Spinodal Decomposition and Mechanical Response of a TiZrNbTa High-Entropy Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

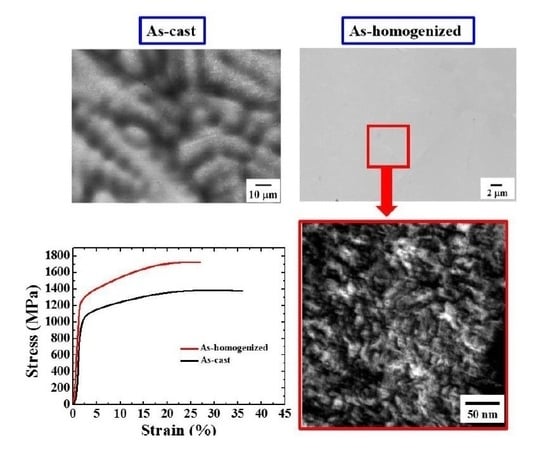

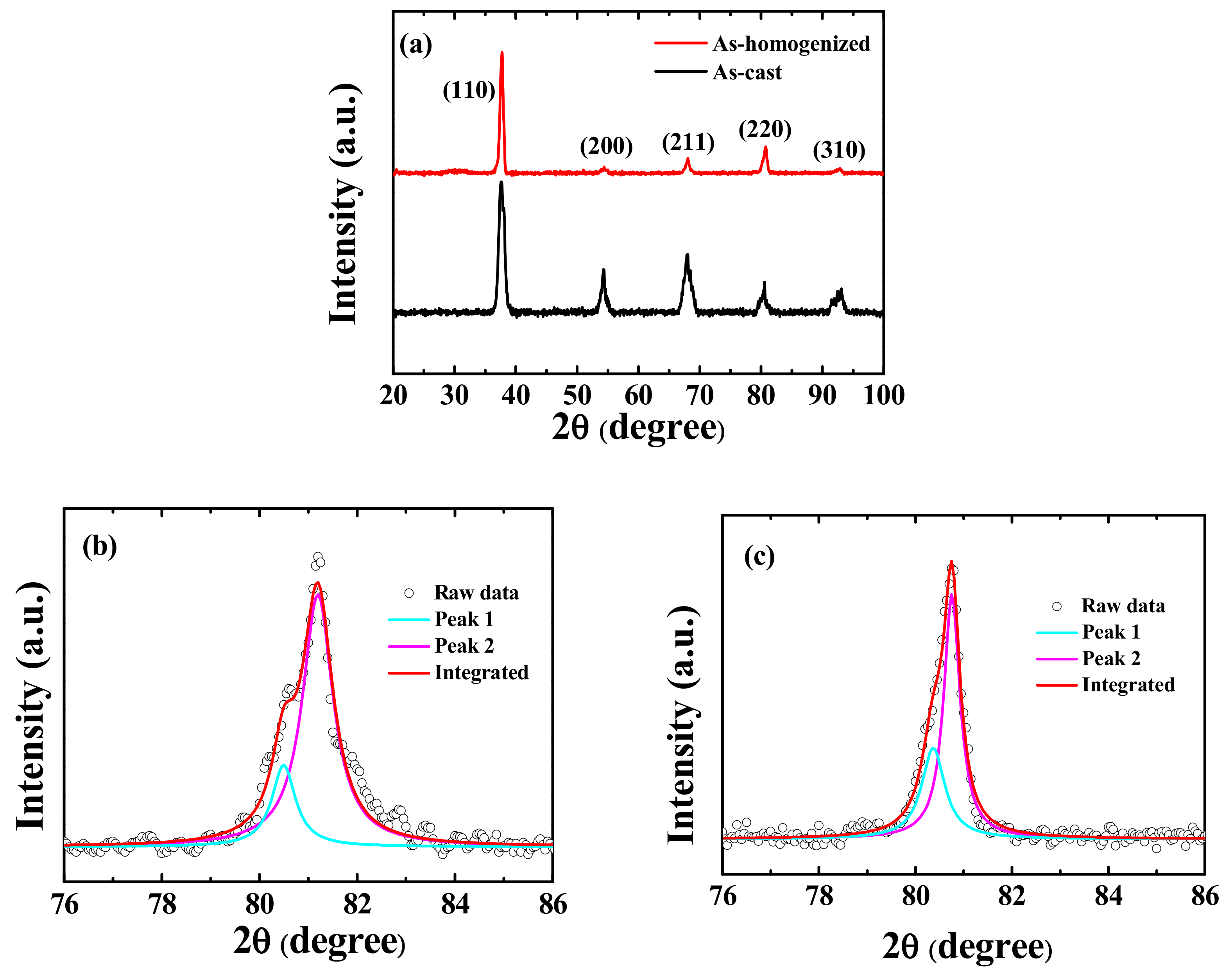

3.1. Structural Identification of TiZrNbTa Alloys

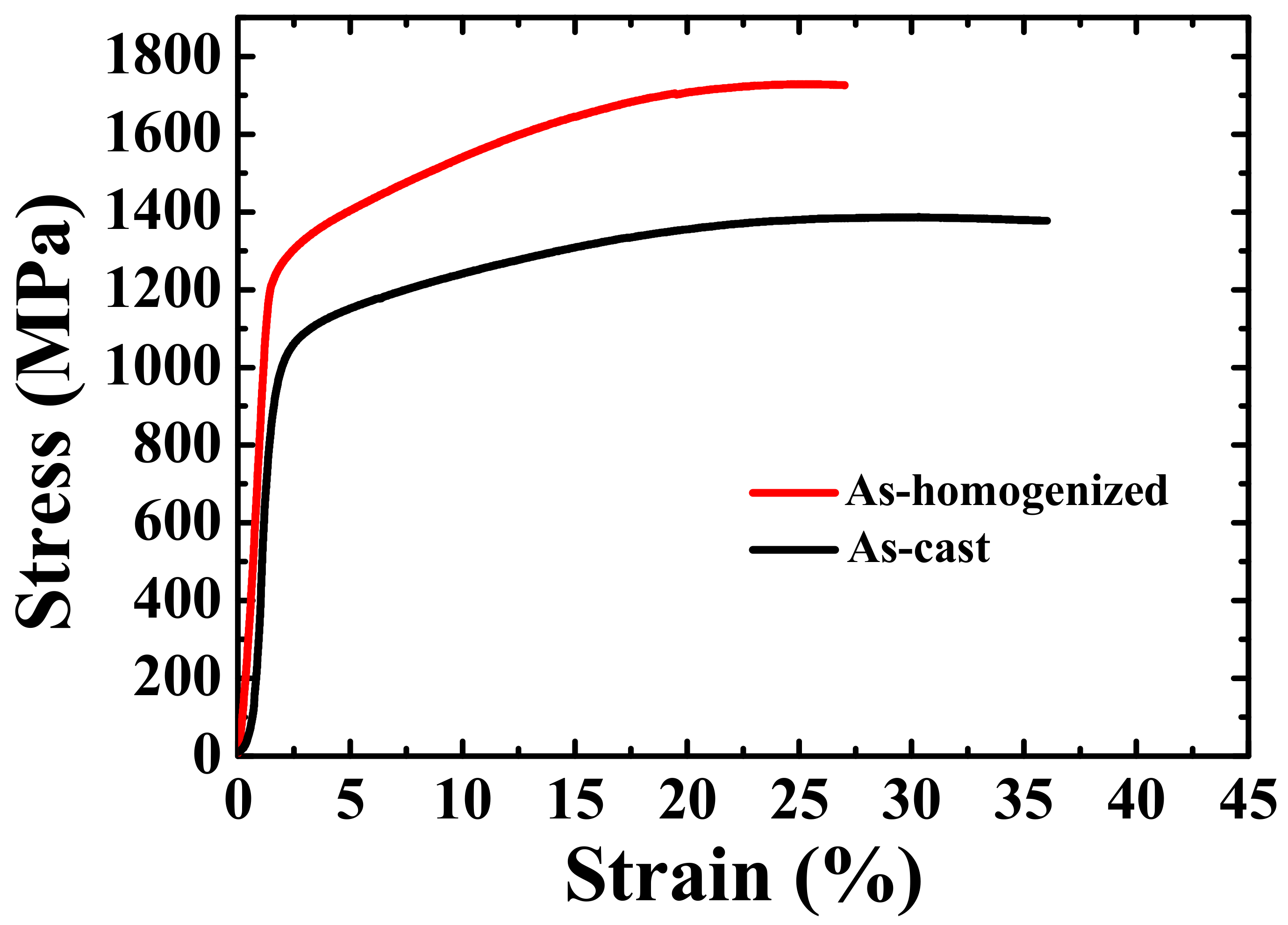

3.2. Mechanical Property Measurement

3.3. Microstructure Characterization

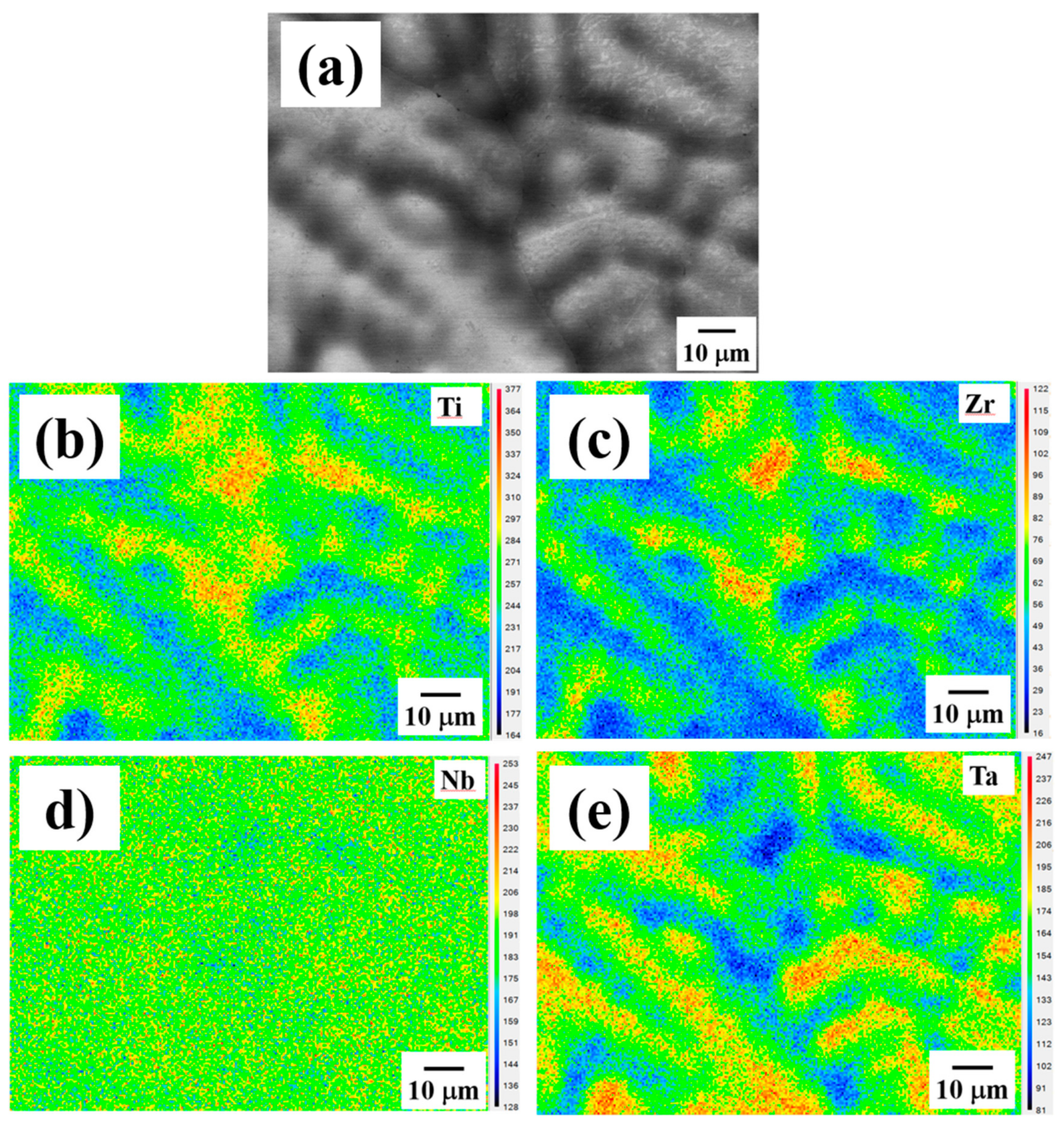

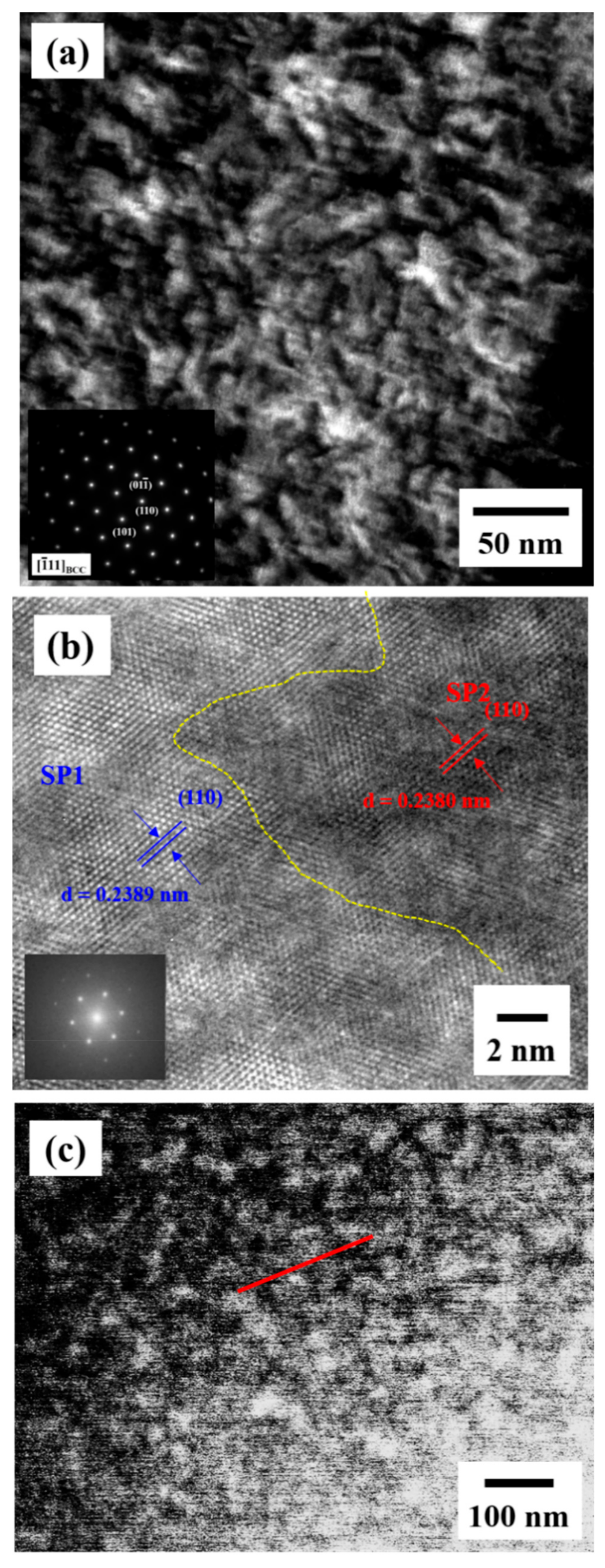

3.3.1. The As-Cast Samples

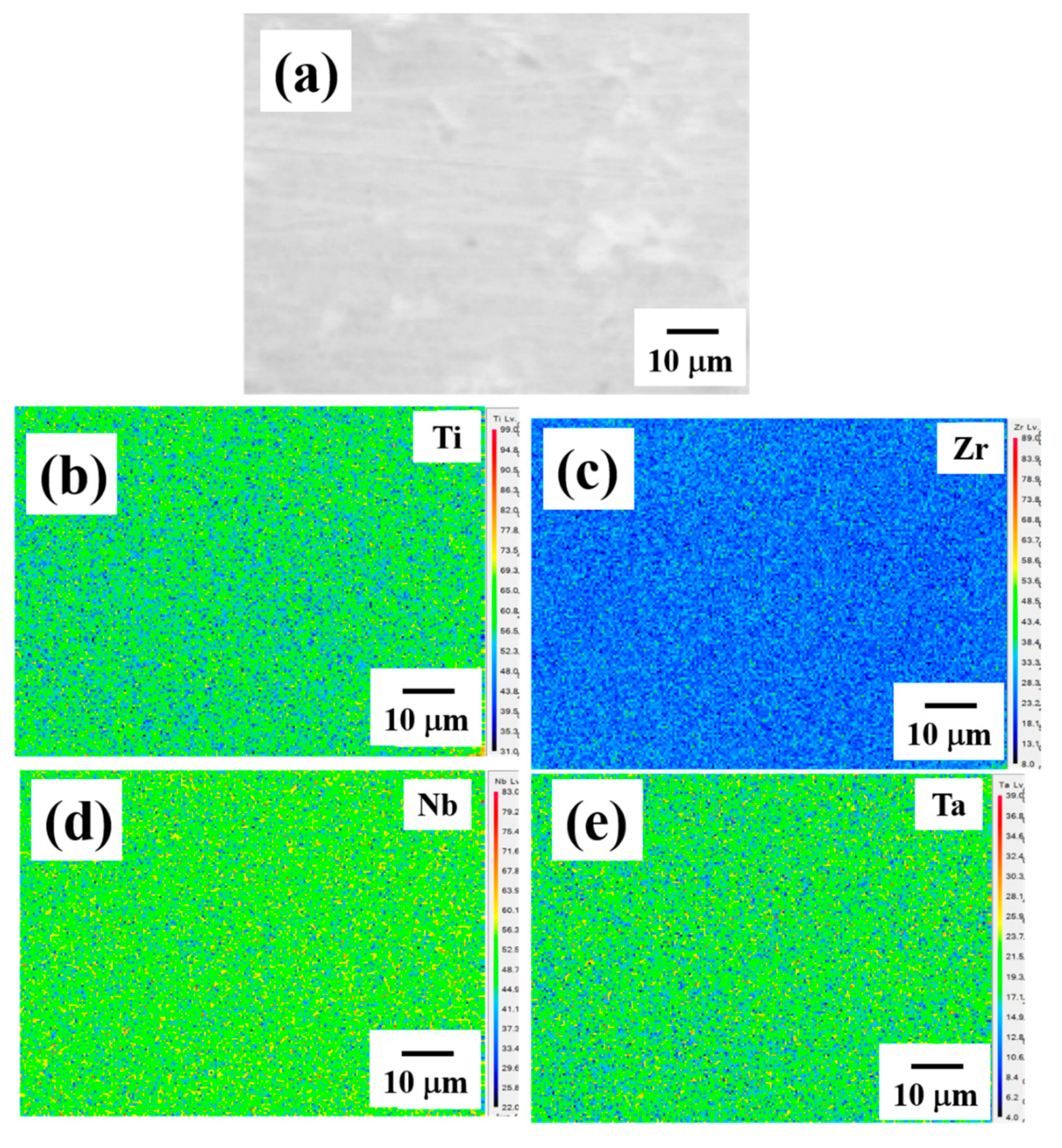

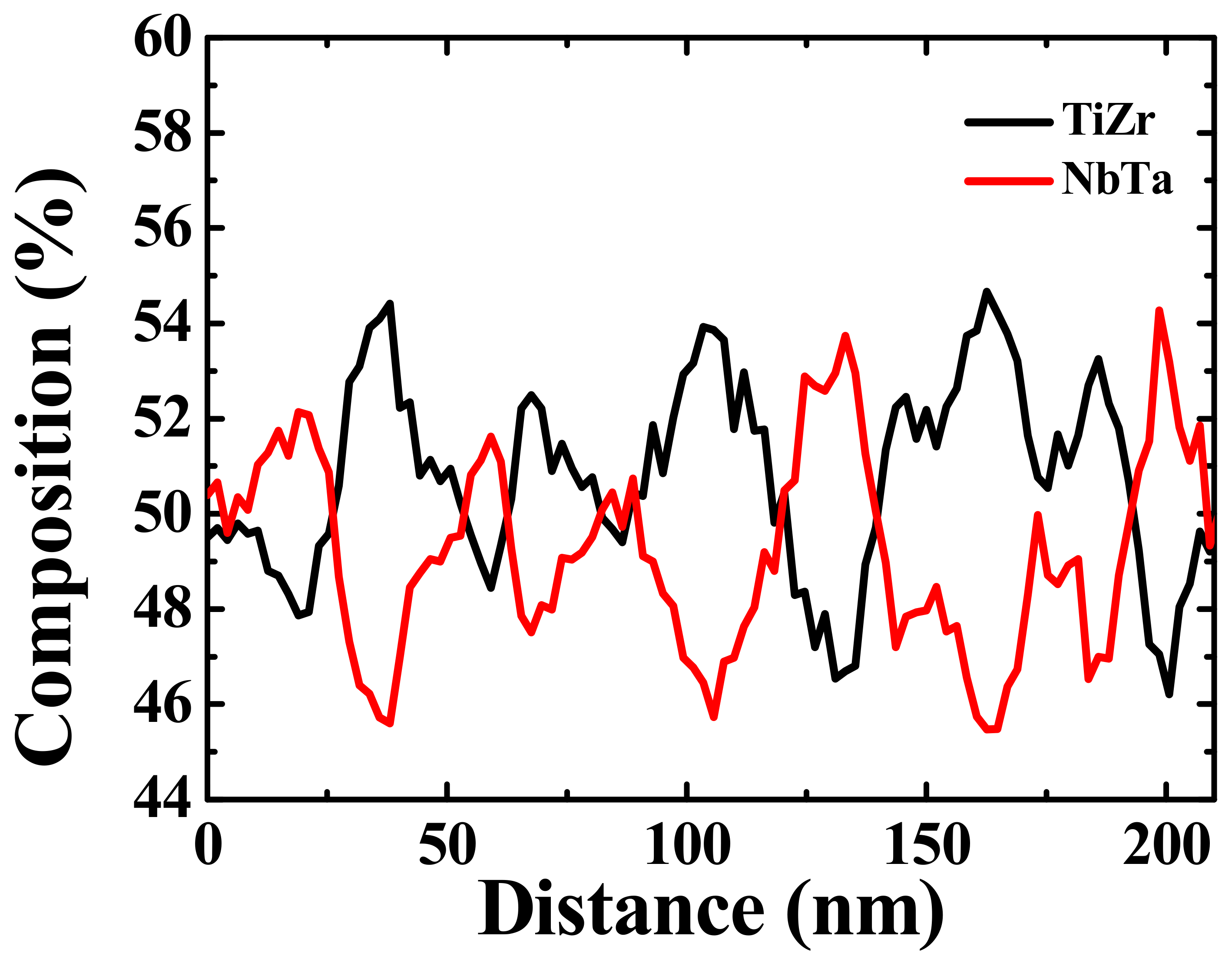

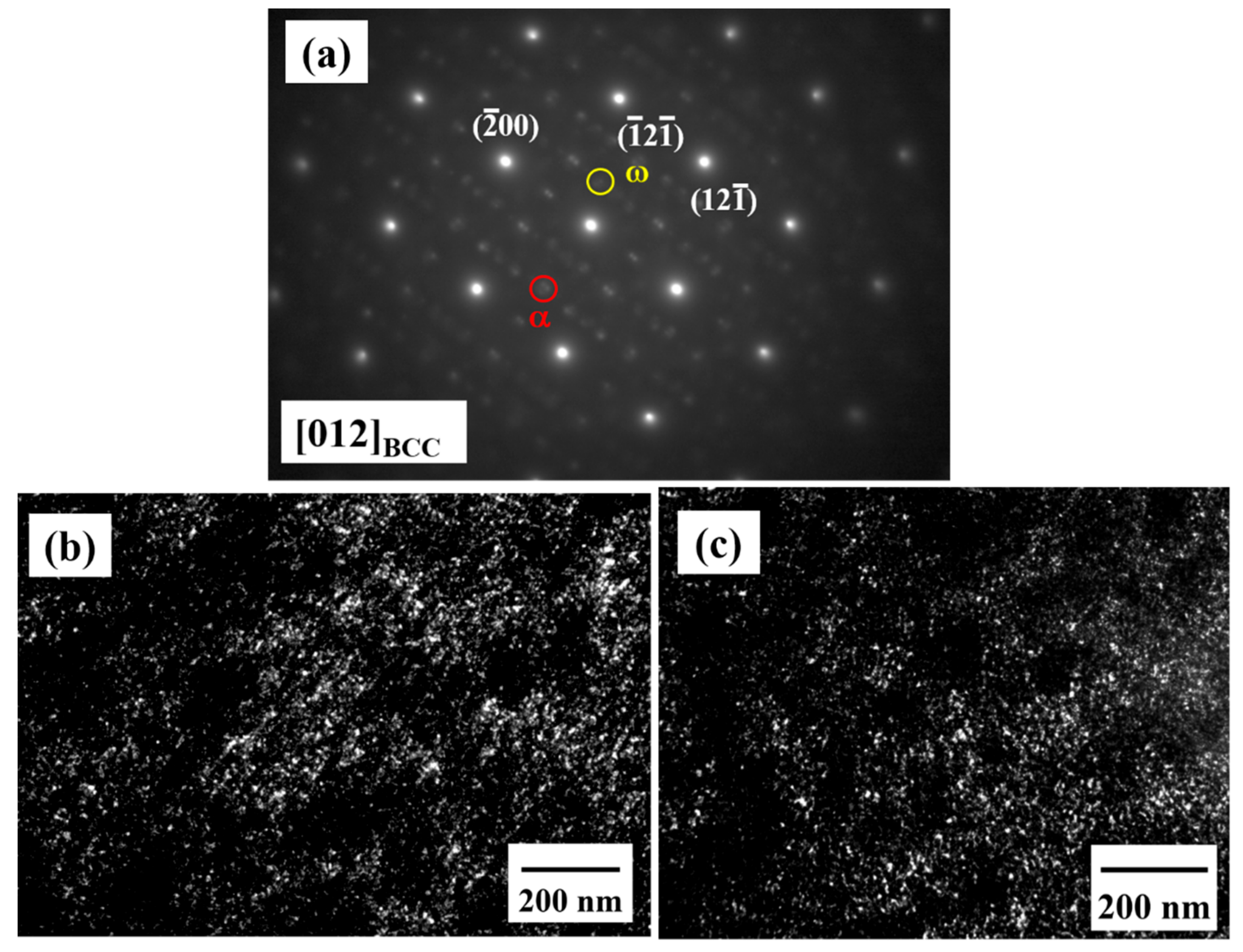

3.3.2. The As-Homogenized Samples

4. Discussion

Relationship between Spinodal Decomposition and the Mechanical Response

5. Conclusions

- The as-cast TiZrNbTa is composed of dual BCC phases, namely, the TiZr-rich inter-dendrite domains (IDs, BCC1) and the NbTa-rich dendrite domains (DRs, BCC2). The lattice constant of BCC1 and BCC2 has been determined to be 0.3375 and 0.3351 nm, respectively. By TEM examinations, α and ω precipitates measuring about 7 and 5 nm, respectively, have been found to be distributed uniformly in the NbTa-rich domains;

- In the as-cast TiZrNbTa alloy, as verified by nanoindentation tests, the NbTa-rich phase, residing within the grains, possesses a higher hardness of 5.8 GPa than that of the TiZr-rich phase (5.4 GPa). The as-cast TiZrNbTa alloy exhibits a compressive yield stress (YS) of 957 MPa and ultimate compressive strength (UCS) of 1389 MPa, with a failure plastic strain of 36%. The strengthening was rationalized to have occurred via Orowan strengthening by the α and ω precipitates;

- After the alloy was homogenized at 1100 °C for 24 h, the DRs and IDs well-dissolved in each other. Furthermore, spinodal decomposition occurred during the quenching and the interconnected structure with a wavelength of about 20 nm has been characterized to be composed of TiZr-rich and NbTa-rich phases, both of which have a BCC structure. In addition, during the quenching, the α and ω particles also precipitated within the grains uniformly;

- The as-homogenized TiZrNbTa alloy possesses a compressive yield stress of 1220 MPa, which is 27% higher than that of the as-cast alloy. Moreover, after homogenization, the UCS increased from 1389 to 1702 MPa with a failure plastic strain of 27%. The increment of strength has been attributed to the formation of a spinodal interconnected structure.

Author Contributions

Funding

Conflicts of Interest

References

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Yeh, Y.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.; Senkov, O. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Gubicza, J.; Heczel, A.; Kawasaki, M.; Han, J.-K.; Zhao, Y.; Xue, Y.; Huang, S.; Lábár, J.L. Evolution of microstructure and hardness in Hf25Nb25Ti25Zr25 high-entropy alloy during high-pressure torsion. J. Alloys Compd. 2019, 788, 318–328. [Google Scholar] [CrossRef]

- Fazakas, E.; Varga, B.; Geantă, V.; Berecz, T.; Jenei, P.; Voiculescu, I.; Coșniță, M.; Ștefănoiu, R. Microstructure, Thermal, and Corrosion Behavior of the AlAgCuNiSnTi Equiatomic Multicomponent Alloy. Materials 2019, 12, 926. [Google Scholar] [CrossRef]

- Guo, S.; Hu, Q.; Ng, C.; Liu, C.T. More than entropy in high-entropy alloys: Forming solid solutions or amorphous phase. Intermetallics 2013, 41, 96–103. [Google Scholar] [CrossRef]

- Lohmuller, P.; Peltier, L.; Hazotte, A.; Zollinger, J.; Laheurte, P.; Fleury, E. Variations of the Elastic Properties of the CoCrFeMnNi High Entropy Alloy Deformed by Groove Cold Rolling. Materials 2018, 11, 1337. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinié, J.-P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Huang, S.; Zhu, S.; Wang, F.; Li, D. Manufacturing and Analysis of High-Performance Refractory High-Entropy Alloy via Selective Laser Melting (SLM). Materials 2019, 12, 720. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Li, D.; Chen, Z.; Huang, S.; Lu, Z.; Yan, H. WxNbMoTa Refractory High-Entropy Alloys Fabricated by Laser Cladding Deposition. Materials 2019, 12, 533. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; Su, K.; Zhang, J.; Liang, X.; Peng, H.; Li, X. Enhanced Strength of a Mechanical Alloyed NbMoTaWVTi Refractory High Entropy Alloy. Materials 2018, 11, 669. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yang, X.; Liaw, P.K.; Zhang, A. Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Senkov, O.; Senkova, S.; Miracle, D.; Woodward, C. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system. Mater. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Han, Z.; Chen, N.; Zhao, S.; Fan, L.; Yang, G.; Shao, Y.; Yao, K. Effect of Ti additions on mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys. Intermetallics 2017, 84, 153–157. [Google Scholar] [CrossRef]

- Wang, S.-P.; Xu, J. TiZrNbTaMo high-entropy alloy designed for orthopedic implants: As-cast microstructure and mechanical properties. Mater. Sci. Eng. C 2017, 73, 80–89. [Google Scholar] [CrossRef]

- Wang, S.-P.; Xu, J. (TiZrNbTa)-Mo high-entropy alloys: Dependence of microstructure and mechanical properties on Mo concentration and modeling of solid solution strengthening. Intermetallics 2018, 95, 59–72. [Google Scholar] [CrossRef]

- Ren, S.M.; Huang, J.X.; Cui, M.J.; Pu, J.B.; Wang, L.P. Improved adaptability of polyaryl-ether-ether-ketone with texture pattern and graphite-like carbon film for bio-tribological applications. Appl. Surf. Sci. 2017, 400, 24–37. [Google Scholar] [CrossRef]

- Moon, B.-H.; Choe, H.-C.; Brantley, W.A. Surface characteristics of TiN/ZrN coated nanotubular structure on the Ti–35Ta–xHf alloy for bio-implant applications. Appl. Surf. Sci. 2012, 258, 2088–2092. [Google Scholar] [CrossRef]

- Nguyen, V.; Qian, M.; Shi, Z.; Song, T.; Huang, L.; Zou, J. A novel quaternary equiatomic Ti-Zr-Nb-Ta medium entropy alloy (MEA). Intermetallics 2018, 101, 39–43. [Google Scholar] [CrossRef]

- Kumar, K.H.; Wollants, P.; DeLacy, L. Thermodynamic assessment of the Ti-Zr system and calculation of the Nb-Ti-Zr phase diagram. J. Alloys Compd. 1994, 206, 121–127. [Google Scholar] [CrossRef]

- Ravi, C.; Panigrahi, B.K.; Valsakumar, M.C.; Walle, A.V.d. First principles calculation of phase diagrams of V-Nb, V-Ta and Nb-Ta alloys. AIP Conf. Proc. 2012, 1447, 839–840. [Google Scholar]

- Takeuchi, A.; Inoue, A. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Liang, Y.-J.; Wang, L.; Wen, Y.; Cheng, B.; Wu, Q.; Cao, T.; Xiao, Q.; Xue, Y.; Sha, G.; Wang, Y.; et al. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys. Nat. Commun. 2018, 9, 4063. [Google Scholar] [CrossRef] [PubMed]

- Findik, F. Improvements in spinodal alloys from past to present. Mater. Des. 2012, 42, 131–146. [Google Scholar] [CrossRef]

- Cheng, W.C.; Cheng, C.Y.; Hsu, C.W.; Laughlin, D.E. Phase transformation of the L12 phase to kappa-carbide after spinodal decomposition and ordering in an Fe–C–Mn–Al austenitic steel. Mater. Sci. Eng. A 2015, 642, 128–135. [Google Scholar] [CrossRef]

- Palisaitis, J.; Hsiao, C.L.; Hultman, L.; Birch, J.; Persson, P.O.A. Direct observation of spinodal decomposition phenomena in InAlN alloys during in-situ STEM heating. Sci. Rep. 2017, 7, 44390. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Cao, D.; Zhang, J.; Zhang, P.; Tao, Q.; Yang, X. Concurrence of spinodal decomposition and nano-phase precipitation in a multi-component AlCoCrCuFeNi high-entropy alloy. J. Mater. Res. Technol. 2019, 8, 726–736. [Google Scholar] [CrossRef]

- Munitz, A.; Salhov, S.; Hayun, S.; Frage, N. Heat treatment impacts the micro-structure and mechanical properties of AlCoCrFeNi high entropy alloy. J. Alloys Compd. 2016, 683, 221–230. [Google Scholar] [CrossRef]

- Saeki, S.; Kobayashi, S.; Okano, S. Effect of Oxygen Addition on the Spinodal Decomposition and Hardness of Ti-4at%Mo Alloy. J. Jpn. Inst. Met. 2018, 82, 197–203. [Google Scholar] [CrossRef]

- Findik, F. Modulated (Spinodal) Alloys. Period. Eng. Nat. Sci. 2013, 1, 47–55. [Google Scholar] [CrossRef]

- Moffat, D.L.; Larbalestier, D.C. The compctition between martensite and omega in quenched Ti-Nb alloys. Metall. Mater. Trans. A 1988, 19, 1677–1686. [Google Scholar] [CrossRef]

- Laughlin, D.E.; Cahn, J.W. Spinodal decomposition in age hardening copper-titanium alloys. Acta Metall. 1975, 23, 329–339. [Google Scholar] [CrossRef]

- Kato, M.; Mori, T.; Schwartz, L. Hardening by spinodal modulated structure. Acta Metall. 1980, 28, 285–290. [Google Scholar] [CrossRef]

- Orowan, E. Symposium on Internal Stress in Metals and Alloys; Institute of Metals: London, UK, 1948. [Google Scholar]

- Martin, J.W. Micromechanisms in Particles-Hardened Alloys; Cambridge University Press: Cambridge, UK, 1980. [Google Scholar]

- Foreman, A.J.E.; Makin, M.J. Dislocation movement through random arrays of obstacles. Philos. Mag. 1966, 14, 911–924. [Google Scholar] [CrossRef]

- Underwood, E.E. Quantitative Stereology; Addison Wesley: Boston, MA, USA, 1970. [Google Scholar]

- Kocks, U. Superposition of alloy hardening, strain hardening, and dynamic recovery. In Strength of Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 1979; pp. 1661–1680. [Google Scholar]

- Huang, J.; Ardell, A. Addition rules and the contribution of δ’precipitates to strengthening of aged Al-Li-Cu alloys. Acta Metall. 1988, 36, 2995–3006. [Google Scholar] [CrossRef]

- Ardell, A.J. Precipitation Hardening. Metall. Trans. A 1985, 16, 2131–2165. [Google Scholar] [CrossRef]

| Ti | Zr | Nb | Ta | |

|---|---|---|---|---|

| Ti | -- | 0 | 2 | 1 |

| Zr | 0 | -- | 4 | 3 |

| Nb | 2 | 4 | -- | 0 |

| Ta | 1 | 3 | 0 | -- |

| a (nm) | 0.295/0.469 | 0.323/0.515 | 0.330 | 0.330 |

| Modulus E (GPa) | 116 | 67 | 105 | 186 |

| Alloy | Region | Structure | Ti | Zr | Nb | Ta | Volume Fraction (%) |

|---|---|---|---|---|---|---|---|

| TiZrNbTa | Overall | BCC | 24 ± 1 | 26 ± 1 | 26 ± 1 | 24 ± 1 | 100 |

| DR | 22 ± 2 | 19 ± 2 | 29 ± 1 | 30 ± 2 | 54 | ||

| ID | 26 ± 1 | 35 ± 2 | 22 ± 1 | 17 ± 2 | 46 |

| Condition | Region | Hv | E (GPa) | H (GPa) | YS (MPa) | UCS (MPa) | e% |

|---|---|---|---|---|---|---|---|

| Overall | 380 | 111 ± 6 | 5.6 ± 0.4 | 957 ± 25 | 1389 ± 5 | 36 ± 1 | |

| As cast | DR | -- | 116 ± 4 | 5.8 ± 0.3 | -- | -- | -- |

| ID | -- | 106 ± 3 | 5.4 ± 0.3 | -- | -- | -- | |

| Overall | 440 | 109 ± 4 | 6.2 ± 0.2 | 1220 ± 19 | 1702 ± 20 | 27 ± 1 | |

| As homogenized | DR | -- | -- | -- | -- | -- | -- |

| ID | -- | -- | -- | -- | -- | -- |

| Parameter | Datum | Parameter | Datum | Parameter | Datum |

|---|---|---|---|---|---|

| <r> for α | ~7 nm | <r> for ω | ~5 nm | h | 65 nm |

| Ap for α | 41% | Ap for ω | 34% | E | 111 GPa |

| f for α | 7.1% | f for ω | 4.1% | G | 42 GPa |

| Ls for α | 27.0 nm | Ls for ω | 34.5 nm | λ | ~20 nm |

| A | ~3 at% | η | ~0.058 | Y | ~115 GPa |

| τc for α | 169 | τc for ω | 146 | τc for SD | 79 |

| σy for α | 507 | σy for ω | 438 | σy for SD | 237 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.-Y.; Huang, J.C.; Chuang, W.-S.; Chou, H.-S.; Wei, J.-Y.; Chao, C.-Y.; Liao, Y.-C.; Jang, J.S.C. Spinodal Decomposition and Mechanical Response of a TiZrNbTa High-Entropy Alloy. Materials 2019, 12, 3508. https://doi.org/10.3390/ma12213508

Liu T-Y, Huang JC, Chuang W-S, Chou H-S, Wei J-Y, Chao C-Y, Liao Y-C, Jang JSC. Spinodal Decomposition and Mechanical Response of a TiZrNbTa High-Entropy Alloy. Materials. 2019; 12(21):3508. https://doi.org/10.3390/ma12213508

Chicago/Turabian StyleLiu, Tai-You, Jacob C. Huang, Wen-Shuo Chuang, Hung-Sheng Chou, Jui-Yu Wei, Chih-Yeh Chao, Yu-Chin Liao, and Jason S.C. Jang. 2019. "Spinodal Decomposition and Mechanical Response of a TiZrNbTa High-Entropy Alloy" Materials 12, no. 21: 3508. https://doi.org/10.3390/ma12213508

APA StyleLiu, T.-Y., Huang, J. C., Chuang, W.-S., Chou, H.-S., Wei, J.-Y., Chao, C.-Y., Liao, Y.-C., & Jang, J. S. C. (2019). Spinodal Decomposition and Mechanical Response of a TiZrNbTa High-Entropy Alloy. Materials, 12(21), 3508. https://doi.org/10.3390/ma12213508