The Wear Responses of the Welded Joints of ASTM A335 Gr. P11 Steels Affected by Accelerated Flow Corrosion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Tested

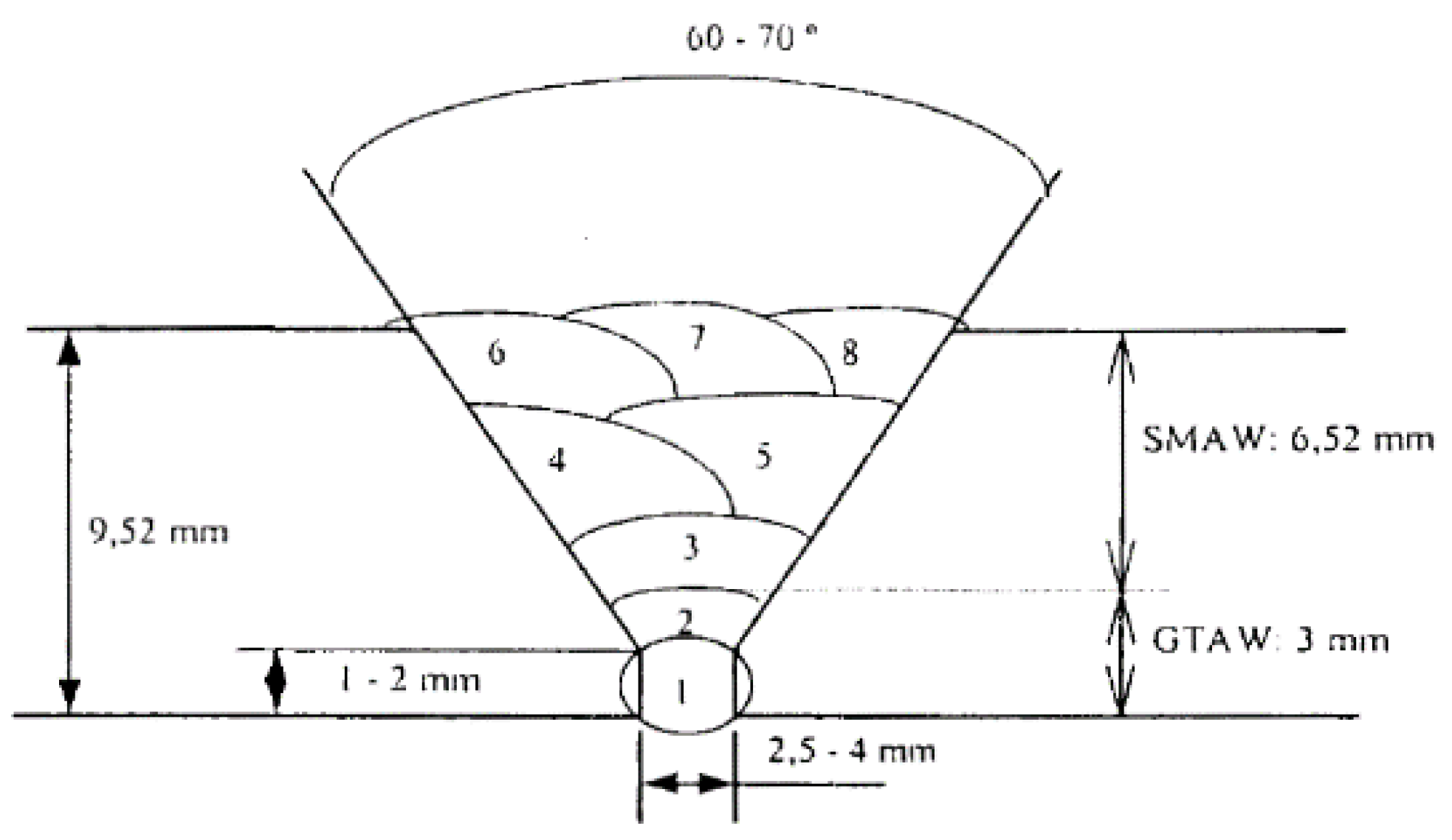

- Preheating with a temperature around 100 °C.

- Welding with tungsten inert gas (TIG) in the root with a BOHLER AWS A5.28-96:ER80S-G and using an electric arc welding rod and manual weld filling. (Table 2).

- Post-weld heat treatment (PWHT) with a temperature around 700 °C.

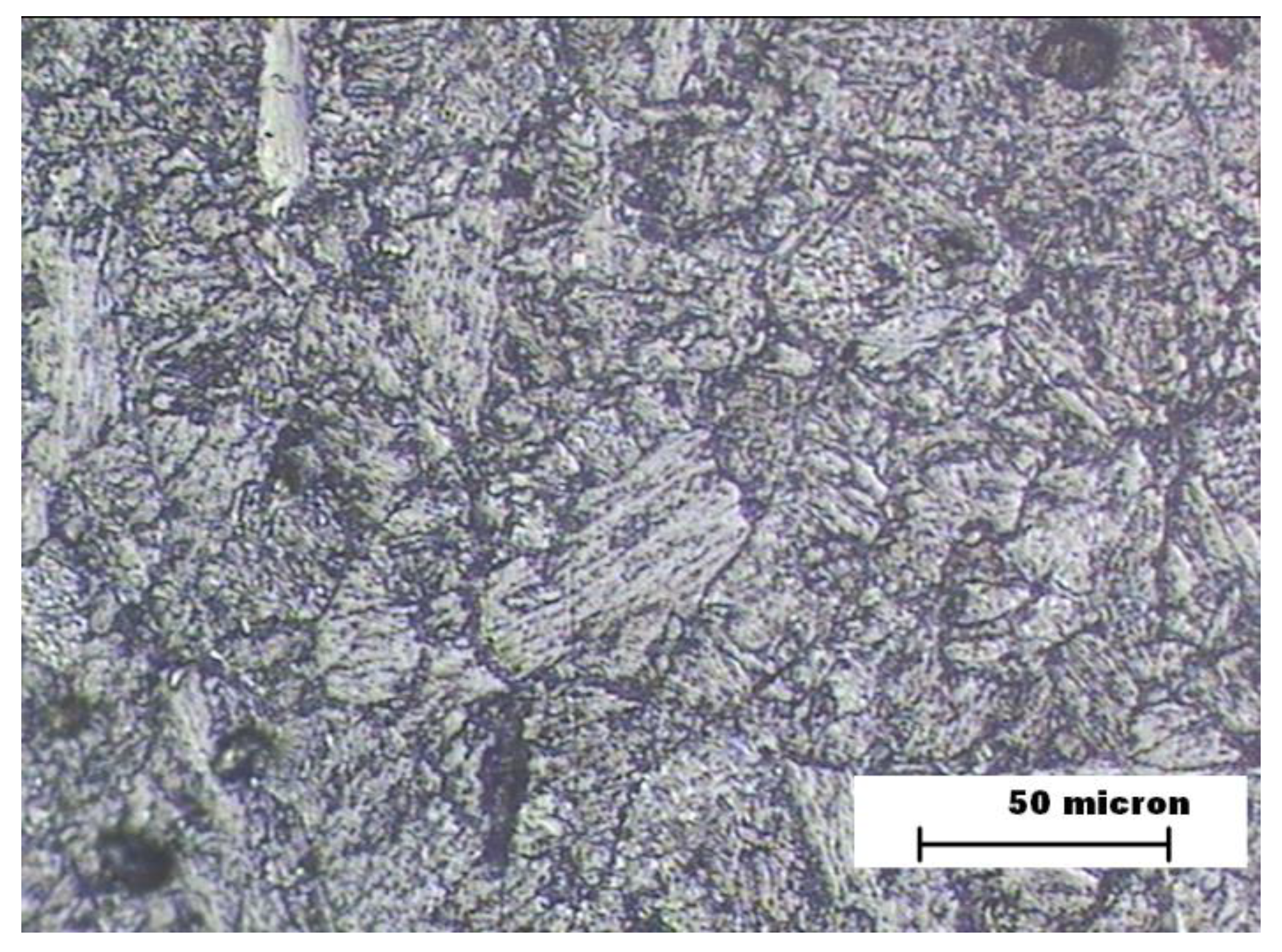

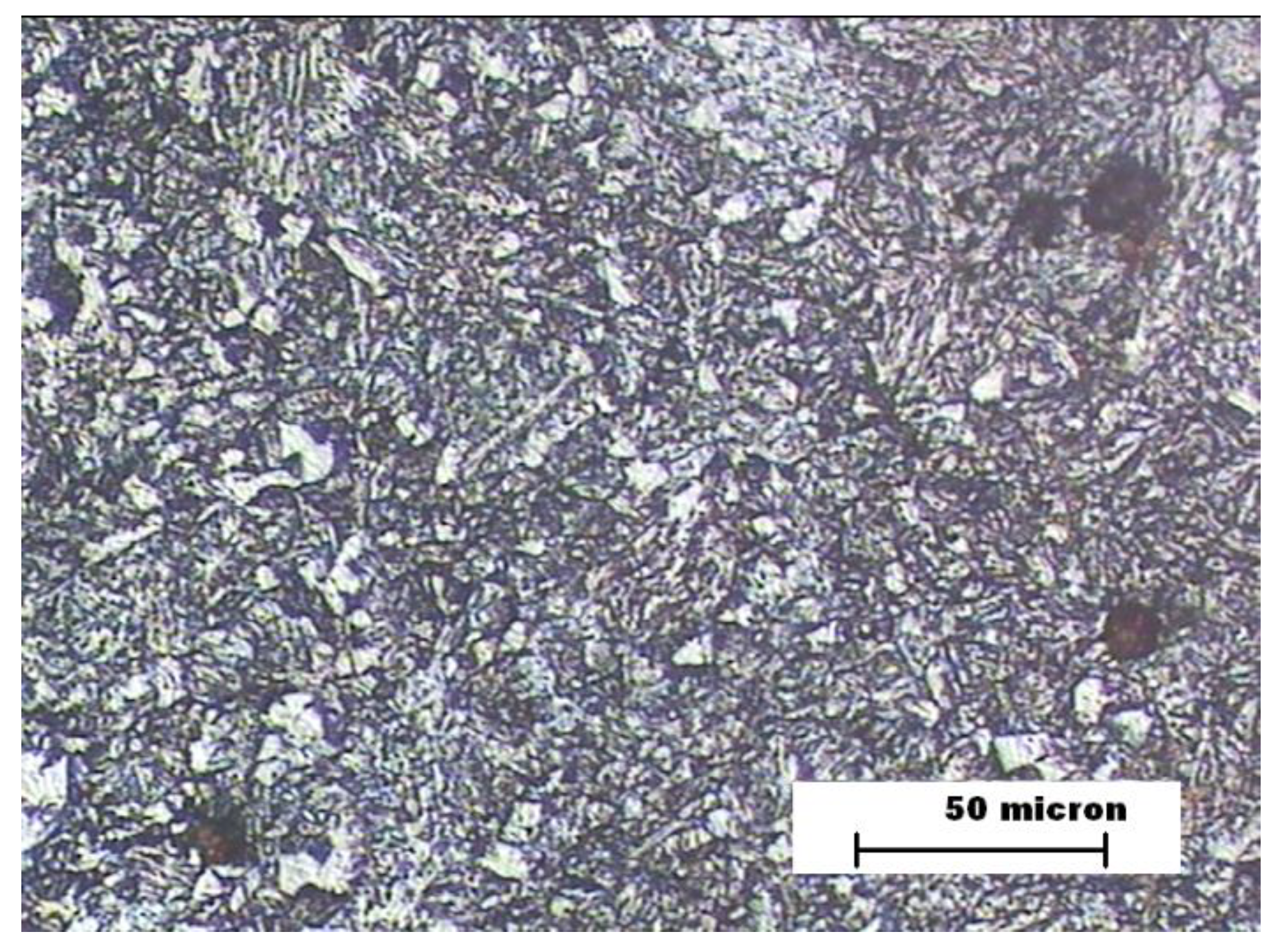

- Sample A. Preheating process and post-welding heat treatment, as indicated in the regulations.

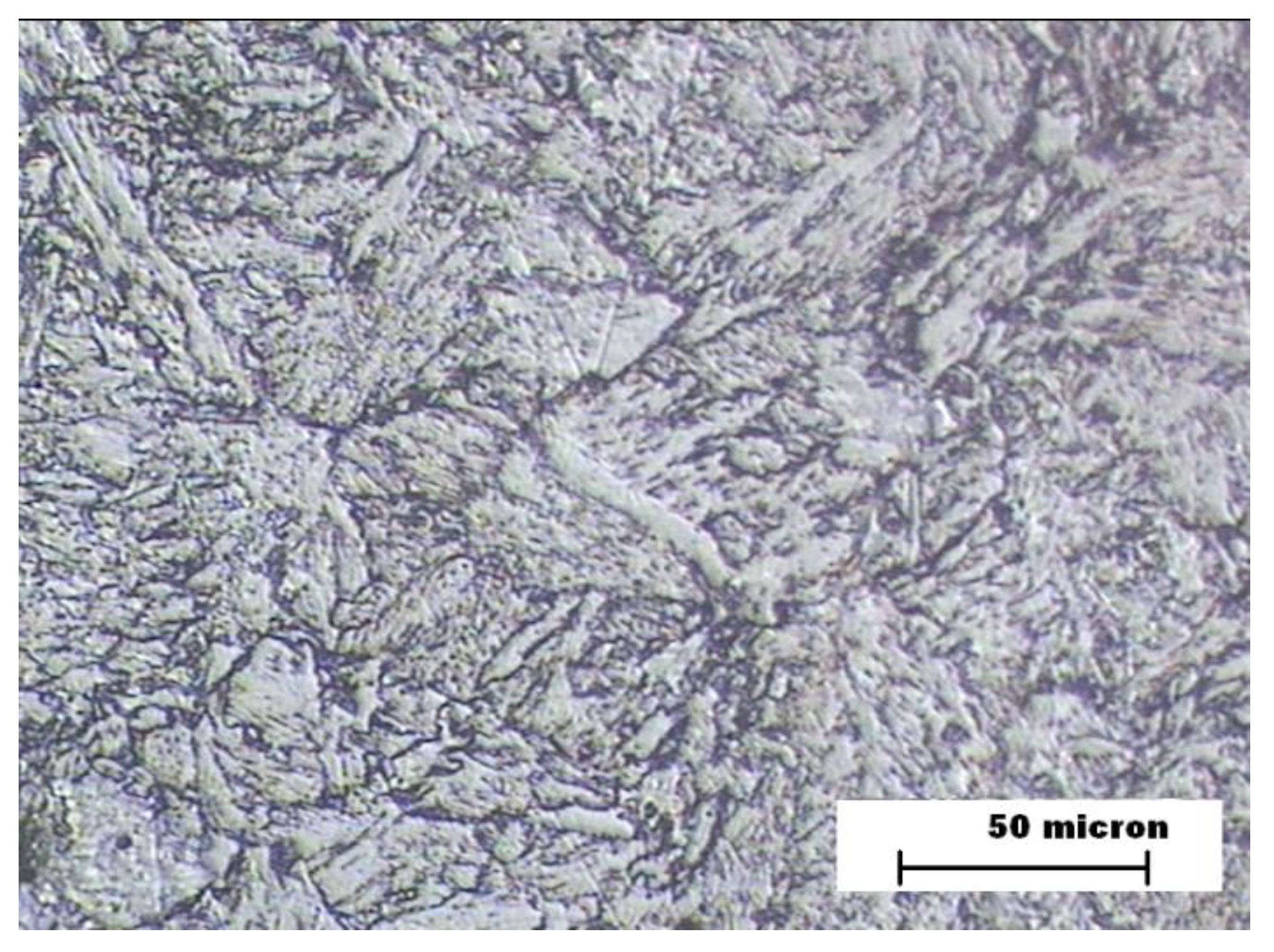

- Sample B. Preheating process and elimination of the PWHT.

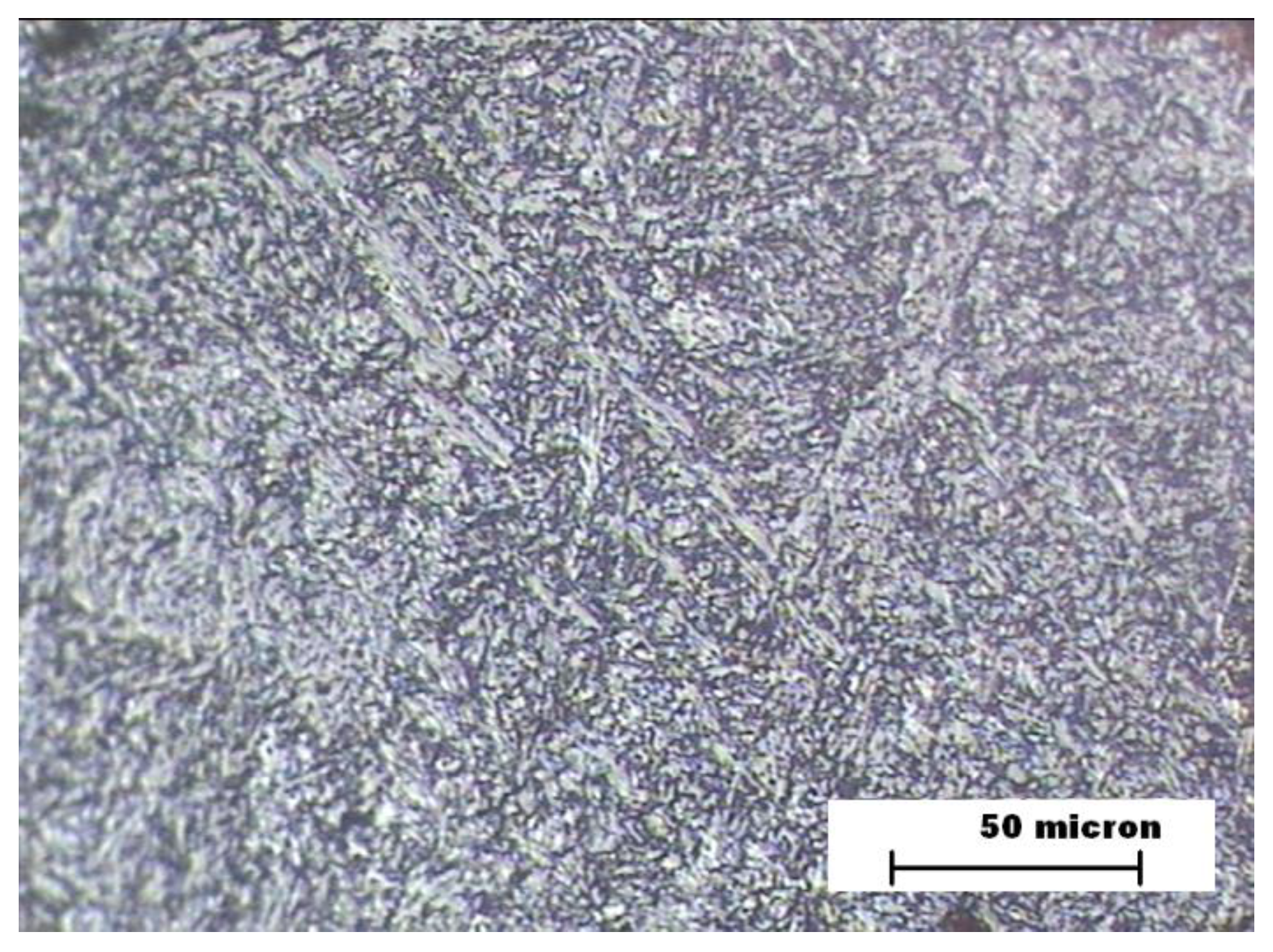

- Sample C. Elimination of preheating and the PWHT.

2.2. Experimental Work

- Applied load of 10 N;

- Rotation speed of 200 rpm with a radius of 3 m;

- Temperature of 200 °C;

- Duration: 1 h;

- Pin: chrome steel ball with a hardness of 775 HV and a diameter of 4 mm.

- Test load: 200 g;

- Application time: 20 s.

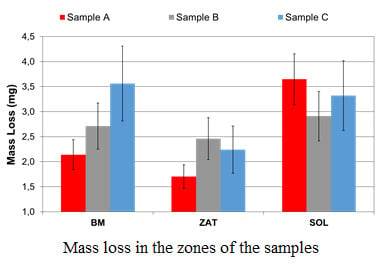

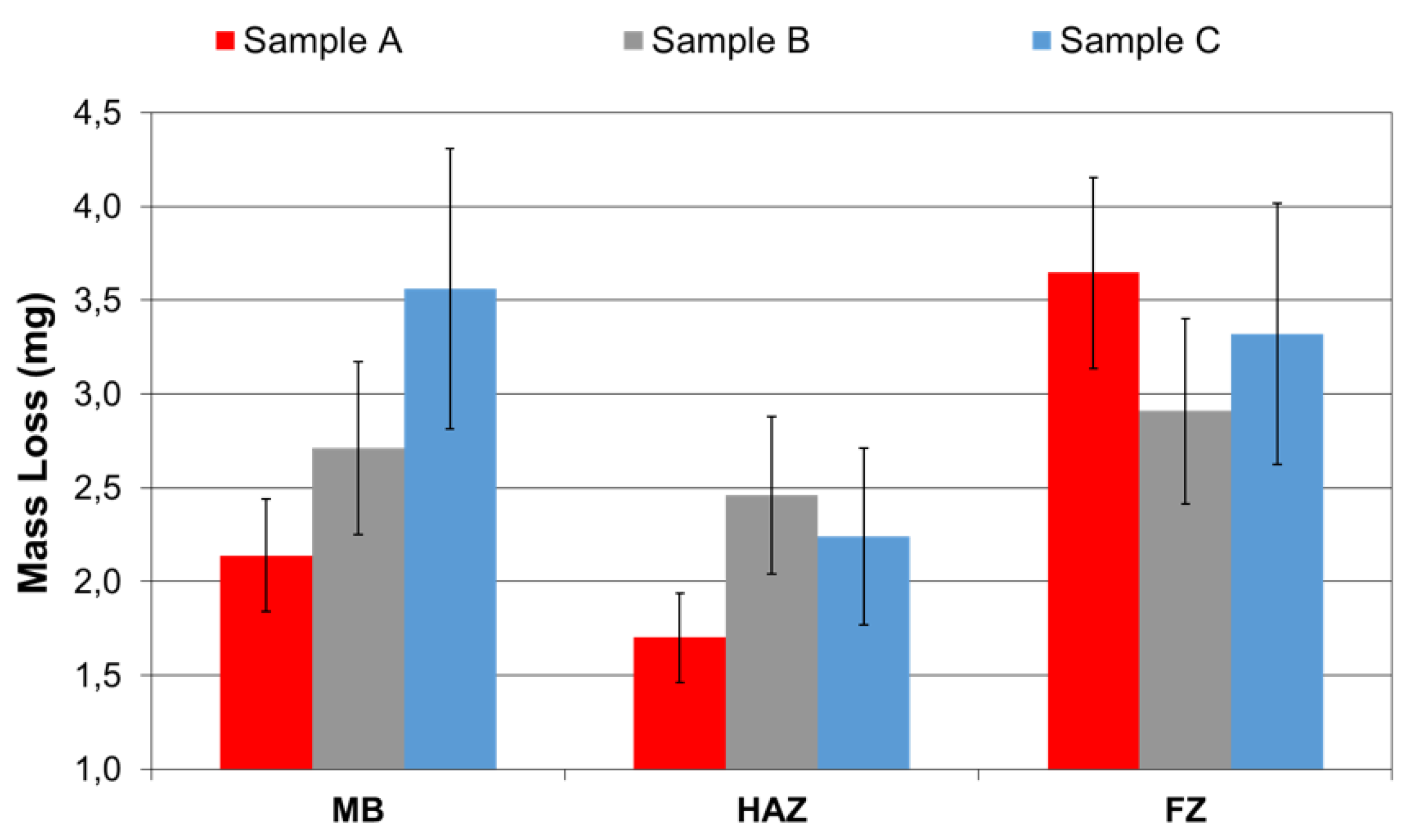

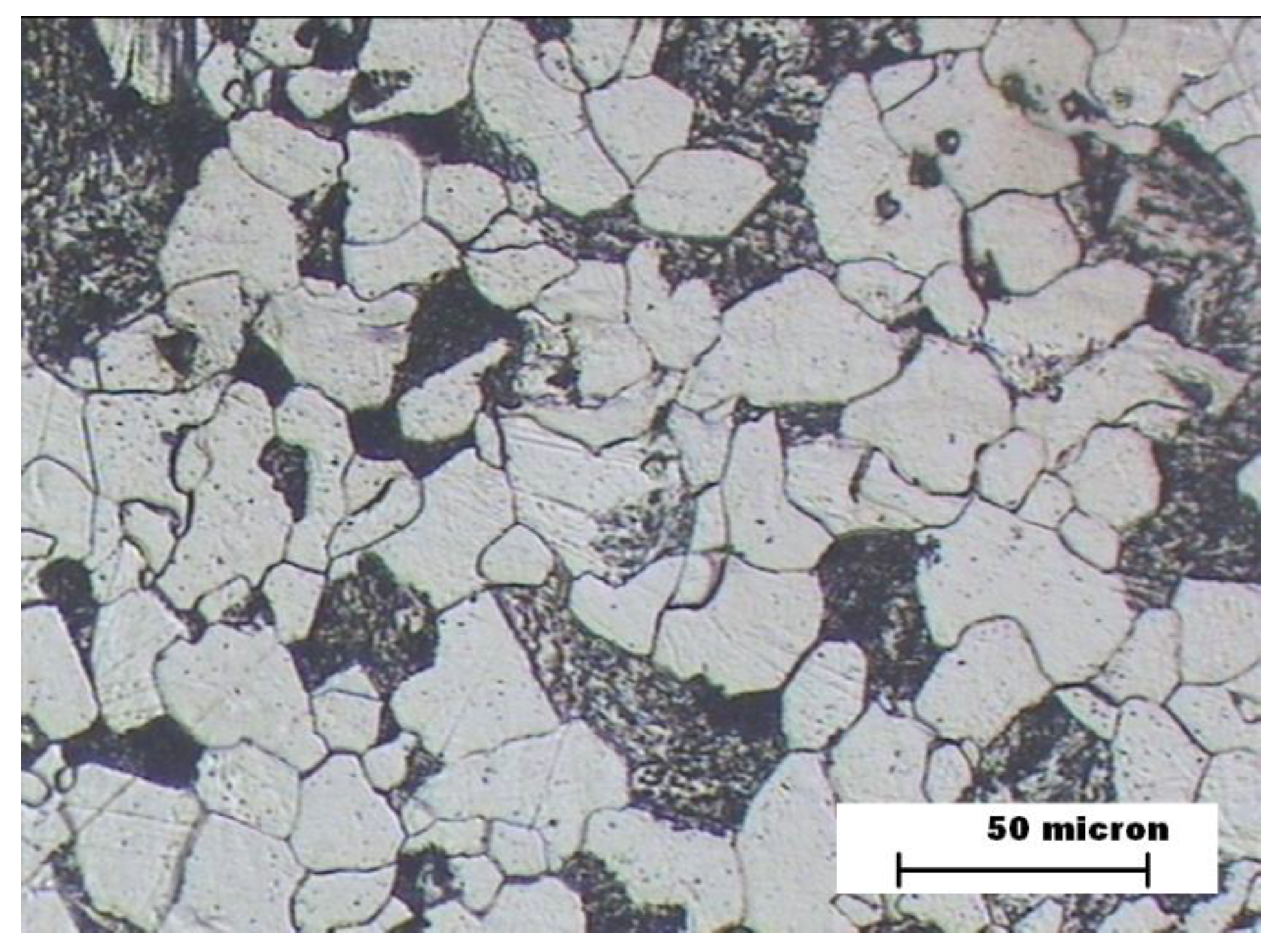

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Horowitz, J. Recommendations for an Effective Program Against Erosive Attack; EPRI: Palo Alto, CA, USA, 2015. [Google Scholar]

- Reina Gómez, M. Soldadura de Los Aceros, 4th ed.; Weld-Work, S.L.: Madrid, Spain, 2003. [Google Scholar]

- Granjon, H. Bases Metalúrgicas de la Soldadura; Publicaciones de la Soldadura Autógena: París, France, 1993. [Google Scholar]

- ASM Metals Handbook. Welding, Brazing and Soldering; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Smith, W.F. Fundamentos de la Ciencia e Ingeniería de Materiales, 3rd ed.; McGraw-Hill: México, DF, USA, 2006. [Google Scholar]

- Medina, S.F.; Fabregue, P.; Lopez, V. Recristalización estática de los aceros de construcción Cr-Mo y microaleados al niobio y al titanio. Rev. Metal. Madr. 1989, 25, 238–246. [Google Scholar]

- De Andres, M.P. Tecnología del acero moldeado. Propiedades mecánicas y tratamientos térmicos en aceros moldeados de baja aleación (1% Cr-0.20% Mo). Rev. Metal. Madr. 1975, 11, 103–118. [Google Scholar]

- ASM Handbook. Corrosion-Fundamentals, Testing and Protection; ASM International: Materials Park, OH, USA, 2003. [Google Scholar]

- Coleman, K.; Gandy, D. Development of Advanced Methods for Joining Low-Alloy Steels; Technical Report; EPRI: Palo Alto, CA, USA, 2003. [Google Scholar]

- Kain, V.; Roychowdhury, S.; Ahmedabadi, P.; Barua, D.K. Flow accelerated corrosion: Experience from examination of components from nuclear power plants. Eng. Fail. Anal. 2011, 18, 2028–2041. [Google Scholar] [CrossRef]

- Findlan, S. Welding and Repair Technology for Power Plants: Four RRAC International Conference; EPRI: Palo Alto, CA, USA, 2000. [Google Scholar]

- Harris, D.; Dedhia, D. Materials Reliability Program, Re-Evaluation in NUREG/CR-6674 for Carbon and Low Alloy Steel Components (MRP-74, Revision I); EPRI: Palo Alto, CA, USA, 2005. [Google Scholar]

- Ahmadi, M.; Mirsalehi, S.E. Investigation on microstructure, mechanical properties and corrosion behavior of AISI 316L stainless steel to ASTM A335-P11 low alloy steel dissimilar welding joints. Mater. High Temp. 2015, 32, 627–635. [Google Scholar] [CrossRef]

- ASTM G99-05. Standard Test Method for Wear Testing with A Pin-on-Disk Apparatus; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Ilevbare, G. Materials Handbook for Nuclear Plant Pressure Boundary Applications; Technical Report; EPRI: Palo Alto, CA, USA, 2013. [Google Scholar]

- Gandy, D.W.; Findlan, S.J. Review of Postweld Heat Treatment Requirements for P-4 And P-5a Cr-Mo Materials; Technical Report; EPRI: Palo Alto, CA, USA, 1997. [Google Scholar]

- Karzov, G.P.; Timofeev, B.T.; Chernaenko, T.A. Analysis of the Events of Failures of Pipelines Made of Austenitic Steel in Nuclear Power-Generating Industry. Strength Mater. 2006, 38, 359–366. [Google Scholar] [CrossRef]

- ASTM A498-98, Standard Specification for Seamless and Welded Carbon, Ferritic, and Austenitic Alloy Steel Heat-Exchanger Tubes with Integral Fins; ASTM International: West Conshohocken, PA, USA, 1998.

- NP-6723-D, BWR Piping System Replacement; EPRI: Palo Alto, CA, USA, 1990.

- ASTM A335, Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service; ASTM International: West Conshohocken, PA, USA, 2010.

- Gorji, N.; O’Connor, R.; Mussatto, A.; Snelgrove, M.; González, M.; Dermot Brabazon, P.G. Recyclability of stainless steel (316 L) powder within the additive manufacturing process. Materialia 2019, 8, 100489. [Google Scholar] [CrossRef]

- Johnson, L. Monitoreo del transporte de hierro. Power Plant Chem. 2015, 17, 218–222. [Google Scholar]

- Wolfe, R. Field Guide: Flow-Accelerated Corrosion and Erosion; EPRI: Palo Alto, CA, USA, 2016. [Google Scholar]

- EPRI. Recommendations for an Effective Flow-Accelerated Corrosion Program (NSAC-202L-R4); EPRI: Palo Alto, CA, USA, 2013; ISBN 3002000563. [Google Scholar]

- Chexal, B.; Horowitz, J.; Dooley, B. Flow-Accelerated Corrosion in Power Plants; EPRI Report TR-106611-R1; EPRI: Palo Alto, CA, USA, 1998. [Google Scholar]

- Horowitz, J. Fac in Power Plants 2; EPRI: Palo Alto, CA, USA, 2016. [Google Scholar]

- Horowitz, J. Mentoring Guide for Flow-Accelerated Corrosion Engineers; EPRI: Palo Alto, CA, USA, 2010. [Google Scholar]

- Chexal, V.K.; Munson, D.P. Recommendations for an Effective Flow Accelerated Corrosion Program; EPRI: Palo Alto, CA, USA, 1999. [Google Scholar]

- Vivekand, K. Flow Accelerated Corrosion: Forms, mechanism and case studies. Procedia Eng. 2014, 86, 576–588. [Google Scholar]

- Horowitz, J. FAC in Steam Generators. In Proceedings of the CHUG Meeting, Riviera Beach, FA, USA, 20 January 2001. [Google Scholar]

- Murariu, A.C.; Plesu, N. Investigations on Corrosion Behavior of Welded Joint in ASTM A355P5 Alloy Steel Pipe. Int. J. Electrochem. Sci. 2015, 10, 10832–10846. [Google Scholar]

- King, B. Welding and Post Weld Heat Treatment of 2.25%Cr-1%Mo Stell. Bachelor’s Thesis, University of Wollongong, Wollongong, Australia, 2005. [Google Scholar]

- Liang, Y.; Wang, P.; Wang, Y.; Dai, Y.; Hu, Z.; Tranca, D.E.; Hristu, R.; Stanciu, S.G.; Toma, A.; Stanciu, G.A.; et al. Growth Mechanisms and the Effects of Deposition Parameters on the Structure and Properties of High Entropy Film by Magnetron Sputtering. Materials 2019, 12, 3008. [Google Scholar] [CrossRef] [PubMed]

- ASM International. Weld integrity and performance. In A Source Book Adapted from ASM International Handbooks, Conference Proceedings, and Technical Books; Lampman, S., Ed.; ASM International: Novelty, OH, USA, 1997. [Google Scholar]

- Bahador, A.; Hamzah, E.; Kondoh, K.; Tsutsumi, S.; Umeda, J.; Bakar, T.A.A.; Yusof, F. Heat-Conduction-Type and Keyhole-Type Laser Welding of TiNi Shape-Memory Alloys Processed by Spark-Plasma Sintering. Mater. Trans. 2018, 59, 835–842. [Google Scholar] [CrossRef]

| C (%) | S (%) | Mn (%) | Si (%) | Cr (%) | Mo (%) |

|---|---|---|---|---|---|

| 0.14 | 0.004 | 0.30 | 0.78 | 1.2 | 0.5 |

| Filler Material | TIG Rod Ø 2.4 mm | Shielded Metal Arc Welding | ||||||

|---|---|---|---|---|---|---|---|---|

| Electrode Ø 3.25 mm AWS A-5.5/Class E8018-B2L | Electrode Ø 2.5 mm AWS A-5.5/Class E8018-B2L | |||||||

| Sample A | Temperature between Passes (°C) | 50–55 | ||||||

| Time (‘) | 90 | 45 | 50 | 40 | 30 | 40 | 30 | |

| Sample B | Temperature between Passes (°C) | 150 | 160 | 170 | 180 | 180 | 180 | 180 |

| Time (‘) | 120 | 45 | 50 | 40 | 30 | 40 | 30 | |

| Sample C | Temperature between Passes (°C) | 180–200 | ||||||

| Time (‘) | 90 | 45 | 45 | 45 | 30 | 35 | 30 | |

| Hardness (HV) | |||

|---|---|---|---|

| Welding Process | BM | HAZ | FZ |

| Sample A | 202 | 183 | 239 |

| Sample B | 212 | 233 | 256 |

| Sample C | 234 | 312 | 306 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montero, J.; Filgueira, A.; García-Diez, A.; Mier, J.L.; Camba, C. The Wear Responses of the Welded Joints of ASTM A335 Gr. P11 Steels Affected by Accelerated Flow Corrosion. Materials 2019, 12, 3630. https://doi.org/10.3390/ma12213630

Montero J, Filgueira A, García-Diez A, Mier JL, Camba C. The Wear Responses of the Welded Joints of ASTM A335 Gr. P11 Steels Affected by Accelerated Flow Corrosion. Materials. 2019; 12(21):3630. https://doi.org/10.3390/ma12213630

Chicago/Turabian StyleMontero, Javier, Almudena Filgueira, Ana García-Diez, José Luís Mier, and Carolina Camba. 2019. "The Wear Responses of the Welded Joints of ASTM A335 Gr. P11 Steels Affected by Accelerated Flow Corrosion" Materials 12, no. 21: 3630. https://doi.org/10.3390/ma12213630

APA StyleMontero, J., Filgueira, A., García-Diez, A., Mier, J. L., & Camba, C. (2019). The Wear Responses of the Welded Joints of ASTM A335 Gr. P11 Steels Affected by Accelerated Flow Corrosion. Materials, 12(21), 3630. https://doi.org/10.3390/ma12213630