Mechanical Properties of Carbon Fiber-Reinforced Polymer Concrete with Different Polymer–Cement Ratios

Abstract

1. Introduction

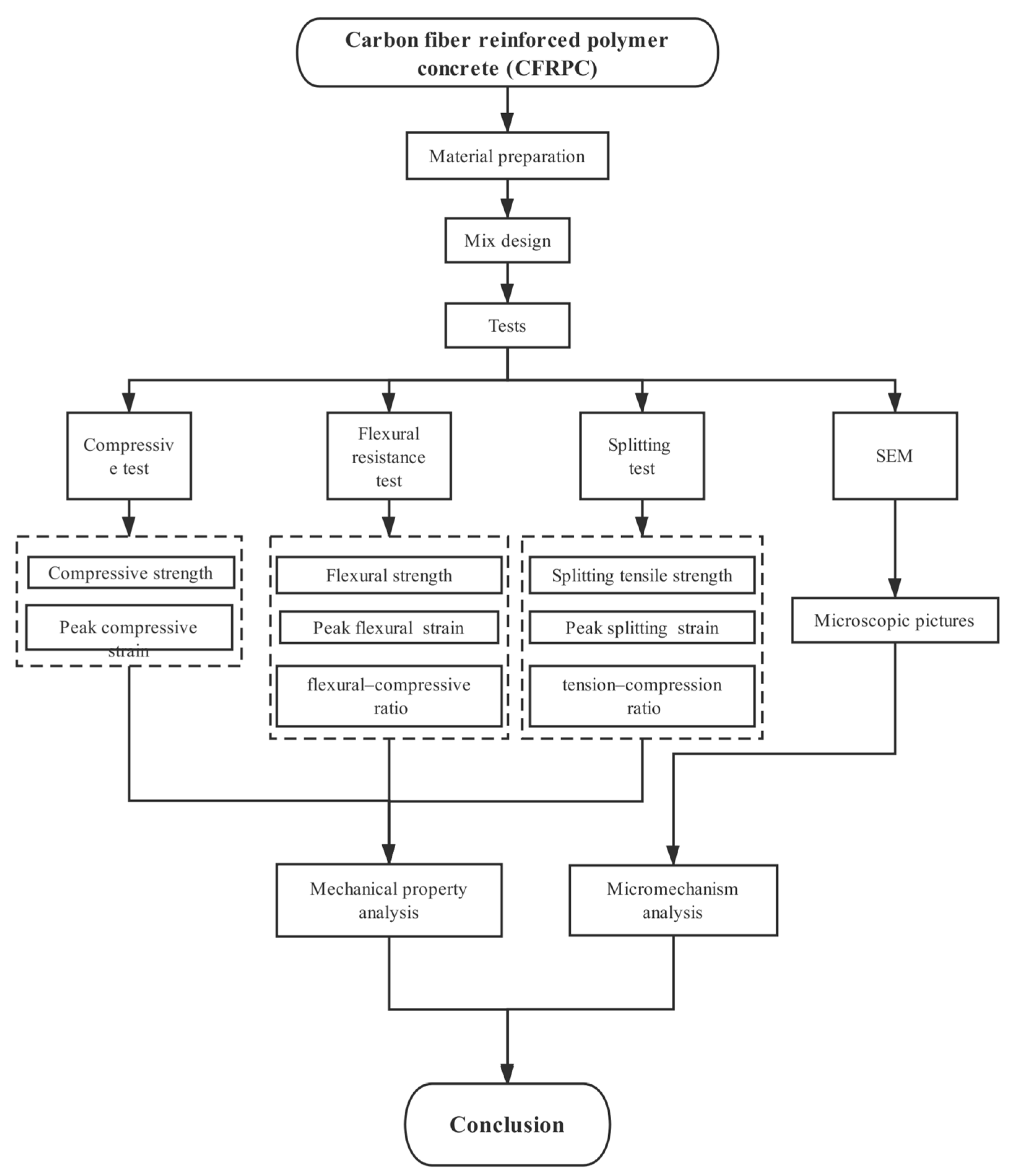

2. Materials and Methods

2.1. Test Materials and Mixing Ratio

2.2. Sample Preparation and Test Scheme

- Compressive test: the instrument was used to apply load uniformly on the cured specimens at a loading speed of 0.5–0.8 MPa/s until the specimens were damaged and the corresponding load was recorded;

- Splitting test: The preserved specimen, pad block, pad strip, and bracket were placed and installed in line with the requirements. Then, the hydraulic tester was used to apply load on the specimen uniformly at a loading speed of 0.05~0.08 MPa/s until the specimen failed; the corresponding failure load and displacement were recorded;

- Flexural test: the cured specimen, support, and hard steel cylinder were placed and installed in line with the requirements, referring to the method for the splitting test.

3. Results

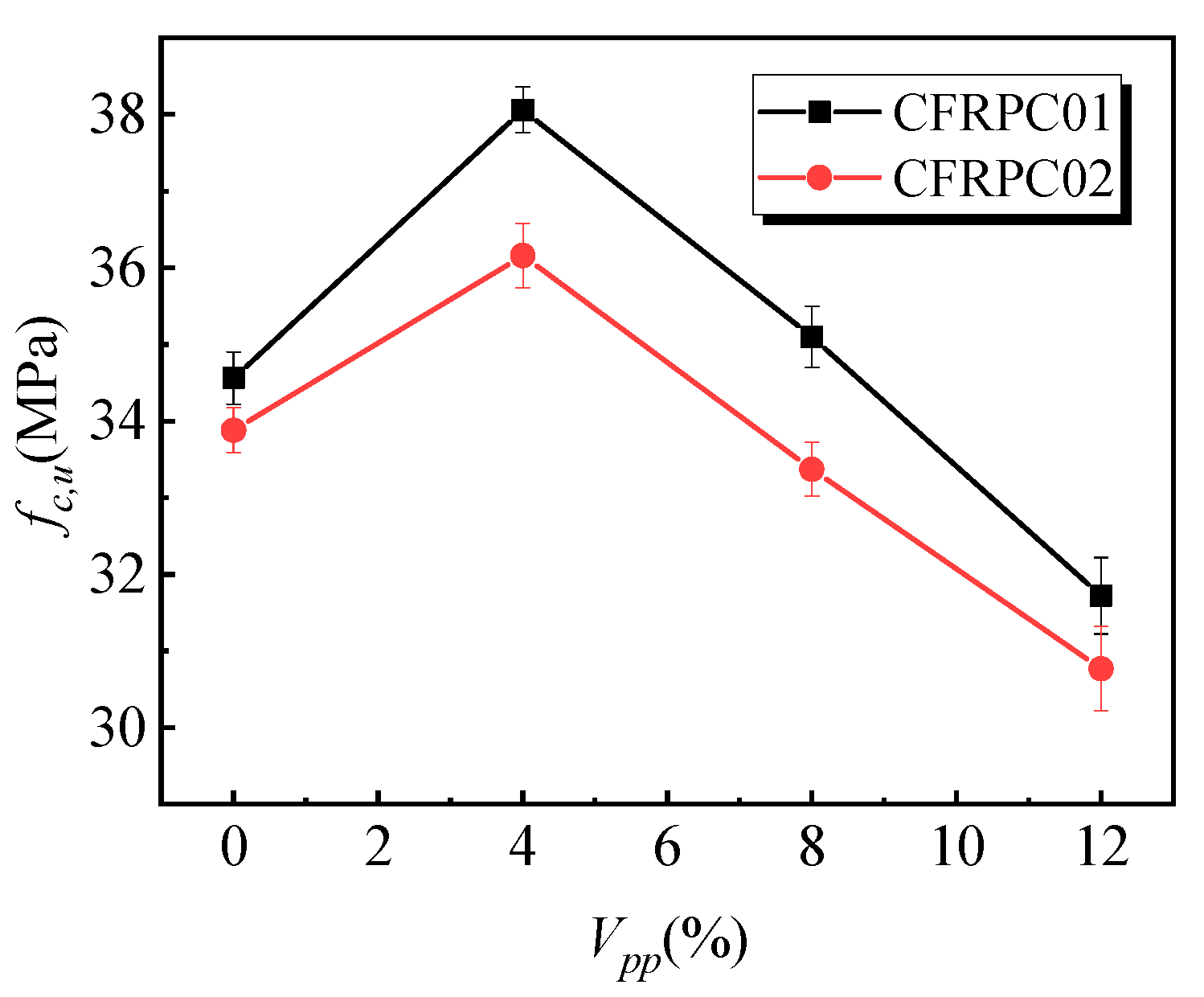

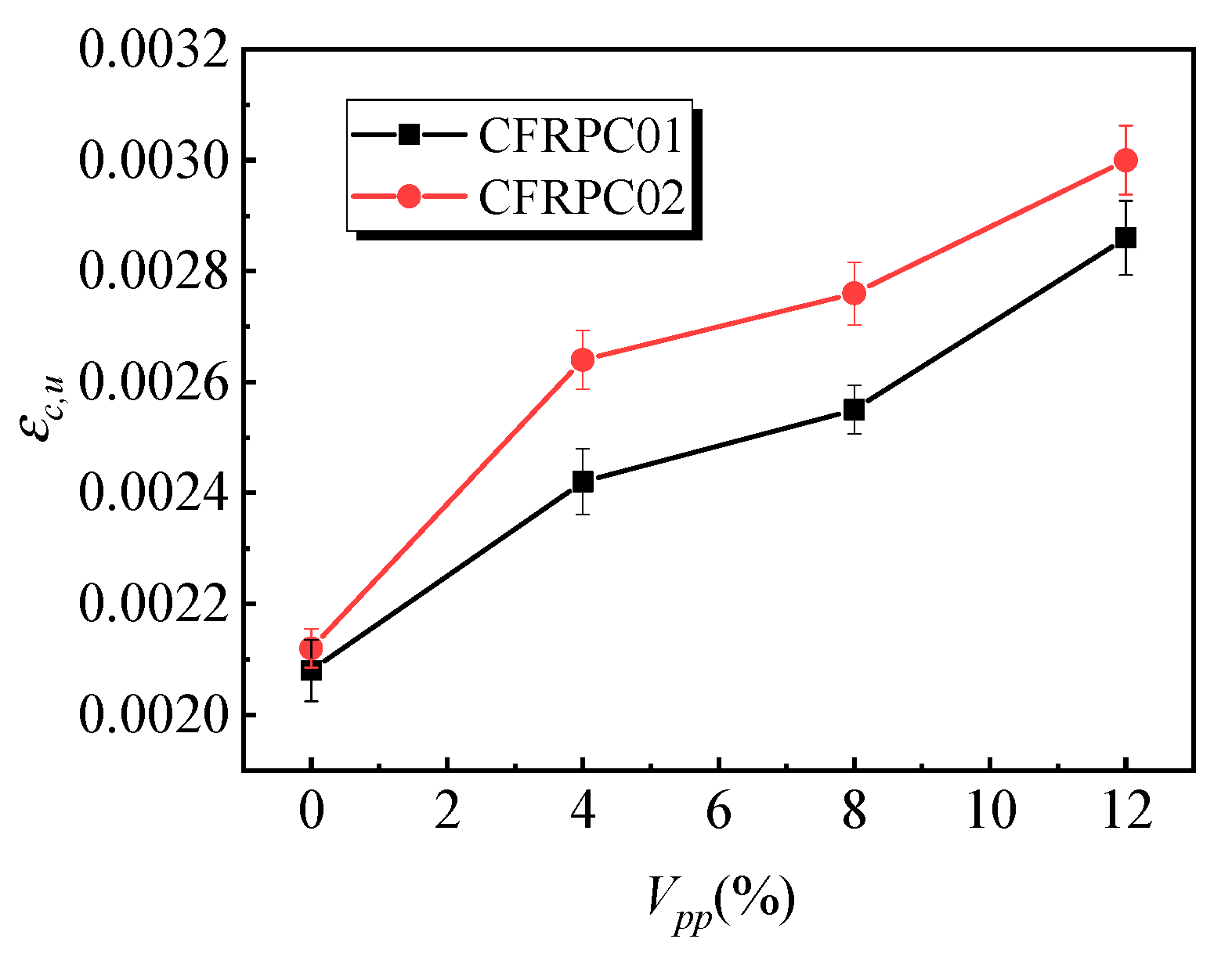

3.1. Compressive Property of CFRPC

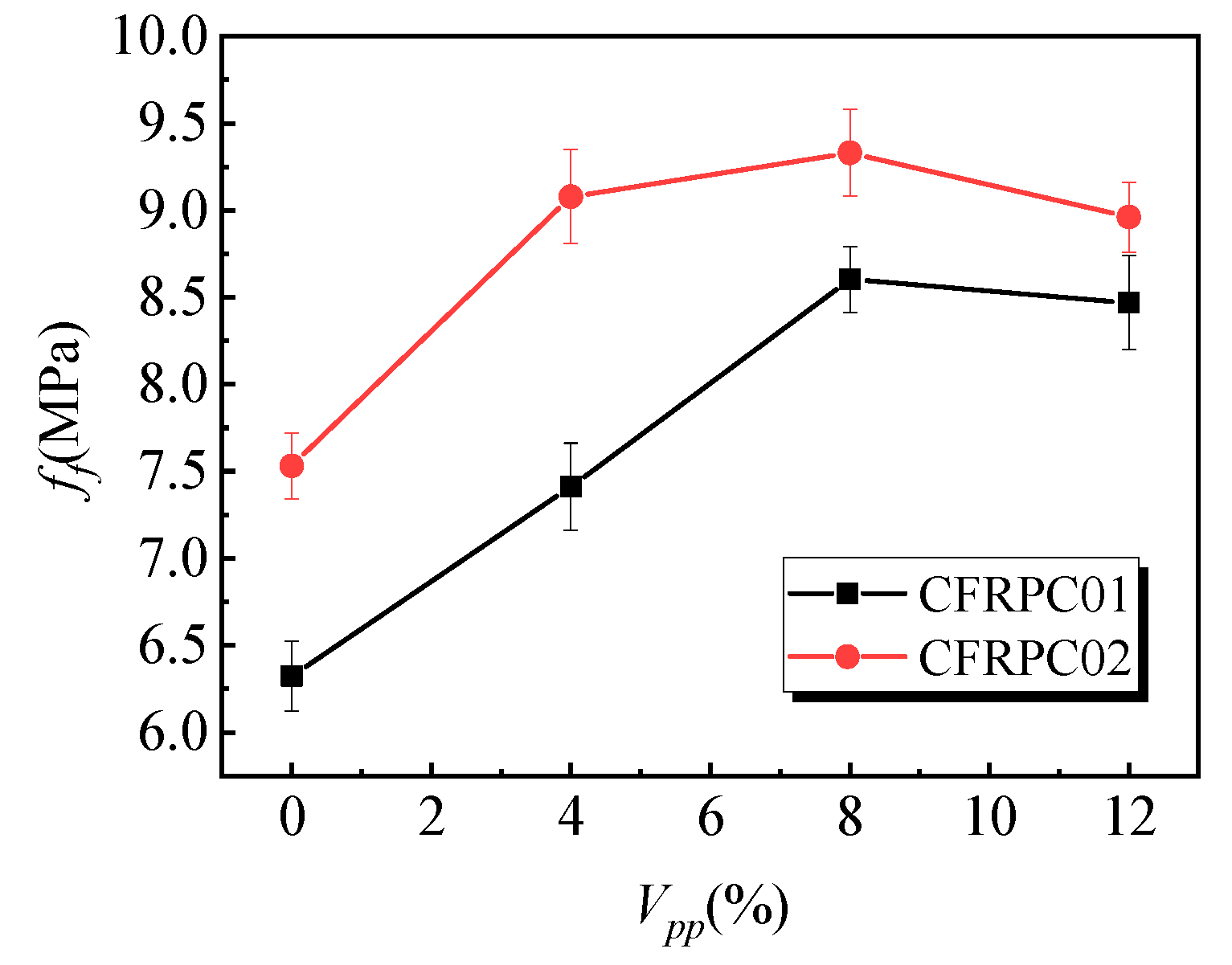

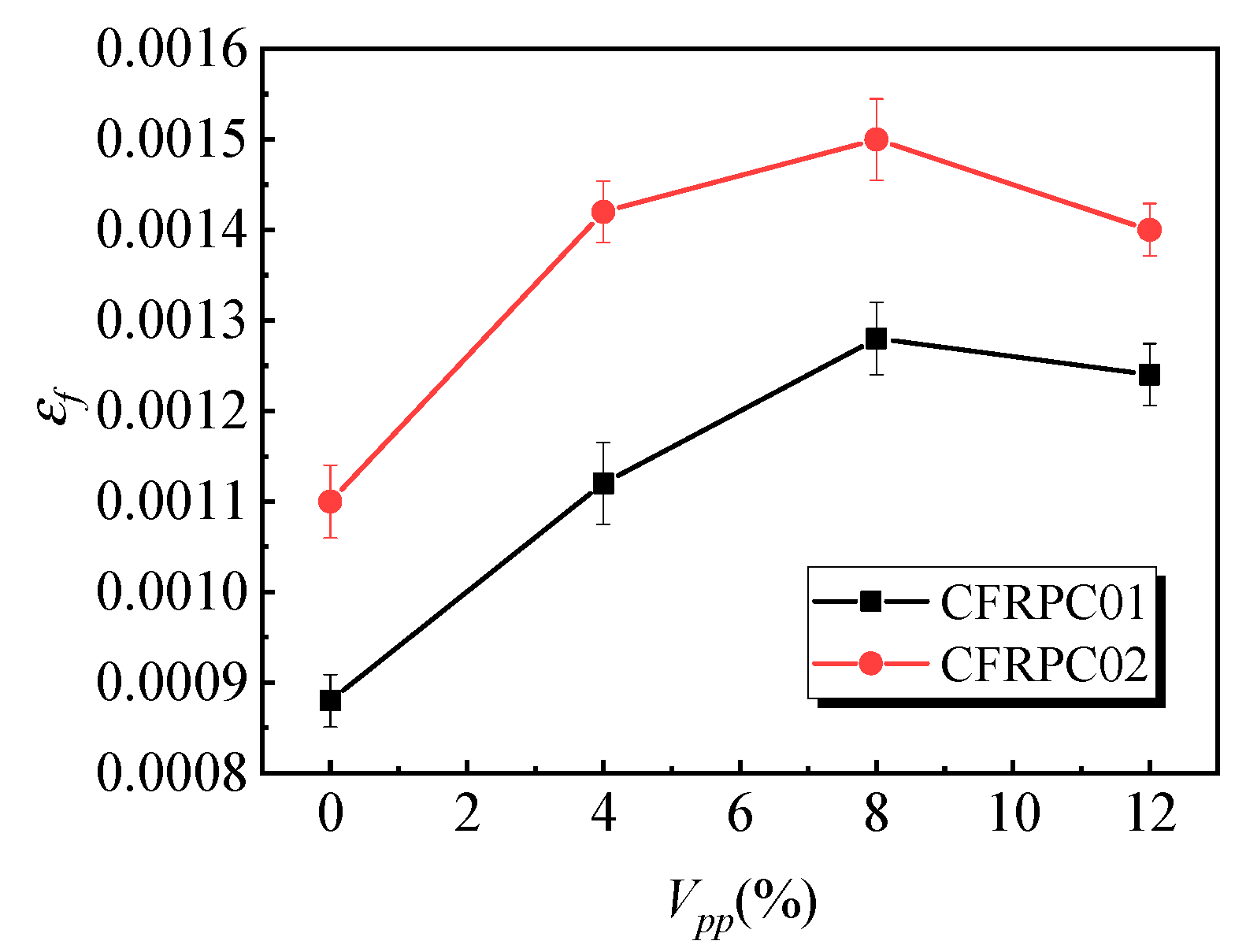

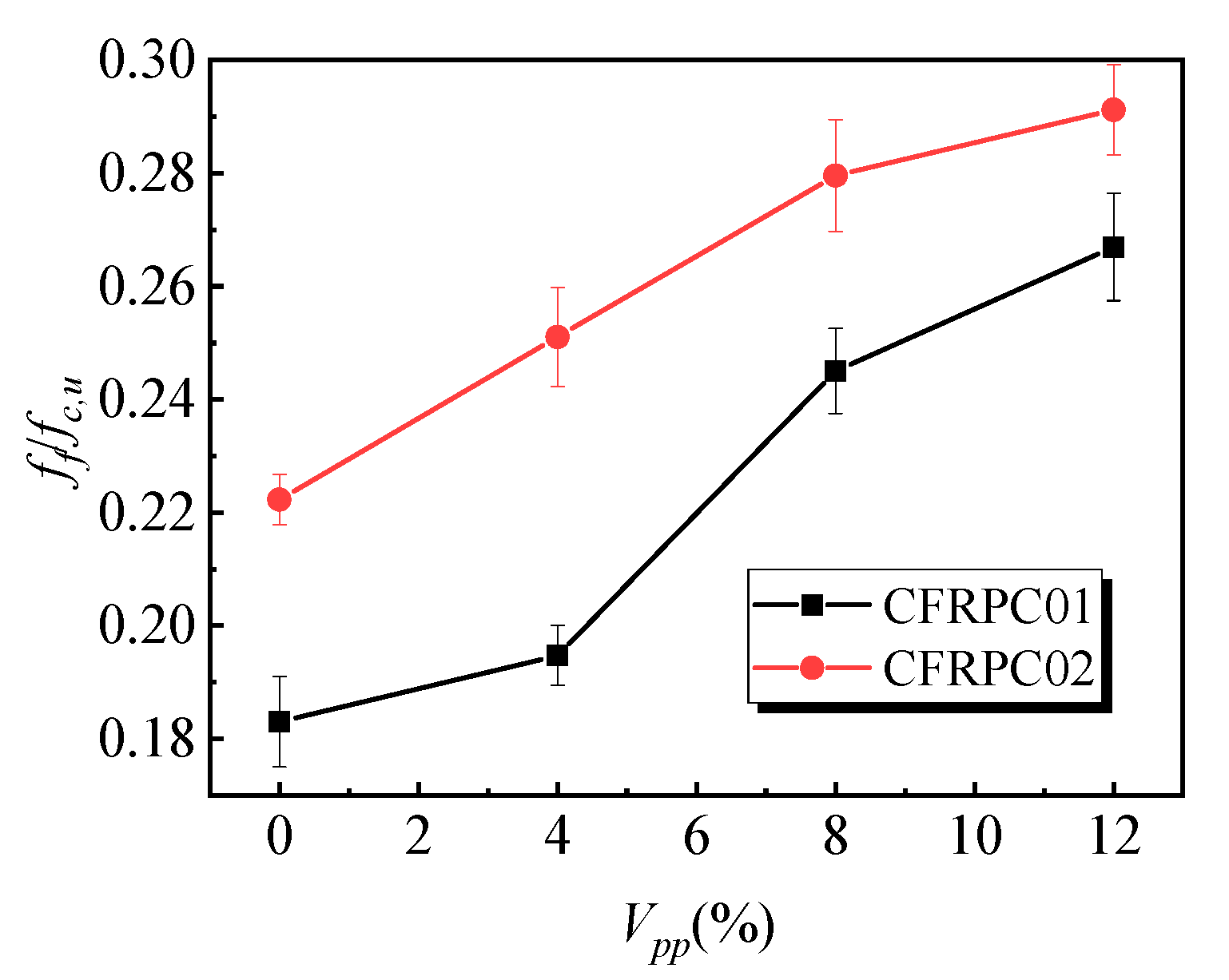

3.2. Flexural Resistance of CFRPC

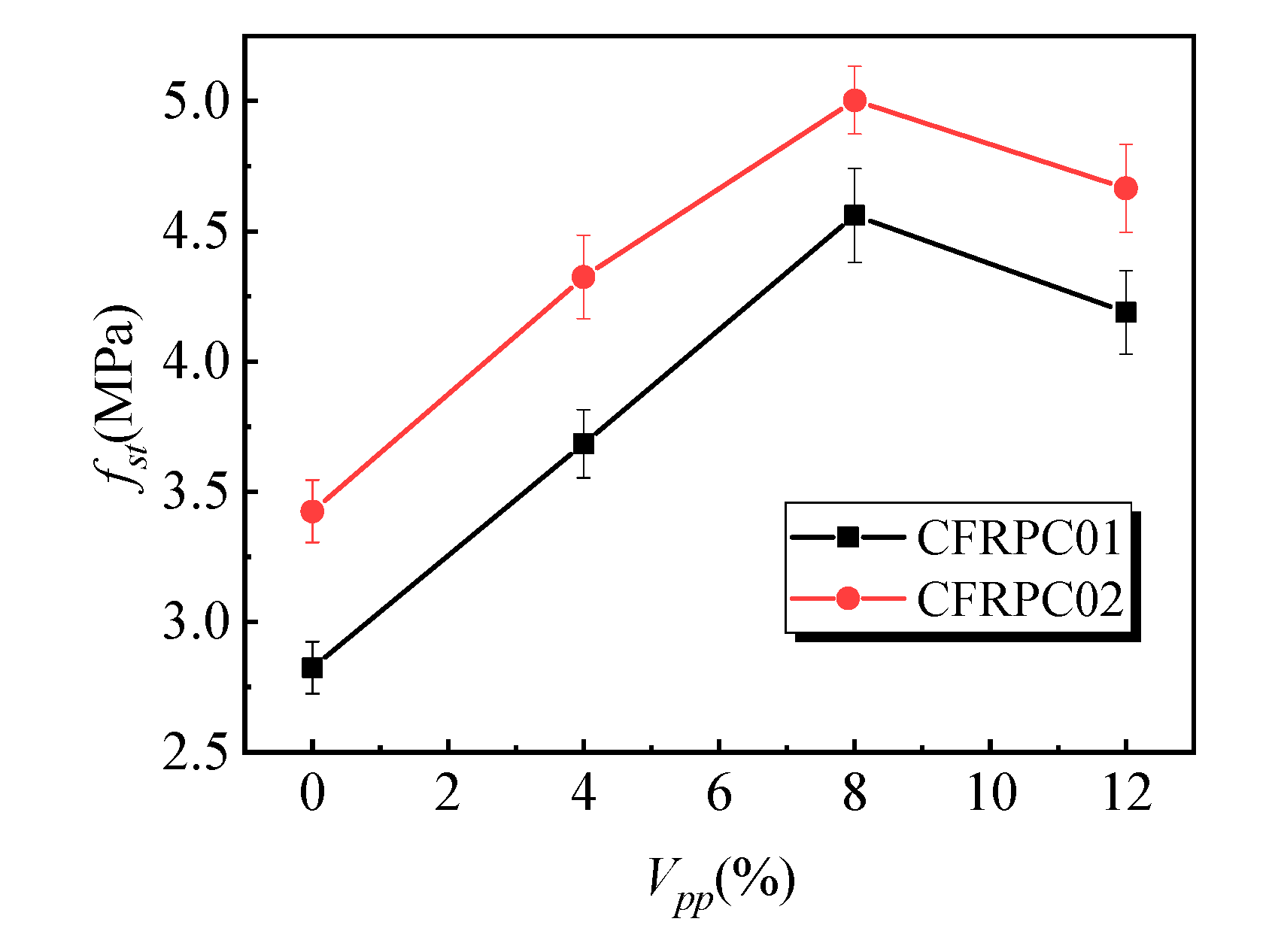

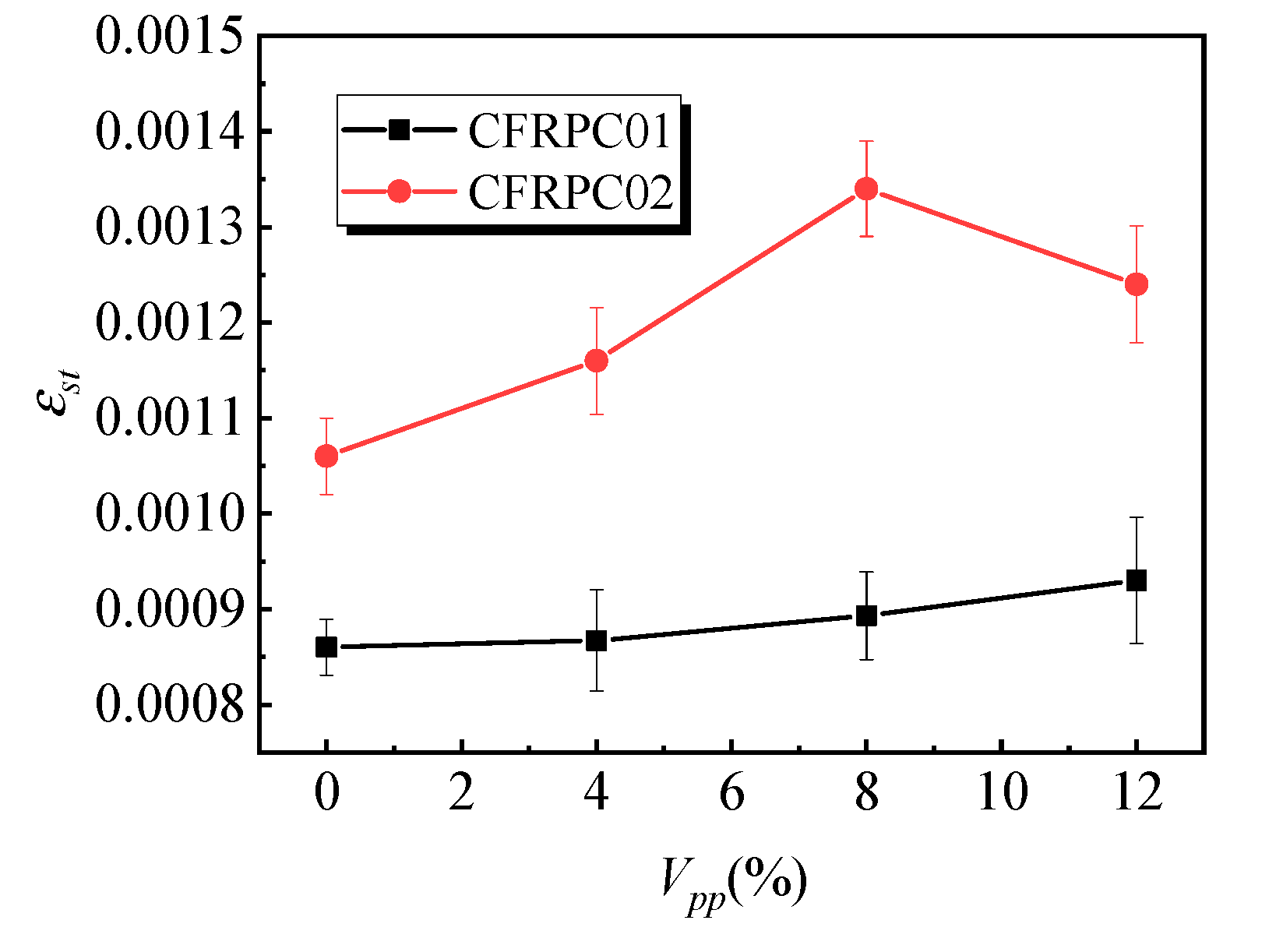

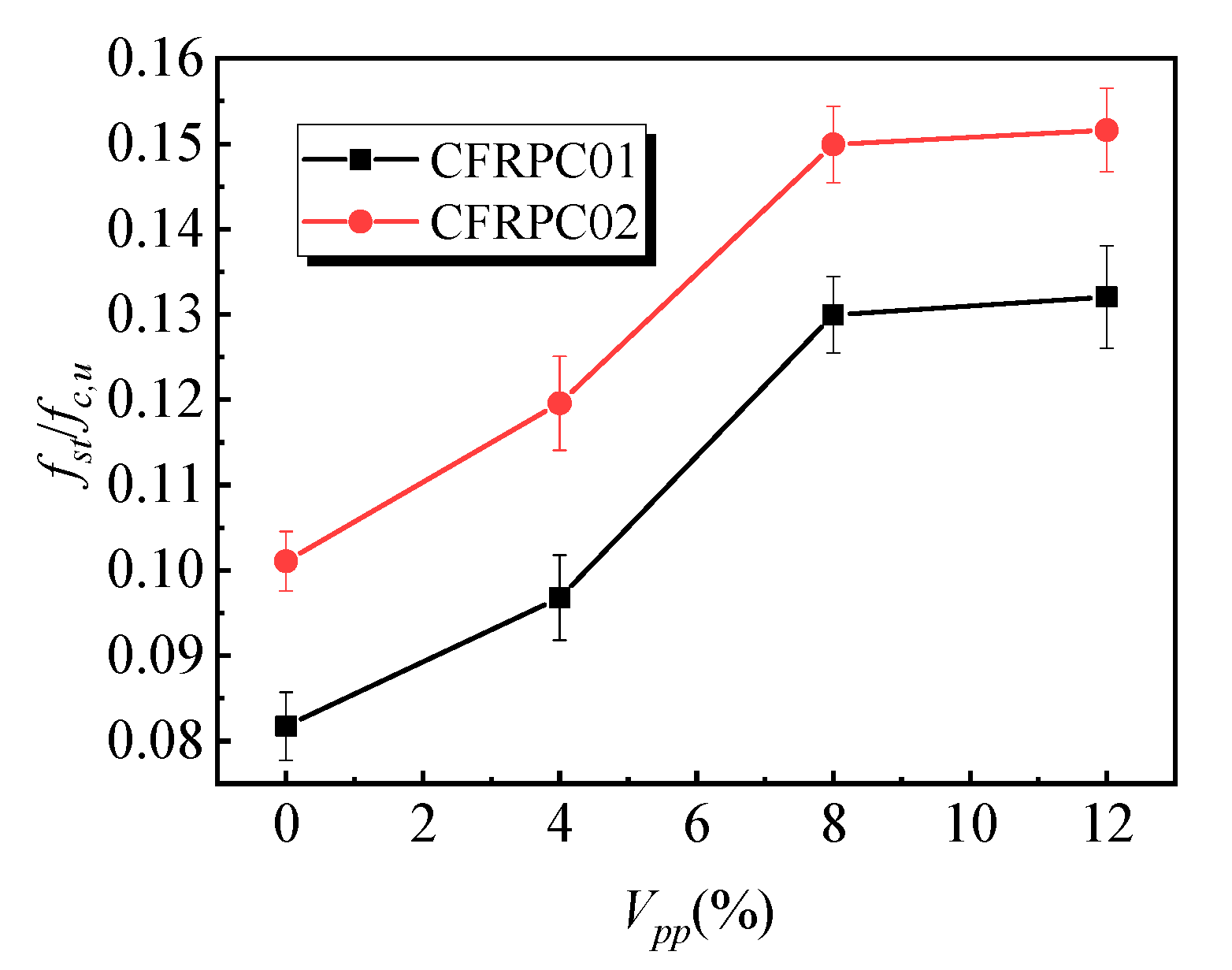

3.3. Splitting Properties of CFRPC

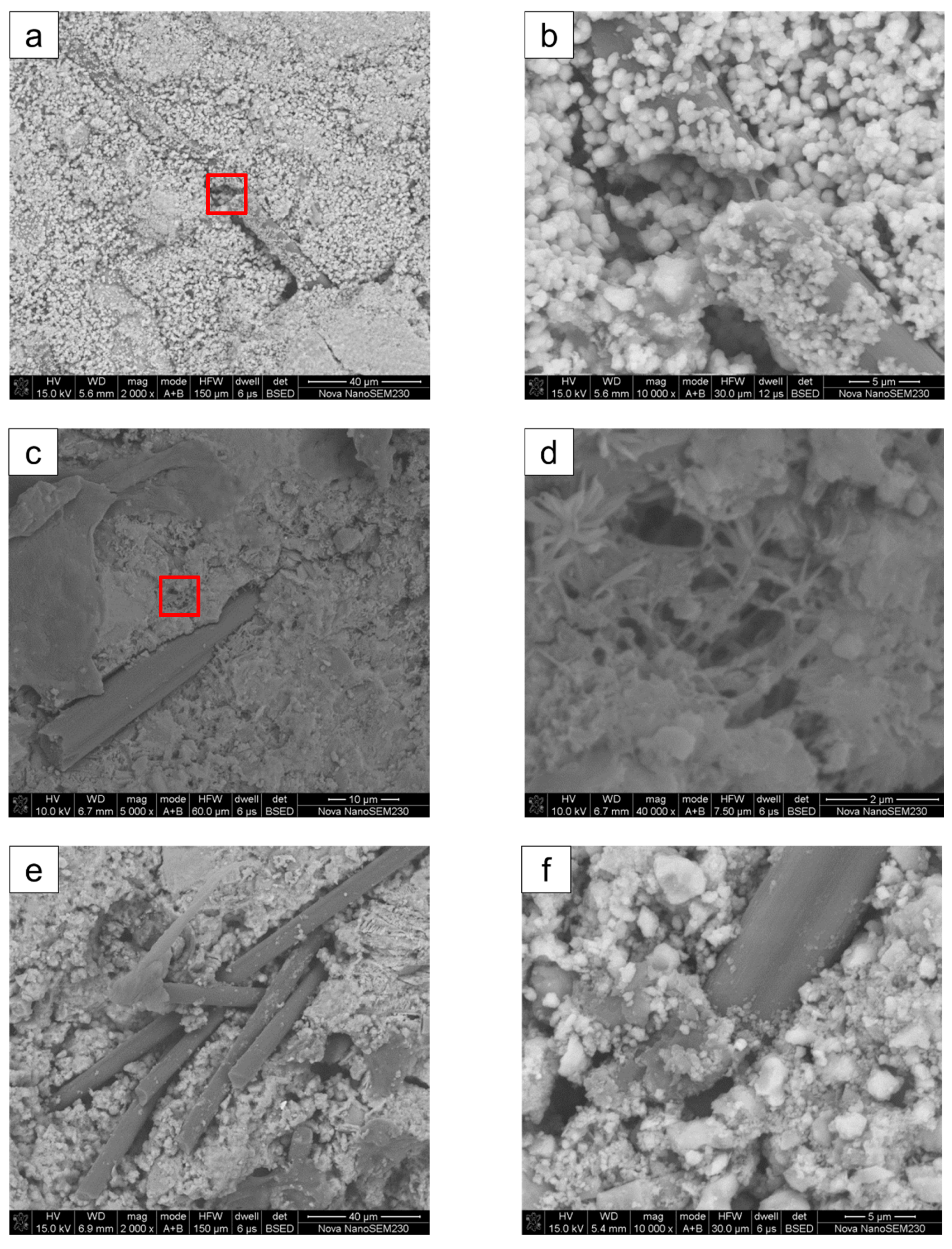

3.4. SEM Analysis

4. Discussion

- Reduction in the thickness of the water film of the carbon fiber–cement interface;

- Decreasing the difference in the water–cement ratio in the interface layer and the cement matrix;

- Enhancing cement adhesion to the fiber surface.

5. Conclusions

- With the increase in the polymer–cement ratio, the flexural and splitting properties of the specimens first increased and then decreased. Within the range of raw material proportions in this paper, the optimum polymer–cement ratio was 8%.

- By adding emulsion powder, the splitting tensile strength of CFRPC had a most significant increase, followed by flexural strength, while the compressive strength increased slightly, even decreasing at a high dosage.

- Scanning electron microscopy (SEM) results show that the emulsion powder tended to form a film in CFRPC and enhanced the bond strength between the fiber and the matrix. In this way, the tensile crack resistance of the fiber can be fully utilized.

Author Contributions

Funding

Conflicts of Interest

References

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Jiang, C.; Li, Z.; Song, X.; Lü, Y. Mechanism of functional responses to loading of carbon fiber reinforced cement-based composites. J. Wuhan Univ. Technol. Sci. Ed. 2008, 23, 571–573. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, X.C.; Liu, H.T. Experimental study of stress-strain curve of carbon fiber reinforced concrete. Eng. Mech. 2013, 30, 200–204. [Google Scholar]

- Han, B.; Zhang, L.; Zhang, C.; Wang, Y.; Yu, X.; Ou, J. Reinforcement effect and mechanism of carbon fibers to mechanical and electrically conductive properties of cement-based materials. Constr. Build. Mater. 2016, 125, 479–489. [Google Scholar] [CrossRef]

- Carrara, P.; Ferretti, D.; Freddi, F.; Rosati, G. Shear tests of carbon fiber plates bonded to concrete with control of snap-back. Eng. Fract. Mech. 2011, 78, 2663–2678. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Damage in carbon fiber-reinforced concrete, monitored by both electrical resistance measurement and acoustic emission analysis. Constr. Build. Mater. 2008, 22, 2196–2201. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.; Yao, H.; Farhan, S.; Zheng, S.; Wang, Z.; Du, C.; Jiang, H. Research on the mechanism of polymer latex modified cement. Constr. Build. Mater. 2016, 111, 710–718. [Google Scholar] [CrossRef]

- Ohama, Y.; Kan, S. Effects of specimen size on strength and drying shrinkage of polymer-modified concrete. Int. J. Cem. Compos. Light. Concr. 1982, 4, 229–233. [Google Scholar] [CrossRef]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Compos. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Beeldens, A. From microstructure to macrostructure: An integrated model of structure formation in polymer-modified concrete. Mater. Struct. 2005, 38, 601–607. [Google Scholar] [CrossRef]

- Wang, P.M.; Liu, E.G. Study on Properties of Styrene-Acrylate Copolymer Powder Modified Cement Mortar. Chin. J. Build. Mater. 2009, 12, 253–258. (In Chinese) [Google Scholar]

- Wang, P.M.; Zhao, G.R.; Zhang, G.F. Research Progress on Microstructure of Polymer Cement Concrete. J. Chin. Ceram. Soc. 2014, 42, 653–660. (In Chinese) [Google Scholar]

- Hai, C.; Xin, L.Z.; Xiao, H.G.; Jin, J.F. Experimental Study on Anti-Penetration Performance of Steel Fiber Reinforced Polymer-Modified Concrete. Adv. Mater. Res. 2014, 1030, 1100–1103. [Google Scholar]

- Le Zhang, X.; Cao, H.; Guo, X.H. Study on Compressive Stress-Strain Relationship of Polymer-Modified Concrete. Adv. Mater. Res. 2013, 779, 122–125. [Google Scholar] [CrossRef]

- Wei, J.; Cheng, F.; Yuan, H. Electrical resistance and microstructure of latex modified carbon fiber reinforced cement composites. J. Wuhan Univ. Technol. Sci. Ed. 2012, 27, 746–749. [Google Scholar] [CrossRef]

- Giustozzi, F. Polymer-modified pervious concrete for durable and sustainable transportation infrastructures. Constr. Build. Mater. 2016, 111, 502–512. [Google Scholar] [CrossRef]

- Rashid, K.; Ueda, T.; Zhang, D.; Miyaguchi, K.; Nakai, H. Experimental and analytical investigations on the behavior of interface between concrete and polymer cement mortar under hygrothermal conditions. Constr. Build. Mater. 2015, 94, 414–425. [Google Scholar] [CrossRef]

- Tian, Y.; Shi, S.; Jia, K.; Hu, S. Mechanical and dynamic properties of high strength concrete modified with lightweight aggregates presaturated polymer emulsion. Constr. Build. Mater. 2015, 93, 1151–1156. [Google Scholar] [CrossRef]

- Pal, S.; Tiwari, S.; Katyal, K.; Singh, A. Effect of Polymer Modification on Structural and Mechanical Properties of Concrete Using Epoxy Emulsion as the Modifier. In Innovation in Materials Science and Engineering; Chattopadhyay, J., Singh, R., Prakash, O., Eds.; Springer: Singapore, Singapore, 2019; pp. 1–10. [Google Scholar]

- Prasad, R.; Nicole, S.; Akshata, K.; Coleen, P.; Jana, S.C. Exploiting arene-perfluoroarene interactions for dispersion of carbon black in rubber compounds. Polymer 2018, 148, 247–258. [Google Scholar]

- Dehghan, A.; Peterson, K.; Shvarzman, A. Recycled glass fiber reinforced polymer additions to Portland cement concrete. Constr. Build. Mater. 2017, 146, 238–250. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P.; Bombik, A. Physico-Mechanical Properties and Microstructure of Polymer Concrete with Recycled Glass Aggregate. Materials 2018, 11, 1213. [Google Scholar] [CrossRef] [PubMed]

- Knapen, E.; Van Gemert, D. Polymer film formation in cement mortars modified with water-soluble polymers. Cem. Concr. Compos. 2015, 58, 23–28. [Google Scholar] [CrossRef]

- Morlat, R.; Orange, G.; Bomal, Y.; Godard, P. Reinforcement of hydrated portland cement with high molecular mass water-soluble polymers. J. Mater. Sci. 2007, 42, 4858–4869. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Szeląg, M.; Maciej, S. Evaluation of cracking patterns of cement paste containing polypropylene fibers. Compos. Struct. 2019, 220, 402–411. [Google Scholar] [CrossRef]

- Knapen, E.; Van Gemert, D. Microstructural Analysis of Paste and Interfacial Transition Zone in Cement Mortars Modified with Water-Soluble Polymers. Key Eng. Mater. 2011, 466, 21–28. [Google Scholar] [CrossRef]

- Lin, D.; Wang, C.J.; Dong, F.B.; Lou, S.; Shou, C.Q. Surface Modification of Carbon Fiber by Polymer Emulsions and Mechanical Property of Modified Carbon Reinforced Concrete. Adv. Mater. Res. 2011, 233, 2002–2005. [Google Scholar] [CrossRef]

- Qian, X.; Zhi, J.H.; Zhang, Y.G.; Yang, J.X. Effect of Surface Chemical Structure of Carbon Fibers on Properties of Carbon Fiber/Epoxy Resin Composites. J. Mater. Eng. 2014, 6, 84–88. [Google Scholar]

- Li, N.; Liu, G.; Wang, Z.; Liang, J.; Zhang, X. Effect of surface treatment on surface characteristics of carbon fibers and interfacial bonding of epoxy resin composites. Fibers Polym. 2014, 15, 2395–2403. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, X.; Xian, G.; Hui, L. Effects of surface treatment of carbon fiber: Tensile property, surface characteristics, and bonding to epoxy. Polym. Compos. 2016, 37, 2921–2932. [Google Scholar] [CrossRef]

- Fu, X.; Lu, W.; Chung, D. Improving the bond strength between carbon fiber and cement by fiber surface treatment and polymer addition to cement mix. Cem. Concr. Res. 1996, 26, 1007–1012. [Google Scholar] [CrossRef]

- Dundar, C.; Erturkmen, D.; Tokgoz, S. Studies on carbon fiber polymer confined slender plain and steel fiber reinforced concrete columns. Eng. Struct. 2015, 102, 31–39. [Google Scholar] [CrossRef]

- Ouyang, L.-J.; Gao, W.-Y.; Zhen, B.; Lu, Z.-D. Seismic retrofit of square reinforced concrete columns using basalt and carbon fiber-reinforced polymer sheets: A comparative study. Compos. Struct. 2017, 162, 294–307. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H.; Bao, Y. Flexural behaviors of fiber-reinforced polymer fabric reinforced ultra-high-performance concrete panels. Cem. Concr. Compos. 2018, 93, 43–53. [Google Scholar] [CrossRef]

- Tabatabaei, Z.S.; Volz, J.S.; Keener, D.I.; Gliha, B.P. Comparative impact behavior of four long carbon fiber reinforced concretes. Mater. Des. 2014, 55, 212–223. [Google Scholar] [CrossRef]

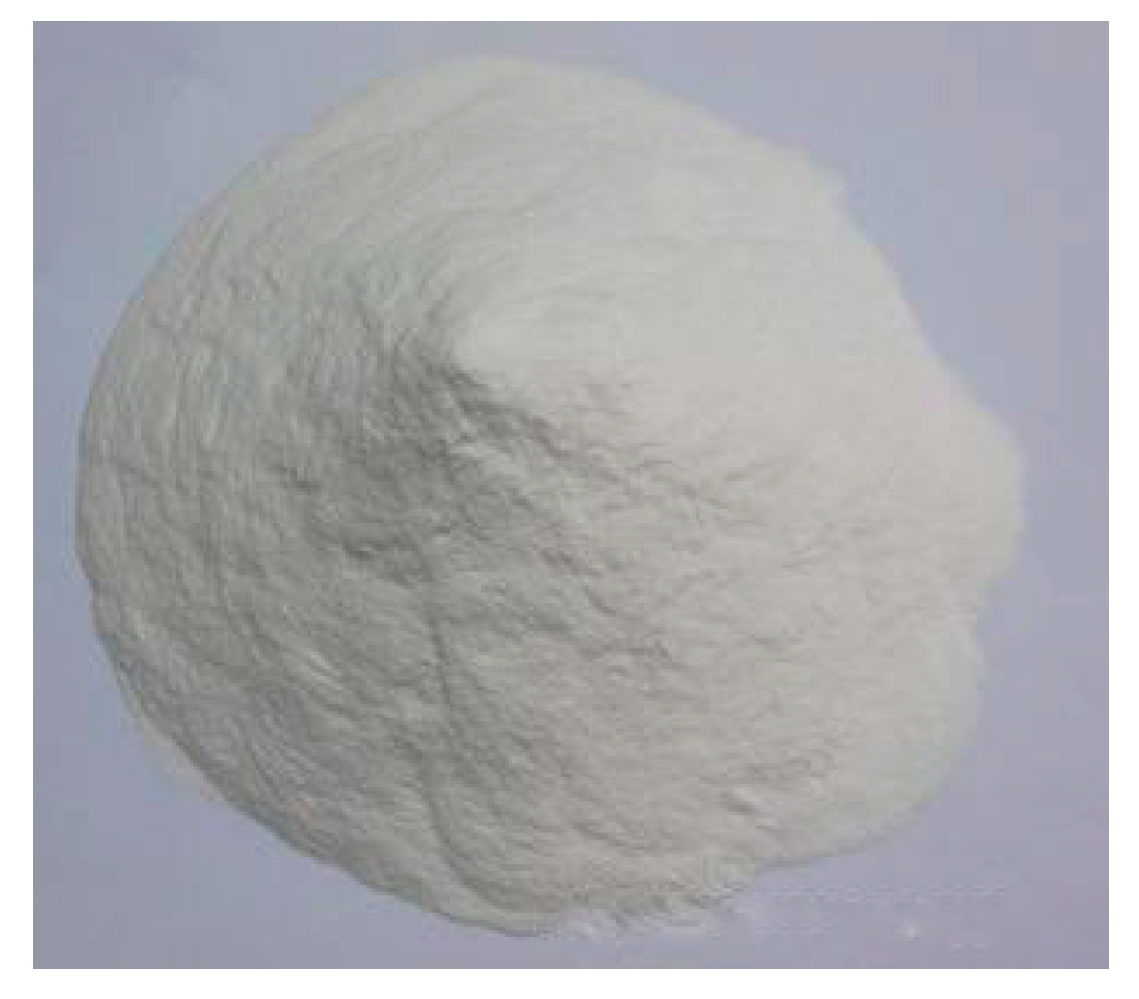

| Appearance | Solid Content | Ash Content | Vitrification Temperature, (°C) | Volume Density, (kg·m−3) | Minimum Film Formation Temperature (MFFT), (°C) | Particle Size, (μm) |

|---|---|---|---|---|---|---|

| White powder | ≥99% | 13 ± 2% | 0 | 400–500 | 0 | 1–7 |

| Diameter, (μm) | Length, (mm) | Carbon Content, (wt.%) | Elongation at Break, (%) | Tensile Strength, (GPa) | Resistivity, (Ω·cm) | Relative Density, (g·cm−3) |

|---|---|---|---|---|---|---|

| 7.0 ± 0.2 | 6 | ≥93 | 1.25–1.60 | >3.0 | 1.5 × 10−3 | 1.76 |

| Test Number | Carbon Fiber | Polymer Emulsion Powder | Cement | Fine Aggregate | Water | Coarse Aggregate | Dispersant | Defoamer | Water-Reducing Agent | Film-Forming Additive |

|---|---|---|---|---|---|---|---|---|---|---|

| CFRPC01 | 0.83 | 0 | 204 | 376 | 100 | 536 | 0.82 | 0.61 | 2.45 | 0 |

| 8.17 | 0.41 | |||||||||

| 16.33 | 0.82 | |||||||||

| 24.50 | 1.23 | |||||||||

| CFRPC02 | 1.66 | 0 | 0 | |||||||

| 8.17 | 0.41 | |||||||||

| 16.33 | 0.82 | |||||||||

| 24.50 | 1.23 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.-J.; Bai, E.-L.; Xu, J.-Y.; Yang, N. Mechanical Properties of Carbon Fiber-Reinforced Polymer Concrete with Different Polymer–Cement Ratios. Materials 2019, 12, 3530. https://doi.org/10.3390/ma12213530

Liu G-J, Bai E-L, Xu J-Y, Yang N. Mechanical Properties of Carbon Fiber-Reinforced Polymer Concrete with Different Polymer–Cement Ratios. Materials. 2019; 12(21):3530. https://doi.org/10.3390/ma12213530

Chicago/Turabian StyleLiu, Gao-Jie, Er-Lei Bai, Jin-Yu Xu, and Ning Yang. 2019. "Mechanical Properties of Carbon Fiber-Reinforced Polymer Concrete with Different Polymer–Cement Ratios" Materials 12, no. 21: 3530. https://doi.org/10.3390/ma12213530

APA StyleLiu, G.-J., Bai, E.-L., Xu, J.-Y., & Yang, N. (2019). Mechanical Properties of Carbon Fiber-Reinforced Polymer Concrete with Different Polymer–Cement Ratios. Materials, 12(21), 3530. https://doi.org/10.3390/ma12213530