Figure 1.

Particle size distribution of the natural aggregates [

19].

Figure 1.

Particle size distribution of the natural aggregates [

19].

Figure 2.

Flow time (t500) test results.

Figure 2.

Flow time (t500) test results.

Figure 3.

Slump-flow (SF) test results.

Figure 3.

Slump-flow (SF) test results.

Figure 4.

V-funnel (Tv) test results.

Figure 4.

V-funnel (Tv) test results.

Figure 5.

L-box test results.

Figure 5.

L-box test results.

Figure 6.

Sieve segregation test results.

Figure 6.

Sieve segregation test results.

Figure 7.

J-ring flow time (t500) test results.

Figure 7.

J-ring flow time (t500) test results.

Figure 8.

J-ring flow spread diameter test results.

Figure 8.

J-ring flow spread diameter test results.

Figure 9.

J-ring passing ability PJ test results.

Figure 9.

J-ring passing ability PJ test results.

Figure 10.

J-ring flow spread diameter SFJ and slump-flow spread diameter SF correlation.

Figure 10.

J-ring flow spread diameter SFJ and slump-flow spread diameter SF correlation.

Figure 11.

Density at 7, 28, and 91 days.

Figure 11.

Density at 7, 28, and 91 days.

Figure 12.

Compressive strength (15 cm × 15 cm × 15 cm cubes) at 7, 28, and 91 days.

Figure 12.

Compressive strength (15 cm × 15 cm × 15 cm cubes) at 7, 28, and 91 days.

Figure 13.

Failure surfaces presented by the different concrete mixes at seven days.

Figure 13.

Failure surfaces presented by the different concrete mixes at seven days.

Figure 14.

Failure surfaces presented by the different concrete mixes at 28 days.

Figure 14.

Failure surfaces presented by the different concrete mixes at 28 days.

Figure 15.

Failure surfaces presented by the different concrete mixes at 91 days.

Figure 15.

Failure surfaces presented by the different concrete mixes at 91 days.

Figure 16.

Correlation between compressive strength in cubes (15 cm × 15 cm × 15 cm) and density at 7, 28, and 91 days.

Figure 16.

Correlation between compressive strength in cubes (15 cm × 15 cm × 15 cm) and density at 7, 28, and 91 days.

Figure 17.

Compressive strength (ϕ15 cm × 30-cm cylinders) at 28 and 91 days.

Figure 17.

Compressive strength (ϕ15 cm × 30-cm cylinders) at 28 and 91 days.

Figure 18.

Failure surfaces presented by the different concrete mixes at 28 days.

Figure 18.

Failure surfaces presented by the different concrete mixes at 28 days.

Figure 19.

Compressive strength correlation among cubic/cylindrical specimens (28 and 91 days).

Figure 19.

Compressive strength correlation among cubic/cylindrical specimens (28 and 91 days).

Figure 20.

Splitting tensile strength (28 and 91 days).

Figure 20.

Splitting tensile strength (28 and 91 days).

Figure 21.

Failure surfaces for all mixes at 28 days.

Figure 21.

Failure surfaces for all mixes at 28 days.

Figure 22.

Failure surface for all mixes at 91 days.

Figure 22.

Failure surface for all mixes at 91 days.

Figure 23.

Splitting tensile strength and compressive strength correlation in cylindrical specimens (28 and 91 days).

Figure 23.

Splitting tensile strength and compressive strength correlation in cylindrical specimens (28 and 91 days).

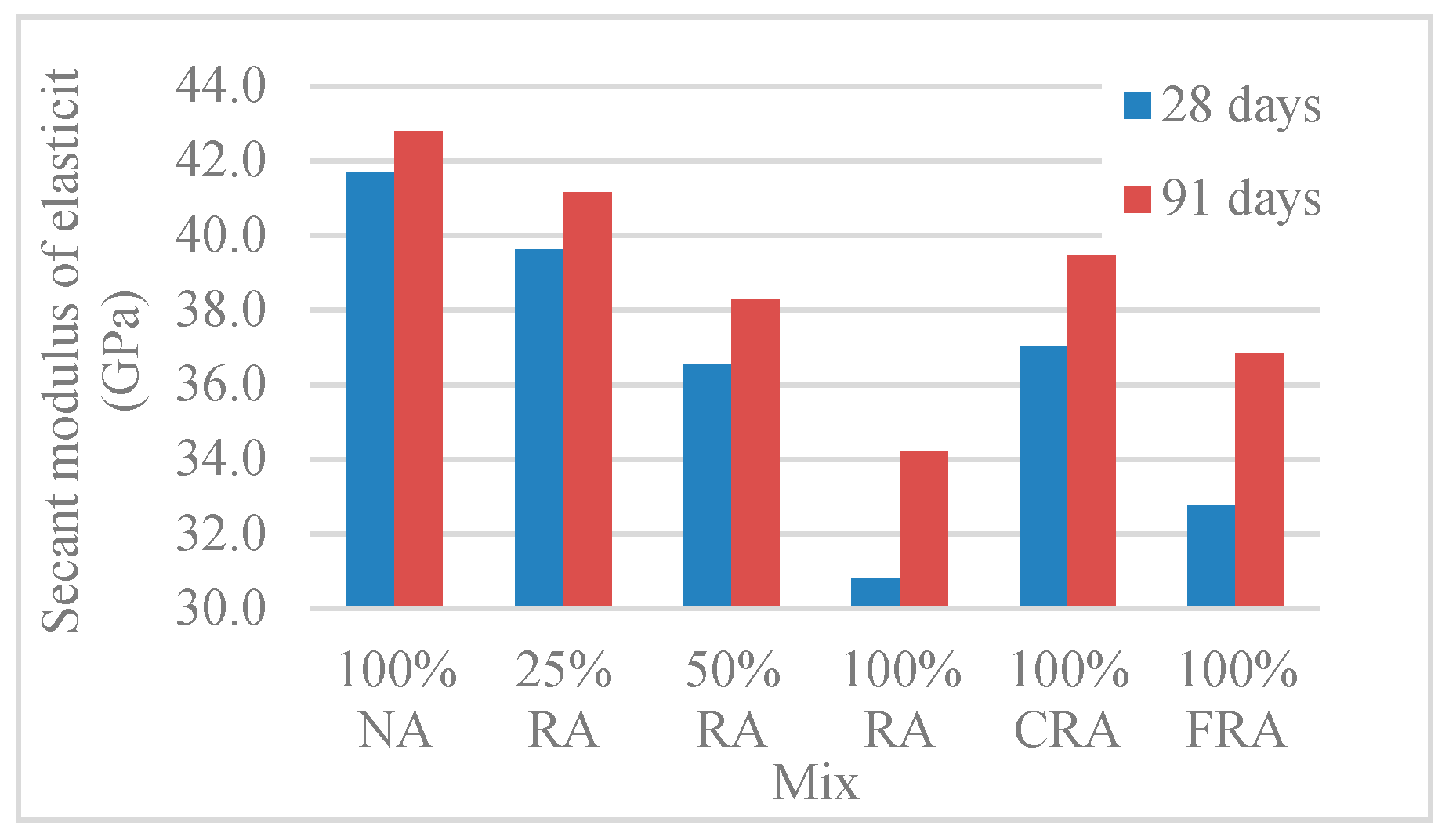

Figure 24.

Secant modulus of elasticity results (28 and 91 days).

Figure 24.

Secant modulus of elasticity results (28 and 91 days).

Figure 25.

Secant modulus of elasticity and compressive strength correlation in cylindrical specimens (28 and 91 days).

Figure 25.

Secant modulus of elasticity and compressive strength correlation in cylindrical specimens (28 and 91 days).

Figure 26.

Secant modulus of elasticity and compressive strength correlation in cubes specimens (28 and 91 days).

Figure 26.

Secant modulus of elasticity and compressive strength correlation in cubes specimens (28 and 91 days).

Figure 27.

Ultrasonic pulse velocity (7, 28, and 91 days).

Figure 27.

Ultrasonic pulse velocity (7, 28, and 91 days).

Figure 28.

Density and ultrasonic pulse velocity correlation (7, 28, and 91 days).

Figure 28.

Density and ultrasonic pulse velocity correlation (7, 28, and 91 days).

Figure 29.

Secant modulus of elasticity and ultrasonic pulse velocity correlation (28 and 91 days).

Figure 29.

Secant modulus of elasticity and ultrasonic pulse velocity correlation (28 and 91 days).

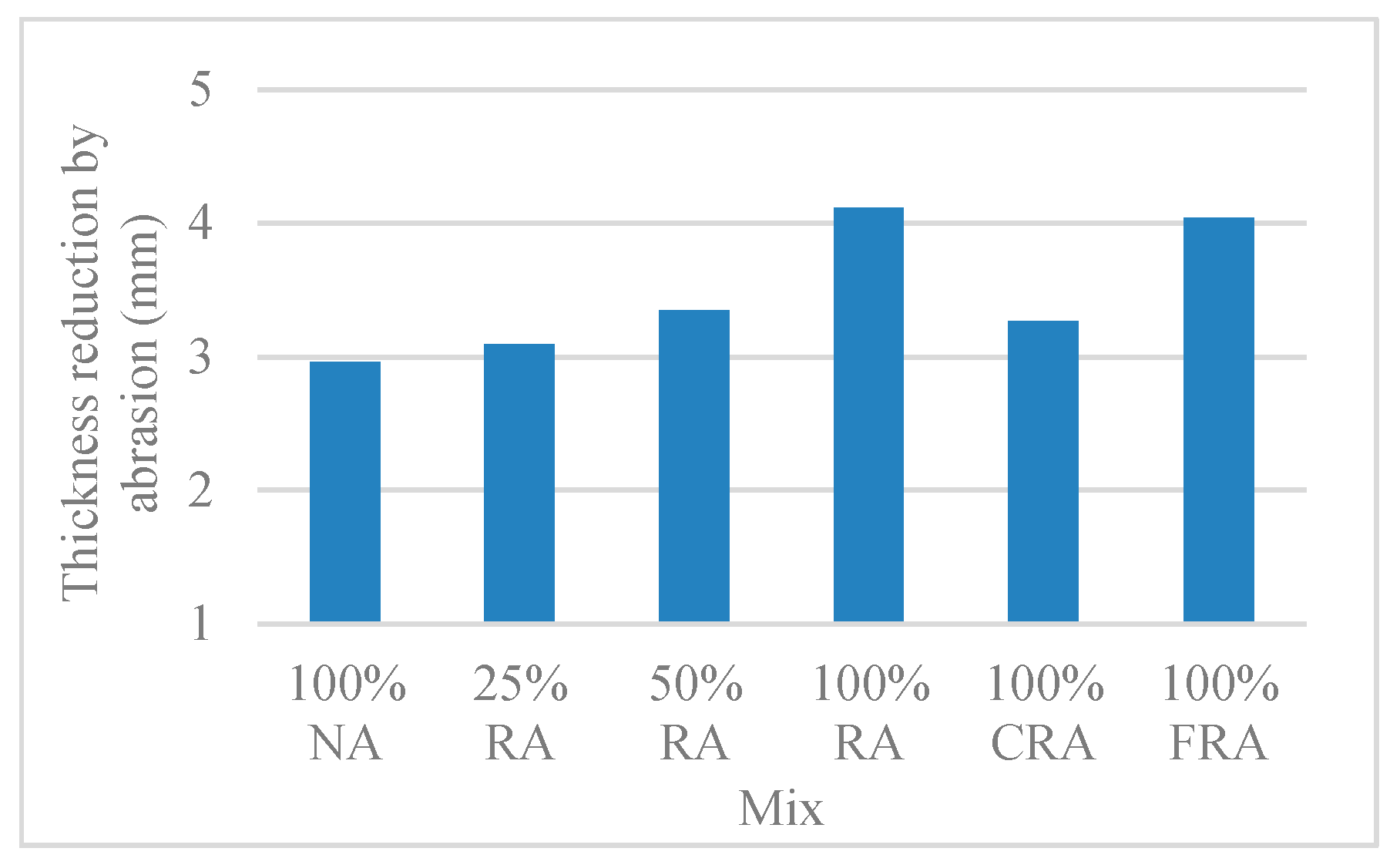

Figure 30.

Abrasion resistance: Thickness reduction (91 days).

Figure 30.

Abrasion resistance: Thickness reduction (91 days).

Figure 31.

Evolution of shrinkage over 91 days.

Figure 31.

Evolution of shrinkage over 91 days.

Figure 32.

Evolution of shrinkage over 91 days: experimental values and based on EUROCODE 2 [

20] values.

Figure 32.

Evolution of shrinkage over 91 days: experimental values and based on EUROCODE 2 [

20] values.

Figure 33.

Shrinkage and secant modulus of elasticity correlation (91 days).

Figure 33.

Shrinkage and secant modulus of elasticity correlation (91 days).

Figure 34.

Shrinkage and compressive strength in cylinders correlation (91 days).

Figure 34.

Shrinkage and compressive strength in cylinders correlation (91 days).

Figure 35.

Creep strain over 91 days.

Figure 35.

Creep strain over 91 days.

Figure 36.

Creep strain and secant modulus of elasticity correlation (28 days).

Figure 36.

Creep strain and secant modulus of elasticity correlation (28 days).

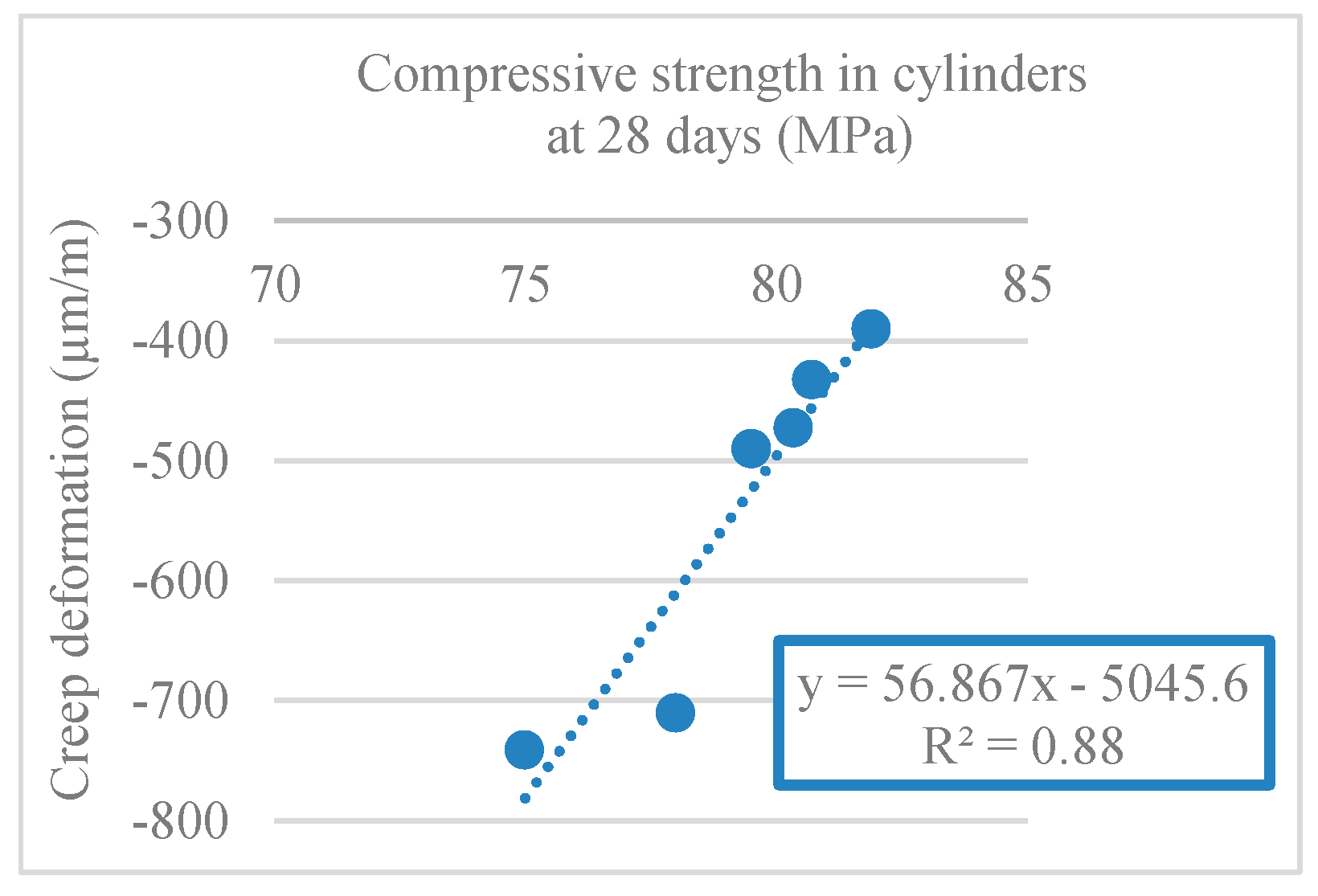

Figure 37.

Creep strain and compressive strength in cylinders correlation (28 days).

Figure 37.

Creep strain and compressive strength in cylinders correlation (28 days).

Table 1.

Chemical composition of the raw materials (%).

Table 1.

Chemical composition of the raw materials (%).

| Chemical Composition * | CEM I | FA | LF | SF |

|---|

| Al2O3 | 5.24 | 24.7 | 0.13 | 0.54 |

| CaCO3 | - | - | 98.35 | - |

| CaO | 62.71 | 2.63 | - | 0.43 |

| Cl− | 0.01 | <0.01 | - | - |

| Fe2O3 | 3.17 | 5.40 | 0.03 | 1.15 |

| K2O | - | 1.11 | 0.02 | 0.86 |

| MgO | 2.23 | 1.01 | 0.40 | 0.43 |

| Na2O | - | 0.89 | - | 0.29 |

| SiO2 | 19.59 | 54.70 | 0.30 | 93.67 |

| SO3 | 3.13 | 1.38 | - | 0.25 |

| TiO2 | - | - | 0.01 | - |

| Insoluble residue | 1.37 | - | - | - |

| Loss of ignition | 2.94 | 5.10 | 43.80 | 2.54 |

Surface area (BET) (m2/kg)

(NP EN 196-6 [30]) | 325 | 430 | 456 | 15000 |

Table 2.

Grading of the raw materials.

Table 2.

Grading of the raw materials.

| Particle Size, in Microns * | Passing (%) |

|---|

| CEM I | FA | LF | SF |

|---|

| 1000 | 100 | 100 | 100 | 100 |

| 100 | 98 | 96 | 60 | 100 |

| 10 | 38 | 45 | 20 | 80 |

| 1 | 5 | 2 | 0 | 10 |

| 0.1 | 0 | 0 | 0 | 2 |

Table 3.

Mix proportions of the high-performance self-compacting concrete with recycled aggregates (HPSCCRA).

Table 3.

Mix proportions of the high-performance self-compacting concrete with recycled aggregates (HPSCCRA).

| Mix Proportions (kg/m3) | 100% NA | 25% RA | 50% RA | 100% RA | 100% CRA | 100% FRA |

|---|

| CEM I 52.5 R (C) | 437 |

| Fly ash (FA) | 145 |

| Limestone filler (LF) | 29 |

| Silica fume (SF) | 27 |

| Superplasticizer (Sp) | 8 |

| Water (W) | 193 |

| Sand0/2 (FNA0/2) | 162 | 122 | 81 | - | 162 | - |

| Sand0/4 (FNA0/4) | 484 | 363 | 242 | - | 484 | - |

| FRA | - | 145 | 290 | 581 | - | 581 |

| Gravel1 (CNA1) | 389 | 292 | 195 | - | - | 389 |

| Gravel2 (CNA2) | 398 | 299 | 199 | - | - | 398 |

| CRA | - | 184 | 369 | 737 | 737 | - |

| W/C ratio | 0.442 |

| W/CM ratio | 0.317 |

| W/FM ratio | 0.303 |

Table 4.

Density at 7, 28, and 91 days.

Table 4.

Density at 7, 28, and 91 days.

| Mix | 7 days | 28 days | 91 days |

|---|

| Density | S.D. | ∆100% NA | Density | S.D. | ∆100% NA | Density | S.D. | ∆100% NA |

|---|

| (kg/m3) | (%) | (kg/m3) | (%) | (kg/m3) | (%) |

|---|

| 100% NA | 2308.5 | 4.9 | 0.0 | 2315.3 | 12.9 | 0.0 | 2319.4 | 14.1 | 0.0 |

| 25% RA | 2285.8 | 9.1 | −1.0 | 2289.0 | 14.7 | −1.1 | 2289.7 | 11.4 | −1.3 |

| 50% RA | 2234.8 | 6.3 | −3.2 | 2246.5 | 9.9 | −3.0 | 2257.7 | 2.5 | −2.7 |

| 100% RA | 2196.0 | 2.5 | −4.9 | 2208.0 | 8.8 | −4.6 | 2212.3 | 11.3 | −4.6 |

| 100% CRA | 2256.1 | 3.6 | −2.3 | 2258.3 | 7.5 | −2.5 | 2261.5 | 5.6 | −2.5 |

| 100% FRA | 2223.9 | 14.5 | −3.7 | 2238.0 | 7.7 | −3.3 | 2245.7 | 6.4 | −3.2 |

Table 5.

Compressive strength (15 cm × 15 cm × 15 cm cubes) at 7, 28, and 91 days.

Table 5.

Compressive strength (15 cm × 15 cm × 15 cm cubes) at 7, 28, and 91 days.

| Mix | 7 days | 28 days | 91 days |

|---|

| fcm,c,7d | S.D. | C.V. | ∆100% NA | fcm,c,28d | S.D. | C.V. | ∆100% NA | fcm,c,91d | S.D. | C.V. | ∆100% NA |

|---|

| (MPa) | (%) | (%) | (MPa) | (%) | (%) | (MPa) | (%) | (%) |

|---|

| 100% NA | 78.4 | 0.3 | 0.4 | 0.0 | 81.9 | 2.5 | 3.1 | 0.0 | 87.5 | 0.5 | 0.6 | 0.0 |

| 25% RA | 76.8 | 2.8 | 3.6 | −2.0 | 80.7 | 0.4 | 0.5 | −1.4 | 86.7 | 1.3 | 1.5 | −0.9 |

| 50% RA | 74.5 | 0.6 | 0.8 | −5.0 | 79.5 | 2.5 | 3.1 | −2.9 | 84.3 | 2.1 | 2.5 | −3.7 |

| 100% RA | 70.8 | 1.4 | 2.0 | −9.7 | 75.0 | 0.5 | 0.7 | −8.4 | 79.9 | 1.9 | 2.4 | −8.7 |

| 100% CRA | 75.9 | 1.2 | 1.6 | −3.1 | 80.3 | 5.9 | 7.3 | −1.9 | 84.7 | 1.0 | 1.2 | −3.2 |

| 100% FRA | 72.6 | 0.2 | 0.3 | −7.4 | 78.0 | 2.2 | 2.8 | −4.8 | 83.6 | 3.1 | 3.7 | −4.5 |

Table 6.

Compressive strength (ϕ15 cm × 30-cm cylinders) at 28 and 91 days.

Table 6.

Compressive strength (ϕ15 cm × 30-cm cylinders) at 28 and 91 days.

| Mix. | 28 days | 91 days |

|---|

| fcm,cyl,28d | S.D. | ∆100% NA | fcm,cyl,91d | S.D. | ∆100% NA |

|---|

| (MPa) | (%) | (MPa) | (%) |

|---|

| 100% NA | 78.9 | 1.1 | 0.0 | 85.9 | 1.4 | 0.0 |

| 25% RA | 75.2 | 1.1 | −4.7 | 82.3 | 2.8 | −4.2 |

| 50% RA | 69.9 | 2.0 | −11.4 | 79.3 | 3.0 | −7.7 |

| 100% RA | 61.0 | 1.8 | −22.6 | 65.8 | 1.0 | −23.4 |

| 100% CRA | 71.1 | 2.1 | −9.9 | 80.7 | 1.1 | −6.1 |

| 100% FRA | 65.9 | 1.2 | −16.5 | 73.3 | 1.3 | −14.7 |

Table 7.

Compressive strength correlation among cubic/cylindrical specimens (28 and 91 days).

Table 7.

Compressive strength correlation among cubic/cylindrical specimens (28 and 91 days).

| Mix. | 28 days | 91 days |

|---|

| fcm,c,28d | fcm,cyl,28d | fcm,cyl,28d/fcm,c,28d | fcm,c,91d | fcm,cyl,91d | fcm,cyl,91d/fcm,c,91d |

|---|

| (MPa) | (MPa) |

|---|

| 100% NA | 81.9 | 78.9 | 0.96 | 87.5 | 85.9 | 0.98 |

| 25% RA | 80.7 | 75.2 | 0.93 | 86.7 | 82.3 | 0.95 |

| 50% RA | 79.5 | 69.9 | 0.88 | 84.3 | 79.3 | 0.94 |

| 100% RA | 75.0 | 61.0 | 0.81 | 79.9 | 65.8 | 0.82 |

| 100% CRA | 80.3 | 71.1 | 0.89 | 84.7 | 80.7 | 0.95 |

| 100% FRA | 78.0 | 65.9 | 0.84 | 83.6 | 73.3 | 0.88 |

Table 8.

NP EN 206-1 [

2] compressive strength classes.

Table 8.

NP EN 206-1 [

2] compressive strength classes.

| Mix. | Experimental Values | NP EN 206-1 Values |

|---|

| fcm,cyl,28d | fcm,c,28d | fck,cyl | fck,c | Class | fck,cyl | fck,c |

|---|

| (MPa) | (MPa) |

|---|

| 100% NA | 78.9 | 81.9 | 70.9 | 73.9 | C55/67 | 55 | 67 |

| 25% RA | 75.2 | 80.7 | 67.2 | 72.7 | C55/67 | 55 | 67 |

| 50% RA | 69.9 | 79.5 | 61.9 | 71.5 | C55/67 | 55 | 67 |

| 100% RA | 61.0 | 75.0 | 53.0 | 67.0 | C50/60 | 50 | 60 |

| 100% CRA | 71.1 | 80.3 | 63.1 | 72.3 | C55/67 | 55 | 67 |

| 100% FRA | 65.9 | 78.0 | 57.9 | 70.0 | C55/67 | 55 | 67 |

Table 9.

Splitting tensile strength (28 and 91 days).

Table 9.

Splitting tensile strength (28 and 91 days).

| Mix. | 28 days | 91 days |

|---|

| fctm,sp,28d | S.D. | C.V. | ∆100% NA | fctm,sp,91d | S.D. | C.V. | ∆100% NA |

|---|

| (MPa) | (%) | (%) | (MPa) | (%) | (%) |

|---|

| 100% NA | 5.6 | 0.5 | 8.9 | 0.0 | 6.2 | 0.1 | 1.6 | 0.0 |

| 25% RA | 5.0 | 0.4 | 8.0 | −10.1 | 5.8 | 0.3 | 5.2 | −6.7 |

| 50% RA | 4.3 | 0.5 | 11.6 | −23.4 | 5.3 | 0.4 | 7.5 | −15.1 |

| 100% RA | 3.8 | 0.7 | 18.4 | −32.0 | 4.3 | 0.1 | 2.3 | −30.5 |

| 100% CRA | 4.5 | 0.1 | 2.2 | −19.2 | 5.5 | 0.1 | 1.8 | −11.0 |

| 100% FRA | 4.0 | 0.4 | 10.0 | −28.4 | 5.0 | 0.4 | 8.0 | −20.2 |

Table 10.

Splitting tensile strength and compressive strength correlation according to Eurocode 2 [

20] (28 and 91 days).

Table 10.

Splitting tensile strength and compressive strength correlation according to Eurocode 2 [

20] (28 and 91 days).

| Mix. | 28 days | 91 days |

|---|

| Average Compressive Strength | Average Splitting Tensile Strength | Average Compressive Strength | Average Splitting Tensile Strength |

|---|

| fcm,cyl,28d | EC2

Value | Experimental Values | fcm,cyl,91d | EC2

Value | Experimental Values |

|---|

| (MPa) | (MPa) |

|---|

| 100% NA | 78.9 | 4.6 | 5.6 | 85.9 | 4.8 | 6.2 |

| 25% RA | 75.2 | 4.5 | 5.0 | 82.3 | 4.7 | 5.8 |

| 50% RA | 69.9 | 4.4 | 4.3 | 79.3 | 4.6 | 5.3 |

| 100% RA | 61.0 | 4.2 | 3.8 | 65.8 | 4.3 | 4.3 |

| 100% CRA | 71.1 | 4.4 | 4.5 | 80.7 | 4.7 | 5.5 |

| 100% FRA | 65.9 | 4.3 | 4.0 | 73.3 | 4.5 | 5.0 |

Table 11.

Secant modulus of elasticity results (28 and 91 days).

Table 11.

Secant modulus of elasticity results (28 and 91 days).

| Mix. | 28 days | 91 days |

|---|

| Ecm,28d | S.D. | C.V. | ∆100% NA | Ecm,91d | S.D. | C.V. | ∆100% NA |

|---|

| (MPa) | (%) | (%) | (MPa) | (%) | (%) |

|---|

| 100% NA | 41.7 | 2.2 | 5.3 | 0.0 | 42.8 | 1.4 | 3.3 | 0.0 |

| 25% RA | 39.6 | 1.5 | 3.8 | −4.9 | 41.2 | 1.9 | 4.6 | −3.8 |

| 50% RA | 36.6 | 0.7 | 1.9 | −12.3 | 38.3 | 0.2 | 0.5 | −10.5 |

| 100% RA | 30.8 | 6.3 | 20.5 | −26.1 | 34.2 | 0.2 | 0.6 | −20.1 |

| 100% CRA | 37.0 | 0.6 | 1.6 | −11.2 | 39.5 | 0.8 | 2.0 | −7.8 |

| 100% FRA | 32.8 | 0.1 | 0.3 | −21.4 | 36.8 | 1.0 | 2.7 | −13.9 |

Table 12.

Secant modulus of elasticity and compressive strength correlation according to Eurocode 2 [

20] in cylindrical specimens (28 and 91 days).

Table 12.

Secant modulus of elasticity and compressive strength correlation according to Eurocode 2 [

20] in cylindrical specimens (28 and 91 days).

| Mix. | 28 days | 91 days |

|---|

| Average Compressive Strength | Secant Modulus of Elasticity | Average Compressive Strength | Secant Modulus of Elasticity |

|---|

| fcm,cyl,28d | EC2

Value | Experimental Values | fcm,cyl,91d | EC2

Value | Experimental Values |

|---|

| (MPa) | (GPa) | (MPa) | (GPa) |

|---|

| 100% NA | 78.9 | 40.9 | 41.7 | 85.9 | 41.9 | 42.8 |

| 25% RA | 75.2 | 40.3 | 39.6 | 82.3 | 41.4 | 41.2 |

| 50% RA | 69.9 | 39.4 | 36.6 | 79.3 | 40.9 | 38.3 |

| 100% RA | 61.0 | 37.9 | 30.8 | 65.8 | 38.7 | 34.2 |

| 100% CRA | 71.1 | 39.6 | 37.0 | 80.7 | 41.2 | 39.5 |

| 100% FRA | 65.9 | 38.7 | 32.8 | 73.3 | 40.0 | 36.8 |

Table 13.

Ultrasonic pulse velocity (7, 28, and 91 days).

Table 13.

Ultrasonic pulse velocity (7, 28, and 91 days).

| Mix. | 7 days | 28 days | 91 days |

|---|

| Vusm,c,7d | S.D. | ∆100% NA | Vusm,c,28d | S.D. | ∆100% NA | Vusm,c,91d | S.D. | ∆100% NA |

|---|

| (m/s) | (%) | (m/s) | (%) | (m/s) | (%) |

|---|

| 100% NA | 4907.6 | 53.0 | 0.0 | 5030.7 | 4.0 | 0.0 | 5123.8 | 58.6 | 0.0 |

| 25% RA | 4843.0 | 74.7 | −1.3 | 4961.9 | 69.6 | −1.4 | 5037.6 | 46.2 | −1.7 |

| 50% RA | 4623.3 | 19.7 | −5.8 | 4819.8 | 29.9 | −4.2 | 4937.8 | 12.5 | −3.6 |

| 100% RA | 4474.7 | 18.0 | −8.4 | 4624.9 | 17.2 | −8.1 | 4702.3 | 30.6 | −8.2 |

| 100% CRA | 4779.3 | 59.5 | −2.6 | 4932.4 | 11.3 | −2.0 | 4972.4 | 26.2 | −3.0 |

| 100% FRA | 4587.2 | 16.2 | −6.5 | 4755.2 | 5.8 | −5.5 | 4851.5 | 64.9 | −5.3 |

Table 14.

Abrasion resistance: Wear depth (91 days).

Table 14.

Abrasion resistance: Wear depth (91 days).

| Mix. | Wear Depth | S.D. | ∆100% NA |

|---|

| (mm) | (%) |

|---|

| 100% NA | 3.0 | 0.1 | 0.0 |

| 25% RA | 3.1 | 0.2 | 4.5 |

| 50% RA | 3.3 | 0.1 | 12.8 |

| 100% RA | 4.1 | 0.1 | 38.6 |

| 100% CRA | 3.3 | 0.1 | 10.2 |

| 100% FRA | 4.0 | 0.3 | 36.2 |

Table 15.

Shrinkage (7, 28, and 91 days).

Table 15.

Shrinkage (7, 28, and 91 days).

| Mix. | 7 Days | 28 Days | 91 Days |

|---|

| ∆100% NA | | ∆100% NA | | ∆100% NA |

|---|

| (µm/m) | (%) | (µm/m) | (%) | (µm/m) | (%) |

|---|

| 100% NA | −205.0 | 0.0 | −320.0 | 0.0 | −377.5 | 0.0 |

| 25% RA | −205.0 | 0.0 | −330.0 | 3.1 | −415.0 | 9.9 |

| 50% RA | −220.0 | 7.3 | −362.5 | 13.3 | −440.0 | 16.6 |

| 100% RA | −260.0 | 26.8 | −395.0 | 23.4 | −510.0 | 35.1 |

| 100% CRA | −225.0 | 9.8 | −360.0 | 12.5 | −450.0 | 19.2 |

| 100% FRA | −247.5 | 20.7 | −385.0 | 20.3 | −477.5 | 26.5 |

Table 16.

Evolution of shrinkage: Experimental values and based on Eurocode 2 [

20] as a function of compressive strength at 7, 28, and 91 days.

Table 16.

Evolution of shrinkage: Experimental values and based on Eurocode 2 [

20] as a function of compressive strength at 7, 28, and 91 days.

| Mix. | 7 Days | 28 Days | 91 Days |

|---|

| EC2 Value | | EC2 Value | | EC2 Value | |

|---|

| (µm/m) | (µm/m) | (µm/m) |

|---|

| 100% NA | −142.5 | −205.0 | −316.5 | −320.0 | −460.2 | −377.5 |

| 25% RA | −142.0 | −205.0 | −319.4 | −330.0 | −466.0 | −415.0 |

| 50% RA | −141.5 | −220.0 | −324.3 | −362.5 | −475.4 | −440.0 |

| 100% RA | −141.5 | −260.0 | −334.4 | −395.0 | −493.9 | −510.0 |

| 100% CRA | −141.6 | −225.0 | −323.2 | −360.0 | −473.2 | −450.0 |

| 100% FRA | −141.4 | −247.5 | −328.6 | −385.0 | −483.3 | −477.5 |

Table 17.

Creep strain coefficient (91 days).

Table 17.

Creep strain coefficient (91 days).

| Mix. | Creep at 91 days (Without Shrinkage) | Ecm,91d | Instantaneous Creep | Final Creep | Creep Coefficient |

|---|

| (µm/m) | (MPa) | (µm/m) | (µm/m) |

|---|

| 100% NA | −3.90 × 10−4 | 41682 | 2.40 × 10−4 | 1.50 × 10−4 | 0.63 |

| 25% RA | −4.33 × 10−4 | 39622 | 2.52 × 10−4 | 1.80 × 10−4 | 0.71 |

| 50% RA | −4.90 × 10−4 | 36556 | 2.74 × 10−4 | 2.16 × 10−4 | 0.79 |

| 100% RA | −7.41 × 10−4 | 30806 | 3.25 × 10−4 | 4.17 × 10−4 | 1.28 |

| 100% CRA | −4.73 × 10−4 | 37032 | 2.70 × 10−4 | 2.02 × 10−4 | 0.75 |

| 100% FRA | −7.10 × 10−4 | 32751 | 3.05 × 10−4 | 4.05 × 10−4 | 1.33 |