Electromechanical Properties of PVDF-Based Polymers Reinforced with Nanocarbonaceous Fillers for Pressure Sensing Applications

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

2.3. Sample Characterization

3. Results and Discussion

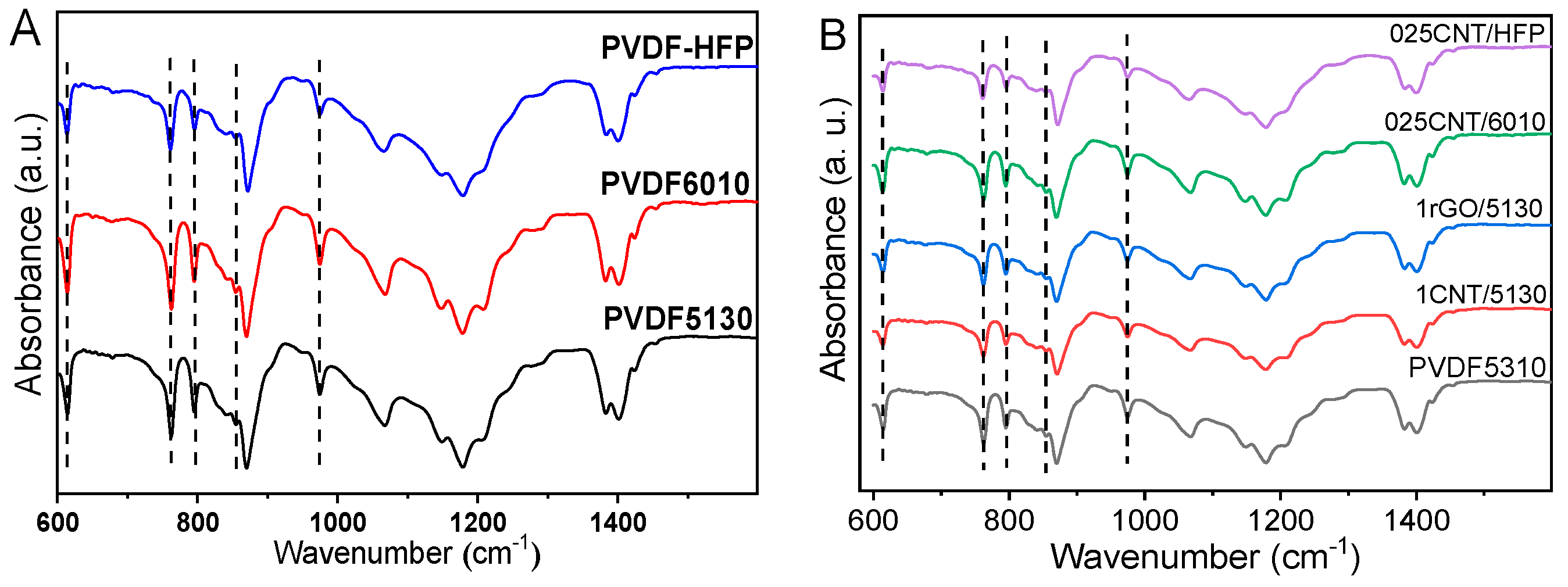

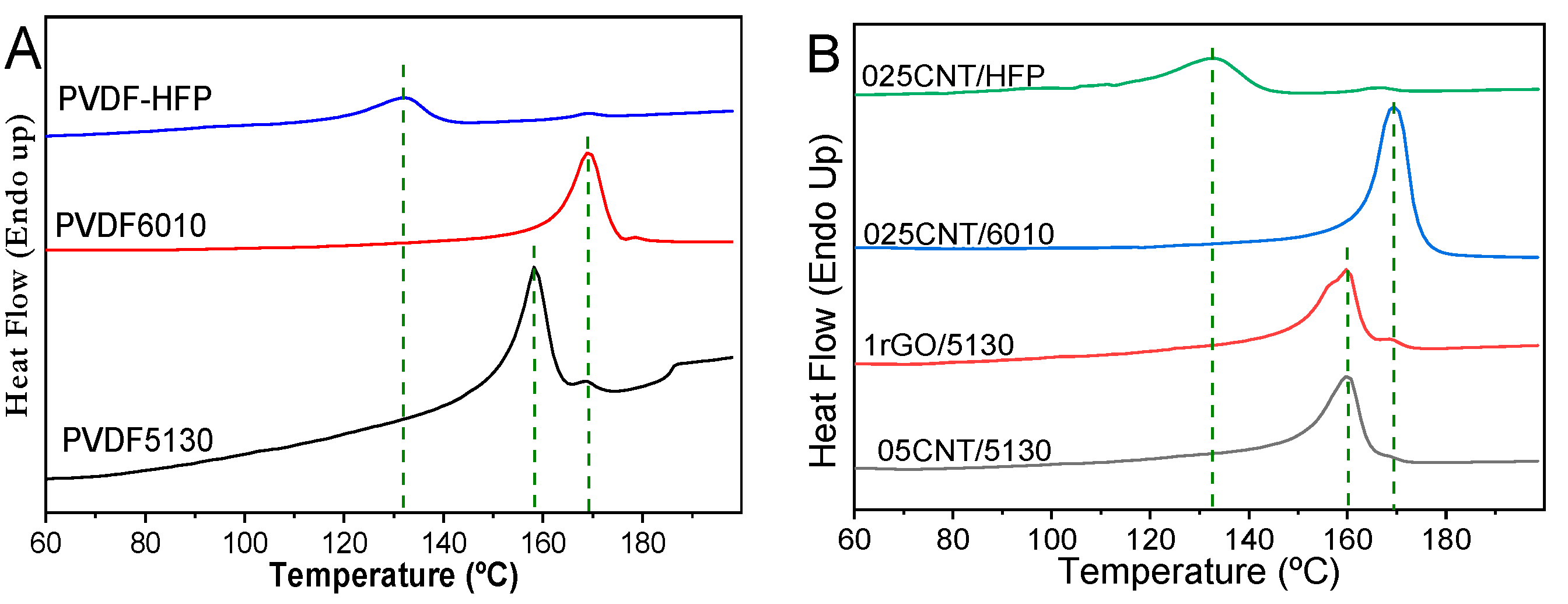

3.1. Chemical and Thermal Characterization

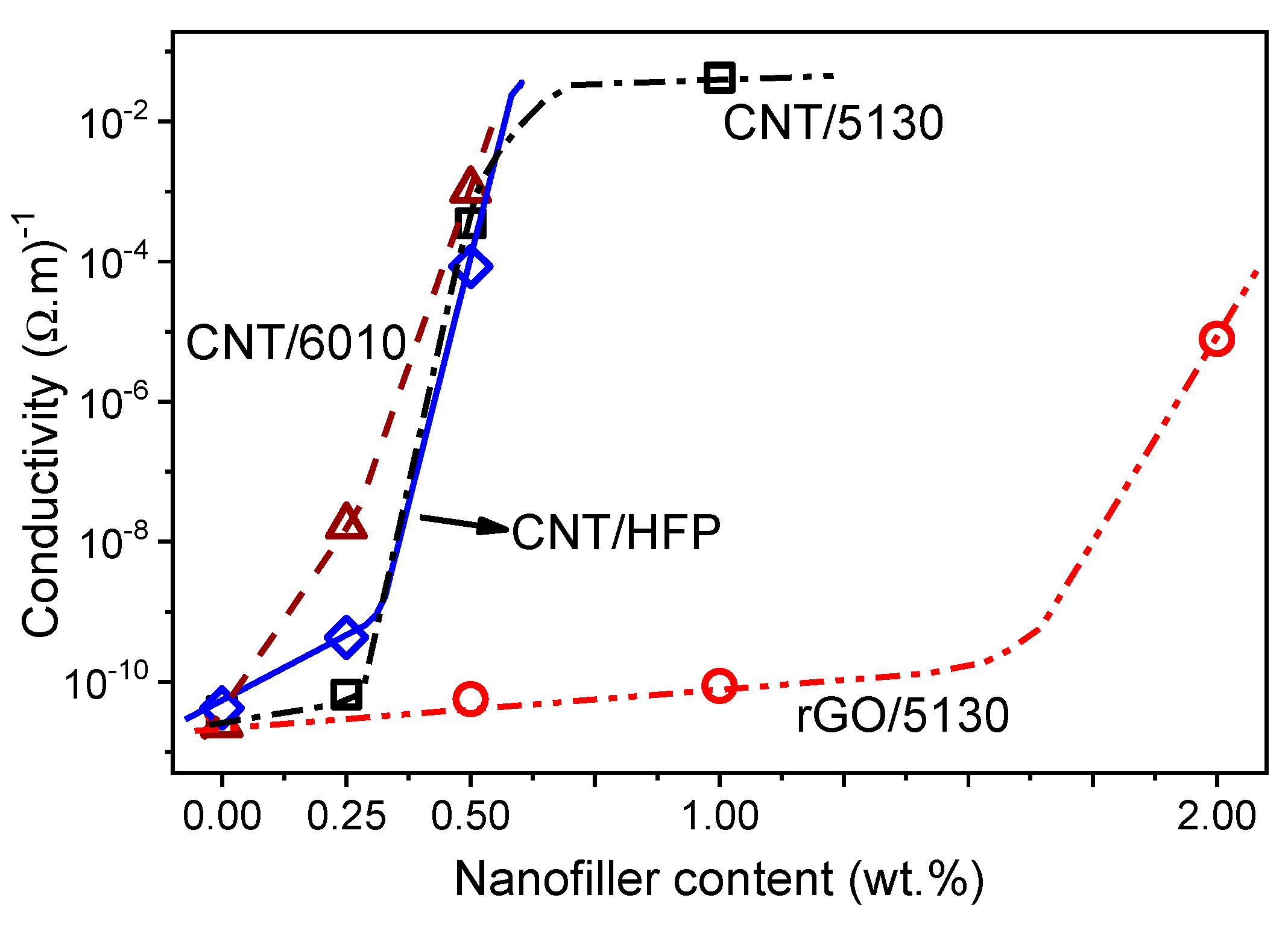

3.2. Electrical Characterization

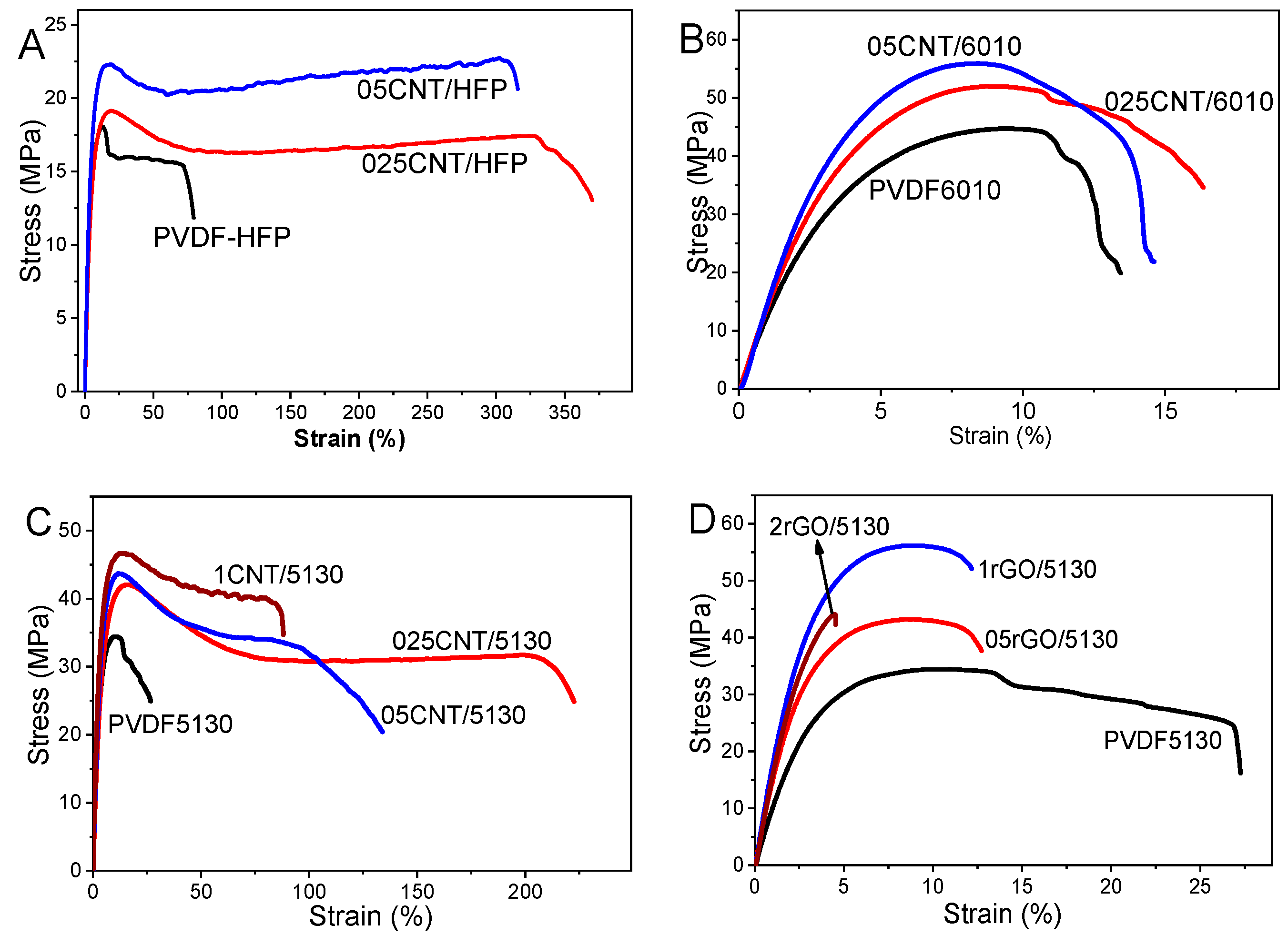

3.3. Mechanical Measurements

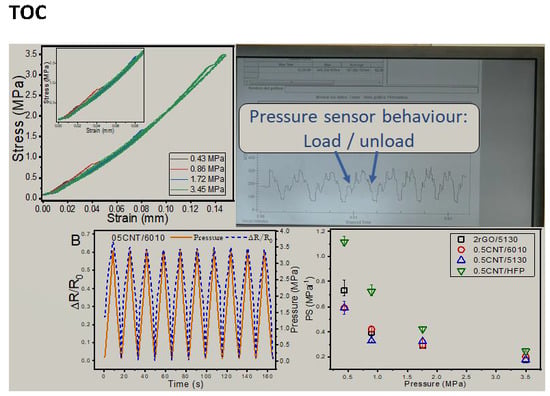

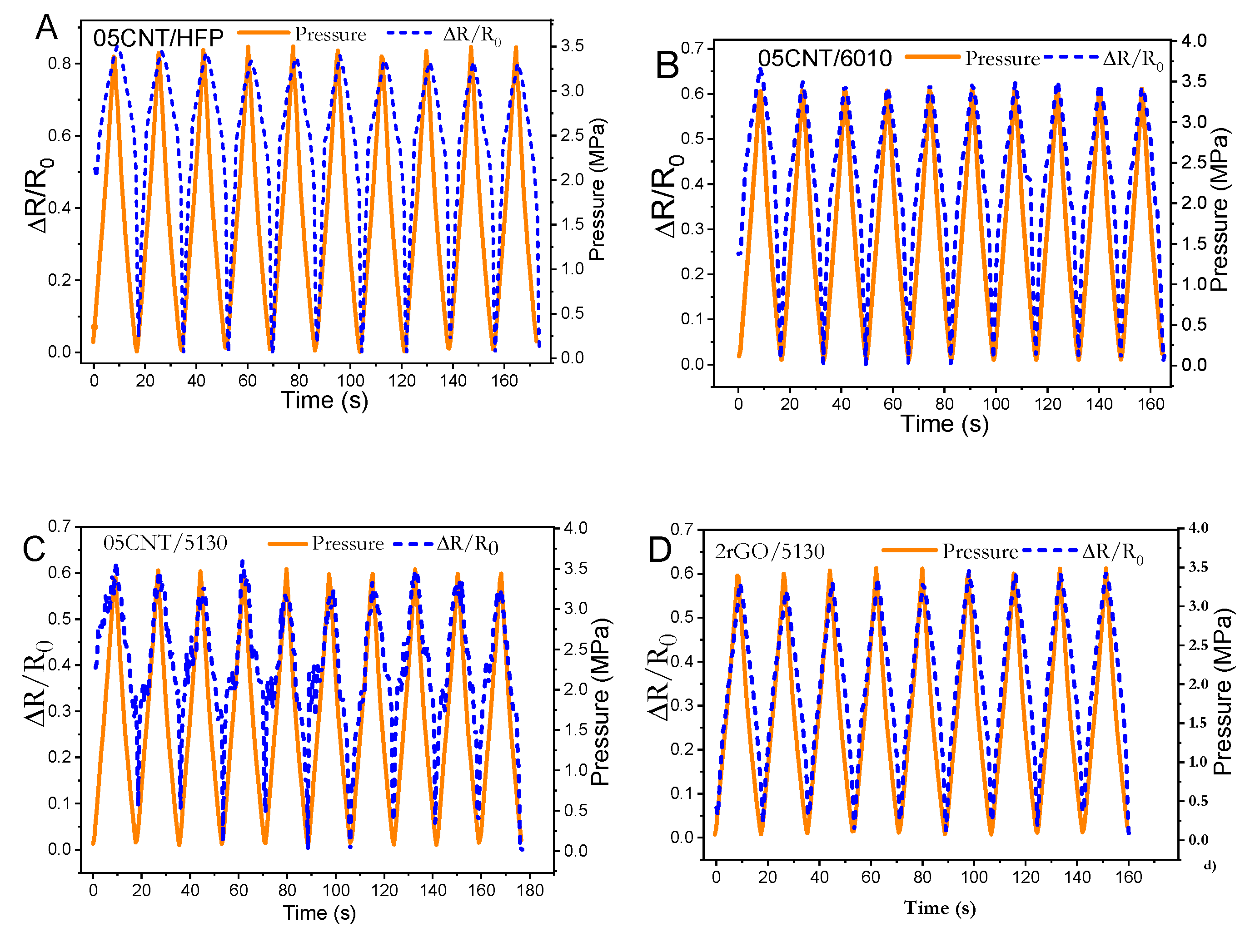

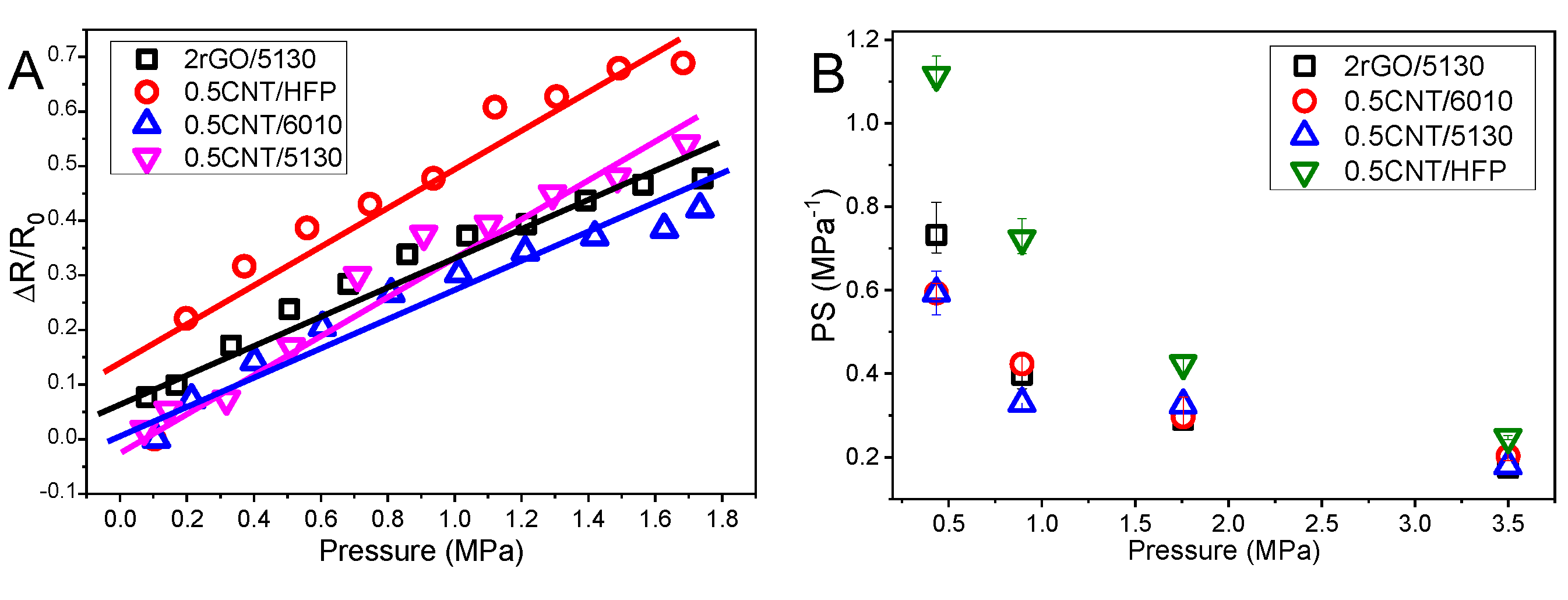

3.4. Electromechanical Measurements

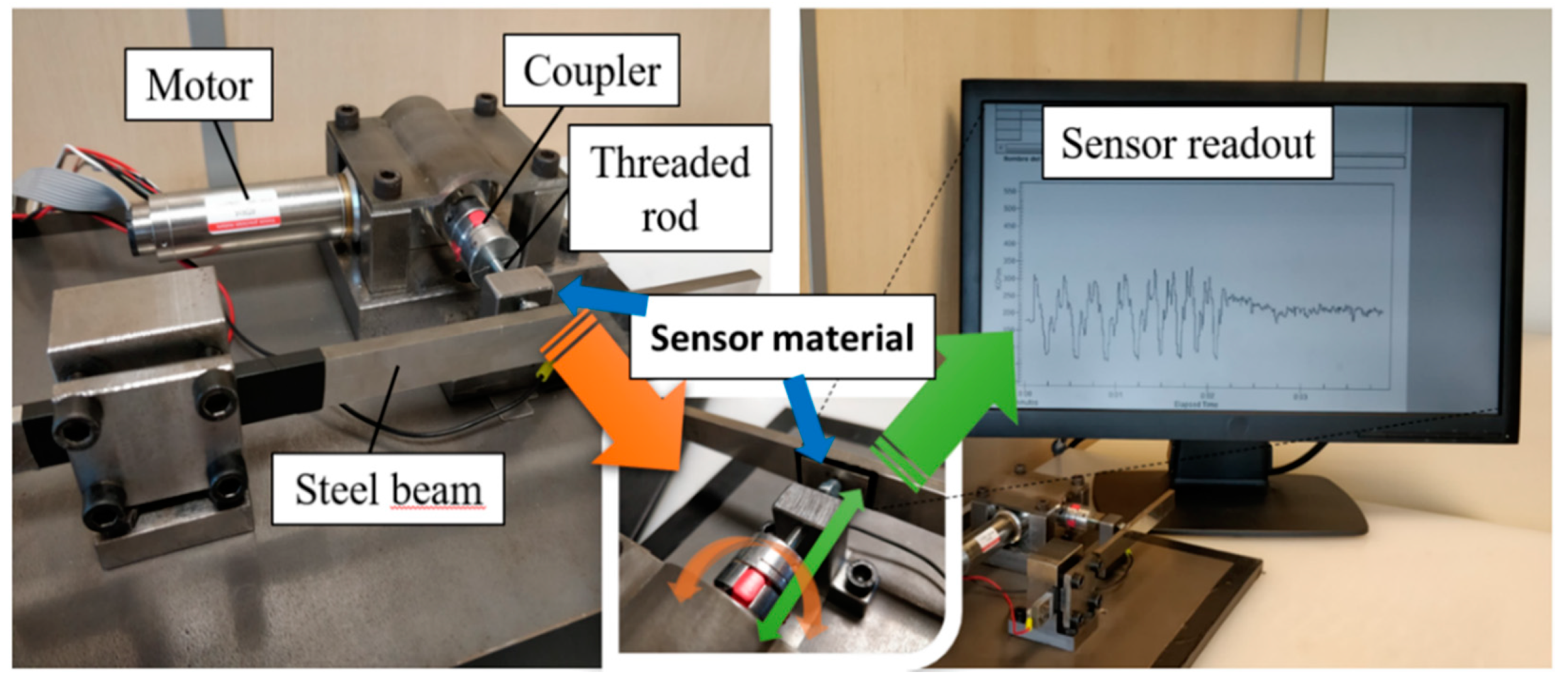

3.5. Proof of Concept Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Naskar, A.K.; Keum, J.K.; Boeman, R.G. Polymer matrix nanocomposites for automotive structural components. Nat. Nanotechnol. 2016, 11, 1026. [Google Scholar] [CrossRef] [PubMed]

- Zhan, C.; Yu, G.; Lu, Y.; Wang, L.; Wujcik, E.; Wei, S. Conductive polymer nanocomposites: A critical review of modern advanced devices. J. Mater. Chem. C 2017, 5, 1569–1585. [Google Scholar] [CrossRef]

- Gu, J.; Yang, X.; Lv, Z.; Li, N.; Liang, C.; Zhang, Q. Functionalized graphite nanoplatelets/epoxy resin nanocomposites with high thermal conductivity. Int. J. Heat Mass Transf. 2016, 92, 15–22. [Google Scholar] [CrossRef]

- Gong, S.; Wu, D.; Li, Y.; Jin, M.; Xiao, T.; Wang, Y.; Xiao, Z.; Zhu, Z.; Li, Z. Temperature-independent piezoresistive sensors based on carbon nanotube/polymer nanocomposite. Carbon 2018, 137, 188–195. [Google Scholar] [CrossRef]

- Zhang, D.; Chang, H.; Li, P.; Liu, R.; Xue, Q. Fabrication and characterization of an ultrasensitive humidity sensor based on metal oxide/graphene hybrid nanocomposite. Sens. Actuators B Chem. 2016, 225, 233–240. [Google Scholar] [CrossRef]

- Adhikari, B.; Majumdar, S. Polymers in sensor applications. Prog. Polym. Sci. 2004, 29, 699–766. [Google Scholar] [CrossRef]

- Chazot, C.A.C.; Hart, A.J. Understanding and control of interactions between carbon nanotubes and polymers for manufacturing of high-performance composite materials. Compos. Sci. Technol. 2019, 183, 107795. [Google Scholar] [CrossRef]

- Shintake, J.; Piskarev, E.; Jeong, S.H.; Floreano, D. Ultrastretchable Strain Sensors Using Carbon Black-Filled Elastomer Composites and Comparison of Capacitive Versus Resistive Sensors. Adv. Mater. Technol. 2018, 3, 1700284. [Google Scholar] [CrossRef]

- Yan, T.; Wang, Z.; Wang, Y.-Q.; Pan, Z.-J. Carbon/graphene composite nanofiber yarns for highly sensitive strain sensors. Mater. Des. 2018, 143, 214–223. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube—Polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Zhang, X.-W.; Pan, Y.; Zheng, Q.; Yi, X.-S. Time dependence of piezoresistance for the conductor-filled polymer composites. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 2739–2749. [Google Scholar] [CrossRef]

- Costa, P.; Nunes-Pereira, J.; Oliveira, J.; Silva, J.; Moreira, J.A.; Carabineiro, S.A.C.; Buijnsters, J.G.; Lanceros-Mendez, S. High-performance graphene-based carbon nanofiller/polymer composites for piezoresistive sensor applications. Compos. Sci. Technol. 2017, 153, 241–252. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/Polymer Nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Yu, S.; Wang, X.; Xiang, H.; Zhu, L.; Tebyetekerwa, M.; Zhu, M. Superior piezoresistive strain sensing behaviors of carbon nanotubes in one-dimensional polymer fiber structure. Carbon 2018, 140, 1–9. [Google Scholar] [CrossRef]

- Costa, P.; Ferreira, A.; Sencadas, V.; Viana, J.C.; Lanceros-Méndez, S. Electro-mechanical properties of triblock copolymer styrene-butadiene-styrene/carbon nanotube composites for large deformation sensor applications. Sens. Actuators A Phys. 2013, 201, 458–467. [Google Scholar] [CrossRef]

- Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar]

- Pu, J.-H.; Zha, X.-J.; Zhao, M.; Li, S.; Bao, R.-Y.; Liu, Z.-Y.; Xie, B.-H.; Yang, M.-B.; Guo, Z.; Yang, W. 2D end-to-end carbon nanotube conductive networks in polymer nanocomposites: A conceptual design to dramatically enhance the sensitivities of strain sensors. Nanoscale 2018, 10, 2191–2198. [Google Scholar] [CrossRef]

- Kazemi, Y.; Ramezani Kakroodi, A.; Ameli, A.; Filleter, T.; Park, C.B. Highly stretchable conductive thermoplastic vulcanizate/carbon nanotube nanocomposites with segregated structure, low percolation threshold and improved cyclic electromechanical performance. J. Mater. Chem. C 2018, 6, 350–359. [Google Scholar] [CrossRef]

- Bessaguet, C.; Dantras, E.; Michon, G.; Chevalier, M.; Laffont, L.; Lacabanne, C. Electrical behavior of a graphene/PEKK and carbon black/PEKK nanocomposites in the vicinity of the percolation threshold. J. Non-Cryst. Solids 2019, 512, 1–6. [Google Scholar] [CrossRef]

- Kale, S.; Karimi, P.; Sabet, F.A.; Jasiuk, I.; Ostoja-Starzewski, M. Tunneling-percolation model of multicomponent nanocomposites. J. Appl. Phys. 2018, 123, 85104. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Simplification and development of McLachlan model for electrical conductivity of polymer carbon nanotubes nanocomposites assuming the networking of interphase regions. Compos. Part B Eng. 2019, 156, 64–71. [Google Scholar] [CrossRef]

- Costa, P.; Oliveira, J.; Horta-Romarís, L.; Abad, M.-J.; Moreira, J.A.; Zapiráin, I.; Aguado, M.; Galván, S.; Lanceros-Mendez, S. Piezoresistive polymer blends for electromechanical sensor applications. Compos. Sci. Technol. 2018, 168, 353–362. [Google Scholar] [CrossRef]

- Seyler, H.; Gómez-Fatou, A.M.; Salavagione, J.H. Preparation of Piezo-Resistive Materials by Combination of PP, SEBS and Graphene. J. Compos. Sci. 2019, 3, 37. [Google Scholar] [CrossRef]

- Rezvantalab, H.; Ghazi, N.; Ambrusch, M.J.; Infante, J.; Shojaei-Zadeh, S. An Aqueous-Based Approach for Fabrication of PVDF/MWCNT Porous Composites. Sci. Rep. 2017, 7, 1716. [Google Scholar] [CrossRef] [PubMed]

- Ogasawara, T.; Tsuda, T.; Takeda, N. Stress-strain behavior of multi-walled carbon nanotube/PEEK composites. Compos. Sci. Technol. 2011, 71, 73–78. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- Tung, T.T.; Karunagaran, R.; Tran, D.N.H.; Gao, B.; Nag-Chowdhury, S.; Pillin, I.; Castro, M.; Feller, J.-F.; Losic, D. Engineering of graphene/epoxy nanocomposites with improved distribution of graphene nanosheets for advanced piezo-resistive mechanical sensing. J. Mater. Chem. C 2016, 4, 3422–3430. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Bidsorkhi, H.C.; D’Aloia, A.G.; De Bellis, G.; Proietti, A.; Rinaldi, A.; Fortunato, M.; Ballirano, P.; Bracciale, M.P.; Santarelli, M.L.; Sarto, M.S. Nucleation effect of unmodified graphene nanoplatelets on PVDF/GNP film composites. Mater. Today Commun. 2017, 11, 163–173. [Google Scholar] [CrossRef]

- Yan, Y.; Potts, M.; Jiang, Z.; Sencadas, V. Synthesis of highly-stretchable graphene—Poly(glycerol sebacate) elastomeric nanocomposites piezoresistive sensors for human motion detection applications. Compos. Sci. Technol. 2018, 162, 14–22. [Google Scholar] [CrossRef]

- Gupta, T.K.; Choosri, M.; Varadarajan, K.M.; Kumar, S. Self-sensing and mechanical performance of CNT/GNP/UHMWPE biocompatible nanocomposites. J. Mater. Sci. 2018, 53, 7939–7952. [Google Scholar] [CrossRef]

- Teixeira, J.; Horta-Romarís, L.; Abad, M.J.; Costa, P.; Lanceros-Méndez, S. Piezoresistive response of extruded polyaniline/(styrene-butadiene-styrene) polymer blends for force and deformation sensors. Mater. Des. 2018, 141, 1–8. [Google Scholar] [CrossRef]

- Xiaomeng, Z.; Zhanyong, Y.; Shuo, Z.; Kai, Y.; Tenghai, Y. Tensile Piezoresistive Behavior of Polyethylene Terephthalate/Carbon Black Composite. J. Mater. Civ. Eng. 2018, 30, 4018107. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Lange, D.; i Cabarrocas, P.R.; Triantafyllidis, N.; Daineka, D. Piezoresistivity of thin film semiconductors with application to thin film silicon solar cells. Sol. Energy Mater. Sol. Cells 2016, 145, 93–103. [Google Scholar] [CrossRef]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, technology and applications of piezoresistive sensors: A review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, Y.; Guo, C.F. Recent progresses on flexible tactile sensors. Mater. Today Phys. 2017, 1, 61–73. [Google Scholar] [CrossRef]

- Yang, T.; Xie, D.; Li, Z.; Zhu, H. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R Rep. 2017, 115, 1–37. [Google Scholar] [CrossRef]

- Ribeiro, C.; Costa, C.M.; Correia, D.M.; Nunes-Pereira, J.; Oliveira, J.; Martins, P.; Goncalves, R.; Cardoso, V.F.; Lanceros-Mendez, S. Electroactive poly(vinylidene fluoride)-based structures for advanced applications. Nat. Protoc. 2018, 13, 681–704. [Google Scholar] [CrossRef]

- Marotti de Sciarra, F. On non-local and non-homogeneous elastic continua. Int. J. Solids Struct. 2009, 46, 651–676. [Google Scholar] [CrossRef]

- Kim, G.H.; Hong, S.M.; Seo, Y. Piezoelectric properties of poly(vinylidene fluoride) and carbon nanotube blends: Beta-phase development. Phys. Chem. Chem. Phys. PCCP 2009, 11, 10506–10512. [Google Scholar] [CrossRef] [PubMed]

- Mendes, S.F.; Costa, C.M.; Caparros, C.; Sencadas, V.; Lanceros-Méndez, S. Effect of filler size and concentration on the structure and properties of poly(vinylidene fluoride)/BaTiO3 nanocomposites. J. Mater. Sci. 2012, 47, 1378–1388. [Google Scholar] [CrossRef]

- Costa, P.; Silva, J.; Lanceros Mendez, S. Strong increase of the dielectric response of carbon nanotube/poly(vinylidene fluoride) composites induced by carbon nanotube type and pre-treatment. Compos. Part B Eng. 2016, 93, 310–316. [Google Scholar] [CrossRef]

- Begum, S.; Kausar, A.; Ullah, H.; Siddiq, M. Potential of Polyvinylidene Fluoride/Carbon Nanotube Composite in Energy, Electronics, and Membrane Technology: An Overview. Polym.-Plast. Technol. Eng. 2016, 55, 1949–1970. [Google Scholar] [CrossRef]

- Yan, T.; Wang, Z.; Pan, Z.-J. Flexible strain sensors fabricated using carbon-based nanomaterials: A review. Curr. Opin. Solid State Mater. Sci. 2018, 22, 213–228. [Google Scholar] [CrossRef]

- Cai, J.; Hu, N.; Wu, L.; Liu, Y.; Li, Y.; Ning, H.; Liu, X.; Lin, L. Preparing carbon black/graphene/PVDF-HFP hybrid composite films of high piezoelectricity for energy harvesting technology. Compos. Part A Appl. Sci. Manuf. 2019, 121, 223–231. [Google Scholar] [CrossRef]

- Costa, P.; Silva, J.; Sencadas, V.; Costa, C.M.; van Hattum, F.W.J.; Rocha, J.G.; Lanceros-Mendez, S. The effect of fibre concentration on the α to β-phase transformation, degree of crystallinity and electrical properties of vapour grown carbon nanofibre/poly(vinylidene fluoride) composites. Carbon 2009, 47, 2590–2599. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Georgousis, G.; Pandis, C.; Kalamiotis, A.; Georgiopoulos, P.; Kyritsis, A.; Kontou, E.; Pissis, P.; Micusik, M.; Czanikova, K.; Kulicek, J.; et al. Strain sensing in polymer/carbon nanotube composites by electrical resistance measurement. Compos. Part B Eng. 2015, 68, 162–169. [Google Scholar] [CrossRef]

- Wang, B.; Ruan, T.; Chen, Y.; Jin, F.; Peng, L.; Zhou, Y.; Wang, D.; Dou, S. Graphene-based composites for electrochemical energy storage. Energy Storage Mater. 2019. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Huang, L.; Essa, K.; Bilotti, E.; Zhang, H.; Peijs, T.; Hao, L. Additive manufacturing high performance graphene-based composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105483. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Evaluation and Development of Expanded Equations Based on Takayanagi Model for Tensile Modulus of Polymer Nanocomposites Assuming the Formation of Percolating Networks. Phys. Mesomech. 2018, 21, 351–357. [Google Scholar] [CrossRef]

- Weon, J.-I. Mechanical and thermal behavior of polyamide-6/clay nanocomposite using continuum-based micromechanical modeling. Macromol. Res. 2009, 17, 797–806. [Google Scholar] [CrossRef]

- Nemes-Incze, P.; Osváth, Z.; Kamarás, K.; Biró, L.P. Anomalies in thickness measurements of graphene and few layer graphite crystals by tapping mode atomic force microscopy. Carbon 2008, 46, 1435–1442. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.H.; Schlagenhauf, L.; Nüesch, F.A.; Chu, B.T.T. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- Li, X.-P.; Li, Y.; Li, X.; Song, D.; Min, P.; Hu, C.; Zhang, H.-B.; Koratkar, N.; Yu, Z.-Z. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J. Colloid Interface Sci. 2019, 542, 54–62. [Google Scholar] [CrossRef]

- Huang, J.; Li, D.; Zhao, M.; Ke, H.; Mensah, A.; Lv, P.; Tian, X.; Wei, Q. Flexible electrically conductive biomass-based aerogels for piezoresistive pressure/strain sensors. Chem. Eng. J. 2019, 373, 1357–1366. [Google Scholar] [CrossRef]

- Ferrreira, A.; Rocha, J.G.; Ansón-Casaos, A.; Martínez, M.T.; Vaz, F.; Lanceros-Mendez, S. Electromechanical performance of poly(vinylidene fluoride)/carbon nanotube composites for strain sensor applications. Sens. Actuators A Phys. 2012, 178, 10–16. [Google Scholar] [CrossRef]

- Niu, D.; Jiang, W.; Ye, G.; Wang, K.; Yin, L.; Shi, Y.; Chen, B.; Luo, F.; Liu, H. Graphene-elastomer nanocomposites based flexible piezoresistive sensors for strain and pressure detection. Mater. Res. Bull. 2018, 102, 92–99. [Google Scholar] [CrossRef]

| DMPU/PVDF Vol/Vol | Carbon Nanotubes (wt.%) | Nomenclature | Reduced Graphene Oxide (wt.%) | Nomenclature | |

|---|---|---|---|---|---|

| PVDF 5130 | 95/5 | 0 0.25 0.5 1 | PVDF5130 | 0 0.5 1 2 | PVDF5130 |

| 0.25CNT/5130 | 0.5rGO/5130 | ||||

| 0.5CNT/5130 | 0.1rGO/5130 | ||||

| 1CNT/5130 | 2rGO/5130 | ||||

| PVDF 6010 | 90/10 | 0 0.25 0.5 | PVDF6010 | ||

| 0.25CNT/6010 | |||||

| 0.5CNT/6010 | |||||

| PVDF-Hexafluropropylene | 90/10 | 0 0.25 0.5 | PVDF-HFP | ||

| 0.25CNT/HFP | |||||

| 0.5CNT/HFP | |||||

| Sample | Initial Modulus (MPa) | Strain at Rupture (%) | Stress at Rupture (MPa) | Yield Strain (%) | Yield Stress (MPa) |

|---|---|---|---|---|---|

| PVDF-HFP | 356 ± 15 | 70.8 ± 4 | 15.5 ± 3 | 12.7 ± 3 | 18.1 ± 4 |

| 025CNT/HFP | 372 ± 16 | 328.2 ± 16 | 17.4 ± 4 | 19.3 ± 5 | 19.1 ± 4 |

| 05CNT/HFP | 439 ± 18 | 309.5 ± 15 | 22.4 ± 4 | 18.3 ± 4 | 22.3 ± 5 |

| PVDF6010 | 1065 ± 45 | 11 ± 2 | 42.8 ± 8 | 9.6 ± 2 | 44.7 ± 10 |

| 025CNT/6010 | 1293 ± 49 | 11.1 ± 2 | 49.5 ± 10 | 8.9 ± 2 | 51.9 ± 11 |

| 05CNT/6010 | 1388 ± 51 | 13.6 ± 3 | 51.9 ± 10 | 8.3 ± 2 | 55.9 ± 12 |

| PVDF5130 | 870 ± 40 | 23.4 ± 5 | 27.3 ± 6 | 9.8 ± 2 | 34.4 ± 7 |

| 025CNT/5130 | 863 ± 40 | 212.9 ± 13 | 30.0 ± 6 | 13.3 ± 3 | 42.0 ± 8 |

| 05CNT/5130 | 1244 ± 54 | 99.2 ± 5 | 32.0 ± 7 | 13.2 ± 3 | 43.6 ± 9 |

| 1CNT/5130 | 1220 ± 53 | 85.9 ± 4 | 38.6 ± 8 | 14.4 ± 4 | 46.6 ± 9 |

| PVDF5130 | 870 ± 41 | 23.4 ± 4 | 27.3 ± 6 | 9.8 ± 2 | 34.4 ± 7 |

| 05rGO/5130 | 1151 ± 52 | 12.3 ± 3 | 39.6 ± 8 | 8.7 ± 2 | 43.2 ± 9 |

| 1rGO/5130 | 1327 ± 55 | 11.9 ± 3 | 53.4 ± 11 | 8.9 ± 2 | 56.1 ± 11 |

| 2rGO/5130 | 1265 ± 54 | 4.5 ± 1 | 44.1 ± 9 | 4.5 ± 1 | 44.1 ± 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vicente, J.; Costa, P.; Lanceros-Mendez, S.; Abete, J.M.; Iturrospe, A. Electromechanical Properties of PVDF-Based Polymers Reinforced with Nanocarbonaceous Fillers for Pressure Sensing Applications. Materials 2019, 12, 3545. https://doi.org/10.3390/ma12213545

Vicente J, Costa P, Lanceros-Mendez S, Abete JM, Iturrospe A. Electromechanical Properties of PVDF-Based Polymers Reinforced with Nanocarbonaceous Fillers for Pressure Sensing Applications. Materials. 2019; 12(21):3545. https://doi.org/10.3390/ma12213545

Chicago/Turabian StyleVicente, Javier, P. Costa, S. Lanceros-Mendez, Jose Manuel Abete, and Aitzol Iturrospe. 2019. "Electromechanical Properties of PVDF-Based Polymers Reinforced with Nanocarbonaceous Fillers for Pressure Sensing Applications" Materials 12, no. 21: 3545. https://doi.org/10.3390/ma12213545

APA StyleVicente, J., Costa, P., Lanceros-Mendez, S., Abete, J. M., & Iturrospe, A. (2019). Electromechanical Properties of PVDF-Based Polymers Reinforced with Nanocarbonaceous Fillers for Pressure Sensing Applications. Materials, 12(21), 3545. https://doi.org/10.3390/ma12213545