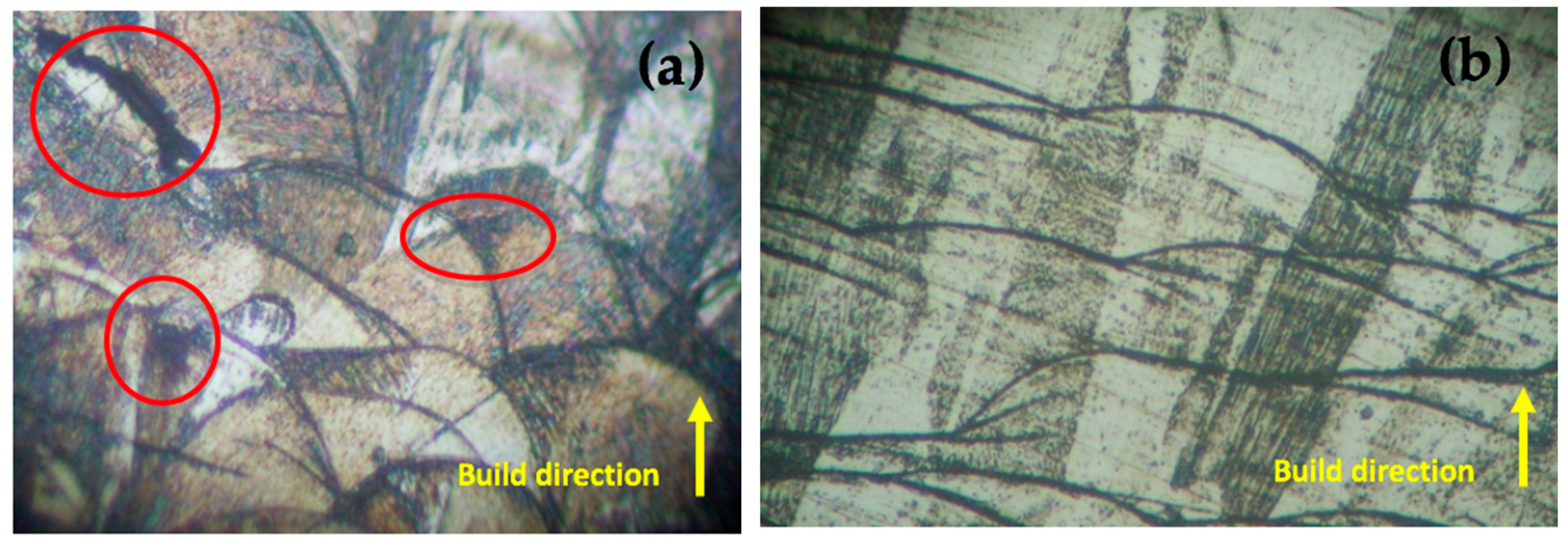

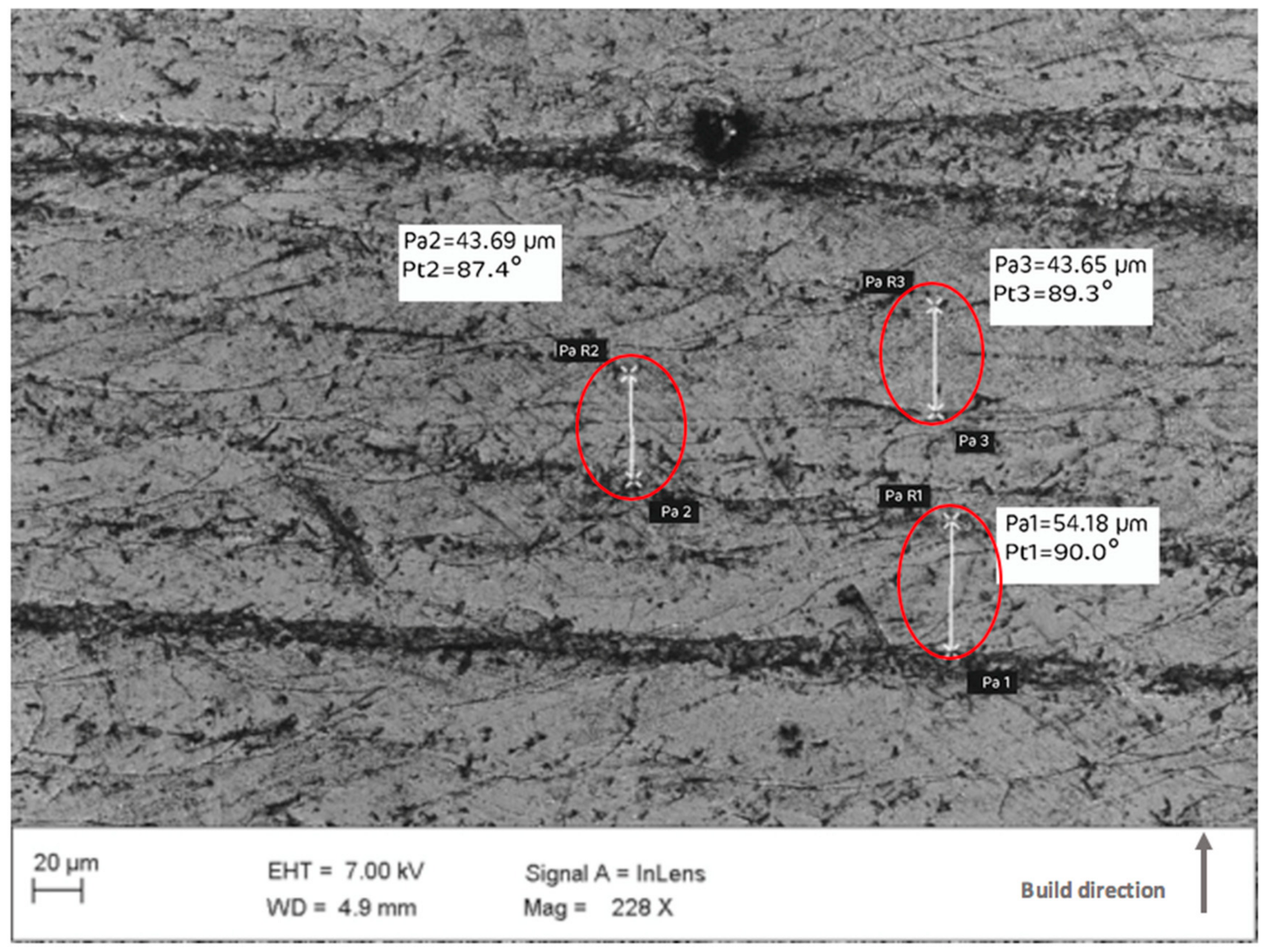

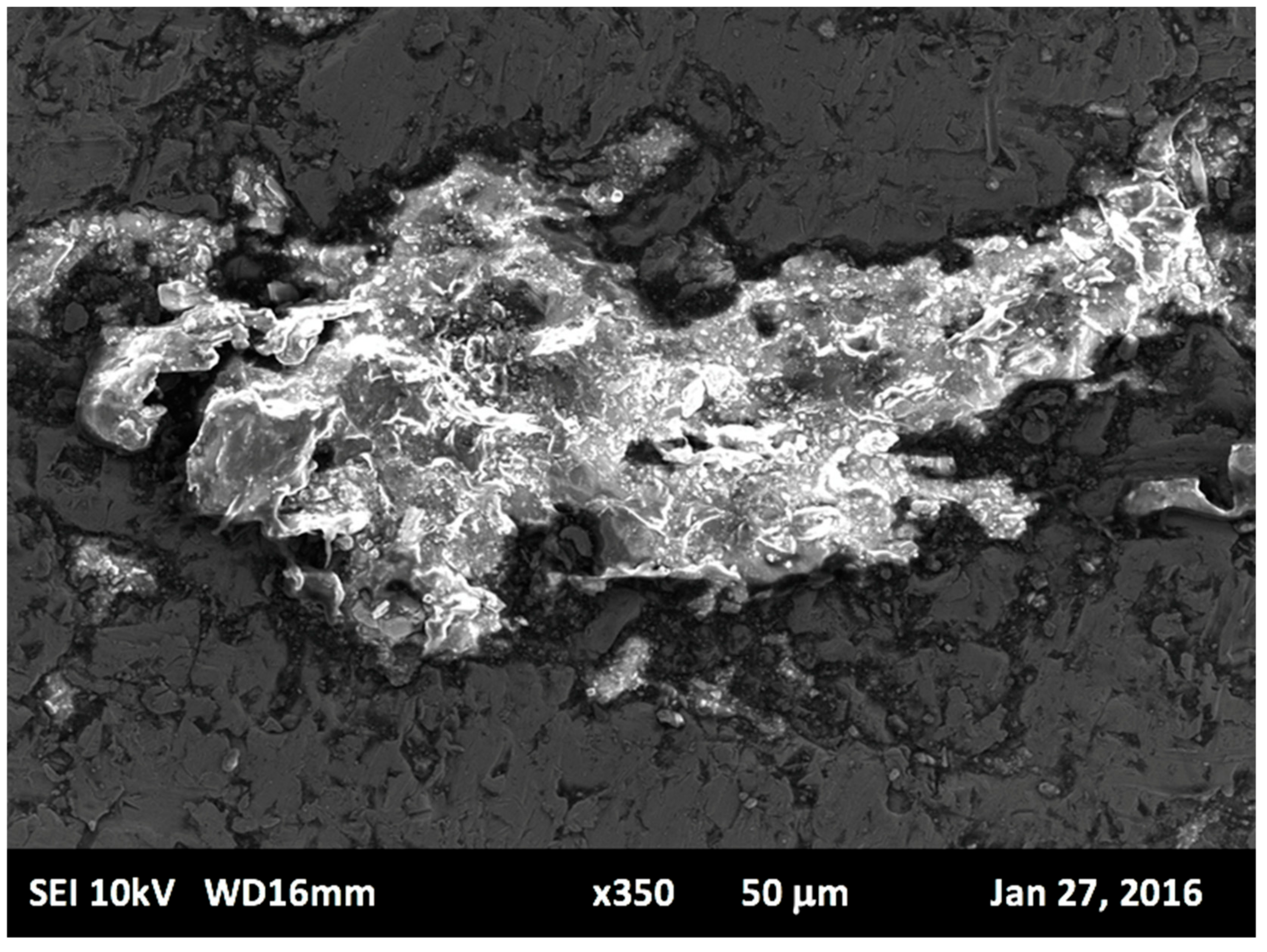

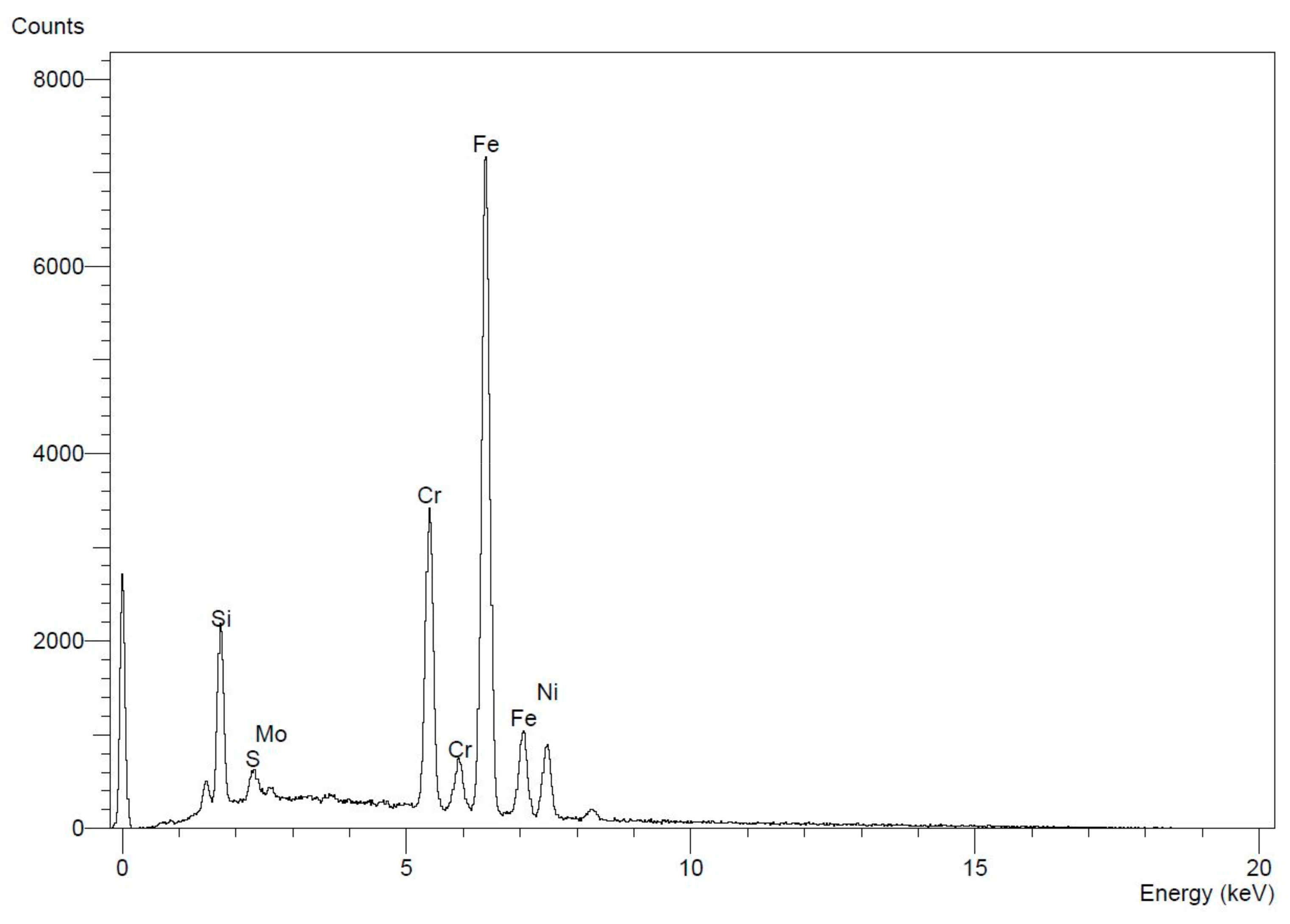

3.1. Microstructure

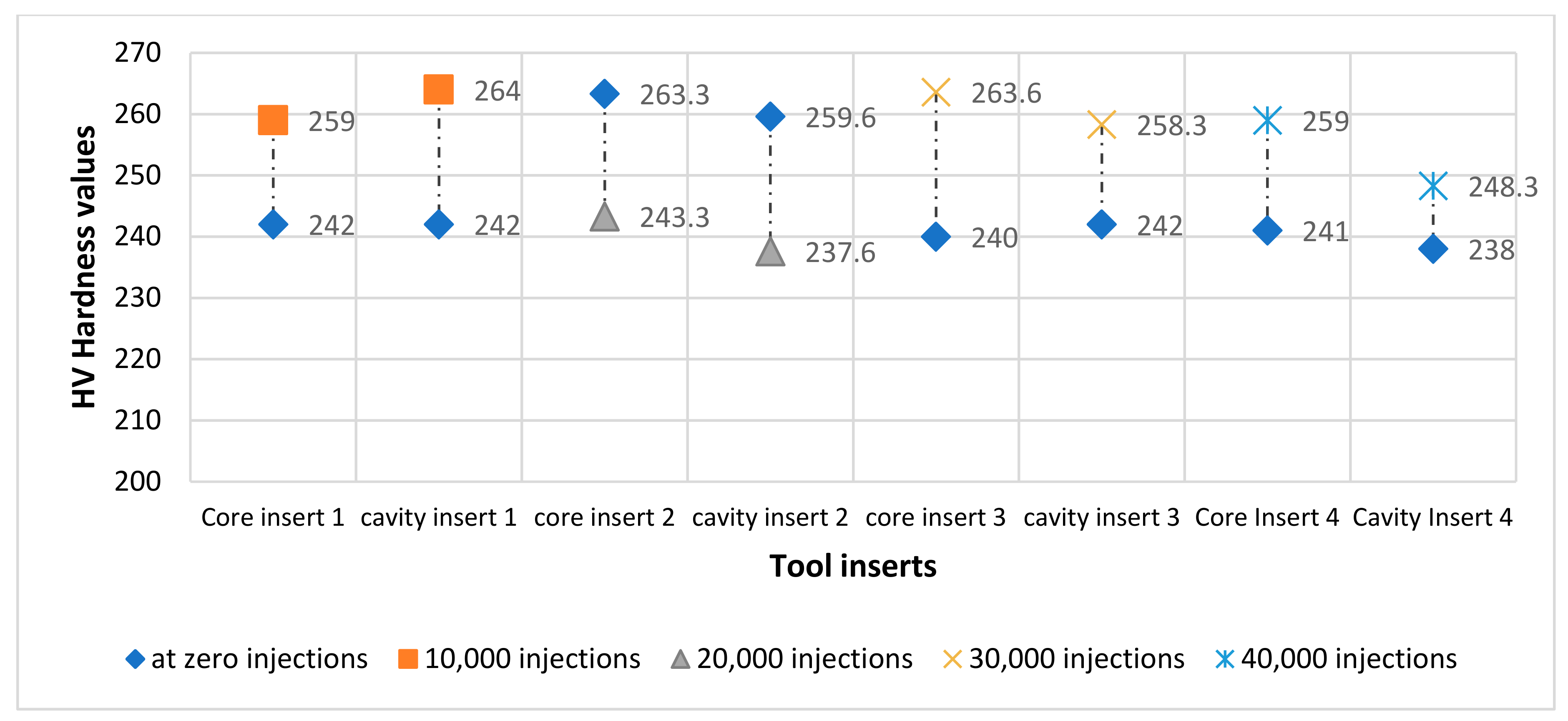

3.2. Hardness Test

3.3. Dimensional Measurements

4. Product Evaluation of Injection Moulding

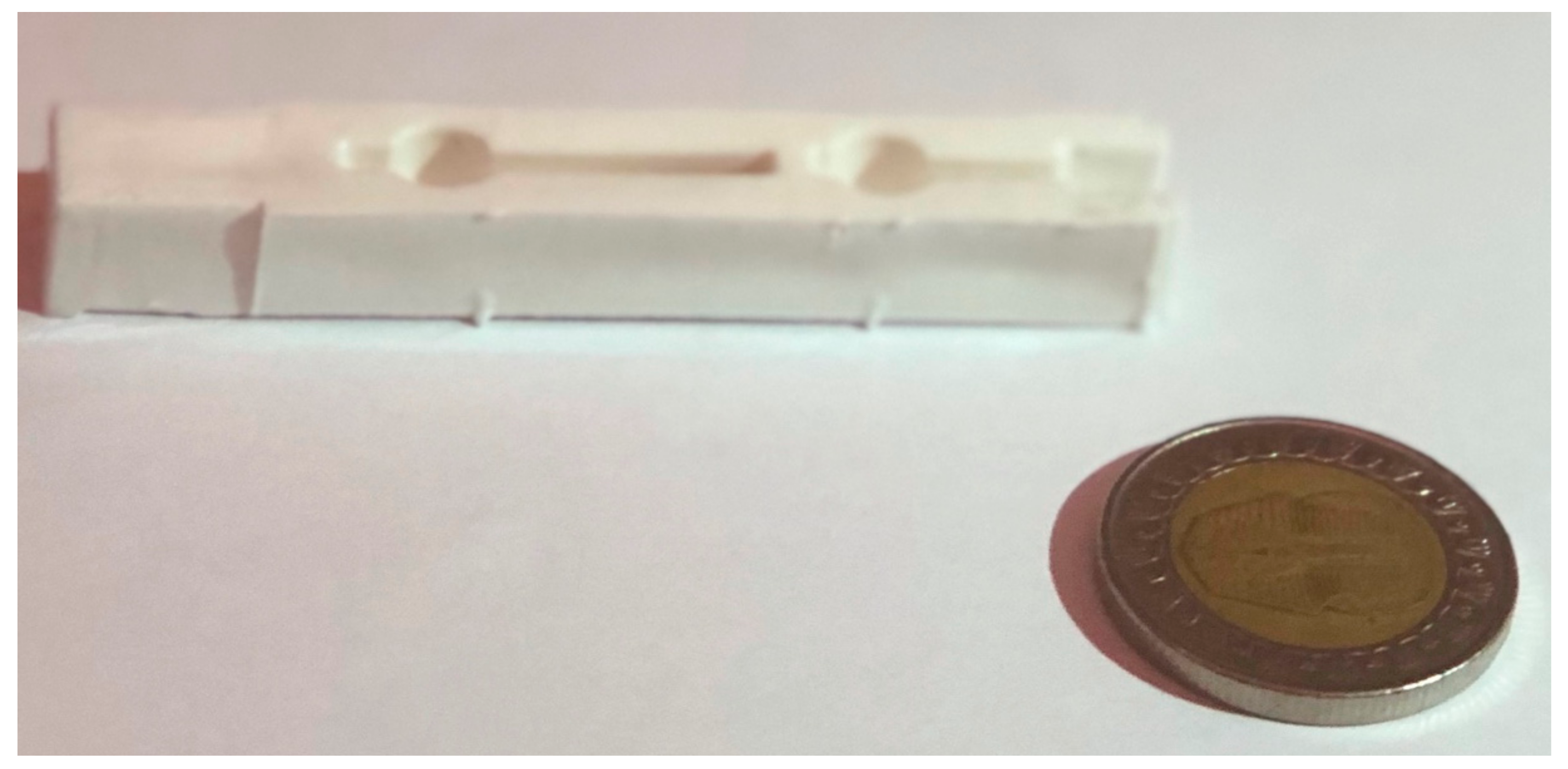

4.1. Injection Moulding

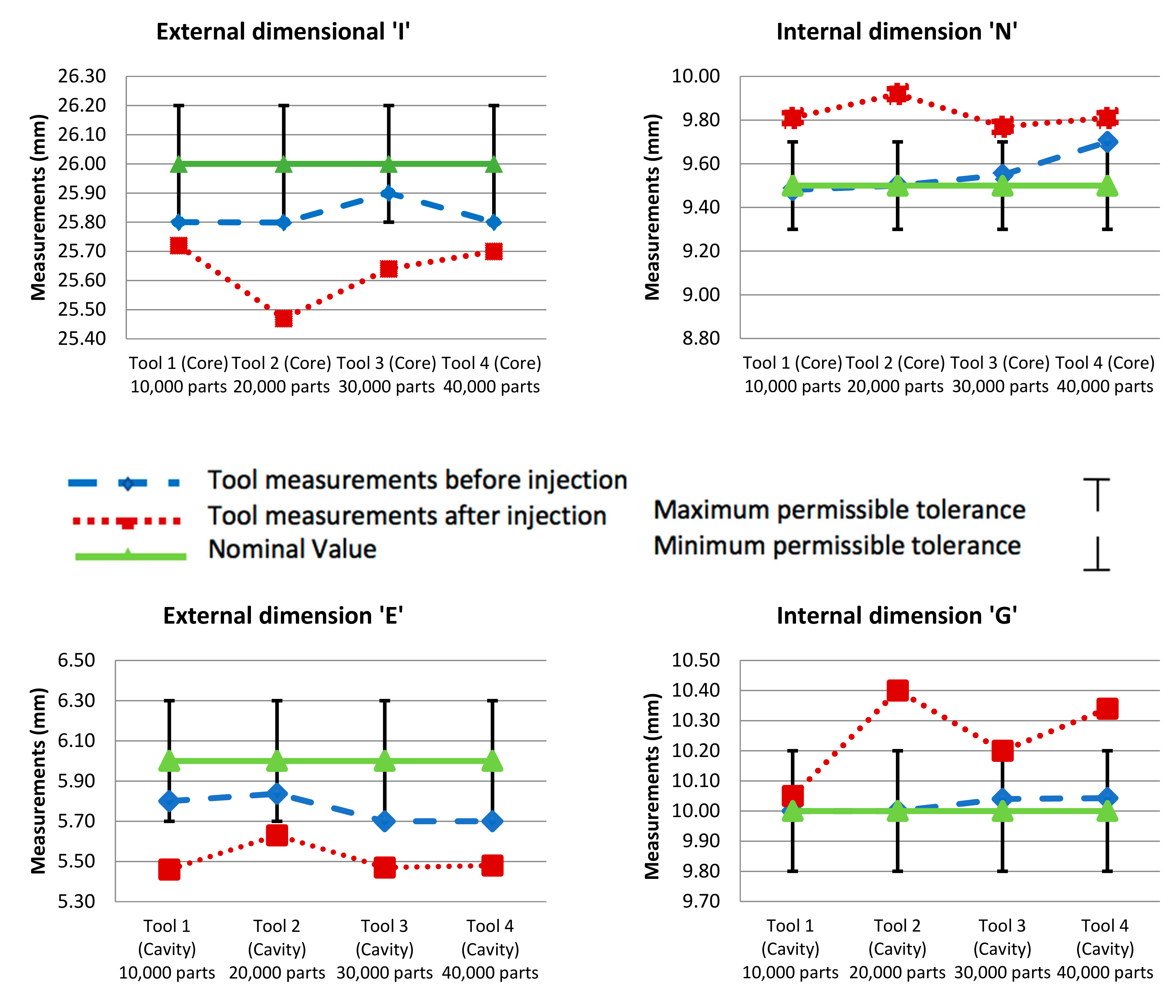

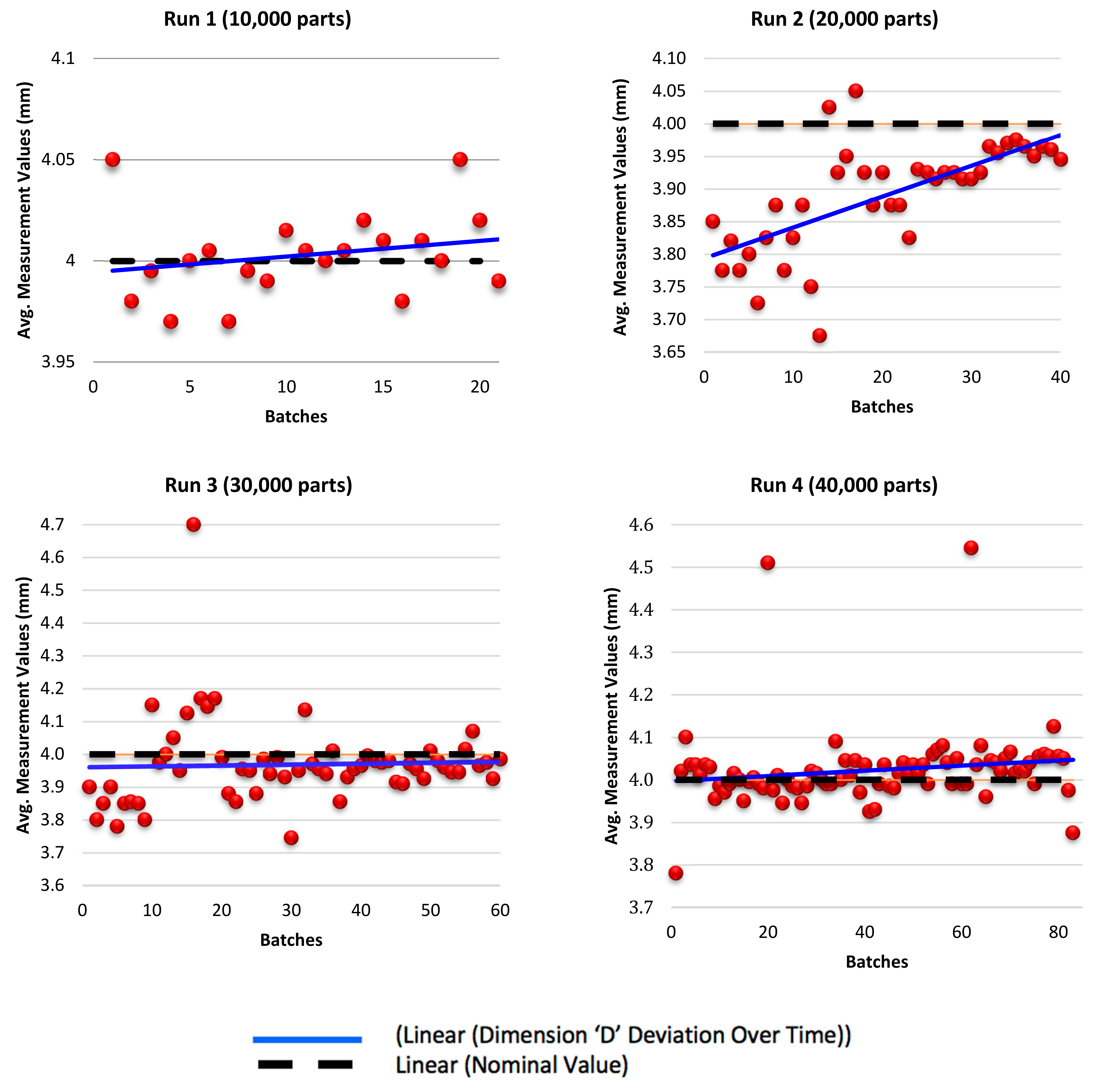

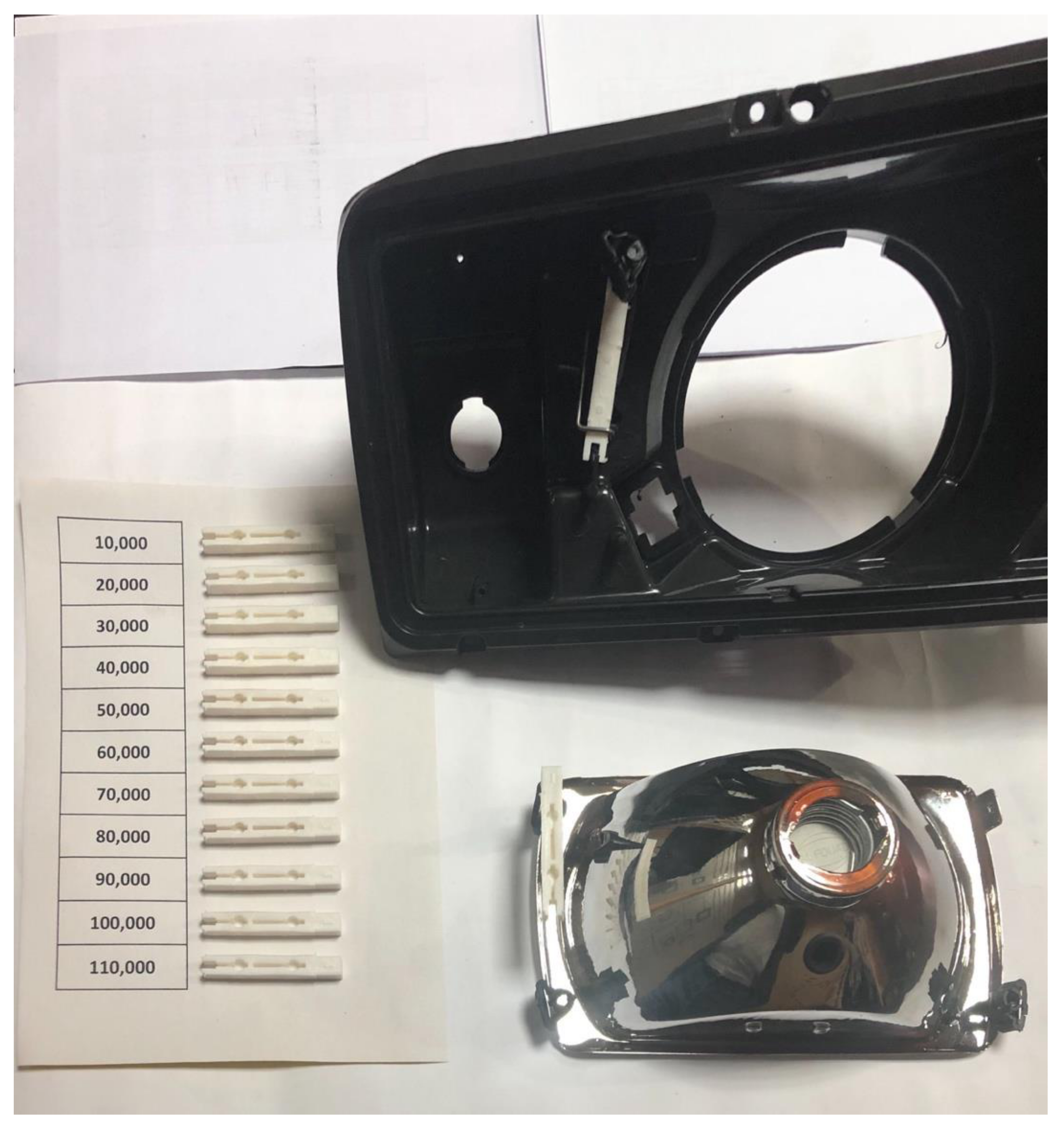

4.2. Dimensional Accuracy of Injection Parts

4.3. Injection Moulding of 150,000 Parts

5. Conclusions

- Microstructure and EDS analysis confirmed the inclusion of a high content of carbides along the edge of each individual layer. The elements with the highest concentration were Chromium, Nickel, and Molybdenum respectively. Therefore, the existence of carbides caused by the laser melting process resulted in reinforcing microhardness and projected a positive outcome for durability due to elemental segregation.

- For the first reported time, SLM fabricated tool inserts proved to be successful in performance with regard to injection moulding of 150,000 parts. The four tool insert sets were run for 10,000, 20,000, 30,000, and 40,000 injections respectively. Finally, after the fourth tool insert successfully completed 40,000 injections, further production runs were continued to achieve 150,000 injections. It was proven that the fourth set of tool inserts was able to withstand 150,000 injections without any significant signs of failure.

- Wear is acknowledged as a result of the progression of the injection moulding process. However, steadiness in the wear rate was noted amid large production runs. Alterations to dimensional accuracy verifies that the tool inserts are liable to wear due to successive loads by the injection moulding process.

- It is concluded from the work done in this research that additive manufacturing SLM technology proved to be a reliable technique for fabricating Stainless steel 316 L injection moulding tool inserts for the aftermarket automotive industry.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Elsayed, M.; Ghazy, M.; Youssef, Y.; Essa, K. Optimization of SLM process parameters for Ti6Al4V medical implants. Rapid Prototyp. J. 2019, 25, 433–447. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N.; Senthilkumaran, K. Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J. Manuf. Process. 2014, 16, 345–355. [Google Scholar] [CrossRef]

- King, D.; Tansey, T. Alternative materials for rapid tooling. J. Mater. Process. Technol. 2002, 121, 313–317. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of Metal and Alloy Components by Additive Manufacturing: Examples of 3D Materials Science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Olakanmi, E.O. Selective laser sintering/melting (SLS/SLM) of pure Al, Al-Mg, and Al-Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid additive and subtractive machine tools - Research and industrial developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef]

- El-sayed, M.A. Parametric analysis of SLM process for fabricating 316L stainless steel samples by response surface method. J. Eng. Technol. 2018, 6, 121–131. [Google Scholar]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Löber, L.; Flache, C.; Petters, R.; Kühn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 316l steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar] [CrossRef]

- Ahn, D.G. Applications of laser assisted metal rapid tooling process to manufacture of molding & forming tools—State of the art. Int. J. Precis. Eng. Manuf. 2011, 12, 925–938. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. On the characterization of stainless steel 316L parts produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 95, 1953–1974. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Journal of Materials Processing Technology Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2017, 240, 12–22. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed]

- Newman, S.T.; Zhu, Z.; Dhokia, V.; Shokrani, A. Process planning for additive and subtractive manufacturing technologies. CIRP Ann. Manuf. Technol. 2015, 64, 467–470. [Google Scholar] [CrossRef]

- Wohlers, T.T. Wohlers Report 2010; Wohlers Associates Inc.: Fort Collins, CO, USA, 2010. [Google Scholar]

- Karunakaran, K.P.; Suryakumar, S.; Pushpa, V.; Akula, S. Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot. Comput. Integr. Manuf. 2010, 26, 490–499. [Google Scholar] [CrossRef]

- Achillas, C.; Tzetzis, D.; Raimondo, M.O. Alternative production strategies based on the comparison of additive and traditional manufacturing technologies. Int. J. Prod. Res. 2017, 55, 3497–3509. [Google Scholar] [CrossRef]

- Ghazy, M.; Dalgarno, K.; Saleh, O. Rapid Tooling Process for Sand Casting Patterns. In Computer Aided Production Engineering (CAPE 21); John Wiley and Sons: Hoboken, NJ, USA, 2010; pp. 1–8. [Google Scholar]

- Zhang, Y.; Liu, H. Application of Rapid Prototyping Technology in Die Making of Diesel Engine. Tsinghua Sci. Technol. 2009, 14, 127–131. [Google Scholar] [CrossRef]

- Lupeanu, M.; Brooks, H.; Rennie, A.; Celik, H.K.; Neagu, C.; Akinci, I. Design for Manufacture using Functional Analysis and CAD Mould Simulation for Rapid Prototyping and Rapid Tooling. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012; pp. 1–8. [Google Scholar]

- Ding, Y.; Lan, H.; Hong, J.; Wu, D. An integrated manufacturing system for rapid tooling based on rapid prototyping. Robot. Comput. Integr. Manuf. 2004, 20, 281–288. [Google Scholar] [CrossRef]

- Au, K.M.; Yu, K.M.; Chiu, W.K. Visibility-based conformal cooling channel generation for rapid tooling. CAD Comput. Aided Des. 2011, 43, 356–373. [Google Scholar] [CrossRef]

- Dunne, P.; Soe, S.P.; Byrne, G.; Venus, A.; Wheatley, A. Some demands on rapid prototypes used as master patterns in rapid tooling for injection moulding. J. Mater. Process. Technol. 2004, 150, 201–207. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. Manuf. Technol. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Kruth, J.P.; Levy, G.; Klocke, F.; Childs, T.H.C. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. Manuf. Technol. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Rahmati, S.; Dickens, P. Rapid tooling analysis of Stereolithography injection mould tooling. Int. J. Mach. Tools Manuf. 2007, 47, 740–747. [Google Scholar] [CrossRef]

- Kashouty, M.F.; El Rennie, A.E.W.; Ghazy, M. Assessing Additive and Subtractive Manufacturing Technologies for the Production of Tools in the Automotive Industry. In Computer Aided Production Engineering (CAPE 23); John Wiley and Sons: Hoboken, NJ, USA, 2015; pp. 1–8. [Google Scholar]

- Zhang, Y.; Pedersen, D.B.; Gøtje, A.S.; Mischkot, M.; Tosello, G. A Soft Tooling process chain employing Additive Manufacturing for injection molding of a 3D component with micro pillars. J. Manuf. Process. 2017, 27, 138–144. [Google Scholar] [CrossRef]

- Khaing, M.W.; Fuh, J.Y.H.; Lu, L. Direct metal laser sintering for rapid tooling: Processing and characterisation of EOS parts. J. Mater. Process. Technol. 2001, 113, 269–272. [Google Scholar] [CrossRef]

- Petrovic, V.; Vicente Haro Gonzalez, J.; Jordá Ferrando, O.; Delgado Gordillo, J.; Ramón Blasco Puchades, J.; Portolés Griñan, L. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2011, 49, 1061–1079. [Google Scholar] [CrossRef]

- Ponche, R.; Kerbrat, O.; Mognol, P.; Hascoet, J.-Y.Y. A novel methodology of design for Additive Manufacturing applied to Additive Laser Manufacturing process. Robot. Comput. Integr. Manuf. 2014, 30, 389–398. [Google Scholar] [CrossRef]

- Nagahanumaiah, R.; Ravi, B.; Mukherjee, N.P. Rapid tooling manufacturability evaluation using fuzzy-AHP methodology. Int. J. Prod. Res. 2007, 45, 1161–1181. [Google Scholar] [CrossRef]

- Brooke, R. FACTUM: A “profound first” for additive manufacturing. TCT Magazine 2014. [Google Scholar]

- Mahshid, R.; Hansen, H.N.; Højbjerre, K.L. Strength analysis and modeling of cellular lattice structures manufactured using selective laser melting for tooling applications. Mater. Des. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Akula, S.; Karunakaran, K.P. Hybrid adaptive layer manufacturing: An Intelligent art of direct metal rapid tooling process. Robot. Comput. Integr. Manuf. 2006, 22, 113–123. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal post-processing of AlSi10Mg parts produced by Selective Laser Melting using recycled powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Rossi, S.; Deflorian, F.; Venturini, F. Improvement of surface finishing and corrosion resistance of prototypes produced by direct metal laser sintering. J. Mater. Process. Technol. 2004, 148, 301–309. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, J.; Zhang, H.; Kent, N.J.; Diamond, D.; Gilchrist, M.D. 3D Printing of Metallic Microstructured Mould Using Selective Laser Melting for Injection Moulding of Plastic Microfluidic Devices. Micromachines 2019, 10, 595. [Google Scholar] [CrossRef]

- Mahshid, R.; Hansen, H.N.; Arentoft, M. Towards mass production by high performance transfer press in micro bulk forming. Procedia Eng. 2014, 81, 1445–1450. [Google Scholar] [CrossRef][Green Version]

- Steel, A.K. Product Data Sheet: Stainless Steel 316/316L; AK Steel Corporation: West Chester, OH, USA, 2007; pp. 1–2. [Google Scholar]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Trelewicz, J.R.; Halada, G.P.; Donaldson, O.K.; Manogharan, G. Microstructure and Corrosion Resistance of Laser Additively Manufactured 316L Stainless Steel. JOM 2016, 68, 850–859. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Chatterjee, A.; Kumar, S.; Saha, P.; Mishra, P.; Choudhury, A. An experimental design approach to selective laser sintering of low carbon steel. J. Mater. Process. Technol. 2003, 136, 151–157. [Google Scholar] [CrossRef]

- Gubicza, J.; El-Tahawy, M.; Huang, Y.; Choi, H.; Cho, H.; Lábár, J.L.; Langdon, T.G. Microstructure, phase composition and hardness evolution in 316L stainless steel processed by high-pressure torsion. Mater. Sci. Eng. A 2016, 657, 215–223. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineering, 3rd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Ravi, B.; Nagahanumaiah, R. Effects of injection molding parameters on shrinkage and weight of plastic part—Produced by DMLS mold. Rapid Prototyp. J. 2009, 15, 179–186. [Google Scholar] [CrossRef]

- Dolinšek, S. Wear characteristics of laser sintered molding tools. Wear 2005, 259, 1241–1247. [Google Scholar] [CrossRef]

| Wt % | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample | C | Si | Mn | P | S | Cr | Mo | Ni | Fe |

| SS 316 L Standard [43] | 0.035 | 0.75 | 2 | 0.045 | 0.03 | 16-18 | 2-3 | 10-14 | Balance |

| SLM | 0.024 | 0.41 | 1.52 | 0.023 | 0.021 | 16.057 | 2.38 | 10.397 | Balance |

| Dimension | Location | Type |

|---|---|---|

| I | Core | External |

| N | Core | Internal |

| E | Cavity | External |

| G | Cavity | Internal |

| Dimension I | Dimension N | |||||

|---|---|---|---|---|---|---|

| Tool Number | Measurements before Injection (mm) | Measurements after Injection (mm) | Deviation from Permissible Tolerance (mm) | Measurements before Injection (mm) | Measurements after Injection (mm) | Deviation from Permissible Tolerance (mm) |

| Tool 1 10,000 parts | 25.8 | 25.72 | −0.08 | 9.48 | 9.81 | 0.11 |

| Tool 2 20,000 parts | 25.8 | 25.47 | −0.33 | 9.50 | 9.92 | 0.22 |

| Tool 3 30,000 parts | 25.9 | 25.64 | −0.16 | 9.55 | 9.77 | 0.07 |

| Tool 4 40,000 parts | 25.8 | 25.70 | −0.10 | 9.70 | 9.81 | 0.11 |

| Dimension E | Dimension G | |||||

| Tool Number | Measurements before Injection (mm) | Measurements after Injection (mm) | Deviation from Permissible Tolerance (mm) | Measurements before Injection (mm) | Measurements after Injection (mm) | Deviation from Permissible Tolerance (mm) |

| Tool 1 10,000 Parts | 5.80 | 5.46 | −0.24 | 10.0 | 10.05 | 0.05 |

| Tool 2 20,000 parts | 5.84 | 5.63 | −0.07 | 10.0 | 10.4 | 0.4 |

| Tool 3 30,000 Parts | 5.67 | 5.47 | −0.23 | 10.04 | 10.2 | 0.16 |

| Tool 4 40,000 Parts | 5.67 | 5.48 | −0.22 | 10.04 | 10.34 | 0.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Kashouty, M.F.; Rennie, A.E.W.; Ghazy, M. Tool Life Performance of Injection Mould Tooling Fabricated by Selective Laser Melting for High-Volume Production. Materials 2019, 12, 3910. https://doi.org/10.3390/ma12233910

El Kashouty MF, Rennie AEW, Ghazy M. Tool Life Performance of Injection Mould Tooling Fabricated by Selective Laser Melting for High-Volume Production. Materials. 2019; 12(23):3910. https://doi.org/10.3390/ma12233910

Chicago/Turabian StyleEl Kashouty, Mennatallah F., Allan E. W. Rennie, and Mootaz Ghazy. 2019. "Tool Life Performance of Injection Mould Tooling Fabricated by Selective Laser Melting for High-Volume Production" Materials 12, no. 23: 3910. https://doi.org/10.3390/ma12233910

APA StyleEl Kashouty, M. F., Rennie, A. E. W., & Ghazy, M. (2019). Tool Life Performance of Injection Mould Tooling Fabricated by Selective Laser Melting for High-Volume Production. Materials, 12(23), 3910. https://doi.org/10.3390/ma12233910