Study of Hybrid Nanoparticles Modified Epoxy Resin Used in Filament Winding Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Casting of Epoxy Resin

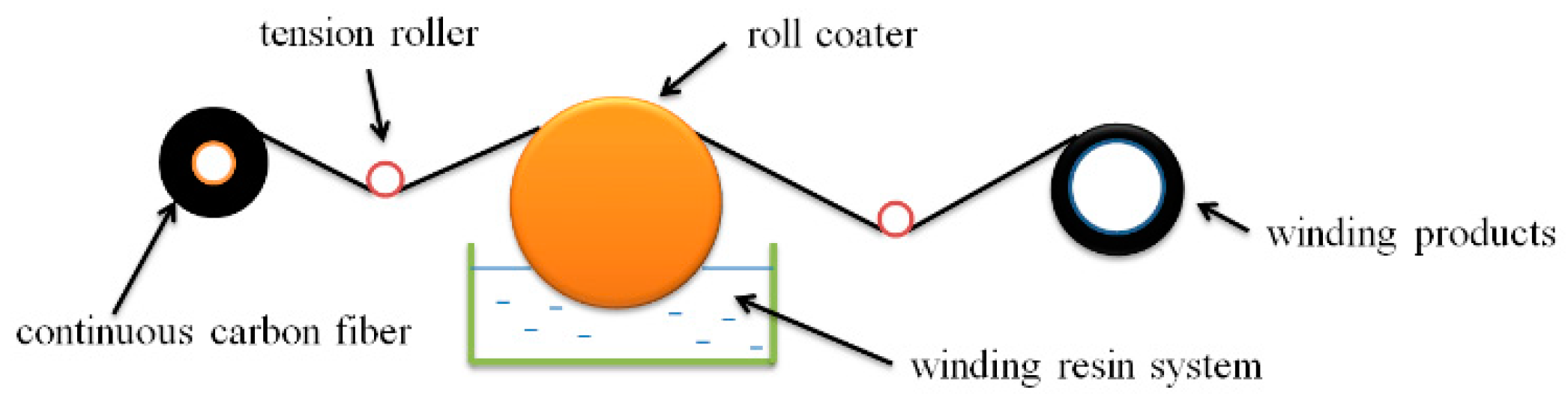

2.2.2. Composite Samples Preparation

2.3. Characterization

3. Results and Discussion

3.1. Properties of Modified Epoxy Resin System

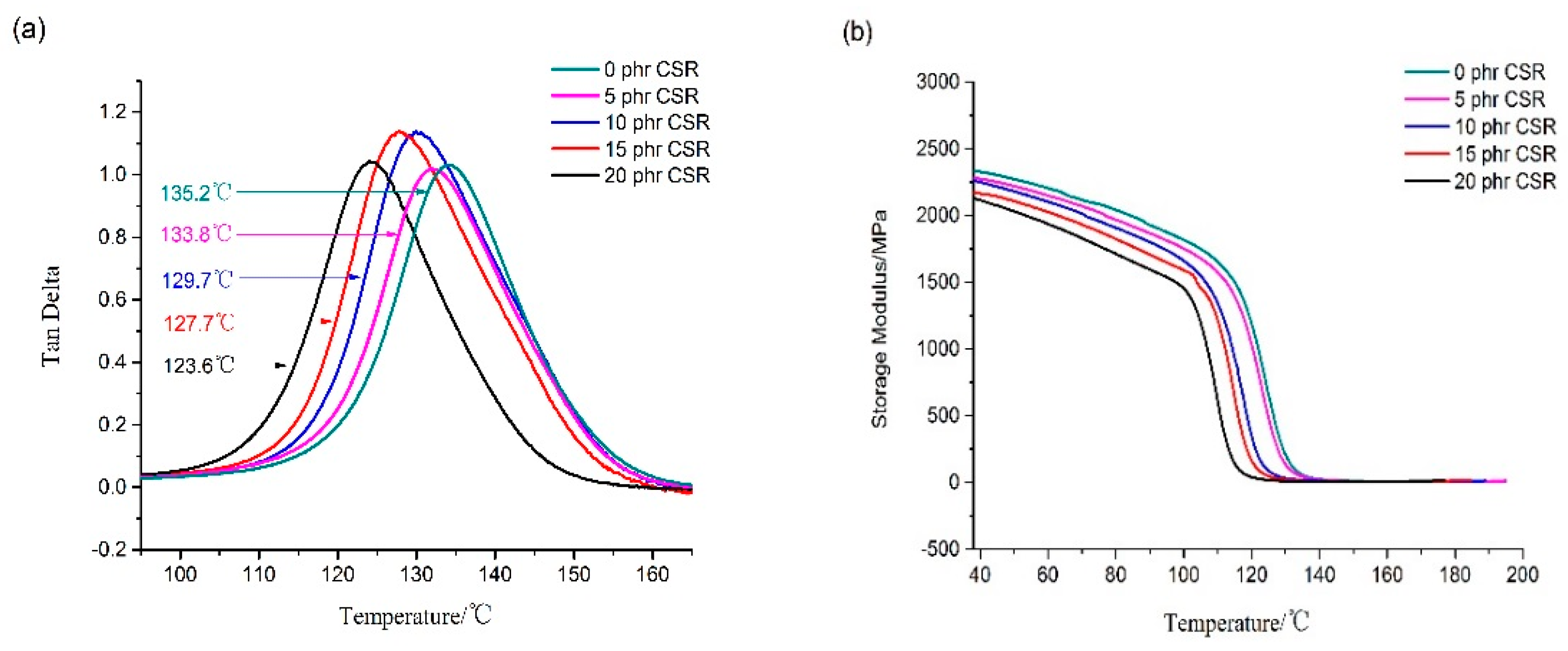

3.1.1. Effects of CSR Nanoparticles on the Epoxy Resin System

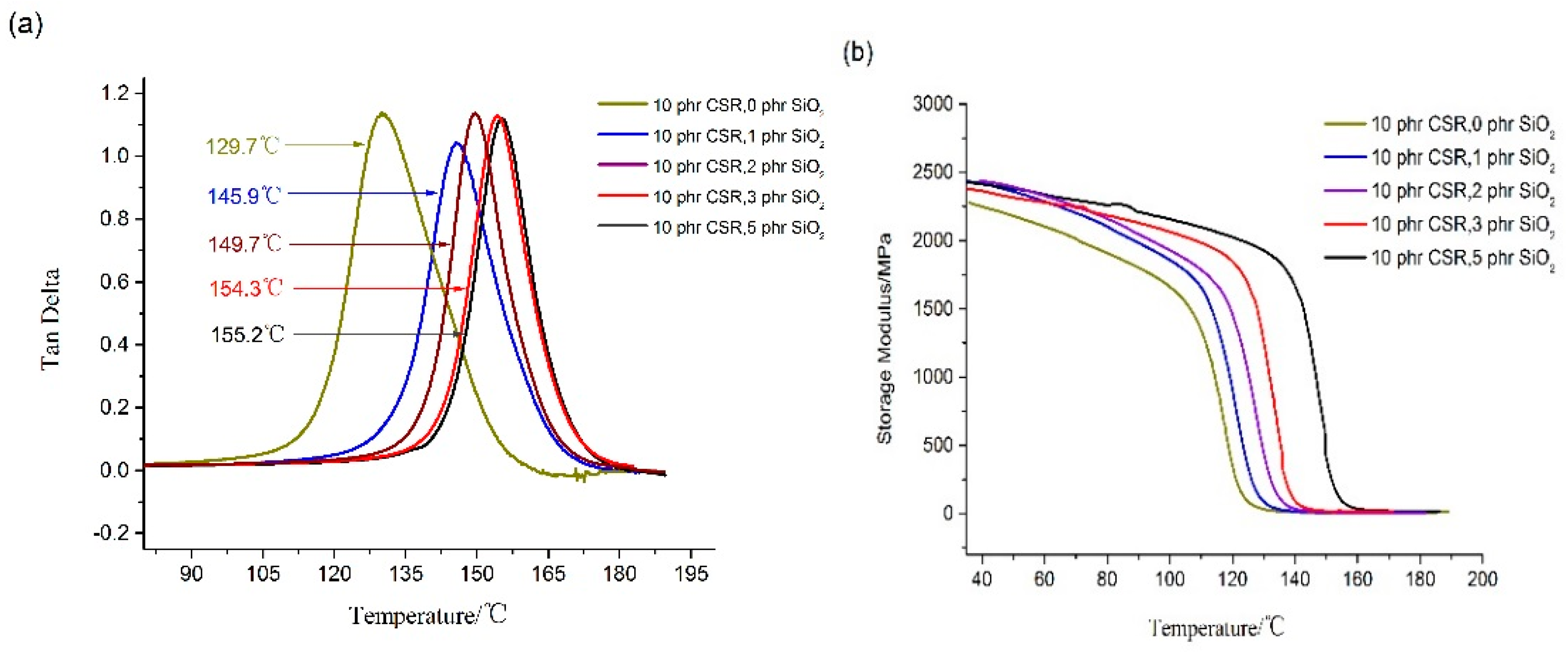

3.1.2. Effects of Nano-SiO2 Particles on the Epoxy Resin System

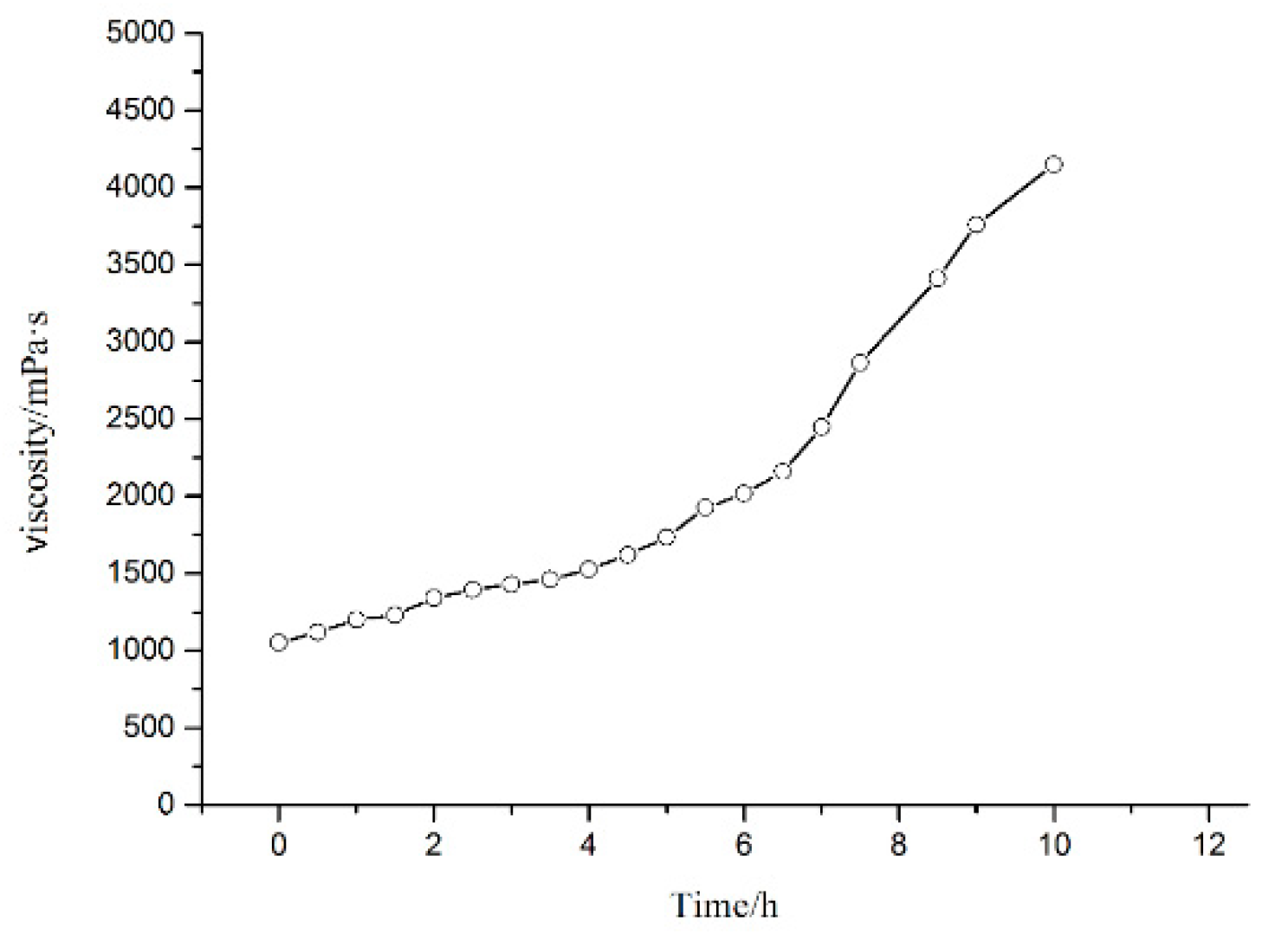

3.1.3. The Process Properties of Nano-CSR/Nano-SiO2/Epoxy Resin System

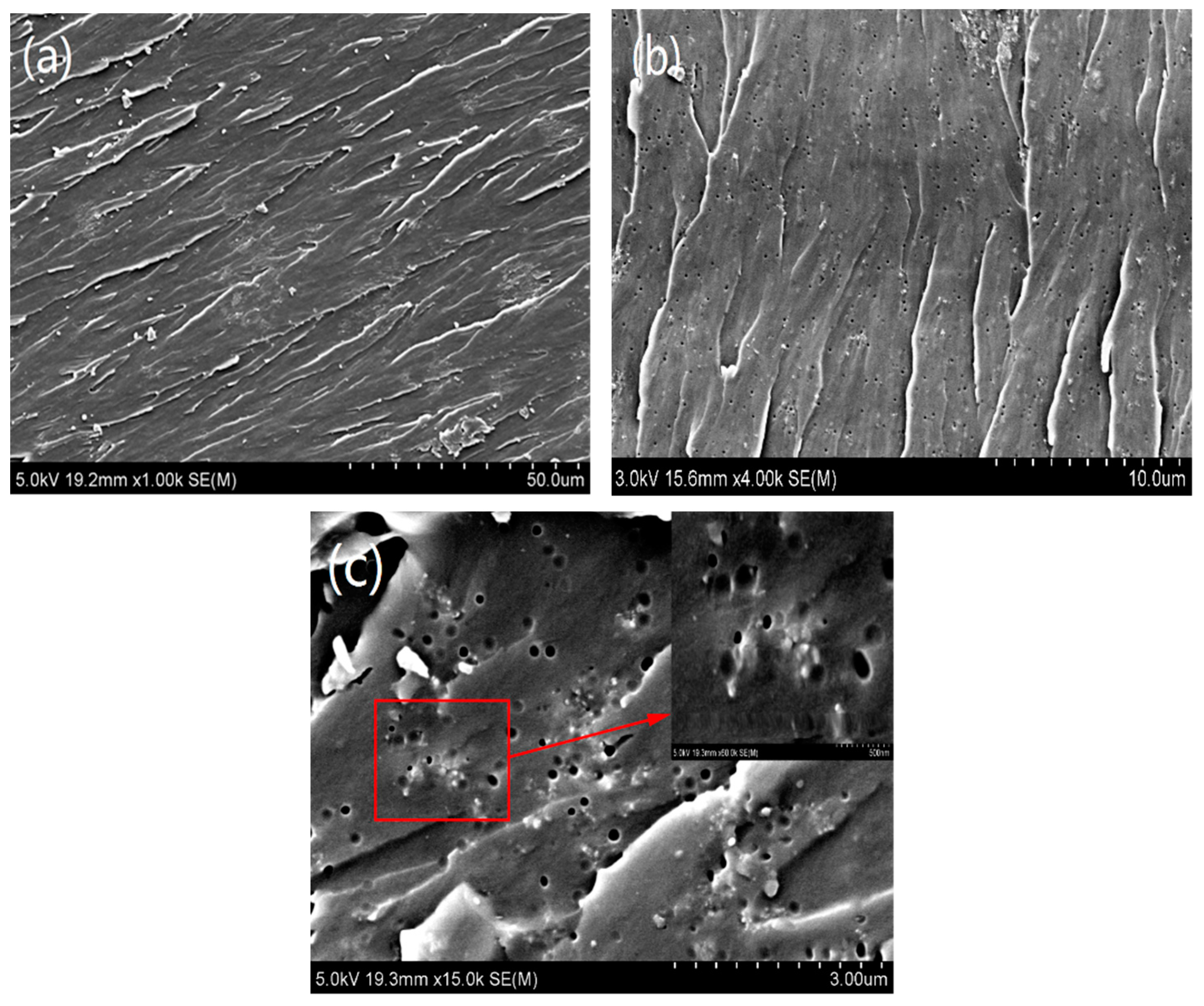

3.1.4. The SEM Analysis of Nano-CSR(10 phr)/Nano-SiO2(2 phr)/Epoxy Resin System

3.2. Properties of NOL Ring Composite

3.2.1. Mechanical Properties of NOL Rings

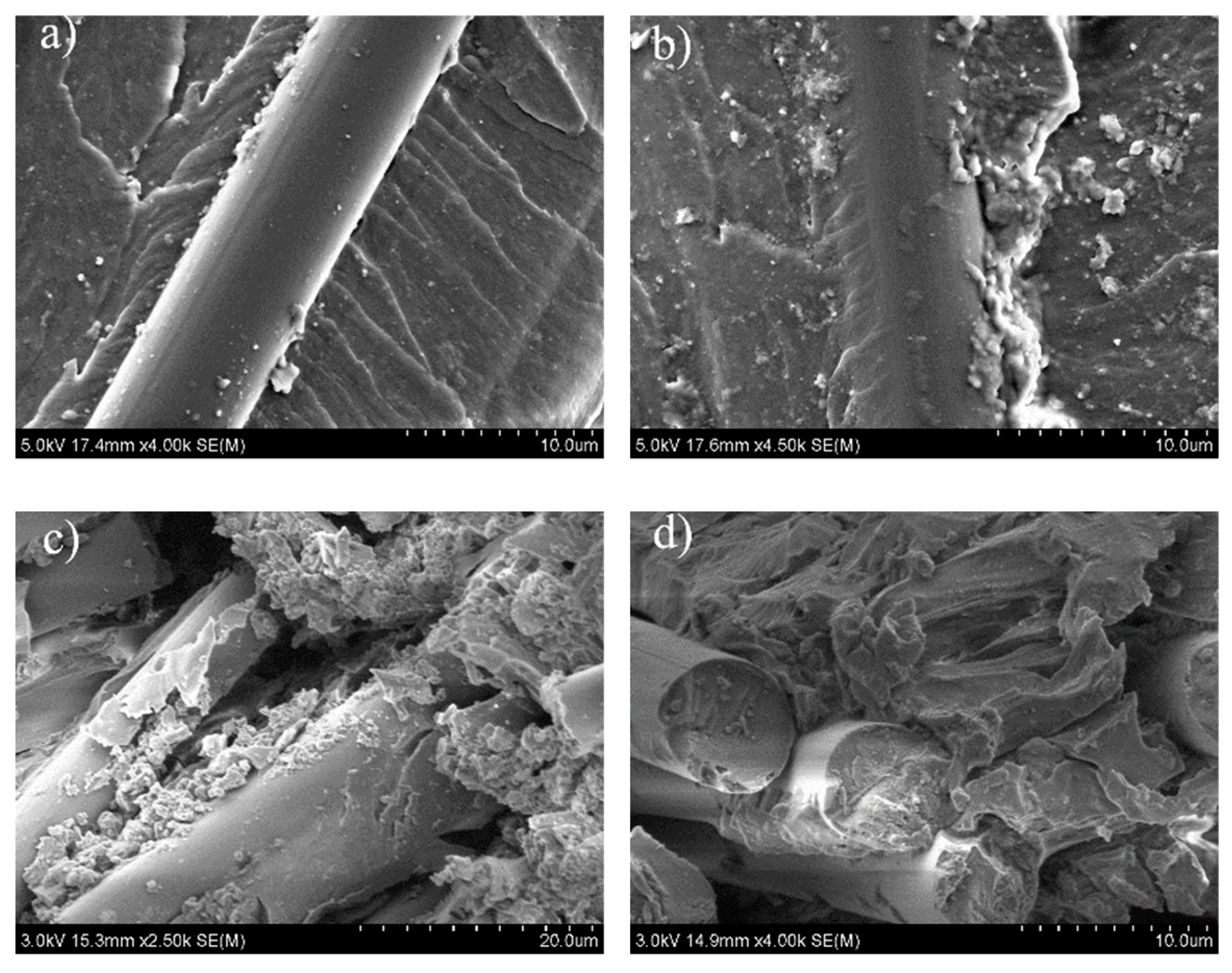

3.2.2. SEM Analysis of NOL Ring Composite with Modified Epoxy Resin

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Komkov, M.A.; Kuznetsov, V.M.; Tarasov, V.A. The influence of epoxide resin viscosity on impregnation of fiber reinforcement. Polym. Sci. Ser. D 2015, 8, 292–295. [Google Scholar] [CrossRef]

- Chen, W.M.; Yu, Y.H.; Li, P. Effect of new epoxy matrix for T800 carbon fiber/epoxy filament wound composites. Compos. Sci. Technol. 2007, 67, 2261–2270. [Google Scholar] [CrossRef]

- Misri, S.; Ishak, M.R.; Sapuan, S.M.; Leman, Z. The effect of winding angles on crushing behavior of filament wound hollow kenaf yarn fibre reinforced unsaturated polyester composites. Fiber Polym. 2015, 16, 2266–2275. [Google Scholar] [CrossRef]

- Akbari, R.; Beheshty, M.H.; Shervin, M. Toughening of dicyandiamide-cured DGEBA-based epoxy resins by CTBN liquid rubber. Iran. Polym. J. 2013, 22, 313–324. [Google Scholar] [CrossRef]

- Yahyaei, H.; Ebrahimi, M.; Tahami, H.V. Toughening mechanisms of rubber modified thin film epoxy resins: Part 2-Study of abrasion, thermal and corrosion resistance. Prog. Organ. Coat. 2017, 113, 136–142. [Google Scholar] [CrossRef]

- Liu, D.; Li, G.; Li, B.; Luan, Y.H.; Ling, H.; Yang, X.P. In-situ toughened CFRP composites by shear-calender orientation and fiber-bundle filtration of PA microparticles at prepreg interlayer. Compos. Appl. Sci. Manuf. 2016, 84, 165–174. [Google Scholar] [CrossRef]

- Dittanet, P.; Pearson, R.A.; Kongkachuichay, P. Thermo-mechanical behaviors and moisture absorption of silica nanoparticle reinforcement in epoxy resins. Int. J. Adhes. Adhes. 2017, 78, 74–82. [Google Scholar] [CrossRef]

- Bittmann, B.; Haupert, F.; Schlarb, A.K. Ultrasonic dispersion of inorganic nanoparticles in epoxy resin. Ultrason. Sonochem. 2009, 16, 622–628. [Google Scholar] [CrossRef]

- Zappalorto, M.; Pontefisso, A.; Fabrizi, A.; Quaresimin, M. Mechanical behaviour of epoxy/silica nanocomposites: Experiments and modelling. Compos. A 2015, 72, 58–64. [Google Scholar] [CrossRef]

- Quan, D.; Ivankovie, A. Effect of core-shell rubber (CSR) nano-particles on mechanical properties and fracture toughness of all epoxy polymer. Polymer 2015, 66, 16–28. [Google Scholar] [CrossRef]

- Lee, M.W.; An, S.; Lee, C.; Liou, M.; Yarin, A.L.; Yoon, S.S. Hybrid self-healing matrix using core-shell nanofibers and capsuleless microdroplets. Polymer 2014, 6, 10461–10468. [Google Scholar] [CrossRef] [PubMed]

- Andreas, K.; Ankur, B.; Bernd, W. The effect of block copolymer and core-shell rubber hybrid toughening on morphology and fracture of epoxy-based fibre reinforced composites. Eng. Fract. Mech. 2018, 203, 81–201. [Google Scholar] [CrossRef]

- Tsang, W.L.; Taylor, A.C. Fracture and toughening mechanisms of silica and core–shell rubber-toughened epoxy at ambient and low temperature. J. Mater. Sci. 2019, 54, 13938–13958. [Google Scholar] [CrossRef]

- Keller, A.; Chong, H.M.; Taylor, A.C.; Dransfeld, C.; Masania, K. Core-shell rubber nanoparticle reinforcement and processing of high toughness fast-curing epoxy composites. Compos. Sci. Technol. 2017, 147, 78–88. [Google Scholar] [CrossRef]

- Giannakopoulos, G.; Masania, K.; Taylor, A.C. Toughening of epoxy using core-shell particles. J. Mater. Sci. 2011, 46, 530–541. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Buchman, A.; Dodiuk-Kenig, H.; Dotan, A.; Tenne, R.; Kenig, S. Toughening of epoxy adhesives by nanoparticles. J. Adhes. Sci. Technol. 2009, 23, 753–768. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S. The mechanisms of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- Sue, H.J.; Gam, K.T.; Bestaour, N.; Clearfield, A. Fracture behavior of α-zirconium phosphate-based epoxy nanocomposites. Acta Mater. 2004, 52, 2239–2250. [Google Scholar] [CrossRef]

- Mezzenga, R.; Boogh, L.; Manson, J.-A.E. A review of dendritic hyperbranched polymer as modifiers in epoxy composites. Compos. Sci. Technol. 2001, 61, 787–795. [Google Scholar] [CrossRef]

- Carolan, D.; Ivankovic, A.; Kinloch, A.J.; Sprenger, S.; Taylor, A.C. Toughened carbon fibre-reinforced polymer composites with nanoparticle-modified epoxy matrices. Mater. Sci. 2017, 52, 1767–1788. [Google Scholar] [CrossRef]

- Macan, J.; Paljar, K.; Burmas, B.; Spehar, G. Epoxy-matrix composites filled with surface-modified SiO2 nanoparticles. J. Therm. Anal. Calorim. 2017, 127, 399–408. [Google Scholar] [CrossRef]

- Li, H.Y.; Zhang, Z.S.; Ma, X.F.; Hu, M.; Wang, X.Y.; Fan, P.F. Synthesis and characterization of epoxy resin modified with nano-SiO2 and γ-glycidoxypropyltrimethoxy silane. Surf. Coat. Technol. 2007, 201, 5269–5272. [Google Scholar] [CrossRef]

- Almeida, J.H.S., Jr.; Angrizani, C.C.; Botelho, E.C.; Amico, S.C. Effect of fiber orientation on the shear behavior of glass fiber/epoxy composites. Mater. Des. 2015, 65, 789–795. [Google Scholar] [CrossRef]

- Da Silva, L.V.; Júnior, J.H.S.A.; Angrizani, C.C.; Amico, S.C. Short beam strength of curaua, sisal, glass and hybrid composites. J. Reinf. Plast. Comp. 2013, 32, 197–206. [Google Scholar] [CrossRef]

| Item | Parameter Indexes |

|---|---|

| Nuclear component | Butadiene rubber (BR) Polymethyl |

| Shell composition | methacrylate(PMMA) |

| Type of epoxy | Bisphenol A epoxy resin |

| Epoxy equivalent | 301 (g/eq) |

| Core-shell rubber size | 100 nm |

| Viscosity (50 °C) | 25000 mPa·s |

| CSR active ingredient content | 40 wt % |

| Item | Parameter Indexes |

|---|---|

| Specific surface area (BET) | 110 ± 20 m/g |

| Average particle size of primary particles | 16 nm |

| carbon content | 0.6–1.2 wt % |

| bulk density | 50 g/L |

| SiO2 content (after burning) | 99.8 wt % |

| Performance | CSR Particles, Addition | ||||

|---|---|---|---|---|---|

| 0 | 5 phr | 10 phr | 15 phr | 20 phr | |

| Tensile strength/MPa | 65 ± 3 | 76 ± 3 | 82 ± 3 | 81 ± 4 | 78 ± 5 |

| Young’s modulus/GPa | 3.2 ± 0.1 | 3.1 ± 0.2 | 3.1 ± 0.1 | 2.9 ± 0.3 | 2.7 ± 0.3 |

| Flexural strength/MPa | 113 ± 3 | 115 ± 4 | 116 ± 3 | 118 ± 5 | 115 ± 4 |

| Flexural modulus/GPa | 3.0 ± 0.1 | 2.9 ± 0.2 | 2.9 ± 0.2 | 2.9 ± 0.2 | 2.8 ± 0.3 |

| Impact strength/KJ·m−2 | 16.5 ± 3.5 | 20.5 ± 4.8 | 25.2 ± 5.1 | 28.5 ± 6.2 | 30.3 ± 6.3 |

| Elongation at break/% | 4.4 ± 0.3 | 4.9 ± 0.3 | 5.5 ± 0.3 | 5.0 ± 0.4 | 4.6 ± 0.4 |

| Heat deflection temperature/°C | 112 ± 1 | 111 ± 1 | 110 ± 1 | 108 ± 1 | 106 ± 1 |

| Performance | Nano-SiO2 Particles, Addition | ||||

|---|---|---|---|---|---|

| 0 phr | 1 phr | 2 phr | 3 phr | 5 phr | |

| Tensile strength/MPa | 82 ± 3 | 87 ± 4 | 89 ± 3 | 80 ± 4 | 73 ± 4 |

| Young’s modulus/GPa | 3.1 ± 0.2 | 3.2 ± 0.2 | 3.5 ± 0.2 | 3.6 ± 0.2 | 3.7 ± 0.3 |

| Flexural strength/MPa | 116 ± 4 | 120 ± 5 | 128 ± 4 | 125 ± 6 | 115 ± 6 |

| Flexural modulus/GPa | 2.9 ± 0.1 | 3.1 ± 0.2 | 3.2 ± 0.2 | 3.3 ± 0.2 | 3.5 ± 0.3 |

| Impact strength/KJ·m−2 | 25.2 ± 5.2 | 26.1 ± 5.4 | 26.6 ± 5.9 | 24.0 ± 6.2 | 16.3 ± 7.5 |

| Elongation at break/% | 5.5 ± 0.2 | 5.2 ± 0.3 | 4.9 ± 0.3 | 4.5 ± 0.3 | 3.9 ± 0.3 |

| Heat deflection temperature/°C | 110 ± 1 | 115 ± 1 | 117 ± 1 | 118 ± 1 | 120 ± 1 |

| Test Project | Tensile Strength/MPa | Young’s Modulus /GPa | Interlaminar Shear Strength/MPa |

|---|---|---|---|

| NOL ring composite with unmodified epoxy | 1987.8 ± 80.3 | 72.3 ± 6.5 | 49.5 ± 5.7 |

| NOL ring composite with modified epoxy | 2266.7 ± 73.5 | 75.6 ± 7.4 | 58.9 ± 4.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, C.; Yu, J.; Wang, B.; Lau, A.K.T.; Zhu, B.; Qiao, K. Study of Hybrid Nanoparticles Modified Epoxy Resin Used in Filament Winding Composite. Materials 2019, 12, 3853. https://doi.org/10.3390/ma12233853

Di C, Yu J, Wang B, Lau AKT, Zhu B, Qiao K. Study of Hybrid Nanoparticles Modified Epoxy Resin Used in Filament Winding Composite. Materials. 2019; 12(23):3853. https://doi.org/10.3390/ma12233853

Chicago/Turabian StyleDi, Chengrui, Junwei Yu, Baoming Wang, Alan Kin Tak Lau, Bo Zhu, and Kun Qiao. 2019. "Study of Hybrid Nanoparticles Modified Epoxy Resin Used in Filament Winding Composite" Materials 12, no. 23: 3853. https://doi.org/10.3390/ma12233853

APA StyleDi, C., Yu, J., Wang, B., Lau, A. K. T., Zhu, B., & Qiao, K. (2019). Study of Hybrid Nanoparticles Modified Epoxy Resin Used in Filament Winding Composite. Materials, 12(23), 3853. https://doi.org/10.3390/ma12233853