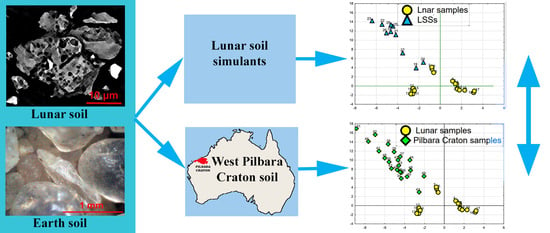

Pilbara Craton Soil as A Possible Lunar Soil Simulant for Civil Engineering Applications

Abstract

1. Introduction

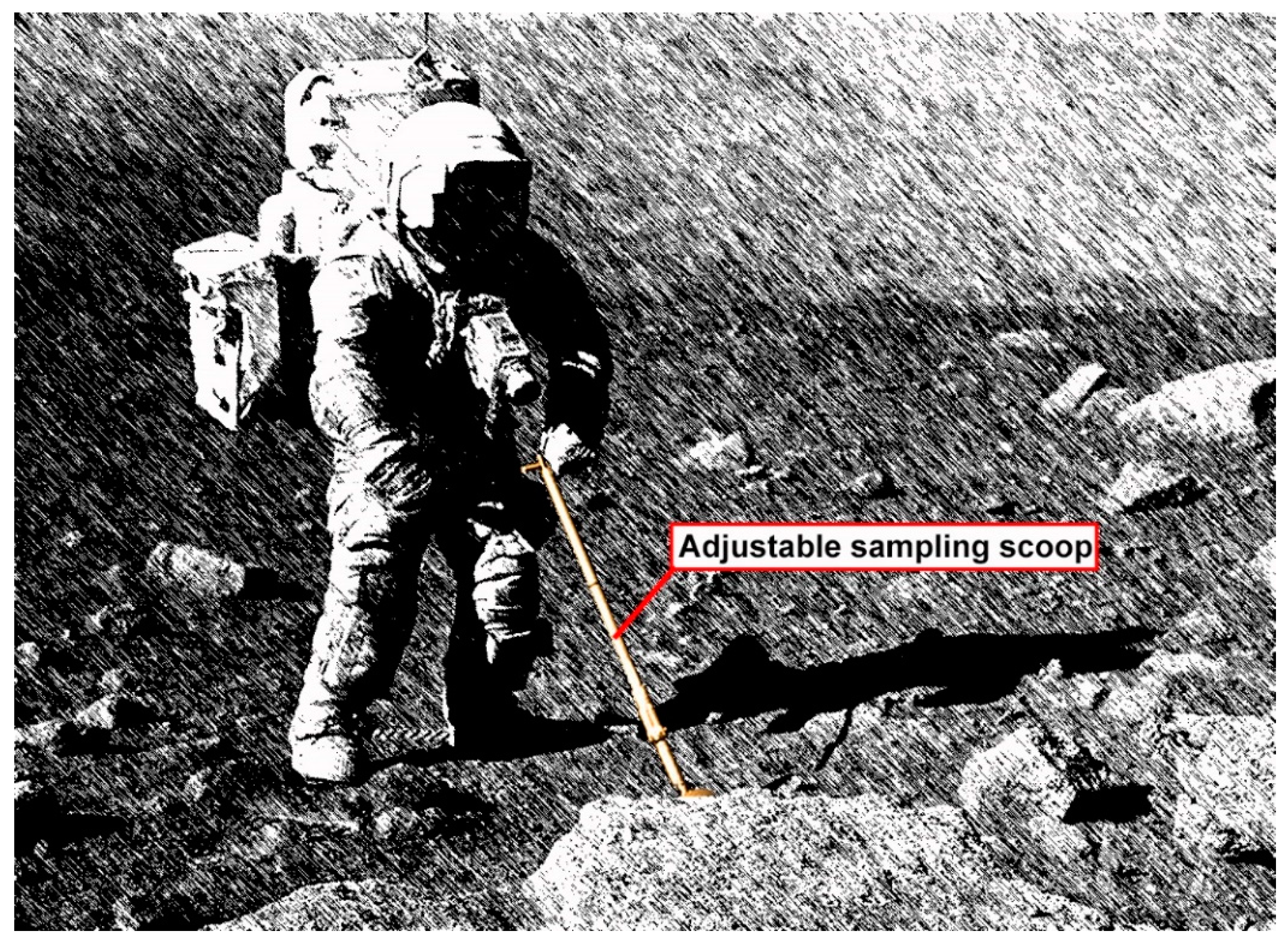

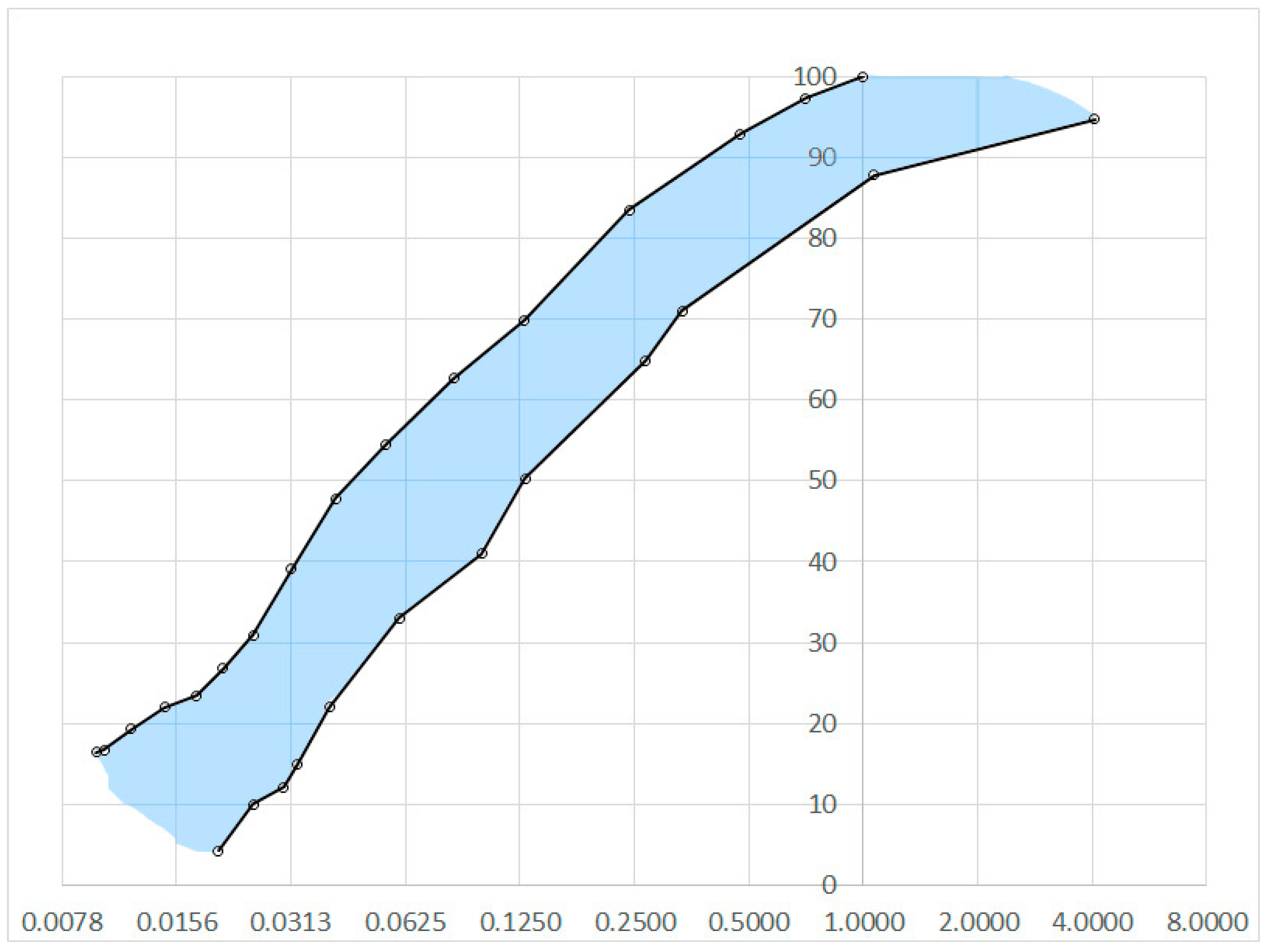

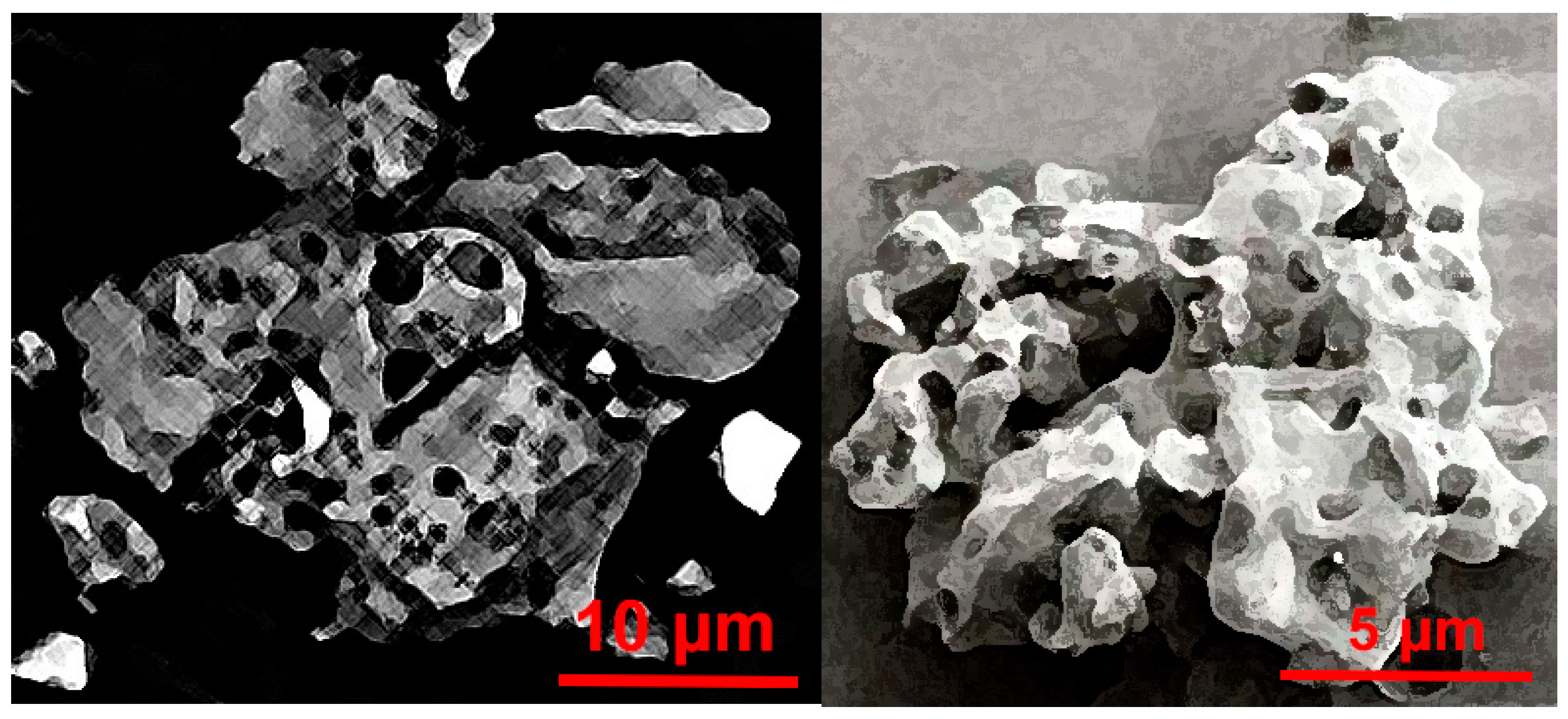

2. Key Properties of Needed LSS

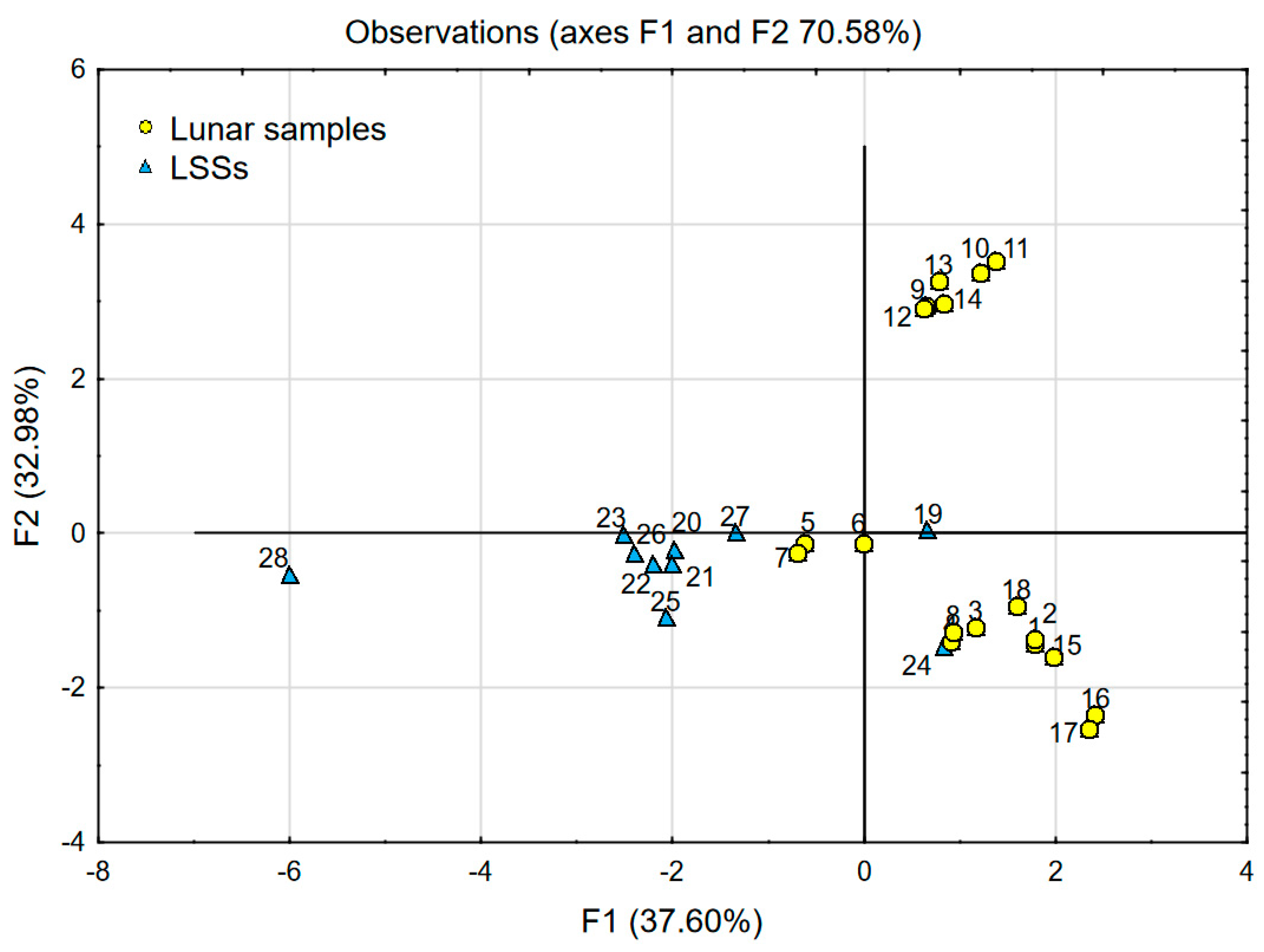

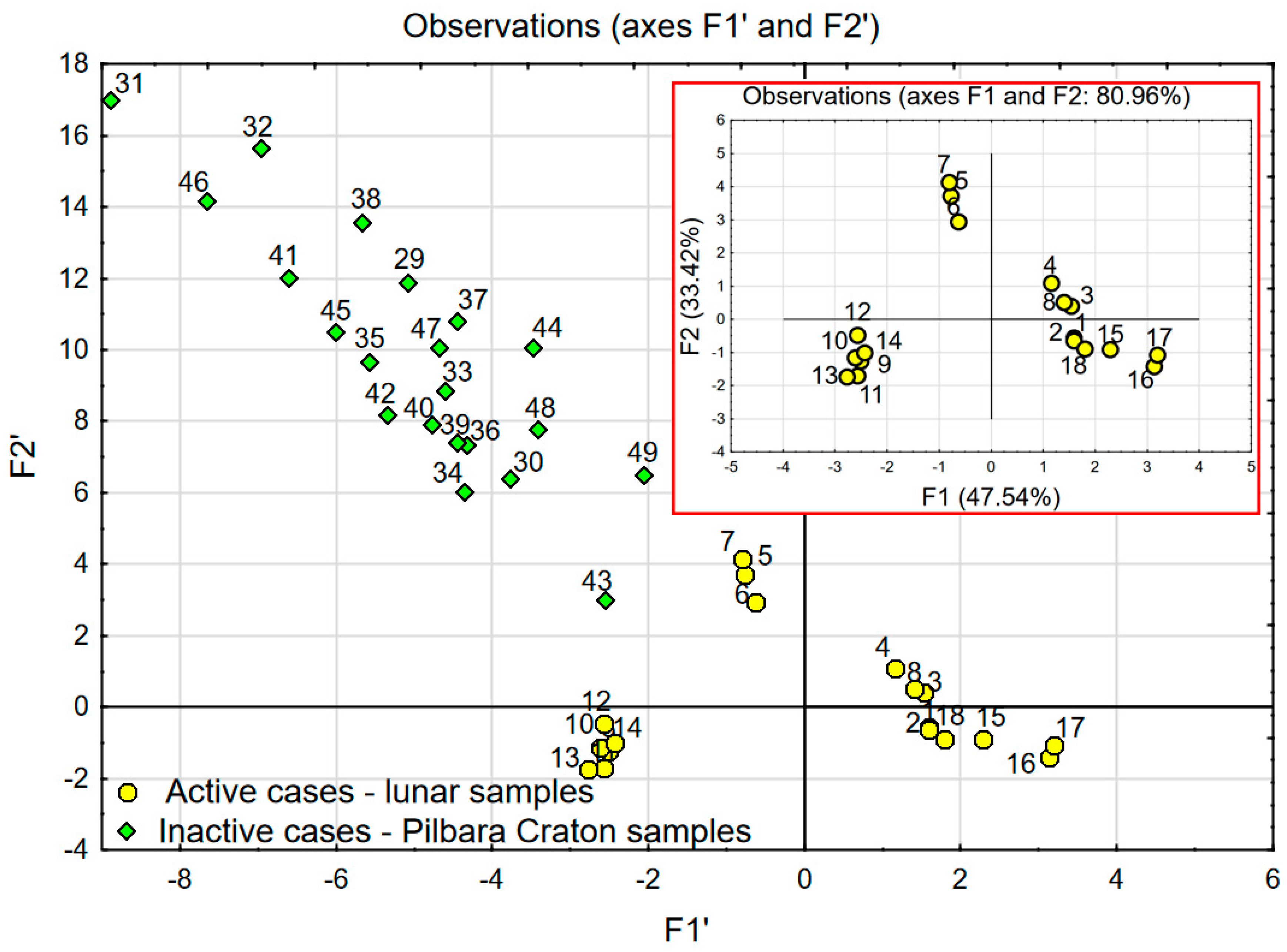

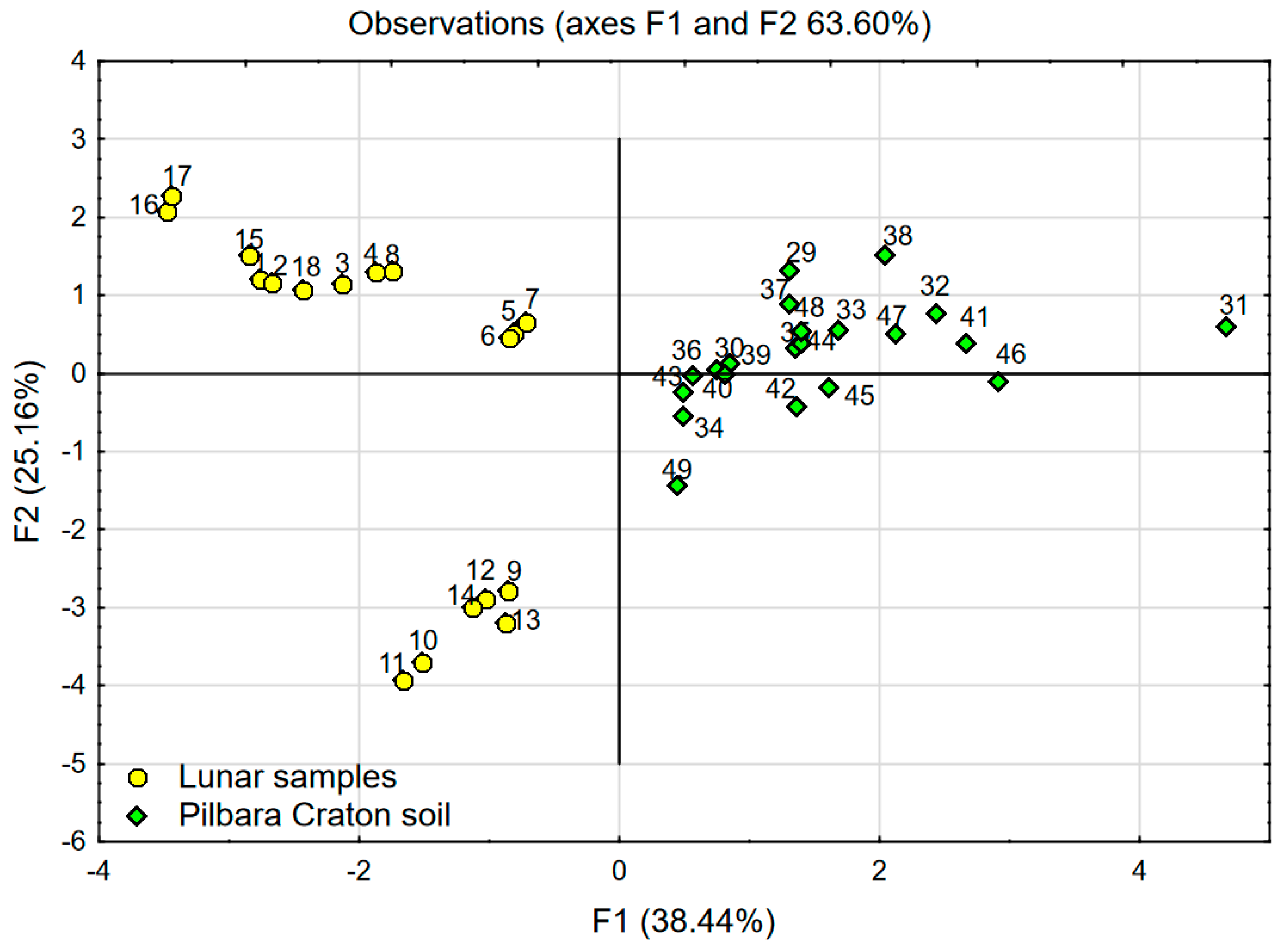

3. PCA Quality Determination of Available LSSs

- Identify hidden patterns in a data set;

- Reduce the dimensionality of the data by removing the noise and redundancy in the data;

- Identify correlated variables.

4. Pilbara Craton

5. Discussion

6. Conclusions

- The chemical composition of Pilbara Craton soil seems to be very similar to current LSSs;

- Pilbara Craton soil should be easily transformed (using traditional civil engineering techniques) into an affordable LSS, which would be available in large quantities;

- LSS based on Pilbara Craton soil would be suitable for a wide range of civil engineering research programmes;

- PCA allows the conduction of complex analyses that give clear results. Such analyses are not feasible using other methods, particularly univariate approaches.

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, M.; Li, L.; Sun, Y. Properties of TJ-1 Lunar Soil Simulant. J. Aerosp. Eng. 2012. [Google Scholar] [CrossRef]

- Arslan, H.; Batiste, S.; Sture, S. Engineering Properties of Lunar Soil Simulant JSC-1A. J. Aerosp. Eng. 2010, 23, 70–83. [Google Scholar] [CrossRef]

- Klosky, J.L.; Sture, S.; Ko, H.Y.; Barnes, F. Geotechnical Behavior of JSC-1 Lunar Soil Simulant. J. Aerosp. Eng. 2000, 13, 133–138. [Google Scholar] [CrossRef]

- Ryu, B.H.; Wang, C.C.; Chang, I. Development and Geotechnical Engineering Properties of KLS-1 Lunar Simulant. J. Aerosp. Eng. 2018. [Google Scholar] [CrossRef]

- Willman, B.M.; Boles, W.W.; Mckay, D.S.; Allen, C.C. Properties of Lunar Soil Simulant JSC-1. J. Aerosp. Eng. 1995, 8, 77–87. [Google Scholar] [CrossRef]

- Zeng, X.; He, C.; Oravec, H.; Wilkinson, A.; Agui, J.; Asnani, V. Geotechnical Properties of JSC-1A Lunar Soil Simulant. J. Aerosp. Eng. 2010. [Google Scholar] [CrossRef]

- Taylor, L.A.; Pieters, C.M.; Britt, D. Evaluations of Lunar Regolith Simulants. Planet. Space Sci. 2016. [Google Scholar] [CrossRef]

- Seweryn, K.; Skocki, K.; Banaszkiewicz, M.; Grygorczuk, J.; Kolano, M.; Kuciński, T.; Mazurek, J.; Morawski, M.; Białek, A.; Rickman, H.; et al. Determining the Geotechnical Properties of Planetary Regolith Using Low Velocity Penetrometers. Planet. Space Sci. 2014. [Google Scholar] [CrossRef]

- Grugel, R.N. Integrity of Sulfur Concrete Subjected to Simulated Lunar Temperature Cycles. Adv. Sp. Res. 2012. [Google Scholar] [CrossRef]

- Toutanji, H.A.; Evans, S.; Grugel, R.N. Performance of Lunar Sulfur Concrete in Lunar Environments. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Benaroya, H.; Bernold, L. Engineering of Lunar Bases. Acta Astronaut. 2008. [Google Scholar] [CrossRef]

- He, C.; Zeng, X.; Wilkinson, A. Geotechnical Properties of GRC-3 Lunar Simulant. J. Aerosp. Eng. 2013. [Google Scholar] [CrossRef]

- Oravec, H.A.; Zeng, X.; Asnani, V.M. Design and Characterization of GRC-1: A Soil for Lunar Terramechanics Testing in Earth-Ambient Conditions. J. Terramech. 2010. [Google Scholar] [CrossRef]

- Dewoolkar, M.M.; Edwards, M.; Walsh, D. Shear Strength and Stiffness Characterization of Lunar Simulant GRC-3. J. Aerosp. Eng. 2018. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. The Assessment of Fine Aggregate Pit Deposits for Concrete Production. Kuwait J. Sci. Eng. 2006, 33, 165. [Google Scholar]

- Katzer, J. Median Diameter as a Grading Characteristic for Fine Aggregate Cement Composite Designing. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Naser, M.Z. Extraterrestrial Construction Materials. Prog. Mater. Sci. 2019. [Google Scholar] [CrossRef]

- Carrier, W.D. Lunar Soil Grain Size Distribution. Moon 1973. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. Influence of Fine Aggregate Grading on Properties of Cement Composite. Silic. Ind. 2009, 74, 9. [Google Scholar]

- Zarzycki, P.K.; Katzer, J. Assessment of Lunar Soil Simulants Based on Multivariate Statistics. J. Aerosp. Eng. 2019. [Google Scholar] [CrossRef]

- Zarzycki, P.K.; Katzer, J. Multivariate Comparison of Lunar Soil Simulants. J. Aerosp. Eng. 2019. [Google Scholar] [CrossRef]

- Pieters, C. Statistical Analysis of the Links among Lunar Mare Soil Mineralogy, Chemistry, and Reflectance Spectra. Icarus 2002, 155, 285–298. [Google Scholar] [CrossRef]

- Kassambara, A. Practical Guide To Principal Component Methods in R: PCA, M (CA), FAMD, MFA, HCPC, Factoextra; STHDA, 2016. [Google Scholar]

- Kaiser, H.F. The Varimax Criterion for Analytic Rotation in Factor Analysis. Psychometrika 1958. [Google Scholar] [CrossRef]

- Petersson, A.; Kemp, A.I.S.; Hickman, A.H.; Whitehouse, M.J.; Martin, L.; Gray, C.M. A New 3.59 Ga Magmatic Suite and a Chondritic Source to the East Pilbara Craton. Chem. Geol. 2019. [Google Scholar] [CrossRef]

- Tessalina, S.G.; Bourdon, B.; Van Kranendonk, M.; Birck, J.L.; Philippot, P. Influence of Hadean Crust Evident in Basalts and Cherts from the Pilbara Craton. Nat. Geosci. 2010. [Google Scholar] [CrossRef]

- Nakajima, M.; Stevenson, D.J. Melting and Mixing States of the Earth’s Mantle after the Moon-Forming Impact. Earth Planet. Sci. Lett. 2015. [Google Scholar] [CrossRef]

- Beintema, K. Geodynamic Evolution of the West and Central Pilbara Craton in Western Australia: A Mid-Archaean Active Continental Margin; Universiteit Utrecht: Utrecht, The Netherlands, 2002. [Google Scholar]

| Sample No. * | SiO2 | TiO2 | Al2O3 | FeO | MgO | MnO | CaO | Na2O | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 42.1 | 7.8 | 13.7 | 15.8 | 7.9 | 0.2 | 12 | 0.5 | 0.1 | 0.1 |

| 2 | 42.2 | 7.8 | 13.6 | 15.3 | 7.8 | 0.2 | 11.9 | 0.47 | 0.16 | 0.05 |

| 3 | 46.6 | 3.6 | 14.2 | 15.4 | 9.7 | 0.22 | 10.4 | 0.43 | 0.24 | 0.156 |

| 4 | 46 | 2.8 | 12.5 | 17.2 | 9.7 | 0.22 | 10.9 | 0.48 | 0.24 | 0.156 |

| 5 | 48.2 | 1.73 | 17.6 | 10.41 | 9.26 | 0.14 | 11.25 | 0.61 | 0.51 | 0.53 |

| 6 | 47.3 | 1.6 | 17.8 | 10.5 | 9.6 | 0.1 | 11.4 | 0.7 | 0.6 | 0.156 |

| 7 | 48.1 | 1.7 | 17.4 | 10.4 | 9.4 | 0.14 | 10.7 | 0.7 | 0.55 | 0.51 |

| 8 | 46.95 | 1.6 | 12.7 | 16.29 | 10.75 | 0.217 | 10.49 | 0.33 | 0.092 | 0.16 |

| 9 | 45.35 | 0.49 | 28.25 | 4.55 | 5.02 | 0.06 | 16.21 | 0.42 | 0.09 | 0.1 |

| 10 | 45.2 | 0.58 | 26.4 | 5.29 | 6.1 | 0.7 | 15.32 | 0.52 | 0.14 | 0.12 |

| 11 | 44.65 | 0.56 | 27 | 5.49 | 5.84 | 0.7 | 15.95 | 0.44 | 0.13 | 0.1 |

| 12 | 44.9 | 0.47 | 27.7 | 5.01 | 5.69 | 0.242 | 15.7 | 0.51 | 0.22 | 0.16 |

| 13 | 44.77 | 0.37 | 28.99 | 4.35 | 4.2 | 0.07 | 16.85 | 0.44 | 0.06 | 0.05 |

| 14 | 45 | 0.54 | 27.3 | 5.1 | 5.7 | 0.3 | 15.7 | 0.46 | 0.17 | 0.11 |

| 15 | 41.67 | 6.52 | 13.57 | 15.37 | 10.22 | 0.21 | 11.18 | 0.34 | 0.09 | 0.06 |

| 16 | 39.82 | 9.52 | 11.13 | 17.41 | 9.51 | 0.25 | 10.85 | 0.32 | 0.07 | 0.06 |

| 17 | 40.09 | 9.32 | 10.7 | 17.85 | 9.92 | 0.24 | 10.59 | 0.36 | 0.08 | 0.07 |

| 18 | 42.2 | 5.09 | 15.7 | 12.4 | 10.3 | 0.15 | 11.5 | 0.24 | 0.07 | 0.156 |

| Sample No. * | SiO2 | TiO2 | Al2O3 | FeO | MgO | MnO | CaO | Na2O | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 47.5 | 0.94 | 15.3 | 11.12 | 9.45 | 0.16 | 13.3 | 1.73 | 0.02 | 0.02 |

| 20 | 47.5 | 1.5 | 15 | 7.25 | 9 | 0.175 | 10.5 | 2.75 | 0.8 | 0.65 |

| 21 | 49.1 | 1.48 | 15.5 | 9.81 | 8.48 | 0.18 | 10.1 | 2.46 | 0.85 | 0.61 |

| 22 | 46.2 | 1.85 | 17.1 | 11.2 | 6.87 | 0.19 | 9.43 | 3.33 | 0.85 | 0.62 |

| 23 | 47.2 | 1.81 | 17.9 | 10.3 | 5.93 | 0.17 | 10.5 | 3.53 | 0.82 | 0.71 |

| 24 | 42.8 | 6.77 | 12.1 | 16.3 | 6.19 | 0.22 | 11.1 | 2.22 | 0.2 | 0.04 |

| 25 | 49.24 | 1.91 | 15.8 | 11.47 | 8.74 | 0.14 | 7.25 | 3.08 | 1.02 | 0.3 |

| 26 | 49.14 | 1.91 | 16.23 | 13.07 | 3.84 | 0.19 | 9.13 | 2.75 | 1.01 | 0.44 |

| 27 | 52.69 | 1.01 | 15.91 | 12.28 | 5.41 | 0.22 | 9.36 | 1.9 | 0.58 | 0.14 |

| 28 | 69.84 | 0.78 | 12.16 | 8.4 | 2.03 | 0.14 | 2.54 | 1.07 | 2.28 | 0.392 |

| Sample No. * | SiO2 | TiO2 | Al2O3 | FeO | MgO | MnO | CaO | Na2O | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| 29 | 50.76 | 0.79 | 12.69 | 3.68 | 9.91 | 0.19 | 8.14 | 3.19 | 0.4 | 0.31 |

| 30 | 50.39 | 1.80 | 12.97 | 4.19 | 5.73 | 0.21 | 10.22 | 1.95 | 0.33 | 0.20 |

| 31 | 65.21 | 0.61 | 14.60 | 1.62 | 2.40 | 0.11 | 4.95 | 3.62 | 1.38 | 0.09 |

| 32 | 51.44 | 0.91 | 15.84 | 2.78 | 7.35 | 0.17 | 7.02 | 3.70 | 1.41 | 0.10 |

| 33 | 54.92 | 0.65 | 12.45 | 3.35 | 7.12 | 0.18 | 9.16 | 2.25 | 0.60 | 0.10 |

| 34 | 48.21 | 1.01 | 14.69 | 3.78 | 5.6 | 0.21 | 12.42 | 2.11 | 0.09 | 0.32 |

| 35 | 51.60 | 1.35 | 14.56 | 3.67 | 6.81 | 0.21 | 9.23 | 3.12 | 0.10 | 0.12 |

| 36 | 48.00 | 1.22 | 14.88 | 4.15 | 7.45 | 0.25 | 10.51 | 2.53 | 0.20 | 0.10 |

| 37 | 50.33 | 1.06 | 13.83 | 3.25 | 9.13 | 0.19 | 8.59 | 2.53 | 1.05 | 0.14 |

| 38 | 54.82 | 0.91 | 8.47 | 3.59 | 8.97 | 0.19 | 8.85 | 3.10 | 1.16 | 0.10 |

| 39 | 49.22 | 1.38 | 14.62 | 4.04 | 6.82 | 0.21 | 10.44 | 2.49 | 0.15 | 0.16 |

| 40 | 49.15 | 1.32 | 14.27 | 3.94 | 6.74 | 0.22 | 10.8 | 2.63 | 0.23 | 0.12 |

| 41 | 56.31 | 0.79 | 13.9 | 3.23 | 4.45 | 0.16 | 7.50 | 3.15 | 0.65 | 0.11 |

| 42 | 51.29 | 1.62 | 15.12 | 3.9 | 4.31 | 0.34 | 8.86 | 2.70 | 0.21 | 0.13 |

| 43 | 49.72 | 1.26 | 14.18 | 4.00 | 5.72 | 0.23 | 10.00 | 1.33 | 0.00 | 0.11 |

| 44 | 49.06 | 1.26 | 14.85 | 3.85 | 7.12 | 0.20 | 8.52 | 1.52 | 2.08 | 0.13 |

| 45 | 51.39 | 0.40 | 17.49 | 1.91 | 7.26 | 0.12 | 10.61 | 2.89 | 0.75 | 0.05 |

| 46 | 54.17 | 0.90 | 14.51 | 1.98 | 3.19 | 0.18 | 8.45 | 3.4 | 1.24 | 0.17 |

| 47 | 55.37 | 0.49 | 13.75 | 2.76 | 6.71 | 0.17 | 8.11 | 2.05 | 1.19 | 0.10 |

| 48 | 51.73 | 0.27 | 16.29 | 2.43 | 8.72 | 0.15 | 7.63 | 1.80 | 0.83 | 0.06 |

| 49 | 39.88 | 0.89 | 15.97 | 3.16 | 3.91 | 0.27 | 12.58 | 0.07 | 3.18 | 0.18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kobaka, J.; Katzer, J.; Zarzycki, P.K. Pilbara Craton Soil as A Possible Lunar Soil Simulant for Civil Engineering Applications. Materials 2019, 12, 3871. https://doi.org/10.3390/ma12233871

Kobaka J, Katzer J, Zarzycki PK. Pilbara Craton Soil as A Possible Lunar Soil Simulant for Civil Engineering Applications. Materials. 2019; 12(23):3871. https://doi.org/10.3390/ma12233871

Chicago/Turabian StyleKobaka, Janusz, Jacek Katzer, and Paweł K. Zarzycki. 2019. "Pilbara Craton Soil as A Possible Lunar Soil Simulant for Civil Engineering Applications" Materials 12, no. 23: 3871. https://doi.org/10.3390/ma12233871

APA StyleKobaka, J., Katzer, J., & Zarzycki, P. K. (2019). Pilbara Craton Soil as A Possible Lunar Soil Simulant for Civil Engineering Applications. Materials, 12(23), 3871. https://doi.org/10.3390/ma12233871