Analysis of Important Fabrication Factors That Determine the Sensitivity of MWCNT/Epoxy Composite Strain Sensors

Abstract

1. Introduction

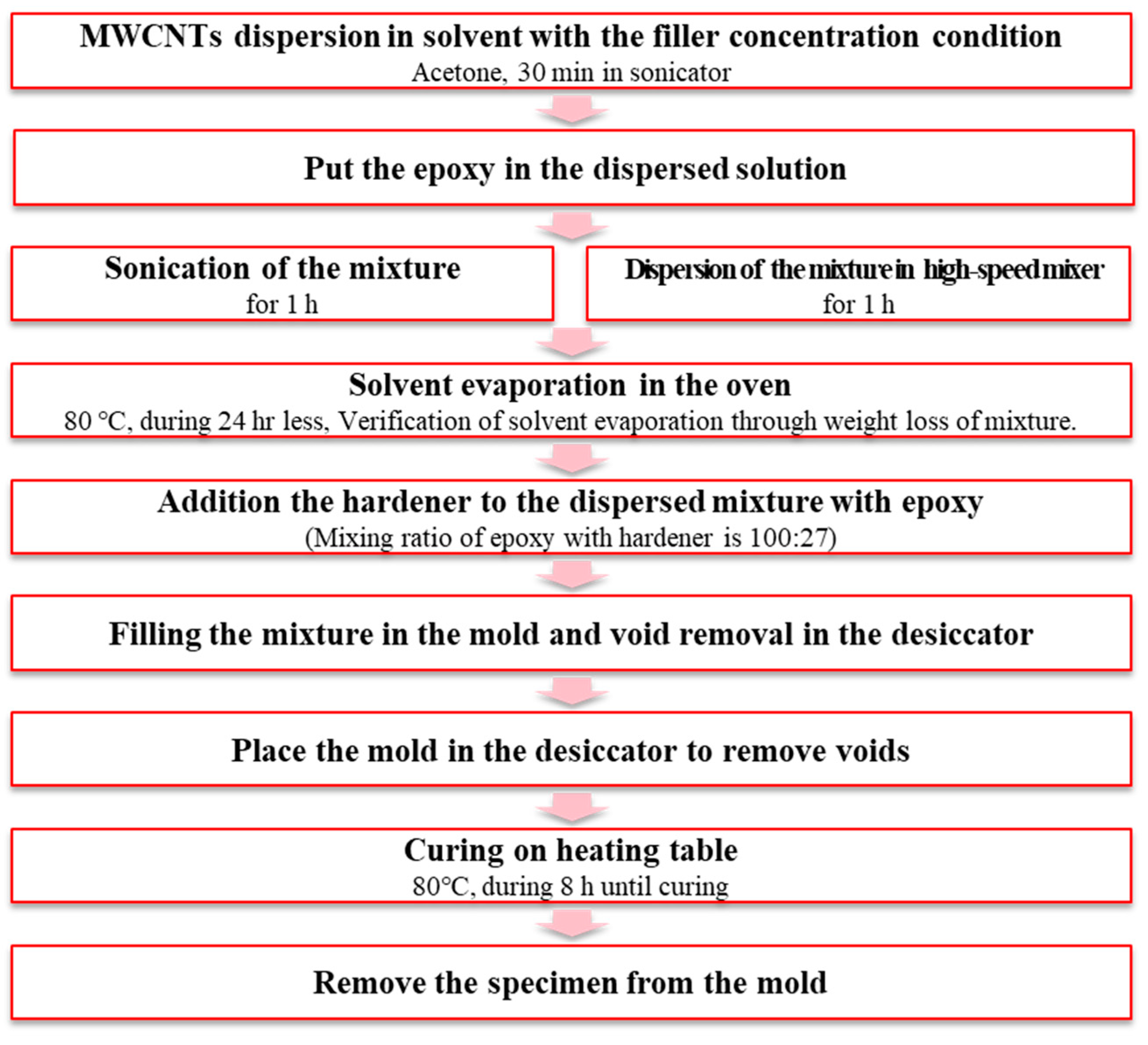

2. Fabrication Process of MWCNT/Epoxy Composite Sensor with Basic Type

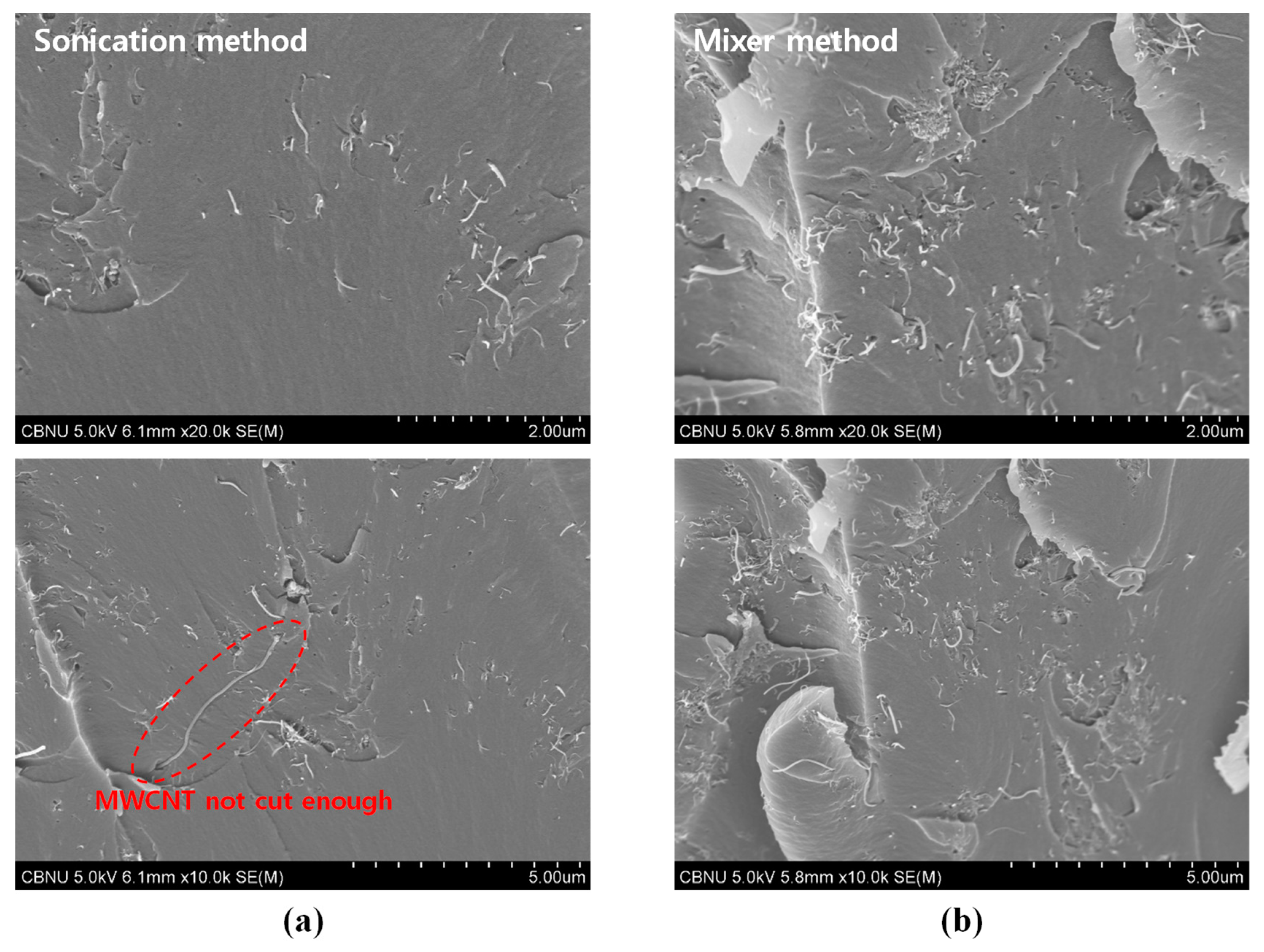

2.1. MWCNT Filler Dispersion Method

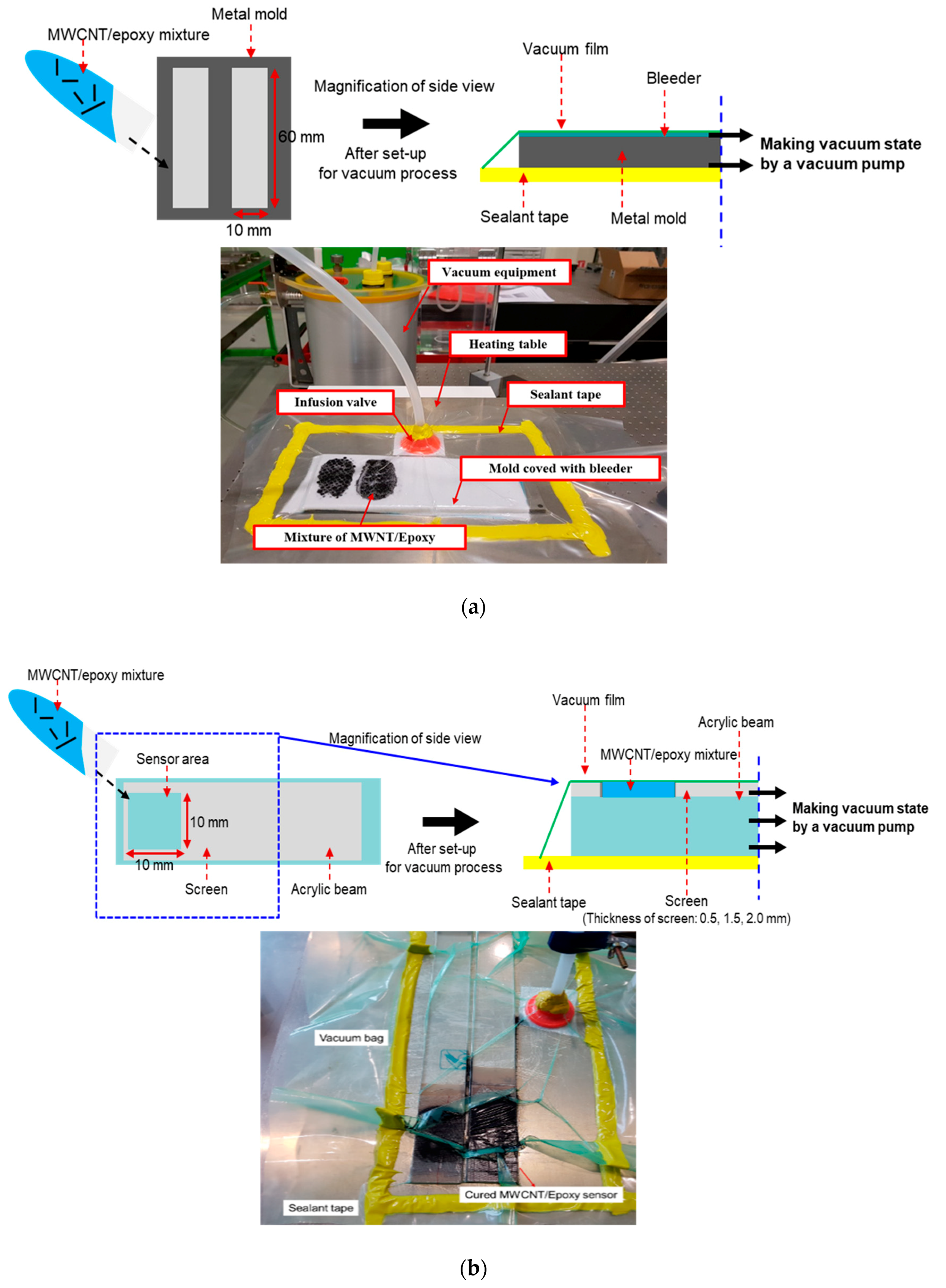

2.2. MWCNT/Epoxy Composite Fabrication

3. Assessment of the Importance of Fabrication Factors in MWCNT/Epoxy Composite Sensor

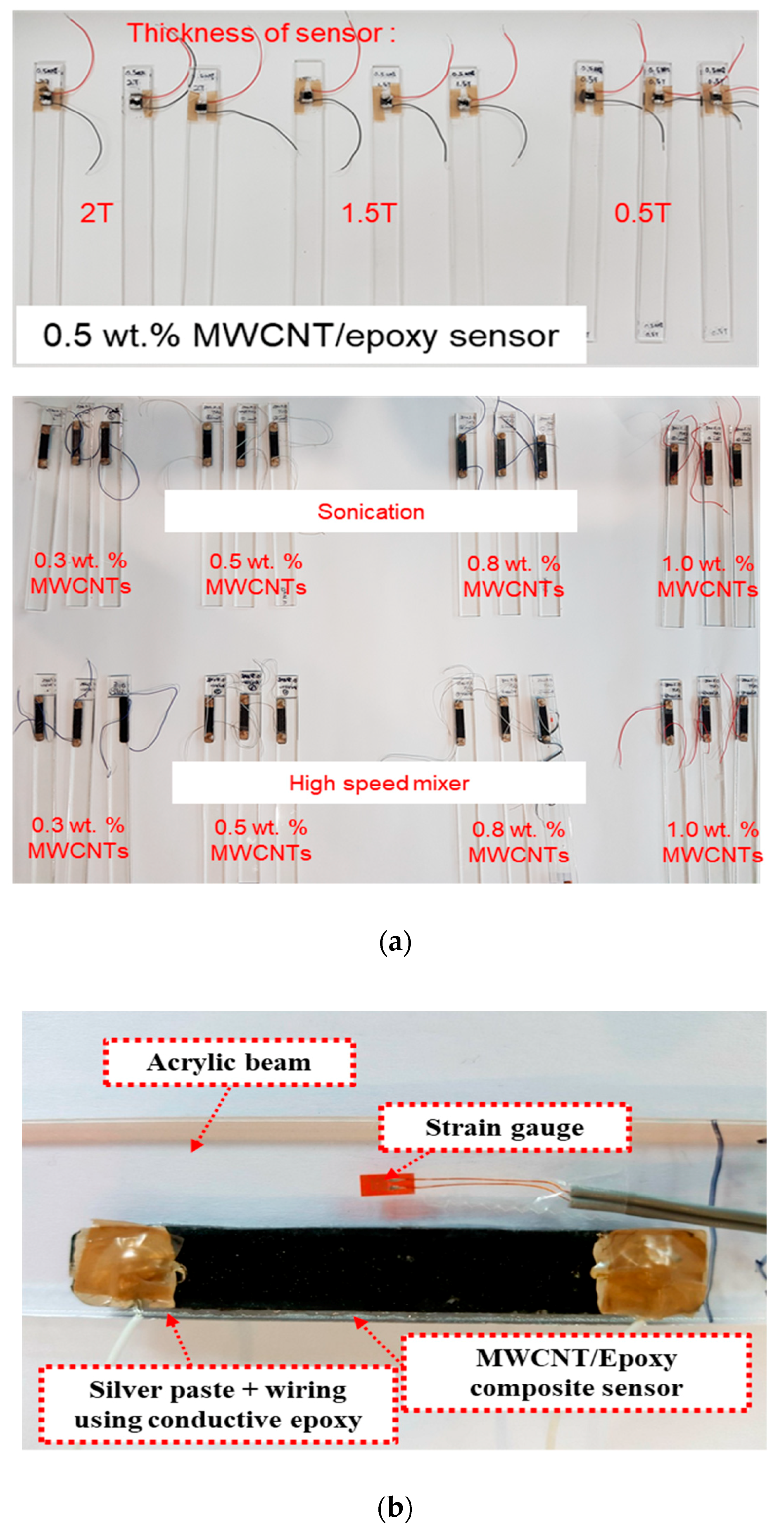

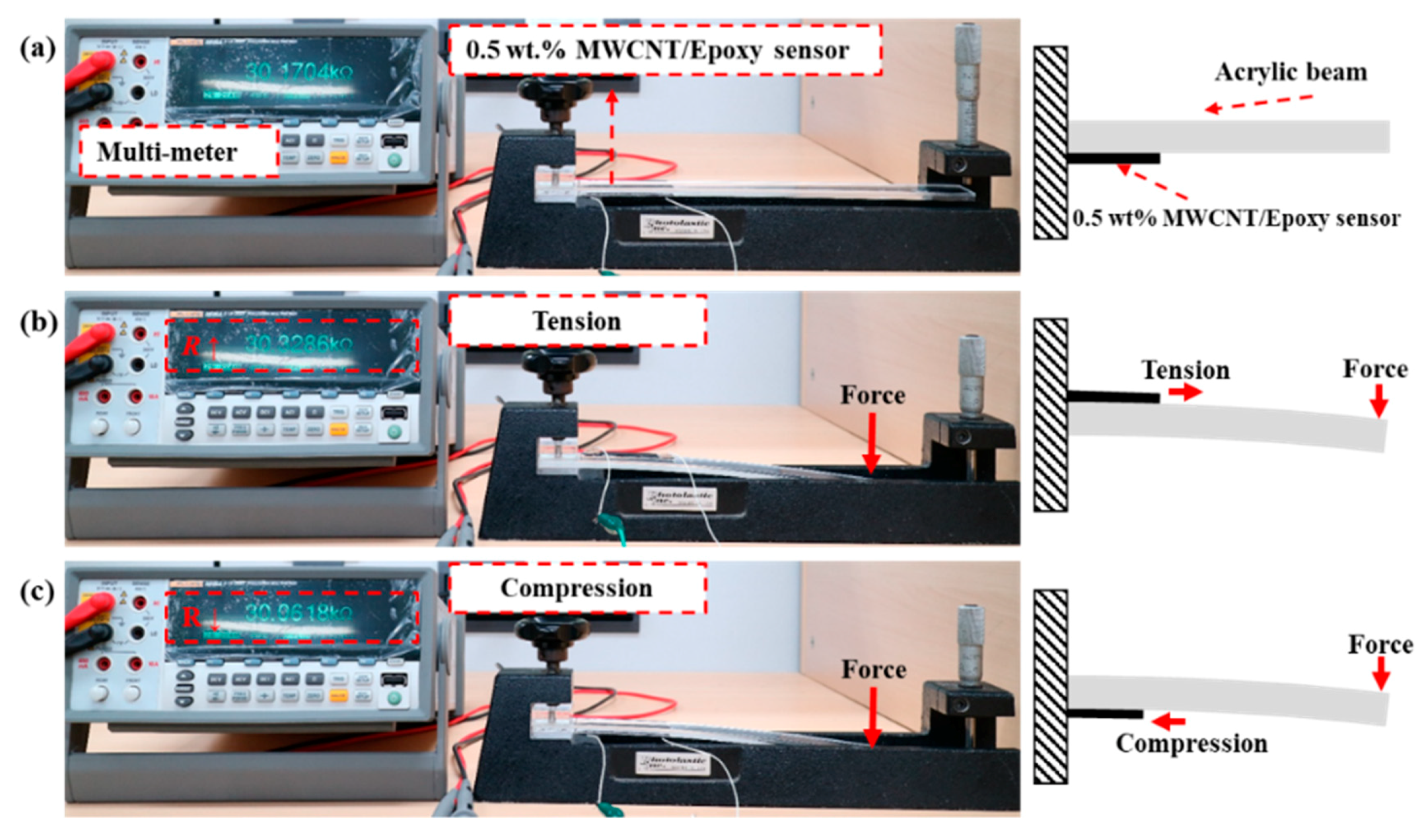

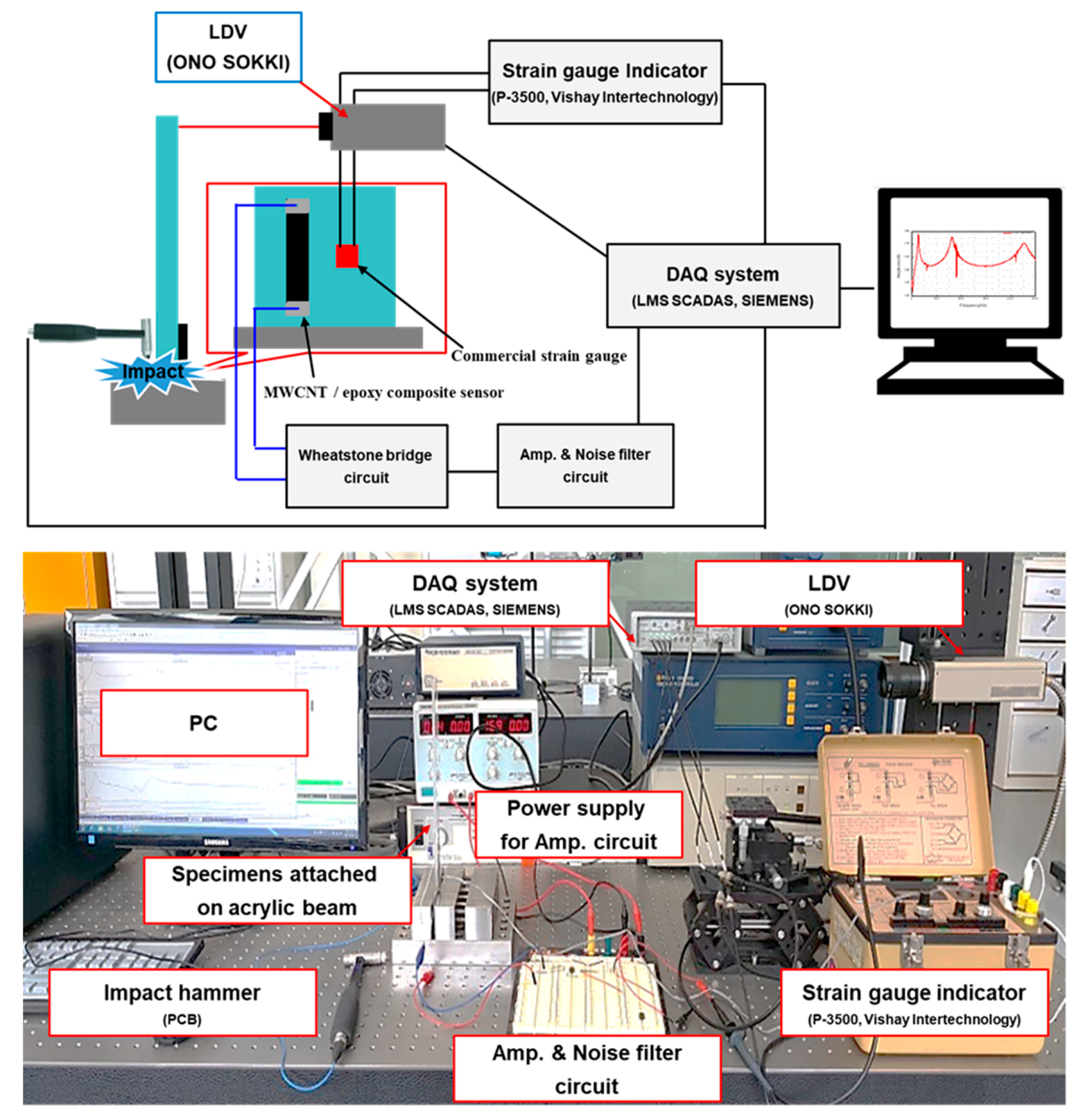

3.1. Experimental Method: Analysis of Filler Concentration, Sensor Dimensions, and Dispersion Method

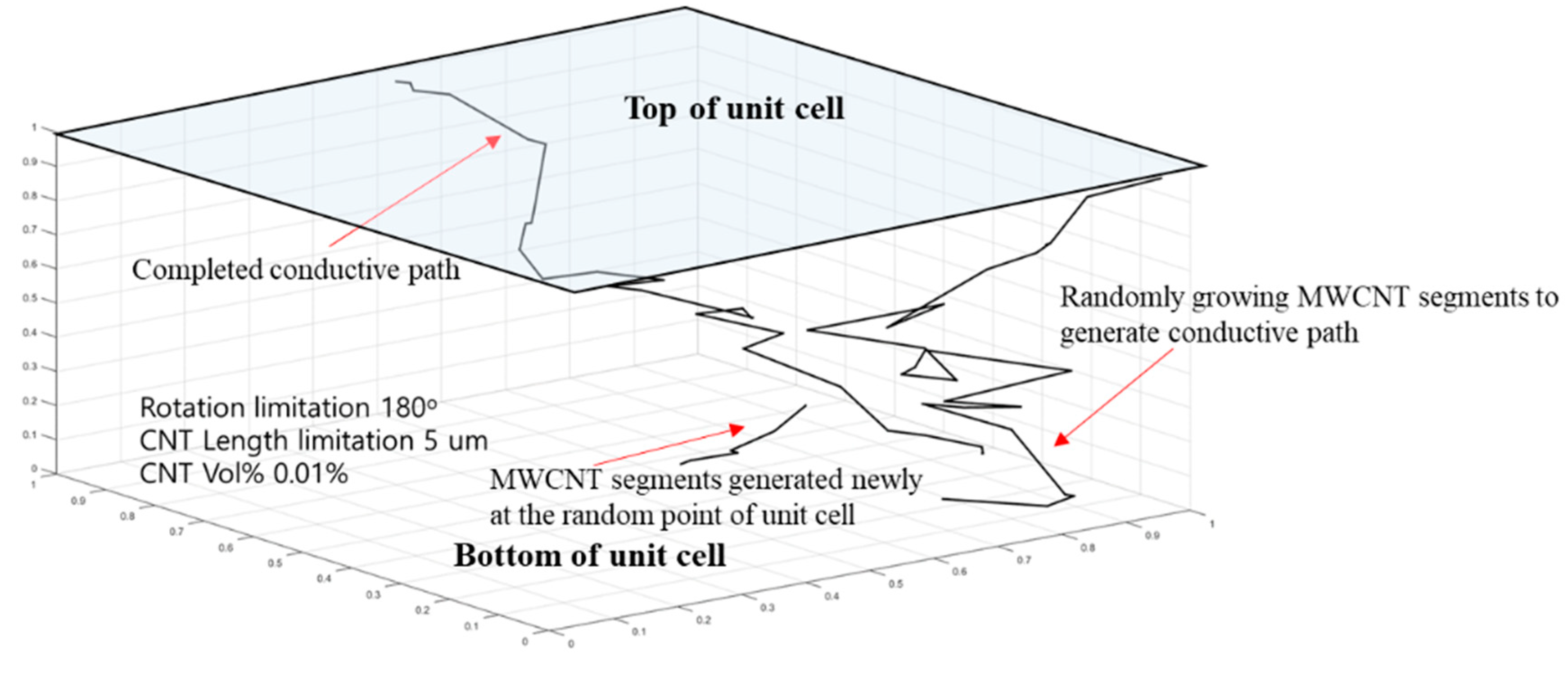

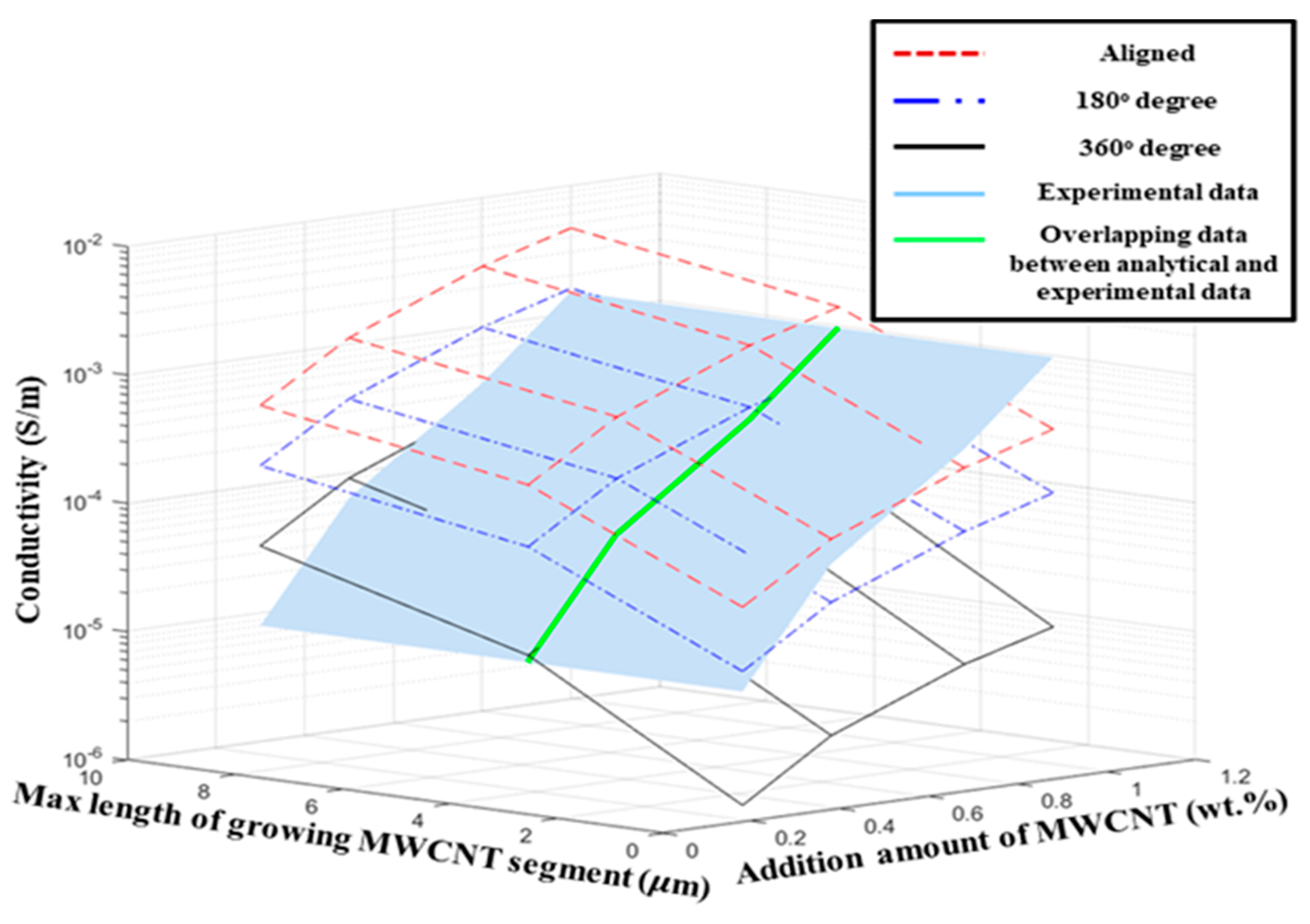

3.2. Simulation Method: Analysis of Filler Concentration and Filler Characteristics

4. Results and Discussion

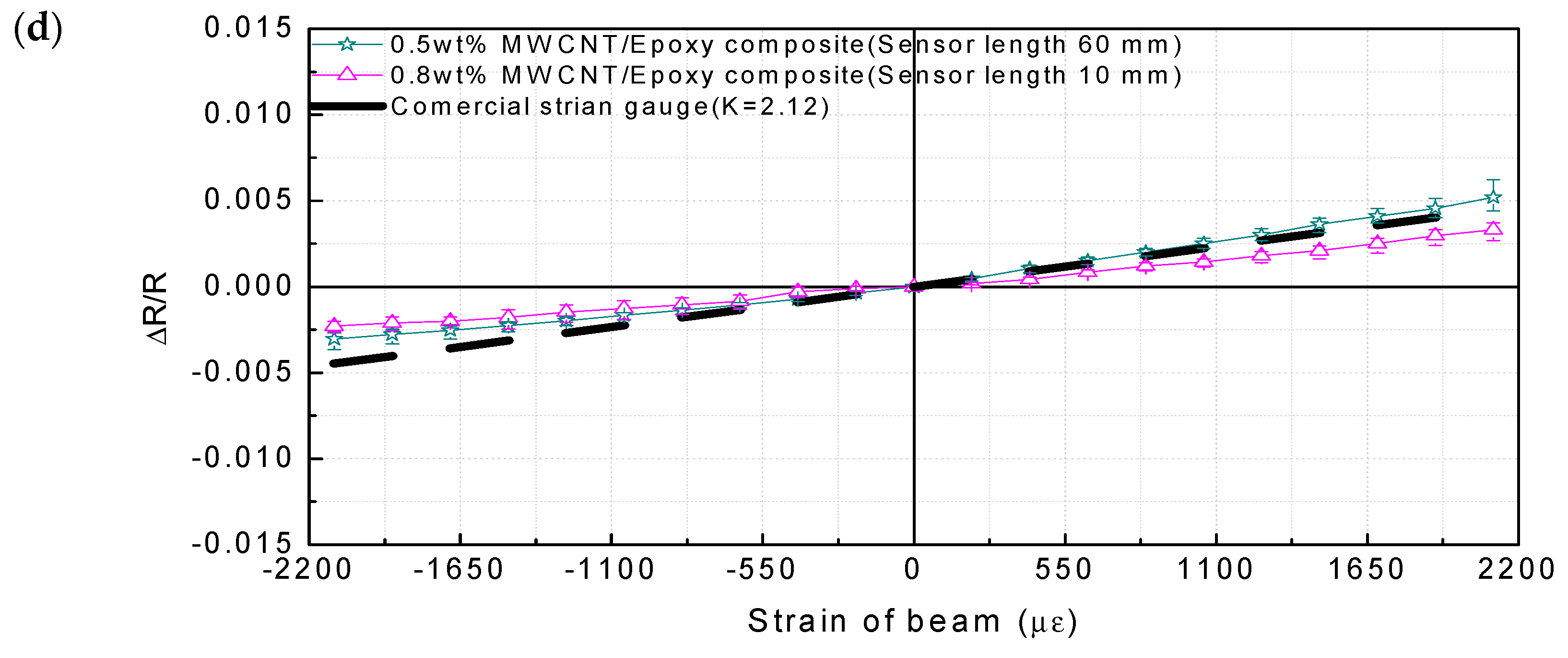

4.1. Sensor Fabrication Results According to Manufacturing Conditions in the Experimental Method

4.2. Analysis of the Range of Conductivity with the Selected MWCNTs in the Simulation Method

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bautista-Quijano, J.; Aviles, F.; Aguilar, J.; Tapia, A. Strain sensing capabilities of a piezoresistive MWCNT-polysulfone film. Sens. Actuators A Phys. 2010, 159, 135–140. [Google Scholar] [CrossRef]

- Choi, K.-S.; Choi, Y.-C.; Park, J.-H.; Kim, W.-W. Source Localization Technique for Metallic Impact Source by Using Phase Delay between Different Type Sensors. Trans. Korean Soc. Noise Vib. Eng. 2008, 18, 1143–1149. [Google Scholar]

- Kang, I.; Schulz, M.J.; Kim, J.H.; Shanov, V.; Shi, D. A carbon nanotube strain sensor for structural health monitoring. Smart Mater. Struct. 2006, 15, 737. [Google Scholar] [CrossRef]

- Park, M.; Kim, H.; Youngblood, J.P. Strain-dependent electrical resistance of multi-walled carbon nanotube/polymer composite films. Nanotechnology 2008, 19, 055705. [Google Scholar] [CrossRef] [PubMed]

- Pham, G.T.; Park, Y.-B.; Liang, Z.; Zhang, C.; Wang, B. Processing and modeling of conductive thermoplastic/carbon nanotube films for strain sensing. Compos. Part B Eng. 2008, 39, 209–216. [Google Scholar] [CrossRef]

- Kim, S.; Lee, W.I.; Park, C.H. Assessment of carbon nanotube dispersion and mechanical property of epoxy nanocomposites by curing reaction heat measurement. J. Reinf. Plast. Compos. 2016, 35, 71–80. [Google Scholar] [CrossRef]

- Siddiqui, N.A.; Sham, M.-L.; Tang, B.Z.; Munir, A.; Kim, J.-K. Tensile strength of glass fibres with carbon nanotube–epoxy nanocomposite coating. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1606–1614. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Sandler, J.; Shaffer, M.; Prasse, T.; Bauhofer, W.; Schulte, K.; Windle, A. Development of a dispersion process for carbon nanotubes in an epoxy matrix and the resulting electrical properties. Polymer 1999, 40, 5967–5971. [Google Scholar] [CrossRef]

- Xie, X.-L.; Mai, Y.-W.; Zhou, X.-P. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Fan, Z.; Hsiao, K.-T.; Advani, S.G. Experimental investigation of dispersion during flow of multi-walled carbon nanotube/polymer suspension in fibrous porous media. Carbon 2004, 42, 871–876. [Google Scholar] [CrossRef]

- Cha, J.; Jin, S.; Shim, J.H.; Park, C.S.; Ryu, H.J.; Hong, S.H. Functionalization of carbon nanotubes for fabrication of CNT/epoxy nanocomposites. Mater. Des. 2016, 95, 1–8. [Google Scholar] [CrossRef]

- Guru, K.; Mishra, S.; Shukla, K. Effect of temperature and functionalization on the interfacial properties of CNT reinforced nanocomposites. Appl. Surf. Sci. 2015, 349, 59–65. [Google Scholar] [CrossRef]

- Kovacs, J.Z.; Velagala, B.S.; Schulte, K.; Bauhofer, W. Two percolation thresholds in carbon nanotube epoxy composites. Compos. Sci. Technol. 2007, 67, 922–928. [Google Scholar] [CrossRef]

- Lipert, K.; Ritschel, M.; Leonhardt, A.; Krupskaya, Y.; Büchner, B.; Klingeler, R. Magnetic properties of carbon nanotubes with and without catalyst. J. Phys. Conf. Ser. 2010, 200, 072061. [Google Scholar] [CrossRef]

- Moaseri, E.; Karimi, M.; Baniadam, M.; Maghrebi, M. Improvements in mechanical properties of multi-walled carbon nanotube-reinforced epoxy composites through novel magnetic-assisted method for alignment of carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2014, 64, 228–233. [Google Scholar] [CrossRef]

- Arguin, M.; Sirois, F.; Therriault, D. Electric field induced alignment of multiwalled carbon nanotubes in polymers and multiscale composites. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 16–25. [Google Scholar] [CrossRef]

- Ma, C.; Liu, H.-Y.; Du, X.; Mach, L.; Xu, F.; Mai, Y.-W. Fracture resistance, thermal and electrical properties of epoxy composites containing aligned carbon nanotubes by low magnetic field. Compos. Sci. Technol. 2015, 114, 126–135. [Google Scholar] [CrossRef]

- Knite, M.; Teteris, V.; Kiploka, A.; Kaupuzs, J. Polyisoprene-carbon black nanocomposites as tensile strain and pressure sensor materials. Sens. Actuators A Phys. 2004, 110, 142–149. [Google Scholar] [CrossRef]

- Wichmann, M.H.; Buschhorn, S.T.; Böger, L.; Adelung, R.; Schulte, K. Direction sensitive bending sensors based on multi-wall carbon nanotube/epoxy nanocomposites. Nanotechnology 2008, 19, 475503. [Google Scholar] [CrossRef] [PubMed]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef]

- Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar]

- Yin, G.; Hu, N.; Karube, Y.; Liu, Y.; Li, Y.; Fukunaga, H. A carbon nanotube/polymer strain sensor with linear and anti-symmetric piezoresistivity. J. Compos. Mater. 2011, 45, 1315–1323. [Google Scholar]

- Hu, N.; Karube, Y.; Arai, M.; Watanabe, T.; Yan, C.; Li, Y.; Liu, Y.; Fukunaga, H. Investigation on sensitivity of a polymer/carbon nanotube composite strain sensor. Carbon 2010, 48, 680–687. [Google Scholar] [CrossRef]

- Knite, M.; Tupureina, V.; Fuith, A.; Zavickis, J.; Teteris, V. Polyisoprene—Multi-wall carbon nanotube composites for sensing strain. Mater. Sci. Eng. C 2007, 27, 1125–1128. [Google Scholar] [CrossRef]

- Xiong, J.; Zheng, Z.; Qin, X.; Li, M.; Li, H.; Wang, X. The thermal and mechanical properties of a polyurethane/multi-walled carbon nanotube composite. Carbon 2006, 44, 2701–2707. [Google Scholar] [CrossRef]

- Zhang, R.; Baxendale, M.; Peijs, T. Universal resistivity—Strain dependence of carbon nanotube/polymer composites. Phys. Rev. B 2007, 76, 195433. [Google Scholar] [CrossRef]

- Zhang, Y.; Sheehan, C.J.; Zhai, J.; Zou, G.; Luo, H.; Xiong, J.; Zhu, Y.; Jia, Q. Polymer—Embedded carbon nanotube ribbons for stretchable conductors. Adv. Mater. 2010, 22, 3027–3031. [Google Scholar] [CrossRef]

- Lu, N.; Lu, C.; Yang, S.; Rogers, J. Highly sensitive skin-mountable strain gauges based entirely on elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Jindal, P.; Pande, S.; Sharma, P.; Mangla, V.; Chaudhury, A.; Patel, D.; Singh, B.P.; Mathur, R.B.; Goyal, M. High strain rate behavior of multi-walled carbon nanotubes–polycarbonate composites. Compos. Part B Eng. 2013, 45, 417–422. [Google Scholar] [CrossRef]

- Pillai, S.K.; Ray, S.S. Epoxy-based carbon nanotubes reinforced composites. In Advances in Nanocomposites-Synthesis, Characterization and Industrial Applications; IntechOpen: London, UK, 2011. [Google Scholar]

- Loos, M.; Pezzin, S.; Amico, S.; Bergmann, C.; Coelho, L. The matrix stiffness role on tensile and thermal properties of carbon nanotubes/epoxy composites. J. Mater. Sci. 2008, 43, 6064–6069. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Lewis, L.; Jeelani, S. Experimental study on the thermal and mechanical properties of multi-walled carbon nanotube-reinforced epoxy. Mater. Sci. Eng. A 2007, 452, 657–664. [Google Scholar] [CrossRef]

- Hu, N.; Masuda, Z.; Yamamoto, G.; Fukunaga, H.; Hashida, T.; Qiu, J. Effect of fabrication process on electrical properties of polymer/multi-wall carbon nanotube nanocomposites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 893–903. [Google Scholar] [CrossRef]

- Andrews, R.; Jacques, D.; Minot, M.; Rantell, T. Fabrication of carbon multiwall nanotube/polymer composites by shear mixing. Macromol. Mater. Eng. 2002, 287, 395–403. [Google Scholar] [CrossRef]

- Park, J.; Alegaonkar, P.; Jeon, S.; Yoo, J. Carbon nanotube composite: Dispersion routes and field emission parameters. Compos. Sci. Technol. 2008, 68, 753–759. [Google Scholar] [CrossRef]

- Wichmann, M.; Sumfleth, J.; Fiedler, B.; Gojny, F.; Schulte, K. Multiwall carbon nanotube/epoxy composites produced by a masterbatch process. Mech. Compos. Mater. 2006, 42, 395–406. [Google Scholar] [CrossRef]

- Huang, Y.; Terentjev, E. Dispersion and rheology of carbon nanotubes in polymers. Int. J. Mater. 2008, 1, 63–74. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Knowles, T.P.; Terentjev, E.M. Strength of nanotubes, filaments, and nanowires from sonication-induced scission. Adv. Mater. 2009, 21, 3945–3948. [Google Scholar] [CrossRef]

- Yamamoto, T.; Miyauchi, Y.; Motoyanagi, J.; Fukushima, T.; Aida, T.; Kato, M.; Maruyama, S. Improved bath sonication method for dispersion of individual single-walled carbon nanotubes using new triphenylene-based surfactant. Jpn. J. Appl. Phys. 2008, 47, 2000. [Google Scholar] [CrossRef]

- Ramasubramaniam, R.; Chen, J.; Liu, H. Homogeneous carbon nanotube/polymer composites for electrical applications. Appl. Phys. Lett. 2003, 83, 2928–2930. [Google Scholar] [CrossRef]

- Huang, Y.; Ahir, S.; Terentjev, E. Dispersion rheology of carbon nanotubes in a polymer matrix. Phys. Rev. B 2006, 73, 125422. [Google Scholar] [CrossRef]

- Chen, G.-X.; Li, Y.; Shimizu, H. Ultrahigh-shear processing for the preparation of polymer/carbon nanotube composites. Carbon 2007, 45, 2334–2340. [Google Scholar] [CrossRef]

- Nguyen, T.Q.; Liang, Q.Z.; Kausch, H.-H. Kinetics of ultrasonic and transient elongational flow degradation: A comparative study. Polymer 1997, 38, 3783–3793. [Google Scholar] [CrossRef]

- Lohse, D. Sonoluminescence: Cavitation hots up. Nature 2005, 434, 33. [Google Scholar] [CrossRef]

- Gedanken, A. Using sonochemistry for the fabrication of nanomaterials. Ultrason. Sonochemistry 2004, 11, 47–55. [Google Scholar] [CrossRef]

- Beer, F.P.; Johnston, R.; Dewolf, J.; Mazurek, D. Mechanics of Materials; McGraw-Hill: Boston, CO, USA, 2006. [Google Scholar]

- Theodosiou, T.; Saravanos, D. Numerical investigation of mechanisms affecting the piezoresistive properties of CNT-doped polymers using multi-scale models. Compos. Sci. Technol. 2010, 70, 1312–1320. [Google Scholar] [CrossRef]

- Celzard, A.; McRae, E.; Deleuze, C.; Dufort, M.; Furdin, G.; Marêché, J. Critical concentration in percolating systems containing a high-aspect-ratio filler. Phys. Rev. B 1996, 53, 6209. [Google Scholar] [CrossRef]

- Seidel, G.D.; Lagoudas, D.C. A micromechanics model for the electrical conductivity of nanotube-polymer nanocomposites. J. Compos. Mater. 2009, 43, 917–941. [Google Scholar] [CrossRef]

- Liu, Z.; Peng, W.; Zare, Y.; Hui, D.; Rhee, K.Y. Predicting the electrical conductivity in polymer carbon nanotube nanocomposites based on the volume fractions and resistances of the nanoparticle, interphase, and tunneling regions in conductive networks. RSC Adv. 2018, 8, 19001–19010. [Google Scholar] [CrossRef]

- Cha, J.; Kim, S.; Lee, S. Effect of continuous multi-walled carbon nanotubes on thermal and mechanical properties of flexible composite film. Nanomaterials 2016, 6, 182. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization, and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef]

- Chang, F.-Y.; Wang, R.-H.; Yang, H.; Lin, Y.-H.; Chen, T.-M.; Huang, S.-J. Flexible strain sensors fabricated with carbon nano-tube and carbon nano-fiber composite thin films. Thin Solid Film. 2010, 518, 7343–7347. [Google Scholar] [CrossRef]

- Yasuoka, T.; Shimamura, Y.; Todoroki, A. Electrical resistance change under strain of CNF/flexible-epoxy composite. Adv. Compos. Mater. 2010, 19, 123–138. [Google Scholar] [CrossRef]

- Sanli, A.; Benchirouf, A.; Müller, C.; Kanoun, O. Piezoresistive performance characterization of strain sensitive multi-walled carbon nanotube-epoxy nanocomposites. Sens. Actuators A Phys. 2017, 254, 61–68. [Google Scholar] [CrossRef]

- Tanabi, H.; Erdal, M. Effect of CNTs dispersion on electrical, mechanical and strain sensing properties of CNT/epoxy nanocomposites. Results Phys. 2019, 12, 486–503. [Google Scholar] [CrossRef]

- Chang, W.-S.; Song, S.-A.; Kim, J.-H.; Han, C.-S. Fabrication of Carbon Nanotube Strain Sensors. Trans. Korean Soc. Mech. Eng. B 2009, 33, 773–777. [Google Scholar] [CrossRef]

- Hobara, R.; Yoshimoto, S.; Ikuno, T.; Katayama, M.; Yamauchi, N.; Wongwiriyapan, W.; Honda, S.-I.; Matsuda, I.; Hasegawa, S.; Oura, K. Electronic transport in multiwalled carbon nanotubes contacted with patterned electrodes. Jpn. J. Appl. Phys. 2004, 43, L1081. [Google Scholar] [CrossRef]

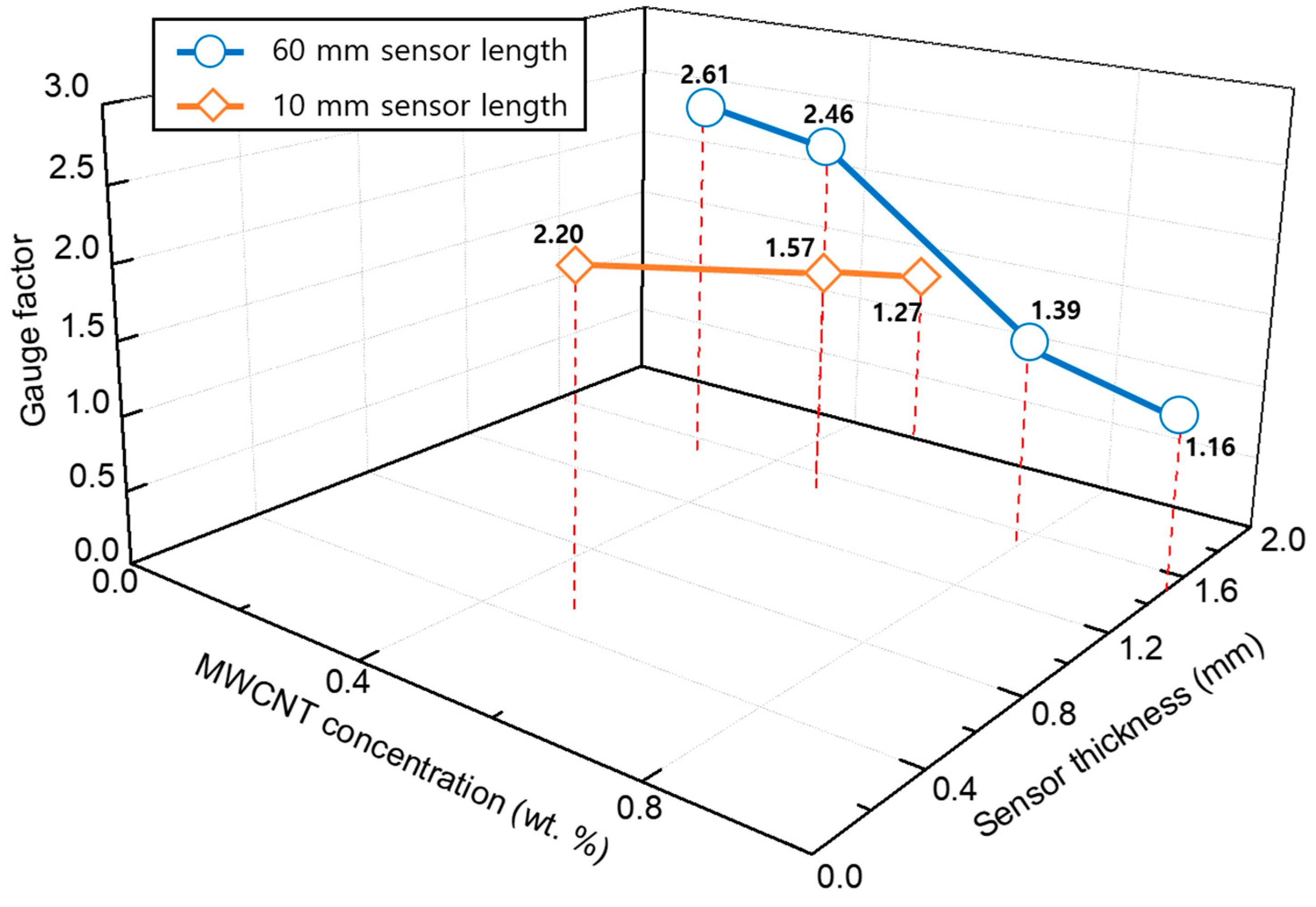

| MWCNT Concentration (wt%) | Gauge Factor in Compression Direction | Gauge Factor in Tension Direction | Dispersion Method | Sensor Dimensions (mm) (Horizontal × Vertical × Thickness) |

|---|---|---|---|---|

| 0.3 | −2.10 | 2.61 | high-speed mixer | 60 × 10 × 1.5 |

| 0.3 | −2.62 | 2.78 | sonication | 60 × 10 × 1.5 |

| 0.5 | −1.44 | 2.46 | high-speed mixer | 60 × 10 × 1.5 |

| 0.5 | −3.14 | 3.77 | sonication | 60 × 10 × 1.5 |

| 0.8 | −1.19 | 1.39 | high-speed mixer | 60 × 10 × 1.5 |

| 0.8 | −1.45 | 2.07 | sonication | 60 × 10 × 1.5 |

| 1.0 | −1.06 | 1.16 | high-speed mixer | 60 × 10 × 1.5 |

| 1.0 | −1.84 | 2.44 | sonication | 60 × 10 × 1.5 |

| 0.5 | −1.43 | 2.20 | high-speed mixer | 10 × 10 × 0.5 |

| 0.5 | −1.08 | 1.57 | high-speed mixer | 10 × 10 × 1.5 |

| 0.5 | −0.72 | 1.27 | high-speed mixer | 10 × 10 × 2.0 |

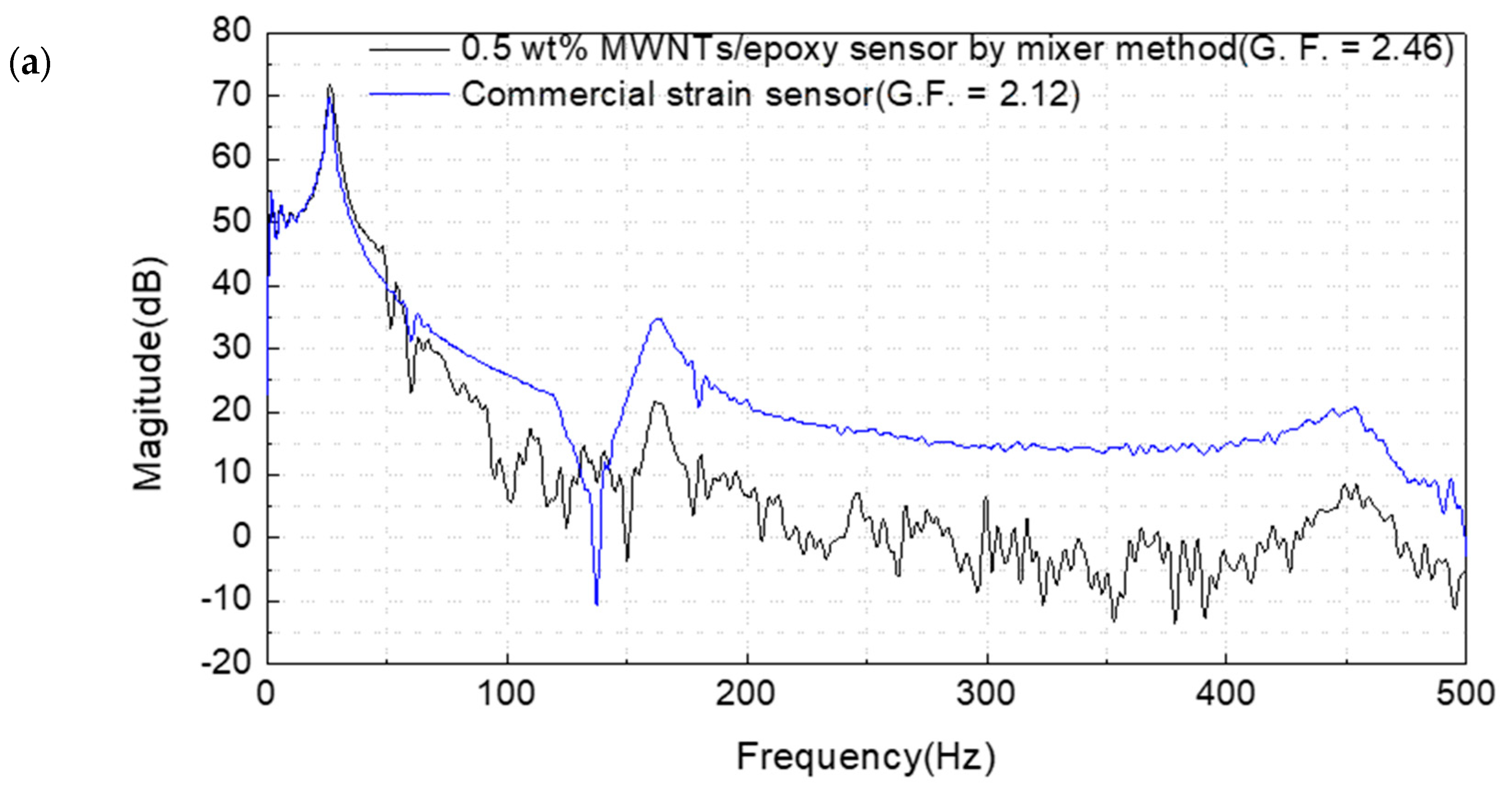

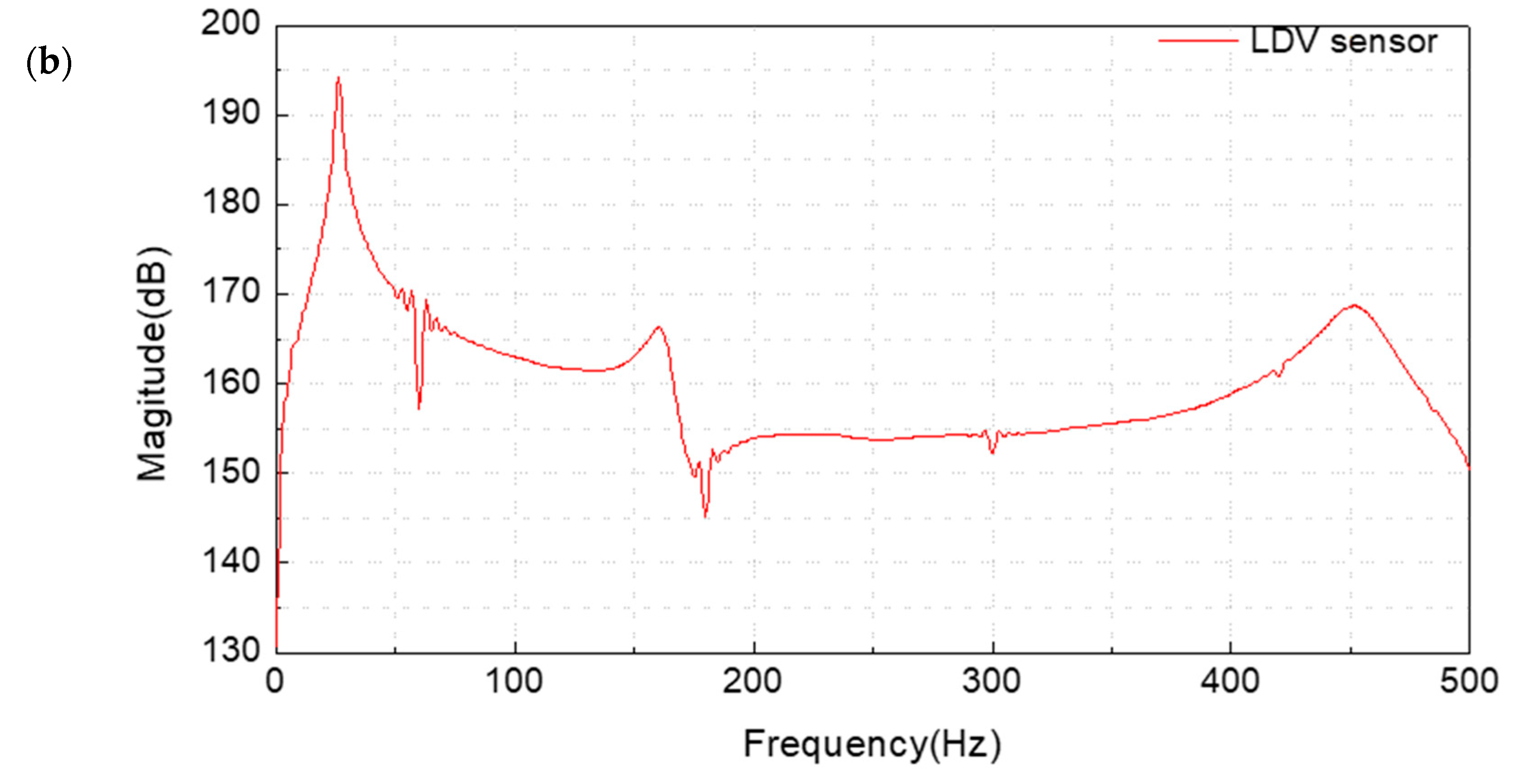

| MWCNT/Epoxy Sensor | Strain Gauge | Laser Doppler Velocimetry | |

|---|---|---|---|

| 1st Frequency | 26.5 Hz | 26.5 Hz | 26 Hz |

| 2nd Frequency | 163 Hz | 163 Hz | 162 Hz |

| 3rd Frequency | 456.5 Hz | 462.5 Hz | 453.5 Hz |

| Fabrication Factors | Dispersion Method | MWCNTs Concentration | Sensor Design |

|---|---|---|---|

| Recommendation in this study | High-speed mixer (shear mixing) | Minimum concentration above the percolation threshold | Thinner, higher aspect ratio to thickness |

| Comparison in this study | With sonication | With four concentration types | With 4 design types |

| Comparison method | By experiments By simulation By reference [54] | By experiments By simulation By reference [55,56] | By experiments By reference [57,58] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, M.-Y.; Kang, L.-H. Analysis of Important Fabrication Factors That Determine the Sensitivity of MWCNT/Epoxy Composite Strain Sensors. Materials 2019, 12, 3875. https://doi.org/10.3390/ma12233875

Hwang M-Y, Kang L-H. Analysis of Important Fabrication Factors That Determine the Sensitivity of MWCNT/Epoxy Composite Strain Sensors. Materials. 2019; 12(23):3875. https://doi.org/10.3390/ma12233875

Chicago/Turabian StyleHwang, Mun-Young, and Lae-Hyong Kang. 2019. "Analysis of Important Fabrication Factors That Determine the Sensitivity of MWCNT/Epoxy Composite Strain Sensors" Materials 12, no. 23: 3875. https://doi.org/10.3390/ma12233875

APA StyleHwang, M.-Y., & Kang, L.-H. (2019). Analysis of Important Fabrication Factors That Determine the Sensitivity of MWCNT/Epoxy Composite Strain Sensors. Materials, 12(23), 3875. https://doi.org/10.3390/ma12233875